Page 1

Instructions - Parts

312185S

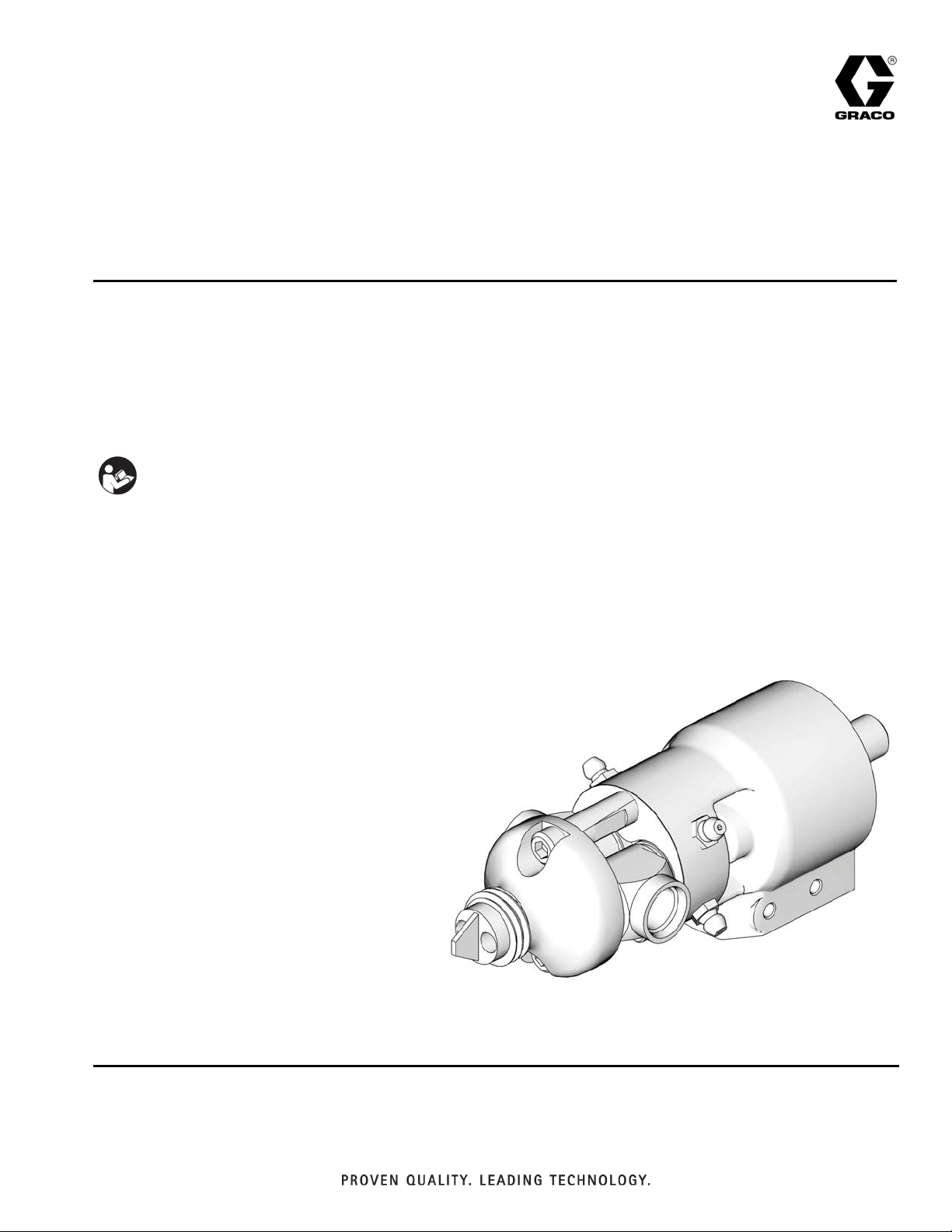

MD2 Valve

For use with disposable mixers to dispense a variety of sealants and adhesives. For

professional use only.

120 psi (0.84 MPa, 8.4 bar) Maximum Air Inlet Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

See page 2 for model information, including maximum working pressure and approvals.

TI9964A

Page 2

MD2 Valve Models

Contents

MD2 Valve Models . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 5

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 30

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 30

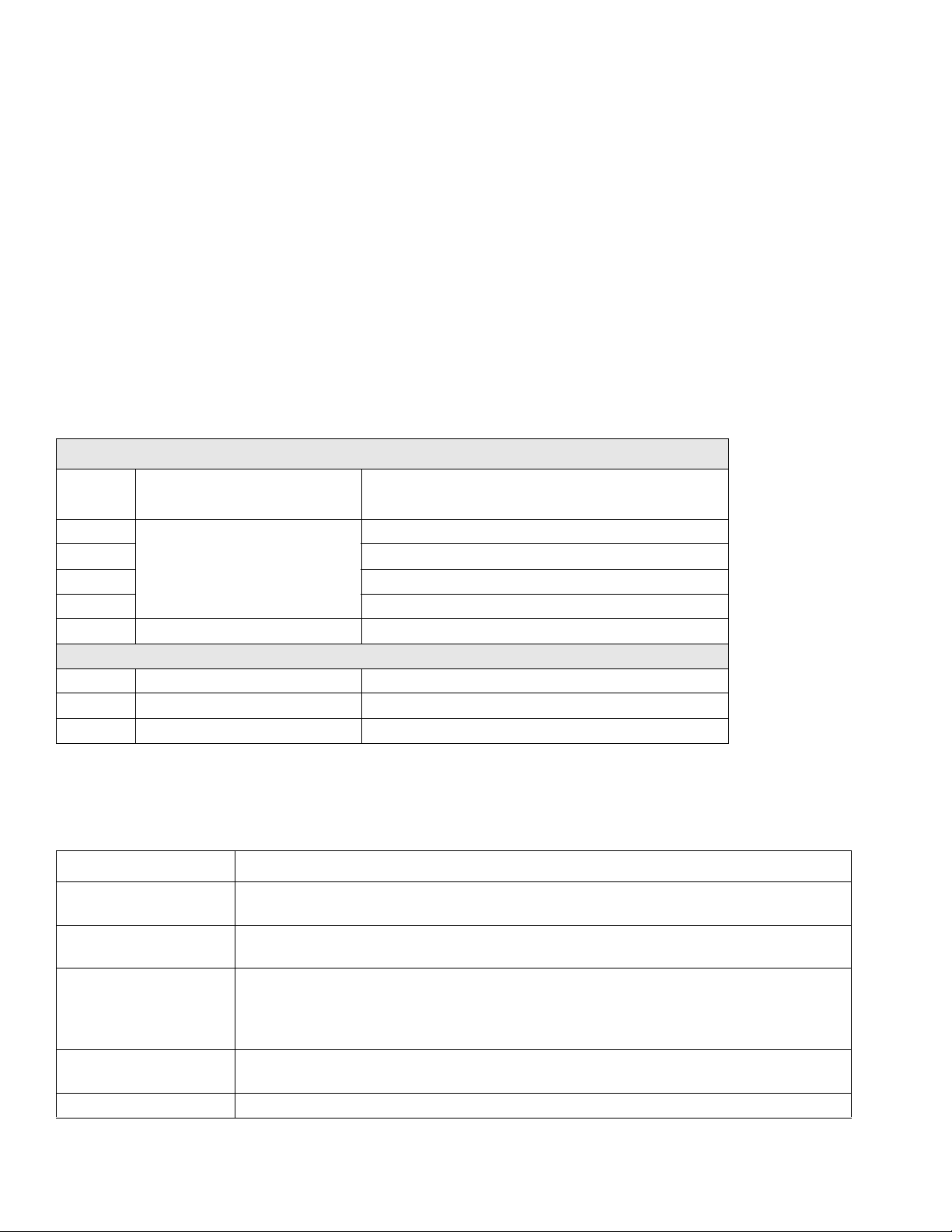

MD2 Valve Models

MD2 Valves

Maximum Working Pressure

Part No.

