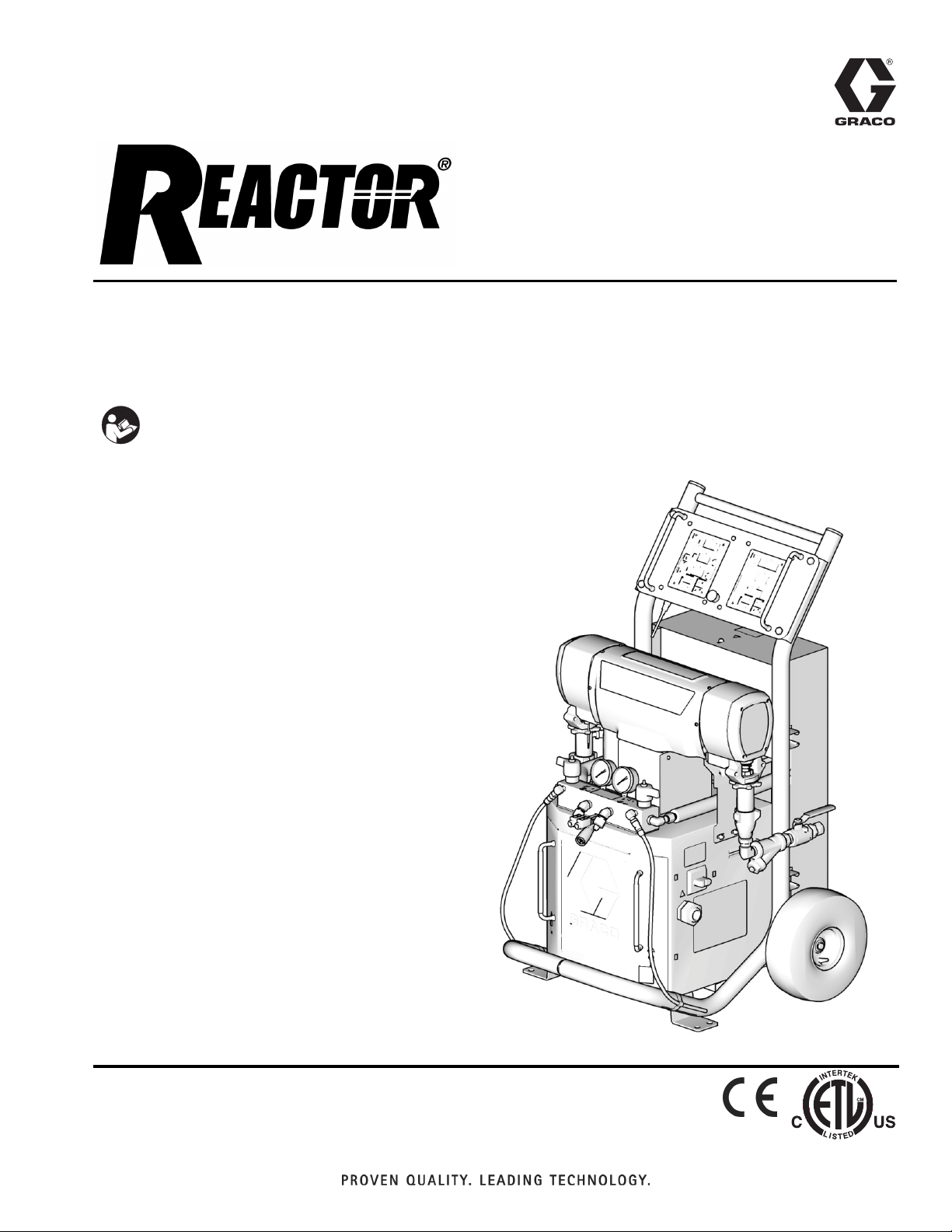

Page 1

Repair - Parts

312066Z

Electric, Heated, Plural Component Proportioner. For spraying polyurethane foam and

polyurea coatings. For professional use only.

Not approved for use in European explosive atmosphere locations.

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

See page 3 for model information, including

maximum working pressure and approvals.

Model E-XP1 Shown

TI10953a

9902471

Conforms to ANSI/UL

Std. 499 Certified to

CAN/CSA Std.

C22.2 No. 88

Page 2

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Supplied Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Temperature Control Diagnostic Codes . . . . . . . . 8

E01: High fluid temperature . . . . . . . . . . . . . . . . 8

E02: High zone current . . . . . . . . . . . . . . . . . . . . 9

E03: No zone current . . . . . . . . . . . . . . . . . . . . 10

E04: Fluid Temperature Sensor (FTS) or

thermocouple disconnected . . . . . . . . . . . . 10

E05: Circuit board overheated . . . . . . . . . . . . . 10

E06: Communication cable unplugged . . . . . . . 10

Motor Control Diagnostic Codes . . . . . . . . . . . . . 11

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

E21: No component A transducer . . . . . . . . . . . 12

E22: No component B transducer . . . . . . . . . . . 12

E23: High fluid pressure . . . . . . . . . . . . . . . . . . 12

E24: Pressure Imbalance . . . . . . . . . . . . . . . . . 12

E25: High line voltage . . . . . . . . . . . . . . . . . . . . 14

E26: Low line voltage . . . . . . . . . . . . . . . . . . . . 14

E27: High Motor Temperature . . . . . . . . . . . . . 14

E28: High current in motor . . . . . . . . . . . . . . . . 14

E29: Brush Wear . . . . . . . . . . . . . . . . . . . . . . . . 14

E31: Motor Control Failure

(E-30 and E-XP2 only) . . . . . . . . . . . . . . . . 15

E32: Motor Control Overtemperature . . . . . . . . 16

Communication Diagnostic Codes . . . . . . . . . . . 16

E30: Momentary loss of communication . . . . . . 16

E99: Loss of communication . . . . . . . . . . . . . . . 16

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Reactor Electronics . . . . . . . . . . . . . . . . . . . . . . 18

Primary Heaters (A and B) . . . . . . . . . . . . . . . . 20

Hose Heat System . . . . . . . . . . . . . . . . . . . . . . 21

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Before Beginning Repair . . . . . . . . . . . . . . . . . . 23

Pressure Relief Procedure . . . . . . . . . . . . . . . . 23

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pump Removal . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pump Installation . . . . . . . . . . . . . . . . . . . . . . . . 26

Drive Housing . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Motor Brushes . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Capacitor Test . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Circuit Breaker Module . . . . . . . . . . . . . . . . . . . 32

Electric Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Motor Control Board . . . . . . . . . . . . . . . . . . . . . 34

Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Electric Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Temperature Control Module . . . . . . . . . . . . . . . 37

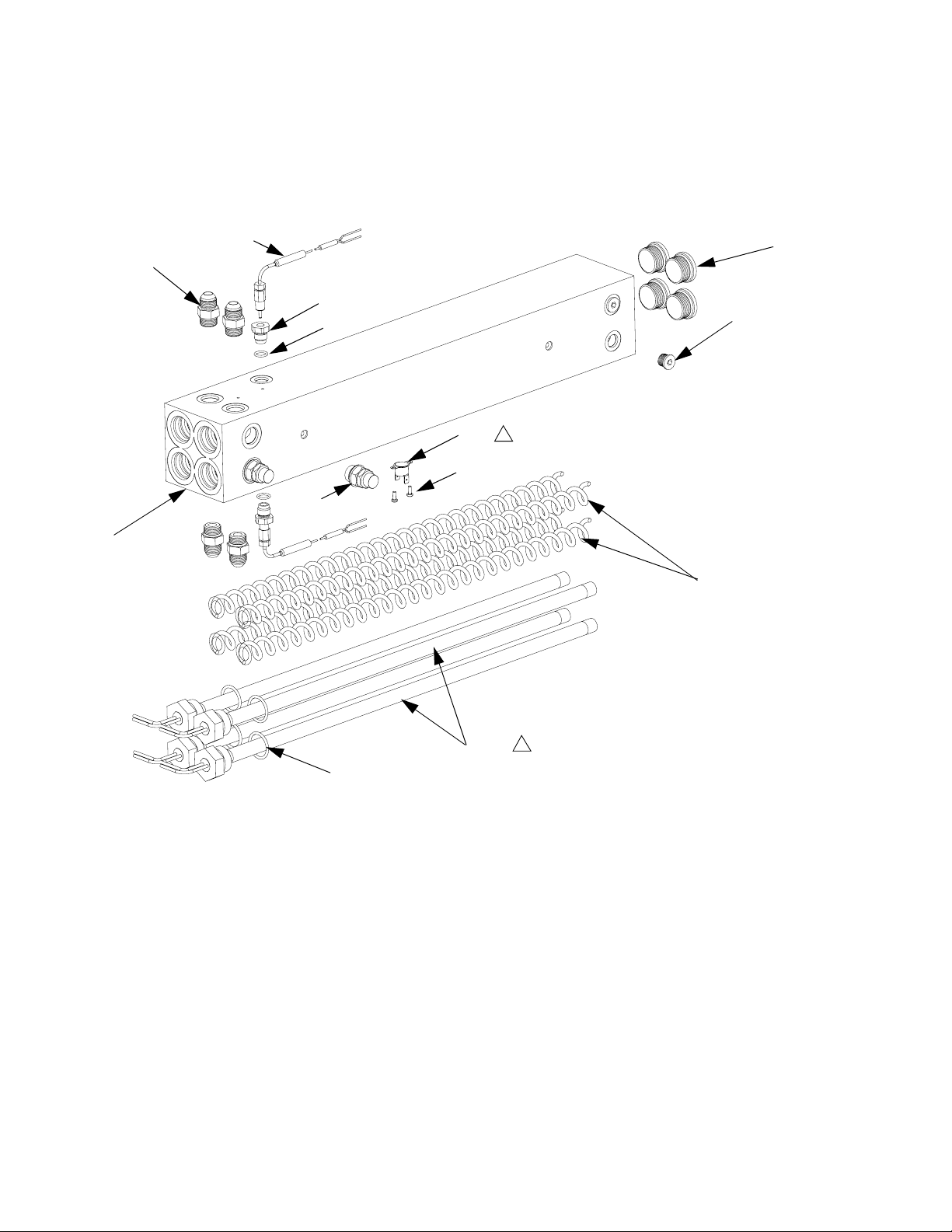

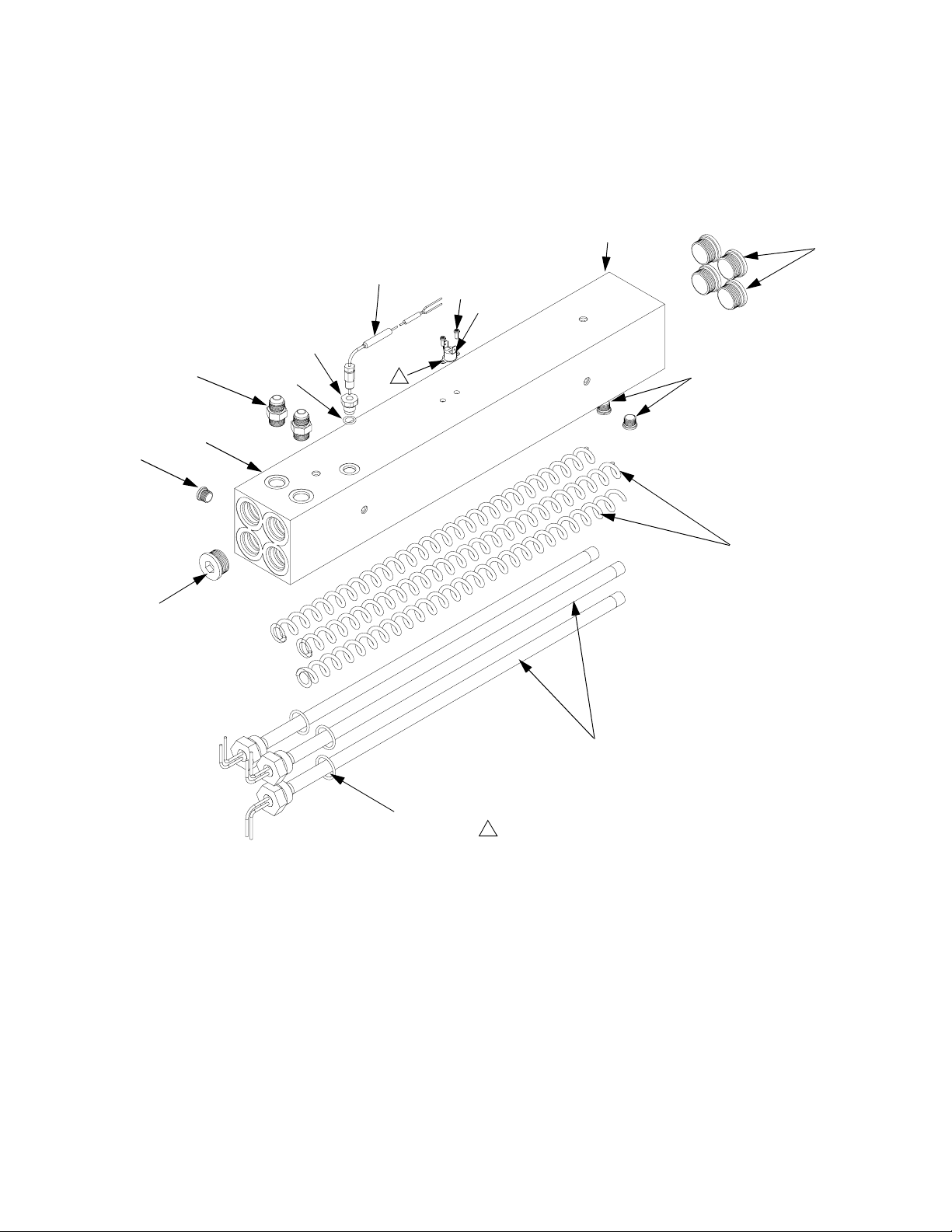

Primary Heaters . . . . . . . . . . . . . . . . . . . . . . . . . 40

Heated Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Fluid Temperature Sensor (FTS) . . . . . . . . . . . . 44

Display Module . . . . . . . . . . . . . . . . . . . . . . . . . 46

Inlet Fluid Strainer Screen . . . . . . . . . . . . . . . . . 48

Pump Lubrication System . . . . . . . . . . . . . . . . . 48

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Reactor Assembly (Model E-XP1 Shown) . . . . . 50

Parts Used on All Models . . . . . . . . . . . . . . . . . 53

Parts that Vary by Model . . . . . . . . . . . . . . . . . . 54

Sub Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . 58

Proportioner Module . . . . . . . . . . . . . . . . . . . . . 58

Fluid Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.65 kW Single Zone Fluid Heater . . . . . . . . . . . 61

