Page 1

Operation

Reactor A-20

Air Operated, Electrically Heated Plural Component Proportioner

For spraying or dispensing 1:1 mix ratio materials, including epoxies and polyurethane

foam. For professional use only.

Not approved for use in European explosive atmosphere locations.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 3 for a list of models and maximum working pressures.

US Patent No. 7822326

Russian Patent No. 2359181

311511G

ENG

TI8447A

Page 2

Contents

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Typical Installation, without Circulation . . . . . . . . 7

Typical Installation, with Circulation . . . . . . . . . . . 8

Moisture Sensitivity of Isocyanates . . . . . . . . . . . . 9

Foam Self-Ignition . . . . . . . . . . . . . . . . . . . . . . . . 9

Isocyanate Hazard . . . . . . . . . . . . . . . . . . . . . . . 9

Keep Components A and B Separate . . . . . . . . . 9

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . 9

Component Identification . . . . . . . . . . . . . . . . . . . 10

Controls and Indicators . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 13

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Locate Reactor A-20 . . . . . . . . . . . . . . . . . . . . . 14

Determine Power Source . . . . . . . . . . . . . . . . . 14

Electrical Requirements . . . . . . . . . . . . . . . . . . 14

Configure to Supply Power . . . . . . . . . . . . . . . . 15

Ground System . . . . . . . . . . . . . . . . . . . . . . . . . 17

Iso Pump Lubrication System Setup . . . . . . . . . 17

Fluid Supply Connections . . . . . . . . . . . . . . . . . 17

Air Supply Connection . . . . . . . . . . . . . . . . . . . 17

Connect FTS and Heated Dual Whip Hose . . . 18

Recirculation / Pressure Relief Lines . . . . . . . . 19

Connect Heated Hose . . . . . . . . . . . . . . . . . . . . 19

Close Gun Fluid Manifold Valves A and B . . . . . 20

Connect Whip Hose to Gun Fluid Manifold . . . . 20

Pressure Check Hose . . . . . . . . . . . . . . . . . . . . 20

Initial Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fluid Temperature Sensor (FTS) Calibration . . . 21

Load Fluid with Feed Pumps . . . . . . . . . . . . . . . 21

Digital Temperature Controllers . . . . . . . . . . . . . 22

Over Temperature Alarms . . . . . . . . . . . . . . . . . 24

Fluid Heater Temperature Offset . . . . . . . . . . . . 24

Hose Heat Manual Mode . . . . . . . . . . . . . . . . . . 24

Supply Wet-Cups with Throat Seal Liquid . . . . . 25

Spraying Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Spray Adjustments . . . . . . . . . . . . . . . . . . . . . . 27

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Daily Start-up Procedure . . . . . . . . . . . . . . . . . . 29

Fluid Circulation . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Circulation Through Reactor . . . . . . . . . . . . . . . 31

Circulation Through Gun Manifold . . . . . . . . . . . 32

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 36

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 36

Related Manuals

Reactor A-20 Repair/Parts Manual 311512

2 311511G

Page 3

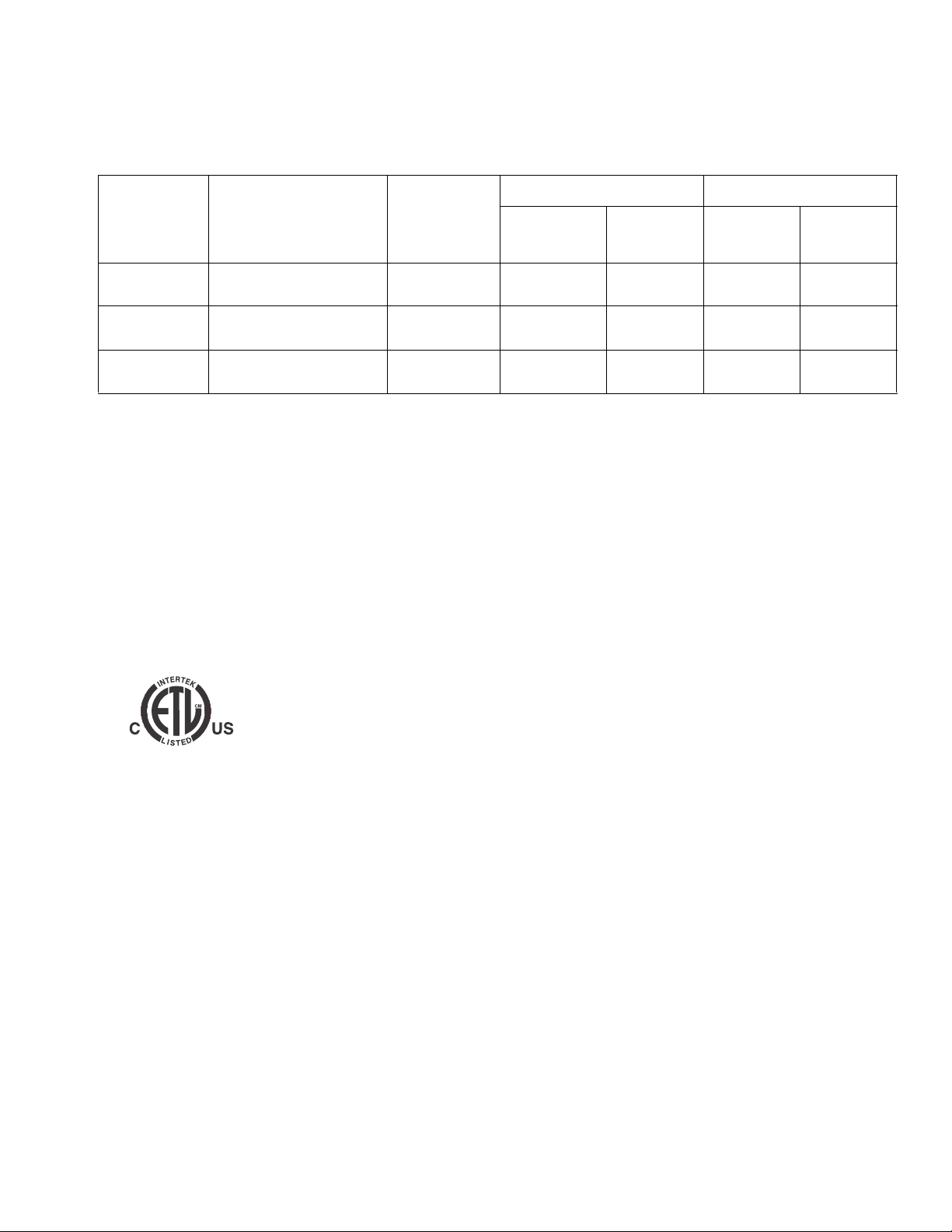

Systems

Systems

Maximum Fluid

Working Pressure

psi

System Part

AP3831 2000

(MPa, bar) Proportioner

253831 246678 246050 Fusion Air

(13.8, 138)

CS3831 2000

253831 246678 246050 Fusion CS CS01RD

(13.8, 138)

P23831 2000

253831 246678 246050 Probler P2 GCP2R1

(13.8, 138)

253831 Proportioner

This model is field-configurable to the following supply

voltages:

230 V, 1 Phase

230 V, 3 Phase

380 V, 3 Phase

2,000 psi (14 MPa,140 bar) Maximum Fluid Working Pressure

120 psi (0.84 MPa, 8.4 bar) Maximum Air Working Pressure

Approvals:

Heated Hose Gun

50 ft (15 m) 10 ft (3 m) Model Part

246101

Purge

#ONFORMSTO!.3)5,

3TD#ERTIFIEDTO

#!.#3!3TD

#.O

311511G 3

Page 4

Warnings

Warnings

The following general warnings are for the setup, use, grounding, maintenance, and repair of this equipment.

Additional, more specific warnings may be found throughout the body of this manual where applicable. Symbols

appearing in the body of the manual refer to these general warnings. When these symbols appear throughout the

manual, refer back to these pages for a description of the specific hazard.

WARNING

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on sprayer and extension cords.

• Do not expose to rain. Store indoors.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

4 311511G

Page 5

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

THERMAL EXPANSION HAZARD

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to

the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

• Open a valve to relieve the fluid expansion during heating.

• Replace hoses proactively at regular intervals based on your operating conditions.

Warnings

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• This equipment is for professional use only.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure in this manual when equipment is not in use.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

311511G 5

Page 6

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

6 311511G

Page 7

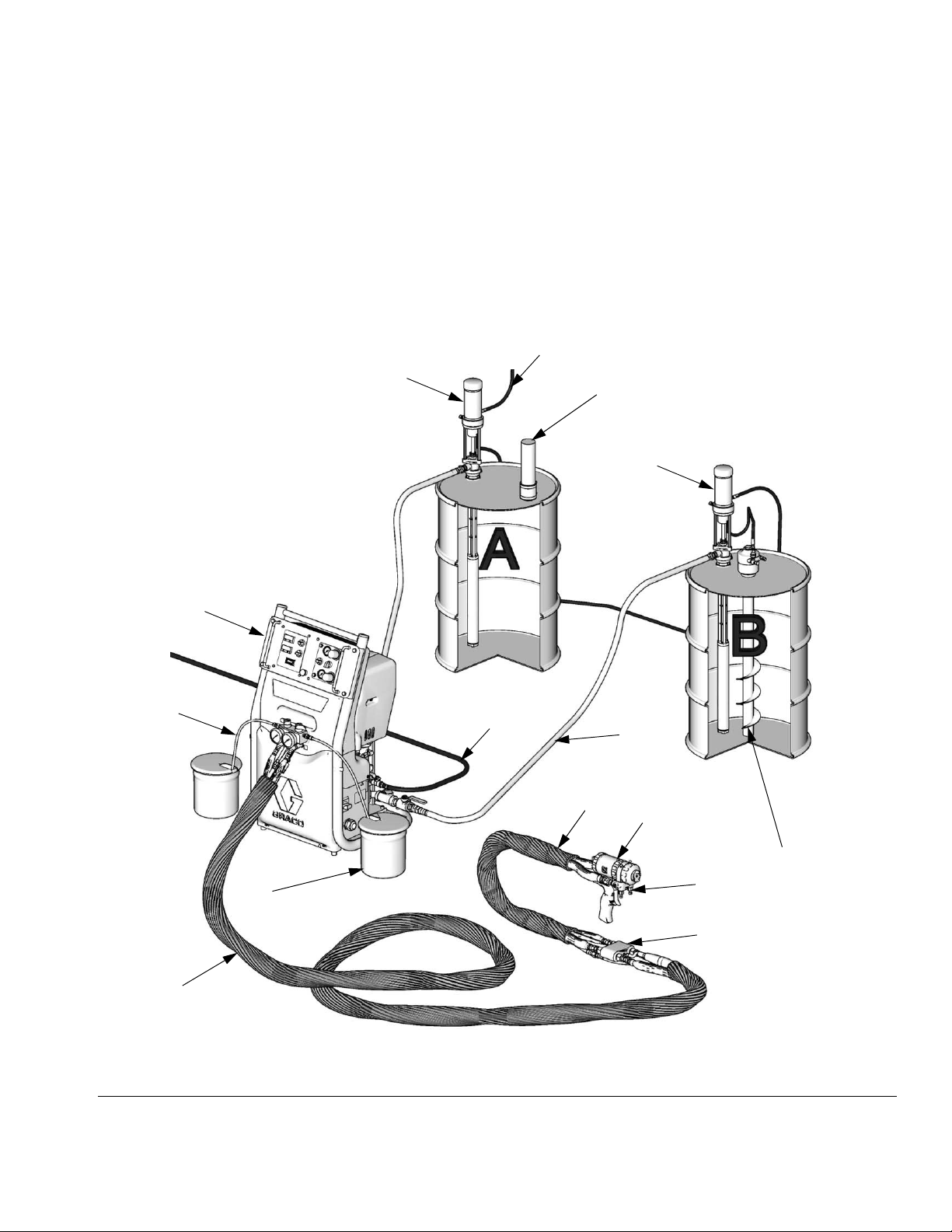

Typical Installation, without Circulation

Typical Installation, without Circulation

Key for FIG. 1

A Reactor Proportioner

BHeated Hose

C Fluid Temperature Sensor (FTS)