255179

255180 1:1 Hard seat, non-adjustable snuff-back

255181 Wide ratio, soft seat, adjustable snuff-back

255182 Wide ratio, hard seat, non-adjustable snuff-back

255183 2000 psi (13.8 MPa, 138 bar) Cold spray/joint fill valve

255206 120 psig (0.84 MPa, 8.4 bar) Air trigger

255208 3A @ 28 VDC Electric air actuated

255249 0.5 @ 28 VDC Electric actuated lever

3000 psi (20.7 MPa, 207 bar

psi (MPa, bar) Description

1:1 Soft seat, adjustable snuff-back

MD2 Valve Handles

Model Selection

The following table provides a summary of the MD2 dispense valves that are described in this manual.

Type Description

Hand held valves with

internal air trigger

Hand held valve with

electric switch

Wide ratio valves The wide ratio MD2 valve has a center injection tip. This feature is helpful with wider

Hard seats Carbide seats and hardened needles are good for abrasive materials and stall against

Soft seats UHMWPE seals are good for precise snuff-back control.

2 312185S

The internal air trigger controls the air piston that operates the MD2 valve. A pilot port

can be used to control a pump motor.

The switch signals the customer’s controller to open and close the ports on the MD2

valve using a remote 4-way air control valve which is not included.

ratio applications, specifically when the low volume material is a much lower viscosity

than the high volume material. Frequent cleaning intervals may be required to maintain

the tip.

pressure applications.

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

312185S 3

Page 4

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

4 312185S

Page 5

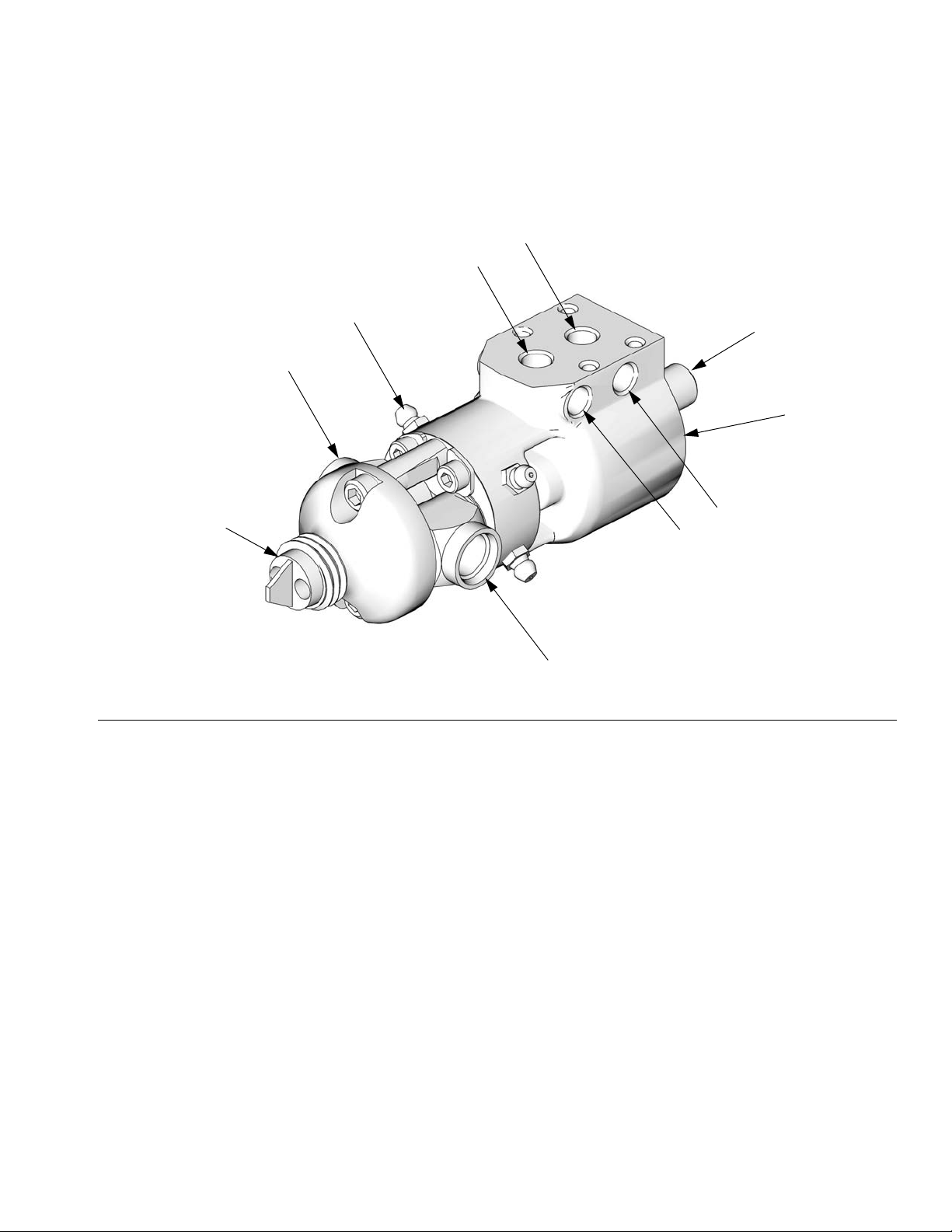

Component Identification

F

D

Component Identification

C

B

A

H

G

FIG. 1: Component Identification

Key:

A Snuff-back adjustment knob (soft seat versions only)

B 1/8 in. npt (f) air to close (O).

C 1/8 in. npt (f) air to open (I).

D 9/16 straight thread o-ring boss “B” fluid inlet (low volume)

E 9/16 straight thread o-ring boss “A” fluid inlet (high

volume)

