Page 1

Instructions – Parts

®

Grease Jockey

Chassis Lubrication

For on-board, automatic lubrication of trucks and heavy-use vehicles. For professional use

only.

Maximum Working Pressure: See Technical Data, page 24

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

312054J

EN

Bulletin GJ-30050

ti9447a

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

2 312054J

Page 3

Warnings

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

• Gloves

• Hearing protection

312054J 3

Page 4

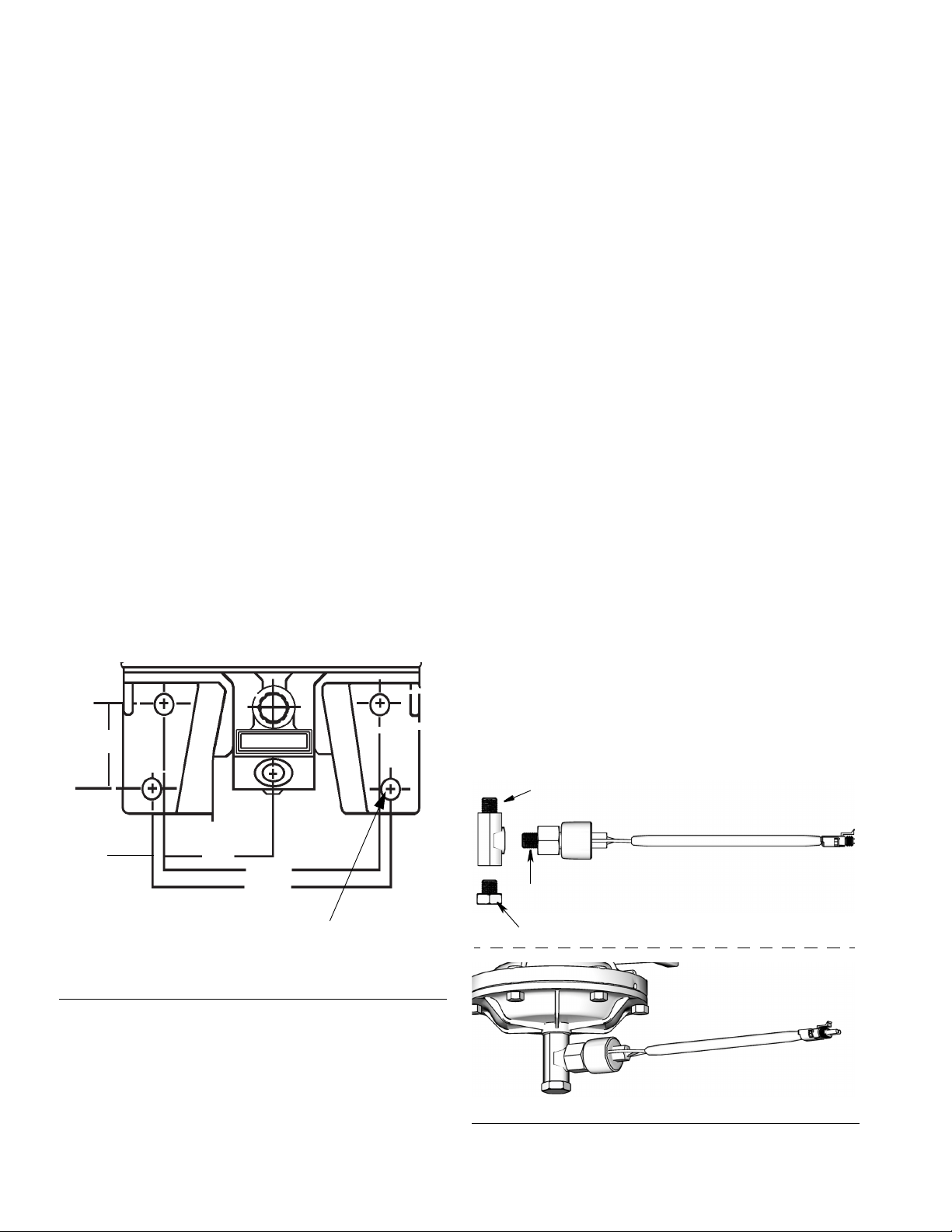

Installation

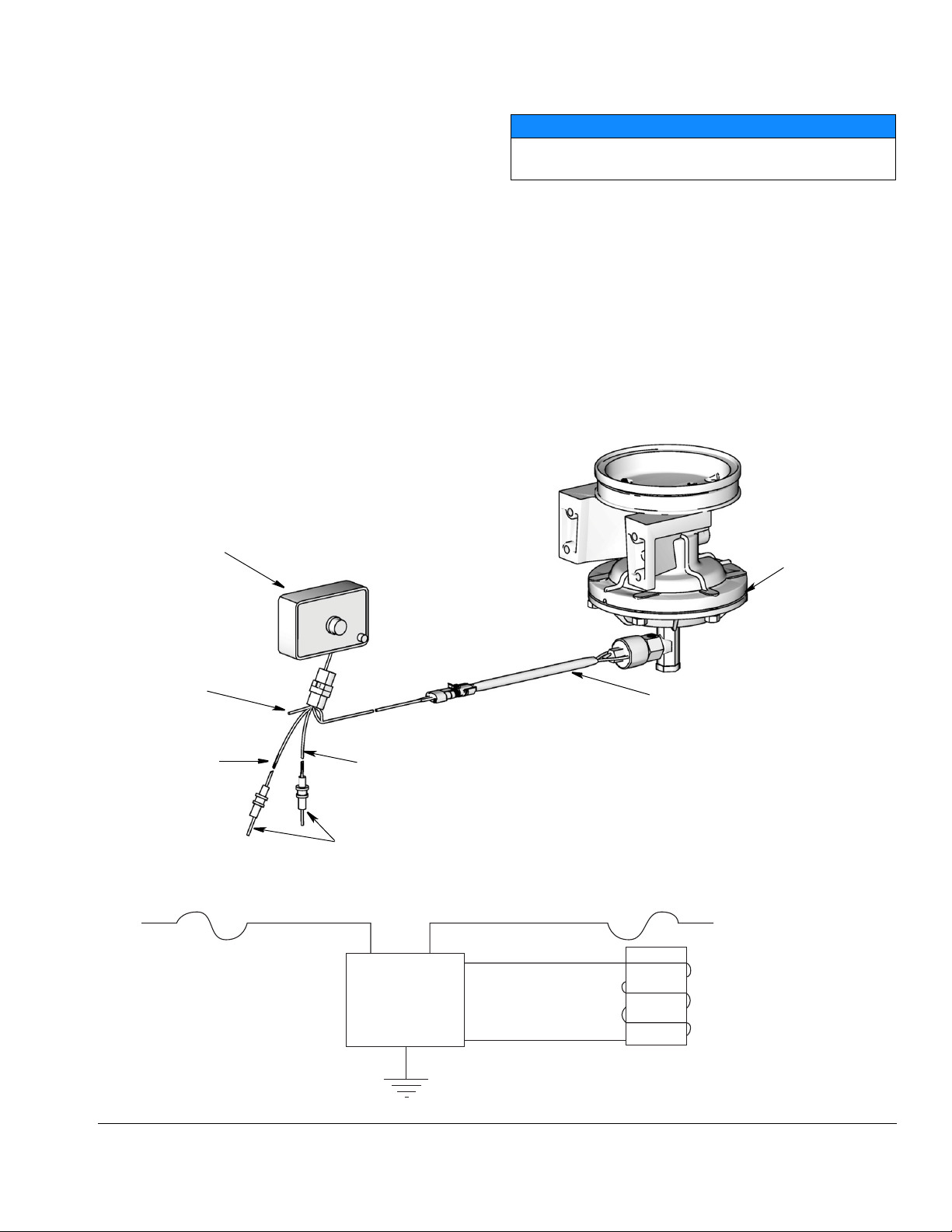

ti9448a

0.25

11/32 thru or tap 5/16-18 thru

(0.6)

Measurements shown in

Inch (cm)

4 Places

Solenoid Only

Solenoid Installed

B

A

ti11846b

ti12241a

C

Installation

Fill all lube points with grease before removing zerk fittings to change to tube connector fittings. This ensures

each lube point will readily accept grease.

Pump Mounting

NOTE:

• Pump mounting is the same for either an air or

electric pump.

• When using an electric pump omit Solenoid

Installation and Timer Installation.

• Mounting holes and dimensions are the same

on both styles of pump (See F

• A pump mounting bracket is available. Contact

your Graco distributor.

The pump inlet is gravity fed, therefore the pump must

be set vertically.

Select a location that is:

• visible

• accessible for filling the reservoir

• protected

IG. 1).

Air Operated Pump

Solenoid Installation

Be sure you have the correct voltage to match your

vehicle's electrical system.

1. Apply thread sealant to fitting threads (A).

2. Thread fitting (A), to the bottom of the pump. Hand

tighten only.

3. Use an open end wrench to tighten fitting. Side port

of fitting must point toward rear of vehicle.

