Page 1

XTR™ 5 and XTR™ 7 Airless Spray Gun

Instructions/Parts

See Parts, beginning on page 8, for model numbers.

Maximum Working Pressure:

XTR 5: 5000 psi (35 MPa, 345 bar)

XTR 7: 7250 psi (50 MPa, 500 bar)

For use with protective coating materials

IMPORTANT SAFETY INSTRUCTIONS.

Refer to your sprayer instruction manual for

pressure relief, priming, and spraying

instructions. Keep these instructions.

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer

to procedure-specific risks. Refer back to these warnings. Additional product-specific warnings

may be found throughout the body of this manual where applicable.

ti5045b

WARNING

312145G

EN

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get

immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and

before cleaning, checking, or servicing equipment.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the

eyes or on skin and cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and

before cleaning, checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

II 2 G c T6

Page 2

WARNING

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or

explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric

lamps, and plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords or turn power or light switches on or off when

flammable fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not

use equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest

rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See

Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s

warnings. For complete information about your material, request MSDS forms from

distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with

genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and

hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Use of fluids that are incompatible with aluminum in pressurized equipment can cause

a serious chemical reaction and equipment rupture. Failure to follow this warning may

result in death, serious injury, or property damage.

• Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents.

• Many other fluids may contain materials that are incompatible with aluminum. Contact your material supplier for verification.

2 312145G

Page 3

WARNING

WARNING

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on

skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To

avoid severe burns, do not touch hot fluid or equipment. Wait until equipment/fluid has

cooled completely.

RECOIL HAZARD

Gun may recoil when triggered. If you are not standing securely, you could fall and be

seriously injured.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in

the operating area of the equipment to help protect you from serious injury, including

eye injury, inhalation of toxic fumes, burns, and hearing loss. This equipment includes

