Page 1

Application Methods

LineLazer™ IV 3900, 5900, 200HS Auto-Layout™,

312307E

and 250SPS System Airless Line Stripers

- For the application of line striping materials. For professional use only. Not for use in

explosive atmospheres. -

3300 psi (22.8 MPa, 228 bar) Maximum Working Pressure.

Important Safety Instructions

Read all warnings and instructions in the

Operations Manual 312190. Save these

instructions.

EN

ti10233a

Page 2

Table of Contents

Quick Guide - LineLazer IV Auto Layout System . 3

Quick Guide - LLIV 250SPS . . . . . . . . . . . . . . . . . . 4

LineLazer IV Auto-Layout System . . . . . . . . . . . . . 5

LLIV 250SPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Measure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Basic Stall Layout: Parking Mode . . . . . . . . . . . . . 8

Basic Stall Layout: Parking Calculation . . . . . . . . 9

Basic Stall Layout: Parking Mode . . . . . . . . . . . . 10

Basic Stall Layout: Parking Mode . . . . . . . . . . . . 11

Basic Stall Layout: Striping Mode . . . . . . . . . . . . 12

Island Stall Layout: Parking Mode . . . . . . . . . . . . 13

Island Stall Layout: Parking Mode . . . . . . . . . . . . 14

Island Stall Layout: Striping Mode . . . . . . . . . . . . 15

Radius Stall Layout: Parking Mode . . . . . . . . . . . 16

Radius Stall Layout: Parking Calculation . . . . . . 17

Radius Stall Layout: Parking Mode . . . . . . . . . . . 18

Radius Stall Layout: Parking Calculation . . . . . . 19

Radius Stall Layout: Parking Mode . . . . . . . . . . . 20

Radius Stalls Paint lines . . . . . . . . . . . . . . . . . . . . 21

Angle Stall Layout: Parking Mode . . . . . . . . . . . . 22

Angle Stall Layout: Angle Calculation . . . . . . . . . 23

Angle Stall Layout: Parking Mode . . . . . . . . . . . . 24

Angle Stall Layout: Striping Mode . . . . . . . . . . . . 25

Cross Hatch Layout: Parking Mode . . . . . . . . . . . 26

Cross Hatch Layout: Striping Mode . . . . . . . . . . . 27

Cross Hatch Layout: Striping Mode . . . . . . . . . . . 28

Marker Mode Layout: Center Lines and Lane Lines

Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Line Layout: Road Mode . . . . . . . . . . . . . . . . . . . . 30

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 32

NOTE: For Best results, always dot in the same direction.

NOTE: Minimum RPM for placing dots is 2600.

NOTE: Minimum pressure on LLIV 250SPS is 1000 psi.