4. Apply thread sealant to solenoid threads (B).

5. Thread solenoid (B) to the side port on fitting (A).

Wrench tighten.

6. Apply thread sealant to plug threads (C).

7. Thread plug (C), to the bottom of fitting (A). Wrench

tighten.

8. Reconnect air line.

9. Attach electric connector.

The completed installation should look like F

IG. 2.

A 22-ft (6.7 m) harness wire kit to supply the signal from

the timer is available (Parts, page 19). This harness

comes with a weather tight connector to mate with the

solenoid connector (F

IG. 2).

IG. 1

F

4 312054J

FIG. 2

Page 5

Installation

Pump

Solenoid

Timer

User Supplied

Red

Orange

+12 Battery

+Ignition

Black

Ground

ti11880a

Timer

Solenvoid Valve

YELLOW

BLUE

WHITE

BLACK

Black (-)

Ground

Red (-)

(ignition on)

from keyswitch

Orange(+)

battery terminal

(memory)

5-amp

fuse

5-amp

fuse

Load wires

blue and

yellow

12 to 32 VDC

Timer Installation

1. Install timer horizontally in a protected, but easily

accessible location, inside the truck cab using the 4

mounting screws provided (F

2. Connect timer leads to solenoid. A wiring harness

kit with a mating connector is available from your

Graco distributor. Order Kit 557929.

NOTE: All connections between timer and solenoid

must be moisture-proof and safe from grounding.

3. Connect the yellow timer lead to the red wire from

the solenoid (F

IG. 3.).

IG. 3).

NOTICE

Do not ground the yellow wires to the solenoid. This

could cause damage to the timer.

4. Connect the red lead wire to the positive side of the

vehicle ignition switch. Install a 5 amp fuse at this

connection.

5. Connect the orange lead wire to the battery positive

terminal circuit. Install a 5 amp fuse at this connection.

