Page 1

Operation/Service/Parts

HP50 High Pressure

311842C

Bulletin 40240/51030

Lubricators

For dispensing non-corrosive and non-abrasive oils and synthetic-based lubricants.

Models: 258262, 258263, 562925, 562926, 562927, 562928, 562929, 564276,

564277, 564278, 564279, 564280, 564281, 564282, 564284

HP50: 50,000 psi (344 MPa, 3,447 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

ti13802

TI8512

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

2 311842C

Page 3

Warnings

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop dispensing and before cleaning,

checking, or servicing equipment.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

SUCTION HAZARD

Never place hands near the pump fluid inlet when pump is operating or pressurized. Powerful suction

could cause serious injury.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

311842C 3

Page 4

Installation

Installation

NOTICE

All installation, maintenance, and repair work must

be completed by qualified personnel.

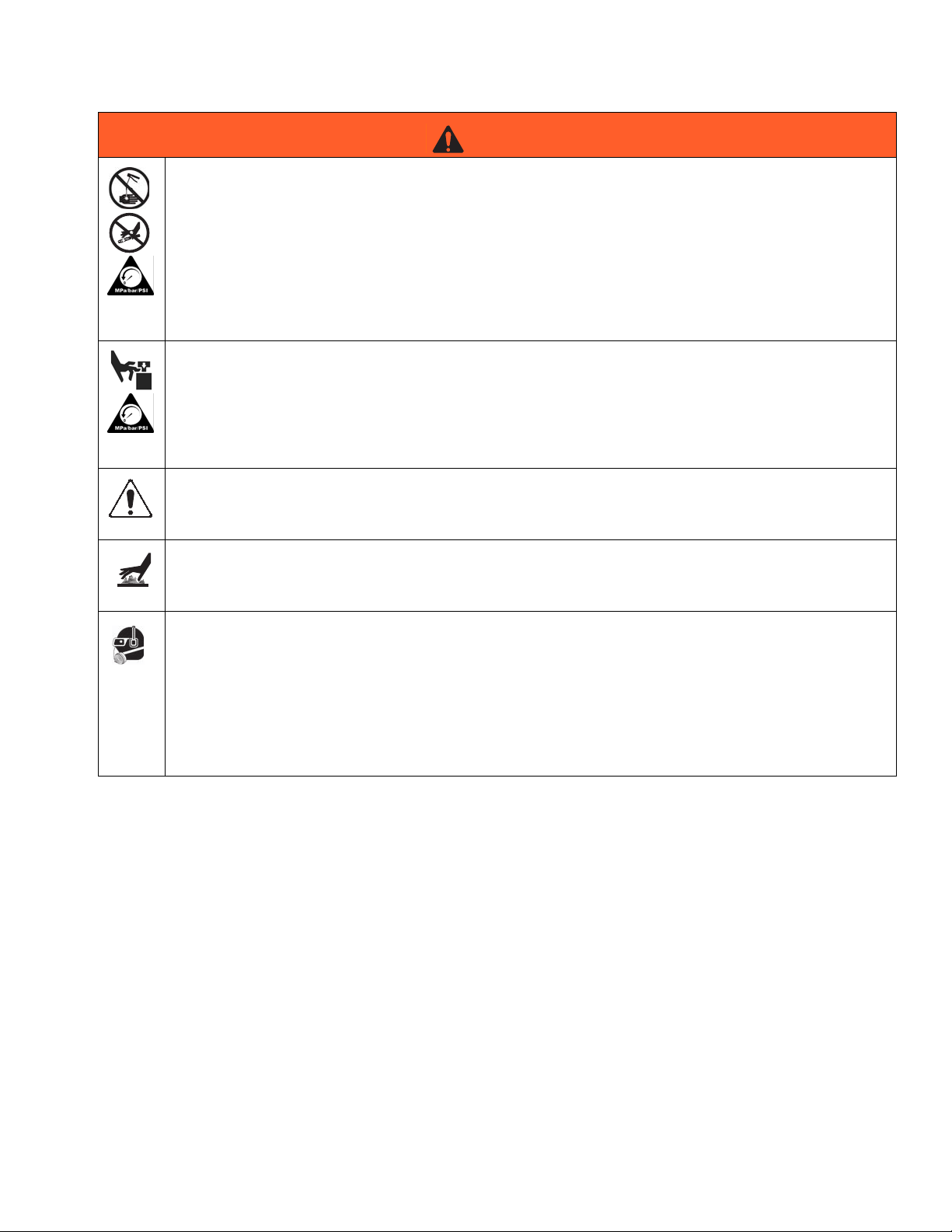

System Connections

ti13803

F

IG. 1

Operation

Oil Level

A

ti13804

FIG. 2

• Install each pumping unit with a high pressure check

valve in the discharge line adjacent to the pump discharge connection so that pump assembly may be

removed from reservoir without loss of lubricant in

lines (F

• Install a second of these valves at the point of lubrication to prevent line drainage and feedback of system pressure to pump (F

IG. 1).

IG. 1).