but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

312145G 3

Page 4

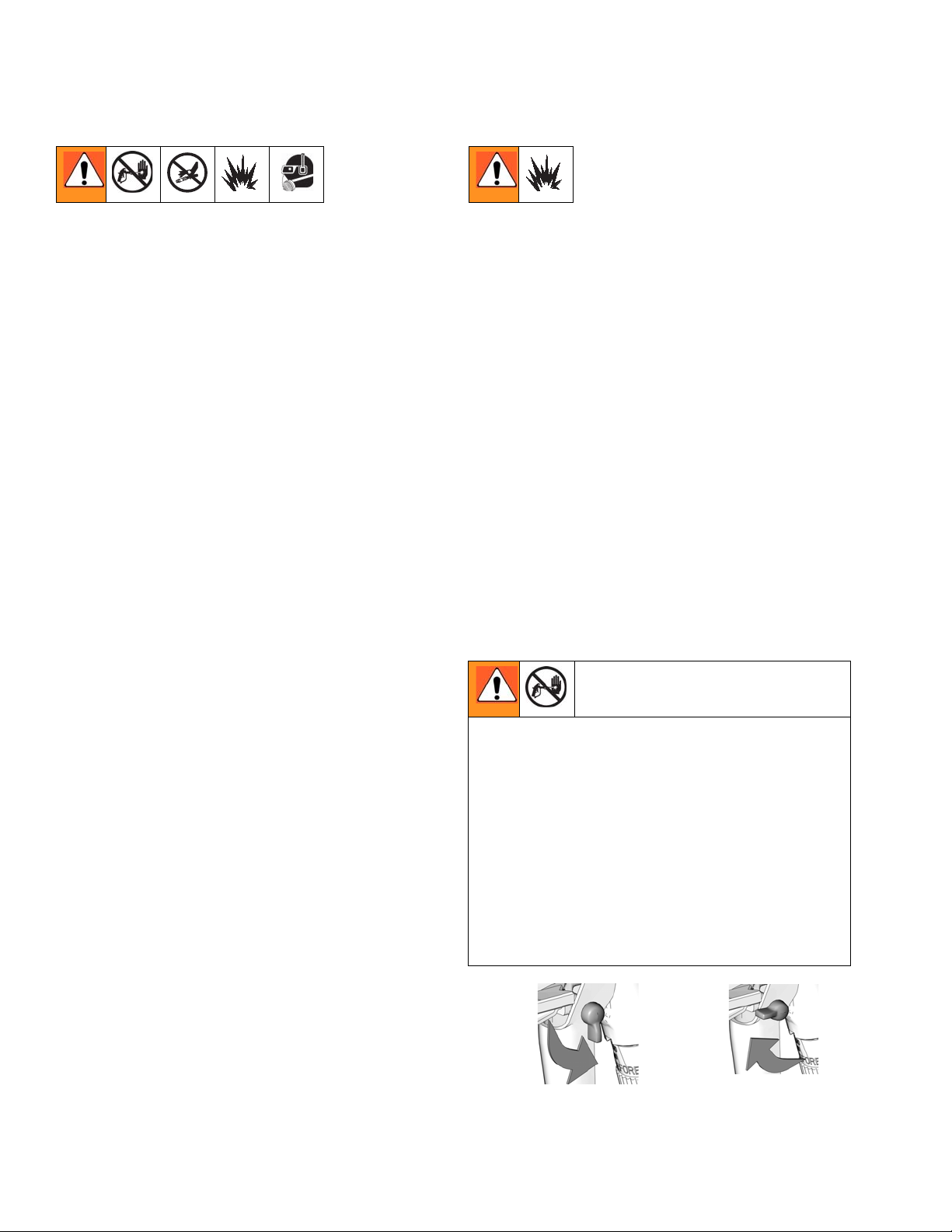

Pressure Relief Procedure

Pressure Relief Procedure

Follow this Pressure Relief Procedure

whenever you are instructed to relieve

pressure, stop spraying, check or service

equipment, or install or clean spray tip.

1. Engage trigger lock.

2. Shut off pump.

3. Disengage trigger lock.

4. Hold a metal part of the gun firmly to a

grounded metal pail. Trigger the gun to

relieve pressure.

5. Engage trigger lock.

6. Open fluid drain valve (see System

Requirements). Leave drain valve open.

If pressure is not fully relieved:

• Spray tip is clogged. For RAC tip, see

Cleaning Tips/Clearing Clogs, page 6.

For flat tip, slowly loosen tip guard retaining

nut to relieve pressure. Remove and clear

tip.

• Hose is clogged. Slowly loosen hose end

coupling to relieve pressure. Clean hose

obstruction.

Grounding

Check your local electrical code and

pump/sprayer manual for detailed grounding

instructions.

• Spray gun: ground through connection to a

grounded fluid hose and pump/sprayer.

• Fluid hose: use only grounded hoses.

• Fluid supply container: follow local code.

• Object being sprayed: follow local code.

• Solvent flushing pails: follow local code.

Use only conductive metal pails placed on

a grounded surface. Do not place pail on a

nonconductive surface, such as paper or

cardboard, which interrupts grounding

continuity.

• To maintain grounding continuity when

flushing or relieving pressure: hold metal

part of gun firmly to side of a grounded

metal pail, then trigger gun.