6. Connect the black lead wire to the chassis ground.

FIG. 3

312054J 5

Page 6

Installation

ti9497

ti9496

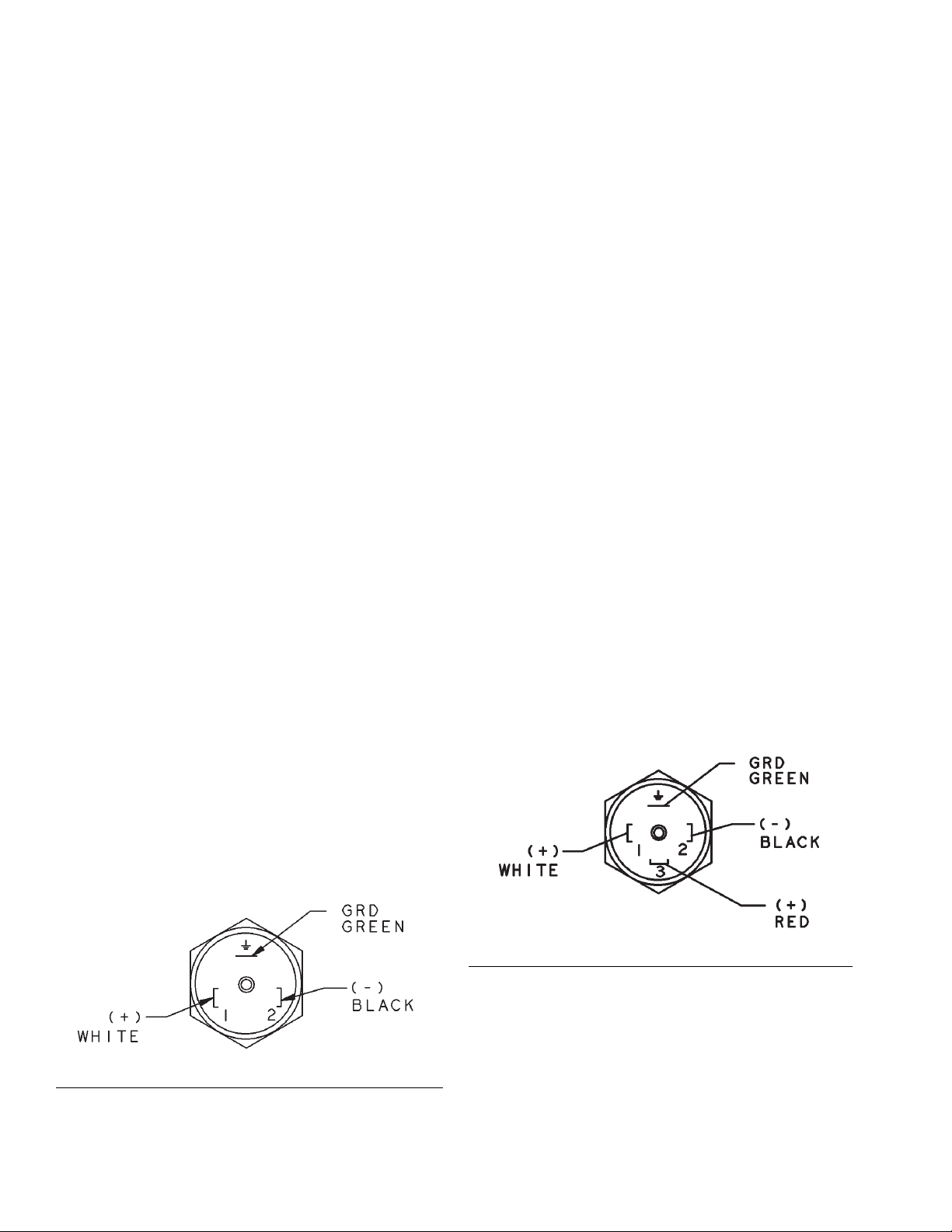

Electric Pump Installation

NOTE: Electric Grease Jockey pumps are available with

or without a timer. Choose the appropriate installation

section.

Fuses

The following fuse information applies to all models:

• Use standard automotive style blade fuses, ATO

series 257. Fuses are available from your Graco

distributor.

• Never use a higher amperage capacity fuse. Damage to the pump and vehicle electrical system could

occur.

• Install fuse holders in a protected area, as far from

the pump as possible. This will provide maximum

protection to the vehicle electrical system.

Pump Models without a Timer

Refer to Wiring Schematic (FIG. 4) for these instructions.

1. Install 10 Amp fuse (12 VDC models) or 5 Amp fuse

(24 VDC model) in line with the White wire connected to the first pole of the Hirschmann connector.

2. Wire as follows. If using a Graco mating cable, the

wire color corresponding to the 3-Pole Hirschmann

connection point is provided in parenthesis.

NOTE: The Hirschmann connection labeled ground, or

the green wire of a Graco mating cable, is not used for

either voltage models.

Pump Models with a Timer

Refer to Wiring Schematic (FIG. 5) for these instructions.

1. Install 10 Amp fuse (12 VDC model) or 5 Amp fuse

(24 VDC model) in line with the wire connected to

the third pole of the Hirschmann connector.

2. Install a 5 Amp fuse in line with the wire connected

to the first pole of the Hirschmann connector

(applies to both 12 and 24 VDC models).

3. Wire as follows. If using a Graco mating cable, the

wire color corresponding to the 4-Pole Hirschmann

connection point is provided in parenthesis.

• Chassis Ground (-) to Hirschmann connection,

labeled number 2 (Black wire)

• Battery (+) to Hirschmann connection, labeled

number 1 (White wire) - This source should

always provide a voltage supply.

• Ignition (+) to Hirschmann connection, labeled

number 3 (Red wire) - This source should only

provide a voltage supply when the vehicle ignition switch is on.

• Chassis Ground (-) to Hirschmann connection,

labeled number 2 (Black wire)

• Ignition (+) to Hirschmann connection, labeled

number 1 (White wire) - This source should only

provide a voltage supply when the vehicle ignition switch is on.

FIG. 5

F

IG. 4

6 312054J

Page 7

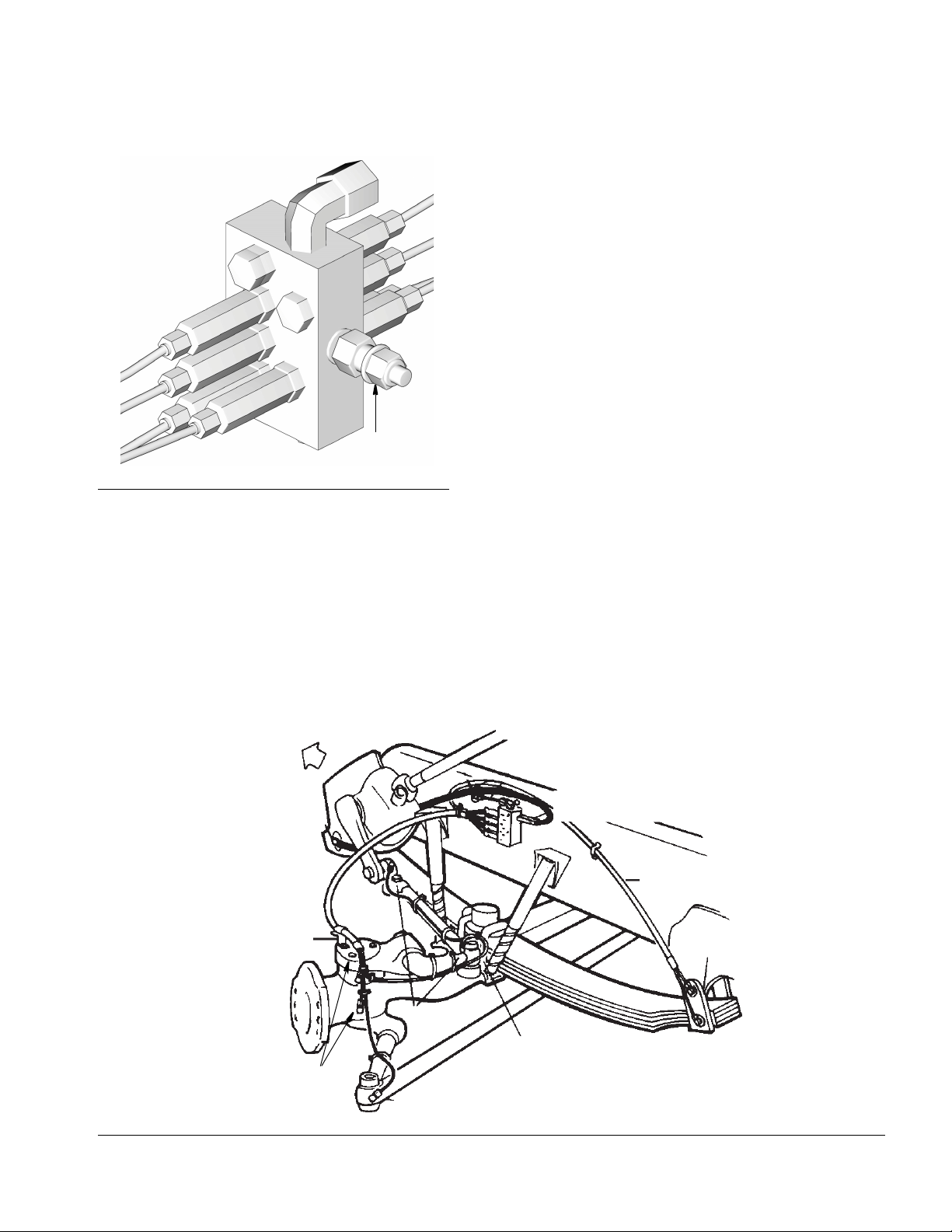

Modules

ti9452a

A

&RONT

&RONTSPRING

PINMETER

$USTCOVER

MOUNTINGBRACKET

ANDCLAMP

$RAG

LINK

4IEROD

!LLOWSLACKFORDRAG

LINKMOVEMENT

3PRINGSHACKLES

TUBEBUNDLE

,EFTFRONTMETERBLOCKASSEMBLY

LOCATEDASNEARTOAXLEASPOSSIBLE

ti9454

tti9454

Upper and Lower

King Pin

F

IG. 6

Installation

• Modules (Fig. 6) are mounted with a ported stud (A)

