Page 1

Instructions - Parts List

Low Pressure

311775E

Fluid Filters

For filtering large volumes of industrial paints and other industrial fluids. For professional

use only.

See page 3 for model numbers.

500 psi (3.5 MPa, 35 bar) Maximum Working Pressure.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

EN

ti10097a

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual, refer back to these Warnings. Product-specific hazard symbols and

warnings not covered in this section may appear throughout the body of this manual where applicable.

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin

and cause serious injury.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

2 311775E

Page 3

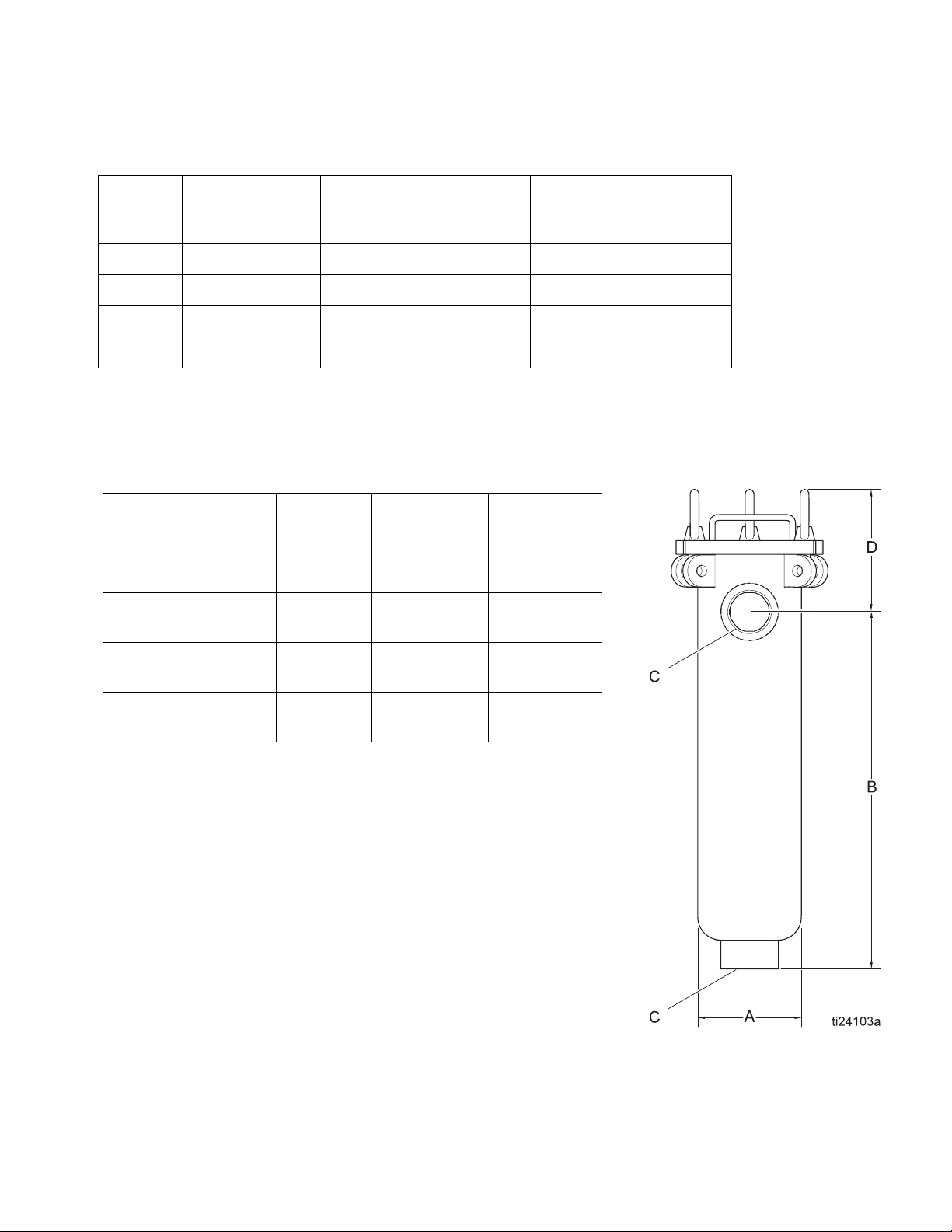

Models

Part Model

Filter

Area

Inlet/Outlet

Fittings

Models

Maximum

Delivery

gpm (lpm) Material

915515

915516*

915517

915518*

* Waterborne compatible

6 0.5 sq ft 1-1/4 npt (f) 15 (57) Carbon steel

6 0.5 sq ft 1-1/4 npt (f) 15 (57) Stainless steel

12 1.0 sq ft 1-1/2 npt (f) 30 (114) Carbon steel

12 1.0 sq ft 1-1/2 npt (f) 30 (114) Stainless steel

Dimensions

Width

Part No.

915515

915516

915517

915518

(A)

4.5 in. 9.5 in.

114.3 mm 241.3 mm (152.4 mm)

4.5 in. 9.5 in.

114.3 mm 241.3 mm (152.4 mm)

4.5 in. 15.5 in.

114.3 mm 393.7 mm (152.4 mm)

4.5 in. 15.5 in.

114.3 mm 393.7 mm (152.4 mm)

Length

(B)

Threads

(C)

1-1/4 NPT

1-1/4 NPT

1-1/2 NPT

1-1/2 NPT

Length

(D)

(6.0 in.)

(6.0 in.)

(6.0 in.)

(6.0 in.)

311775E 3

Page 4

Installation

Installation

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the parts drawing. (See

page 5.)

1. Connect the inlet line to the inlet (A) on the side of

the filter.

2. Connect the outlet line to the outlet (B) on the bottom of the filter.

NOTE: The 1/4 npt port in the cover of the filter can

remain plugged or be used for pressure gauges or special fittings.

3. Some installations require electrical grounding of all

equipment. Follow your local electrical code.

4. Remove cover by loosening the cover eye-nuts (3).