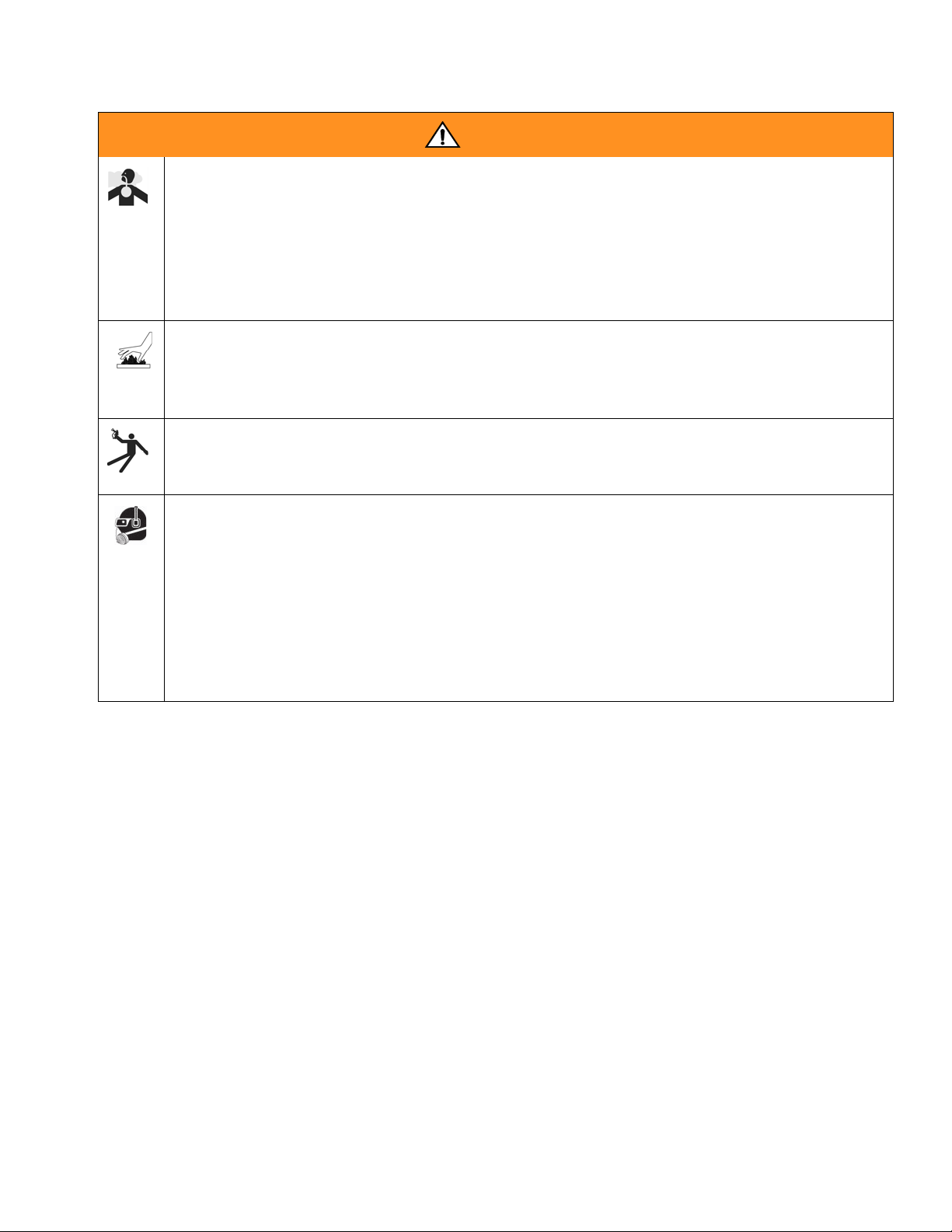

Gun Trigger Lock

System Requirements

• Install a bleed-type master air valve on a

pneumatic pump air supply line to relieve

air trapped between this valve and pump

after air regulator is shut off. Trapped air

can cause the pump to cycle unexpectedly.

• Install a fluid drain valve between the pump

and gun to relieve pressure in displacement pump, hose, and gun. Triggering to

relieve pressure may not be sufficient. See

Pressure Relief Procedure.

To prevent injury when the gun is not in use,

always engage the gun’s trigger lock if unit is

being shut down or left unattended. A

wallet-sized warning card with important

injection treatment information is included

with the gun. Additional cards are available at

no charge. Provide a card to all operators.

The trigger lock must move freely, and easily

snap into a locked position. If the trigger lock

is damaged or movement is restricted,

replace with new trigger kit (16) immediately.

Trigger

Locked

(no spray)

Trigger

Unlocked

(spray)