through a 5/8 in. (16 mm) hole.

• Mount all modules on the frame rail or a cross member close to the points they will be lubricating.

• Grease Jockey kits come with module assemblies

for each strategic area of the chassis to be lubricated: Left Front (F

Axle(s) (F

• The unused ports in the manifolds should have

plugs in them. If additional lube points are needed

these plugs can be replaced with appropriate sized

meters and lines.

IG. 9) and Fifth Wheel (FIG. 10).

IG. 7), Right Front (FIG. 8), Rear

Left Front Module (FIG. 7)

The Left Front Module assembly contains meters, hardware and tubing for:

• 2 king pins,

• 1 spring pin,

• 2 spring shackle pins,

• 1 tie rod,

• 2 drag links,

• 1 S-cam,

• 1 slack adjuster lube points.

• Optional points from this module typically are

linkage and steering box points.

FIG. 7

312054J 7

Page 8

Installation

TO TRANSMISSION CROSS

SHAFT LUBE POINTS

TWO

-TUBE BUNDLE

FRONT SPRING

PIN METER

FRONT

ALLOW

AMPLE SLACK FOR TIE

RODMOVEMENT

THREE

-TUBE BUNDLE

ALLOW SLACK FOR

WHEEL MOVEMENT

ti9455

UPPER AND LOWER

KING PIN

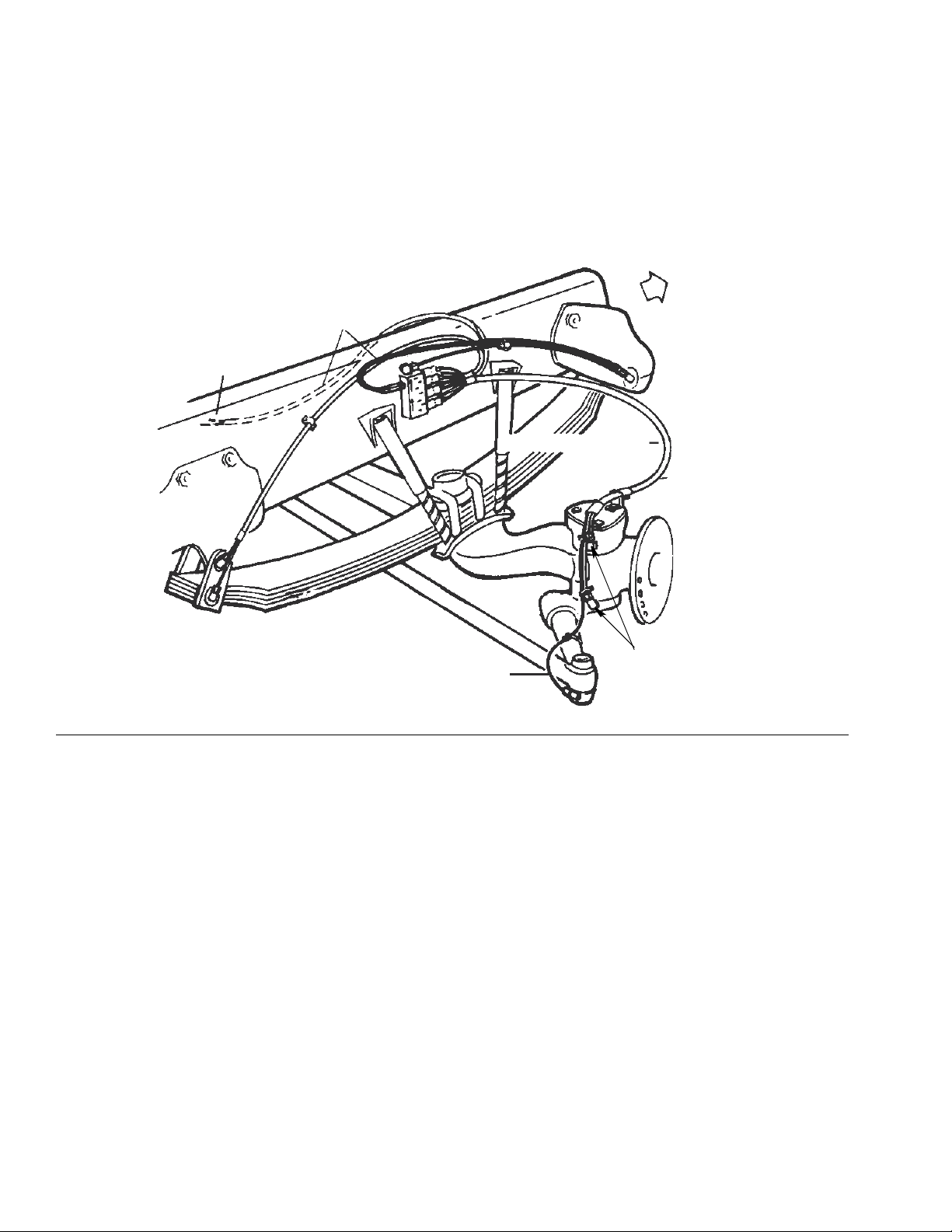

Right Front Module (FIG. 8)

The Right Front Module assembly contains meters, hardware and tubing for:

• 2 king pins,

• 1 spring pins,

• 2 spring shackles,

• 1 tie rod,

• 2 clutch cross shafts,

• 1 S-cam, and 1 slack adjuster lube points.

• Optional points from this module typically may be body pivot pins.

F

IG. 8

8 312054J

Page 9

Rear Axle(s) (FIG. 9)

!LLOWSLACKFORAXLEMOVEMENT

INTUBING

MAINLINE

&RONT

-ODULE!SSEMBLY

2EARAXLEMETERBLOCKASSEMBLY

LOCATEASNEARTOAXLEASPOSSIBLE

"RAKESHAFT

3LACKADJUSTER

3ECUREALLLINESWITHNYLON

STRAPSTOAVOIDTUBINGABRASION

4WOTUBE

BUNDLES

ti9456

This assembly contains the meters, hardware, and tubing for:

Installation

• (2 or 4) S-cams

• (2 or 4) slack adjuster lube points. The number

of points is determined by the application (single

or tandem axle).