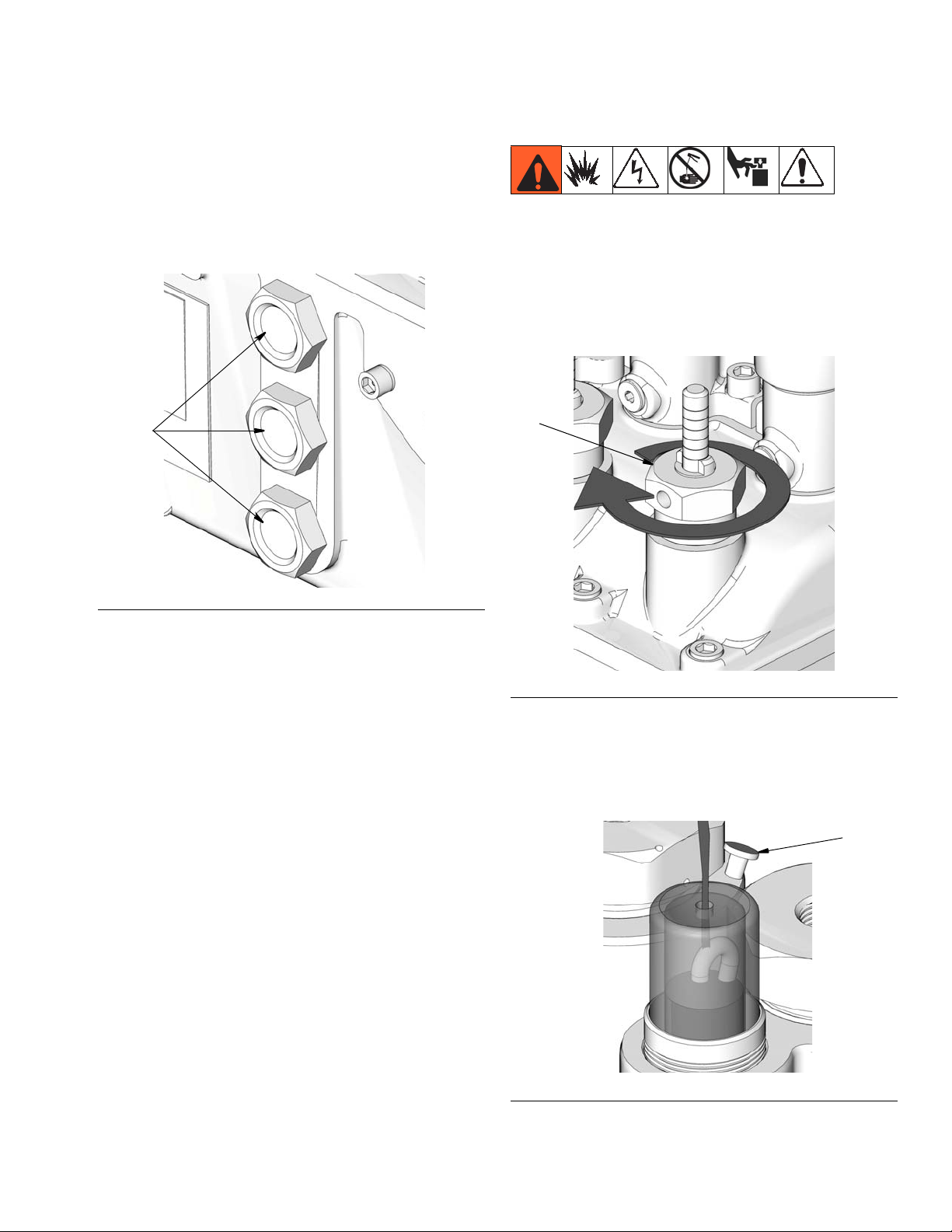

1. Remove vent plugs (A) located on the top of the

pump sight glasses to allow lubricant to rise in the

drip tube to the level of the oil in the reservoir and

reduce the priming required at start up (F

2. Completely fill the lubricator reservoir with clean filtered lubricant.

IG. 2).

4 311842C

Page 5

Operation

NOTE:

• Three sight glasses (B) are provided in the reservoir at various levels to permit observation of

fluid level (F

IG. 3).

• Oil level should not be allowed to drop below the

bottom sight glass.

B

ti13805

Pump Priming

To prime the pump:

1. Turn the feed adjustment nut (C) on the indicator

stem as far as possible in a clockwise direction (F

4).

C

IG.

F

IG. 3

ti13806

FIG. 4

2. Remove the vent plug (A) on top of the sight glass

and fill the housing sight well with oil to 3/8-inch

below the discharge of the drip tube (F

IG. 5).

A

ti13708

F

IG. 5

311842C 5

Page 6

Operation

3. Replace the vent plug (A). Check the sight glass to

insure that it is properly seated against the o-ring

(D) to prevent air leakage into the sight well (F

IG. 6).

A

D

ti13709

F

IG. 6

4. Adjust the pumping rate to the desired delivery.

Pumping Rate

During the pump suction stroke an amount of oil equal

to the pump displacement is drawn through the drip tube

into the sight well. The amount of fluid in the site tube

indicates the pumping rate.

NOTE: Allow sufficient time to insure an accurate rate

indication. The drip tube flow rate is only accurate after