2 312307E

Page 3

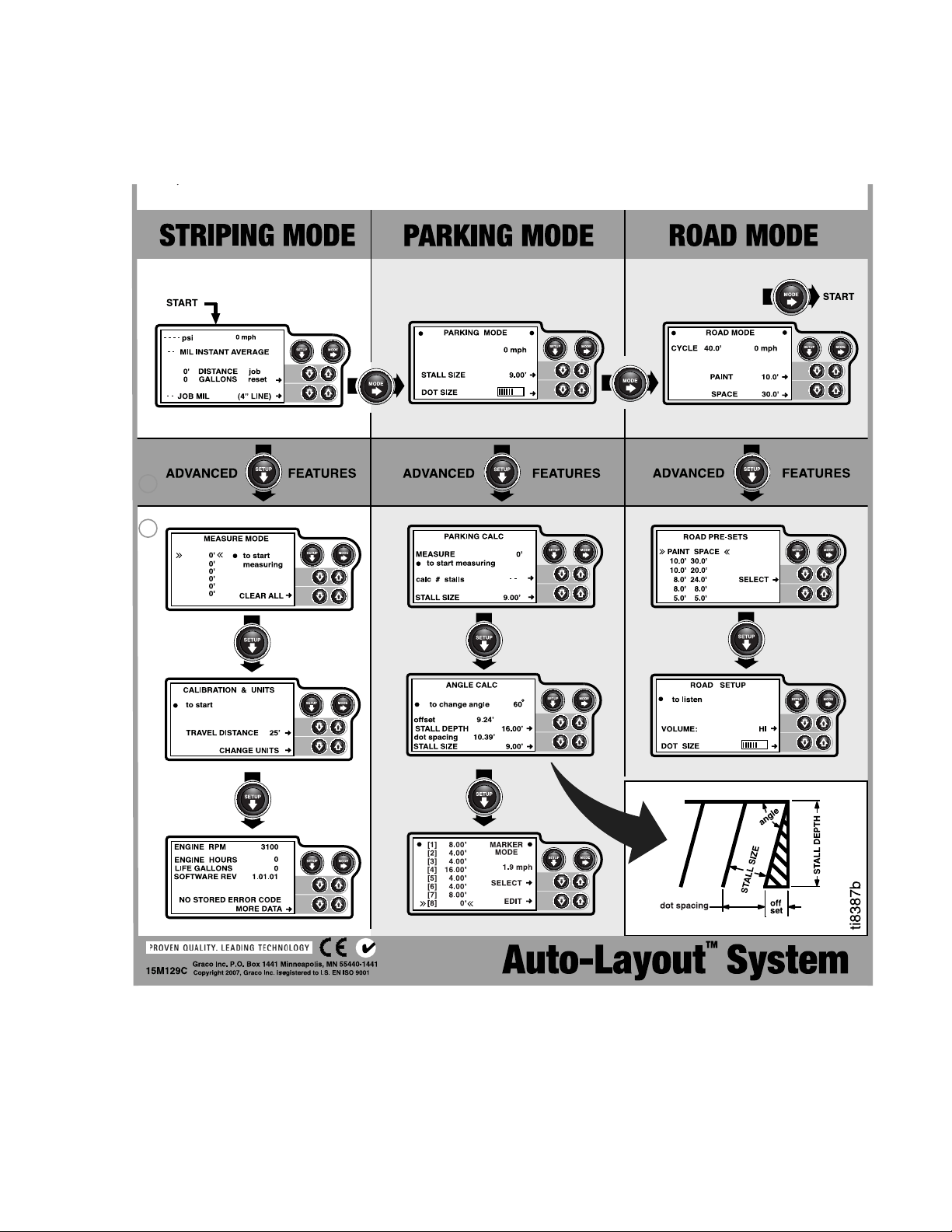

Quick Guide - LineLazer IV Auto Layout System

Quick Guide - LineLazer IV Auto Layout System

ti8387b_front

312307E 3

Page 4

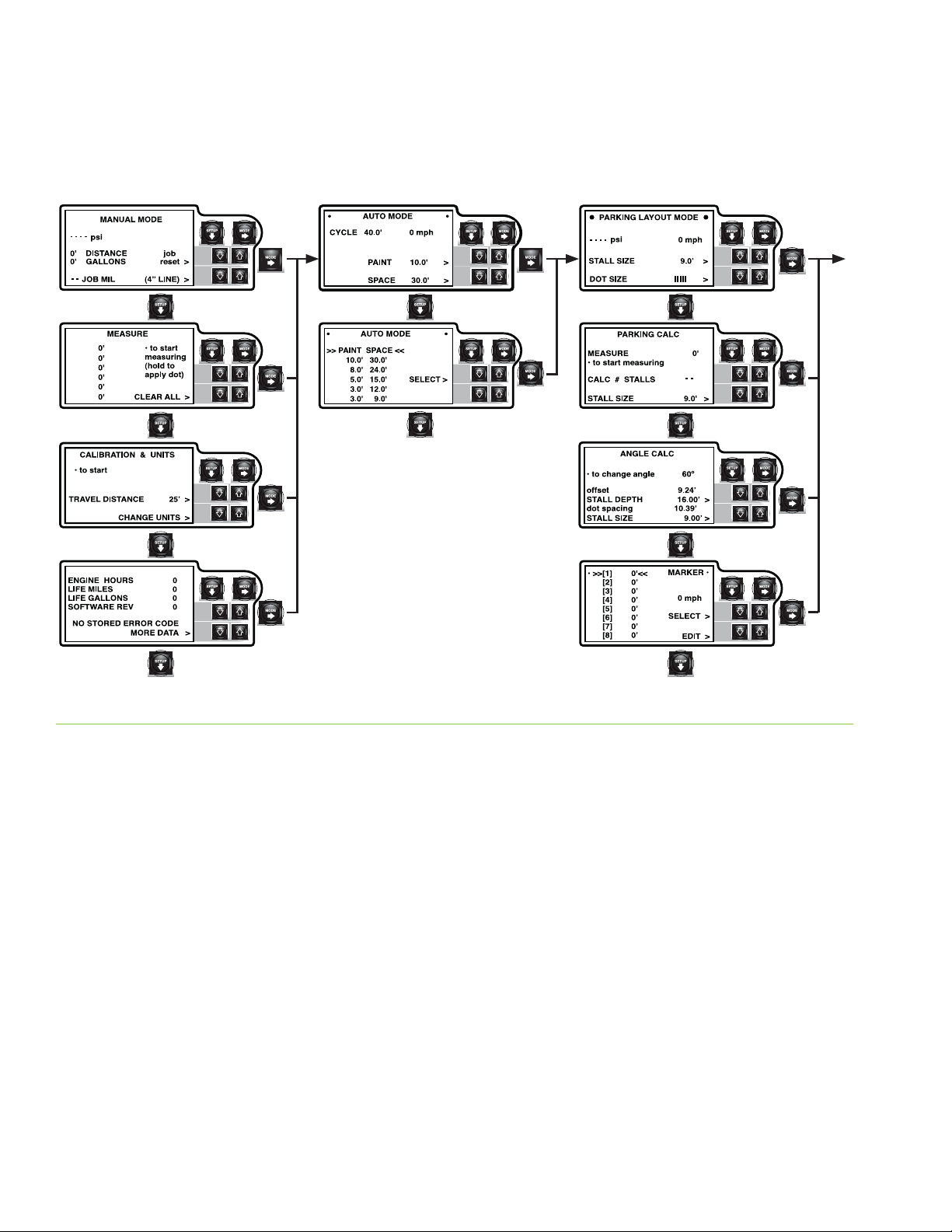