D Heated Whip Hose

E Fusion Spray Gun

F Proportioner and Gun Air Supply Hose

G Feed Pump Air Supply Lines

A

H Waste Containers

J Fluid Supply Lines

K Feed Pumps

L Agitator

M Desiccant Dryer

N Bleed Lines/Over Pressure Relief

P Gun Fluid Manifold

G

K

M

K

N

H

B

FIG. 1: Typical Installation, without Circulation

F

J

D

E

L

P

C*

ti8489a

* Shown exposed for clarity. Wrap with tape during operation.

311511G 7

Page 8

Typical Installation, with Circulation

Typical Installation, with Circulation

Key for FIG. 2

A Reactor Proportioner

B Heated Hose

C Fluid Temperature Sensor (FTS)

D Heated Whip Hose

E Fusion Spray Gun

F Proportioner and Gun Air Supply Hose

A

G Feed Pump Air Supply Lines

J Fluid Supply Lines

K Feed Pumps

L Agitator

M Desiccant Dryer

N Recirculation/Over Pressure Relief Return Hoses

P Gun Fluid Manifold

K

G

M

M

K

N

B

FIG. 2: Typical Installation, with Circulation

F

J

D

E

L

N

P

C*

ti8488a

* Shown exposed for clarity. Wrap with tape during operation.

8 311511G

Page 9

Moisture Sensitivity of Isocyanates

Moisture Sensitivity of

Isocyanates

Isocyanates (ISO) are catalysts used in two component

foam and polyurea coatings. ISO will react with moisture

(such as humidity) to form small, hard, abrasive crystals,

which become suspended in the fluid. Eventually a film

will form on the surface and the ISO will begin to gel,

increasing in viscosity. If used, this partially cured ISO

will reduce performance and the life of all wetted parts.

The amount of film formation and rate of

crystallization varies depending on the blend of

ISO, the humidity, and the temperature.

To prevent exposing ISO to moisture:

• Always use a sealed container with a desiccant

dryer in the vent, or a nitrogen atmosphere. Never

store ISO in an open container.

• Keep the Iso (A) Pump Lube system jar 3/4 filled

with clean Throat Seal Lubricant (TSL) 206995.

Change whenever fluid appears cloudy.

Isocyanate Hazard

Spraying materials containing isocyanates creates

potentially harmful mists, vapors, and atomized particulates.

Read material manufacturer’s warnings and material

MSDS to know specific hazards and precautions

related to isocyanates.

Prevent inhalation of isocyanate mists, vapors, and

atomized particulates by providing sufficient ventilation in the work area. If sufficient ventilation is not

available, a supplied-air respirator is required for

everyone in the work area.

To prevent contact with isocyanates, appropriate personal protective equipment, including chemically

impermeable gloves, boots, aprons, and goggles, is

also required for everyone in the work area.

Keep Components A and B

• Use moisture-proof hoses specifically designed for

ISO, such as those supplied with your system.

• Never use reclaimed solvents, which may contain

moisture. Always keep solvent containers closed

when not in use.

• Never use solvent on one side if it has been

contaminated from the other side.

• Always park pumps when you shutdown.

• Always lubricate threaded parts with Part 217374

ISO pump oil or grease when reassembling.

Foam Self-Ignition

Some materials may become self-igniting if applied

too thick. Read material manufacturer’s warnings and

material MSDS.

Separate

NOTICE

To prevent cross-contamination of the equipment’s

wetted parts, never interchange component A

(isocyanate) and component B (resin) parts.

Changing Materials

• When changing materials, flush the equipment

multiple times to ensure it is thoroughly clean.

• Always clean the fluid inlet strainers after flushing.

• Check with your material manufacturer for chemical

compatibility.

• Most materials use ISO on the A side, but some use

ISO on the B side.

• Epoxies often have amines on the B (hardener)

side. Polyureas often have amines on the B (resin)

side.

311511G 9

Page 10

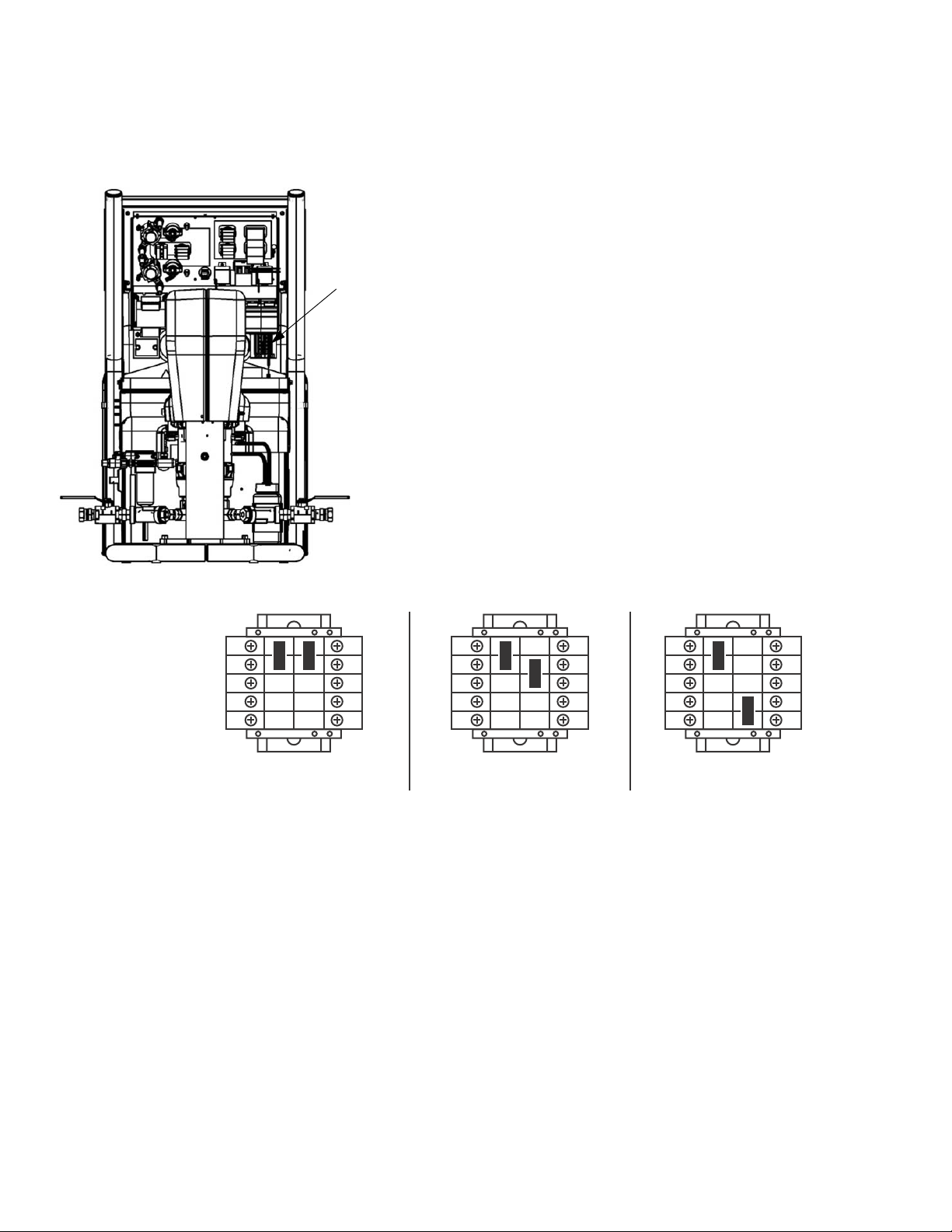

Component Identification

Component Identification

W

T

DD

AD

AI

ti8447a

R

AK

AA

AH

S

FF

GG

ti8448a

X

U

Y

V

AG

ti8481a

Z

FIG. 3: Typical Installation

10 311511G

Page 11

Key:

Component Identification

R Main Disconnect Switch - Controls power to all

circuits. It must be ON for proportioning unit to

operate. Temperature displays are lit when main

switch is ON.

S Main Air Filter - Filters system air supply.

T Resin (B) Pressure Gauge - Displays pressure in

resin proportioning system (B side).

U Resin (B) - Inlet Supply Valve

V Resin (B) Fluid Y-Strainer

W ISO (A) Pressure Gauge - Displays pressure in

isocyanate proportioning system (A side).

X ISO (A) - Inlet Supply Valve

Y ISO (A) Fluid Y-Strainer

Z ISO (A) Pump Lube System - (A side only)

AH Resin (B) Proportioning Pump - Draws in and

dispenses a fixed volume of resin to gun.

AI Power-Lock

™

Hose Heat Connection - Connects

power to heated hoses.

*AJ Primary Heater Over-Temperature Switch -

Sends signal to temperature controller if heater

exceeds maximum temperature condition.

AK Resin (B) Pump Wet Cup - Access for daily wet

cup refill.

DD Air Inlet Ball Valve - (3/8 NPT male fitting)

FF ISO (A) Inlet - Fitting (1/2 swivel fitting)

GG Resin (B) - Inlet (3/4 swivel fitting)

* Components not shown.

AA ISO (A) - Packing Nut and Lube Cup - (A side

only)

*ABPressure Limit Switches - Factory set to turn off

air drive system when proportioning pump exceeds

designed operating pressure limit.

*ACPrimary Heater Thermocouple - Senses

temperature of primary heater and inputs that

information.

AD FTS Jumper Harness - Carries electrical signal

from FTS sensor in isocyanate hose to hose

temperature controller.

*AEAir Motor Reversing Switch - (Front of air motor)

Energizes and de-energizes air solenoid valve coils

to reverse direction.

*AFPrimary Heater - Heats material to required

dispensing temperature.