F Zerk grease fitting

G Nosepiece with 7/8-9 bell outlet

H Air cylinder

C

B

E

TI10391A

312185S 5

Page 6

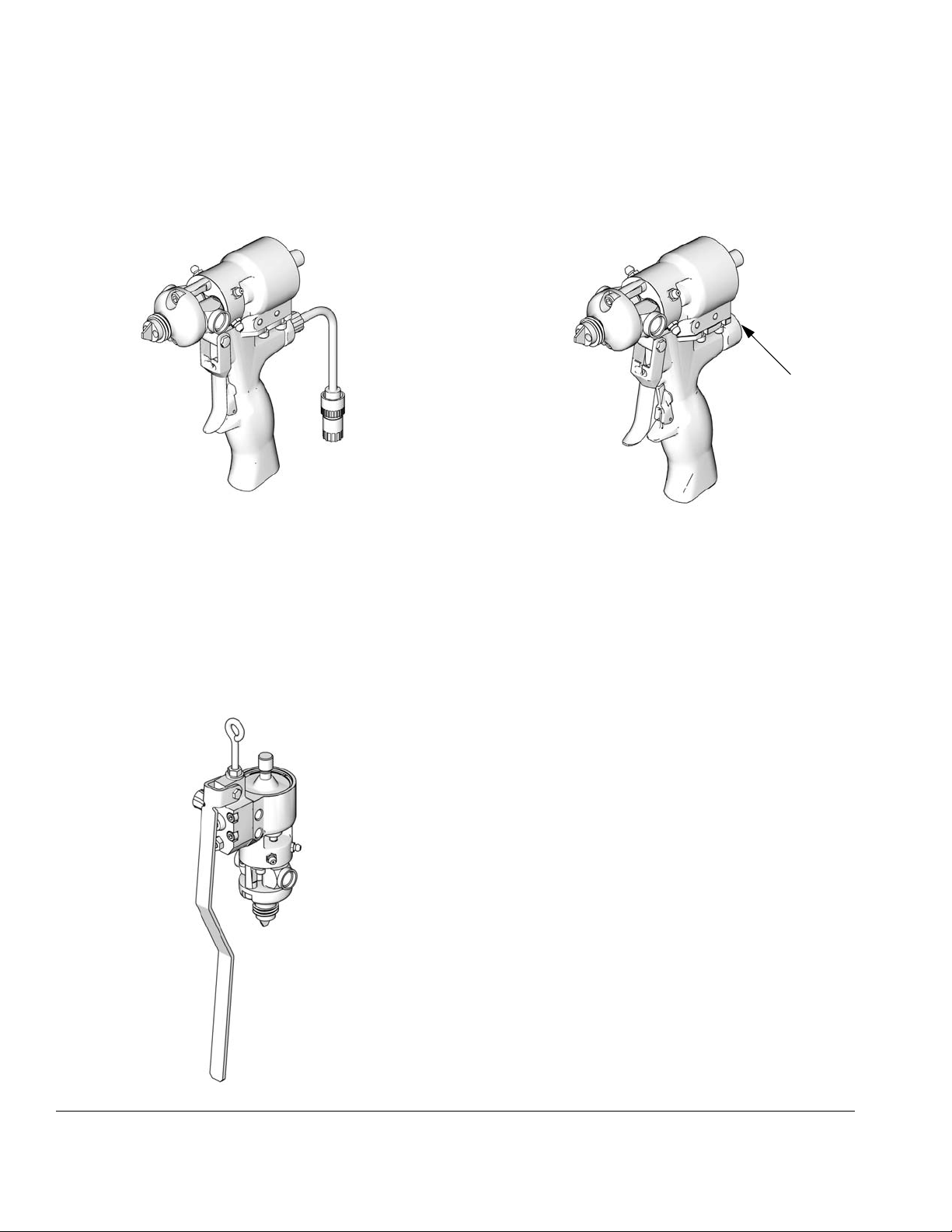

Features

Features

Electric Switch Valve

Series A handle shown

TI10383A

Normally open momentary contact switch

Note: The Trigger/Lever activates an electrical switch in

the handle, which activates a remote 4 way solenoid

valve. Bring an “OPEN” air signal to the 1/8 in. npt(f)

port (I) on this side of the valve, and a “CLOSE” signal

to the port (O). See Accessories, page 23, to order fittings and tubing.

Pneumatic Valve

1/4 in npt (f)

air inlet

TI10407A

The 1/8 in. npt (f) port (I) can be used to send an “ON”

signal back to a pump pilot or control. See F

IG. 1.

Electric Actuated Lever Valve

FIG. 2: Features of the MD2 Valves

TI10409A

6 312185S

Page 7

Installation

Installation

Grounding

The following grounding instructions are minimum

requirements for a basic dispensing system. Your system may include other equipment or objects which must

be grounded. Check your local electrical code for

detailed grounding instructions for your area and type of

equipment. Your system must be connected to a

true-earth ground.

• Pump: ground the pump by connecting ground wire

and clamp as described in your separate pump

instruction manual.

• Air compressors and hydraulic power supplies:

ground the equipment according to the manufac-

turer's recommendations.

• Fluid hoses: use only grounded fluid hoses with a

maximum of 500 feet (150 m) combined hose length

to ensure grounding continuity. Check the electrical

resistance of your fluid hoses at least once a week.

If your hose does not have a tag on it which speci-

fies the maximum electrical resistance, contact the

hose supplier or manufacturer for the maximum

electrical resistance limits, replace the hose immedi-

ately.

• Dispensing valve: ground the valve by connecting

it to a properly grounded fluid hose and pump.

• Fluid supply container: ground according to your

local code.

• Flammable liquids in the dispense area: must be

in approved, grounded containers. Do not store

more than the quantity needed for one shift.

• All solvent pails used when flushing: ground

according to local code. Use only metal pails, which

are conductive. Do not place the pail on a non-con-

ductive surface, such as paper or cardboard, which

interrupts the grounding continuity.

• To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the valve

firmly to the side of a grounded metal pail, then trig-

ger the valve.

