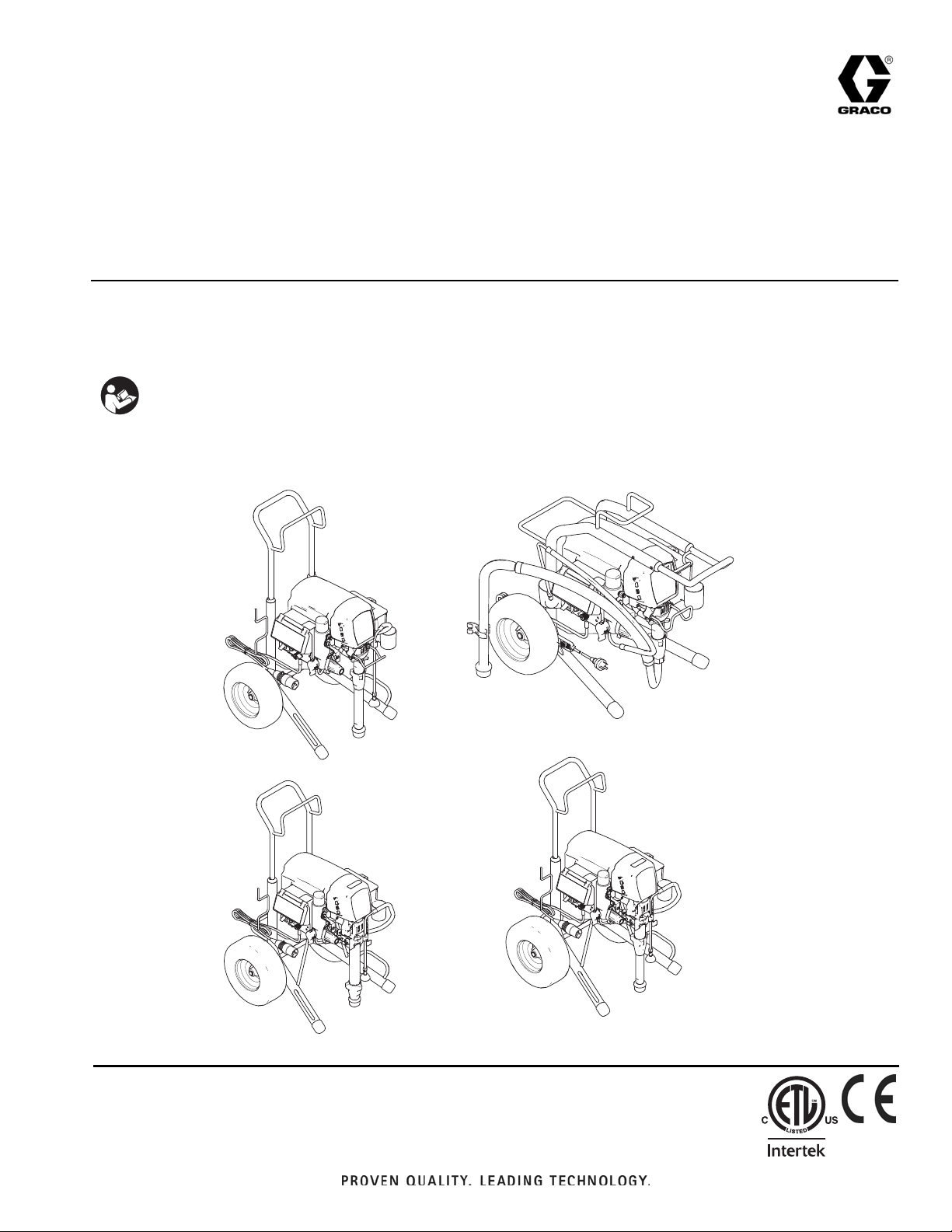

Page 1

Repair

®

Ultra

- For Portable Airless Spraying of Architectural Coatings and Paints. For professional use only.

Not for use in explosive atmospheres.-

3300 psi (22.8 MPa, 227 bar) Maximum Working Pressure

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and instructions in this

manual. Save these instructions.

See page 3 for model information, including maximum working pressure and approvals.