AG ISO (A) - (Isocyanate) Proportioning Pump -

Draws in and dispenses a fixed volume of

isocyanate to gun.

311511G 11

Page 12

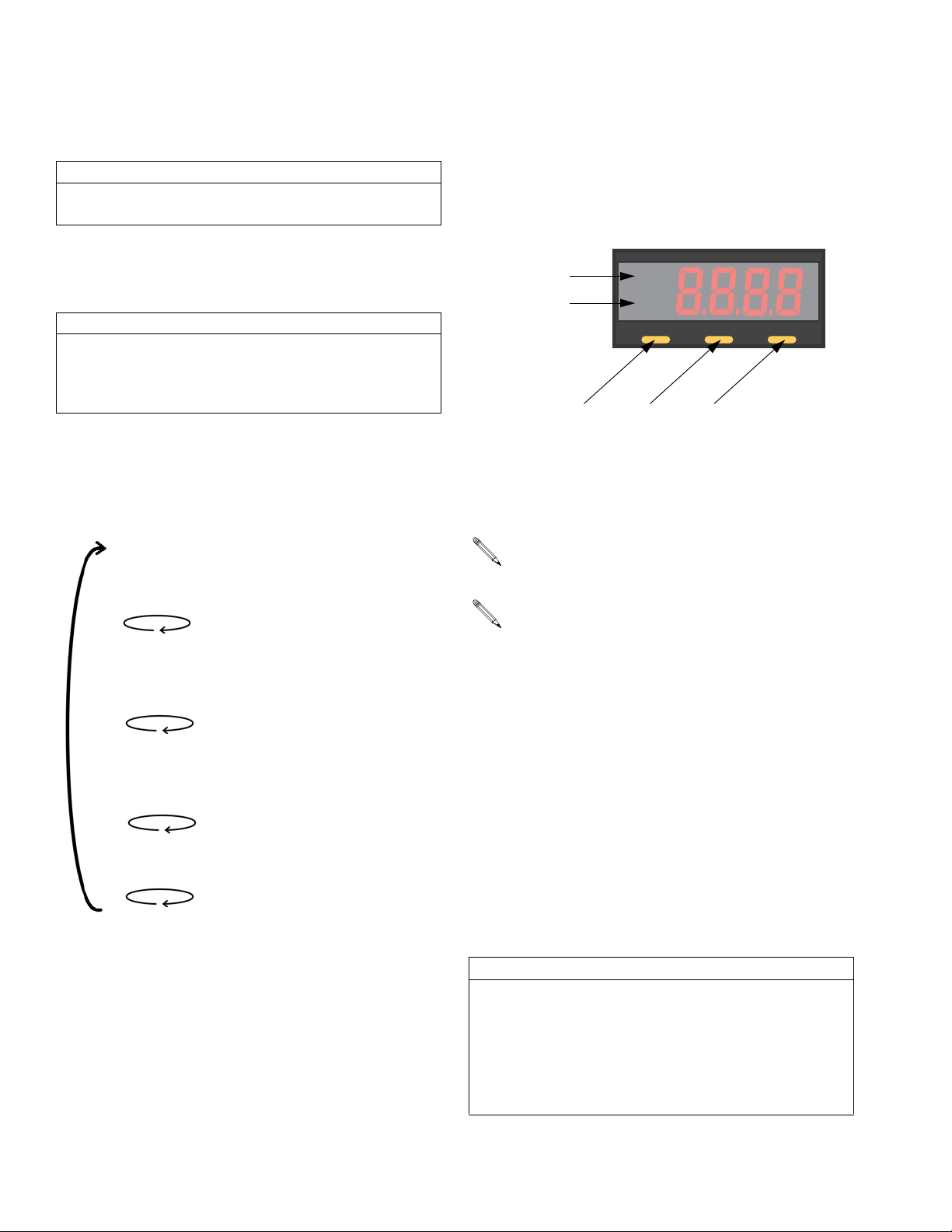

Controls and Indicators

Controls and Indicators

AN

AM

AR

AK

34!24

/.

/&&

34!24

/.

/&&

AL

Key:

AK Primary Heater Switch - Controls and protects

primary heater. It must be ON and lit green for

primary heater to operate.

AL Hose Heater Switch - Controls and protects hose

heat circuit. It must be ON and lit green for hose

heater to operate.

AM Hose Temperature Controller - Controls

temperature of hose heat. Adjust set point to

desired temperature. From this point, the

temperature control is automatic. Displays current

temperature after time-out.

AN Primary Heater Temperature Controller - Controls

temperature of primary heater. Adjust set point to

desired temperature. From this point, the

temperature control is automatic.

AO Pump Mode Function Knob - Controls operation

of air drive system.

• OFF - Air drive system is off.

• ON - Must be in this position for unit to operate.

• START - Momentary position that starts the air

motor movement and illuminates green light in

switch.

AU

AS

AW

AQ

AV

34!24

/.

/&&

AO

AP

B

A

R

A

0

-

0

3

)

25.

0!2+

B

A

R

A

0

-

0

3

)

AT

AP Park/Run Switch -

• PARK - Use this position for shutdown. Stops air

motor at bottom of stroke with proportioning

pumps in retracted position when trigger is

pulled.

• RUN - Enables Air Motor Power

AQ Pump Directional Indicator Lights (Green) -

Indicates direction the proportioning pump travels.

Both lights are off when pump switch is OFF or

when either proportioning pump exceeds its

operating pressure limit switch.

AR Counter - Records cycle count of proportioning

pumps. One cycle count equals two strokes (one in

each direction). One cycle equals .028 gal. (.106 l).

AS Downstroke Air Pressure Regulator - Controls air

pressure to air motor during downstroke.

AT Downstroke Air Pressure Gauge - Displays air

pressure in air drive system during downstroke.

AU Upstroke Air Pressure Regulator - Controls air

pressure to air motor during upstroke.

AV Upstroke Air Pressure Gauge - Displays air

pressure in air drive system during upstroke.

AW Emergency Stop Switch - Shuts off electrical

power to pump control and both heat control

circuits.

12 311511G

Page 13

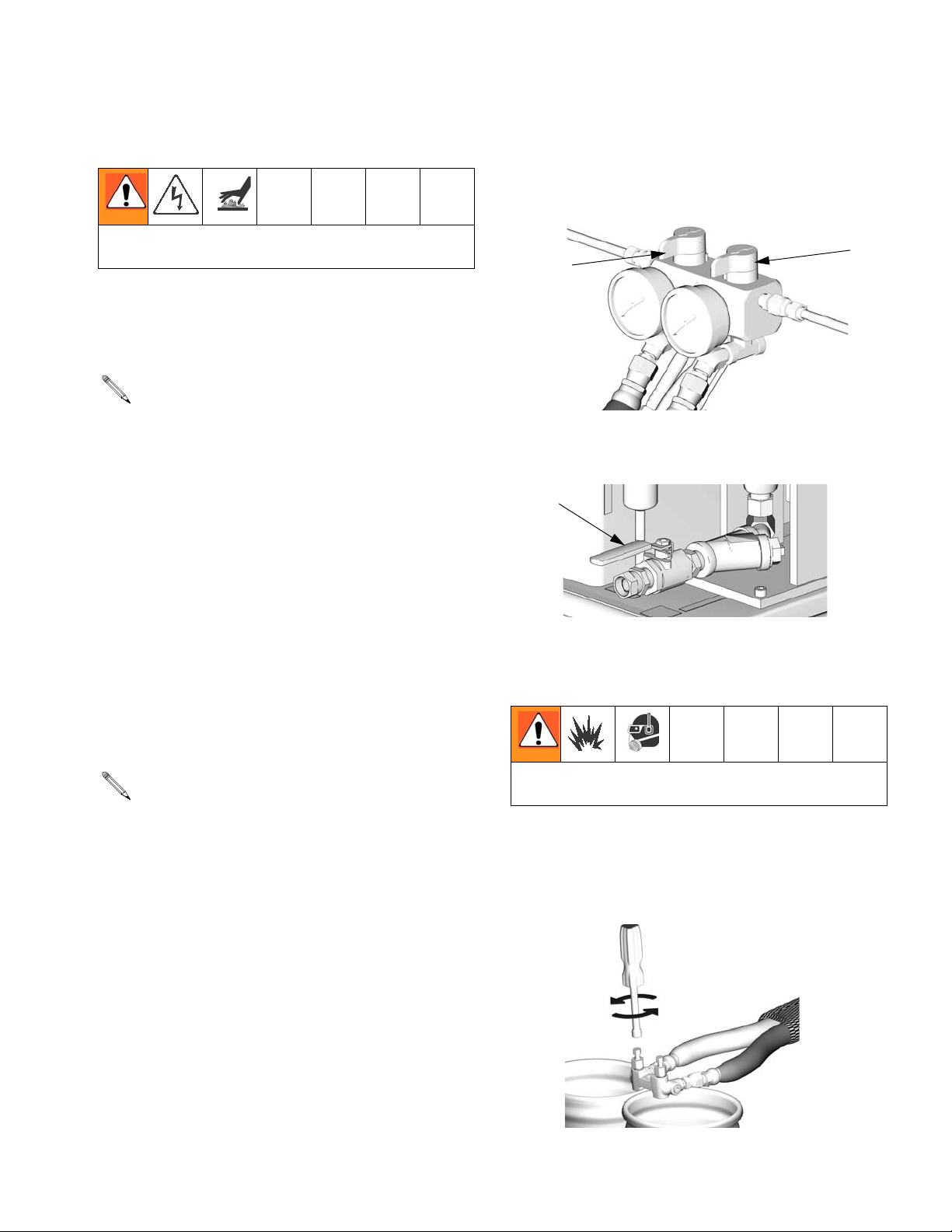

Pressure Relief Procedure

Pressure Relief

Procedure

1. Turn off feed pumps and agitator if used.

2. Turn PARK/RUN switch to PARK.

3. Trigger gun to relieve pressure.

4. Turn off air inlet valve.

5. Engage gun piston safety lock.

Flushing

Flush equipment only in a well-ventilated area. Do not

spray flammable fluids. Do not turn on heaters while

flushing with flammable solvents.

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent, such as toluene,

naptha, or mineral spirits before introducing new

fluid.

• Use lowest possible pressure when flushing.

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• Always leave hydraulic oil or a non-water based,

non-water absorbent fluid in system. Do not use

water.

ti2409a

6. Verify gun fluid manifold valves A and B are closed.

ti2421a

7. Close pump inlet supply valves.

Only use flush solvents that are compatible with Fluoroelastomer seals. Non-compatible solvents will damage seals and cause hazardous conditions, such as

high pressure leaks and pressure switch failure.

311511G 13

Page 14

Setup

Setup

Locate Reactor A-20

1. Locate Reactor A-20 on a level surface and bolt in

place to the floor with 3/8 in. (10 mm) bolts.

• Two bolts through the 2 in. (50 mm) deep caster

bushings in the rear.