Quick Guide - LLIV 250SPS

Quick Guide - LLIV 250SPS

4 312307E

Page 5

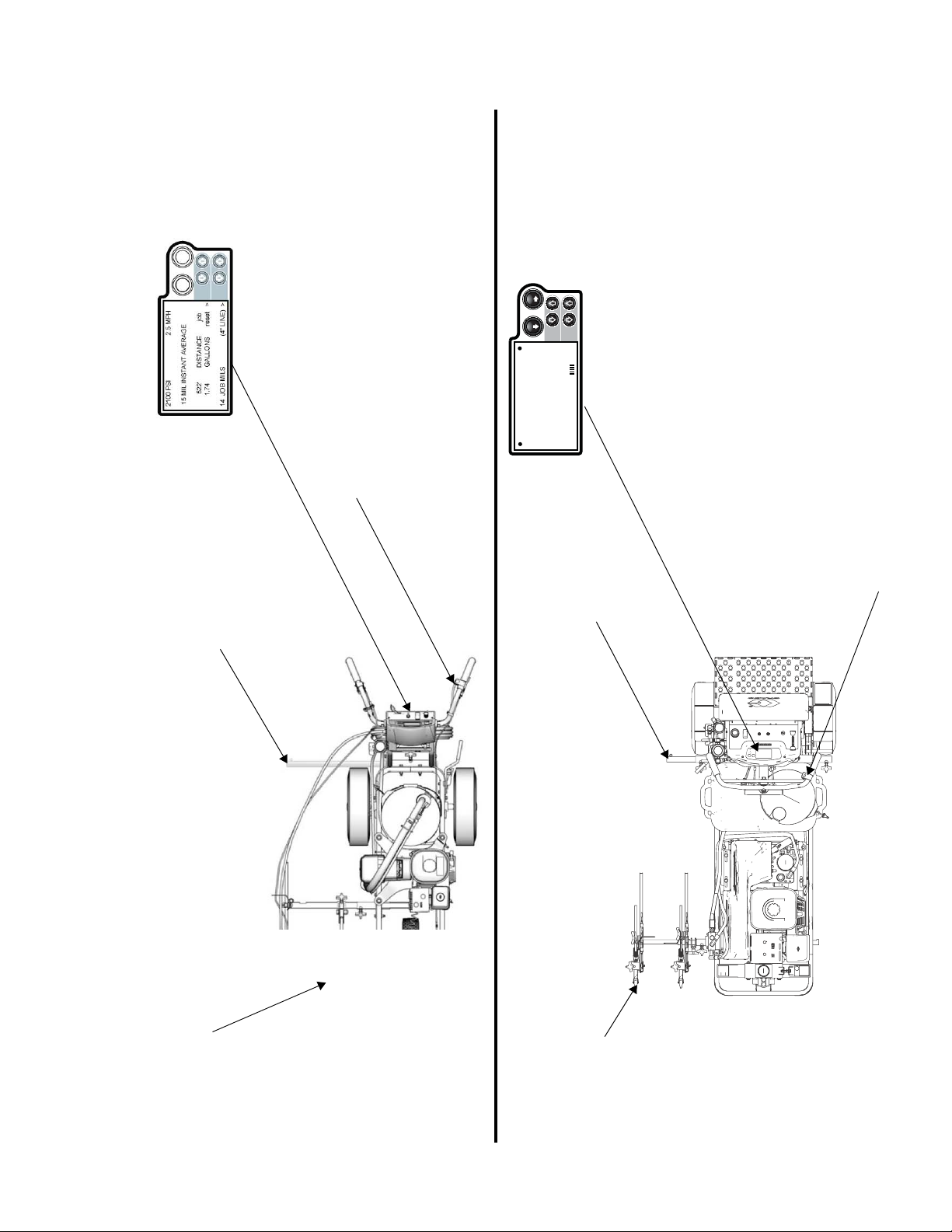

Display

Rear Gun Mount

Calibration Bar &

02'(

6(783

Display

PSK

SVL

3DUNLQJ/D\RXW0RGH

67$//6,=(ҋ!

'276,=( !