Korean patent 10-0579681

Max II/Ultimate Mx II

ti13459a

311365J

EN

ti13450a

ti13461a

695/795 LOW

695/795 HI

ti13460a

1095/1595 HI

MARK V

Page 2

Table of Contents

Table of Contents ............................2

Models ....................................3

Warnings .................................. 5

Component Identification and Function ........... 8

General Repair Information .................... 9

Pressure Relief Procedure .................9

Grounding ................................10

Troubleshooting ............................11

Mechanical/Fluid Flow ....................11

Electrical ..............................13

Pressure Control Board ......................20

100 - 120 Vac North American and

Japan/Taiwan Motor Control Board ..........20

240 Vac Motor Control Board ..............23

240 Vac Filter Board .....................25

110 Vac U.K. Motor Control Board .......... 26

110 Vac U.K. Filter Board ................. 28

Pressure Adjust Potentiometer .............30

Pressure Control Transducer ...............31

Notes .................................... 33

Drive and Bearing Housing Replacement ........34

Disassembly ...........................34

Assembly .............................. 34

Motor Replacement .........................36

Removal .............................. 36

Installation ............................. 36

Displacement Pump Replacement for 695/795 ....38

Removal .............................. 38

Installation ............................. 39

Displacement Pump Replacement

1095/1595/Mark V ..........................40

Removal .............................. 40

Installation ............................. 41

Wiring Diagram ............................43

Wiring Diagram ............................44

Wiring Diagram ............................45

Wiring Diagram ............................46

Notes .................................... 47

Graco Standard Warranty ....................48

Table of Contents

2 311365J

Page 3

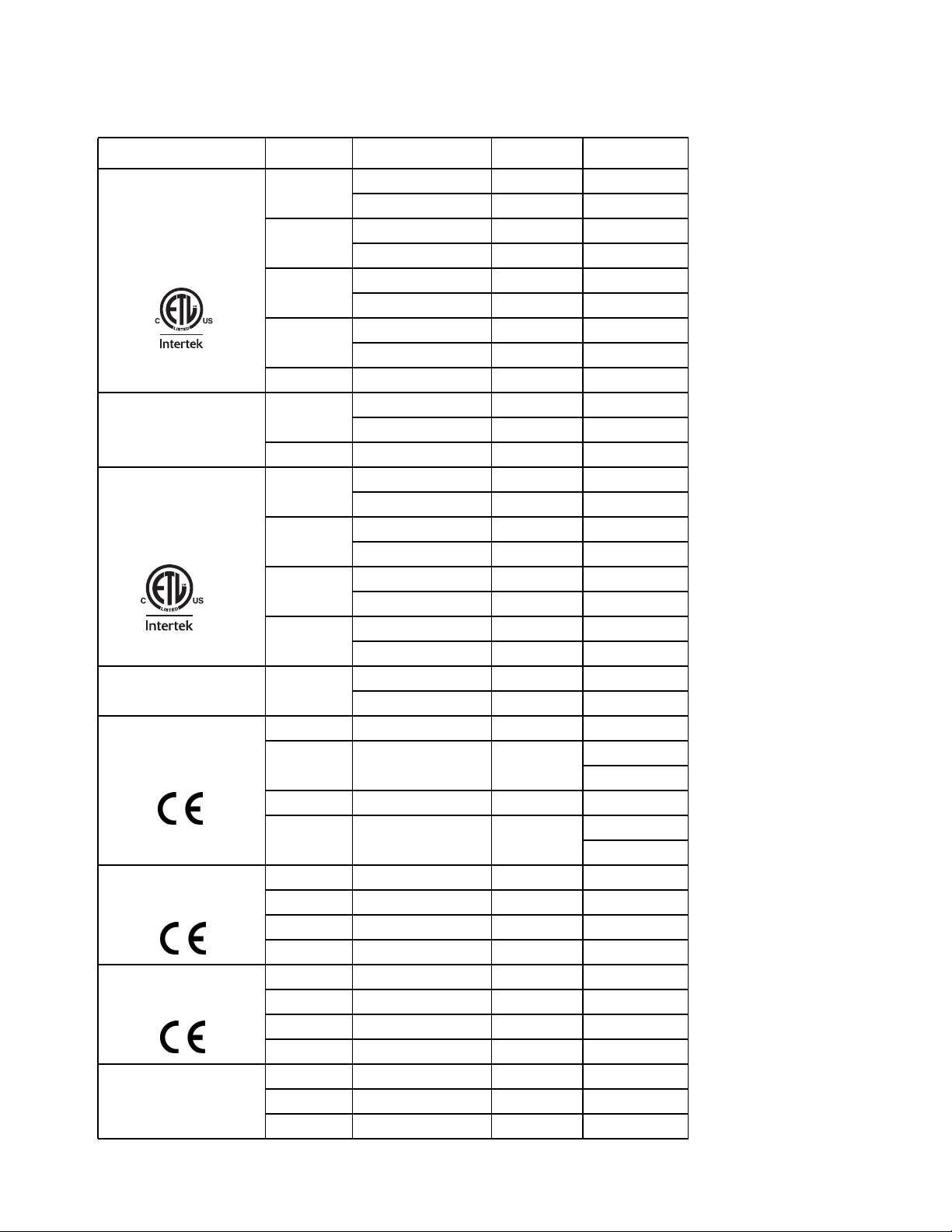

Models

Vac Model Type Lo-Boy Hi-Boy

120

North America

120

North America

Ultimate Mx II

Ultimate Mx II

240

Europe

240

Europe Multi-cord

110

UK

240

Asia

695 Standard 255130 249642

Premium 255131 249644

795 Standard 255132 249646

Premium 255133 249648

1095 Standard 249651

Premium 249653

1595 Standard 253060

Premium 253059

Mark V 249904

1595 Standard 249658**

Premium 249659**

Mark V 249903**

695 Standard 826093 826067

Premium 826094 826069

795 Standard 826071

Premium 826072

1095 Standard 826073

Premium 826074

1595 Standard 826082

Premium 826081

1595 Standard 826075

Premium 826076

695 255134 249663

249666

795

256165

1095 249667

249905

Mark V

256166

695 255135 249668

795 249671

1095 249672

Mark V* 249907

695 249673

795 249674

1095 249675

Mark V 249906

695 255138 249681

795 249683

1095 249684

Models

*Also for Asia and Australia;

**Not ETL Approved

All models not available in all

countries.