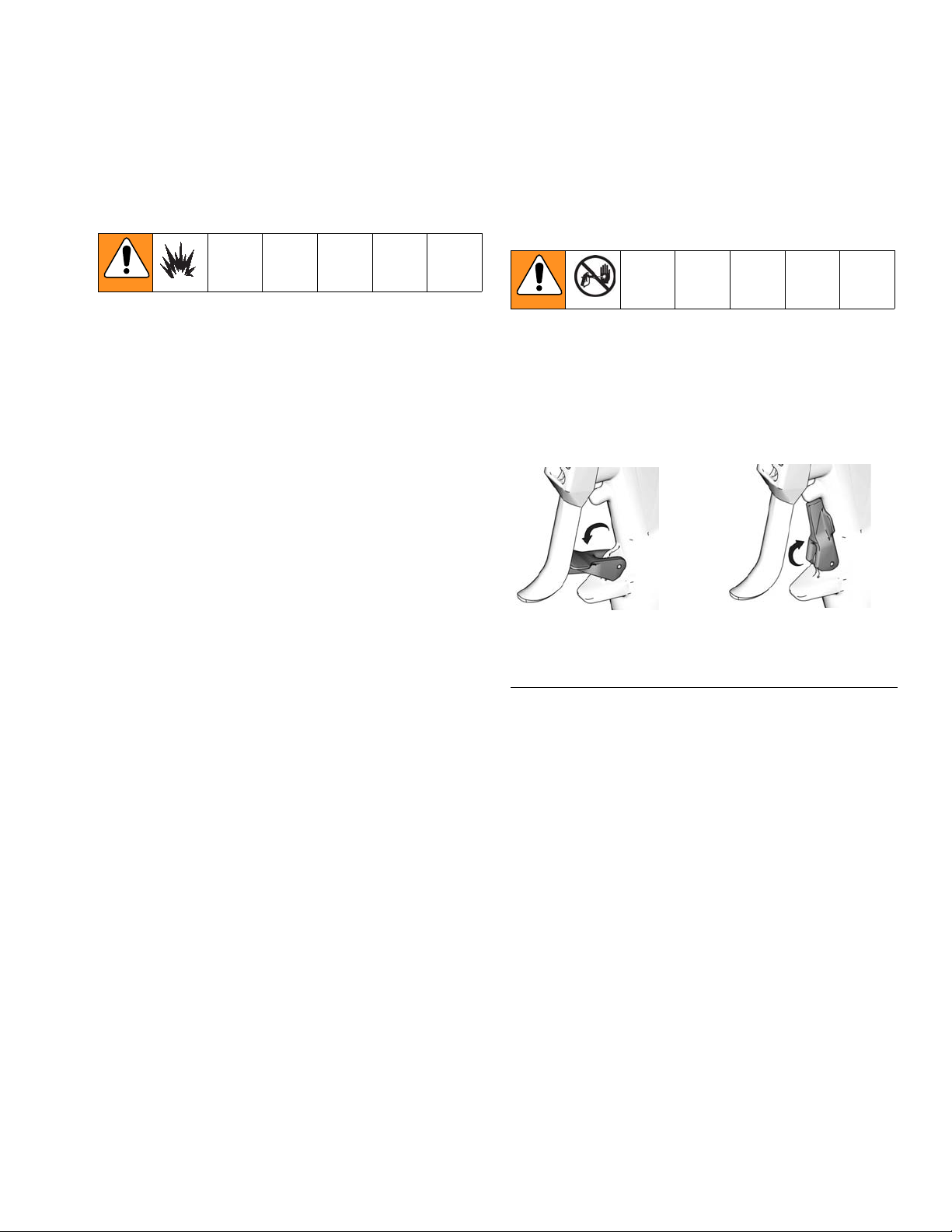

How to Use the Valve Trigger Safety

1. If you are using one of the hand-held versions of the

valve, lock the valve trigger safety by turning the

latch to a right angle with the gun body. See F

2. To unlock the valve trigger safety turn it parallel with

the gun body.

LOCKED

TI10442A

FIG. 3

UNLOCKED

IG. 3.

TI10441A

312185S 7

Page 8

Setup

Setup

Fluid and Air Connections

9/16 Straight Thread O-Ring Boss Fluid

Inlets

There is one fluid inlet on the A-side and one fluid inlet

on the B-side. The fluid inlets are located on the side of

the valve and swivel to permit various mounting and

hose configurations.

1/8 npt(f) Air Inlets

The machine mount valves and the electric switch

hand-held valves have an on port (I) and off port (O),

which are operated by a remote 4-way air control valve.

Use one of the two air inlets located on the bottom and

on the back of the valve.

The air switch hand-held valves have a single air inlet

with an internal 4-way spool which operates the air piston.

See Accessories on page 19, to order air control valves

and tubing.

Inlet Check Valves

Inlet check valves are recommended on the fluid inlets

where viscosity allows. An inlet check valve prevents

back-flow or crossover when the mixer is plugged or one

fluid is much lower viscosity than the other. When

required, a high crack pressure check valve is installed

to maintain back-pressure on low viscosity fluids.

See Accessories on page 19 for a list of check valves.

Balancing the System

Selecting Hoses

Hoses between your proportioner and the MD2 valve

should be selected carefully. Many factors effect hose

selection.

1. Fluid Compatibility: Fluid must not degrade the

core material or end fittings of the hose. Nylon or

PTFE cores are commonly used for chemical compatibility. If your fluid is moisture sensitive you

should use PTFE or Moisture-Lok hoses.

2. Pressure Rating: Be sure hoses have a working

pressure rating above the pressure capability of the

system.

3. Compressibility: Hoses, especially nylon paint

hoses, expand with an increase in pressure. A pressure change in the system may cause a volume

change, which can appear as a ratio error with wide

mix ratios. Compressible hoses absorb pressure

spikes which is helpful to the operator during an

application, such as trying to lay a bead.

4. Internal Diameter: Small I.D.'s create higher back

pressures, lower flows, and small retained volume.

Typically hose I.D.'s are selected for:

a. System Pressure Balance. “A” pressure drop

vs. “B” pressure drop.

b. Volume Balance. A:B volume ratio vs. Hose

retained volume.

c. Flexibility and weight for operator or robot.

d. Overall Pressure Drop. Pressure drop should be

minimum possible within the above guidelines.

A proportioner is used to feed the two-component dispense valve. The system must be pressure balanced to

avoid “lead-lag” ratio errors when starting and stopping

the flow.

Balancing is done by hose sizing or inlet check restriction. A properly balanced system has near equal

back-pressure on the gauges when flowing without a

mixer installed.

8 312185S

5. Length: Hoses normally are kept as short as practical to minimize pressure drop and compressible volume. 10 ft (3.1 m) is recommended for reciprocating

pump systems.

Page 9

System Start-up

When initially loading the fluids through the system,

leave the mixer off until both fluids flow freely from the

nose piece without any air. This prevents cross contamination from having fluid on one side pushing back up the

other side.

Mixer Selection

Disposable mixers are available from 3/16 in. I.D. to 1/2

in. I.D. in lengths from 12 elements to 36 elements. In

general, wide viscosity or mix ratios require more mix

elements. Small I.D. mixers produce lower flow, higher

back-pressure, and waste little material. Large I.D. mixers produce higher flow, lower back-pressure, and fewer

lead-lag ratio errors. Different mixers can have differing

snuff-back characteristics.

Setting the Amount of

Setup

Snuff-back

NOTE: For Models 255179 and 255181 only

The MD2 valves with hard seats use two snuff-back

restrictor rings (13) to set the amount of snuff-back.

These two rings are trapped between the main valve

body and the nose piece. When the fluid valve pulls

back to close, it enters the restrictions, stops flow, and

pulls the fluid back until the needle reaches its carbide

seat.

Maximum snuff-back results when both restrictors are

used. Some snuff-back is still achieved without the

restrictors because of the pull-back action of the needles.

When dispensing wide mix ratios, it is best to use a

snuff-back restrictor only on the high volume side. This

keeps the high volume side from being pulled back into

the low volume side.

The MD2 valves with soft seats have an adjustable

snuff-back. Turn the knob on the back of the soft seat

MD2 valve to adjust the amount of snuff-back.

In general, use only as much snuff-back as necessary to

give a good cut-off of flow. Too much snuff-back pulls an

air bubble into the mixer. This can cause a drip, or cause

the mixer to spit when the valve is re-opened.

312185S 9

Page 10

Operation

Operation

Pressure Relief Procedure

1. Shut off the air to the supply pumps.

2. Close the bleed-type master air valve (required in

your system).

3. Hold a metal part of the valve firmly to the side of a

grounded metal pail, and trigger the dispense valve

to relieve pressure.

4. Shut off the air to the dispense valve, if applicable.

If you suspect that the dispense needle or hose is completely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the hose end coupling and relieve pressure gradually, then loosen completely. Now clear the needle or

hose.

• Apply and maintain air pressure to the ON (I) air

port on the valve, and remove air pressure from the

OFF (O) air port on the valve to open the valve.

• Apply and maintain air pressure to the OFF (O) air

port on the valve, and remove air pressure from the

ON (I) air port on the valve to close the valve.

Pneumatic Hand-held Valve

The valve operation is such that it is either fully open or

fully closed.

The valve is opened and closed by the internal air control valve. Trigger the gun to open the valve. Release the

trigger to close the valve.

Ratio Checking

The output mix ratio of your proportioner can be

checked by dispensing the two fluids separately out of

the nosepiece into tared cups. The cups can then be

weighed and the weights divided to get the mix ratio by

weight.

Lever Actuated Valve and Electric Switch Hand-held Valve

• Be sure the air supply lines are connected correctly

to the (I) and (O) valve air ports.

• To open or close the valve and maintain the open or

closed status, a minimum of 40 psi (280 kPa, 2.8

bar) air pressure must be supplied and maintained

at the (I) or (O) port.

• The trigger and lever only activates the electrical

switch in the handle, which turns the remote solenoid on and off. See page 20 for electrical diagram.

• Trigger the gun or pull the lever to turn the solenoid

on. Release the trigger or lever to turn the solenoid

off.

Machine Mount Valve

• Be sure the air supply lines are connected correctly

to the ON (I) and OFF (O) valve air ports.