the pump has operated long enough to stabilize the

pressure inside the sight well.

C

F

IG. 7

• Turn the feed adjustment nut (C) counter-clockwise

to reduce the pump stroke and delivery (F

IG. 8).

C

F

There is a time lag at start-up, during low pumping rates,

IG. 8

and during pump rate changes.

Regulating Pump Rate

The pumping rate is adjusted by hand during the pump

suction stroke.

• Turn feed adjustment nut (C) clockwise as far as it

can go to achieve maximum pumping rate (F

6 311842C

IG. 7.

Page 7

Service

Pressure Relief Procedure

The equipment stays pressurized until pressure is

relieved. To reduce the risk of serious injury from pressurized fluid, accidental spray from the dispenser, or

splashing fluid, follow this Pressure Relief Procedure

whenever you:

• Check, clean or service any system equipment.

• Install or clean fluid nozzles.

1. Disconnect power supply.

2. Open any bleed-type master air valves and fluid

drain valves in the system.

Service

A

3. Leave drain valves open until you have completed

repairs and are ready to pressurize system.

NOTICE

• All installation, maintenance, and repair work

must be completed by qualified personnel.

• If the correct pumping rate is maintained, no service is required other than periodic replenishment of the reservoir.

Service Instructions

1. Check lubricator operation by observing the drip

tube. If the sight glass well pumps dry or no flow is

observed, check the following points until the cause

is determined and corrected.