Remote Switch

Gun Trigger Control

Bar

Calibration

ti10100a

Spray Module with

Aerosol Chalk Can

Spray Tip

Gun and 286111

LineLazer IV Auto-Layout System

312307E 5

LLIV 250SPS

Page 6

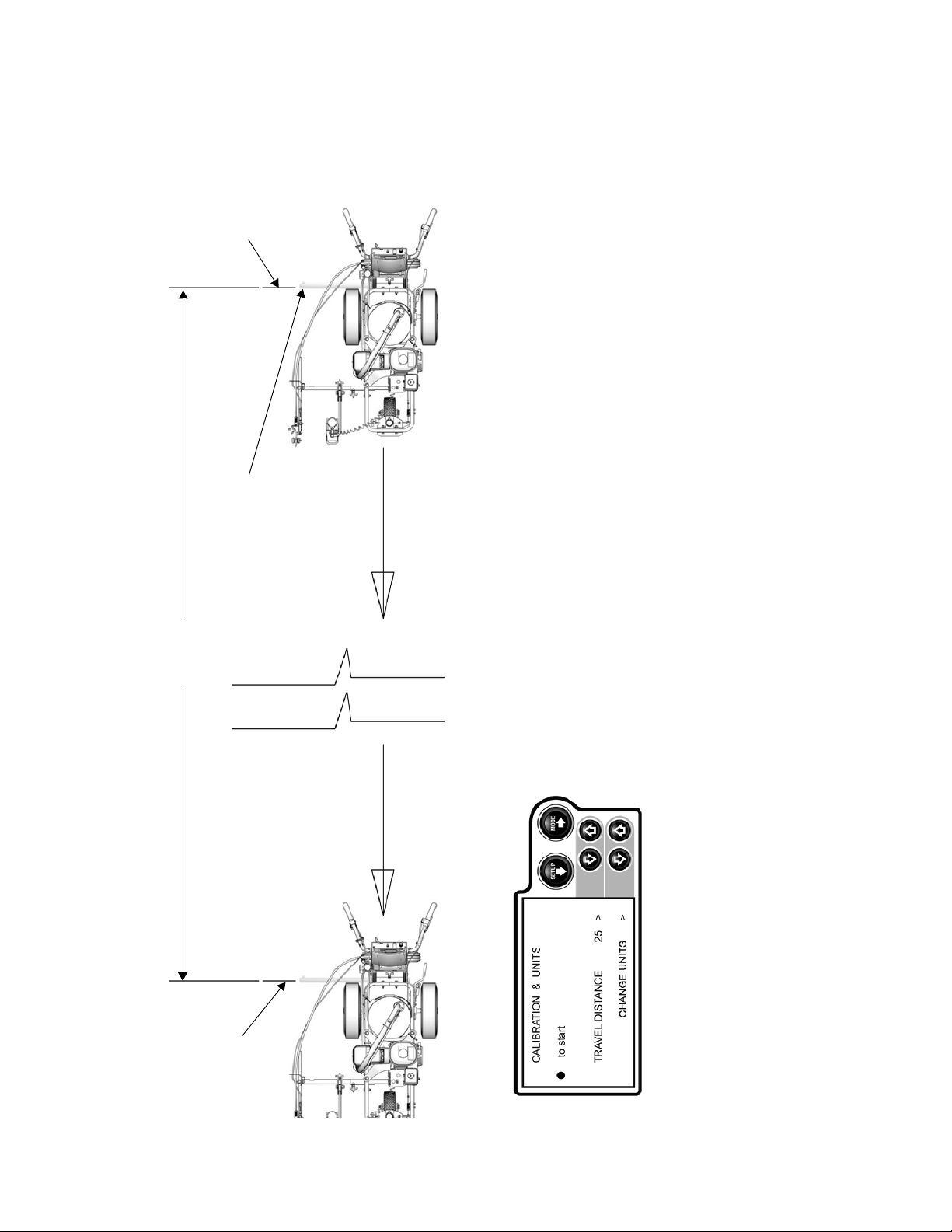

START

25 feet

Rotate calibration arm

FINISH

pointing down to ground

CALIBRATION AND UNITS

Press REMOTE SWITCH to START calibration. Press REMOTE SWITCH to FINISH

calibration.

IMPORTANT NOTE: For best results, calibrate to a minimum of 25 ft. Use only steel

measuring tape. Precise start and stop are necessary. Calibration distance above 100 ft is

not recommended due to inaccuracy with setting up the course. Tire air pressure

variations can negatively impact accuracy of unit.

CHANGE UNITS changes all displayed values to metric or standard units of measure.

ti10101a

Calibration

Minimum 25 ft precision course

6 312307E

Page 7

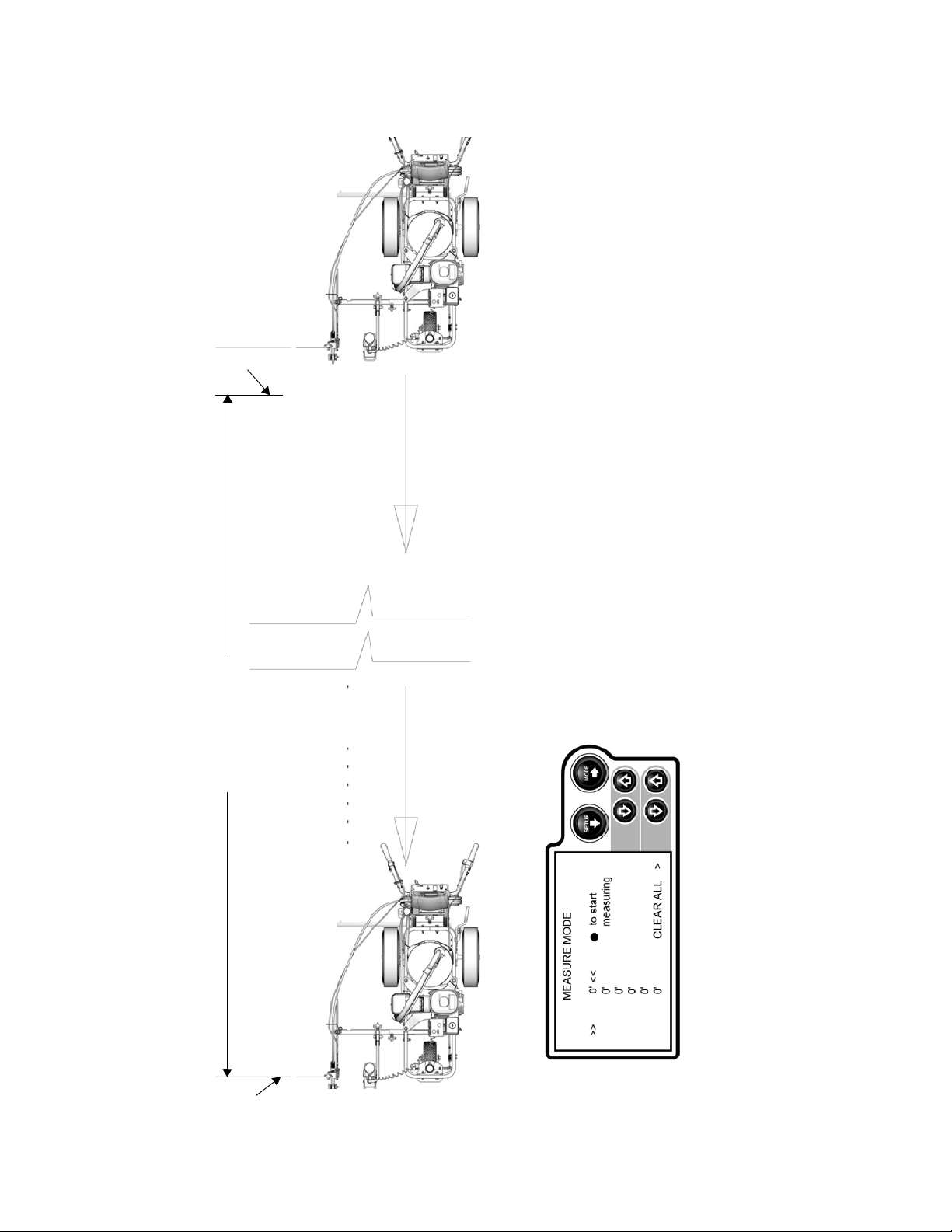

START

Measurements automatically increment down on screen, last measurements display

at all times.