• To open or close the valve and maintain the open or

closed status, a minimum of 40 psi (280 kPa, 2.8

bar) air pressure must be supplied and maintained

at the ON (I) or OFF (O) port.

Use ratio check nozzles 255247 with 15K688 retaining

nut for 1:1 models, or 255245 with 15K688 retaining nut

for 10:1 models to make ratio checks.

Ratio checks provide information on the ratio of an overall sample. Transient problems (soft spots) caused by

starting and stopping the flow (lead-lag) may not show

up in this kind of ratio check. Physical tests of the mixed

fluid are the best check of correct ratio and mix quality.

10 312185S

Page 11

Maintenance

Daily Shutdown

When you are through using the MD2 valve, the outlet to

the mixer should be cleaned and protected from drying

or crystallization.

1. Remove and properly dispose of the static mixer.

2. Dispense a shot of material into a waste container

to clear any crossover in the nosepiece.

3. Wipe the nose with a clean rag being careful not to

let the materials contact each other.

Maintenance

4. Install the PTFE night cap (1:1 valves - 15K652,

10:1 valves - 15K628) and retaining nut (15K688).

Preventive Maintenance

There is a grease filled secondary seal/bearing area on

each valve shaft. Every 10,000 cycles, or twice each

month, new grease should be flushed across this area.

To grease the valve:

1. Remove the zerk grease fitting from each side of the

front or back of the valve.

2. Pump grease (115982) with grease gun (117792)

across the valve until clean grease comes out of the

other side.

3. Reinstall the zerk grease fitting.

312185S 11

Page 12

Troubleshooting

Troubleshooting

Problem Cause Solution

Valve does not open. Insufficient air pressure. Turn on air or increase air pressure.

Air not exhausted from the front side

of air cylinder piston.

Valve does not close and leaks. Insufficient air pressure. Turn on air or increase air pressure.

Air not exhausted from the back side

of air cylinder piston.

Blockage between needle and seat. Remove and clean needle and seat.

Damaged or missing gasket between

seat and housing (hard seat only).

Damaged or worn needle or seat. Replace both the needle and seat.

Too little snuff-back. Unscrew snuff-back adjustment nee-

Higher than normal back pressure. Nose piece is clogged. Remove and clean.

Mixer is curing. Replace mixer.

Soft spots in mixed material. Nose piece is clogged on one side. Remove and clean.

System is not properly balanced. Balance system with hoses, check

High static pressures build when

valve shuts off.

Low flow rate. Snuff-back rings (13) are installed

(hard seat only).

Use 4-way, relieving type air valve.

Use 4-way, relieving type air valve.

Replace gasket (38).

dle (25) 1/4 turn at a time.

valves, restrictors.

Turn off proportioner pump when

valve closes.

Remove snuff-back rings if they are

not required for maximum snuff-back.

12 312185S

Page 13

Repair

Repair

Disassembly

1. Relieve all air and fluid pressure, page 10.

2. Disconnect the valve from the system.

NOTE: In the following steps, keep the parts

from the A side and B side separate to prevent

cured material from forming on them.

3. Remove the two nosepiece screws (19), and pull the

nosepiece (29) away from the valve. Remove the

needle seats (27) and o-rings (20) for the 255179

and 255181 models. See F

4. 255179 and 255181 only: use a 5/32 in. socket

(4mm) to unscrew the needle (25). If the shaft (5)

spins, insert a dowel pin in the shaft hole to hold it

steady, then unscrew the needle. Slide the seal (26)

off the needle. Repeat for the other needle (25).

255180 and 255182 models: use a 3/32 pin punch

to remove the needle, then remove the seats (27)

and gaskets (28) from the inlet housing.

IG. 4.

5. Remove the two fluid housing screws (18) and

clamps (17) from the fluid housing (14). Slide the

fluid housing (14) off of the air cylinder (2). See F

5.

6. Remove the bearings (11), bearing o-rings (36, 13),

and secondary fluid seals (12, 15).

2

14

FIG. 5

16

13

36

15

11

12

17

18

IG.

TI9974A

20

26

27

25

19

F

IG. 4

312185S 13

29

14

TI9972A

Page 14

Repair

7. Remove the retaining ring (1) from the back of the

air cylinder (2). Push the two shafts (5) into the air

cylinder (2) to dislodge the air cylinder cap (22). See

F

IG. 6.

8. Push the two shafts (5) to dislodge the piston (9)

assembly from the air cylinder (2).

9. Use an o-ring pick to remove the o-rings (23) and

use a screwdriver to remove the sleeve bearings (7)

from the air cylinder (2).

10. Remove the o-rings (6) from the piston (9) and air

cylinder cap (22).

11. Remove the screw (24) and snuff-back adjustment

knob (21) from the cap (22). Use an o-ring pick to

remove the o-ring (23).

12. Remove the lock nuts (3), the pin (8), o-rings (4),

and piston o-ring (6) from the shaft (5).

210

FIG. 7

204

212

201

214

203

205

206

202

203

213

TI10408A

211

1

6

21

22

23

3

24

39

2

6

9

4

8

5

7

F

23

IG. 6

TI9975B

Pneumatic Handle (if equipped)

1. Remove the four screws (214). Pull the handle (205)

and gasket (204) away from the air cylinder (2).

2. Unscrew air valve plug (211) and remove spring

(213). Using a small diameter tool, push spool (202)

out from front. Inspect o-rings (203).

Electric Switch Handle (if equipped)

1. Disconnect the power from the gun.

2. The switch and cable are not repairable. Replace

these parts as a complete assembly. Use kit 255463

for series A handles. Use kit 24D049 for series B

handles.

3. Loosen the relief connector (112) and remove the

air valve plug (111).

4. Remove the wire which will take the electric

switch (114) and spacer (115) with it.

112

111

115

114

116

113

120

F

101

104

IG. 8

TI10384B

14 312185S

Page 15

Repair

Reassembly

Air Cylinder Section

1. Lubricate the shaft o-rings (23) and the bearings (7).

Insert o-rings into the air cylinder (2) and air cap

(22) cavities.See F

NOTE: The snuff-back adjustment knob (21),

shaft o-rings (23), and screw (24) are not present in models 255180, 255182, and 255183.

2. 255179 and 255182 only: Insert the snuff-back

adjustment knob (21) in the cap (22). Tighten the

screw (24) on the end of the snuff-back adjustment

knob (21). Torque to 25-30 in.-lb (2.8-3.4 N•m).

3. Press the bearings (7) flush into the air cylinder

housing (2) and air cap (22), trapping the o-rings

(23).

4. Lubricate and reassemble the piston assembly: piston (9), o-ring (6), dowel pin (8), nuts (3), o-ring (4),

and air cylinder shafts (5). Tighten nuts (3) to 25-30

in-lb (2.8-3.4 N•m). The shafts (5) should hang with

some play to be self-aligning in the bearing.

5. Lubricate the air cylinder (2) ID. Push the piston (9)

assembly into the air cylinder.

IG. 6.

6. 255179 and 255181, Insert the seals (26) with the

springs facing into the fluid housing (14).

7. With the “X” on the nosepiece on the same side as

the “MD2” on the air cylinder, install the nosepiece

(31) with the o-rings (20), seats (27), and nosepiece

screws (19). Tighten the nosepiece screws to

115-120 in-lb (14-15 N•m).

8. 255181 and 255182, Install injector tube (30) with

assembly tool (48). Torque to 168-192 in-lb

(19.0-21.7 N•m).