311365J 3

Page 4

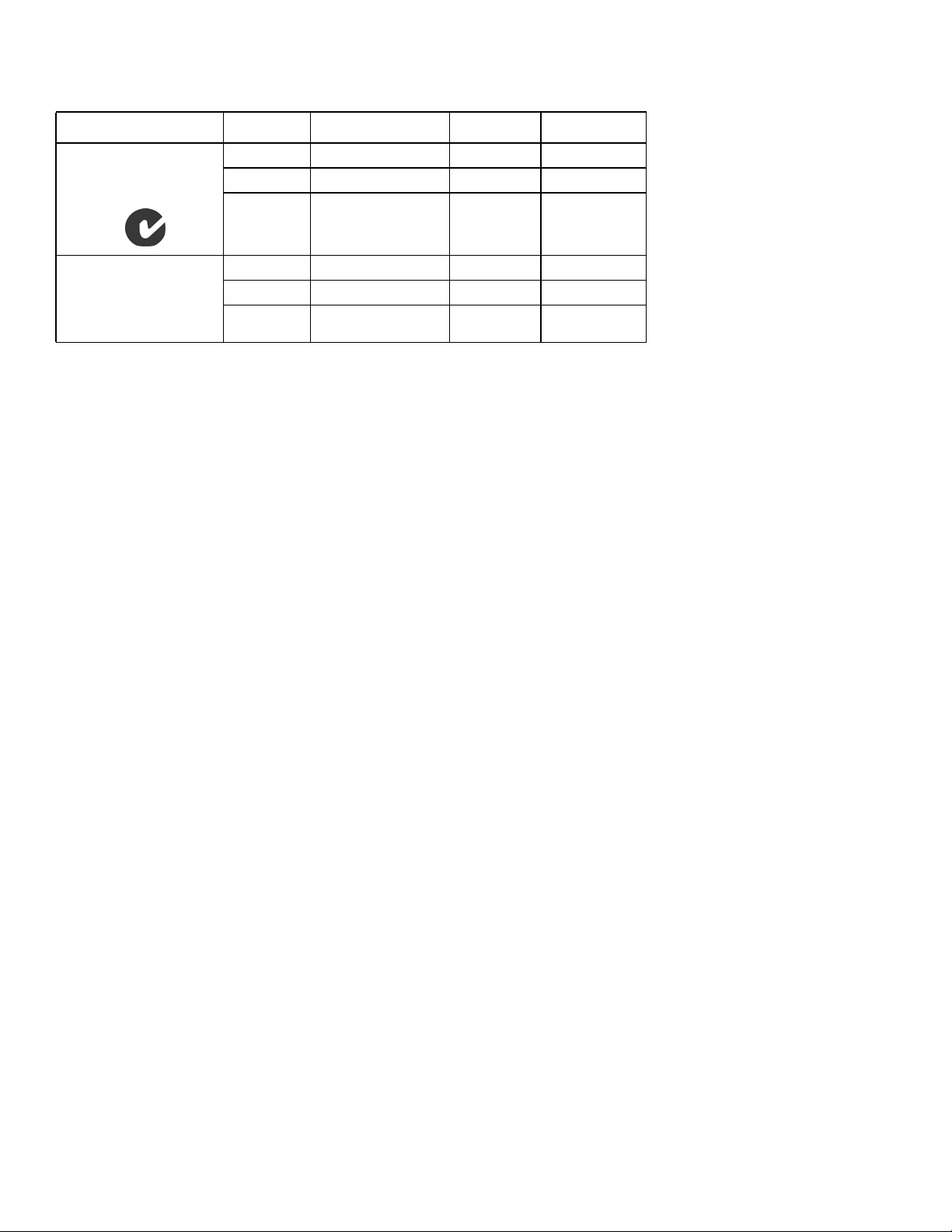

Vac Model Type Lo-Boy Hi-Boy

Models

240

Australia

100

Japan & Taiwan

695 255139 249685

795 255140 249687

1095 249688

695 255136 249676

795 255137 249678

1095 249680

4 311365J

Page 5