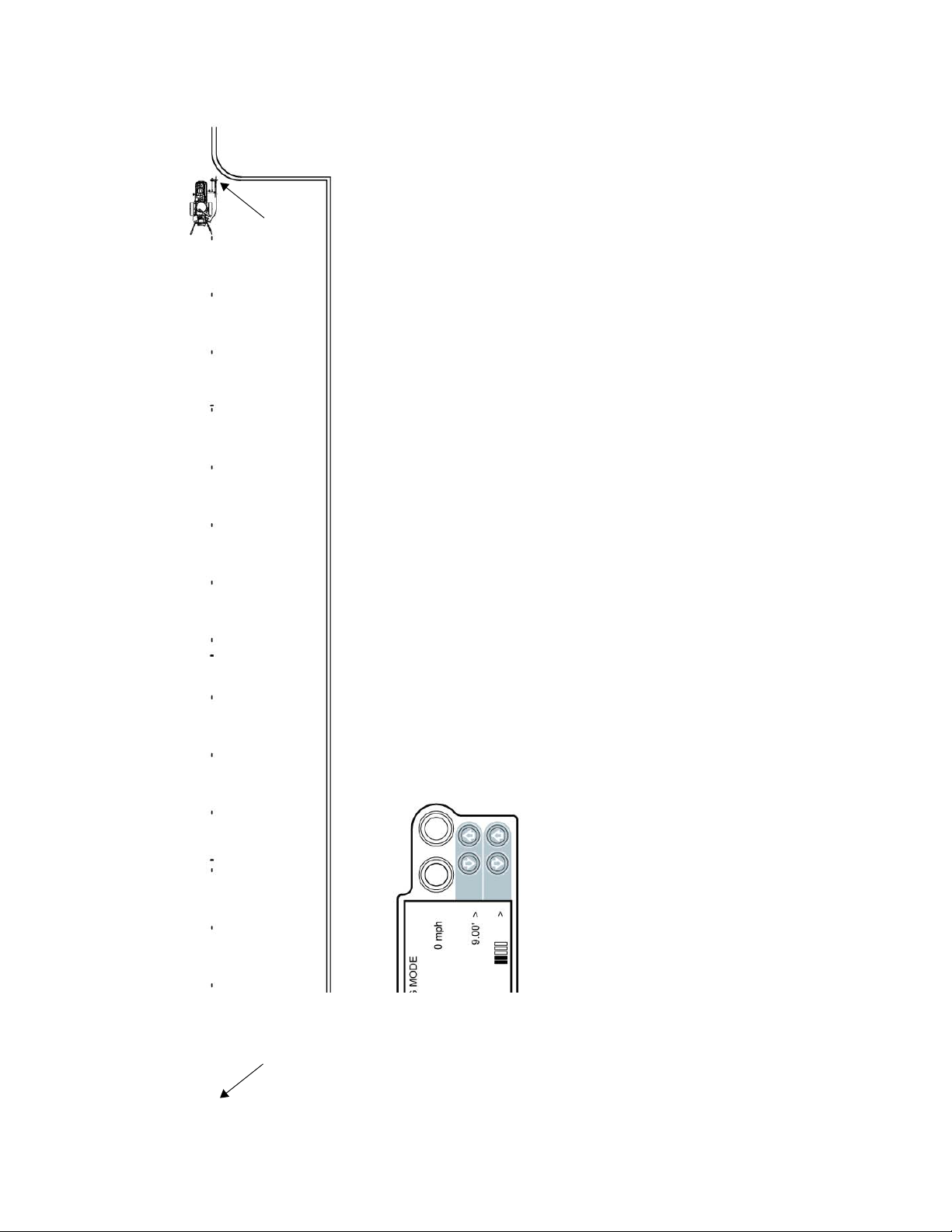

MEASURE MODE

At any time while in MEASURE MODE, momentarily hold down REMOTE SWITCH

to apply dot. Holding down REMOTE SWITCH will produce continuous dotted line 1

foot dot spacing when moving, used for pre-marking.

Press REMOTE SWITCH to START. Press REMOTE SWITCH to FINISH.

Measured Distance

NOTE: The striper measures moving forward or reverse.