9. 255181 and 255182, Install injector tip (47) and

torque to 60-72 in-lb (6.8-8.1 N•m).

10. Remove zerk grease fitting (39). Fill grease in the

grease port below until grease begins to exit where

the zerk grease fitting (39) was located. Repeat for

the other zerk grease fitting (39). See F

IG. 6.

Pneumatic Handle (if equipped)

1. Liberally lubricate o-rings (203) and reassemble.

Install spool (202) and spring (213). Torque plug

(211) to 125-135 in-lb (14-15 N•m). See F

2. Align the gasket (204) and dispense valve on the

top of the handle (205). Torque the four screws

(214) evenly to 15-20 in-lb (1.7-2.2 N•m).

IG. 7.

6. Lubricate and assemble the o-ring (6) onto cap (22).

Push cap (22) into cylinder (2).

7. Install the outside retaining ring (1).

Fluid Section

1. Lubricate the bearings (11), o-rings (13, 36) and

seals (12, 15). Put the o-rings (13, 36) on the bearings. Carefully insert the seals (12) into the bearing

recess, with the lips of the seals facing into the bearing. Insert the seals (15) into the bearing with the

spring facing out of the housing. Be careful not to

damage the seal lips. See F

2. Push the bearings (11) into the air cylinder (2).

3. Grease the fluid housing (14) and install over the

bearings (11). Install the clamps (17) and screws

(18). Tighten to 25-30 in-lb (2.8-3.4 N•m).

4. For 255180 and 255182, insert the gaskets (28) and

seats (27).

5. Screw in the needle (25) and tighten it to 25-30 in.-lb

(2.8-3.4 N•m). See F

IG. 4.

IG. 5.

Electric Switch Handle (if equipped)

1. Install the plunger (113) and spring (116). See FIG.

8.

2. Insert the switch assembly (255463) while routing

the ground lug (108) through the hole in the top of

the handle.

3. Torque plug (111) to 125-135 in-lb (14-15 N•m).

4. Tighten the strain relief (112).

5. Install the ground screw (110) through the lock

washer (109) and ground lug (108). Torque to 15-20

in-lb (1.7-2.2 N•m).

6. Align the dispense valve on the top of the handle

(101). Torque the four screws (120) evenly to 15-20

lb (1.7-2.2 N•m).

312185S 15

Page 16

Parts

Parts

255179 and 255181

29

255181

47

30

18

16

2

1

17

11

12✖

13✖

36✖

15✖

19

2

29

14

20*†

26*

27*

25*

1

4❖✖

5✖

8

7❖

39

2

23❖

23❖

24

1

21

1

6

22

1

Torque to 25-30 in-lb (2.8-3.4 N•m).

2

Torque to115-120 in-lb (14-15 N•m).

6❖

3

1

TI21240A

9

16 312185S

Page 17

MD2 Valve

Parts

The parts listed below are common to all MD2 Dispense

valves. Parts which vary are found in the table at the bottom of this page.

Ref Part Description Qty

1 120762 RING, retainer 1

2 15K496 HOUSING, air cylinder 1

3 102920 NUT, lock 2

4❖✖ 157628 O-RING, buna-n 2

5✖ 15K421 SHAFT, primary 2

6❖ 156593 O-RING, buna-n 2

7❖ 551181 BEARING, sleeve 1/4, 3/8, 1/4,

nylon

8 551183 PIN, dowel 1/8 x 1.25 18-8 sst 1

9 626067 PISTON, air cylinder 1

11 15K422 BEARING, seal 2

12✖ 551191 PACKING, u-cup, nitrile 2

13✖ 113746 O-RING 2

14 15K441 HOUSING, inlet 2

15✖ 120768 SEAL, UHMWPE 2

16 15K442 SPACER, valve 2

17 15K444 CLAMP, adapter, inlet 2

18 121224 SCREW, cap, socket head, M5 x

0.8 x 8 mm

Ref Part Description Qty

19 107530 SCREW, cap, socket head, high

strength

20*† 117517 O-RING, fluoroelastomer 2

32 15K688 NUT, mixer; not shown 1

33 104765 PLUG, pipe, headless; not shown 2

36✖ 118594 O-RING, fluoroelastomer 2

38 551189 LUBRICANT, grease 3 oz. car-

tridge; not shown

39 120892 FITTING, grease 4

2

❖ Parts included in Valve Air Cylinder Repair Kit

255217 (purchase separately).

✖ Parts included in Valve Lube Seal Repair Kit 255218

(purchase separately).

* Parts included in Front Valve Repair Kit 255219 (pur-

chase separately).

† Parts included in Front Valve Repair Kit 255220 (pur-

chase separately).

2

2

1

Ref.

No. Description

21

KNOB, snuff-back, adjust

22a

CAP, air cylinder, snuff-back

❖23 O-RING, buna-n

24

STOP, snuff-back

25

NEEDLE, snuff-back *15K428 *15K428

26

SEAL, UHMWPE *120784 *120784

27

SEAT, needle *15K460 *15K460

29

HOUSING, nose

30

TUBE, injector, sst

31

CAP; not shown

40 ADAPTER, ratio check 255247 256794 1

47 TIP, injector 15V623 1

48 TOOL, assembly aid; not shown

1:1 10:1

15K419 15K419 1

15K420 15K420 1

156454 156454 3

15V627 15V627 1

15K445 15K649 1

15V624 1

15K652 15V628 2

256793 1

Qty255179 255181

2

2

2

312185S 17

Page 18

Parts

255180, 255182, and 255183

29

16

2

18

1

255182

25†

47

27†

30

2

26†

19

28†

20*†

39

29

17

12✖

11

13✖

36✖

15✖

14

4❖✖

5✖

8

7❖

2

23❖

1

6

22

1

Torque to 25-30 in-lb (2.8-3.4 N•m).

2

Torque to115-120 in-lb (14-15 N•m).

6❖

3

1

TI21241A

9

18 312185S

Page 19

MD2 Valve

Parts

The parts listed below are common to all MD2 Dispense

valves. Parts which vary are found in the table at the bottom of this page.

Ref Part Description Qty

19 107530 SCREW, high strength 2

20*† 117517 O-RING, fluoroelastomer 2

32 15K688 NUT, mixer; not shown 1

Ref Part Description Qty

1 120762 RING, retainer 1

2 15K496 HOUSING, air cylinder 1

3 102920 NUT, lock 2

4❖✖ 157628 O-RING, buna-n 2

5✖ 15K421 SHAFT, primary 2

33 104765 PLUG, pipe, headless; not shown 2

36✖ 118594 O-RING, fluoroelastomer 2

38 551189 LUBRICANT, grease 3 oz. car-

tridge; not shown

39 120892 FITTING, grease 4

42 299518 CAP, plug; not shown 2

6❖ 156593 O-RING, buna-n 2

7❖ 551181 BEARING, sleeve 1/4, 3/8, 1/4,

nylon

8 551183 PIN, dowel 1/8 x 1.25 18-8 sst 1

9 626067 PISTON, air cylinder 1

11 15K422 BEARING, seal 2

12✖ 551191 PACKING, u-cup, nitrile 2

13✖ 113746 O-RING 2

14 15K441 HOUSING, inlet 2

15✖ 120768 SEAL, UHMWPE 2

16 15K442 SPACER, valve 2

2

❖ Parts included in Valve Air Cylinder Repair Kit

255217 (purchase separately).