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risks. Refer back to

these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

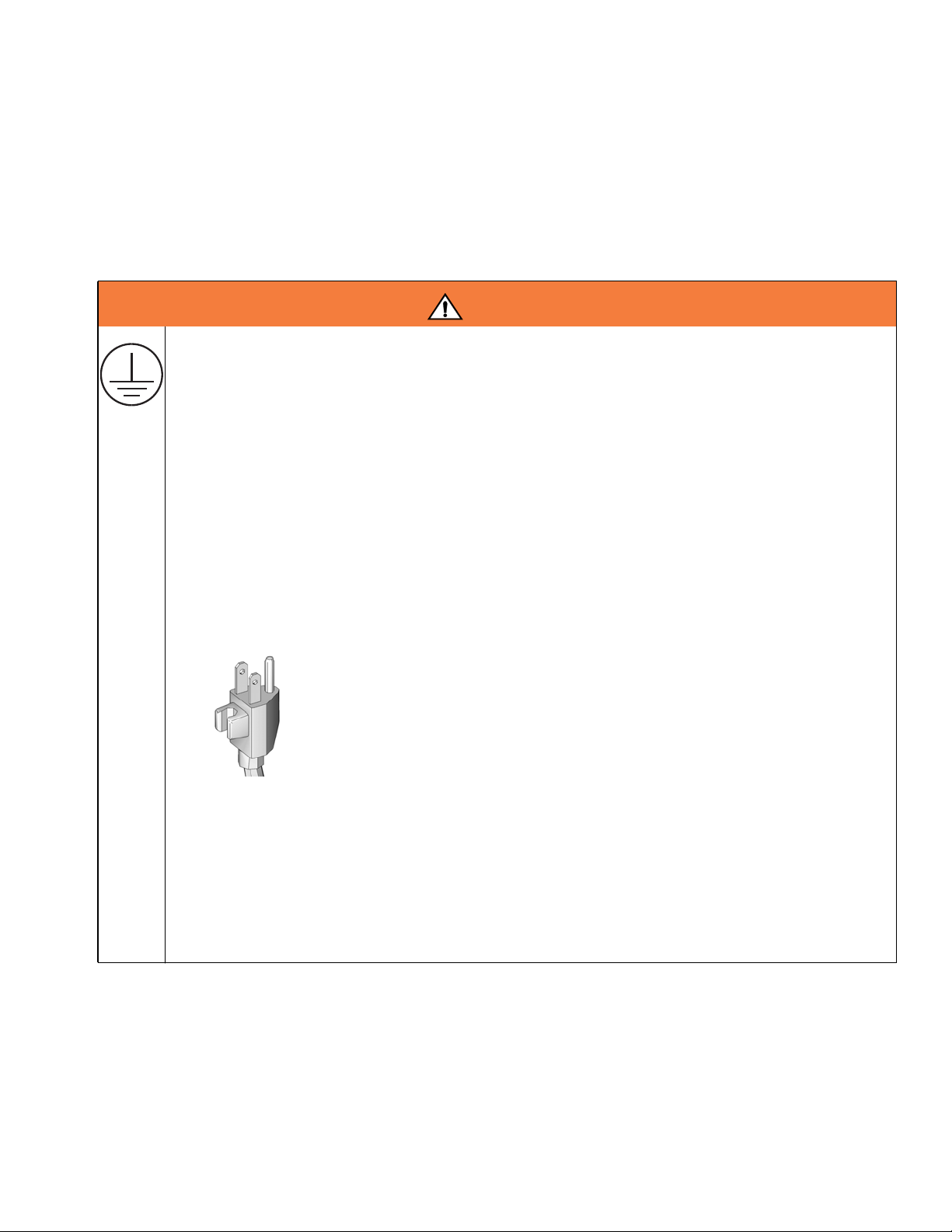

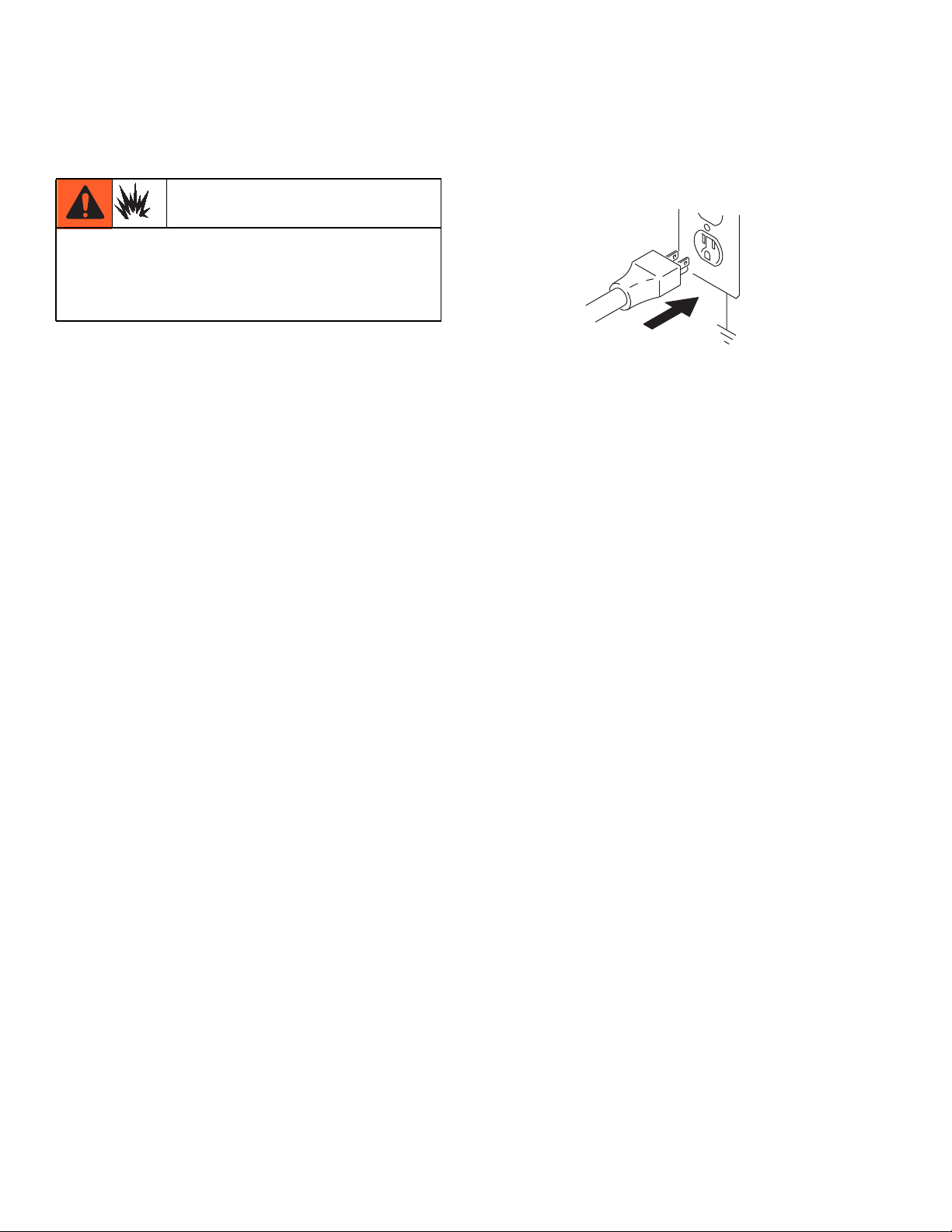

WARNING

GROUNDING

This product must be grounded. In the event of an electrical short circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current. This product is equipped with a cord

having a grounding wire with an appropriate grounding plug. The plug must be plugged into an outlet

that is properly installed and grounded in accordance with all local codes and ordinances.