• Two bolts through the 3-5/8 in. (168 mm) deep

caster bushings in the front.

2. Do not expose Reactor A-20 to rain.

3. If you need to move the machine, add

provided casters.

4. Lift with hoist only from bar spanning across top of

cart.

Determine Power Source

Reactor A-20 can be wired to 3 types of power source:

• 230 Volt / 1 Phase

• 230 Volt / 3 Phase Delta

Electrical Requirements

Improper wiring may cause electric shock or other

serious injury if work is not performed properly. Have a

qualified electrician connect power and ground to main

power switch terminals. Ensure your installation

complies with all National, State, and Local safety and

fire codes.

Also ensure that incoming power is disconnected and

locked out at the source.

NOTICE

Ensure main power source meets all electrical

requirements specified on nameplate of proportioning

unit. Also ensure main power source has a dedicated

fuse disconnect. Power cord is not supplied.

• 380 Volt / 3 Phase WYE

(220 Volts to Neutral)

14 311511G

Page 15

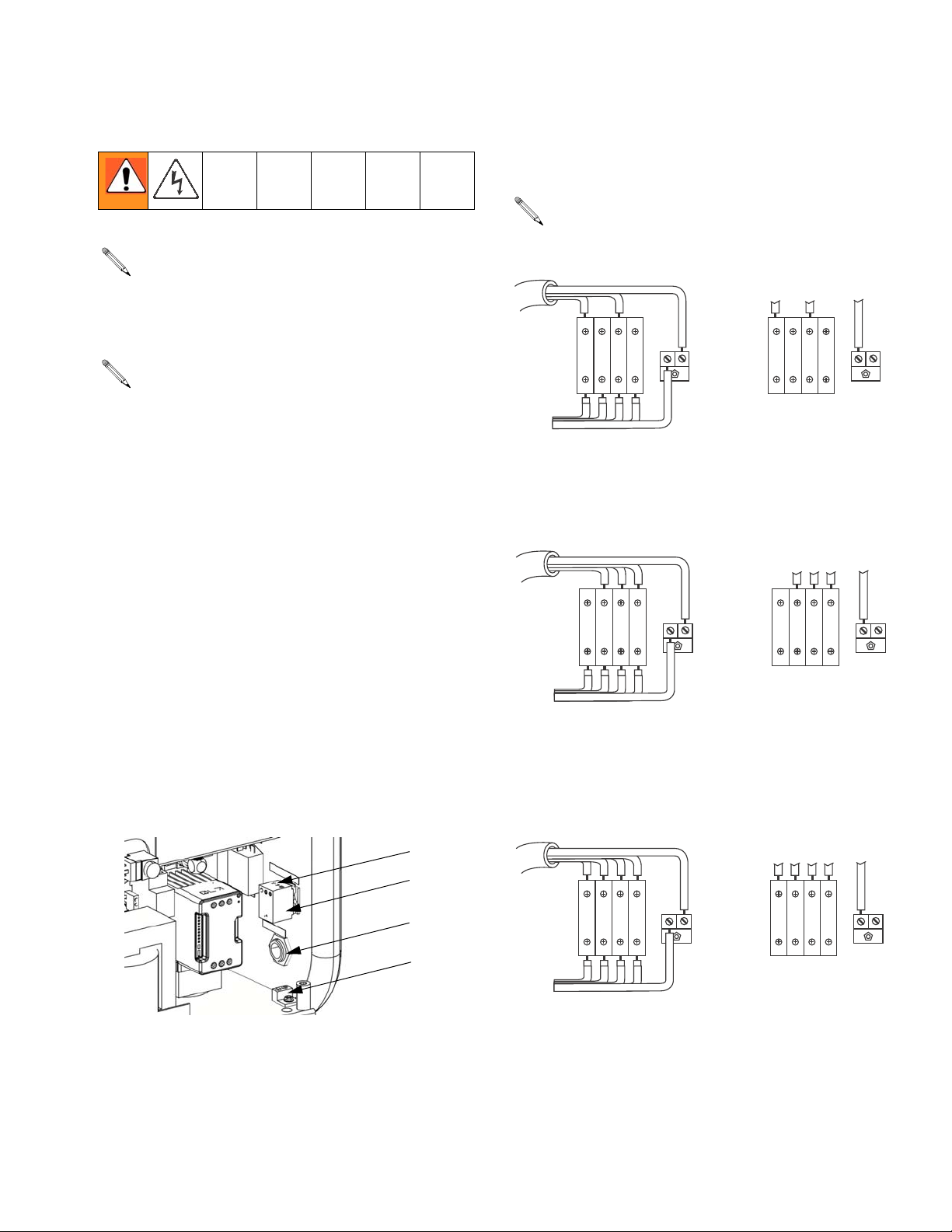

Configure to Supply Power

Both cord connection AND jumper positioning

steps on page 16 must be completed.

Step One - Connect Electrical Cord

Setup

green to ground (GND). See page 16 for proper jumper

positions.

Disregard terminal numbers on disconnect switch

blocks. Wire to positions shown.

,

,

,

0%

Disregard terminal numbers on disconnect switch

blocks. Wire to positions shown. Terminals will

2

accept up to #8 AWG (10 mm

) conductors.

1. Remove and retain two screws from lower front

shroud and remove.

2. Connect main power cord to electrical console as

follows:

a. Feed power cord through strain relief (SR) on

right side of unit. Push black die release lever

(RL) down to release contacts block (PD) for

easy wiring.

b. Connect power leads to Power Disconnect

Switch (PD). Snap contacts block (PD) back

onto switch.

c. Tighten strain relief nut.

d. Strain relief accepts cords 0.59 to 1.0 in. (15-25

mm) diameter.

e. Connect ground wire to ground lug (GL).

, , ,.

,

ti8611a

.

'2.$

230V, 3 Phase Delta: Use a screwdriver to connect

three power leads to top terminals L1, L2, and L3.

Connect green to ground (GND). See page 16 for

proper jumper positions.

,

,

, , ,.

,

ti8612a

.

0%

,

'2.$

380V, 3 Phase WYE (as shipped from factory): Use a

screwdriver to connect three power leads to the top

terminals L1, L2, and L3. Connect neutral to N. Connect

green to ground (GND). See page 16 for proper jumper

positions.

ti8608a

RL

PD

SR

GL

.

, , ,

,

,.

,

.

,

ti8613a

0%

,

'2.$

3. Replace lower front shroud. Reinstall the two

screws retained in Step 1.

230V, 1 Phase: Use a screwdriver to connect two power

leads to the top terminals N and L2 positions. Connect

311511G 15

Page 16

Setup

Step Two - Reposition Power Jumpers

Find location of Power Jumpers.

Power Jumper

Location

ti8609a

For 230V, 1 Phase and 230V, 3 Phase Installations,

change jumper positions as shown below. Machine is

shipped with jumpers in the fail-safe 380 3Ø position.

1. Remove upper rear control cover screws and cover.

2. Move one red jumper from the storage positions to

the positions shown for your power.

• A flat-blade screwdriver can be used under the

ridge on the side of the jumper to remove them.

• Push the jumper firmly into the new position.

3. Replace rear cover and two screws.

Step Two

TB2

Terminal Blocks

Position red jumpers

(under back cover on

opposite side)

, , , .

679%

(as shipped)

, , , .

6$ELTA

, , , .

6

ti8610a

16 311511G

Page 17

Setup

Ground System

• Reactor: is grounded through power cord; see page

15.

• Spray gun: connect whip hose ground wire to FTS;

see page 18. Do not disconnect wire or spray without whip hose.

• Fluid supply containers: follow your local code.

• Object being sprayed: follow your local code.

• Solvent pails used when flushing: follow your local

code. Use only metal pails that are conductive.

Place them on a grounded surface. Do no place pail

on a nonconductive surface, such as paper or

cardboard, which interrupts grounding continuity.

• To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of spray gun

firmly to the side of a grounded metal pail, then

trigger gun.