Reactor Frame . . . . . . . . . . . . . . . . . . . . . . . . . . 62

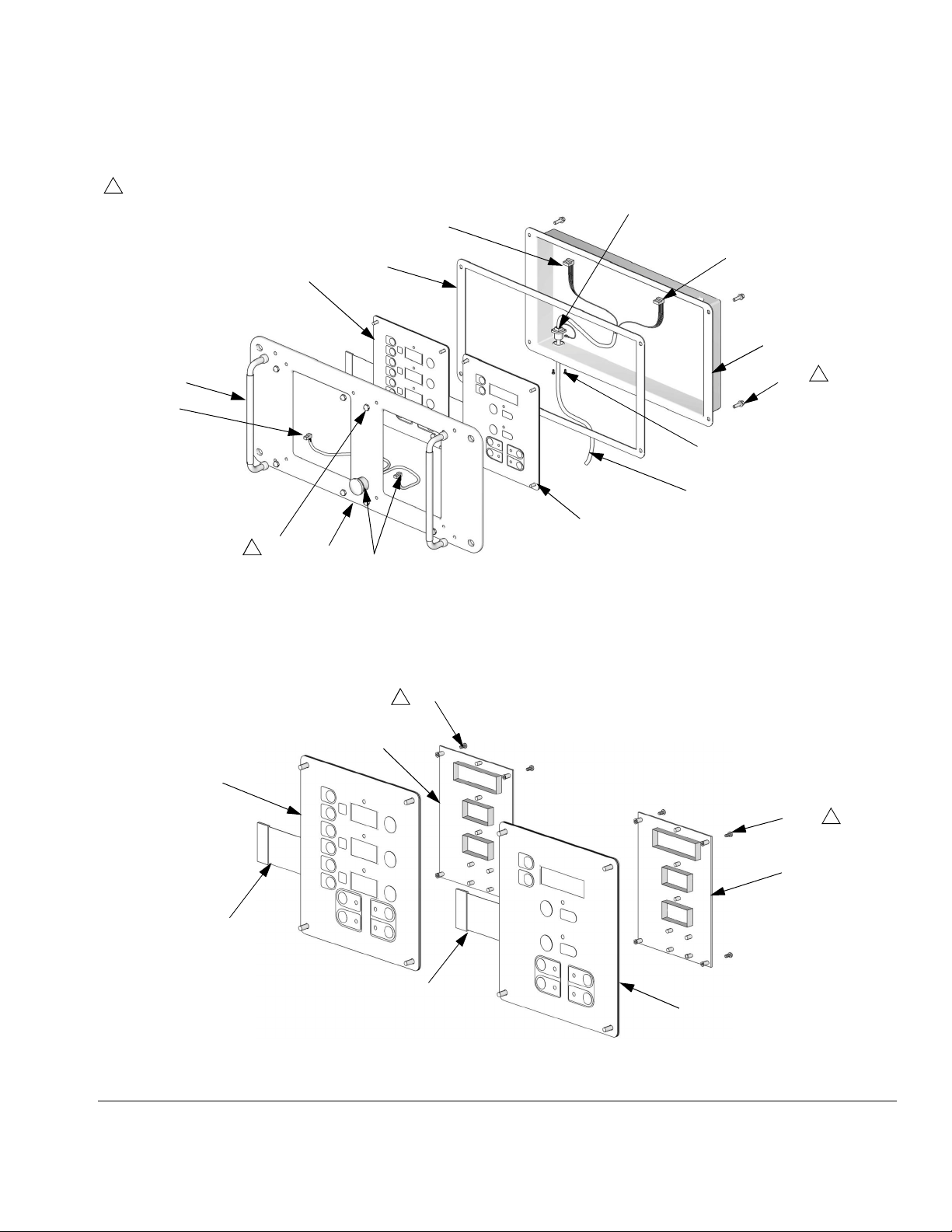

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Temperature Control . . . . . . . . . . . . . . . . . . . . . 64

Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Fluid Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Circuit Breaker Modules . . . . . . . . . . . . . . . . . . 67

248669 Conversion Kit . . . . . . . . . . . . . . . . . . . . . 71

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 74

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 74

2 312066Z

Page 3

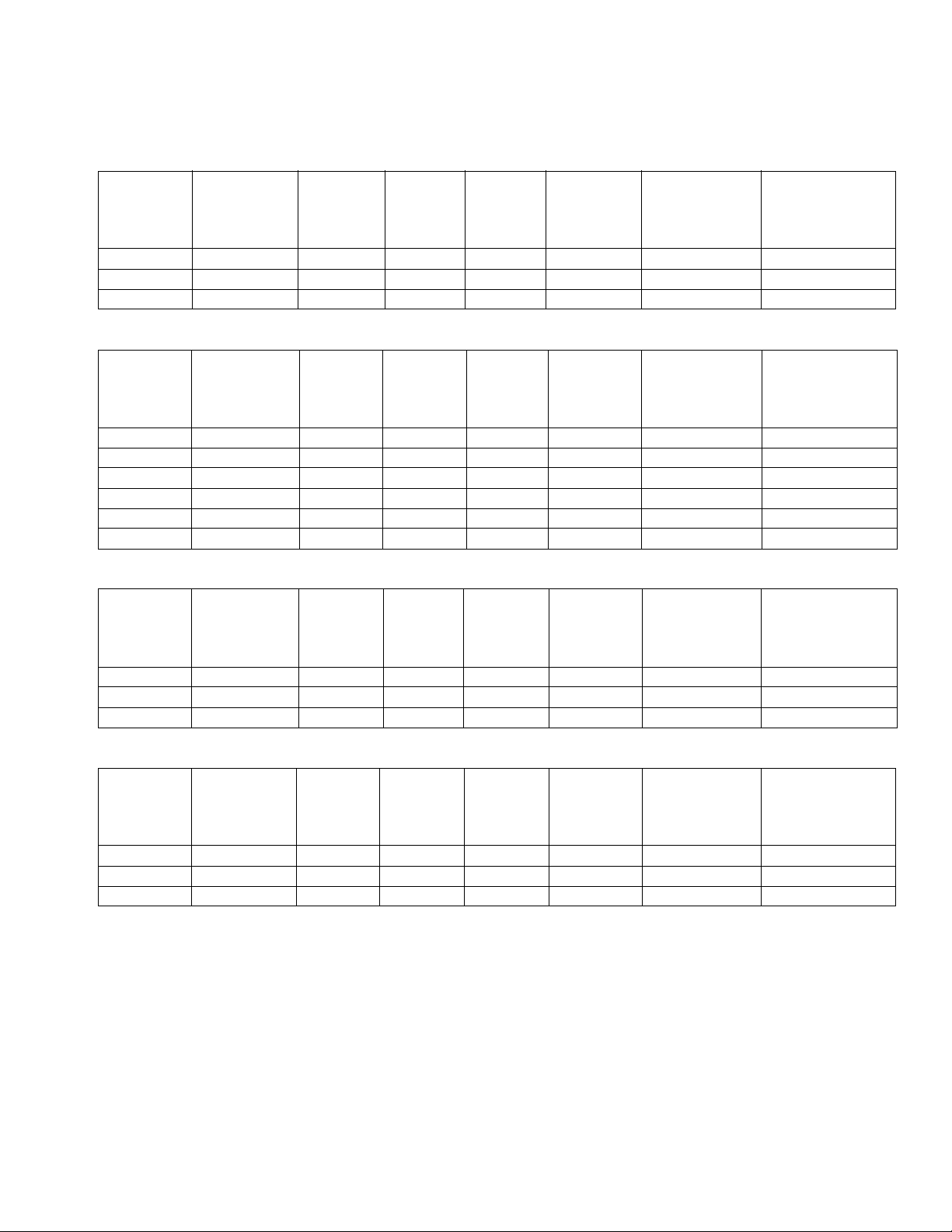

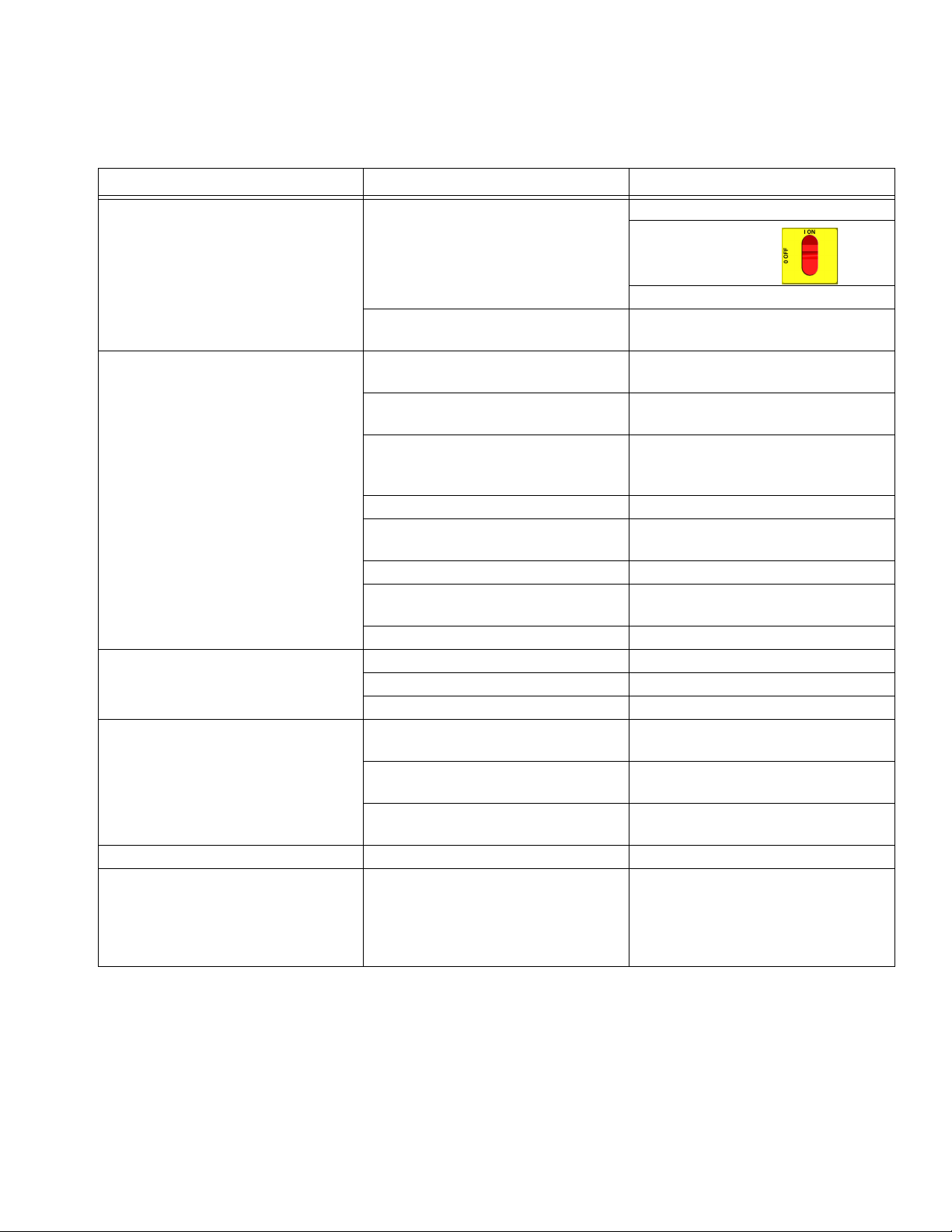

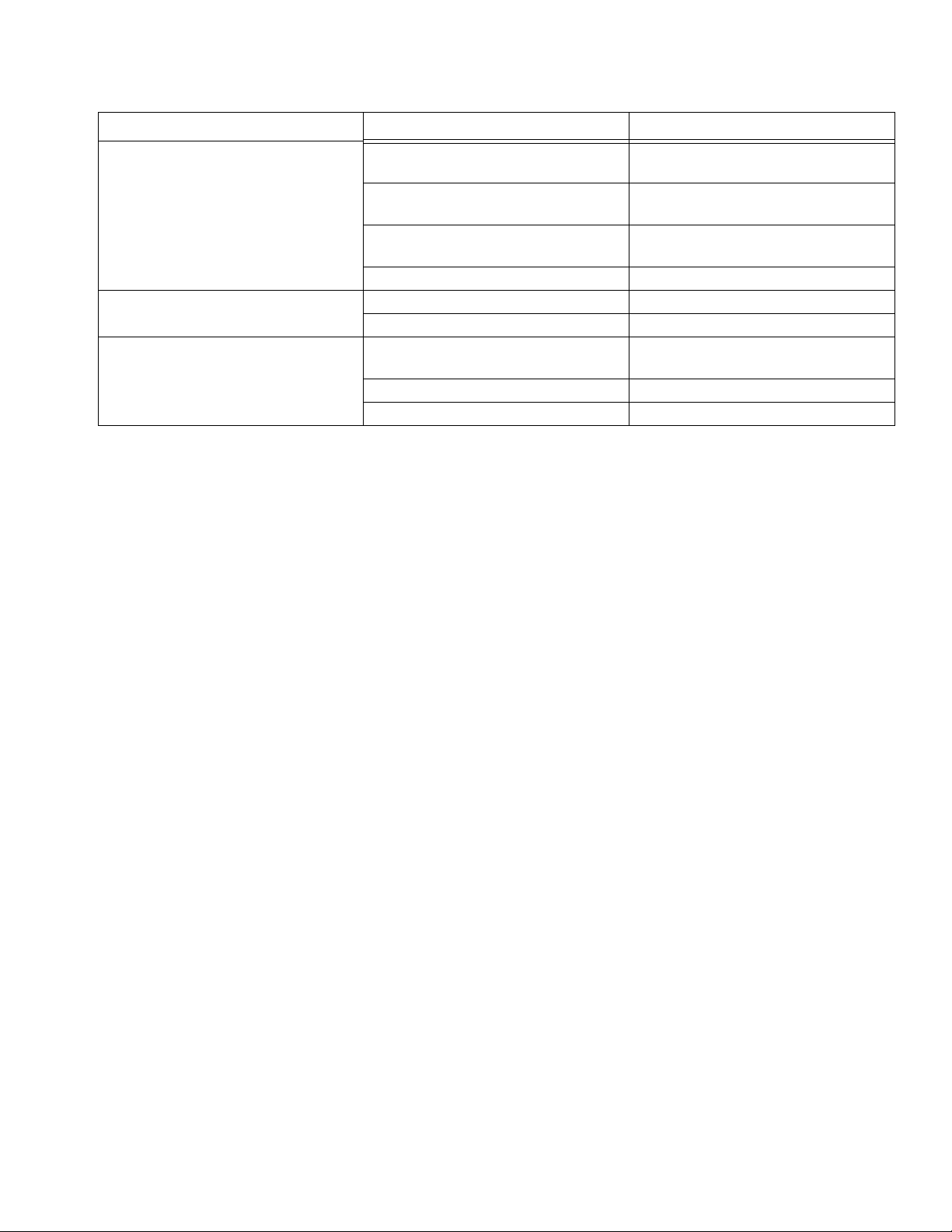

Models

E-20 SERIES

Models

Max Flow

Primary

Full Load Peak

Part, Series

259025, E 48 230V (1) 10,200 6,000 20 (9) 0.0104 (0.04) 2000 (14, 140)