ti5049b

ti5048b

4 312145G

Page 5

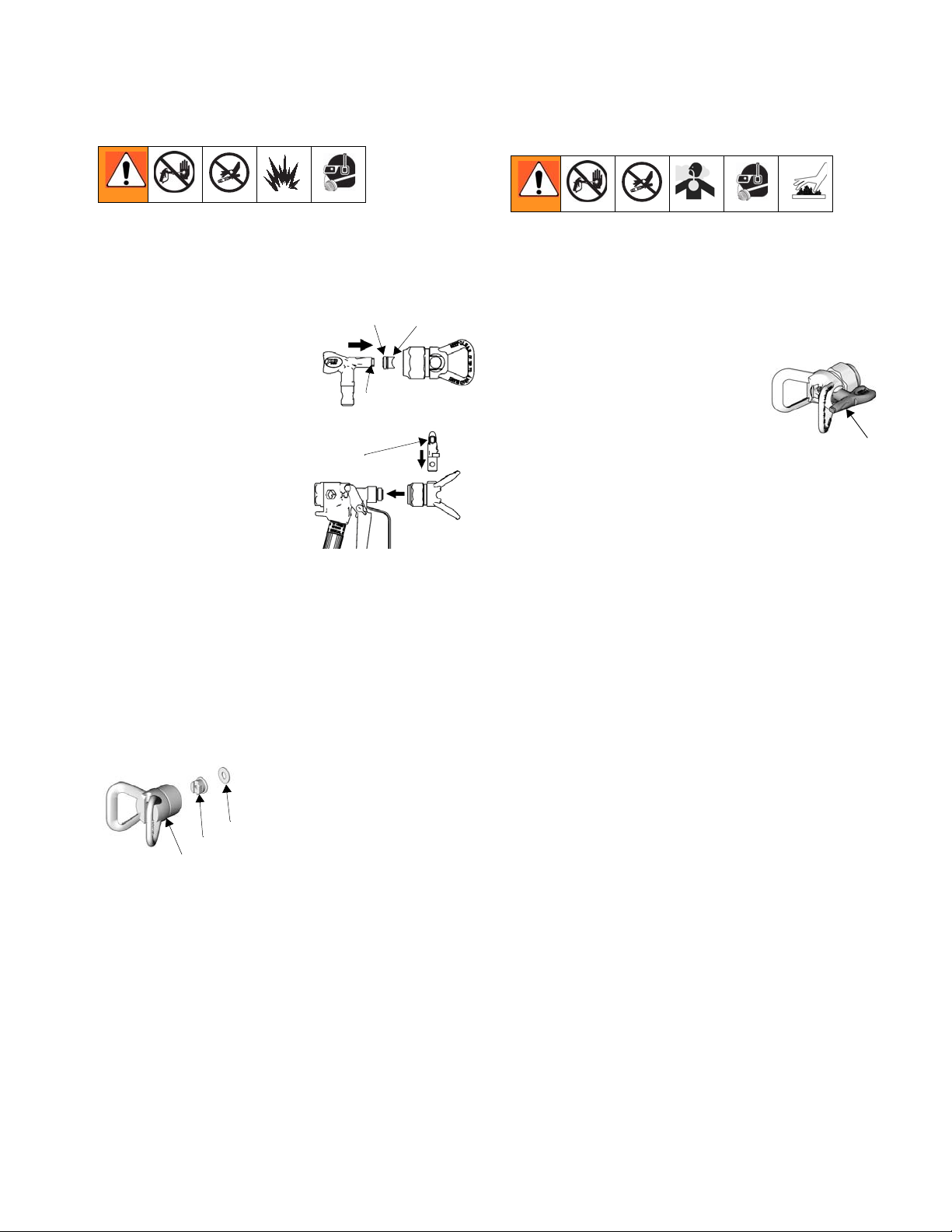

Tip Installation

Tip Installation

RAC Tip

1. Follow Pressure Relief Procedure.

Engage trigger lock.

2. Snap gasket (20b) on

fluid seal (20a). Use

tool (A) to insert

gasket and seal into

housing, seal first.

Tip the tool to remove

it when seal is in

place.

3. Install tip cylinder

(20c) as shown. Turn

90 ° counterclockwise

to spray position, so

the arrow faces

forward. Install assembled RAC onto spray

gun.

Flat Tip

1. Follow Pressure Relief Procedure.

Engage trigger lock.

2. Insert tip (32) and gasket (30) into back of

guard (31).

3. Install guard over end of gun.

20c

20b

A

20a

ti10635c

ti10636b

Operation

1. Connect a grounded fluid hose.

2. Without spray tip, flush pump. Use lowest

pressure possible.

3. Prime. Refer to sprayer manual.

4. Follow Pressure Relief Procedure.

5. Install spray tip and tip guard.

6. RAC tips only: In spray

position, arrow on tip

cylinder (20c) faces

forward.

ti11482a

7. Hold gun perpendicular and approximately

12 inches (304 mm) from surface. Wear

gloves if fluid temperature exceeds 110°F

(43°C).

8. Move gun first, then pull gun trigger to

spray onto test paper.

a. Adjust fluid pressure until spray is com-

pletely atomized.

b. If adjusting pressure does not give a

good spray pattern, follow Pressure

Relief Procedure, then try another tip

size.

9. Trigger gun full-open or full-close.

Adjusting Spray Pattern

20c

The spray tip orifice and spray angle

determine pattern coverage and size. When

you need more coverage, use a larger spray

31

30

32

ti10051a

tip rather than increasing fluid pressure.

1. Follow Pressure Relief Procedure.

Engage trigger lock.