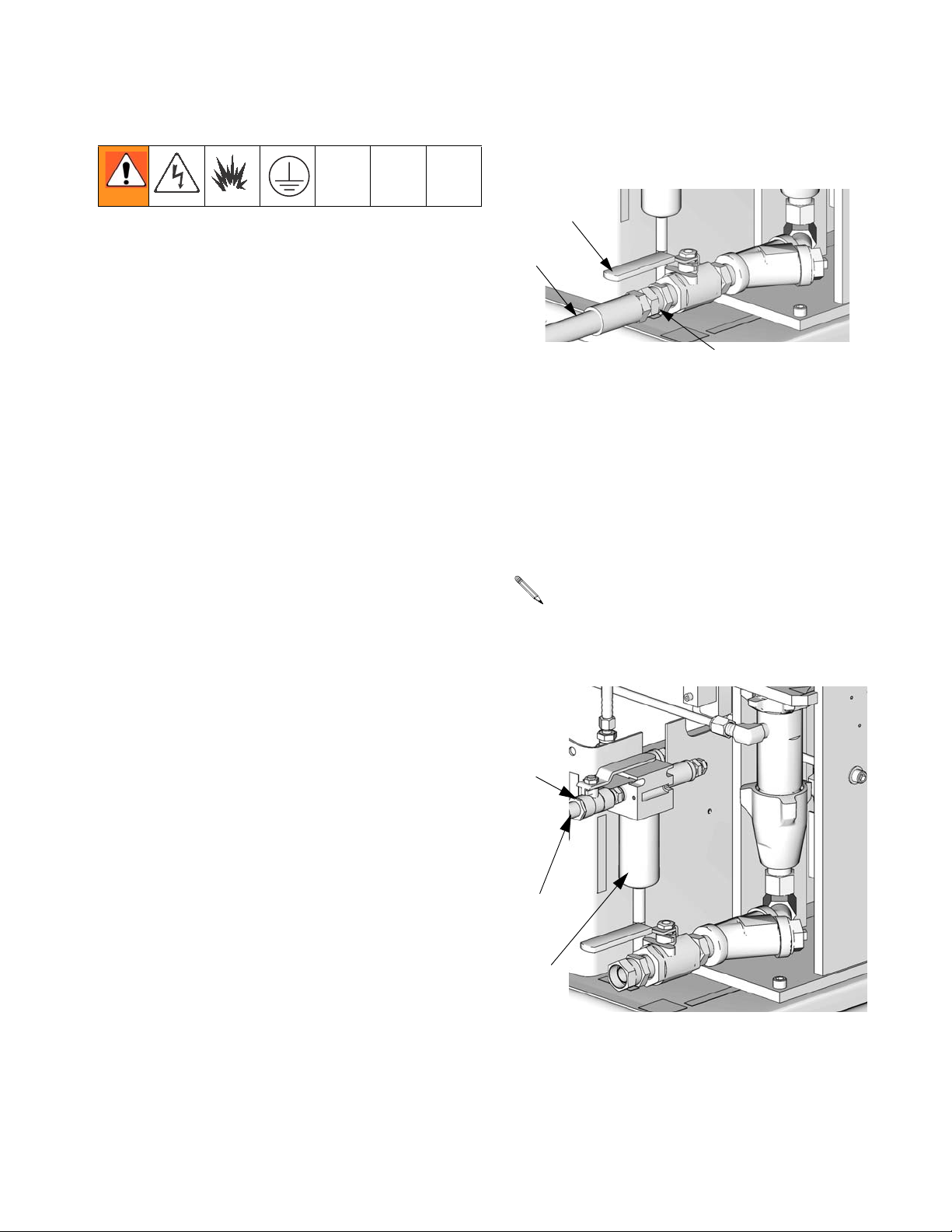

Iso Pump Lubrication System

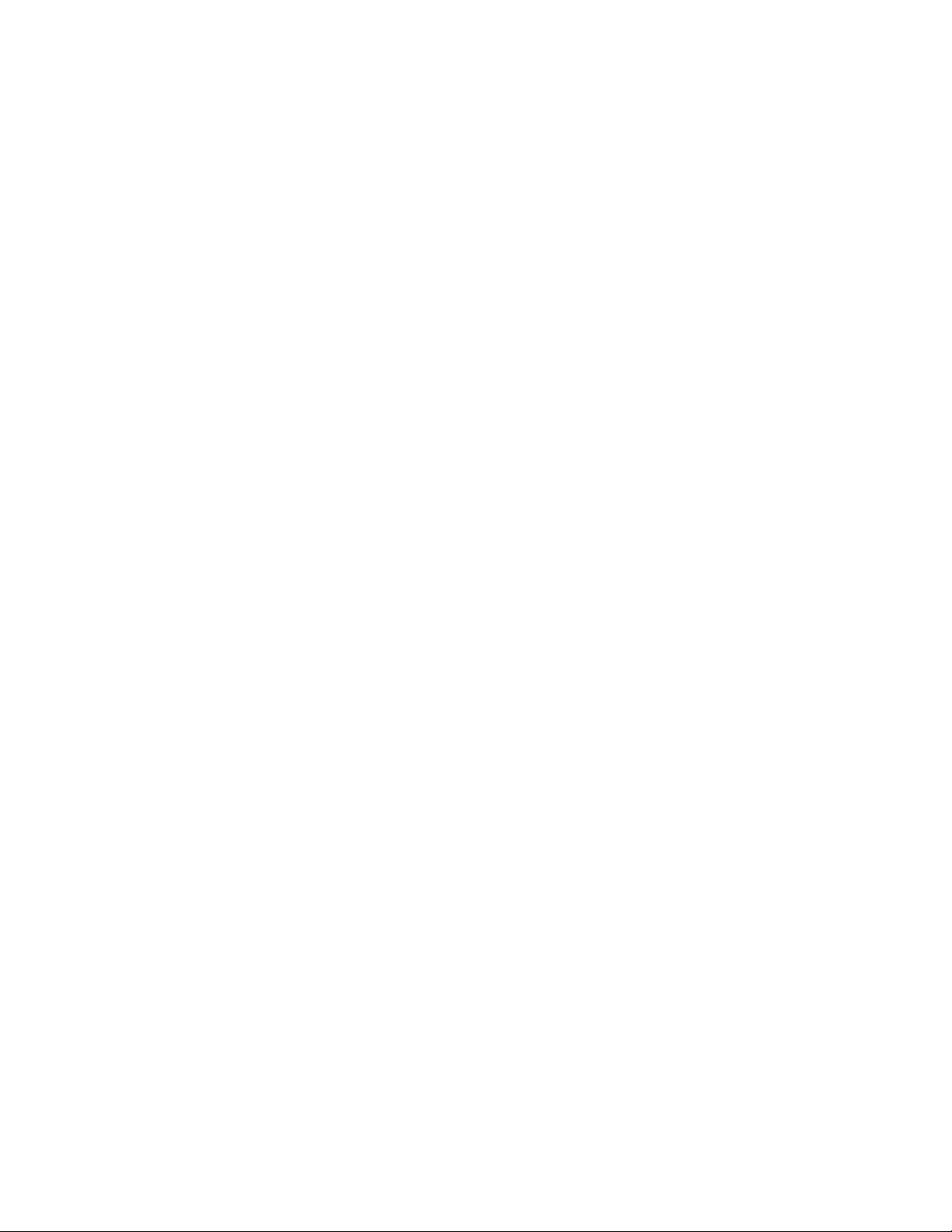

2. Connect and tighten B- supply hose (J) to 3/4 NPT

swivel fitting (GG) on B- inlet ball valve (U), and to

resin transfer pump.

U

J

GG

3. Connect and tighten A- supply hose (BB) to 1/2 NPT

swivel fitting (FF) on A- inlet ball valve (X), and to

isocyanate transfer pump. See F

ti8451a

IG. 3, page 10.

Air Supply Connection

Connect main air supply (F) to air inlet fitting (DD) at air

filter (S). Hose fitting requires a 3/8 NPT female fitting.

Use a minimum of 3/8 in. ID air line (not supplied)

to deliver air supply to proportioning unit. Use 1/2

in. ID hose if over 15 ft long.The main air supply

must be clean and free of oil and contaminants.

Setup

Prepare isocyanate pump lubrication system as follows:

1. Lift lubricant reservoir out of bracket and remove

reservoir from cap.

2. Fill reservoir 3/4 full with TSL; see Accessories

section in manual 311512.

3. Thread reservoir onto cap assembly and place it

into bracket.

The lubrication system is now ready for operation; no

priming is required.

Fluid Supply Connections

Connect material supply to inlets of proportioning unit as

follows:

1. Ensure the A- and B- inlet ball valves (U,X) on

proportioning unit are closed.

DD

F

S

ti8456a

311511G 17

Page 18

Setup

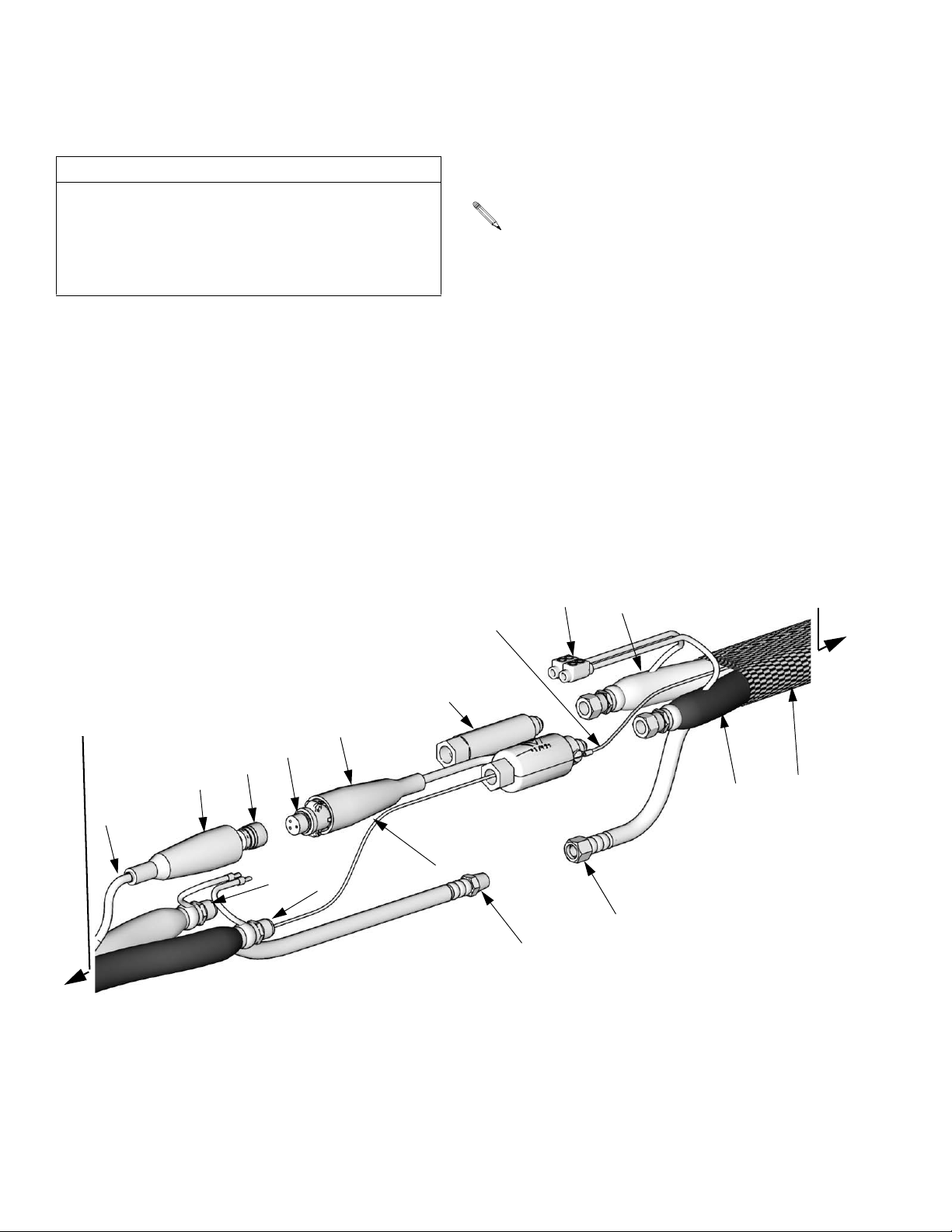

Connect FTS and Heated Dual Whip Hose

NOTICE

To prevent damage to probe, do not kink or

excessively bend hose. Do not coil hose

tighter than the minimum bend radius of 3 ft

(0.9 m). Do not subject hose to excessive

weight, impact, or other abuse.

1. Carefully extend FTS probe (H) into the

hose section from the proportioner. Do not

bend or kink probe. Insert in component A

(ISO) side of main hose for foam or polyurea systems.

2. Connect FTS (J) to whip hose (W).

3. Connect whip hose ground wire (K) to

ground screw on underside of FTS.

4. Connect fluid hoses to FTS (J).

To use 1/2 in. (13 mm) ID fluid hoses,

remove the adapters from the proportioner fluid manifold and install them in

the FTS swivel inlets.

5. Connect electrical connectors (D).

6. Connect air hose (C) to whip air hose (L).

7. Connect hose assembly cable (F) to FTS

cable (R). Slide insulator sleeves (S) over

connection. Leave slack (G) in cables as

stress relief, to prevent cable failure.

8. Check hoses for leaks (see your Heated

Hose manual).