✖ Parts included in Valve Lube Seal Repair Kit 255218

(purchase separately).

* Parts included in Front Valve Repair Kit 255219 (pur-

chase separately).

† Parts included in Front Valve Repair Kit 255220 (pur-

chase separately).

17 15K444 CLAMP, adapter, inlet 2

18 121224 SCREW, cap, socket head, M5 x

2

0.8 x 8 mm

Ref.

No. Description

22

CAP, air cylinder

❖23 O-RING, buna-n

25

NEEDLE, snuff-back † 626062 † 626062 † 626062

26

SEAL, UHMWPE † 185467 † 185467 † 185467

27

SEAT, needle † 626060 † 626060

28

GASKET, seat † 171860 † 171860 † 171860

29

HOUSING, nose

30

TUBE, injector, sst

31

CAP; not shown

40 ADAPTER, ratio check 255247 255247 24P850 1

47 TIP, injector

48 TOOL, assembly aid 256793 1

1:1 1:1 10:1

15K447 15K447 15K447 1

156454 156454 156454 2

15K445 16T648 15K649 1

15V624 15V624 1

15K652 15K652 15V628 2

15V623 1

1

Qty255180 255183 255182

2

2

2

2

312185S 19

Page 20

Parts

Electric Switch Handle, 255208

NOTE: Extension cable 123660 is available.

1

105

106

1

120

113

116

114*

115*

111*

112*

2

119*

104

101

TI10384B

Series B handle shown

Ref Part Description Qty

101 15K666 HANDLE, 2K, dispense valve,

electric

104 15B209 TRIGGER, gun 1

105 192272 PIN, pivot 1

106 203953 SCREW, cap, hex hd, 10-24

UNC-3A x 3/8

111* PLUG, air valve 1

112* CONNECTOR, relief 1/4 npt 1

113 15K668 PLUNGER, trigger, 2K handle 1

114* SWITCH, elect mini snap action 1

115* SPACER, switch 1

116 551396 SPRING, 0.26X, 0.37X, 0.51 music

wire

119* CABLE, trigger, female, 3-pin con-

nector (Series A Handles Only)

CABLE, trigger, male, 4-pin con-

nector (Series B Handles Only)

120 117026 SCREW, cap, sch, M5 x 0.80 x

12 mm

* Parts included in Series A Handles Kit 255463 and

Series B Handles Kit 24D049 (purchase separately).

TI14761A

1

Torque to 25 in-lb (2.8 N•m).

2

Torque to 125-135 in-lb (14-15 N•m).

1

1

1

1

1

4

20 312185S

Page 21

Pneumatic Handle, 255206

204

4

210

214

203

202

2

203

213

2

211

3

215

Parts

216

3

207

205

212

206

1

201

3

TI21242A

Ref Part Description Qty

201 100721 PLUG, pipe 1

202 15B202 VALVE, spool 1

203* O-RING, chemically resistant fluorocarbon 3

204 15K661 GASKET, handle 1

205 15K658 HANDLE, 2K dispense valve, air 1

206 119626 PLUG, breather 1

207 192272 PIN, pivot 1

210 203953 SCREW, cap hex hd, 10-24 UNC-3A x 3/8 1

211 15B208 PLUG, air valve, 1/4 npt 1

212 15B209 TRIGGER, gun 1

213 117485 SPRING, compression 1

214 117026 SCREW, cap, sch, M5 x 0.80 x 12 mm 4

215 117509 COUPLER, line, air, 1/4 npt 1

216 117510 FITTING, line, air, 1/4 npt 1

1

Torque to 35 in-lb (4 N•m).

2

Apply lubricant on seals.

3

Apply thread sealant. Torque to 130 in-lb (15 N•m).

4

Torque to 25 in-lb (2.8 N•m).

* Parts included in Kit 246354 (purchase separately).

312185S 21

Page 22

Parts

Actuated Lever, 255249

305

1

319

310

307

308

302

303

301

304

306

1

309

303

Ref Part Description Qty

301 15K922 BLOCK, mounting lever, 2K 1

302 121191 BOLT, eye, 1/4-20 x 2 in. (51 mm) 1

303 100015 NUT, hex, 1/4-20 UNC 2-B 2

304 100016 WASHER, lock 1

305 192272 PIN, pivot 1

306 203953 SCREW, cap, hex, hd 1

307 551318 CONNECTOR, relief, 1/4 npt 1

308 121192 SWITCH, pushbutton 1

309 121193 PLUNGER, spring, 1/4-20 1

310 15M479 LEVER, actuator, valve 1

311 121194 SCREW, socket head cap, M5 - 0.8 x

30 mm (not shown)

319 123619 CABLE, trigger 1

1

Torque to 25 in-lb (2.8 N•m).

TI10410B

4

22 312185S

Page 23

Accessories

Plastic Tube Fittings to Connect Air Signals

Tube OD 1/8 NPT (M) Straight 1/8 NPT (M) 90° Swivel

Accessories

5/32 in.

1/4 in.

Tube OD 1/4 NPT (M) Straight 1/4 NPT (M) 90° Swivel

5/32 in.

1/4 in.

114263

115671

598252

104165

114151

112698

114469

114109

Inlet Check Valves (3000 psi working pressure)

Part No. Size Description

501867

501684

949709

949710

1/4 NPT (M x M)

3/8 NPT (M x M)

3/8 NPT (M x M)

3/8 NPT (M x M)

303 sst with PTFE o-ring poppet (2 psi crack pressure).

303 sst with PTFE o-ring poppet (2 psi crack pressure).

Carbon steel carbide seat (50 psi crack pressure).

Carbon steel carbide seat (100 psi crack pressure).

Catalyst Injectors

Catalyst injectors are restrictive check valves which are often used to create back pressure on the catalyst side inlet

to the MD2 valve. Catalyst injectors are also used to balance pressures and flow on wide-ratio, low-viscosity catalyst

applications.

Typical

Injector No. Size Code Bore Dia. Needle Dia.

Application

Viscosity

Typical Used

Sealant*

948291 #125 0.125 in. 0.086 in. 500-50,000 cps Polysulfide

948258 #35 0.110 in. 0.086 in. 1000-10,000 cps Silicone

947937 #40 0.098 in. 0.086 in. 200-1,500 cps Urethane

570251 #42 0.0935 in. 0.086 in. 50-800 cps Urethane

* Wide ratio applications 8:1 to 13:1 by volume.

** Injectors have a “snout” and must be screwed into a 1/4 npt(f) female coupling. Inlet is 1/4 npt(f).

312185S 23

Page 24

Accessories

Plastic Tubing for Air Signal Lines

Part No. Description

514607 5/32 in. O.D. Nylon

C12509 1/4 in. O.D. Nylon

Mixers and Shroud

ID x # elements 50 pack 250 pack Shroud

3/16 x 32 LC0077 LC0084 LC0063

1/4 x 24 LC0078 LC0085 LC0057

3/8 x 24 LC0079 LC0086 LC0058

3/8 x 36 LC0080 LC0087 LC0059

3/8 Combo LC0081 LC0088 LC0060

3/16 x 32 Luer Lock LC0082 LC0089 LC0061

1/4 x 24 Luer Lock LC0083 LC0090 LC0062

Nose Piece Accessories

Part No. Description Notes

15K652 1:1 nightcap PTFE cap to protect the 1:1 outlet when not in use

15V628 10:1 nightcap PTFE cap to protect the 10:1 outlet when not in use

255247 1:1 ratio check nozzle Splits the flow on 1:1 valves to facilitate ratio checks

24P850 10:1 ratio check nozzle Splits the flow on 10:1 valves to facilitate ratio checks

258687 10:1 check tip Assembly for low volume side material that is very thin

256793 Tool Assembly tool to aid in the installation and removal of

injector tube 15V623

15K688 7/8-9 retaining nut Use to hold 15K652, 255247 and 255245 on to valve

24 312185S

Page 25

Accessories

Orifice Kits

In the following table, shaded rows indicate “Super Standard” items that are typically stocked and provide the best

delivery dates.