2. Loosen tip guard retaining nut.

3. Align guard horizontally to spray a

horizontal pattern. Align guard vertically to

spray a vertical pattern.

4. Tighten nut.

312145G 5

Page 6

Maintenance

Cleaning Tips/Clearing Clogs

Clean tip and tip guard at end of each work

day.

1. Follow Pressure Relief Procedure.

Engage trigger lock.

2. Clean spray tip as follows:

a. RAC tips: Rotate tip 180°

so arrow on tip cylinder

(20c) faces backward.

Disengage trigger lock.

Trigger gun into pail or

ti11483a

onto ground to remove

clog. Engage trigger lock. Rotate tip

180° back to spray position.

b. Flat tips: Remove tip and clean with a

solvent-soaked brush.

3. RAC tips: If tip is still clogged:

a. Shut off sprayer and disconnect power

source.

b. Open fluid drain valve (see System

Requirements on page 4) to relieve

pressure.

c. Remove and clean spray tip.

Maintenance

Failure to clean or replace the filter or

damaged handle bore can result in serious

injury.

20c

5. Disengage trigger lock, then trigger gun

into the paint pail. When solvent appears,

release trigger.

6. Trigger gun into solvent pail. Circulate fluid

until system is thoroughly flushed.

7. Follow Pressure Relief Procedure.

Engage trigger lock.

Cleaning/Replacing Filter

(Not applicable for XTR510)

1. Follow Pressure Relief Procedure.

Engage trigger lock.

2. Disconnect trigger

guard from gun body

by pushing up on

guard hook and

pulling it out of notch.

ti5052a

3. The trigger guard

beneath the gun

handle can then be

used as a wrench to

loosen the nut.

ti5054a

4. When alignment

notches are no longer engaged, use your

hand to twist handle and remove it from

gun head.

5. Remove filter.

6. Clean filter using a soft brush.

7. Replace filter.

8. Apply light coating of grease to threads and

then attach.

9. Use trigger guard to tighten the nut.

10.Reattach the trigger guard to the gun.

Before performing any maintenance on the

Cleanup

gun, read all warnings in this manual and

relieve pressure.

Flush gun after each work shift and store in a

dry location. Do not leave the gun or any parts

Flushing

in water or cleaning solvents.

Flush pump and gun before fluid can dry in it. If

available, use flushing procedure provided in

your pump or sprayer manual instead of this

procedure.

1. Follow Pressure Relief Procedure.

Engage trigger lock.

2. Remove spray tip and guard from gun.

Clean with solvent.

3. Put the pump intake in a grounded pail of

compatible solvent.

4. Start pump at its lowest pressure.

6 312145G

Page 7

Repair

Repair

Disassembly

1. Follow Pressure Relief Procedure.

Engage trigger lock.

2. Disconnect fluid hose. Remove RAC tip

guard and tip (19 and 20a-20c) or flat tip

guard and tip (30, 31 and 32).

3. RAC tip only: use tool to push gasket and

seal out back of housing.

ti10637b

4. Using a wrench, remove the cap (4) with

spring (5) (releases spring tension on

needle).

5. Remove the valve seat (10) and

gasket (9).

6. Holding the needle with

tool (36) remove the

needle retainer (6).

7. Pull the needle (8) out.

8. Using a socket wrench,

remove the seal retainer

(2) from the back of the

gun. Use a pick to remove

the gasket (3).

9. Clean and replace parts as needed.

If you need to remove the trigger

To avoid losing parts, be ready for two

actuator pins (7) to fall out of the gun body

when the trigger (16) is removed.

XTR 7 Guns

1. Using a wrench,

remove screw

(16b) from the

pivot pin (16a).

2. Slide the pivot pin

(16a) out of the

gun body, and

remove the trigger

(16).

16b

7

16

36

16a

ti5187a

ti5190a

3. Before installing trigger, grease the

actuator pins (7) and the pivot pin (16a).

XTR 5 Guns

1. Using a socket wrench, remove screw

(16c) from each side of the gun body and

remove trigger.

2. Before installing trigger, grease the

actuator pins (7).

Assembly

1. Press a new gasket (3*) into the gun body.

Lightly grease the seal retainer (2*) and

install. Torque to 48-72 in-lb (5-8 N•m).

2. Lightly grease and replace the needle (8*).

Press the needle through the seal retainer.