D

K

B

To G u n

To Proportioner

R

F

S

G

B

FIG. 4: Connect FTS and Heated Dual Whip Hose

S

A

J

A

H

L

C

W

TI9581C

18 311511G

Page 19

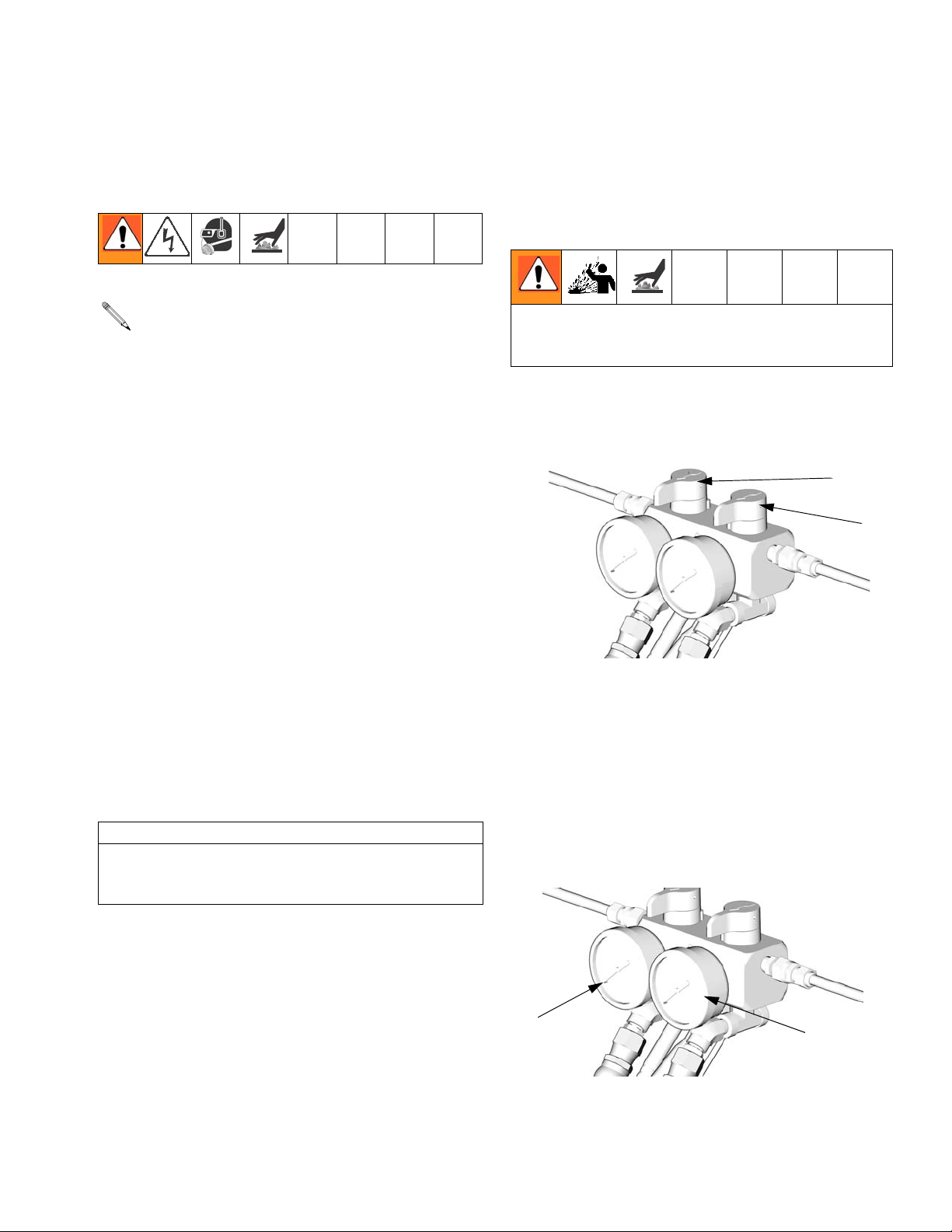

Setup

Recirculation / Pressure Relief Lines

Do not install shutoffs downstream of the PRESSURE

RELIEF/SPRAY valve outlets (BA, BB). The valves

function as over pressure relief valves when set to

SPRAY. Lines must be open so valves can

automatically relieve pressure when machine is

operating.

If circulating fluid back to the supply drums, use high

pressure hose rated to withstand the maximum

working pressure of this equipment.

If Recirculating to Supply Drum: Connect high

pressure hose (R) to relief fittings (BA, BB) of both

PRESSURE RELIEF/SPRAY valves. Route hose back

to component A and B drums. Refer to manual 309852.

Alternate recirculation hoses (requires adapter

fittings):

1. Turn main power OFF.

2. Assemble heated hose sections, FTS, and whip

hose; see manual 309572.

3. Connect A and B hoses to A and B outlets on

Reactor fluid manifold (FM). Hoses are color coded:

red for component A (ISO), blue for component B

(RES). Fittings are sized to prevent connection

errors.

FM

VV

WW

ti8444a

Manifold hose fittings (VV, WW) allow use of 1/4 in.

and 3/8 in. ID Reactor heated fluid hoses.

249508 - ISO (A) (moisture guard) red hose, 1/4 in. (6

mm) ID; #5 JIC fittings (m x f); 35 ft (10.7 m) long.

249509 - Resin (B) blue hose; 1/4 in. (6 mm) ID, #6 JIC

fittings (m x f), 35 ft (10.7 m) long.

R

BA

ti8441a

BB

R

Connect Heated Hose

See manual 309572 for detailed instructions for

Graco heated hoses.

The fluid temperature sensor (FTS) and whip hose

must be used with heated hose; see page 19. Hose

length, including whip hose, must be 60 ft (18.3 m)

minimum.

4. Connect cables (SS). Connect electrical connectors

(NN). Be sure cables have slack when hose bends.

Wrap cable and electrical connections with electrical

tape.

SS

NN

ti8444a

311511G 19

Page 20

Setup

Close Gun Fluid Manifold Valves A and B

ti2411a

Connect Whip Hose to Gun Fluid Manifold

Do not connect manifold to gun.

ti2417a

Pressure Check Hose

See hose manual. Pressure check for leaks. If no leaks,

wrap hose and electrical connections to protect from

damage.

20 311511G

Page 21

Initial Startup

Initial Startup

3. Turn both PRESSURE RELIEF/SPRAY valves (SA,

SB) to SPRAY.

Do not operate Reactor without all covers and shrouds

in place.

Fluid Temperature Sensor (FTS) Calibration

Calibrate the FTS ONLY at initial startup (the first

time the unit is operated) and any time the hose

length changes.

1. Before turning on the unit, ensure all hoses and

cables are properly connected. To ensure that the

FTS in the hose is at the same temperature as the

heaters, keep heat off and store the hose FTS near

the machine for several minutes.

2. While holding down the temperature unit button

(Fahrenheit - “F” or Celsius - “C”) turn the Reactor

main power ON.

3. Hold the temperature unit button until temperature is

shown on the display. The fluid temperature sensor

is now correctly calibrated.

SB

SA

ti8442a

4. Open both fluid valves (FV).

FV

ti8449a

5. Start feed pumps. Do not start proportioner air

motor or pumps.

Load Fluid with Feed Pumps

The Reactor is tested with oil at the factory. Flush

out the oil with a compatible solvent before

spraying; see page 13.

1. Check that Setup process is complete; see page 14.

2. Turn on component B agitator, if used.

311511G 21

Always provide two grounded waste containers to

keep component A and component B fluids separate.

6. Hold gun fluid manifold over two grounded waste

containers. Open fluid valves A and B until clean,

air-free fluid comes from valves. Close valves.

TI2484a

Page 22

Initial Startup

Digital Temperature Controllers

NOTICE

Do not turn power on to the hose heat until after all

hose power connectors are connected.

The proportioner has two temperature controllers that

automatically manage the temperature for the primary

heater and the hose heat.

NOTICE

To prevent damage to primary heaters and hoses, do

not turn on heat controller switches next to temperature controllers until purging procedures are complete

and heater and hoses are filled with chemical.

To change or enter the set point, proceed as follows:

1. Ensure red main disconnect switch is ON.

Temperature Controllers will illuminate.

Heat Output

Alarm Normal

Hose Only

A1

A2 A3

Controller Screens

Push the left side scroll button to cycle through the

following screens.

Home

“XXXX”

“_SP1”

“_SP2”

“Hxx.x”

“UNIT”

Current temperature

reading.

Set Point 1. Use arrow

keys to enter set point.

Set Point 2. Only shows

on Hose Controller.

High temperature deviation alarm. Leave set at

30°F (17°C).

This screen indicates

power output in percent.

Use the arrow keys to

select °F or °C.

2. Press and release Scroll button (A1). Display will

read “SP1”. Press and release Up (A2) or Down

(A3) button to display set point.

Do not change SP2; see Over Temperature Alarm

section.

Temperature controller normally displays actual

temperature. When illuminated, red “01” display at

upper left indicates controller is asking for heat. The

“01” disappears when liquid in heater or hose

reaches set point temperature. The “01” cycles on

and off to indicate temperature maintenance.

3. Press and hold Up (A2) or Down (A3) button to

increase or decrease value.

4. After set point is entered, press and release Up (A2)

and Down (A3) buttons together to display actual

temperature. Actual temperature will also display

after a time-out period.

5. To start heaters, turn green control power switch

from ON to START. Light within switch will

illuminate.

NOTICE

Controllers are factory programmed and are not field

programmable. If you encounter problems with a controller, order a replacement. Do not change any programmed parameters. Do not substitute with

controller from alternate supplier; its use may damage

equipment.The heater and hose controllers are not

interchangeable.

22 311511G

Page 23

Change Between Fahrenheit and Celsius

The temperature controller is factory-set to display in

Fahrenheit units.

To change to Celsius units:

1. Press and release Scroll button (A1) until Controller

displays “UNIT”.

2. Press and release Down button (A3) once to display

“F”.

3. Press and release Down button (A3) once again to

display “C”.

4. Press and release Scroll button (A1) twice.

Controller will display Celsius units.

To change back to Fahrenheit units:

1. Press and release Scroll button (A1) until Controller

displays “UNIT”.

Initial Startup

2. Press and release Down button (A3) once to display

“C”.

3. Press and release Down button (A3) once again to

display “F”.

4. Press and release Scroll button (A1) twice.

Controller will display Fahrenheit units.

311511G 23

Page 24

Initial Startup

Over Temperature Alarms

Both the fluid heater and the hose heat have over

temperature alarms that will turn off the heat zone if high

temperatures are detected. If this happens, the green

light in the switch for that heat zone will go out.

The fluid heater has a fixed temperature switch on the

aluminum heater that opens at 230 °F (110 °C) and

turns off the heat zone. The temperature switch will

automatically reset, but the heat zone will need to be

manually restarted. The over-temperature condition

should never happen unless the solid state relay

(165SSR) fails closed.

The hose heat uses the temperature controller alarm,

monitoring the hose thermocouple (FTS) to watch for

high temperature conditions. This alarm is controlled by

SP2 (Set Point 2) and is factory set for 30 °F (17 °C).