ti10102a

Measure Mode

Used for measuring and marking specific distances

312307E 7

FINISH

Page 8

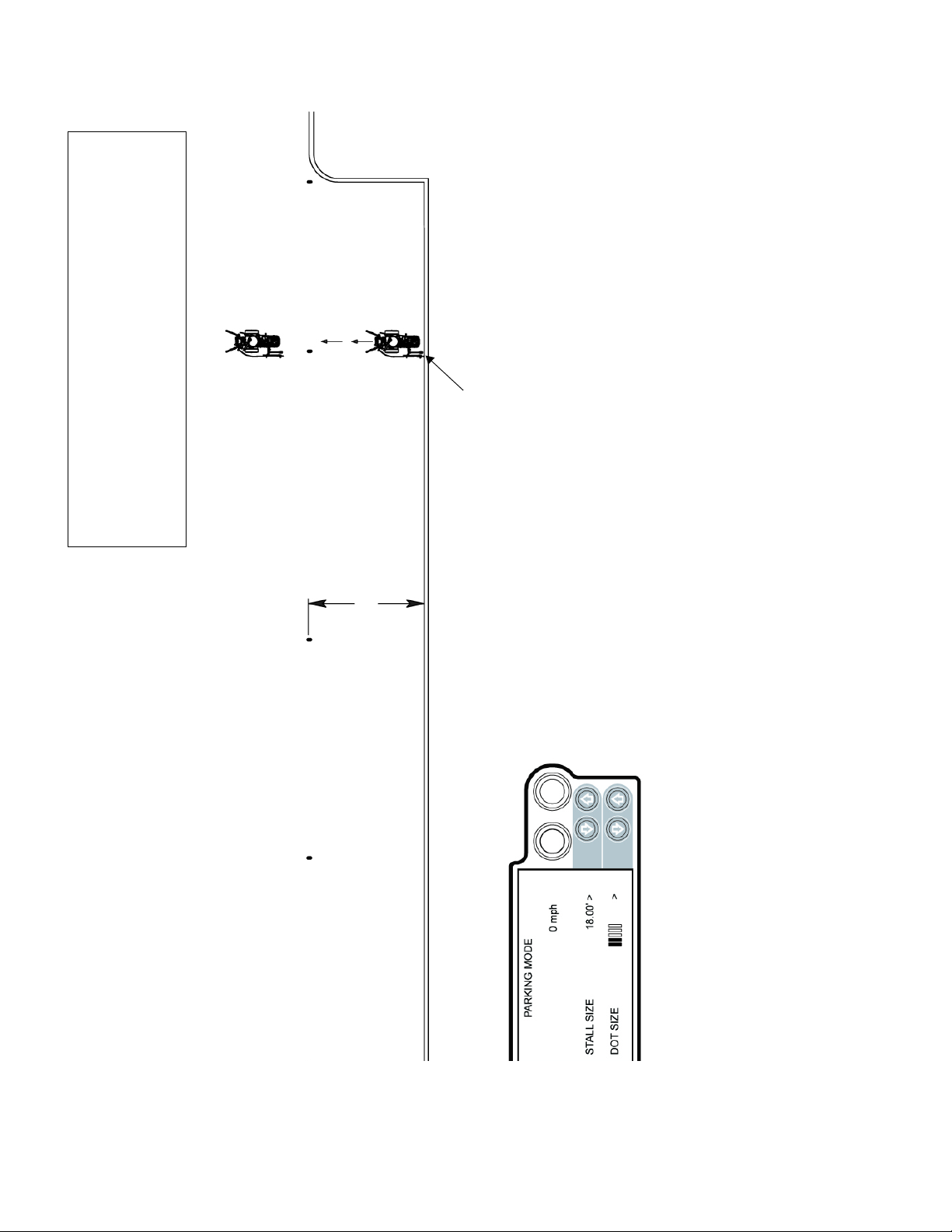

NOTE: For Best results, always dot in the same direction.

NOTE: Minimum RPM for placing dots is 2600.

NOTE: Minimum pressure on LLIV 250SPS is 1000 psi.

FINISH

START

PARKING MODE

Press REMOTE SWITCH to START and FINISH.

Establish enough reference dots to guide striper for applying stall lines.

In this case, 18 ft from inner curbing.