• Improper installation of the grounding plug is able to result in a risk of electric shock.

• When repair or replacement of the cord or plug is required, do not connect the grounding wire to

either flat blade terminal.

• The wire with insulation having an outer surface that is green with or without yellow stripes is the

grounding wire.

• Check with a qualified electrician or serviceman when the grounding instructions are not completely

understood, or when in doubt as to whether the product is properly grounded.

• Do not modify the plug provided; if it does not fit the outlet, have the proper outlet installed by a qualified electrician.

• This product is for use on a nominal 120V circuit and has a grounding plug similar to the plug illustrated in the figure below.

ti9164a

• Only connect the product to an outlet having the same configuration as the plug.

• Do not use an adapter with this product.

Extension Cords:

• Use only a 3-wire extension cord that has a 3-blade grounding plug and a 3-slot receptacle that

accepts the plug on the product.

• Make sure your extension cord is not damaged. If an extension cord is necessary, use 12 AWG

(2.5 mm2) minimum to carry the current that the product draws.

• An undersized cord results in a drop in line voltage and loss of power and overheating.

311365J 5

Page 6

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Do not spray flammable or combustible materials near an open flame or sources of ignition such as

cigarettes, motors, and electrical equipment.

• Paint or solvent flowing through the equipment is able to result in static electricity. Static electricity

creates a risk of fire or explosion in the presence of paint or solvent fumes. All parts of the spray system, including the pump, hose assembly, spray gun, and objects in and around the spray area shall

be properly grounded to protect against static discharge and sparks. Use Graco conductive or

grounded high-pressure airless paint sprayer hoses.

• Verify that all containers and collection systems are grounded to prevent static discharge.

• Connect to a grounded outlet and use grounded extensions cords. Do not use a 3-to-2 adapter.

• Do not use a paint or a solvent containing halogenated hydrocarbons.

• Keep spray area well-ventilated. Keep a good supply of fresh air moving through the area. Keep

pump assembly in a well ventilated area. Do not spray pump assembly.

• Do not smoke in the spray area.

• Do not operate light switches, engines, or similar spark producing products in the spray area.

• Keep area clean and free of paint or solvent containers, rags, and other flammable materials.

• Know the contents of the paints and solvents being sprayed. Read all Material Safety Data Sheets

(MSDS) and container labels provided with the paints and solvents. Follow the paint and solvents

manufacturer’s safety instructions.

• Fire extinguisher equipment shall be present and working.

• Sprayer generates sparks. When flammable liquid is used in or near the sprayer or for flushing or

cleaning, keep sprayer at least 20 feet (6 m) away from explosive vapors.

SKIN INJECTION HAZARD

• Do not aim the gun at, or spray any person or animal.

• Keep hands and other body parts away from the discharge. For example, do not try to stop leaks

with any part of the body.

• Always use the nozzle tip guard. Do not spray without nozzle tip guard in place.

• Use Graco nozzle tips.

• Use caution when cleaning and changing nozzle tips. in the case where the nozzle tip clogs while

spraying, follow the Pressure Relief Procedure for turning off the unit and relieving the pressure

before removing the nozzle tip to clean.

• Do not leave the unit energized or under pressure while unattended. When the unit is not in use, turn

off the unit and follow the Pressure Relief Procedure for turning off the unit.

• High-pressure spray is able to inject toxins into the body and cause serious bodily injury. In the event

that injection occurs, get immediate surgical treatment.

• Check hoses and parts for signs of damage. Replace any damaged hoses or parts.

• This system is capable of producing 3300 psi. Use Graco replacement parts or accessories that are

rated a minimum of 3300 psi.

• Always engage the trigger lock when not spraying. Verify the trigger lock is functioning properly.

• Verify that all connections are secure before operating the unit.

• Know how to stop the unit and bleed pressure quickly. Be thoroughly familiar with the controls.

6 311365J

Page 7

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Always wear appropriate gloves, eye protection, and a respirator or mask when painting.

• Do not operate or spray near children. Keep children away from equipment at all times.

• Do not overreach or stand on an unstable support. Keep effective footing and balance at all times.

• Stay alert and watch what you are doing.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not kink or over-bend the hose.

• Do not expose the hose to temperatures or to pressures in excess of those specified by Graco.

• Do not use the hose as a strength member to pull or lift the equipment.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power cord before servicing equipment.

• Use only grounded electrical outlets.

• Use only 3-wire extension cords.