• Optional points for this module may be spring

pin points or trailer system meters.

F

IG. 9

312054J 9

Page 10

Installation

INTUBING

0LATE

INTUBING

0IVOT

-ODULE

ASSEMBLY

INTUBING

TRUNKLINE

4WOINTUBEBUNDLES

!LLOWSLACKFORTHWHEELMOVEMENT

3ECUREALLLINESWITHNYLON

STRAPSTOAVOIDTUBINGABRASION

&RAMERAIL

ti9457

Fifth Wheel (FIG. 10)

This assembly contains the meters, hardware, and tubing for:

• 4 face plates

• 2 pivot pin lube points.

NOTE: Most 5th wheel plates do not have grease fittings in the plate. This requires four holes to be drilled and

tapped (1/8 in. npt) through the plate. These meters should be #8.

F

IG. 10

10 312054J

Page 11

Installation

Tubing

NOTICE

• When installing the tubing avoid routing it close to a

heat source such as an exhaust manifold, muffler,

turbocharger, etc.

• Non-approved nylon or air brake tubing should not

be used.

• Always use approved 3/16 in. (5 mm) and 5/16 in.

(8 mm) OD tubing.

The 3/16 in. (5 mm) tubing comes in three configurations.

• Single tubes: black or orange,

• 2 tube bundles: black with an orange tube

inside sheath.

• 3 tube bundle: black, blue and orange tube

inside a sheath.

• The orange tube is connected to the highest

output meter.

• The blue tube is connected to a lesser or

equal output meter.

Installation

A self aligned ferrule is supplied with all 3/16 in. and

5/16 in. fittings. It is not necessary to remove the nut and

ferrule to seat the tube into the fitting.

1. Make sure the tube is well seated into each fitting.

Brass inserts are supplied with kits for use with 5/16

in. tubing. These inserts must be used at every 5/16

in. connection.

2. Route the 5/16 in. main line tube from the pump to

the manifolds.

NOTE: The 5/16 in. main line tube may also be used as

the air supply line to the solenoid. It should be routed

inside the frame for protection and well secured.

Filling System and Start Up

NOTICE

• The Grease Jockey system is designed to pump

lightweight fluid greases and oil over a wide range

of conditions.

• Choose a lubricant compatible with the system’s

operating temperature.

• The black tube is connected to the lowest or

equal output meter of the bundle group.

Preparation

1. Measure approximate lengths of tube bundles, leaving extra length for trimming at the lube points.

2. Cut the outside sheath on tube bundles back to the

point where this bundle meets it’s first lube point. Be

careful not to puncture or cut the tubes inside.

Use a stripper to help prevent damage to the tubes.

3. Peel back the outside sheath onto itself to create a

collar and cut off the excess. Be careful not to

sever the remaining sheath or tubes.

4. Align tubing with fitting. Make cuts square and clean

with an anvil type cutter.

5. Allow ample slack for tube movement and ease of

installation.

• Use lubricant part number 557941, or a quality

NLGI “0” or “00” lithium base grease with an “EP”

additive.

• Systems using fluid grease:

• MUST use NGLI grade “00” grease at tempera-

tures below 50°F (10 °C).

• MAY use NGLI grade “0” or “0” at temperatures

above 50°F (10 °C).

312054J 11

Page 12

Installation

ti11499

Reservoir Bag

Stiffener

Clamp

ti11495

Depress bag

inside stiffener

to purge air

from bag

Reservoir Bag Installation (FIG. 11)

F

IG. 11

1. Lightly coat inside of reservoir bag with grease.

2. Insert stiffener inside bag, approximately 1/2-inch

(1.27 cm) up from bottom.

3. Position bottom of bag over flange on pump body.

Be sure stiffener is seated in pump body.

4. Place clamp over bag and position loosely around

bottom of bag.

5. Depress top of bag inside stiffener to purge air from

bag. Fully depressed bag will contact pump casting.

Flexible Reservoir Fill and Refill

1. Fill reservoir through fill stud. Pump output port

should be connected to system or plugged to avoid

spillage.

2. Fill reservoir bag until bag takes its original shape

(top of bag slightly domed). Do not overfill.

Rigid Reservoir Fill and Refill

1. Fill reservoir through fill stud. Pump output port

should be connected to system or plugged to avoid

spillage.

2. Fill reservoir to full line. Do not overfill.

Reducing Grease in Reservoir When Overfilled

Follow this procedure to reduce the grease in the reservoir if the pump is accidentally overfilled.

1. Disconnect the main line from the pump or at the

first module.

2. Cycle pump with the timer on “test” for a few minutes until the level of grease is acceptable. Be sure

to capture grease.

3. In rigid reservoir, clean breather tube of residual

grease.

4. Return timer to original setting and reconnect main

line.

Pump Filter

The pump assembly contains a filter to remove impurities and dirt that may be present in the lubricant used to

fill the reservoir.

Clean filter after every four or five reservoir refills. To

clean the filter:

1. Remove the quick fill fluid fitting.

2. Remove the filter and clean with solvent or compressed air as appropriate.

3. Replace filter in pump body, flanged end facing out.

4. Reassemble the quick fill fluid fitting.

F

IG. 12

A mating female quick disconnect is available. Contact

your Graco distributor. Order part number 557877.

6. Tighten clamp after air is purged out of reservoir

bag.

12 312054J

Page 13

Adjusting Grease Output Volume

Installation

If a meter is not producing the correct amount of lubricant for a specific location on a vehicle or if a replacement meter of correct size is not available, output

spacer washers can be installed to adjust the meter’s

output volume.

TABLE 1: Meter Identification and Usage

Meter

Size

0

1

2

3

4

8*

Number of

Washers

0 No 0.002 Brake Shafts, transmissions, cross shafts, “S” cams

1 No 0.005 Slack adjusters, 5th wheel pivot, and miscellaneous points

2 No 0.009 Drag link, tie rod ends, power steering linkage

3 No 0.012 Kin pins, spring pins, spring shackles

4 No 0.020 Misceallenous points

4 Yes 0.026 5th Wheel plate

*Size 8 high output meters cannot

Hex

Flat

be changed.

Output

3

(in.

)

Use Table 1 to determine which size meter is appropriate for the grease location.

Recommendations for

Specific Lubrication Points

To change output volume:

1. Relieve pressure, page 15.

2. If the meter is located on a manifold, use a 7/16”

wrench to remove tubing (F

IG. 13).