18 feet

15 stalls

ti10103a

Basic Stall Layout: Parking Mode

Establishing outer boundary with reference dots

8 312307E

Page 9

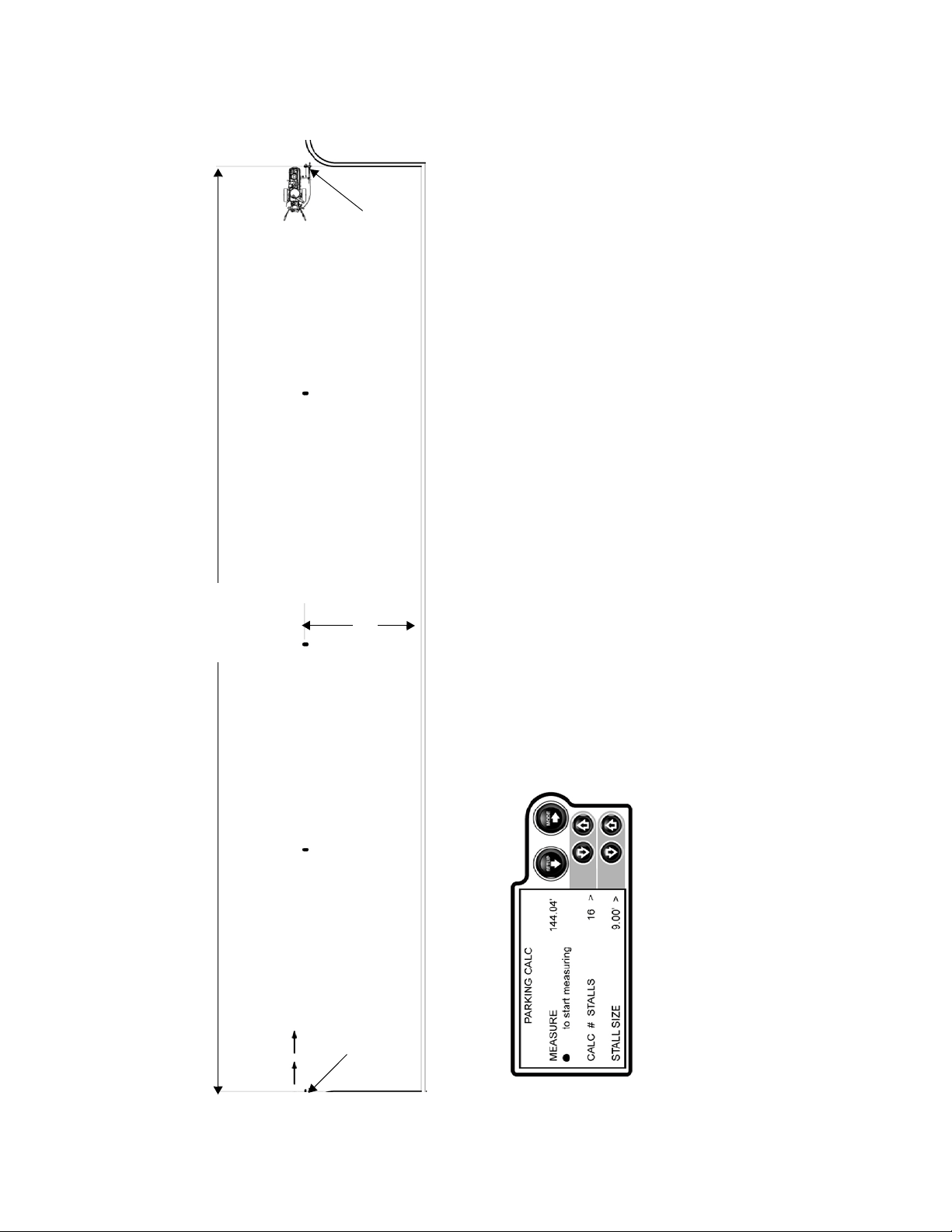

FINISH

144.04 feet

18 feet

START

16 Stalls

PARKING CALC

Press REMOTE SWITCH to START and FINISH calculation. IMPORTANT NOTE:

Start-point and finish-point accuracy is critical.

Press remote switch to start measuring. Follow the established 18 ft reference dots,

measure from start to finish. Press remote switch to stop measuring.

Use up/down arrows to adjust number of stalls as desired.

NOTE: System automatically transfers the calculated STALL SIZE from PARKIN G

CALC to PARKING MODE screen.

ti10104a

Basic Stall Layout: Parking Calculation

Measure for automatic calculation or select desired stall size

312307E 9

Page 10

FINISH

16 Stalls

Utilizing calculated stall size, apply dots, traveling from start to finish.

NOTE: System automatically transfers the calculated STALL SIZE from

PARKING MODE

Press REMOTE SWITCH to START and FINISH dots.

START

PARKING CALC screen if desired.

ti10105a

Basic Stall Layout: Parking Mode

Mark dots at beginning of each stall

10 312307E

Page 11

FINISH

PARKING MODE

Press remote switch at start while following curbing as a reference applying

evenly spaced dots. Press remote switch at finish to stop dots.

Establish first stall perpendicular to curb as shown (if curbing does not allow

Press REMOTE SWITCH to START and FINISH dots.

room for striper).

16 Stalls

9 ft

Basic Stall Layout: Parking Mode

Mark dots at end of each stall

312307E 11

START

ti10106a

Page 12

STRIPING MODE

Simply connect the dots with your sprayer.

ti10107a

Basic Stall Layout: Striping Mode

Paint lines (connect the dots)

12 312307E

Page 13

32 Stalls

START

Establish enough reference dots to guide striper for applying stall lines by

using PARKING M O DE measuring 18 ft out from centerline.

NOTE: The striper measures moving forward or reverse, as shown,

PARKING MODE

Press REMOTE SWITCH to start and stop dots.

placing evenly spaced dots at desired spacing.

START

Island Stall Layout: Parking Mode

Establish the center line and outer boundary first

312307E 13

ti10108a

Page 14

NOTE: For Best results, always dot in the same direction.

START

NOTE: Minimum RPM for placing dots is 2600.

NOTE: Minimum pressure on LLIV 250SPS is 1000 psi.

32 Stalls

START

PARKING M O DE

Press REMOTE SWITCH to start and stop dots.

NOTE: See Basic Stalls section (pages 4-8) to automatically measure

and calculate stall size.

ti10109a

Island Stall Layout: Parking Mode

Place dots at the beginning of each stall line

14 312307E

Page 15

STRIPING MODE

Simply connect the dots with the striper.

ti10110a

Island Stall Layout: Striping Mode

Paint lines (connect the dots)

312307E 15

Page 16

FINISH

START

15 Stalls

NOTE: For best results, always dot in the same direction.

NOTE: Minimum RPM for placing dots is 2600.

NOTE: Minimum pressure on LLIV 250SPS is 1000 psi.

Establish enough reference dots to guide striper for measuring and

PARKING MODE

18 ft

Press REMOTE SWITCH to START and FINISH.

applying stall lines. In this case, 18 feet from inner curbing.

ti10113b

Radius Stall Layout: Parking Mode

Place evenly spaced dots at beginning of each stall

16 312307E

Page 17

121.49

FINISH

18 feet

Radius Stall Layout: Parking Calculation

Measure inner perimeter distance

NOTE: Measure start-point and finish-point accuracy is critical.

Press remote switch at start, follow the curbing as a reference to guide striper along path

measuring from start to finish. Press remote switch at finish to stop measuring.

Use up/down arrows to adjust correct number of stalls. New parking stall size will display

under STALL SIZE. Establish first stall if curbing does not allow room for striper (in this

case 15 less 1 = 14 for the calculation).

NOTE: System automatically transfers the calculated STALL SIZE from PARKING CALC

PARKING MODE

Press REMOTE SWITCH to START and FINISH measuring.