• Ensure ground prongs are intact on sprayer and extension cords.

• Do not expose to rain. Store indoors.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1, 1, 1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eye wear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

• Gloves

• Hearing protection

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects or

other reproductive harm. Wash hands after handling.

311365J 7

Page 8

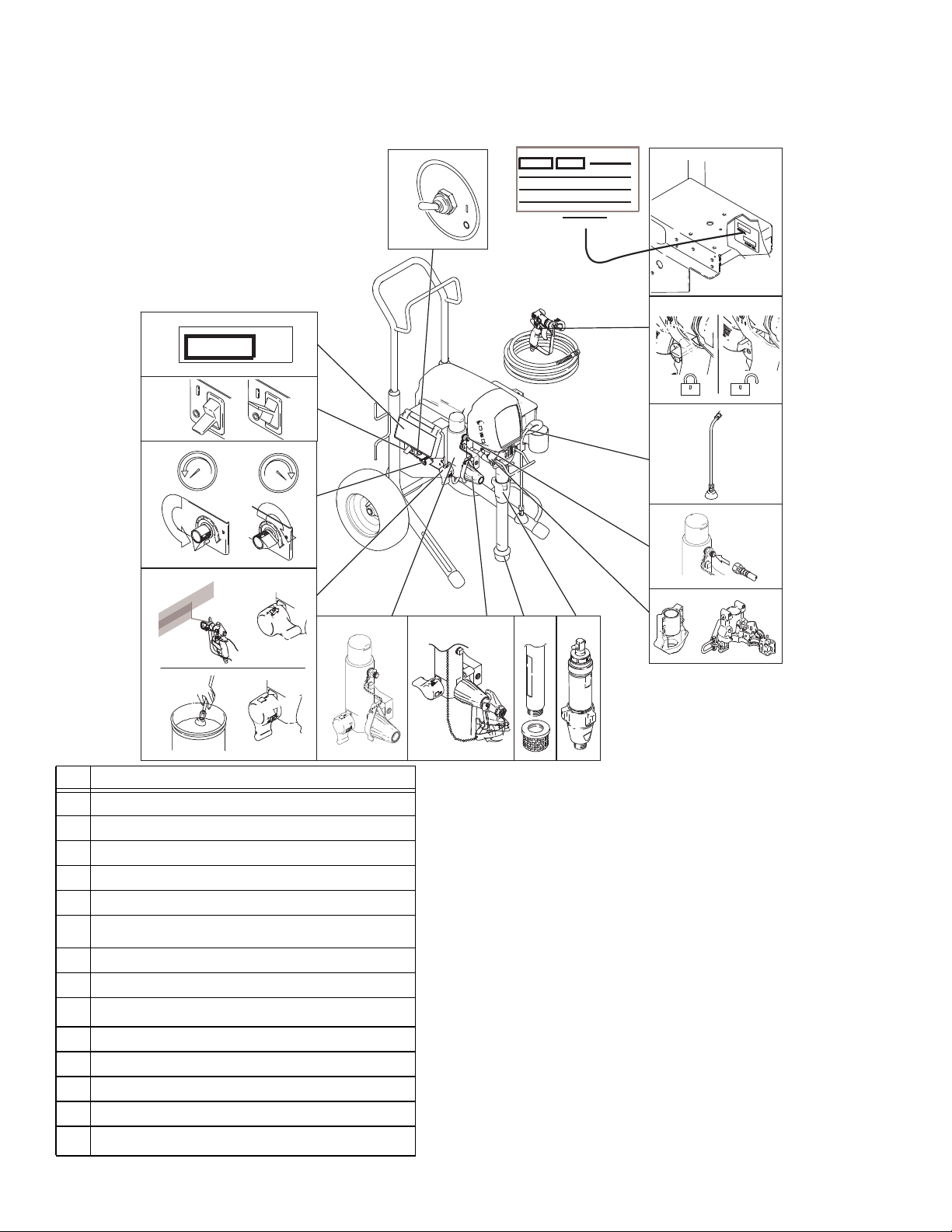

Component Identification and Function

Component Identification and Function

13.14.

1.

2.

3.

4.

12.

11.

10.

9.

5. 6. 7. 8.

ti13451a

English

1 Premium Digital Display

2 ON/OFF switch

3 Pressure control

4 Prime / Spray valve

5 Filter

6

AutoClean

™

2

7 Siphon tube

8 Pump

9

Bearing Housing / ProConnect

™

10 Fluid Outlet

11 Drain tube

12 Trigger Lock

13 Model/serial tag

14

WatchDog

8 311365J

™

Switch (not Mark V)

Page 9

General Repair Information

Pressure Relief Procedure

General Repair Information

NOTICE

To reduce risk of pressure control malfunction:

System pressure must be manually relieved to prevent system from starting or spraying accidentally.