Impingement

Port Size

Kit Type and Kit Number

250 Model Polyol

Orifice Kit

250 Model Iso

Orifice Kitin. mm

0.016 0.41 24C805 24D229

0.020 0.51 24C751 24D223

0.024 0.61 24C806 24D230

0.028 0.71 24C807 24D231

0.031 0.79 24C752 24D224

0.035 0.89 24C808 24D232

0.039 0.99 24C809 24D233

0.042 1.07 24C810 24D234

Impingement

Port Size

0.047 1.19 24C753 24D225

0.052 1.32 24C811 24D235

0.055 1.40 24C812 24D236

0.060 1.52 24C754 24D226

0.063 1.60 24C813 24D237

0.067 1.70 24C755 24D227

0.073 1.85 24C815 24D238

0.086 2.18 24C756 24D228

Kit Type and Kit Number

250 Model Polyol

Orifice Kit

250 Model Iso

Orifice Kitin. mm

Orifice Kit

504

503

502

501

505

4

3

507

3

506

3

509

Ref. Part Description Qty.

501 --- HOUSING, orifice 1

502†‡ --- O-RING, 0.63 in. diameter 1

503† --- O-RING, 0.44 in. diameter 1

504†◆ --- O-RING, 0.37 in. diameter 1

505 --- STEM, valve 1

506† --- RING, backup, PTFE 1

507† --- O-RING, 0.28 in. diameter 1

509 --- CAP, orifice 1

510 --- TOOL, cleanout; #78 drill bit (not

shown)

1

ti21829a2

3

Apply a light coating of lubricant to seals and surfaces

specified.

4

Fasten stem (505) into housing (501). Fasten

cap (509) onto housing (501) and torque to 60-70 in-lb

(6.8-7.9 N•m). Unscrew stem (505) until it bottoms out

against cap (509).

† Parts included in kit 24D321.

‡ Parts included in kit 248130 (pack of 6).

◆ Part included in kit 248128 (pack of 6).

312185S 25

Page 26

Accessories

24E505 Orifice Block Kit

401

Part 122737, Swivel Adapter - JIC 6 x 1/4 npt,

not included in kit

Part 122961, Swivel Adapter - JIC 5 x 1/4 npt,

not included in kit

402b

MD2 Valve not included

401d

1

Lubricate all o-rings and specified surfaces.

2

Torque to 20-30 in-lb (2.2-3.4 N•m).

Ref. Part Description Qty.

401 HOUSING, orifice, assy;

includes 401a-401d

401a HOUSING, orifice 1

401b WASHER 1

401c NUT 1

401d 123886 O-RING 1

402 KIT, orifice block plug; includes

402a and 402b

402a PLUG, orifice 1

402b 117724 O-RING 1

24E505 does not include an MD2 valve. See MD2

Valve Models on page 2.

402a

1

2

401b

401c

401a

ti21829a1

1

1

24E505 does not include swivel adapters. Swivel

adapters 122961 and 122737 must be purchased

separately.

See manual 3A0861 for ratio check assembly

24F227.

26 312185S

Page 27

Valve Accessories

Accessories

551351 Short Throw Spacer

A spacer under the air piston that limits how far the fluid

needles push open. It reduces the amount of material

surge when the valve opens, and reduces the amount of

snuff-back available. Used for dispensing low flow small

diameter beads. For 255180 and 255182 only.

123660 Extension Cable, 6.0 m (19.7 ft)

For locating the valve further from the base system than

allowed with the original cable provided. For use with the

electric handle 255208 and actuated lever 255249.

Conversion Kits

Part No. Description Notes

255206 Pneumatic Handle Convert any valve to a hand held valve with an internal

pneumatic 4-way valve. See page 21.

255208 Electric Handle Convert any valve to a hand held valve with an internal nor-

mally open switch. See page 20.

255249 Electric Lever Switch Convert any valve to a hanging valve with an internal nor-

mally open switch. See page 22.

255273 Hanger Adapter Add to any hand held valve to allow it to be hung.

123902 Cable Replaces trigger cable included with electric handle 255208

and actuated lever 255249. For converting handle/lever to

connect to systems previously connected to a TwinMixer

gun. Use pins 1 (brown) and 3 (blue).

®

Hanger Adapter

255273

TI10512A

312185S 27

Page 28

Accessories

Front Valve Repair Kits

Part No. Description

255219 Repair Kit for adjustable

snuff-back valves 255179 and

255181 only.

255220 Repair Kit for non-adjustable

snuff-back valves 255180,

255182, and 255183 only.

G 1/2 Outlet Kit

Part No. Description

16T802 Adapter to allow for the mounting

of G 1/2 threaded mixers. Applicable for 10:1 MD2 valves only.

Angled Adapter Kits

24W045 - 25° angle

24W046 - 15° angle

24W047 - 5° angle

Ref. Part Description Qty.

601 17B515 25° adapter block 1

17B516 15° adapter block 1

17B517 5° adapter block 1

602 15K661 GASKET, handle 2

603 117026 SCREW, socket head, M5x12 8

602

603

601

602

o

x

r_16t802

28 312185S

Page 29

Technical Data

Technical Data

Maximum Fluid Pressure 255179-255182: 3000 psi (20.7 MPa, 207 bar)

255183: 2000 psi (13.8 MPa, 138 bar)

Maximum Cylinder Air Pressure 120 psi (0.84 MPa, 8.4 bar)

Air Inlets (open (I) and close (O) ports) 1/8 npt(f)

Fluid Inlets 9/16 straight thread o-ring boss “A” and “B”

Fluid Outlet 7/8-9 bell outlet

Fluid Viscosity Range

Soft Seats 1-1 million cps

Hard Seats 20-1 million cps

Fluid Section Sealing Isolation chamber with zerk fittings and dual seals.

Divorced Air Cylinder Double acting, buna-n o-rings

Weight

255179 / 255180 (1:1 valves) 1.45 lb (0.66 kg)

255181 / 255182 (10:1 valves) 1.50 lb (0.68 kg)

255206 (pneumatic handle) 0.85 lb (0.39 kg)

255208 (electric handle) 0.90 lb (0.41 kg)

255249 (electric lever) 0.75 lb (0.34 kg)

Wetted Parts

Stainless Steel Valve 303 sst, 17-4 SS, UHMWPE, PEEK, Chemical Resistant

o-rings. 440C SS and C2 carbide with cobalt binder (hard

seat only)

Dimensions

6.64 in. (168.7 mm)

5.64 in. (143.3 mm)

0.28 in. (7.1 mm)

M5 x 0.8 mounting holes (2)

4.29 in. (109 mm)

1.06 in. (26.9 mm)

M5 x 0.8 mounting

holes (4)

0.73 in. (18.5 mm)

0.73 in. (18.5 mm)

4.60 in. (116.8 mm)

TI9977A

312185S 29

TI10654A

Page 30

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective par ts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2007, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 312185

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised June 2014

Loading...

Loading...