START

ti10411a

to PARKING MODE screen.

312307E 17

Page 18

FINISH

15 Stalls

Press REMOTE SWITCH to START and FINISH dots.

ti10412a

Utilizing calculated stall size, apply dots, traveling from start to finish.

PARKING MODE

Establish first stall perpendicular to curb as shown (if curbing does not allow

room for striper).

NOTE: System automatically transfers the calculated STALL SIZE from

PARKING CALC to PARKING MODE screen.

Radius Stall Layout: Parking Mode

Mark dots at end of each stall

18 312307E

START

Page 19

141.79

FINISH

15 Stalls

NOTE: Start-point and finish-point accuracy is crucial.

Press remote switch at start to begin measuring. Follow the established 18 ft

reference dots measuring from start to finish. Press remote switch again to stop

measuring.

PARKING CALC

Press REMOTE SWITCH to START and FINISH measuring.

START

ti10413a

Use up/down arrows to adjust correct number of stalls.

CALC to PARKING MODE screen.

NOTE: System automatically transfers the calculated STALL SIZE from PARKI NG

Radius Stall Layout: Parking Calculation

Measure outer perimeter distance

312307E 19

Page 20

FINISH

15 Stalls

PARKING M O DE

Press REMOTE SWITCH to START and FINISH dots.

Utilizing calculated stall size, apply dots traveling from start to finish.

NOTE: System automatically transposes the calculated STALL SIZE

from PARKING CALC to PARKING MODE screen.

START

ti10414a

Radius Stall Layout: Parking Mode

Place evenly spaced dots at beginning of each stall

20 312307E

Page 21

STRIPING MODE

Simply connect the dots with the striper.

ti10116b

Radius Stalls

Paint lines

312307E 21

Page 22

START

NOTE: For best results, always dot in the same direction.

NOTE: Minimum RPM for placing dots is 2600.

NOTE: Minimum pressure on LLIV 250SPS is 1000 psi.

PARKING Mode

Press REMOTE SWITCH to START and FINISH dots.

Establish enough reference dots to guide striper for applying stall lines by

using PARKING MODE measuring 18 ft out from centerline.

NOTE: The striper measures moving forward or reverse, as shown, placing

32 Stalls

START

evenly-spaced dots at desired spacing.

ti10117b

Angle Stall Layout: Parking Mode

Establish the center line and outer boundary

22 312307E

Page 23

9.00

75°

14 Stalls

4.82

desired STALL DEPTH and STALL SIZE. System automatically calculates

ANGLE CALC

“offset” and “dot spacing”.

Press REMOTE SWITCH to adjust desired angle. Use up/down arrows to set

NOTE: System automatically transfers calculated “dot spacing” from ANGLE

CALC to PARKING MODE screen.

14 Stalls

Angle Stall Layout: Angle Calculation

Measure outer boundary

312307E 23

ti10118a

Page 24

START

14 Stalls

FINISH

14 Stalls

PARKING MODE

Press REMOTE SWITCH to START and FINISH dots.

If necessary, use PARKING CALC to determine how many 9.32 ft parking

stalls will fit.

ti10119a

Angle Stall Layout: Parking Mode

Mark dots at end of each stall

24 312307E

FINISH

Page 25

STRIPING MODE

Simply connect the dots with the striper.

ti10120a

Angle Stall Layout: Striping Mode

Paint lines (connect the dots)

312307E 25

Page 26

6 feet

FINISH

3 feet

NOTE: For Best results, always dot in the same direction.

NOTE: Minimum RPM for placing dots is 2600.

NOTE: Minimum pressure on LLIV 250SPS is 1000 psi.

Adjust STALL SIZE to achieve desired cross hatch spacing.

PARKING MODE

Press REMOTE SWITCH to START and FINISH dots.

Place dots around perimeter of area.

36 feet

START

Cross Hatch Layout: Parking Mode

Establish the boundary and apply dots at desired spacing

26 312307E

ti10121a

Page 27

STRIPING MODE

Simply connect the dots with the striper.

Paint interior by connecting the dots. If ends are rounded as shown,

make sure you establish this before painting.

Cross Hatch Layout: Striping Mode

Paint lines (connect the dots)

312307E 27

ti10122a

Page 28

Cross Hatch Layout: Striping Mode

Paint perimeter (connect the dots)

STRIPING MODE

Large or small, cross hatching jobs can be simplified by following

these simple steps, eliminating the inconsistencies found on many

job sites today.

ti10123a

28 312307E

Page 29

48.00’

8.00’ 8.00’

16.00’8.00’ 8.00’

4.00’ 4.00’

MARKER MODE

Automatic marker layout example shows typical lane line layout for reflective

markers. Set space sizes up to 8 consecutive measurements. By leaving

zeros in any space, AutoLayout will skip to the next measurement in a

continuous loop.

OTHER USES:

• Multiple spaced handicap stall layout

• Double line stalls

ti10126a

Marker Mode Layout: Center Lines and Lane Lines Mode

Paint lines (connect the dots)

312307E 29

Page 30

ROAD MODE

Automatic skipline layout for roads, bike trails, and airports.

ti10128a

Line Layout: Road Mode

Skip line

30 312307E

Page 31

Notes

Notes

312307E 31

Page 32

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental

or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject

to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder,

or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présent document ainsi que de tous les documents, avis et procédures judiciaires exécutés, donnés ou intentés à la suite de ou en

rapport, directement ou indirectement, avec les procédures concernées, sera en anglais.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty Program”.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2007, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 312307

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised March 2013

Loading...

Loading...