Page 1

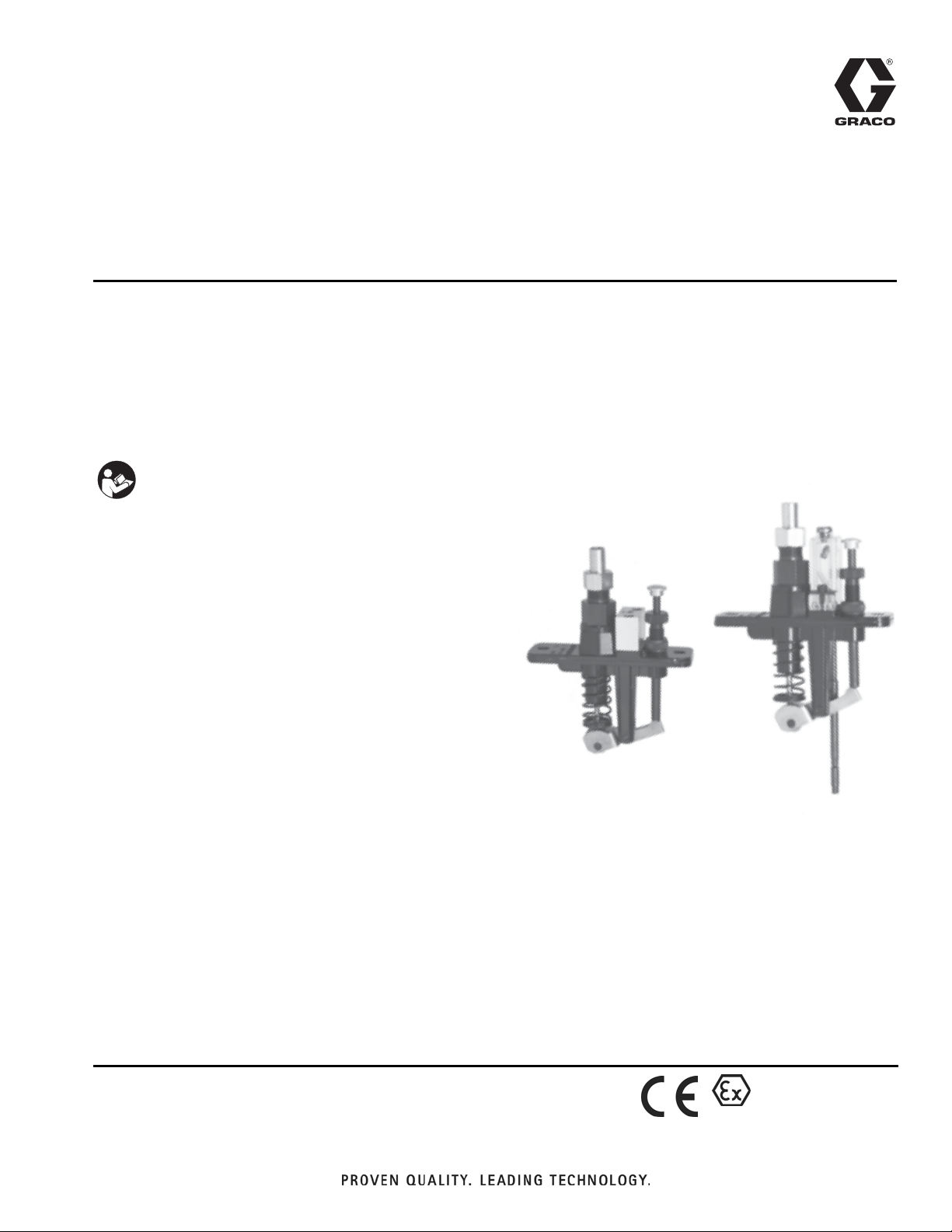

Instructions/Parts

Modular

Box Lubricators

For dispensing non-corrosive and non-abrasive oils and lubricants.

Model MBXXXX

See page 4 for model numbers and maximum working pressures.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 3

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 10

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 10

Model 88 Pumps

312147B

ti9848a

II 2 G c T4

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

2 312147B

Page 3

Pressure Relief Procedure

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

Pressure Relief Procedure

Fluid under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of an

injuiry from injection, splashing fluid, or moving parts,

follow the Pressure Relief Procedure whenever you:

• are instructed to relieve the pressure,

• check, clean, or service any system equipment,

• or install or clean fluid nozzle.

1. Turn off the power supply to the pump.

2. Open any fluid drain valves in the system.

3. Leave the drain valve open until you are ready to

pressurize the system.

If you suspect that pressure is not fully relieved

after following the previous steps, using a rag very

slowly loosen the hose end coupling or a fitting on

the fluid line and allow pressure to be relieved gradually, then loosen the part completely and clear the

clog.