Caution

Use only tool (36) and fingers to tighten needle. Do not overtighten or breakage may

occur.

3. Apply light-strength Loctite™ to needle

threads. Holding the needle with tool (36*),

install needle retainer (6). Tighten until it

bottoms out. Do not overtighten.

4. Lightly grease valve seat (10*) threads.

6

Squeeze the trigger to retract the needle

and install gasket (9*) and valve seat (10*).

Torque valve seat to 26-32 ft-lb

(34-43 N•m).

5. Grease and install the spring (5) and cap

(4). Tighten the cap to 10-13 ft-lb

(8-10 N•m).

Test Gun Before Using

1. Engage trigger lock. Connect fluid hose to

gun.

2. Start and prime the pump.

3. Disengage the trigger lock and trigger the

gun into a metal waste container.

4. Release the trigger. The gun should

immediately stop spraying and there

should be no leaks. If there is a problem,

follow Pressure Relief Procedure. Check

through Assembly procedure and correct

problem.

5. Install tip and tip guard before regular use.

312145G 7

Page 8

Parts

Parts

XTR5

16c†

1

4

2*

3*

5

RAC Tip

19 20c

20b

20a

ti10050a

9*

10*

Flat Tip

31

8*

32

16

30

ti10051a

7

6

16c†

21*

26

24

13‡

15

ti21834a

14

8 312145G

Page 9

Parts

Ref. Part Description

1 15J771 BODY, gun 1 1 1 1 1 1 1

2* 245881 SEAL, retainer assembly 1 1 1 1 1 1 1

3* --- GASKET 1 1 1 1 1 1 1

4 15K000 CAP, end 1 1 1 1 1 1 1

5 117350 SPRING 1 1 1 1 1 1 1

6 15E088 RETAINER, needle 1 1 1 1 1 1 1

7 15E085 PIN, actuator 2 2 2 2 2 2 2

8* 248591 NEEDLE 1 1 1 1 1 1 1

9* 156766 GASKET 1 1 1 1 1 1 1

10* 245858 SEAT, valve 1 1 1 1 1 1 1

13‡

14 248952 HANDLE KIT 1 1

15 276997 HANDLE SLEEVE, insulated 1 1

16†

16c† 117602 SCREW, shoulder, #8-32 2 2 2 2 2 2 2

19 XHD001 GUARD, RAC tip 1 1 1 1 1 1

20

20a✓ --- SEAL, fluid 1 1 1 1 1

20b✓ --- GASKET 1 1 1 1 1

20c --- TIP, spray, XHD RAC 1 1 1 1 1

21* 179733 SEAL, sleeve 1 1 1 1 1 1 1

24 119740 O-RING 1 1

26

29▲ 222385 TAG, warning (not shown) 1 1 1 1 1 1 1

30 166969 GASKET 1

31 220251 GUARD, flat tip 1

32 163519 TIP, flat 1

36* 194744 TOOL, repair, packing 1 1 1 1 1 1 1

255275 HANDLE; includes trigger guard and

swivel

287449 TRIGGER KIT, 4-finger, straight;

includes 16c

287451 TRIGGER KIT, 4-finger, curved;

includes 16c

287450 TRIGGER KIT, 2-finger; includes 16c 1 1

XHDxxx SWITCH, RAC tip; 519 size included 1 1 1 1

XHDxxx SWITCH, RAC tip; 519 size 1

287032 FILTER, 60 mesh included with gun 1 1 1 1 1 1

287034 FILTER, 60 mesh and 100 mesh

combo

XTR500 XTR501 XTR502 XTR503 XTR504 XTR505 XTR510

1 1 1 1 1

1 1 1 1

1 1 1 1 1 1

Quantity

1

--- Not for sale.

▲

Replacement Danger and Warning labels, tags, and

✓

Included in OneSeal™ Repair Kit XHD010

(5 each per package, purchase separately).

cards are available at no cost.

* Parts included in Repair Kit 248837, purchased sep-

arately.

† Trigger kit (16) includes mounting hardware for either

XTR5 or XTR7 gun. See table and illustration for

which parts to use.

‡ Handle is not pressure rated for use with the XTR 7.

For an XTR 7, order handle 248952 and sleeve

276977 or 15E083 depending on your model.