This means that the alarm set point is 30° (17 °C) over

the SP1 operating temperature set point. Under normal

conditions, the output 02 light will be lit on the hose

controller. This output holds the hose heat power

contact ON and lights the green light in the switch any

time power is available to heat the hose. If the hose

temperature reading is 30 °F (17 °C) (SP2 setting) over

the temperature set point (SP1), the output 02 light and

switch light will go out. Hose heat will only return after a

manual START of the control switch, after alarm

conditions are gone.

Hose Heat Manual Mode

If the hose temperature controller does not see the Fluid

Temperature Sensor (FTS), it will shut off the hose heat

and give a flashing error alternating between:

SbEr = Sensor break error

H20.0 = Heat output 20%

The hose can be manually heated by turning the hose

back on with the hose switch and green light. The

up/down arrows can be used to adjust the default 20%

power output.

There is no monitoring or alarm in manual mode. You

must monitor the temperature by inserting a probe

thermometer inside the hose insulation against the

hose. The thermometer will read 10-20 °F less than

actual fluid temperature. Repair the temperature sensor

or cable as soon as possible to avoid damaging the

heated hose.

The hose heat deviation alarm is controlled by the SP2

setpoint. This is factory set to 30 °F (17 °C) and should

not be changed. A loss of alarm function and loss of

automatic over temperature shut-down could result.

Fluid Heater Temperature Offset

The fluid heater has been calibrated to provide setpoint

temperature fluid under flow conditions. When the

machine is powered up and no heat has been turned on,

the heater display will read somewhat lower than the

hose display. This is normal. The hose display has no

offset and will always read the actual temperature at the

sensor in the hose.

24 311511G

Page 25

Initial Startup

Supply Wet-Cups with Throat Seal Liquid

Pump rod and connecting rod move during operation.

Moving parts can cause serious injury such as

pinching or amputation. Keep hands and fingers away

from wet-cup during operation. Turn main power OFF

before filling wet-cup.

1. Component A (ISO) Pump: Keep reservoir (Z) 3/4

filled with TSL. Wet-cup piston circulates TSL

through wet-cup to carry away isocyanate film on

displacement rod. Change the fluid in the reservoir

when it becomes milky-looking.

2. Component B (Resin) Pump: Check felt washers

in packing nut/wet-cup (AK) daily. Keep saturated

with TSL to prevent material from hardening on

displacement rod. Replace felt washers when worn

or contaminated with hardened material.

AK

ti8448a

ti8610a

Z

311511G 25

Page 26

Spraying Setup

Spraying Setup

1. After reaching spray temperatures, engage gun

piston safety lock.

ti2409a

2. Close gun fluid manifold valves A and B.

ti2728a

5. Open air inlet ball valve (DD).

S

DD

ti8449a

6. Turn both air regulators (AU, AS, page 12)

counterclockwise to 0 pressure.

7. Turn RUN/PARK switch to RUN.

8. Turn Pump Mode Function knob to START.

9. Slowly increase each UP/DN air regulator setting by

alternating pattern 5-10 psi (0.035-0.07 MPa,

0.35-0.7 bar) at a time until the approximate stall

(static) pressure is achieved on fluid gauges (GA)

and (GB). Leave UP stroke regulator setting at

approximately 10 psi (0.07MPa, 0.7 bar) lower than

DN stroke.

3. Attach gun fluid manifold. Connect gun air line.

Open air line valve.

ti2543a

4. Set PRESSURE RELIEF/SPRAY valves (SA, SB) to

SPRAY.

SB

SA

ti8442a

GA

ti8441a

10. Open gun fluid manifold valves A and B.

ti2414a

GB

26 311511G

Page 27

Spraying Setup

11. Disengage gun piston safety lock.

ti2410a

12. Test spray onto cardboard. Adjust for desired fluid

pressure on the DN stroke with regulator (AS).

Briefly spray until the UP stroke indicator light is on

and increase the UP regulator setting until the fluid

pressure (GA, GB) matches the DN stroke pressure.

This compensates for feed pump pressure boost.

Pumps have fluid to air ratio of 17.5 to 1. Feed

pumps add 2X feed pressure boost to outlet

pressure (on the up stroke only).

13. Check A and B fluid pressure gauges (GA, GB) to

ensure proper pressure balance between A and B. If

imbalanced, see repair manual 311512.

Spray Adjustments

Flow rate, atomization, and amount of overspray are

affected by four variables.

• Fluid pressure setting. Too little pressure results in

an uneven pattern, coarse droplet size, low flow,

and poor mixing. Too much pressure results in

excessive overspray, high flow rates, difficult control,

and excessive wear.

• Fluid temperature. Effects are similar to when fluid

pressure setting is too high or too low.

• Mix chamber size. Choice of mix chamber is based

on desired flow rate within machine capability and

fluid viscosity.

• Cleanoff air adjustment. Too little cleanoff air

results in droplets building up on the front of the

nozzle, and no pattern containment to control overspray. Too much cleanoff air results in air-assisted

atomization and excessive overspray.

14. Equipment is ready to spray.

311511G 27

Page 28

Shutdown

Shutdown

1. Shut off Primary and Hose heat switches.

34!24

/.

/&&

2. Park component A pump. Turn PARK/RUN switch to

PA RK .

7. Check and fill wet-cups (AK, Z).

8. Follow gun shutdown procedure.

3. Follow Pressure Relief procedure; see page 13.

4. Turn Pump Mode Function knob to OFF.

34!24

/.

/&&

5. Turn Main Power Disconnect switch (R) OFF.

6. Close air inlet ball valve (DD) and fluid inlet valves

(X, U).

28 311511G

Page 29

Operation

Operation

Daily Start-up Procedure

The daily start-up procedures describe normal

operation. Assume that all temperature and

pressure settings have been previously set, but that

the heating system is not up to operating

temperature.

1. Check condition isocyanate lubrication system and

service as required. Change pump lubricant when it

shows signs of change to a milky color.

2. Ensure supply fluid is at correct temperature as

recommended by chemical system supplier. Ensure

individual chemicals are correctly agitated within

their drums/day tanks, and moisture protection

system is properly set for operation. Recirculate

heated fluid back to supply drums if necessary; see

page 31.

3. Turn on main air supply to transfer pumps.

11. Turn on primary heater switch past ON to START.

Ensure heater setpoint is correct. Wait for operating

temperature to be reached.

To prevent excessive pressure build-up in heated

hoses, always bring hoses and primary heater up to

operating temperature before turning on pump switch.

12. Set PRESSURE RELIEF/SPRAY valves (SA, SB) to

SPRAY.

SA

SB

ti8442a

4. Pressurize transfer pumps and open A- and B-inlet

supply valves.

5. Open air inlet ball valve.

6. Switch ON main power disconnect switch.

7. Uncoil heated hose.

NOTICE

Uncoil heated hoses before turning on hose heater

switch to prevent overheating and hot spots within

hose.

8. Check that hose setpoint temperature is correct.

9. Turn hose heat control switch past ON to START.

Switch will illuminate.

10. The hose power controller automatically adjusts the

hose current to the hose to compensate for hose

length and ambient temperature. Wait for actual

hose temperature readout to match hose setpoint

temperature.

13. Turn PARK/RUN switch to RUN.

14. Turn Pump Mode Function switch to ON and

momentarily to START. Pumps will pressurize the

fluid according to air regulator pressure.

15. Check A and B fluid pressure gauges (GA, GB) to

ensure proper pressure balance between A and B. If

imbalanced, bleed off the high side with valves SA

and SB until balanced.

GA

ti8442a

GB

311511G 29

Page 30

Operation

16. Open gun fluid manifold valves A and B.

ti2414A

17. Disengage gun piston safety lock.

ti2410A

18. Test spray onto cardboard.

19. Observe isocyanate-A and resin-B gauges on up

and down strokes. Readjust upstroke pressure

regulator as required to ensure proportioning pump

pressure is equal on both the up and down strokes.

20. Equipment is ready to spray.

30 311511G

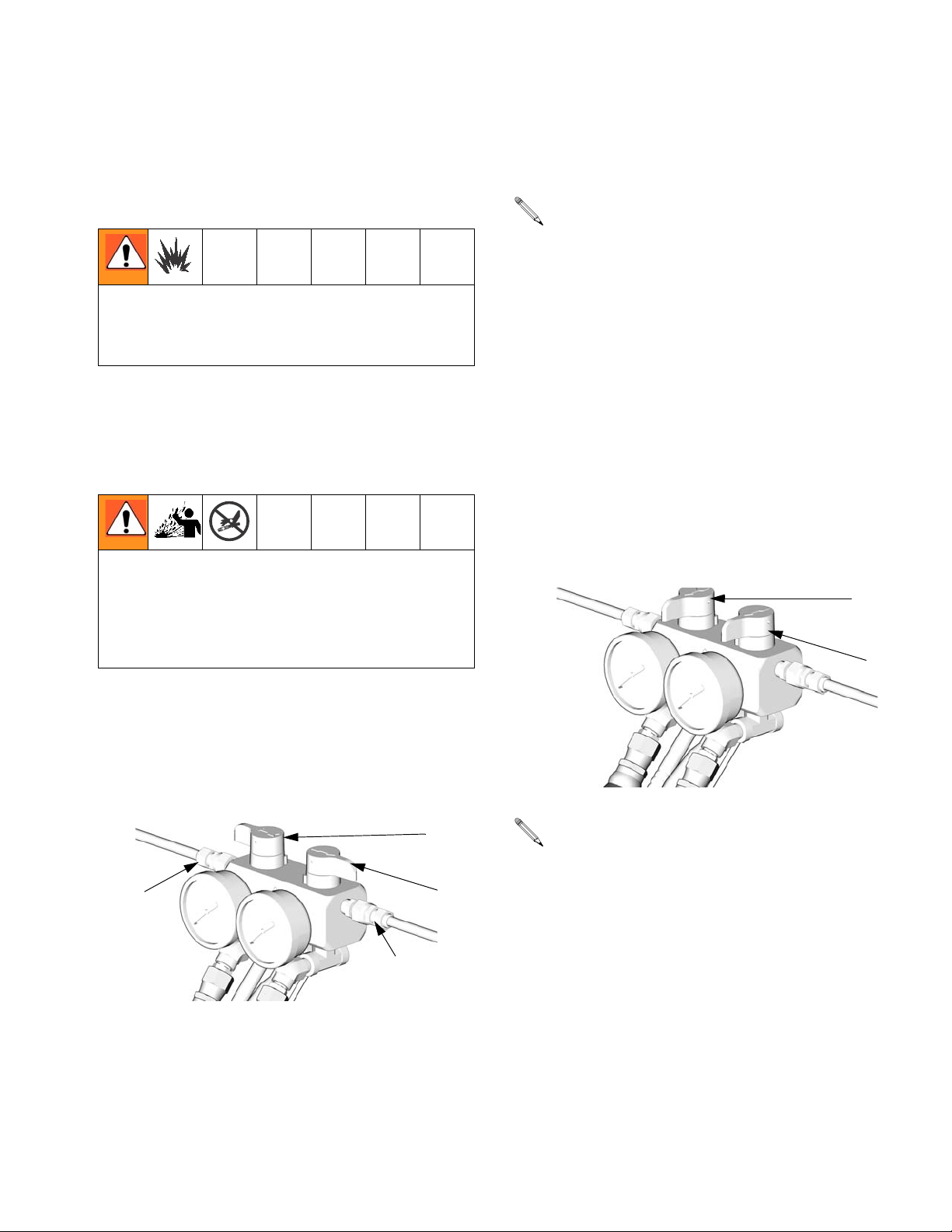

Page 31

Fluid Circulation

Fluid Circulation

Circulation Through Reactor

Read Warnings; see page 4. Do not circulate fluid

containing a blowing agent without consulting with

your material supplier regarding fluid temperature

limits.