• Check the vent plug (A) for proper sealing. Any

knicks or cracks in the rubber plug will cause an

air leak into the sight glass (F

IG. 9).

FIG. 9

• Check shaft rotation. If the lubricator shaft is not

rotating, determine the cause and repair as necessary.

• Check oil level and viscosity. Be sure the reservoir is filled with oil, and if necessary heat the

reservoir to maintain viscosity at the correct

level for the desired flow.

• Check pump priming. If necessary, prime the

pump in accordance with the operating instructions, page 5.

• Check the feed adjustment (C, F

page 6) and adjust if the pumping rate is too

low.

IG. 7 and FIG. 8,

• Check the actuating linkage for proper operation. If defective, isolate the broken part and

repair or replace as required.

311842C 7

Page 8

Service

‘

2. If items listed in step 1 are not the cause, check the

pump assembly. The following items should be

checked before removing the pump assembly from

the cover.

• Check the sight glass for inward leakage due to

a crack in the sight glass, improper sight glass

seating, or a defective o-ring. Repair as

required (F

IG. 6, page 6).

• Check for an obstruction in the drip tube and

remove if found.

• If these steps do not isolate the malfunction:

a. Relieve system pressure, page 7.

b. Disconnect the discharge tubing (E) (F

c. Remove 4 screws (F) holding pump to cover

IG. 10).

(F

d. Remove the pump assembly (G) (F

NOTE:

• Keep a spare pump on hand for use during

emergencies and when the pump is being

repaired.

• If a spare pump is available, it will not be necessary to stop the equipment the lubricator is

installed on or to empty the reservoir.

IG. 10).

IG. 10).

A

MOVING PARTS HAZARD

Exercise extreme care if equipment is operating.

Rotating equipment can cause serious injury.

E

F

G

F

IG. 10

IG. 11

F

• If the sight glass fills with lubricant proceed as

follows:

a. Remove system pressure, page 7.

b. Remove vent plug (A) (F

IG. 11).

c. Allow the lubricant to pump down to the

proper level.

8 311842C

Page 9

Service

d. Replace vent plug (A).

The pump should operate normally.

• If the sight glass continues to fill with lubricant:

a. Check all terminal check valves for proper

operation.

b. Relieve system pressure, page 7.

c. If valves are operating properly, disconnect

the discharge tubing (E) (F

IG. 10)

d. Remove 4 screws holding pump to cover

(F

IG. 10, page 8).

e. Remove pump assembly.

f. Clean pump assembly.

g. Reinstall pump assembly to cover and check

operation.

• When the unit is operating the sight level will

vary depending on temperature variations.

a. If the level falls to less than 1/4 inch above

the sight glass flange, add lubricant to the

proper level (3/8 inch below the discharge of

the drip tube) through the vent hole.

b. If the level is too high, remove the vent plug

and allow the unit to pump down before

replacing the vent plug.

Other servicing that may be required is listed below:

• Clean lubricator periodically to eliminate contamination that may have occurred in the oil. To accomplish

this, remove all pumping units and clean the pumps

and reservoir by brushing loose all foreign matter,

dipping in solvent and blowing dry with compressed

air.

• If external leakage is observed, determine the

cause (loose bolts, defective gaskets, or seals) and

repair as required.

3. If the sight glass still fills with lubricant it may be

caused by temperature variation.

• When the unit is not operating:

a. Relieve system pressure, page 7.

b. Remove vent plug (F

IG. 11, page 8).

c. Allow lubricant to pump down to the proper

level.

d. Replace vent plug.

The pump will now function properly. The

sight glass may fill with fluid without affecting

the operation of the lubricator as long as the

drip tube remains above the lubricant level to

show the rate of pumping.