259030, E 24 400V (3) 10,200 6,000 20 (9) 0.0104 (0.04) 2000 (14, 140)

259034, E 32 230V (3) 10,200 6,000 20 (9) 0.0104 (0.04) 2000 (14, 140)

Amps*

Voltage

(phase)

System

Watts†

Heater

Watts

Rate◆

lb/min

(kg/min)

Approximate

Output per Cycle

(A+B)

gal. (liter)

Maximum Fluid

Working Pressure

psi (MPa, bar)

E-30 SERIES

Max Flow

Primary

Part,

Series

259026, F 78 230V (1) 17,900 10,200 30 (13.5) 0.0272 (0.1034) 2000 (14, 140)

259031, F 34 400V (3) 17,900 10,200 30 (13.5) 0.0272 (0.1034) 2000 (14, 140)

259035, F 50 230V (3) 17,900 10,200 30 (13.5) 0.0272 (0.1034) 2000 (14, 140)

259057, F 100 230V (1) 23,000 15,300 30 (13.5) 0.0272 (0.1034) 2000 (14, 140)

259058, F 62 230V (3) 23,000 15,300 30 (13.5) 0.0272 (0.1034) 2000 (14, 140)

259059, F 35 400V (3) 23,000 15,300 30 (13.5) 0.0272 (0.1034) 2000 (14, 140)

Full Load Peak

Amps*

Voltage

(phase)

System

Watts†

Heater

Watts

Rate◆

lb/min

(kg/min)

Approximate

Output per Cycle

(A+B)

gal. (liter)

Maximum Fluid

Working Pressure

psi (MPa, bar)

E-XP1 SERIES

Approximate

Primary

Full Load Peak

Part, Series

259024, E 69 230V (1) 15,800 10,200 1.0 (3.8) 0.0104 (0.04) 2500 (17.2, 172)

259029, E 24 400V (3) 15,800 10,200 1.0 (3.8) 0.0104 (0.04) 2500 (17.2, 172)

259033, E 43 230V (3) 15,800 10,200 1.0 (3.8) 0.0104 (0.04) 2500 (17.2, 172)

Amps*

Voltage

(phase)

System

Watts†

Heater

Watts

Max Flow

Rate◆

gpm (lpm)

Output per Cycle

(A+B)

gal. (liter)

Maximum Fluid

Working Pressure

psi (MPa, bar)

E-XP2 SERIES

Approximate

Primary

Part,

Series

259028, F 100 230V (1) 23,000 15,300 2.0 (7.6) 0.0203 (0.0771) 3200 (22, 220)

259032, F 35 400V (3) 23,000 15,300 2.0 (7.6) 0.0203 (0.0771) 3200 (22, 220)

259036, F 62 230V (3) 23,000 15,300 2.0 (7.6) 0.0203 (0.0771) 3200 (22, 220)

Full Load Peak

Amps*

Voltage

(phase)

System

Watts†

Heater

Watts

Max Flow

Rate◆

gpm (lpm)

Output per Cycle

(A+B)

gal. (liter)

Maximum Fluid

Working Pressure

psi (MPa, bar)

* Full load amps with all devices operating at maximum capabilities. Fuse requirements at various flow rates and mix

chamber sizes may be less.

†

Total system watts, based on maximum hose length for each unit:

• E-20 and E-XP1 series, 210 ft (64 m) maximum heated hose length, including whip hose.

• E-30 and E-XP2 series, 310 ft (94.5 m) maximum heated hose length, including whip hose.

◆

Maximum flow rate given for 60 Hz operation. For 50 Hz operation, maximum flow rate is 5/6 of 60 Hz maximum

flow.

312066Z 3

Page 4

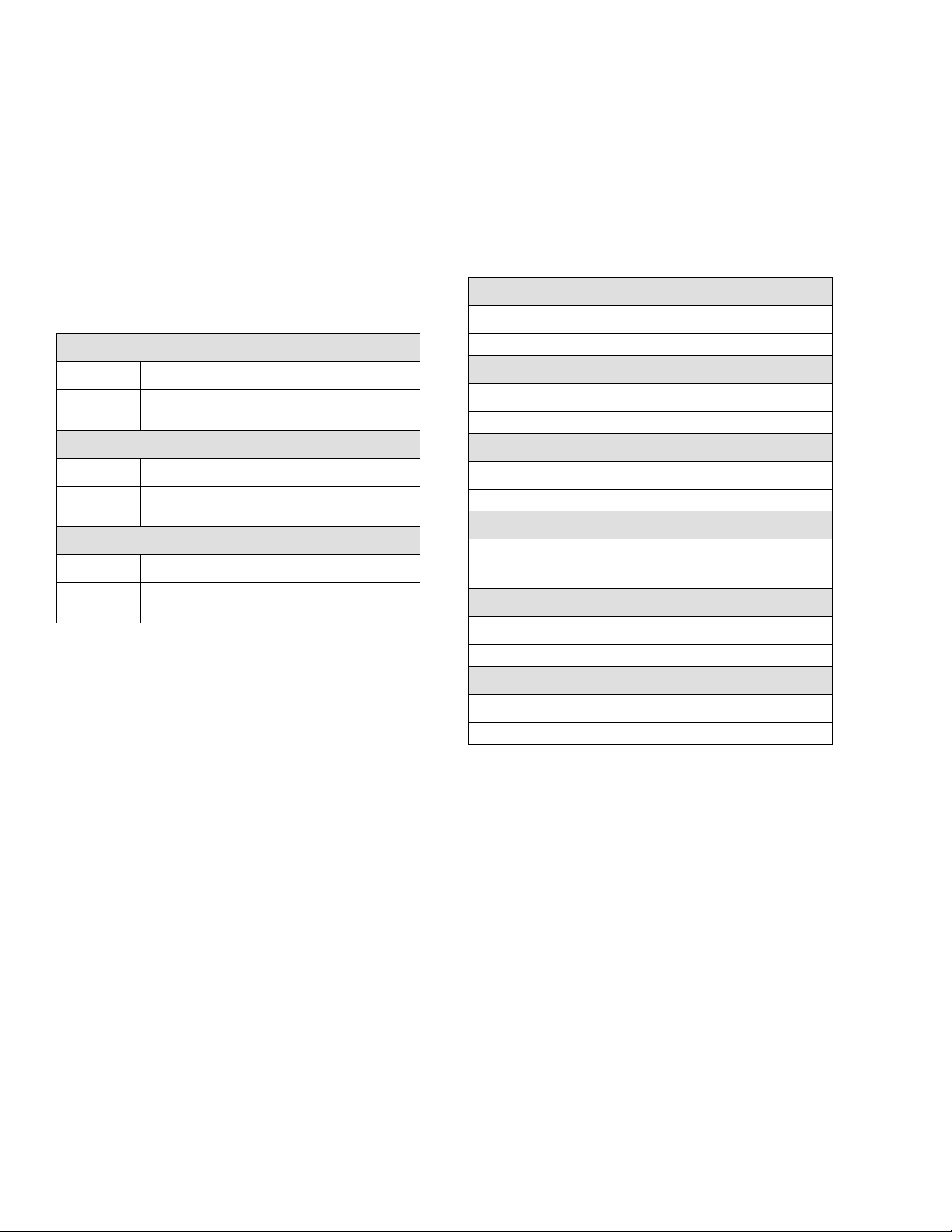

Supplied Manuals

Supplied Manuals

The following manuals are shipped with the Reactor™

Proportioner. Refer to these manuals for detailed equipment information.

Order Part 15M334 for a compact disk of Reactor manuals translated in several languages.

Manuals are also available at www.graco.com.

Reactor Electric Proportioner

Part Description

312065 Reactor Electric Proportioner,

Operation Manual (English)

Reactor Electrical Diagrams

Part Description

312067 Reactor Electric Proportioner,

Electrical Diagrams (English)

Displacement Pump

Part Description

309577 Electric Reactor Displacement Pump

Repair-Parts Manual (English)

Related Manuals

The following manuals are for accessories used with the

™

Reactor

Order Part 15M334 for a compact disk of Reactor manuals translated in several languages.

Reactor Data Reporting Kit

Part Description

309867 Instruction-Parts Manual (English)

Fusion Spray Gun

Part Description

309550 Instruction-Parts Manual (English)

Heated Hose

Part Description

309572 Instruction-Parts Manual (English)

Circulation and Return Tube Kit

Part Description

309852 Instruction-Parts Manual (English)

Rupture Disk Assembly Kit

Part Description

312416 Instruction-Parts Manual (English)

Electric Reactor Installation

.

Part Description

310815 Instruction Manual (English)

4 312066Z

Page 5

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on sprayer and extension cords.

• Do not expose to rain. Store indoors.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the

equipment to help protect you from serious injury, including eye injury, inhalation of toxic fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just a cut,

but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard and trigger guard installed.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning, checking,

or servicing equipment.

• Tighten all fluid connections before operating equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

312066Z 5

Page 6

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and

explosion:

• Use and clean equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths

(potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground equipment, personnel, object being sprayed, and conductive objects in work area. See Grounding

instructions.

• Use only Graco grounded hoses.

• Check gun resistance daily.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until you

identify and correct the problem.

• Do not flush with gun electrostatics on. Do not turn on electrostatics until all solvent is removed from system.

• Keep a working fire extinguisher in the work area.

THERMAL EXPANSION HAZARD

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

• Open a valve to relieve the fluid expansion during heating.

• Replace hoses proactively at regular intervals based on your operating conditions.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical reaction and

equipment rupture, and result in death, serious injury, and property damage.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• This equipment is for professional use only.

• Do not leave the work area while the equipment is energized or under pressure. Turn off all equipment and

follow Pressure Relief Procedure in this manual when the equipment is not in use.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equip-

ment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

6 312066Z

Page 7

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow

the Pressure Relief Procedure in this manual. Disconnect power or air supply.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe burns, do not

touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

Warnings

312066Z 7

Page 8

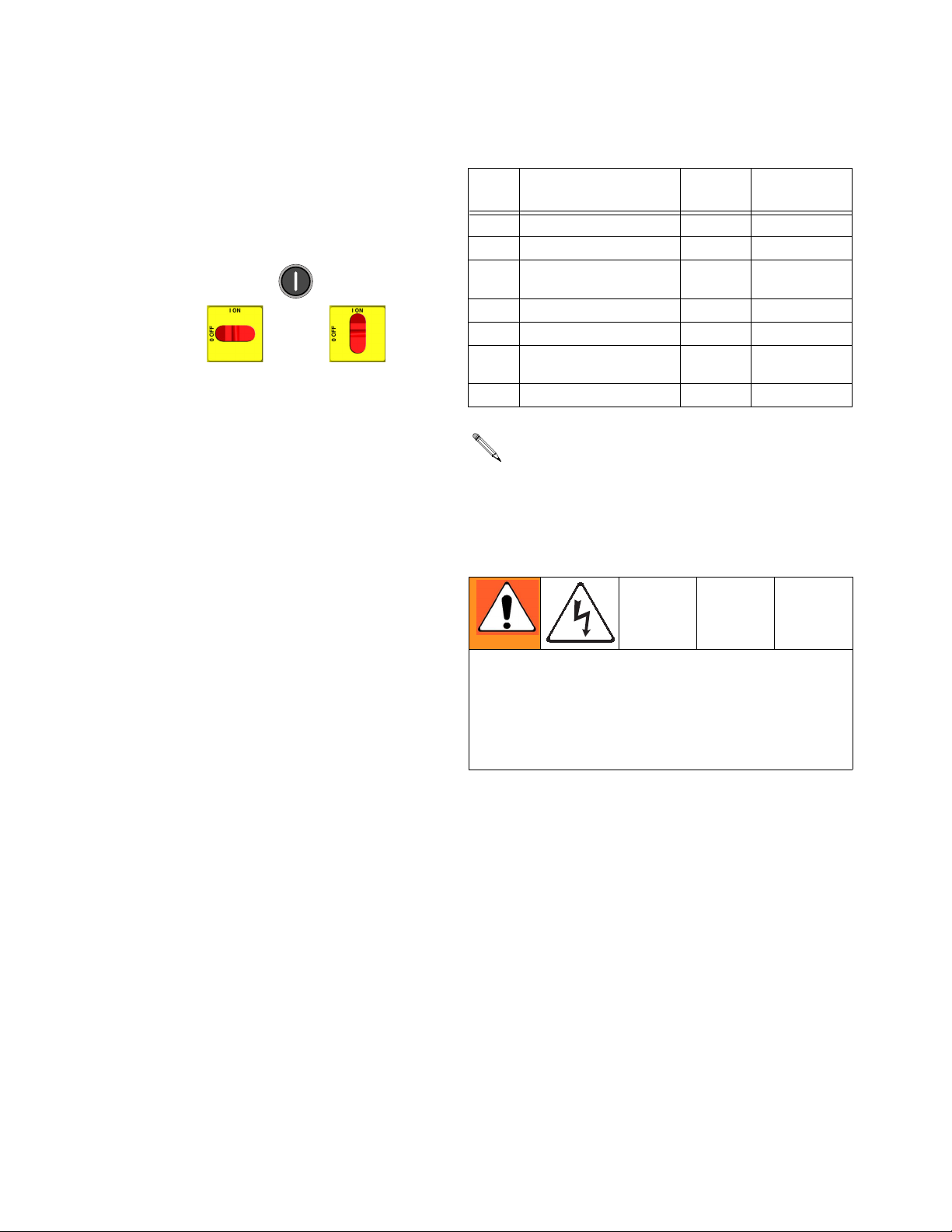

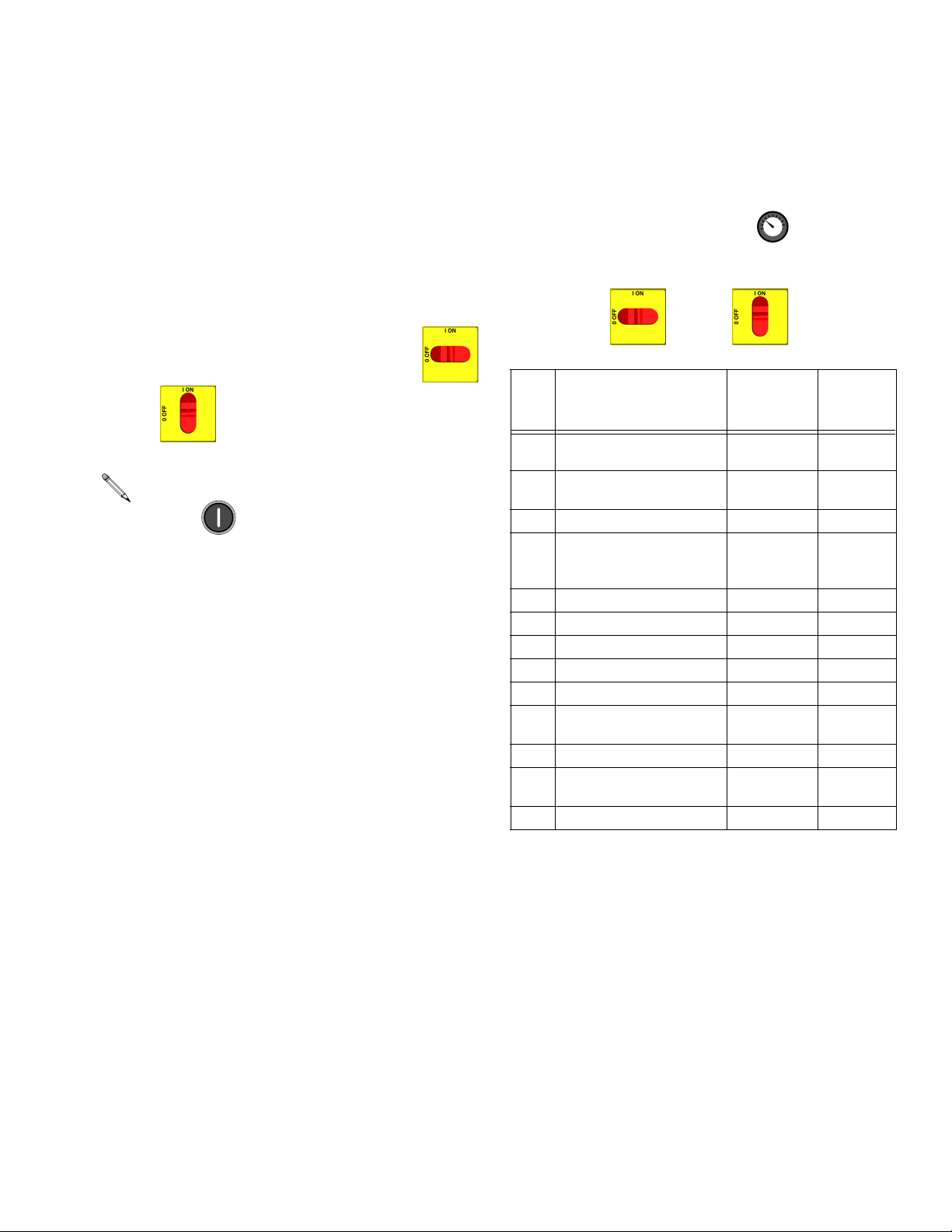

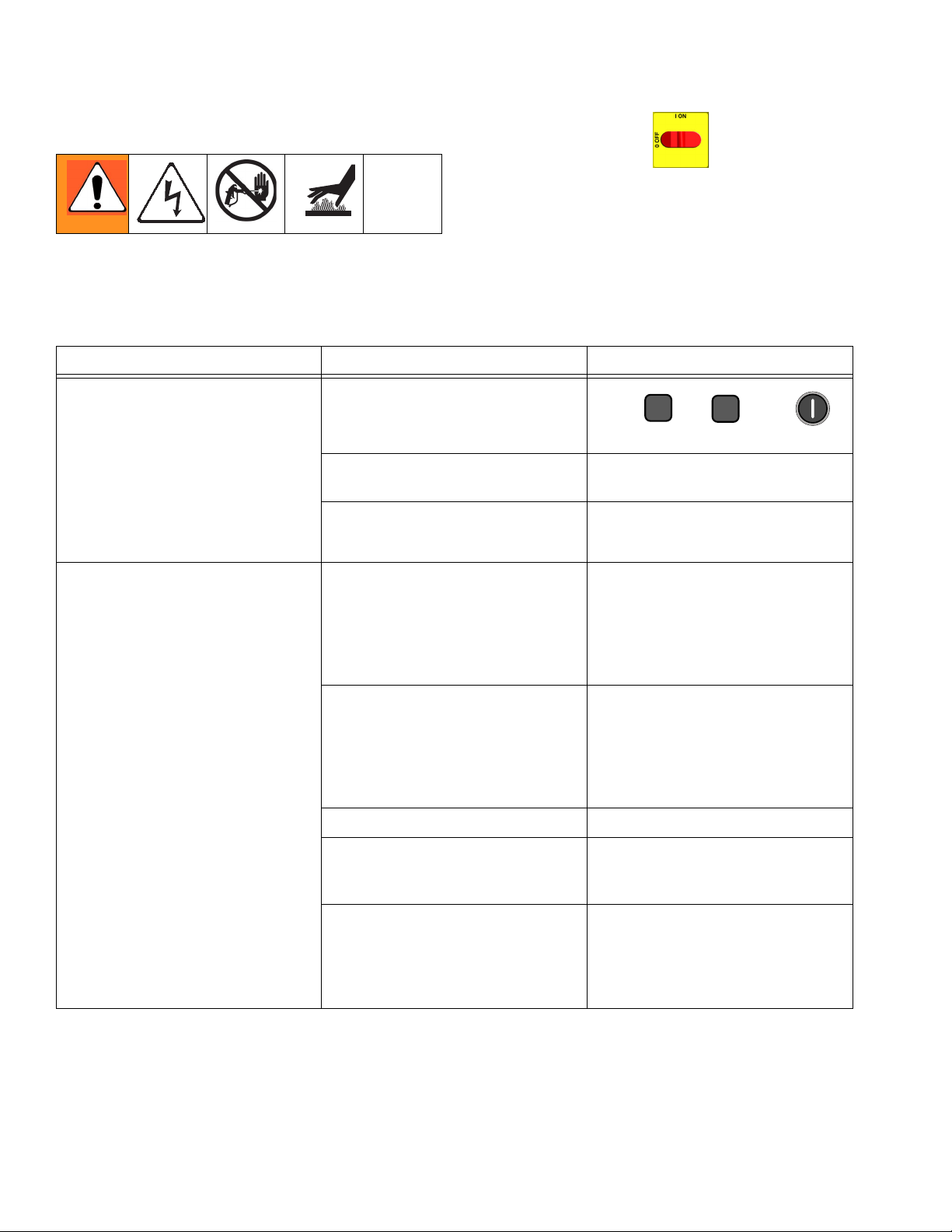

Temperature Control Diagnostic Codes

Temperature Control Diagnostic Codes

Temperature control diagnostic codes appear on temperature display.

These alarms turn off heat. E99 clears automatically

when communication is regained. Codes E03 through

E06 can be cleared by pressing . For other codes,

turn main power OFF then ON to

clear.

E01: High fluid temperature

Causes of E01 Errors

• Thermocouple A or B (310) senses a fluid temperature above 230°F (110°C).

Code Code Name Alarm

Zone

01 High fluid temperature Individual

02 High zone current Individual

03 No zone current with

hose heater on

04 FTS not connected Individual

05 Board overtemperature Individual

06 Communication cable

unplugged from module

99 Loss of communication ALL

For hose zone only, if FTS is disconnected at

startup, display will show hose current 0A.

Individual

Individual

Checks

Corrective

Action page

8

9

10

10

10

10

16

• Fluid temperature sensor (FTS) senses a fluid temperature above 230°F (110°C).

• Overtemperature switch A or B (308) senses a fluid

temperature above 230°F (110°C) and opens. At

190°F (87°C) the switch closes again.

• Thermocouple A or B (310) fails, is damaged, is not

touching the heater element (307), or has a poor

connection to the temperature control board.

• Overtemperature switch A or B (308) fails in the

open position.

• The temperature control board fails to turn off any

heat zone.

• Zone power wires or thermocouples are switched

from one zone to another.

• Failed heater element where thermocouple is

installed.

• Loose wire

• On 6.0 and 10.2 kW heater models only: Jumper

wire on J1 connector, between module (3) and display (4), is loose or incorrectly wired.

Troubleshooting this equipment requires access to

parts that may cause electric shock or other serious

injury if work is not performed properly. Have a qualified electrician perform all electrical troubleshooting.

Be sure to shut off all power to the equipment before

repairing.

Check which zone is displaying the E01 error.

1. Check that connector B is firmly plugged into temperature control board (see F

2. Clean and re-plug connections.

3. Check connections between the temperature control board and overtemperature switches A and B

(308), and between temperature control board and

thermocouples A and B (310) or FTS (21) [depending on which zone is displaying E01]. See Table 5,

page 37. Ensure that all wires are securely connected to connector B.

IG

. 5, page 37).

8 312066Z

Page 9

Temperature Control Diagnostic Codes

4. Remove connector B from temperature control module, and check continuity of overtemperature

switches A and B, thermocouples A and B, or FTS

by measuring resistance across the pins on the plug

end; see T

Before doing the following checks, note which zone

(A, B, FTS, or all) has high fluid temperature.

Table 1: Sensor Connector Continuity Checks

Pins Description Reading

1 & 2 OT switch A nearly 0 ohms

3 & 4 OT switch B nearly 0 ohms

5 & 6 Thermocouple A 4-6 ohms

8 & 9 Thermocouple B 4-6 ohms

11 & 12 FTS approximately 35

10 & 12 FTS open

ABLE

1.

ohms per 50 ft (15.2

m) of hose, plus

approximately 10

ohms for FTS

E02: High zone current

1. Turn main power OFF .

2. Relieve pressure, page 23.

Disconnect whip hose.

3. Disconnect hose connector (D) at Reactor.

4. Using an ohmmeter, check between the two terminals of the connector (D). There should be no continuity.

5. Exchange zone module with another one. Turn

zone on and check for error. If error disappears,

replace faulty module.

For hose zone:

former Primary Check and Transformer Secondary

Check starting on page 45.

If error still occurs, perform Trans-

5. Verify fluid temperature, using an external temperature sensing device.

• If temperature

229°F [109°C] or above):

6. Check if thermocouples A and B are damaged, or

not contacting the heater element, page 42.

7. To test that temperature control module turns off

when equipment reaches temperature setpoint:

a. Set temperature setpoints far below displayed

temperature.

b. Turn zone on. If temperature rises steadily,

power board is failing.

c. Verify by swapping with another power module.

See Replacing Temperature Control Assem-

bly Modules, page 38.

d. If the swapped module does not fix the problem,

the power module is not the cause.

is

too high (sensor reading is

When there is a a high current error, the LED on

that zone’s module will turn red while the error is

displayed.

8. Verify continuity of heater elements with an ohmmeter, see page 40.

312066Z 9

Page 10

Temperature Control Diagnostic Codes

E03: No zone current

1. Check for tripped circuit breaker inside electrical

cabinet or at power source for that zone. Replace

circuit breaker if it trips habitually.

2. Check for loose or broken connection at that zone.

3. Exchange zone module with another one. Turn

zone on and check for error (see page 38). If error

disappears, replace faulty module.

4. If E03 occurs for all zones, the contactor may not be

closing. Verify wiring from heater control to contactor coil.

a.

Hose zone

b. Perform Transformer Primary Check and

Transformer Secondary Check, starting on

page 45.

When a no current error occurs, the LED on the

specific zone’s module turns red when the error is

displayed.

: test hose continuity, page 43.

5. To verify heater control module is not causing the

problem, use a wire to short-circuit the two pins corresponding to the FTS (red and yellow for A or B

zone, red and purple for hose). The display will

show the control heater module temperature.

6. If an error occurred for the hose zone, temporarily

use the current control mode. Refer to Reactor

Operation manual 312062.

E05: Circuit board overheated

Each module has an on-board temperature sensor.

Heat is turned off if module temperature exceeds

185°F (85°C) within the heater module.

1. Check that fan above electrical cabinet is operating.

2. Check that electrical cabinet door is properly

installed.

3. Check for obstructions blocking cooling holes in bottom of electrical cabinet.

E04: Fluid Temperature Sensor (FTS) or thermocouple disconnected

1. Check temperature sensor connections to long

green connector (B) on temperature control module,

page 37. Unplug and re-plug sensor wires.

2. Test fluid temperature sensor continuity with ohmmeter, page 8.

3. If an error occurred for the hose zone, check FTS

connections at each section of hose.

4. If an error occurred for the hose zone, test FTS by

plugging directly into machine.

F

D

4. Clean heatsink fins behind heater control modules.

5. Ambient temperature may be too high. Allow Reactor to cool by moving to a cooler location.

E06: Communication cable unplugged

1. Unplug and re-plug cable that connects heater control module to heater module.

2. Replace communication cable if problem persists.

TI10964a

10 312066Z

Page 11

Motor Control Diagnostic Codes

Motor Control Diagnostic Codes

Motor control diagnostic codes E21 through E29 appear

on pressure display.

There are two types of motor control codes: alarms and

warnings. Alarms take priority over warnings.

Alarms

Alarms turn off Reactor. Turn main power OFF

then ON to clear.

Alarms can also be cleared, except for code 23, by

pressing .

Warnings

Reactor will continue to run. Press to clear. A

warning will not recur for a predetermined amount of

time (varies for different warnings), or until main power

is turned OFF then ON .

Code Code Name Alarm (A) or

Warning (W)

21 No transducer (compo-

nent A)

22 No transducer (compo-

nent B)

23 High fluid pressure A

24 Pressure imbalance A/W (to

25 High line voltage A

26 Low line voltage A

27 High motor temperature A

28 High current A

29 Brush wear W

30 Momentary loss of

communication

31 Motor control failure A

32 Motor control

overtemperature

99 Loss of communication -

A

A

select, see

page 34)

-

A

Corrective

Action

page

16

16

16

16

18

18

18

29

19

16

15

16

16

312066Z 11

Page 12

Motor Control Diagnostic Codes

E21: No component A transducer

1. Check transducer A connection at J3 on motor control board, page 34, and clean contacts.

2. Reverse A and B transducer connections. If error

moves to transducer B (E22), replace transducer A,

page 36. If error does not move, replace motor control board, page 34.