FIG. 13

3. Use a 5/8” deep well socket to remove meter from

manifold (F

IG. 14).

FIG. 14

4. Place meter in a vise, output end (tube connector)

facing up.

5. Use two 5/8” wrenches to separate the meter

halves.

6. Separate the meter body from the valve assembly.

Be careful not to misplace or damage springs and/or

312054J 13

Page 14

Installation

A

o-rings that may be attached (FIG. 15).

force to seat output washers firmly (F

IG. 16).

FIG. 16

9. Align hex flats so a deep well socket will slide down

to the meter body for assembly onto manifold.

10. Reassemble meter onto manifold using the 5/8”

deep well socket. Torque to 2-3 ft.-lbs.

NOTICE

Do not xceed 12 ft-lbs torque or meter damage may

occur.

F

IG. 15

7. Add or remove output spacer washers (A) from the

meter valve assembly.

NOTE:

• Add spacer washers (A) to increas output vol-

ume.

• Remove spacer washers (A) to decrease output

volume.

8. Reassemble meter body on meter valve assembly.

Use a 5/8” wrench to tighten using only enough

11. Hand tighten the tube nut onto the meter and tighter

1/8 turn beyond hand tight.

NOTE: Tube nuts can be reused a maximum of 8

times after the initial tightening.

12. Reconnect tubing to manifold using a 7/16” wrench

to securely tighten fitting.

14 312054J

Page 15

Installation

Bottom Cover O-Ring

This section applies to Electrically Operated Grease

Jockey Systems only. For Air Operated Grease

Jockey System installations, skip this section and go

right to Purging Air from the Main Line, page 15.

An o-ring for sealing between the bottom cover and

pump body was shipped loose with the pump. This

o-ring must be installed prior to assembling the bottom

cover to the pump.

1. Gently stretch the o-ring to enlarge it slightly.

2. Coat the o-ring with a light film of grease or oil.

3. Insert the o-ring into the groove in the pump body.

4. If using a pump with a timer, adjust the timer settings:

a.

• The knob on the left controls cycle off time,

• The knob on the right controls cycle on time.

b.

• Turning knob clockwise increases current

cycle setting.

• Turning knob counter-clockwise decreases

the current cycle setting.

c.

• Off time is continuously adjustable from 10-45

minutes.

• On time is continuously adjustable from 30-90

seconds.

5. Coat the top lip of the cover with a light film of

grease or oil.

6. Assemble the cover to the pump body.

7. Approximately 3/8 in. (10 mm) of the tie rod will be

visible when the cover is seated correctly.

8. Place the washer and nut onto the portion of the

threads exposed and tighten securely.

Pressure Relief

Purging Air from the Main Line

NOTE:

• Check the vehicle air supply. At least 100 psi

(0.7 MPA, 7 bar) gauge pressure is required.

• All the air must be removed from the main lines

and manifolds.

1. Remove all 1/4 npt end port and 1/8 npt stud plugs

on the module manifolds.

2. With the vehicle ignition switch turned ON, set timer

to the test position and press MANUAL RUN.

3. As the pump cycles, check the open module ports

for flow of grease with no air.

4. Check the open port closest to the pump first, proceeding to the port furthermost from the pump last.

This will push out the air in the main line(s).

5. When the flow of grease from a port is free of air,

close the port and continue this process until all

ports have been checked.

NOTE: The 3/16 in. (5 mm) distribution lines are

pre-filled. They should not require purging of air.

6. Let the system run in the test position for a few minutes. Check all line connections to be sure they are

holding pressure. Check at lube points to be sure

lubricant is moving to this point in the system.

7. Reset the timer to the desired setting for your application. Use the following table as a starting point:

Recommended Timer Setting

Timer Setting Driving Conditions

1/2 or 1 hr Off Highway

Start and stop city, heavy salt,

1.5 or 2 hr

3 hr

NOTE: These are recommended settings only. Experience with individual applications will determine timer

setting.

snow and ice, rough pavement,

wet climate, heavy loads, dusty

roads.

Normal city or highway driving,

normal climate, moderate loads.

If any part of the system has not functioned as it should,

refer to Troubleshooting, page 16.

312054J 15

Page 16

Troubleshooting

Troubleshooting

Problem Cause Solution

Too much grease at all lube points Timer cycle too frequent Adjust the timer one click to a higher time

cycle. (Example, from 2 to 3 hours.)

Too much grease at one lube point Meter leaking Remove and replace meter

Not enough grease at all lube

points

No sign of fresh grease at all points Lubricant reservoir filled with

Timer cycle is too infrequent Adjust the timer one click to a lower time

cycle. (Example, from 3 to 2 hours.)

Remove and clean reservoir, refill with

heavy grease which will not

work in system.

Blown fuse, or break in wiring

circuit

Broken air line (air pump only) Repair or replace line.

Inoperative solenoid air valve

(Air pump only)

Inoperative air pump

Inoperative electric pump See Troubleshooting, Electrically operated

proper lubricant. Remove main line plugs

from meter blocks, and cycle pump until old

lubricant is removed from lines, replace

main line plugs.

Check for electrical short circuit or broken

wire, and repair.

Check electrical circuit to make sure volt-

age is reaching the solenoid coil from the

timer. Connect a meter from the supply

“black” wire to the return “white” wire at the

connector of the solenoid. Do not connect

direct to ground. Repair or replace wiring

as required: Check coil resistance for

approx. 20 ohms. Check valve operation;

repair or replace if necessary.

See Troubleshooting, Air-operated pump

not working, page 18.

pump not working, page 18.

16 312054J

Page 17

Troubleshooting

Problem Cause Solution

(cont.) Inoperative timer With the ignition switch on, check the input

voltage of both the memory (orange) and

the (red) switch wires; if there is not 12

VDC (or greater) repair electric supply. Set

the timer to TEST. Check the output signal

to the solenoid. Connect a meter from the

timer supply to the return. Not to a ground.

(At the timer connector the supply is the

blue wire and yellow is the return), (At the

solenoid connector the supply may be a

black wire and return a white wire). It

should show 12 VDC during the ON cycle

(approx. 45 sec.) and 2 VDC or less during

the OFF period (approx. 45 sec.) If there is

no signal or a constant 12 VDC output,

check lines from the timer to the solenoid

for grounding or breakage; replace timer if

necessary.

Main line broken See Troubleshooting, Main tube line dam-

aged, page 17.

None of the above Using 2500 PSI pressure gauge, check for

pressure at last module in system. The

minimum gauge reading should be 500

PSI. If not, check pressure at pump. Pressure should reach 1000PSI. If it does,

check for blocked, broken or collapsed

main line. Otherwise repair or replace

pump.

No sign of fresh grease at some

lube points

Main line broken See Troubleshooting, Main tube line dam-

aged, page 17.