311842C 9

Page 10

High Pressure Lubricator Parts

High Pressure Lubricator Parts

44

45

43

12

1

17

16

25

46

42

4

40

41

13

14

27

15

30

24

23

20

18

9

Ref Part No. Description Qty

1 556340 BEARING, ecc shaft 2

2 556343 BEARING, slv, bronze 2

3 560148 BUSHING, reservoir 2

4 560157 NUT, fluid adjustment 4

5 560169 PIN, lever 4

7 560171 PIN, adjustment rod 4

8 555444 PLUG, 3/8” pipe square head 1

9 555450 PLUG, 3/4” pipe hex soc 3

10 556450 PLUG, hex-sckt 1 1/4 npt 1

11 555552 RING, retainer 8

12 555603 SCREW, 3/8-16 X .75 soc hd cap 4

13 555605 SCREW, 3/8-16 X 1.25 soc hd cap 26

14 555606 SCREW, 3/8-16 X 3.50 soc hd cap 4

15 556523 WASHER, copper 1.0 id 4

16 555664 O-RING ,-228 buna-n 70 duro 2

17 556579 SEAL,LIP 1.25 ID 2.00 OD .25 W 2

18 556683 SIGHTGLASS 3

20 556685 PLATE, oil level 3

21 560281 ROD, fluid adjusment 4

28

22

12

2

21

8

31

32

47

5

11

7

3

17

9

39

26

16

10

2

1

12

Ref Part No. Description Qty

22 560284 LEVER, pump 4

23 556836 LABEL, operating instructions 1

24 556872 LABEL, identification 1

25 557062 SHAFT, crank 1

26 15M340 RESERVOIR 1

27 560398 COVER, reservoir 1

28 560483 LEVER, shoe 4

29 562952 PUMP (page 11) 4

30 555379 KEY 2

31 110208 PLUG, pipe, headless 4

32 15W154 WASHER 2

36 555451 PLUG, steel 1

37 563024 SWITCH, low level exp proof (not

shown)

38 557122 COVER, shaft end 1

39 555483 SCREW, #4 X .187 pan head self

tap

40 556745 GASKET 1

41 563090 PLATE, filler 1

38

1

2

10 311842C

Page 11

Ref Part No. Description Qty

42 557149 STRAINER, filter 2

43 557171 COVER, oil hole 1

44 557391 PLUG, dryseal, 1/4 nptf 1

45 555451 PLUG, pipe 1

46 556517 SCREW, socket head 3/8 x 15 x

0.875

47 555424 PIN, 0.312 Diameter groove type

2A

Pump Parts

Ref Part No. Description Qty

101 560162 NUT 1

102 560172 PIN, collar 1

103 555564 RING, retainer 1

104 560195 RING, retaining spring 1

105 556522 DISK, thrust 1

106 555691 O-RING, -127 1

107 555694 O-RING, -217 1

108 560233 SPACER, .995 id x .500 long 1

109 560235 TUBE, drip 1

110 562989 TUBE, suction 1

111 555724 PLUG, #4 SAE 1

112 564151 KIT, sight glass 1

113 556746 GASKET, suction tube nut 1

114 556747 O-RING 2

115 555746 SEAL, wire lead .437 diameter 1

116 556936 SPRING, check valve 1

117 556937 SPRING, plunger 1

118 560340 SEAT, valve 1

119 560344 VALVE, 1

120 557155 STRAINER, suction 1

122 560425 PLUNGER, pusher 1

123 563111 VALVE, plunger 1

124 560443 HOUSING, pump 1

125 557191 COLLAR, piston 1

126 560492 COLLAR 1

High Pressure Lubricator Parts

1

2

115

112

109

111

119

126

106

113

101

124

116

118

114

123

107

103

125

108

117

110

120

311842C 11

105

104

102

122

Page 12

High Pressure Lubricator Parts

Check Valve Parts Drawing and Parts List

564335 - Discharge check valve

564336 - Terminal check valve

1

2

Tubing furnished

by customer

9*

1

2

8

1*

2*

*Supplied with Discharge Check Valve 564335 only.

Not supplied with Terminal Check Valves.