312147B 3

Page 4

Models

Models

ti9849a

Model 88 Pumps

Part Number

Standard

Pump

562953 562961 76B 3/16 7500 psi (52.5 MPa, 525 bar) 6 1 0.013 0.002 0.213 0.033 50 3

562955 562963 76C 1/4 6000 psi (42.5 MPa, 425 bar) 12 2 0.024 0.004 0.393 0.066 50 3

562957 562965 76E 3/8 2500 psi (17.5 MPa, 175 bar) 27 4 0.055 0.008 0.901 0.131 50 3

562954 562962 88B 3/16 7500 psi (52.5 MPa, 525 bar) 6 1 0.013 0.002 0.213 0.033 50 3

562956 562964 88C 1/4 6000 psi (42.5 MPa, 425 bar) 12 2 0.024 0.004 0.393 0.066 50 3

562958 562966 88E 3/8 2500 psi (17.5 MPa, 175 bar) 27 4 0.055 0.008 0.901 0.131 50 3

Pressurized

Pump Max. Min. Max. Min. Max. Min. Max. Min.

Option

Piston

Size

(in.) Maximum pressure

ti9848a

Model 76 Pumps

Drops

per stroke

Cu. In.

per stroke

3

Cm

per stroke

Strokes

per

minute

4 312147B

Page 5

Installation

Installation

CAUTION

The installation and all work concerning assembly,

maintenance, and repair must be completed by qualified personnel.

Mounting

When possible, mount the lubricator on a surface

that experiences little to no vibration.

Reservoirs have end mounting lugs as shown in outline

drawings on page 9. Use all mount features provided to

ensure the lubricator is rigidly fixed after installation.

Select a mounting location that will accomplish the following goals:

• Allow easy access to the lubricator for filling the

reservoir and periodic maintenance.

• Provide a stable surface upon which the lubrica-

tor can operate.

• The lubricator must be connected to a ground

source.

System Connections

It is recommended that each pumping unit be installed

with a check valve in the discharge line so that the pump

assembly may be removed from the reservoir without

loss of lubricant in the discharge lines. The installation of

a second check valve at the end of the discharge line

will prevent line drainage and act as a positive means of

avoiding feedback of system pressure to pump.

When using Model 88 pumps, torque the union fitting on

the outlet check valve to 37- 42 ft-lb (50-57 N•m)

Lubricant Types and Viscosities

Graco Modular Box Lubricators are suitable for use with

mineral oil or synthetic base lubricants with viscosities in

the range of 100 to 5000 SUS under pumping conditions.

Drive Mechanism

A 5/8 in. diameter shaft is provided to connect the lubricator to a rotary power source. A number 5 woodruff key

and key way on the shaft are provided to aid in connecting this source.

Install protective guards around all drive components

upon installation.

CAUTION

The recommended speed of the mechanism driving

the lubricator is 3 - 50 rpm. Do not exceed the maximum value of 50 rpm to avoid pump damage.

312147B 5

Page 6

Operation

Operation

Oil Level

When necessary, completely fill the lubricator reservoir

with clean filtered lubricant. A sight level gauge is provided on the reservoir to monitor the fluid level. Oil level

should not be allowed to drop below the line indicating

an empty reservoir.

During the initial filling, remove the vent plug from

pumps using sight glasses prior to filling the reservoir.

This allows lubricant to rise in the vacuum tube up to the

level of lubricant in the reservoir and reduces the priming required at start up.

If pressurized pumps are used, the reservoir should

be filled with lubricant to extend the life of the internally moving components.

Pump Priming

1. Loosen the adjustment rod lock nut.

2. Turn the adjustment rod guide clockwise to

decrease the amount of lubricant dispensed, or

counterclockwise to increase the amount of lubricant dispensed.

3. Once the desired settings have been achieved,

tighten the adjustment rod lock nut by hand.

.

The vacuum tube dispense rate is accurate after

the pump has operated long enough to stabilize

the pressure inside the sight glass. There is a time

lag at start-up, low dispense rates, and during the

adjustment of dispense rates. Allow sufficient time

to ensure the proper amount of lubricant is dispensed.

If the sight well on the pump does not contain oil, the

pump should be primed using the following procedure:

1. If using a vacuum type pump with a sight glass,

remove the vent screw located on the top of the

sight glass.

2. Adjust the pump stroke length to its maximum setting.

3. Depress the hand plunger assembly and release

when the cap contacts the adjustment rod guide.

4. Repeat until an air free stream of fluid exits the

pump outlet.

5. Replace the vent screw at the top of the sight glass.

Pumping Rate

The amount of lubricant dispensed from each pump can

be adjusted. The volume dispensed by each pump is

indicated by the amount of lubricant dripping from the

vacuum tube inside the sight glass.

The amount of dispensed volume can be adjusted by

performing the following steps:

6 312147B

Page 7

Service

CAUTION

The installation and all work concerning assembly,

maintenance, and repair must be completed by qualified personnel.

1. Follow the Pressure Relief Procedure on page 3.

2. Lubricator operation can be checked by observing

the drip tube. If the correct pumping rate is maintained, no servicing is required other than periodic

replenishment of the reservoir. If the sight glass well

pumps dry or no flow is observed, check the following points until the cause is determined and corrected.

a. Check the vent plug for proper sealing. Any

nicks or cracks will cause an air leak into the

sight glass.

b. Check shaft rotation. If the lubricator shaft is not

rotating, determine the cause and repair as necessary.