312145G 9

Page 10

Parts

XTR7

16b†

1

4

2*

3*

5

RAC Tip

19 20c

20b

20a

ti10050a

10*

Flat Tip

31

9*

32

ti10051a

8*

30

16

7

6

16a†

21*

26

24

15

24

15

14

ti21835a

10 312145G

Page 11

Quantity

Ref Part Description

1 15E178 BODY, gun 1 1 1 1 1 1

2* 245881 SEAL, retainer assembly 1 1 1 1 1 1

3* --- GASKET 1 1 1 1 1 1

4 15A864 CAP, end 1 1 1 1 1 1

5 117350 SPRING 1 1 1 1 1 1

6 15E088 RETAINER, needle 1 1 1 1 1 1

7 15E085 PIN, actuator 2 2 2 2 2 2

8* 248591 NEEDLE 1 1 1 1 1 1

9* 156766 GASKET 1 1 1 1 1 1

10* 245858 SEAT, valve 1 1 1 1 1 1

14 248952 HANDLE KIT 1 1 1 1 1 1

15

16

16a† 192272 PIN, pivot 1 1 1 1 1 1

16b† 203953 SCREW, cap, #10-24 1 1 1 1 1 1

19 XHD001 GUARD, RAC tip 1 1 1 1 1

20

20a✓ --- SEAL, fluid 1 1 1 1

20b✓ --- GASKET 1 1 1 1

20c --- TIP, spray, XHD RAC 1 1 1 1

21* 179733 SEAL, sleeve 1 1 1 1 1 1

24 119740 O-RING 1 1 1 1 1 1

26

29▲ 222385 TAG, warning (not shown) 1 1 1 1 1 1

30 166969 GASKET 1

31 220251 GUARD, flat tip 1

32 163519 TIP, flat 1

36* 194744 TOOL, repair, packing 1 1 1 1 1 1

276997 HANDLE SLEEVE, insulated 1 1

15E083 HANDLE SLEEVE, round 1 1 1 1

287449 TRIGGER KIT, 4-finger, straight;

includes 16a and 16b

287451 TRIGGER KIT, 4-finger, curved;

includes 16a and 16b

287450 TRIGGER KIT, 2-finger; includes

16a and 16b

XHDxxx SWITCH, RAC tip; 519 size

included

287032 FILTER, 60 mesh included with

gun

287034 FILTER, 60 mesh and 100 mesh

combo

XTR700 XTR701 XTR702 XTR703 XTR704 XTR705

1 1 1

1

1 1

1 1 1 1

1 1 1 1 1 1

1 1 1 1 1 1

Parts

--- Not for sale.

▲

Replacement Danger and Warning labels, tags, and

✓

Included in OneSeal™ Repair Kit XHD010

(5 each per package, purchase separately).

cards are available at no cost.

* Parts included in Repair Kit 248837, purchased sep-

arately.

† Trigger Kit (16) includes mounting hardware for

either the XTR5 or XTR7 gun. See table and illustration for which parts to use.

312145G 11

Page 12

Parts

12 312145G

Page 13

Technical Data

Technical Data

Maximum working pressure:

XTR 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . 5000 psi (35 MPa, 345 bar)

XTR 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . 7250 psi (50 MPa, 500 bar)

Fluid orifice. . . . . . . . . . . . . . . . . . . . . . . 0.090 in. (2.3 mm)

Fluid inlet . . . . . . . . . . . . . . . . . . . . . . . . 1/4 npsm (m)

Max. fluid temperature . . . . . . . . . . . . . . 160°F (71°C)

Sound pressure . . . . . . . . . . . . . . . . . . . 84.3 dB(A)*

Sound power . . . . . . . . . . . . . . . . . . . . . 95.7 dB(A)*

Wetted parts. . . . . . . . . . . . . . . . . . . . . . aluminum, stainless steel, acetal, polyethylene, nylon,

polypropylene, carbide, polyurethane, solvent-resistant

o-rings.

*Results are maximum readings taken at 6000 psi (41 MPa, 414 bar), with HD519 tip, using

water. Sound power level was tested to ISO 9614-2.

312145G 13

Page 14

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER,

Phone:

612-623-6921

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2007, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

contact your Graco distributor or call to identify the nearest distributor.

or Toll Free:

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions.

International Offices: Belgium, China, Japan, Korea

1-800-328-0211

This manual contains English. MM 312145

Graco Headquarters: Minneapolis

www.graco.com

Revised February 2014

Fax:

612-378-3505

Loading...

Loading...