E22: No component B transducer

1. Check transducer B connection at J8 on motor control board, page 35, and clean contacts.

2. Reverse A and B transducer connections. If error

moves to transducer A (E21), replace transducer B,

page 36. If error does not move, replace motor control board, page 34.

E23: High fluid pressure

1. Relieve pressure. Verify low pressure with analog

b. Turn on the Reactor master power.

• If the error is gone, turn off the Reactor main

power, remove test transducer, and replace “A”

transducer.

• If the error persists, unplug the “test” transducer

from the “A” socket, and reinstall the “A” pressure transducer back into the “A” socket.

Repeat this test procedure on the “B” side.

4. If the error persists and no root cause is found

through the above testing, replace the motor control

board, page 34.

E24: Pressure Imbalance

If the pressure difference between components A

and B exceeds 500 psi (3.5 MPa, 35 bar), an E24

will occur. This default value is adjustable; see the

operation manual.

E24 can be an alarm or a warning, as desired. Set

DIP switch on motor control board ON for alarm,

OFF for warning. See page 34.

gauges. Turn main power OFF then ON

. If error persists, do checks below.

1. Check the jumpers and the wiring. Check jumper on

motor control board J10 for E20 and E-XP1, or J7

for E30 and E-XP2, pins 7-10, page 34.

2. Remove, clean and re-install the pressure transducer leads

If the jumpers and the wiring are in good working condition and you still have the error, then you will need to

replace the “A” and “B” pressure transducers.

3. To determine if it’s the “A” or the “B” transducer, you

will need a known good Reactor pressure transducer to use as a “test” transducer. The test is done

without removing the existing pressure transducers

from the fluid manifold.

a. Unplug the “A” transducer from the Motor con-

trol board socket (page 36) and replace with

“test” transducer.

Fast E24 Errors

Fast E24 errors occur:

• within 10 seconds of turning the pumps on, or

• as soon as you trigger the gun.

Causes of Fast E24 Errors

• one side of the gun is plugged.

• a pressure transducer has failed.

• damaged pump seals or check valve.

• no feed pressure or empty material drum

• plugged heater.

• plugged hose.

• plugged manifold.

• one PRESSURE RELIEF/SPRAY valve is leaking or

is set to PRESSURE RELIEF/CIRCULATION

12 312066Z

Page 13

Motor Control Diagnostic Codes

Checks for Fast E24 Errors

If a fast E24 error occurs, first check the readings of

the analog gauges.

If gauge pressures are very close

1. Clear the error and run the unit.

2. Check plug J10 (E20/E-XP1) or J7 (E30/E-XP2) or

the jumpers 7 to 8, or 9 to 10 on the motor control

board.

3. Check pressure transducer performance:

The digital display on a Reactor always shows the

higher of the two pressures. As soon as the higher analog pressure drops below the lower analog pressure the

digital display will switch to the new highest reading.

Determine which transducer is performing poorly.

1. For testing purposes only, find the dip switches

labeled SW2 on the motor control board, page 35.

Set dips witch 3 to OFF. This will allow the Reactor

to run with a pressure imbalance alarm.

2. Run the unit to build up some pressure (1000 –

1200 psi). Shut down the unit, clear the alarm and

power back up. Do not depressurize the unit.

3. Check the analog gauges to see which pressure is

higher. Check if the display pressure matches, indicating that the motor control board “sees” that transducer. If not, the motor control board does not “see”

that transducer. Check the wire connections and or

replace the transducer.

4. With the pump zone off, use the pressure relief

valves to slowly relieve the “high” side pressure,

while watching the digital display and the analog

gauges. Once the higher analog gauge drops below

the lower analog pressure the motor control board

should start reading the “new” high side pressure

(because it is now the higher of the two). Continue

dropping the original “high” side pressure - the digital display should stop dropping. Repeat the process to check the other pressure transducer.

The last test determines if the pressure transducer has

failed or if the socket on the pressure control board has

gone bad.

1. Swap the transducer plug-ins on the motor control

board. (J3 and J8 for the E-20 and E-XP1. J3 and

J5 for the E30 and E-XP1).

2. Repeat above test.

3. If the problem stays with the same side as before,

then the pressure transducer is bad.

4. If the problem switches to the other transducer, then

the problem is in the motor control boards socket.

If the gauge readings are

1. Clear the error and balance the pressures using the

dump valves.

2. If you cannot get the pressures to balance:

• Check for pump failure.

• Check for adequate material.

• Using the feed pump to push fluid out through the

gun manifold, check for a plugged fluid path.

• Run the unit.

• Check and clean the gun inlet screens.

• Check and clean the mix chamber “A” and “B”

impingement ports a well as the center port. Note:

Some mix chambers have counter bored holes,

and require two drill sizes to clean impingement

ports completely.

“Slow” E24:

• When spraying, gradual pressure imbalance and

eventual E24.

Possible Causes:

• One side of the Gun is partially blocked.

• The “A” or the “B” pump on the Reactor has failed.

• The “A” or the “B” feed pump has failed.

• The “A” or the “B” feed pump pressure is set too

high.

• The “A” or the “B” inlet screen is plugged.

• The hose is not heating properly.

• Kinked supply hose.

• Bottom of the drum is damaged causing a blockage

to the inlet of the feed pump.

• The drum is not vented properly.

not

equal.

312066Z 13

Page 14

Motor Control Diagnostic Codes

E25: High line voltage

Supply voltage too high. Check Reactor voltage requirements, page 73.

E26: Low line voltage

Supply voltage too low. Check Reactor voltage requirements, page 73.

E27: High Motor Temperature

1. Motor temperature too high. Reduce pressure, gun

tip size, or move Reactor to a cooler location. Allow

one hour for cooling.

2. Check fan operation.

3. Ensure there is no obstruction around the fan area

that would cause lack of airflow; ensure the

motor/fan shroud is installed.

4. Ensure the unit is being operated with the front

cover on.

5. Ensure the brush wear/over temp switch wire

assembly is plugged into J7 (E-20/E-XP1) or J6

(E-30/E-XP2) of the motor control board.

6. With the main power off, unplug the wire harness

from J7 (E-20/E-XP1) or J6 (E-30/E-XP2) on the

motor control board and install a jumper wire on

pins 1 and 2. Turn the main power back on.

E28: High current in motor

Check motor control board:

1. Turn the master power off.

2. Disconnect socket J4 (E-20/E-XP1) J1

(E-30/E-XP2) on the motor control board.

3. Turn the master power back on.

4. If the E28 error did not go away then there is a problem with the motor control board. Replace board,

page 34.

Check motor:

1. Check to see if the motor rotates freely.

2. Check to see if the brushes are damaged.

3. Check that the voltage going to the motor is good.

4. Check the three wire (yellow, yellow, orange) motor

connector to the motor board. A gentle tug on each

wire individually at the connector should identify the

loose wire. If a wire pulls out, bend the locking tab

on the crimp end, insert the wire until it seats and

repeat gentle tug.

5. If the above does not resolve the problem, replace

the motor, page 33.

E29: Brush Wear

If E27 is gone:

If the E27 error is gone and the motor is truly not overheated, then the problem can be in the motor/motor wire

harness assembly. Measure the resistance between the

two yellow wires that go to pins 1 and 2 of the motor

connector. If there is an open connection, the thermal

overload switch is open or there is a broken wire inside

the motor, or a broken wire in the motor harness.

If the E27 error code is still there, double check if pins 1

and 2 are jumpered properly. If jumpered properly, then

it would appear that the problem is with in the motor

control board.

14 312066Z

Prolonged operation of motor after a brush wear

warning may result in failure of motor and motor control board.

1. Check for normal brush wear, which causes the

brush sensor to come in contact with the motor

commutator. Replace the brushes, page 30.

2. Check spade plug. The spade plug inside the motor

housing may be twisted and contacting the commutator side of the brush sensor assembly, causing a

false alarm. Follow the orange wire coming from J7

(E-20/E-XP1), or J6 (E-30/E-XP2), up to the spade

connector on the motor. Using a flashlight, ensure

the spade plug assembly is not making contact with

the metal housing of the brush assembly.

CAUTION

Page 15

3. Check wiring. The orange brush sensor wire coming

out of the brush may be routed online with the commutator wiring (thick red wire), causing a false

alarm. Reroute the orange wire coming out of the

brush, away from the commutator wiring.

4. Check motor control board.

• Remove the plug in J7 (E-20/E-XP1), or J6

(E-30/E-XP2). (This will cause an E27 alarm).

• To remove the E27 alarm, use a jumper wire on the

motor control board, across the two pins that the

two yellow wires plug into. Then turn the unit on.

Motor Control Diagnostic Codes

1. Turn main power OFF . Disconnect power

supply.

Wait 5 minutes for stored voltage to discharge (E-30

and E-XP2 models only).

2. Relieve pressure, page 23.

• The E27 as well as the E29 alarm should be gone. If

the E27 alarm is not gone double-check your

jumper.

• If the jumper is installed correctly and the E29 alarm

is still there, replace the motor control board, page

34.

E31: Motor Control Failure (E-30 and E-XP2 only)

The E31 error code represents a motor drive error. This

indicates that the 24G881 motor control board has malfunctioned and needs to be replaced. A motor control

board failure may also be indicated by the motor starting

up immediately upon the application of power to the sys-

tem, without pressing . This is an indication that

the output drivers of the motor control have shorted out

and are delivering full power to the motor at all times.

The cause of the failure may be one of the following conditions: motor failure, capacitor failure, shorted or frayed

wiring, or inadequate power supply. Perform the following procedure before replacing the motor control board.

3. Perform the following inspections.

a. Motor failure: Inspect the motor commutator by

removing the top brush (see Brush Removal,

page 30). Rotate the motor, inspecting the

whole commutator for burns, pocking, or shorts

between poles. Continue rotating the motor for a

complete pump cycle, up and down, to ensure

that there is no mechanical interference or

restriction in the pump lower or gear drive system.

b. Capacitor failure: Inspect and test the motor

start capacitor, following the Capacitor Test

instructions on page 32.

c. Shorted or frayed wiring: Inspect all wiring

connected to the motor control board and the

motor, for shorts or frayed insulation. Replace

any compromised wires with wire of the same

gauge, color. and temperature rating.

d. Inadequate power supply: Verify that the

power source is of the correct voltage and current rating for the system, and that all phases

are properly connected. Ensure that the power

does not dip or surge during operation.

Prior to shutting down the generator, ensure

that the motor has stopped and the main disconnect is opened. If the generator is stopped

during operation, even due to running out of

fuel, the drop in supply voltage may cause a

motor drive failure.

312066Z 15

Page 16

Communication Diagnostic Codes

E32: Motor Control

1. Relieve pressure, page 23. Verify low pressure with

analog gauges.

Overtemperature

The E32 error code indicates a high temperature condition within the motor control board (701). This could be

caused by an abnormally high ambient temperature in

the work location, blockage of cooling vents in the cabinet, or the failure of the cooling fan inside the cabinet.

2. Turn main power OFF then ON .

If error still remains, identify cause of the overtemperature condition and remedy.

Communication Diagnostic Codes

E30: Momentary loss of communication

Communications between the display and the motor

control board or the temperature control board have

been momentarily lost. Normally, when communication

is lost, the corresponding display will show E99. The

corresponding control board will register E30 (The red

LED will flash 30 times). If communications are reconnected, the display can show the E30 for a short time

(no more than about two seconds). It should not be possible for E30 to be shown continuously, unless there is a

loose connection causing the display and the board to

continuously lose and regain communication.

E99: Loss of communication

Communications between the display and the motor

control board or the temperature control board has been

lost. When communication is lost, the corresponding

display will show E99.

1. Check all wiring between the display and the corresponding control board. Pay close attention to the

wire crimping on plug J13 for each board.

Check all wiring between the display and the corresponding control board.

Step 2 measures line voltage and should be done by a

qualified electrician. If work is not performed properly

it may cause electric shock or other serious injury.

2. Measure the incoming voltage to the board (it

should be ~ 230Vac).

3. If it was only receiving 1 leg of the 230Vac the board

may light up, and still not function properly. Correct

the incoming voltage problem.

16 312066Z

Page 17

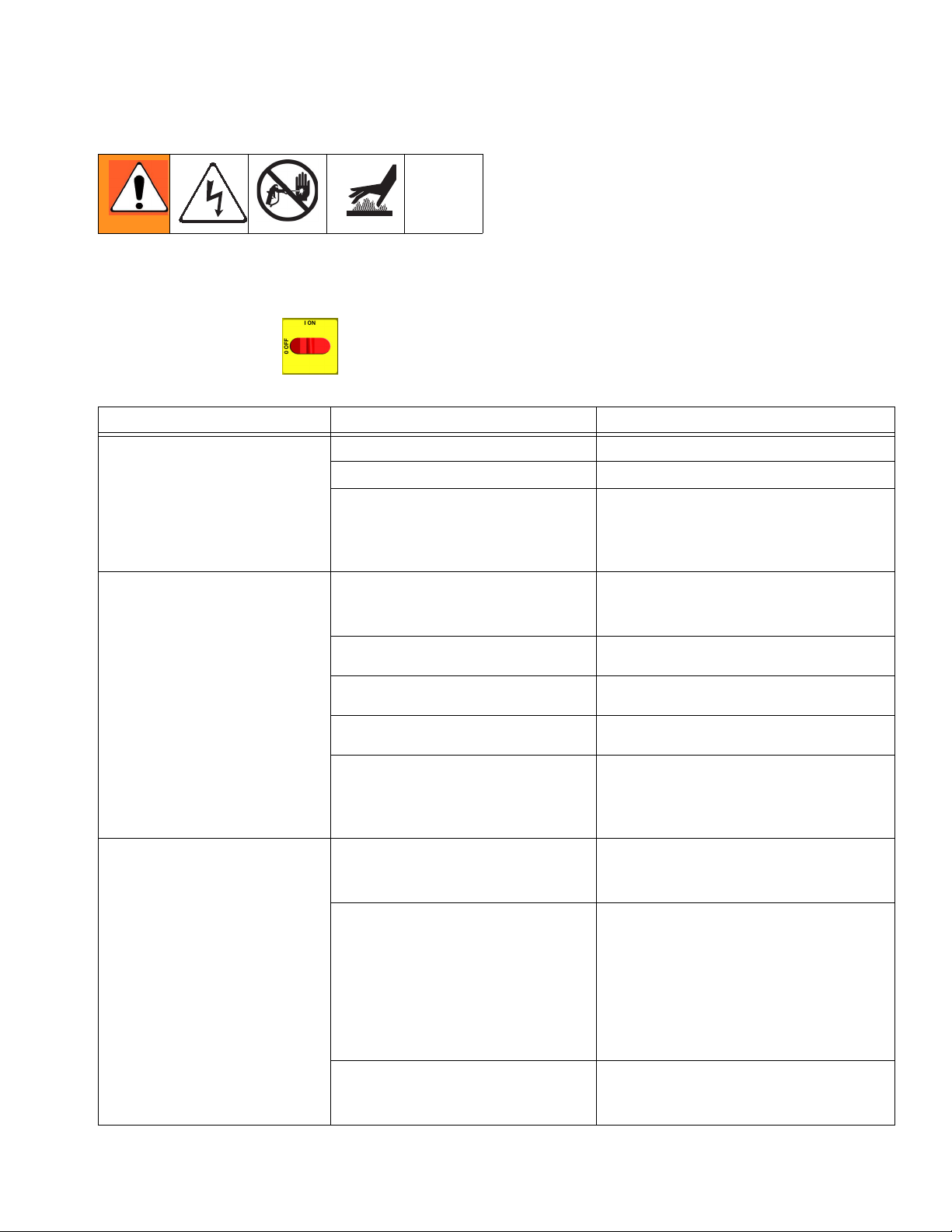

Troubleshooting

Troubleshooting

PROBLEM CAUSE SOLUTION

Reactor does not operate. No power. Plug in power cord.