Service

seating, or a defective o-ring. Repair as

required.

b. Check for an obstruction in the drip tube and

remove if found.

4. If these steps do not isolate the malfunction, disconnect the discharge tubing and remove the pump

assembly which is attached to the cover with two

screws. It is not necessary to stop the equipment on

which the lubricator is installed or to empty the reservoir. A spare pump should be on hand for use during emergencies when a pump is being repaired.

5. If the sight glass fills with lubricant proceed as follows:

a. Remove the vent plug and allow the lubricant to

pump down to the proper level. Replace the

vent plug. The pump should operate normally.

b. If the sight glass continues to fill with lubricant

check all terminal check valves for proper operation. If the valves are operating properly,

remove and clean the pump assembly, then

reinstall the pump in the system and check

operation.

c. Check oil level and viscosity. Be sure the reser-

voir is filled with oil.

d. Check pump priming. If necessary, prime the

pump in accordance with the “Operating

Instructions”.

e. Check the feed adjustment and readjust if the

pumping rate is too low.

f. Check the actuating linkage for proper opera-

tion. If defective, isolate the broken part and

repair or replace as required.

3. If none of the above steps isolate the malfunction,

the cause is in the pump assembly. The following

items should be checked before removing the pump

assembly from the cover.

a. Check the sight for inward leakage due to a

crack in the sight glass, improper sight glass

6. If the sight glass still fills with lubricant it may be

caused by temperature variation.

a. When the unit is not operating, remove the vent

plug and allow the lubricant to pump down to

the proper level. Replace the vent plug. The

pump will now function properly. The sight glass

may fill with fluid without affecting the operation

of the lubricator as long as the drip tube

remains above the lubricant level to show the

rate of pumping.

b. When the unit is operating, the sight level will

vary depending on temperature variations. If the

level falls to less than 1/4 inch above sight glass

flange, add lubricant to the proper level (3/8 inch

below the discharge of the drip tube) through

the vent hole. If the level is too high, remove the

vent plug and allow the unit to pump down

before replacing the vent plug.

312147B 7

Page 8

Technical Data

Other servicing that may be required is listed below:

• Periodic cleaning of the lubricator is desirable to

eliminate contamination that may have occurred in

the oil. To accomplish this, remove all pumping units

and clean the pumps and reservoir by brushing

loose all foreign matter, dipping in solvent and blowing dry with compressed air.

• If external leakage is observed, determine the

cause (loose bolts, defective gaskets, or seals) and

repair as required.

Technical Data

Plunger diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/16 in. (4.8 mm) for Models 76B and 88B

3/8 in. (9.5 mm) for Models 76E and 88E

1/4 in. (6.4 mm) for Models 76C and 88C

Maximum Working Pressure*. . . . . . . . . . . . . . . . . . . . . . 2500-7500 psi (17.5-52.5 MPa; 175-525 bar)

Minimum Pump Dispensing Rate* . . . . . . . . . . . . . . . . . . 0.002 - 0.008 cu. in.

Maximum Pump Dispensing Rate* . . . . . . . . . . . . . . . . . 0.013 - 0.055 cu. in.

Operating Temperature Range. . . . . . . . . . . . . . . . . . . . . -20°F to 140°F (-29°C to 60°C)

Dispensing Fluid Viscosity . . . . . . . . . . . . . . . . . . . . . . . . 100 - 5000 SUS

Wetted Materials music wire, carbon steel, nylon, aluminum, nitrile rubber

*Varies with pump selection, see Models chart on page 4.

8 312147B

Page 9

Dimensions

Dimensions

)NCHES

MILLIMETERS

"LANKCOVER

ASSEMBLY

DIAMETER

FOURMOUNTINGHOLES

490

!

"

NPSF

LUBEOUTLET

(ANDPLUNGERAND

PUMPOUTPUTADJUSTMENT

NPTDRAINPLUG

BOTHSIDES

&ILLCUP

,EVELSIGHT

GAUGE

ti9847

Size Dimensions - inches (millimeters

Options

T1

T2

T3

T4

T5

T6

T7

T8

Note: A blank cover assembly will be provided for all unused pump stations.

Pints Liters A B

4 1.9 5.50 (139.70) 6.75 (171.45)

6 2.8 7.25 (184.15 8.50 (215.90)

8 3.8 10.75 (273.05) 12.00 (304.80)

12 5.7 16.00 (406.40) 17.25 (438.15)

16 7.6 23.00 (584.20 24.25 (615.95)

24 11.3 30.00 (762.00) 31.25 (793.75

32 15.1 37.00 (939.80) 38.25 (971.55)

40 18.9 44.00 (1117.60) 45.25 (1149.35)

312147B 9

Page 10

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 312147

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2007, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 06/2009

Loading...

Loading...