5

6

4

7

564335 Discharge Check Valve - 3/8” OD Tube 564336 Terminal Check Valve

Ref. Part No. Description Qty.

1 556783 NUT, Gland 3

2 556781 COLLAR 3

4 556936 SPRING, Valve 1

5 560343 VALVE 1

6 560339 SEAT, Valve 1

8 561354 BODY, Check Valve 1

9 558823 NIPPLE, Check Valve 1

10 560161 NUT 2

Ref. Part No. Description Qty.

1 556783 NUT, Gland 2

2 556781 COLLAR 2

4 556936 SPRING, Valve 1

5 560343 VALVE 1

6 560339 SEAT, Valve 1

8 561354 BODY, Check Valve 1

10 560161 NUT 2

11 556747 O-RING 2

11 556747 O-RING 2

TI8477

Steam Heater Parts Drawing and Parts List

3

4

2

Ref. Part No. Description Qty.

1 558792 ELBOW, 1/4 NPT Steam Pipe 2

2 561335 SEAL PLUG, Steam Pipe 2

3 558693 SEAL, Steam Pipe 2

4 560179 STEAM PIPE 1

12 311842C

1

TI8478

Page 13

Technical Data

Technical Data

Plunger Diameter 1/4 in. (0.64 cm)

HP-50 Maximum Operating Pressure 50,000 psi (344 MPa, 3,447 bar)

Reservoir Capacity 9 quarts (8.5 liters) from centerline of top gauge

glass to centerline of bottom gauge glass

Maximum Pumping Rate based on SAE 40 oil — (approx. 4 drops)

Minimum Pump Rate

Reservoir Heating (optional) Steam or Electric

Lubricant Viscosity 100 to 5000 SUS

Operating Temperature -200°F to 1200°F (-129°C to 649°C)

0.008 in

0.001 in

3

(0.133 cc) per stroke

3

(0.017 cc) at max. pressure

LUBRICATOR CHARACTERISTICS

Model Number of

Feeds

HP-50 1 to 4 50,000 9 1/4 4 1 0.008 0.002 0.133 0.033 36 3

† Usable reservoir capacity, as measured from centerline of top gauge glass to centerline of bottom gauge glass

(see page 10).

‡ All displacements are based on SAE 30 oil (500 S.U.S. at 100°F.) at room temperature. Volumetric equivalents of

drops are: 14,115 drops equal 1 pint, 490 drops equal 1 cu. in., 30 drops equal 1 cc.

Maximum

Operating

Pressure

Reservoir

Capacity

(Quarts)†

Plunger

Diameter

(Inches)

Drops /

Stroke

Max. Min. Max. Min. Max. Min. Max. Min.

Pumping Unit Displacements‡

cu. in. /

Stroke

cc / Stroke Strokes / min.

Construction Materials

Reservoir and Cover - Heavily ribbed cast iron.

Cylinder - Hardened alloy steel, precision-honed.

Plunger - Hardened alloy steel, precision-ground and

fitted.

Valves - Poppet type, flat face, hardened and ground

alloy steel.

Valve Seats - Hardened and ground alloy steel.

Driveshaft - Integral crankshaft type, hardened, ground

and polished alloy steel, machined from solid bar.

Bearings - Bronze bushed, high load capacity, long-life,

self-lubricating type.

Regulating Lever - Forged steel.

311842C 13

Page 14

Dimensions

Dimensions

7.68 in

(19. 5 cm)

4.125 in.

(10.4 cm)

3.125 in.

(

7.93 cm)

2.75 in.

(6.98 cm)

11.75 in.

(29.84 cm)

14.765 in.

(37.5 cm)

13.5 in.

(34.29 cm)

16.625 in. (42.22 cm)

22.68 in. (57.6 cm)

TI8514

11.56 in (29.36 cm)

14 311842C

Page 15

NOTES

NOTES

311842C 15

Page 16

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2007, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 311842

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised April 2012

Loading...

Loading...