Turn main power ON .

Turn circuit breakers ON, page 32.

Red stop button circuit open. Check button connections. See page

46 and electrical diagrams.

Motor does not operate. Loose connections. Check connections at motor control

board.

Circuit breaker tripped. Reset breaker (CB5), page 32.

Check 230Vac at output of breaker.

Worn brushes. Check both sides. Length must be

0.7 in. (17 mm) minimum. To replace,

page 30.

Broken or misaligned brush springs. Realign or replace, page 30.

Brushes or springs binding in brush

holder.

Shorted armature. Replace motor, page 33.

Check motor commutator for burn

spots or other damage.

Damaged motor control board. Replace board. See page 34.

Fan not working. Blown fuse. Replace, page 36.

Loose wire. Check.

Defective fan. Replace, page 36.

Pump output low. Obstructed fluid hose or gun; fluid

hose ID too small.

Worn piston valve or intake valve in

displacement pump.

Pressure setpoint too high. Reduce setpoint and output will

Fluid leak in pump packing nut area. Worn throat seals. Replace. See pump manual.

No pressure on one side. Fluid leaking from heater inlet rupture

disk (314).

Clean brush holder and align brush

leads for free movement.

Remove motor. Have motor shop

resurface commutator, if possible.

Open, clear; use hose with larger ID.

See pump manual.

increase.

Check if heater (2) and PRESSURE

RELIEF/SPRAY valve (SA or SB) are

plugged. Clear. Replace rupture disk

(314) with a new one; do not replace

with a pipe plug.

312066Z 17

Page 18

Troubleshooting

Reactor Electronics

2. Turn main power OFF .

3. Allow equipment to cool.

Try the recommended solutions in the order given for

each problem, to avoid unnecessary repairs. Also,

Before performing any troubleshooting procedures:

1. Relieve pressure, page 23.

PROBLEM CAUSE SOLUTION

No power.

Both sides of display do not

illuminate.

Temperature display does not

illuminate.

Pressure display does not

illuminate.

Erratic display; display turns on and

off.

Hose display reads OA at startup. FTS disconnected or not installed. Verify proper installation of FTS (see

Low voltage. Ensure input voltage is within specifi-

Loose wire. Check connections, page 46.

Display disconnected. Check cable connections, page 46.

Display disconnected. Check cable connections, page 46.

Display cable damaged or corroded. Clean connections; replace cable if is

Defective circuit board. Swap display connection to motor

Display disconnected. Check cable connections, page 46.

Display cable damaged or corroded. Clean connections; replace cable if is

Defective circuit board. Swap display connection to motor

Low voltage. Ensure input voltage is within specifi-

Poor display connection. Check cable connections, page 46.

Display cable damaged or corroded. Clean connections; replace cable if is

Display cable not grounded. Ground cable, page 46.

Display extension cable too long. Must not exceed 100 ft (30.5 m)

determine that all circuit breakers, switches, and controls are properly set and wiring is correct before assuming there is a problem.

Plug in power cord.

Turn disconnect ON .

cations, page 46.

damaged.

control board with connection to

heater control board. If temperature

display illuminates, heater control

board is causing problem. Otherwise,

display cable or display is failing.

damaged.

control board with connection to

heater control board. If pressure display illuminates, motor control board

is causing problem. Otherwise, display cable or display is failing.

cations, page 46.

Replace damaged cable.

damaged.

Operation manual 312065), or adjust

FTS to desired current setting.

18 312066Z

Page 19

PROBLEM CAUSE SOLUTION

Poor display connection. Check cable connections, page 46.

Replace damaged cable.

Display does not respond properly to

button pushes.

Display cable damaged or corroded. Clean connections; replace cable if is

damaged.

Ribbon cable on display circuit board

Connect cable (page 46) or replace.

disconnected or broken.

Broken display button. Replace, page 46.

Red stop button does not work. Broken button (fused contact). Replace, page 46.

Loose wire. Check connections, page 46.

Blown fuse. Verify with ohmmeter; replace if nec-

essary (page 46).

Fan not working.

Loose wire. Check fan wire.

Defective fan. Replace, page 46.

Troubleshooting

312066Z 19

Page 20

Troubleshooting

Primary Heaters (A and B)

Before performing any troubleshooting procedures:

1. Relieve pressure, page 23.

PROBLEM CAUSE SOLUTION

Heat turned off.

Primary heater(s) does not heat.

Temperature control alarm. Check temperature display for diag-

2. Turn main power OFF .

3. Allow equipment to cool.

Try the recommended solutions in the order given for

each problem, to avoid unnecessary repairs. Also,

determine that all circuit breakers, switches, and controls are properly set and wiring is correct before assuming there is a problem.

Press or zone

keys.

nostic code, page 8.

A

B

Control of primary heat is abnormal;

high temperature overshoots or E01

error occurs intermittently.

Signal failure from thermocouple. See E04: Fluid Temperature Sen-

sor (FTS) or thermocouple disconnected, page 10.

Dirty thermocouple connections. Examine connection of thermocou-

ples to long green plug on heater

control board. Unplug and re-plug

thermocouple wires, cleaning off any

debris. Unplug and re-plug long

green connector.

Thermocouple not contacting heater

element.

Failed heater element. See Primary Heaters, page 20.

Signal failure from thermocouple. See E04: Fluid Temperature Sen-

Thermocouple wired incorrectly. See E04: Fluid Temperature Sen-

Loosen ferrule nut (N), push in thermocouple (310) so tip (T) contacts

heater element (307). Holding themocouple tip (T) against heater element,

tighten ferrule nut (N) 1/4 turn past

tight. See page 42 for illustration.

sor (FTS) or thermocouple disconnected, page 10.

sor (FTS) or thermocouple disconnected, page 10. Power up zones

one at a time and verify that temperature for each zone rises.

20 312066Z

Page 21

Troubleshooting

Hose Heat System

Before performing any troubleshooting procedures:

1. Relieve pressure, page 23.

2. Turn main power OFF .

PROBLEM CAUSE SOLUTION

Ambient temperature is too cold. Use auxiliary hose heat system.

Hose heats but heats slower

than usual or it does not reach

temperature.

FTS failed or not installed correctly. Check FTS, page 10.

Low supply voltage. Verify line voltage. Low line voltage signifi-

3. Allow equipment to cool.

Problems

Try the recommended solutions in the order given for

each problem, to avoid unnecessary repairs. Also,

determine that all circuit breakers, switches, and controls are properly set and wiring is correct before assuming there is a problem.

cantly reduces power available to hose

heat system, affecting longer hose

lengths.

Hose does not maintain temperature while spraying.

Hose temperature exceeds setpoint.

A and B setpoints too low. Increase A and B setpoints. Hose is

designed to maintain temperature, not to

increase it.

Ambient temperature is too cold. Increase A and B setpoints to increase

fluid temperature and keep it steady.

Flow too high. Use smaller mix chamber. Decrease pres-

sure.

Hose was not fully preheated. Wait for hose to heat to correct tempera-

ture before spraying.

Low supply voltage. Verify line voltage. Low line voltage signifi-

cantly reduces power available to hose

heat system, affecting longer hose

lengths.

A and/or B heaters are overheating

material.

Faulty thermocouple connections. Verify that all FTS connections are snug

Check primary heaters for either a thermocouple problem or a failed element

attached to thermocouple, page 10.

and that pins of connectors are clean.

Examine connection of thermocouples to

long green plug on heater control board.

Unplug and re-plug thermocouple wires,

cleaning off any debris. Unplug and

re-plug long green connector on heater

control board.

Missing/damaged insulation around

FTS, causing the hose heat to be ON

constantly.

312066Z 21

Ensure hose bundle has adequate insulation evenly covering the entire length and

connection joints.

Page 22

Troubleshooting

PROBLEM CAUSE SOLUTION

Erratic hose temperature.

Faulty thermocouple connections. Verify that all FTS connections are snug

and that pins of connectors are clean.

Examine connection of thermocouples to

long green plug on heater control board.

Unplug and re-plug thermocouple wires,

cleaning off any debris. Unplug and

re-plug long green connector.

FTS not installed correctly. FTS should be installed close to end of

hose in same environment as gun. Verify

FTS installation, page 44.

Missing/damaged insulation around

FTS, causing the hose heat to be ON

constantly.

FTS failed or is not contacting

Ensure hose bundle has adequate insulation evenly covering the entire length and

connection joints.

Check FTS, page 44.

correctly.

FTS not installed correctly. FTS should be installed close to end of

Hose does not heat.

hose in same environment as gun. Verify

FTS installation, page 44.

Temperature control alarm. Check temperature display or diagnostic

code, page 44.

Hoses near Reactor are warm,

but hoses downstream are cold.

Shorted connection or failed hose

heating element.

With hose heat on and temperature setpoint above displayed hose zone temperature, verify voltage between

connectors at each section of hose.

Voltage should drop incrementally for

each section of hose further from Reactor.

Use safety precautions when hose heat is

turned on.

No hose heat. Loose hose electrical connections. Check connections. Repair as necessary.

Circuit breakers tripped. Reset breakers (CB1 or CB2), page 32.

Hose zone not turned on.

Press zone key.

A and B temperature setpoints too

Check. Increase if necessary.

low.

Failed temperature control board. Open cabinet. Check if board LED is

blinking. If not, check power wiring connections to ensure board has power. If

board has power and LED is not blinking,

replace board, page 37.

Low hose heat. A and B temperature setpoints too

low.

Increase A and B setpoints. Hose

designed to maintain temperature, not

increase temperature.

Hose temperature setpoint too low. Check. Increase if necessary to maintain

heat.

Flow too high. Use smaller mix chamber. Decrease pres-

sure.

Low current; FTS not installed. Install FTS, see operation manual.

Hose heat zone not turned on long

Allow hose to heat up, or preheat fluid.

enough.

Loose hose electrical connections. Check connections. Repair as necessary.