To circulate through gun manifold and preheat hose; see

page 32.

1. Load fluid with feed pumps; see page 21.

Do not install shutoffs downstream of the PRESSURE

RELIEF/SPRAY valve outlets (BA, BB). The valves

function as overpressure relief valves when set to

SPRAY. Lines must be open so valves can

automatically relive pressure when machine is

operating.

2. Route circulation lines back to respective

component A or B supply drum. Use hoses rated at

the maximum working pressure of this equipment,

see hose manual.

Do not turn on hose heat unless hoses are already

loaded with fluid.

7. Set both Air Regulator pressures to start at 15 psi

(1.0 bar).

8. Turn PARK/RUN switch to RUN.

9. Turn Pump Mode Function switch to START.

10. Recirculate until desired temperature reaches set

point.

11. Turn Pump Mode Function knob to OFF.

12. Turn on hose heat if hose is filled with fluid without

air pockets or solvent.

13. Set PRESSURE RELIEF/SPRAY valves (SA, SB) to

SPRAY.

SA

SB

ti8442a

3. Set RECIRC/SPRAY valves (SA, SB) to RECIRC.

SA

BA

BB

ti8442a

4. Turn Main Disconnect Switch (R) ON.

5. Open air inlet ball valve.

6. Set temperature targets; see page 22. Turn on

heater.

311511G 31

SB

For additional circulation information, refer to

manual 309852.

Page 32

Fluid Circulation

Circulation Through Gun Manifold

Read Warnings; see page 4. Do not circulate fluid

containing a blowing agent without consulting with

your material supplier regarding fluid temperature

limits.

Circulating fluid through the gun manifold allows rapid

preheating of hose.

1. Install gun fluid manifold (FM) on Part 246362

accessory circulation kit (CK).

2. Connect high pressure circulation lines (N) to

circulation manifold (CK). Route circulation lines

back to respective component A or B supply drum.

Use hoses rated at the maximum working pressure

of this equipment.

3. Follow Load Fluid with Feed Pumps procedure; see

page 21.

4. Turn Main Power Disconnect Switch (R) ON.

5. Open air inlet ball valve.

6. Set temperature targets; see page 22. Turn on

heater.

Do not turn on hose heat unless hoses are already

loaded with fluid.

7. Set both Air Regulator pressures to start at 15 psi

(1.0 bar).

8. Turn PARK/RUN switch to RUN.

FM

CK

9. Turn Pump Mode Function switch to START.

10. Recirculate until desired temperature reaches set

N

ti2767a

point.

11. Turn Pump Mode Function switch to OFF.

12. Close gun fluid manifold valves.

13. Reconnect gun to fluid manifold and air hose.

For additional recirculation information, refer to

manual 309818.

32 311511G

Page 33

Maintenance

• Check and add TSL to B side pump wet-cup daily.

• Check ISO lube bottle for significant discoloration or

crystallization daily. Replace with fresh TSL when

needed.

• Ensure ISO (A) pump is down and in PARK position

during every shutdown.

• Keep any ISO (A) fluid from being exposed to atmosphere to prevent crystallization.

• Remove inlet filter screen plug (V, Y) and clean

screens if increased unbalanced pressures between

A and B is noticed or as needed for fluids used. Also

clean after flushing.

• Close gun fluid shutoff valves when not in use.

• If using a Fusion Air Purge gun, add grease with

grease gun per manual.

Fluid Circulation

• Clean gun filter screens and mix chamber ports regularly, or when increased unbalanced pressures

between A and B is noticed. See gun manual.

• Use lithium grease or Iso Pump Oil on all threaded

fluid fittings on the “A” side.

311511G 33

Page 34

Technical Data

Technical Data

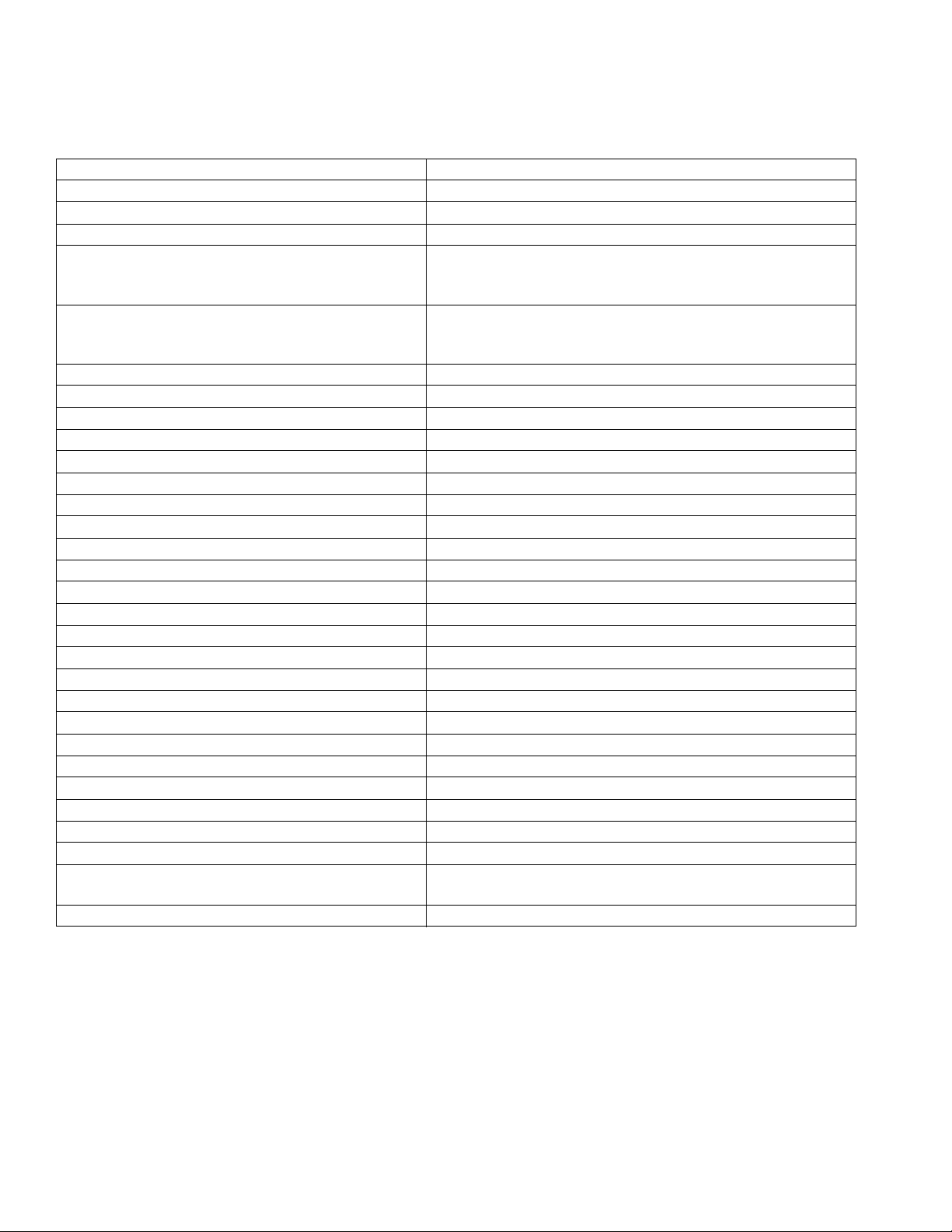

Category Data

Maximum Fluid Working Pressure 2000 psi (1.4 MPa, 140 bar)

Maximum Air Working Pressure 120 psi (0.84 MPa, 8.4 bar)

Machine Maximum Power with hose 9000 Watts

Voltage Requirement (50/60 Hz)

(230 V Nominal: 195-253 VAC)

(380 V Nominal: 338-457 VAC)

Amperage Requirement (Full Load Peak)* 40 amps @ 230 V, 1 Phase

Maximum Heater Fluid Temperature 190 °F (88 °C)

Maximum Hose Fluid Temperature 180 °F (82 °C)

Maximum Ambient Temperature 120 °F (49 °C)

Maximum Output 20 lb/min. (9.0 kg/min.)

Output Per Cycle (A and B) .028 gal/cycle (.105 ltr/cycle)

Overpressure Relief Shutdown 2250 psi (15.5 MPa, 155 bar)

Over Temperature Shutdown (Primary Heater) 230 °F (110 °C)

Heater Power 6000 Watts

Hose Power 2790 Watts

Sound Pressure 86.3 dB(A) at 2000 psi (14 MPa, 140 bar), 0.5 gpm (1.9 lpm)

Sound Power, per ISO 9614-2 91.6 dB(A) at 2000 psi (14 MPa, 140 bar), 0.5 gpm (1.9 lpm)

Viscosity Range 250-1500 centipoise

Maximum Fluid Inlet Pressure 400 psi (2.7 MPa, 27 bar)

Fluid Inlet/Strainer Filter 20 mesh standard

Air inlet Filter Mesh 5 Micron

Component B (Resin) Inlet 3/4 npt(f) swivel

Component A (Isocyanate) Inlet 1/2 npt(f) swivel

Recirculation/Block Hose Connections Iso (A) side: #5 JIC (m); Resin (B) side: #6 JIC (m)

Maximum Heated Hose Length*** 210 ft of 3/8 ID

Height 39.5 in. (1003.3 cm)

Width 27.2 in. (690.9 cm)

Depth 25.0 in. (635 cm)

Weight 250 lb (117.6 kg)

Wetted Parts Carbon steel, stainless steel, chrome, aluminum,

Certification CE **

230 V, 1 Phase

230 V, 3 Phase (Delta)

380 V, 3 Phase (WYE 220 V Neutral)

32 amps @ 230 V, 3 Phase

18.5 amps @ 380 V, 3 Phase

Fluoroelastomer, PTFE, nylon

*Full load amps with all devices operating at maximum

capabilities with 210 ft (64.1 m) of hose.

**When a surge transient is applied to the power lines of the unit, heat to the hose may be interrupted and require the

hose heat switch to be manually cycled.

***210 ft (64 m) of heated hose will produce the maximum allowable heat capacity. 310 ft (94 m) of heated hose may

be used, but will have 25% less heat capacity.

34 311511G

Page 35

Technical Data

311511G 35

Page 36

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 311511

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2006, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 01/2011

Loading...

Loading...