Loosen the eye-nuts in the slotted corners so the

bolts swing down. Loosen the third eye-nut so the

top cover can swing open.

5. Put basket (2) into filter housing. Make sure the basket flange is seated firmly on top of the basket collar.

6. Put bag into the bag basket. Be sure the filter bag

ring is seated firmly on top of the basket flange. For

best results, be sure the filter bag extends to the

bottom of the basket.

Operation

Prior to turning on the flow to the inlet, check the

following:

1. Be sure a basket and filter bag (if applicable) are in

place. Clean or replace as necessary.

2. Be sure the filter cover is securely fastened to housing.

Slowly open the inlet line to approximately 25% of normal operational flow. When the filter is pressurized and

vented, slowly open outlet line valve until completely

open. Open inlet line to reach desired flow rate.

NOTICE

Inlet pressure must not exceed outlet pressure by

more than 15 psi (0.1 MPa, 1 bar). Operating the filter

with a high differential may cause filter bags to rupture,

causing damage to filter system and downstream

equipment.

To prevent excessive drop through the filter, regularly

inspect the basket and filter bag. Monitor the differential

pressure through the filter to determine whether the basket or filter bag needs to be cleaned or replaced.

7. Make sure that the cover gasket groove is clean and

free of debris. Put in cover seal gasket (1).

NOTE: If the cover has ever been tightened down, the

cover seal gasket must be replaced.

8. Close cover and alternately tighten the three clamp

assemblies (by small increments) to a recommended torque of 30-45 ft-lb (40-60 N•m).

4 311775E

Page 5

Service

PRESSURIZED EQUIPMENT HAZARD

Before removing, cleaning, or servicing the filter,

close the inlet and outlet ball valves and open the

fluid drain valve to relieve pressure.

1. Relieve all fluid pressure from the system. See the

Warning above and your pump/sprayer manual.

NOTE: In some applications, closing outlet valve is not

required.