22 312066Z

Page 23

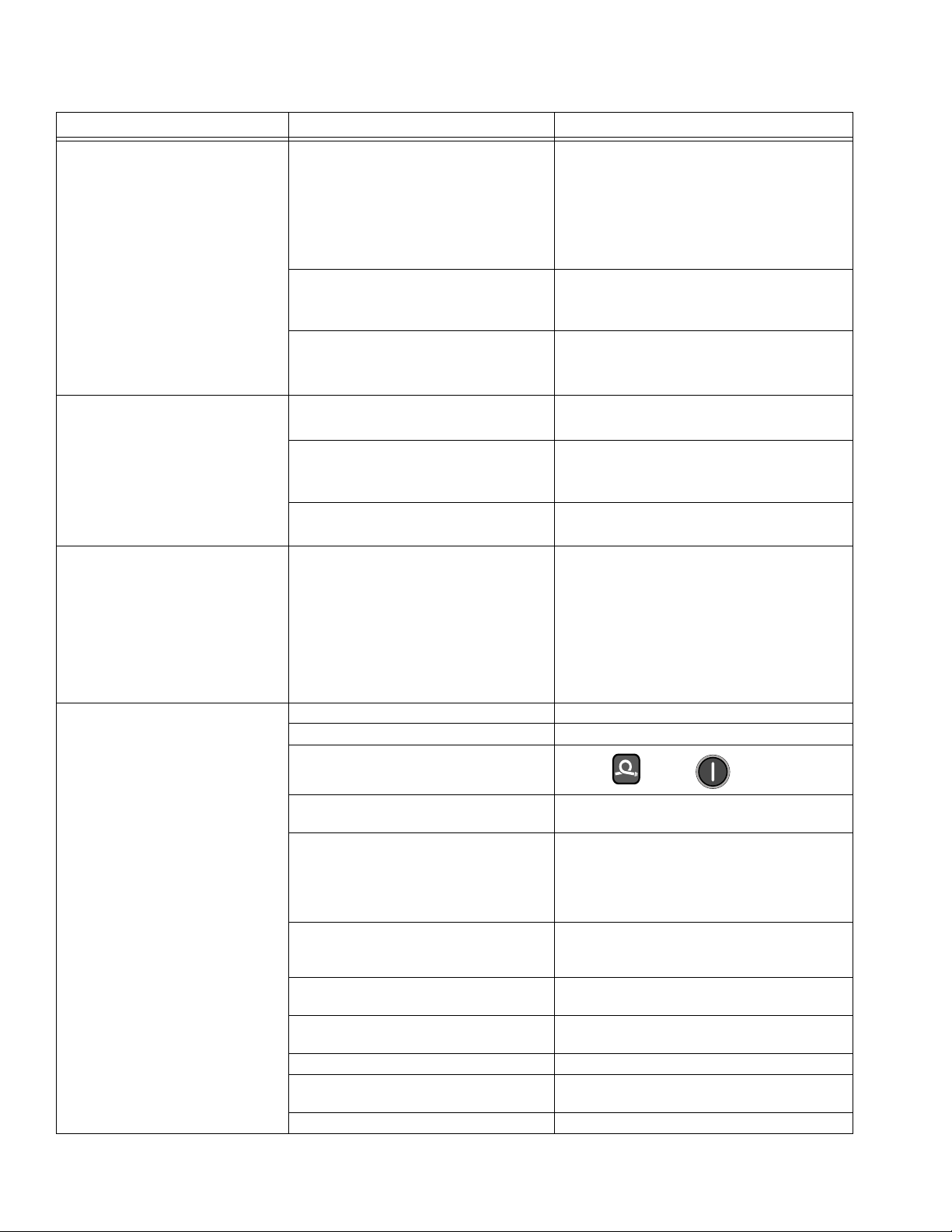

Repair

Repair

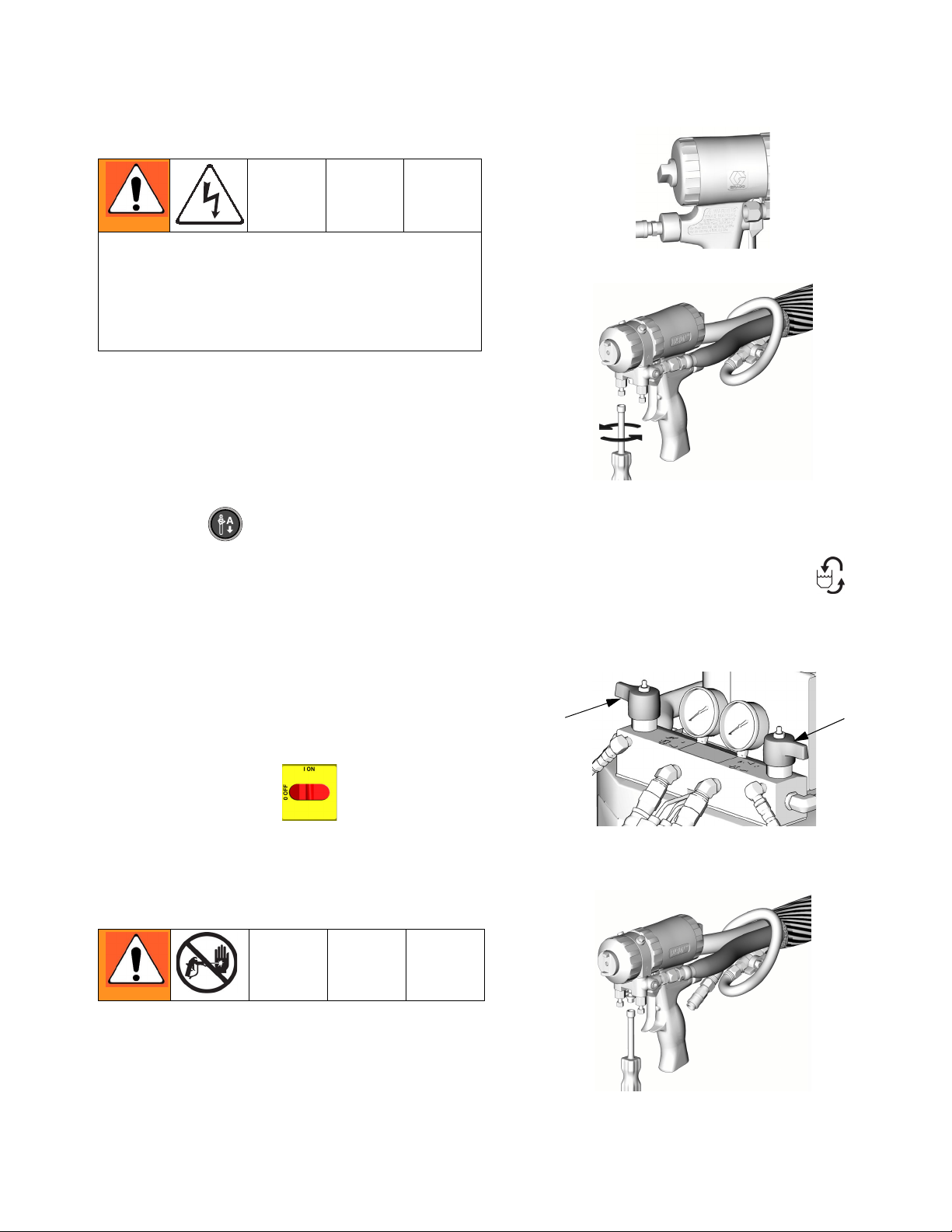

Repairing this equipment requires access to parts

that may cause electric shock or other serious injury if

work is not performed properly. Have a qualified electrician connect power and ground to main power

switch terminals, see operation manual. Be sure to

shut off all power to the equipment before repairing.

Before Beginning Repair

1. Flush if necessary; see Flushing.

2. Park component A pump.

a. Press .

2. Engage gun piston safety lock.

ti2409a

3. Close gun fluid manifold valves A and B.

ti2421a

4. Shut off feed pumps and agitator, if used.

5. Turn PRESSURE RELIEF/SPRAY valves (SA, SB)

b. Trigger gun until pump A stops. After fluid pres-

sure drops below 700 psi (7.9 MPa, 79 bar),

motor will run until component A pump is at bottom of its stroke, then shut off.

c. Check ISO reservoir for component A pump. Fill

wet cup on component B pump. Refer to Reactor Operation manual 312065.

3. Turn main power OFF .

4. Relieve pressure.

Pressure Relief Procedure

to PRESSURE RELIEF/CIRCULATION .

Route fluid to waste containers or supply tanks.

Ensure gauges drop to 0.

SA

6. Disconnect gun air line and remove gun fluid manifold.

SB

ti10955a

1. Relieve pressure in gun and perform gun shutdown

procedure. See gun manual.

ti2554a

312066Z 23

Page 24

Repair

Flushing

Flush equipment only in a well-ventilated area. Do not

spray flammable fluids. Do not turn on heaters while

flushing with flammable solvents.

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent before introducing

new fluid.

• Use the lowest possible pressure when flushing.

• All fluid components are compatible with common

solvents. Use only moisture-free solvents.

• To flush feed hoses, pumps, and heaters separately

from heated hoses, set PRESSURE

RELIEF/SPRAY valves (SA, SB) to PRESSURE

See manual 309577 for pump repair instructions.

1. Shut off , , and heat zones.

2. Flush pump.

3. If pumps are not parked, press . Trigger gun

until pumps stop.

4. Turn main power off . Disconnect power

supply.

5. Shut off both feed pumps. Close both fluid inlet ball

valves (B).

A

B

RELIEF/CIRCULATION . Flush through bleed

lines (N).

SA

SB

N

N

TI10954a

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• To prevent moisture from reacting with isocyanate,

always leave the system dry or filled with a moisture-free plasticizer or oil. Do not use water.

Pump Removal

ti4147a

6. Turn both PRESSURE RELIEF/SPRAY valves (SA,

SB) to PRESSURE RELIEF. Route fluid to waste

containers or supply tanks. Ensure gauges drop to

0.

SA

SB

TI10956a

Pump rod and connecting rod move during operation.

Moving parts can cause serious injury such as pinching or amputation. Keep hands and fingers away from

connecting rod during operation.

24 312066Z

Page 25

Repair

Use drop cloth or rags to protect Reactor and surrounding areas from spills.

Steps 7-9 apply to pump A. To disconnect pump B,

go to steps 10 and 11.

7. Disconnect fittings at fluid inlet (C) and outlet (D, out

of view). Also disconnect steel outlet tube from

heater inlet.

8. Disconnect tubes (T). Remove tube fittings (U) from

wet-cup.

9. Loosen locknut (G) by hitting firmly with a

non-sparking hammer. Unscrew pump far enough to

separate and push up finger guard (P), to expose

rod retaining pin. Push retaining wire clip up. Push

pin out. Continue unscrewing pump.

Steps 10 and 11 apply to pump B.

10. Disconnect fluid inlet (C) and outlet (D). Also disconnect steel outlet tube from heater inlet.

11. Push retaining wire clip (E) up. Push pin (F) out.

Loosen locknut (G) by hitting firmly with a

non-sparking hammer. Unscrew pump.

E

F

G

D

G

D

P

U

T

C

TI3765a-1

C

TI3765a-2

312066Z 25

Page 26

Repair

Pump Installation

Steps 1-5 supply to pump B. To reconnect pump A,

proceed to step 6.

1. Ensure locknut (G) is screwed on pump with flat

side up. Screw pump into bearing housing (M) until

pin holes align. Push pin (F) in. Pull retaining wire

clip (E) down.

E

M

N

3

2. Continue screwing pump into housing until fluid outlet (D) is aligned with steel tube and top threads are

+/- 1/16 in. (2 mm) of bearing face (N).

3. Tighten locknut (G) by hitting firmly with a

non-sparking hammer.

4. Reconnect fluid inlet (C) and outlet (D).

5. Go to step 13.

F

G

1

2

C

2

D

2

1

Flat side faces up.

2

Lubricate threads with ISO

oil or grease.

3

Pump top threads must be

nearly flush with bearing face

(N).

TI3765a-1

26 312066Z

Page 27

Steps 6-12 apply to pump A only.

6. Ensure star-shaped locknut (G) is screwed on pump

with flat side up. Carefully twist and extend displacement rod 2 in. (51 mm) above wet-cup.

7. Start threading pump into bearing housing (M).

Place finger guard (P) over rod when it is accessible

through window of bearing housing. When pin holes

align, insert pin. Pull retaining wire clip down.

Finger guard is not used on Model E-30.

8. Seat finger guard (P) on wet-cup. Continue threading pump into bearing housing (M) until top threads

are +/- 1/16 in. (2 mm) of bearing face (N). Ensure

Repair

that barbed fittings at wet-cup flush ports are accessible.

9. Connect component A outlet tube loosely at pump

and at heater. Line up tube, then tighten fittings

securely.

10. Tighten star-shaped locknut (G) by hitting firmly with

a non-sparking hammer.

11. Apply thin film of TSL to barbed fittings. Using two

hands, support tubes (T) while pushing straight onto

barbed fittings.

Do not let tubes kink or buckle.

Secure each tube with a wire tie between two barbs.

12. Reconnect fluid inlet (C).

13. Purge air and prime the system. See Reactor operation manual.

1

Flat side faces up.

2

Lubricate threads with ISO oil

or grease.

3

Pump top threads must be nearly

flush with bearing face (N).

4

Finger guard (P) not used on

Model E-30.

T

D

2

P

U

M

N

G

C

4

3

1

2

2

TI3765a-2

312066Z 27

Page 28

Repair

Drive Housing

Removal

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 23.

3. Remove screws (38) and motor shield (9), page 50.

4. Remove screws (209) and front cover (217).

Examine bearing housing (203) and connecting

rod (205). If these parts need replacing, first

remove the pump (206), page 28.

5. Disconnect pump inlet and outlet lines. Remove

screws (213), washers (215), and bearing housing

(203).

CAUTION

Do not drop gear cluster (204) when removing drive

housing (202). Gear cluster may stay engaged in

motor front end bell (R) or drive housing.

Installation

1. Apply grease liberally to washers (207, 208, 218),

all gears, and inside drive housing (202).

2. Install one bronze washer (208) in drive housing,

then install steel washers (207, 218) as shown.

3. Install second bronze washer (208) on gear cluster

(204) and insert gear cluster in drive housing.

Drive housing crankshaft (S) must be in line with

crankshaft at other end of motor.

4. Push drive housing (202) onto motor (201). Install

screws (212, 219) and washers (214).

If bearing housing (203), connecting rod (205), or

pump (206) were removed, reassemble rod in

housing and install pump, page 26.

5. Install bearing housing (203), screws (213), and

washers (215). Pumps must be in phase (both at

same position in stroke).

6. Install front cover (217) and screws (209).

6. Remove screws (212, 219) and washers (214) and

pull drive housing (202) off motor (201).

The A side drive housing includes cycle counter

switch (221). If replacing this housing, remove

pins (P) and switch. Reinstall pins and switch on

new drive housing. Switch wires connect to J10

pins 5 and 6 on motor control board, page 34.

221

P

TI3250

7. Install motor shield (9) and screws (38).

28 312066Z

Page 29

214

Repair

214

219

201

202

209

217

203

213

206B

1

Crankshaft must be in line with

crankshaft at other end of motor.

205

215

212

R

S

R

S

1

218

206A

204

207208

208

TI3152

312066Z 29

Page 30

Repair

Motor Brushes

Brush Removal

Replace brushes worn to less than 1/2 in. (13

mm). Brushes wear differently on each side of

motor; check both sides. Brush Repair Kit 234037

is available.

1. Turn main power OFF . Disconnect power

supply.

Wait 5 min for stored voltage to discharge (E-30 and

E-XP2 models only).

2. Relieve pressure, page 23.

5. Loosen terminal screw (R). Pull away brush lead

(L), being careful motor lead terminal (T) remains in

place. Remove and discard brush (B).

B

RLT

6. Inspect commutator for excessive pitting, burning,

or gouging. Black color on commutator is normal.

Have commutator resurfaced by qualified motor

repair shop if brushes wear too quickly.

7. Repeat for other side.

01227-4

3. Remove motor cover, screw, and washers. Remove

inspection covers, screws, and gaskets from each

end of motor.

4. Push in spring clip (C) to release hooks (H) from

brush holder. Pull out clip and spring (S).

H

C

S

One brush has a wire on top for brush wear signal. Note which side of motor it is on. Unplug at

spade connector provided.

01227-2

30 312066Z

Page 31

Repair

Brush Installation

CAUTION

When installing brushes, follow steps carefully.

Improper installation damages parts beyond use.

Install brush with wires on same side of motor as

before. Plug spade terminal into connector.

1. Install new brush (B) so lead (L) is in long slot (D) of

holder.

D

L

B

01227-5

4. Install spring clip (C) and push in until hooks (H)

catch slots in housing. Incorrect installation may jam

clip.

H

C

01227-2

01227-6

2. Slide terminal (L) under terminal screw (R). Make

sure motor lead terminal (T) is still connected at

screw. Tighten screw.

B

T

L

R

01227-4

3. Install spring (S) so it will uncoil onto brush (B), as

shown. Spring will be damaged if installed backwards.

1

Note direction of spring coil.

Do not touch brushes, leads, springs, or brush holders

while equipment is plugged in, to reduce the risk of

electric shock and serious injury.

CAUTION

Do not run pumps dry for more than 30 sec while

checking brushes, to avoid damaging pumps.