Air lock in main line Purging Air From the Mainline; Step 7,

page 15.

No sign of fresh grease at one lube

point

Secondary line damaged See Troubleshooting, Secondary line dam-

aged, page 17.

Meter inoperative Replace meter.

Lube point fitting has broken off Remove broken fitting and replace

Main tube line damaged Trapped and broken, rubbed

through

Replace or repair (re-route or protect the

line to prevent the damage from happening

again). Purge with grease to expel air

before connecting new main line into system. Be sure to use a tube insert at all main

line connections.

Main line has popped out of fitting

Secondary line damaged Trapped and broken, rubbed

through

Refit line to the fitting using a new compression sleeve and a tube insert.

Replace or repair (re-route or protect the

line to prevent the damage from happening

again).

Secondary line has popped out

of fitting

Refit line to the fitting using a new compression sleeve.

Lube point fitting has broken off Remove broken fitting and replace.

312054J 17

Page 18

Troubleshooting

Problem Cause Solution

Air-operated pump not working Solenoid valve not working See Troubleshooting, No sign of fresh

grease at all points “Inoperative solenoid

air valve”, page 16.

Air line damaged Repair or replace if necessary.

Low air pressure Build up air pressure in truck system.

Electrical circuit to timer or

solenoid is damaged

Check connections; repair or replace if nec-

essary.

Timer is not working Repair or replace timer.

Electrically operated pump not

working

Electrical circuit is damaged Check electrical circuit to make sure volt-

age is reaching motor.

Inoperative motor Repair or replace motor if necessary.

18 312054J

Page 19

Rebuilding Grease Jockey Pump

6

7

8

9

10

2

1

5

3

ti11523

1

14

16

15

4

1

Ref. Description Qty.

1 SCREW, 3/8” x 3/4” 6

2 WASHER, flat, 3/8” 6

3 O-RING, fluoroelastomer A, 70

DURO, 1/16”

4 O-RING, fluoroelastomer A, 70

DURO, 1/8”

5 GASKET, pump 1

6 SPRING, check valve 1

7 SPRING, return, piston 1

8 PISTON, lube 1

9 DIAPHRAGM

10 COVER, chamber

14 BODY, pump

15 FITTING, coupling 3/8” x 1/4”

16 PISTON, check valve

* For reference only. Not included in kit.

Rebuilding Grease Jockey Pump

1

1

1

1

*

*

*

F

IG. 17

Use Pump Rebuild Kit 563762. Numbers in parentheses

refer to F

IG. 17.

Piston Chamber Repair

1. Remove the grease mainlines from the pump.

2. Relieve Pressure, page 15. Remove air supply line

and electrical connector from solenoid valve.

3. Remove pump from vehicle.

It may be necessary to empty reservoir of grease for

remaining steps.

4. Turn pump upside down to remove bottom air

chamber cover screws.

Torque to 15-22 ft.-lbs (20-30 N.m) and

apply Loctite

®

242

5. Using a 9/16” wrench, remove solenoid valve from

cover (10) by unscrewing the brass nipple from the

pump body.

6. Using a 9/16” wrench, remove six hex screws (1)

and washers (2) from cover. Use care in removing

the last screw since the internal components are

under compression and the cover will pop off. Discard all screws and washers.

7. Remove the diaphragm (9) and any fragments of

the gasket (5) and discard.

8. Remove the piston (8) and spring (7) from the pump

cavity. Discard both the piston and spring.

9. Remove o-ring (4) from top of piston and discard.

10. Clean excess grease, grit and dirt from the inside of

the pump with a clean paper or cloth towel. Check

312054J 19

Page 20

Rebuilding Grease Jockey Pump

piston cavity for scoring or scrapes. Clean piston.

Make sure there are no fibers from cloth left behind.

11. Check to make sure flapper valve is visible and

loose in top of piston cavity. If flapper is not visible

or frozen in place, the pump cannot be repaired.

Replacement part number is 563625.

12. Assemble new o-ring and new spring to the new piston and insert in pump. To aid in reinsertion, apply a

small amount of grease to the o-ring.

13. Position new diaphragm on piston. Make sure orientation is according to F

14. Position new gasket and cap back onto pump and

screw into place. Replace o-ring and hex screws.

Torque to 15-22 ft.-lbs. Alternate tightening screws

around cover to avoid excessive tilting of cover.

IG. 17.

Check Valve Repair

1. Using a 3/4” wrench, remove fill stud fitting (15)

from pump body.

2. Using a 5/16” wrench, remove check valve spring

(6), o-ring (3) and check valve piston (16). Discard

spring and o-ring.

5. After vehicle air pressures has reached a minimum

of 100 psi (6.89 bar, 0.689 MPa):

• turn ignition to ON

• Timer to TEST position

• push the MANUAL RUN button

Watch the pump outlet for grease flow.

6. Once grease flows from the outlet:

• stop the cycling

• return the timer to the original setting

• reconnect the mainline to the pump

NOTE: Any tube nut can be removed and reconnected

up to 8 times. to reattach, hand tighten up to original

make-up position plus 1/16 turn to seat ferrule.

7. Pump can now be returned to service.

3. Clean cavity with clean paper or cloth towel. Make

sure no fibers are left in the cavity.

4. Replace o-ring (3) and reinstall check valve piston in

cavity. Make sure piston is properly oriented in cavity -- o-ring on the outside end.

5. Install new check valve spring (6) in cavity.

6. Apply pipe dope to fitting (15) and reinstall.

Assembling Pump Onto Vehicle

1. Assemble pump onto vehicle.

2. Connect solenoid air supply line to the side port of

the solenoid.

3. Reconnect solenoid electrical harness.

4. If reservoir was emptied, refill with appropriate

grease.

20 312054J

Page 21

Parts

ti9460

ti9461

ti9462

ti9463

ti9464

ti9466

ti9467

ti9468

Installation kit:

Description Part Number

30 pt single axle tractor, air pump,

and flexible reservoir

34 pt tandem axle tractor, air

pump, and flexible reservoir

30 pt single axle tractor, electric

drive pump, flexible reservoir

Air pump repair/rebuild kit 563762

Soft to hard conversion kit 563931

Manual Trailer kits:

6 pt single axle system 563805

12 pt tandem axle system 563806

5 pt landing gear system 563807

FILLER PUMP ASSEMBLY

Fits 35 lb pail

563569

563801

563802

563804

Parts

AIR PUMP ASSY.

W/6 LB RIGID RESER.

563584

6LB RESERVOIR

REPLACEMENT KIT

563774

TIMER FOR AIR SYSTEM

(12-32) VDC

557926

ELECTRICAL WIRE LEAD

FOR AIR PUMP TIMER

557929

35 LB. PAIL GREASE

NLGI “00”

Non-Moly

557941

AIR PUMP ASSY.