2. Drain housing sufficiently to access filter basket (2).

Service

1

2

3. Remove cover by loosening the cover eye-nuts (3).

Loosen the eye-nuts in the slotted corners so the

bolts swing down. Loosen the third eye-nut so the

top cover can swing open.

4. Remove filter basket (2) and clean thoroughly.

5. Remove the filter bag (if applicable, not shown) and

throw away. (Cleaning and reusing the filter bag is

not recommended.)

6. Thoroughly clean the inlet (A) to avoid interference

with cover seal or fluid flow.

7. Remove basket seal (if applicable) and inspect.

Replace if necessary.

8. Install clean filter basket and filter bag (if applicable). Put basket (2) into filter housing. Make sure the

basket flange is seated firmly on top of the basket

collar. Put bag into the bag basket. Be sure the filter

bag ring is seated firmly on top of the basket flange.

For best results, be sure the filter bag extends to the

bottom of the basket.

9. Make sure that the cover gasket groove is clean and

free of debris. Replace cover seal gasket (1).

3

A

B

ti10098a

NOTE: If the cover has ever been tightened down, the

cover seal gasket must be replaced.

10. Close cover and alternately tighten the three clamp

assemblies (by small increments) to a recommended torque of 30-45 ft-lb (40-60 N•m).

311775E 5

Page 6

Replacement Parts

Replacement Parts Replacement Filter Bags

Part Number

Ref.

1 521691 521691 Gasket, PTFE encapsu-

2 521268 521276 Bag filter basket, perfo-

521273 521280 Strainer basket, perfo-

3 521306 521306 Eye-bolt and nut

DescriptionModel 6 Model 12

lated fluoroelastomer

rated stainless steel,

standard with complete

assemblies

rated stainless steel with

100 mesh liner

Part Number

Model 6

(15 gpm)

521312 --

521316 --

521317 --

521183 --

521184 --

521186 521177

521187 521178

-- 521179

-- 521180

-- 521342

-- 521344

521335 --

521336 --

521337 --

521212 521240

521213 --

521215 --

521216 521244

521217 521245

521218 521246

521226 521254

521227 521255

521228 521256

521229 521257

521230 521258

521231 521259

521232 521260

521233 521261

521234 521262

521235 521263

521236 521264

Model 12

(30 gpm)

Material

Glazed polyester felt

without cover

Glazed polyester felt,

spun bonded nylon

cover

Glazed polyester felt,

nylon multi-filament

mesh cover

Glazed polyester felt,

nylon mono-filament

mesh cover

Nylon monofilament

mesh

Micron

size.

10

75

100

5

10

25

50

75

100

10

25

50

75

100

5

10

25

50

75

100

5

10

25

50

75

100

125

150

200

250

300

6 311775E

Page 7

Accessories

Pressure Gauge

2-1/2 in dial bourdon tube pressure gauge; range 0-200

psi (0-1.4 MPa, 1-14 bar); with pulsation dampener and

diaphragm seal.

Part Number

(Models 6 and 12) Description

Accessories

206171 carbon steel, 1/4 npt(f), bottom

208855 stainless steel, 1/4 npt(m), bot-

inlet

tom inlet

Ball Valve

For drain or air blowdown; 500 psi (3.5 MPa, 35 bar)

Part Number

(Models 6 and 12) Description

208390 carbon steel, 1/4 x 1/4 npt

208393 carbon steel, 3/8 x 3/8 npt

237534 stainless steel, 3/8 x 3/8 npt

NOTE: To order complete fluid filter assembly, see

Models on page 3.

(mbe)

(mbe)

(m x f)

311775E 7

Page 8

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER,

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2007, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

contact your Graco distributor or call to identify the nearest distributor.

Graco reserves the right to make changes at any time without notice.

Original instructions.

International Offices: Belgium, China, Japan, Korea

This manual contains English. MM 311775

Graco Headquarters: Minneapolis

www.graco.com

Revision E, June 2014

Loading...

Loading...