5. Reinstall brush inspection covers, gaskets, and

screws. Reinstall motor cover, screws, washers,

and drive housing/pump assemblies.

6. Test brushes with both pump pins (F) disconnected,

page 30.

Select J 1 (jog mode). Press motor to start

motor. Slowly increase jog setting to J 6. Inspect

brush and commutator contact area for excessive

arcing. Arcs should not “trail” or circle around commutator surface.

B

Run motor for 20-30 min at J 6 to seat brushes.

S

1

312066Z 31

01227

Page 32

Repair

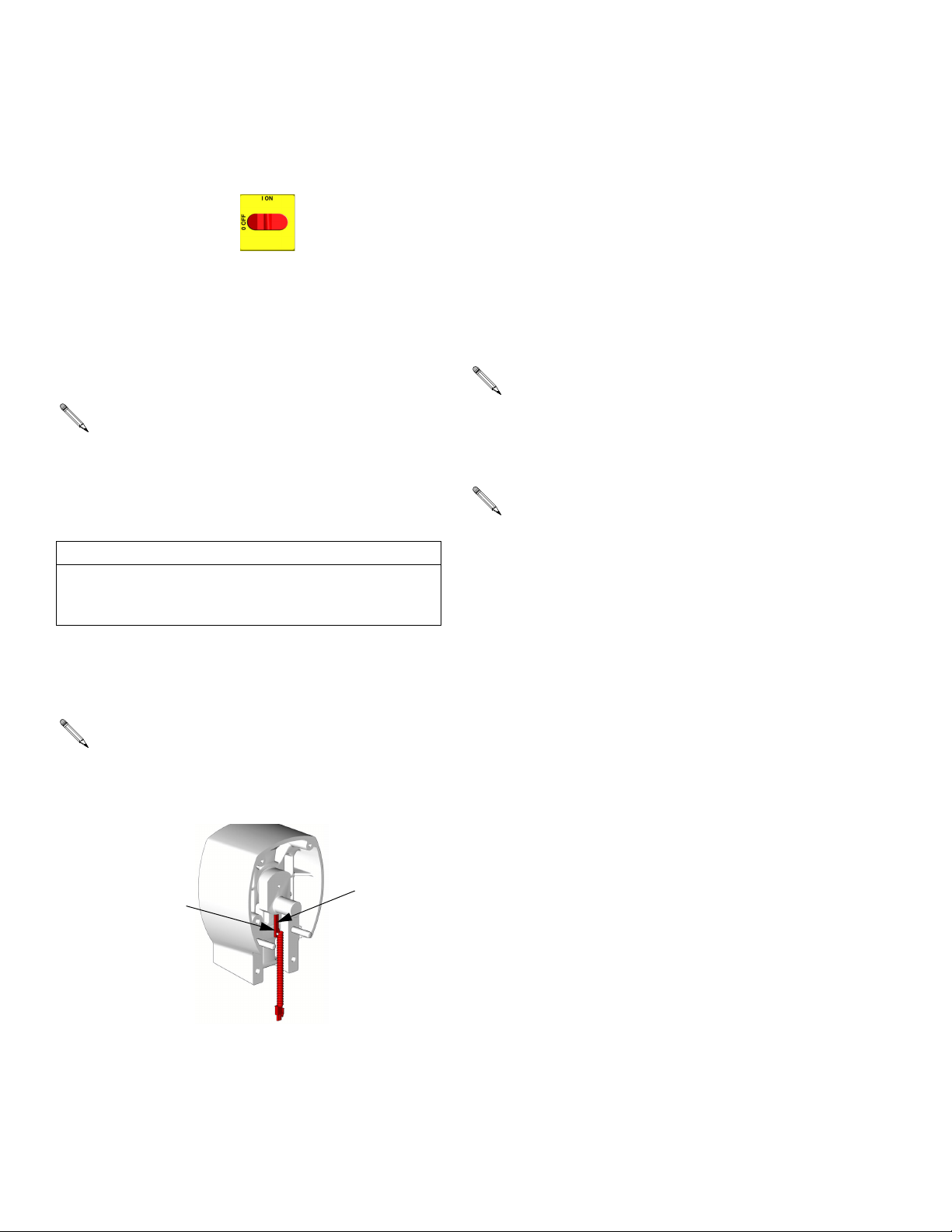

Capacitor Test

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 23.

3. Locate the large, blue capacitor in the upper right

corner of the lower cabinet.

4. With a DC voltmeter, measure the voltage across

the capacitor terminals to verify that the voltage has

discharged to below 10 volts.

5. With an insulated handle screw driver, short across

the two contacts on the end of the capacitor to complete discharging it. Hold for two seconds.

NOTE: A small spark may issue from the contact point.

6. Inspect the capacitor for irregularities such as

cracks, leakage, burn marks, or irregular shape.

7. Set an Ohmmeter to a range of at least 1K

connect the meter leads to the capacitor with the

red lead to the positive (+) terminal and the black

lead to the negative (-) terminal.

8. Observe the meter reading. It should start near 0

Ω

and climb up to 10K

battery charges the capacitor. This indicates a good

capacitor.

9. A reading of 0

bad capacitor. In this case, replace the capacitor.

with the exact replacement part, item 76 on pages

55 and 56.

Ω

, 20KΩ, etc., as the meter

(shorted) or O.L (open) indicates a

Ω

and

Ω

Circuit Breaker Module

1. Turn main power OFF . Disconnect power

supply. Turn circuit breakers on to test.

2. Relieve pressure, page 23.

3. Using an ohmmeter, check for continuity across circuit breaker (top to bottom). If no continuity, trip

breaker, reset, and retest. If still no continuity,

replace breaker as follows:

a. Refer to electrical diagrams and to T

connect wires and remove bad breaker.

b. Install new breaker and reconnect wires.

Table 2: Circuit Breakers, see FIG. 1

Ref. Size Component

909 50A Hose/Transformer

911 40A Transformer

912A 25A, 40A* Heater A

912B 25A, 40A* Heater B

913 20A Motor/Pumps

* Depending on model.

Secondary Side

Primary

ABLE

2. Dis-

NOTE: To reference cables and connectors, see the electrical diagrams and

the parts drawings on pages 67-68.

FIG. 1. Circuit Breaker Module

32 312066Z

909

911

912A

912B

913

ti9884a

Page 33

Repair

Electric Motor

Removal

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 23.

3. Remove drive housing/pump assemblies, page 28.

4. Disconnect motor cables as follows:

a. Refer to electrical diagrams. Motor control

board is on right side inside cabinet, see page

34.

Installation

1. Place motor on unit. Thread motor cables into cabinet and into bundles as before. See electrical diagrams.

2. Fasten motor with screws.

3. Plug 3-pin connector J7 to board.

4. Plug motor power harness to connector J4 on

board.

5. Install drive housing/pump assemblies, page 28.

6. Return to service.

b. Unplug motor power harness from connector J4

on board. See F

c. Unplug 3-pin connector J7 from board.

d. Thread cables through top of cabinet to free

motor.

Motor is heavy. Two people may be required to lift.

5. Remove screws holding motor to bracket. Lift motor

off unit.

IG

. 2, page 35.

CAUTION

312066Z 33

Page 34

Repair

Motor Control Board

Motor control board has one red LED (D11). Power

must be on to check. See F

tion is:

• Startup: 1 blink for 60 Hz, 2 blinks for 50 Hz.

• Motor running: LED on.

• Motor not running: LED off.

• Diagnostic code (motor not running): LED

blinks diagnostic code, pauses, then repeats

(for example, E21=21 blinks, pause, 21 blinks).

CAUTION

Before handling board, put on a static conductive wrist

strap to protect against static discharge which can

damage board. Follow instructions provided with wrist

strap.

1. Turn main power OFF . Disconnect power

supply.

IG

. 2 for location. Func-

8. Set DIP switch (SW2) on new board. See T

for factory settings. See F

IG

. 2 for location on board.

ABLE

Table 3: DIP Switch (SW2) Settings

DIP

Switch Switch Position

Switch 1 not used

Switch 2 ON for E-20 and

E-30 models

Switch 3 ON to enable pres-

sure imbalance

warning

OFF for E-XP1 and

E-XP2

OFF to enable

pressure imbalance

alarm

Switch 4 not used

9. Install new board in reverse order. Apply thermal

heatsink compound to mating surfaces of board and

heatsink.

Order Part 110009 Thermal Compound.

Table 4: Motor Control Board Connectors

3

Wait 5 minutes for stored voltage to discharge (E-30

and E-XP2 models only).

2. Relieve pressure, page 23.

3. Refer to electrical diagrams. Motor control board is

on right side inside cabinet.

4. Put on static conductive wrist strap.

5. Disconnect all cables and connectors from board.

6. Remove nuts (40) and take entire motor control

assembly to workbench.

7. Remove screws and take board off heatsink.

Model

E-20

and

E-XP1

J1 N, L n/a Main motor power

J8 J3 n/a Transducer B

J4 J1 n/a Motor output

J7 J6 1, 2 Motor thermal overload signal

J3 J5 n/a Transducer A

J10 J7 1-4 Not used

J12 J12 n/a Data reporting

J13 J13 n/a To display board

Model

E-30

and

E-XP2 Pin Description

3 Brush wear signal

5, 6 Cycle switch signal

7-10 Jumper 15C866 (available in

repair kit 246961)

34 312066Z

Page 35

24G879 Motor Control, for E-20 and E-XP1

DIP Switch (SW2) Settings

Model E-20

ON (UP)

TI3178b-3

Repair

J3 (A)

J8 (B)

Model E-XP1

ON (UP)

TI3178b-4

24G881 Motor Control, for E-30 and E-XP2

DIP Switch (SW2) Settings

Model E-30

J1

J4

J7

J13

J10

J12

1

D11

J12

SW2

TI3153A-1

SW2

J13

J5 (A)

ON (Down)

Model E-XP2

TI3178b-2

J3 (B)

J7

ON (Down)

1

Apply 110009 thermal heatsink

compound to mating surfaces.

TI3178b-1

N

L

J1

D7

J6

1

TI2576A-1

FIG. 2. Motor Control Board

312066Z 35

Page 36

Repair

Transducers

1. Turn main power OFF . Disconnect power

supply.

IG

4. Disconnect transducer cables at board; see F

. 2,

page 35. Reverse A and B connections and check if

diagnostic code follows; see E21: No component A

transducer, page 12.

5. If transducer fails test, thread cable through top of

cabinet. Note path as cable must be replaced in

same way.

2. Relieve pressure, page 23.

3. Refer to electrical diagrams. Motor control board is

on right side inside cabinet.

806 (A Side)

801

6. Install o-ring (820) on new transducer (806), F

IG

. 3.

7. Install transducer in manifold. Mark end of cable

with tape (red=transducer A, blue=transducer B).

8. Route cable into cabinet and thread into bundle as

before.

9. Connect transducer cable at board; see F

IG

. 2, page

35.

806 (B Side)

820

TI10957a

FIG. 3. Transducers

Electric Fan

4. Refer to electrical diagrams. Disconnect fan wires

from fuses (F).

5. Remove fan.

1. Turn main power OFF . Disconnect power

supply.

6. Install fan in reverse order.

F

2. Relieve pressure, page 23.

3. Check fuses (F) at left of breaker module, F

Replace if blown. If good, continue with step 4.

IG

. 4.

ti9884a-1

FIG. 4. Fan Fuses

36 312066Z

Page 37

Temperature Control Module

Repair

Table 5: Temperature Control Module Connections

Connector Description

DATA (A) Data reporting

PIN

HOSE T/C P; FTS (purple)

12

11 HOSE T/C R; FTS (red)

10 HOSE T/C S; FTS (silver

(unshielded bare wire))

9 HEATER T/C B, Y;

Thermocouple (yellow)

SENSOR (B)

8 HEATER T/C B, R;

Thermocouple (red)

7 Not used

6 HEATER T/C A, Y;

Thermocouple (yellow)

5 HEATER T/C A, R;

Thermocouple (red)

4, 3 OVERTEMPERATURE B;

Overtemperature switch B

2, 1 OVERTEMPERATURE A;

Overtemperature switch A

DISPLAY (C) Display

COMMUNICATION (D) Communication to power

boards

PROGRAM (E) Software programming

BOOT (F) Software bootloader

POWER/RELAY (G) Circuit board power input and

contactor control output

A

H

B

C

ti9875a

D

E

F

G

ti9843a1

Right Side of

Control Heater Module

J

Table 6: Temperature Power Module Connections

Connector Description

COMMUNICATION

(H)

POWER (J) Power to heater

Communication to control

board

ti9843a4

Bottom of Power Modules

FIG. 5: Temperature Control Module Connections

312066Z 37

Page 38

Repair

Test SCR Circuit

1. Test the SCR circuit in the on position:

a. Make sure everything is connected, including

the hose.

b. Turn main power ON .

c. Adjust the hose heat setpoint

ent hose temperature.

d. Turn on heat zone by pressing .

e. Hold down to view electrical current.

Hose current should ramp up to 45A. If there is

no hose current, see E03: No zone current,

page 10. If hose current exceeds 45A, see E02:

High zone current, page 9. If hose current

stays several amps below 45A, hose is too long

or voltage is too low.

above

Replacing Temperature Control Assembly

Modules

CAUTION

Before handling assembly, put on a static conductive

wrist strap to protect against static discharge which

can damage assembly. Follow instructions provided

with wrist strap.

the ambi-

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 23.

3. Refer to electrical diagrams; see Electrical Diagrams manual 312067. Temperature control assembly is on left side inside cabinet.

4. Remove bolts that secure transformer assembly

and slide assembly to side in cabinet.

2. Test the SCR circuit in the off position:

a. Make sure everything is connected, including

the hose.

b. Turn main power ON .

c. Adjust the hose heat setpoint

ent hose temperature.

d. Turn on heat zone by pressing .

e. Using a voltmeter, carefully measure the volt-

age at the hose connector. You should not get a

voltage reading. If you do, the SCR on the temperature control board is bad. Replace the temperature control assembly.

below

the ambi-

5. Put on static conductive wrist strap.

6. Disconnect all cables and connectors from assembly; see Parts - Temperature Control, page 64.

7. Remove nuts and take entire temperature control

assembly to workbench.

8. Replace defective module.

9. Install assembly in reverse order.

38 312066Z

Page 39

Repair

312066Z 39

Page 40

Repair

Primary Heaters

Heater Element

1. Turn main power OFF . Disconnect power

supply.

2. Relieve pressure, page 23.

3. Wait for heaters to cool.