W/FLEX RESER.

563570

FLEXIBLE RESERVOIR

REPLACEMENT KIT

563761

RESERVOIR ONLY

557884

CLAMP

557878

SOLENOID VALVE KIT

12 VDC - 557932

24 VDC - 24E017

WIRE LEAD - 22 FT.

FOR SOLENOID VALVE

563642

METER VALVES

#0 = 563627

#1 = 563629

#2 = 563631

#3 = 563633

#4 = 563635

#8 = 563637

METER OUTPUT

PORT PLUG

557901

METER OUTPUT

SIZING SPACER

557898

312054J 21

Page 22

Parts

ti9469

ti9470

ti9471

ti9472

ti9473

ti9474

ti9475

ti9476

ti9477

ti9478

ti9479

ti9480

ti9481

12 PORT MANIFOLD

WITH STUD

563758

REPLACEMENT STUD

563946

MANIFOLD METER

PORT PLUG

15M038

TUBE STRIPPER

558058

DISTRIBUTION LINES

3/16” OD TUBING

BUNDLES PREFILLED

563786 = 1 TUBE BLACK

563788 = 2 TUBE BUNDLE

563783 = 3 TUBE BUNDLE

MAIN LINE TUBING

5/16” OD X 60 FT.

561132

CLAMPS 9/32” HOLE

5/16” - 557943

3/8” - 557946

7/16” - 557944

1/2” - 557947

5/8” - 557945

NUT, TUBE WITH

CAPTIVE SLEEVE

3/16” TUBE - 556660

5/16” TUBE - 556666

MALE CONNECTOR

1/8” NPT

3/16” TUBE - 556644

5/16” TUBE - 556645

1/4” NPT

5/16” TUBE - 556646

MALE 90° ELBOW

1/8 NPT

3/16” TUBE - 556638

5/16” TUBE - 556639

1/4” NPT

5/16” TUBE - 556640

5/16” TUBING INSERT

PACKAGE OF 20

557963

FITTING ADAPTER STRAIGHT

1/4”-28 SAE X 3/16” TUBE

562995

NYLON STRAPS

PACKAGES OF 100

563770

ELBOW, STREET

1/8” NPT TO 1/4” - 28 SAE

STANDARD - 15K740

SHORT - 15K784

22 312054J

Page 23

Parts

ti9482

ti9483

ti9484

ti9485

ti9486

ti9487

ti9488

ti9489

ti9490

ti9491

ti9492

ti9493

ti9494

ti9495

ELBOW STREET

1/8” NPT TO 1/8” NPT

90° - 15K783

45° - 557395

3/8” NPT TO 3/8” NPT

90° - 560534

ADAPTER, STRAIGHT

1/8” NPT TO 1/4” - 28 SAE

MALE

557955

ADAPTER, PRESS TO FIT TO

REPLACE UNTHREADED

GREASE FITTINGS, 1/8” NPT

15M037

TUBE UNION

3/16” TUBE - 556647

5/16” TUBE - 556648

ZERK ADAPTER

PRESS-ON

3/16” TUBE CONNECTION

ELBOW - 563776

ZERK ADAPTER

PRESS-ON

3/16” TUBE CONNECTION

STRAIGHT - 563777

ELECTRIC PUMP

ASSY, FLEX. RESERVOIR

WITH TIMER FOR:

12 VDC - 563595

24 VDC - 563596

TEE MALE BRANCH

1/8” NPT TO 5/16” TUBE

556636

TEE, TUBE UNION

5/16” TUBE - 556637

BULKHEAD FITTING

557950

EXTENSION, 1/8” NPT

3/4” - 557392

1 1/4” - 557393

UNIVERSAL PUMP

MOUNTING BRACKET

557966

RESERVOIR FILL

COUPLING FEMALE

1/4” NPT FEMALE

557877

RESERVOIR FILL

COUPLING MALE

3/8” NPT MALE

557880

DUST CAP

557875

SERVICE START-UP KIT

563775

CONTAINS SOLENOID,

TUBES, FITTINGS, INSERTS,

AND PUMP REPAIR KIT

312054J 23

Page 24

Technical Data

Technical Data

Timer (Air Operated Pump)

Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 -24 VDC

Timer Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5, 1, 1.5, 2, 3, 4, 6 hours

Wire Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . Packard Connector

Air Solenoid

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-Way, Normally-Closed, Free Venting

Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 or 24 VDC, 9 Watt Continuous Duty Coil

Inlet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/8 npt threads

Outlet Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/4 npt threads

Maximum Working Pressure . . . . . . . . . . . . . . . . . . . 150 psi (1.05 MPa, 10.5 bar)

Air Operated Pump

Ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9:1

Output per Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inlet Pressure (air) . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 - 150 psi (0.28 - 0.35 MPa, 2.8 - 3.5 bar)

Outlet Pressure (lubricant). . . . . . . . . . . . . . . . . . . . . 360 - 1350 psi (2.5 - 9.4 MPa, 25.2 - 94.5 bar)

Operating Temperature . . . . . . . . . . . . . . . . . . . . . . . -4 to 135°F (-20 to 57.2 °C)

Fluid Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . Oil and Grease, NLGI #0 or lighter

Electrically Operated Pump

Fluid Outlet Pressure . . . . . . . . . . . . . . . . . . . . . . . . . 1,000 psi (7.0 MPa, 70 bar)

Pump Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . Oil (all temperatures)

Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 or 24 VDC, 5 Amps

Duty Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Maximum 30% (cycle on time not to exceed 2 minutes)

Modules (includes tubing, manifolds and meters)

Manifold

Maximum Working Pressure . . . . . . . . . . . . . . . . . . . 2,500 psi (17.5 MPa, 175 bar)

Meters

Maximum Working Pressure . . . . . . . . . . . . . . . . . . . 2,000 psi (13.7 MPa, 137 bar)

Minimum Operating Pressure . . . . . . . . . . . . . . . . . . 450 psi (3.2 MPa, 31.5 bar)

Vent Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 psi (1.1 MPa, 11.2 bar)

Minimum Cycle On Time . . . . . . . . . . . . . . . . . . . . . . 30 seconds

Minimum Cycle Off Time . . . . . . . . . . . . . . . . . . . . . . 3 minutes

Tubing

5/16” OD Main Line Maximum Working Pressure . . . 375 psi (2.6 MPa, 25.8 bar)

3/16” OD Distribution Line Maximum Working Pres-

sure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

1.5 in

2.0 in

NLGI #0 grease at 50°F (10 °C) or higher

NLGI #00 grease for at 50°F (10 °C) or lower

800 psi (5.5 MPa, 55 bar)

(24.58 cc)

3

(32.77 cc) per minute

24 312054J

Page 25

Notes

Notes

312054J 25

Page 26

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2008, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 312054

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised May 2014

Loading...

Loading...