Fluid under high pressure can be injected through

skin and cause serious injury. To reduce risk of injury from injection, splashing fluid, or moving parts,

follow Pressure Relief Procedure whenever you:

• are instructed to relieve pressure

• stop spraying

• check or service any system equipment

• install or clean spray tip

1. Turn pressure control knob to zero.

2. Turn ON/OFF switch to OFF.

3. Unplug power supply cord.

4. Hold metal part of gun firmly to grounded metal

pail. Trigger gun to relieve pressure.

5. Lock gun safety latch.

6. Open prime valve. Leave pr ime valve open

until ready to spray again.

NOTE: If suspected that spray tip or hose is completely clogged, or that pressure has not been fully

relieved after following steps above, VERY SLOWLY loosen tip guard retaining nut or hose end coupling to relieve pressure gradually, then loosen

completely. Then clear tip or hose obstruction.

• Use needle-nose pliers to disconnect wire.

Never pull on wire, pull on connector.

• Mate wire connectors properly. Center flat

blade of insulated male connector in

female connector.

• Route wires carefully to avoid interference

with other connections of pressure control.

Do not pinch wires between cover and

control box.

1. Keep all screws, nuts, washers, gaskets, and

electrical fittings removed during repair

procedures. These parts are not normally

provided with replacement assemblies.

To reduce risk of serious injury, including electric

shock, do not touch moving or electrical parts with

fingers or tools while testing repair. Shut off and unplug sprayer when inspection is complete. Install all

covers, guards, gaskets, screws, washers and

shroud before operating sprayer.

2. Test repair after problem is corrected.

3. If sprayer does not operate properly, review

repair procedure to verify procedure was done

correctly. If necessary, see Troubleshooting,

page 11, for other possible solutions.

311365J 9

Page 10

Grounding

Improper installation or alteration of grounding

plug results in risk of electric shock, fire or

explosion that could cause serious injury or

death.

1. Ultra Max II 695, 795 and 1095 100-200 Vac

models require a 50/60 Hz, 15A circuit with a

grounding receptacle. Ultra Max II 1595/Mark V

120 Vac models require a 50/60 Hz 20A circuit

with a grounding receptacle; 220-240 Vac

models require a 50/60 Hz, 10A circuit with a

grounding receptacle.

Grounding

2. Do not alter ground prong or use adapter.

ti2810a

3. 120 Vac: A 12 AWG, 3 wires with grounding

prong, 300 ft (90 m) extension cord may be

used. 220-240 Vac: You may use a 3-wire, 1.0

mm (12 AWG) (minimum) extension cord up to

90 m long. Long lengths reduce sprayer

performance.

10 311365J

Page 11

Troubleshooting

Mechanical/Fluid Flow

Relieve pressure; page 9.

Troubleshooting

WHAT TO CHECK

TYPE OF PROBLEM

E=XX is displayed 1. Fault condition exists 1. Determine fault correction from table,

False tripping of WatchDog

system. EMPTY is displayed. Pump does not run.

Pump output is low 1. Spray tip worn 1. Follow Pressure Relief procedure Warn-

If check is OK, go to next check

1. Operating conditions out of

WatchDog parameters. Pump

output is low, see below.

2. Spray tip clogged 2. Relieve pressure. Check and clean spray

3. Paint supply 3. Refill and reprime pump.

4. Intake strainer clogged 4. Remove and clean, then reinstall

5. Intake valve ball and piston ball

are not seating properly

6. Suction hose connections 6. Tighten any loose connections. Check for

7. Fluid filter, tip filter, or tip is

clogged or dirty.

8. Prime valve leaking 8. Relieve pressure. Repair prime valve.

9. Verify pump does not continue to

stroke when gun trigger is

released. (Prime valve not leaking.)

10. Leaking around throat packing

nut which may indicate worn or

damaged packings.

11. Pump rod damage 11. Repair pump. See pump manual 310643

12. Low stall pressure 12. Turn pressure knob fully clockwise. Make

13. Piston packings are worn or

damaged

When check is not OK, refer to this column

page 13.

1. Turn pressure down. Refer to operation

manual for adjusting. Operate without

WatchDog active; see operation manual.

ing, then replace tip. See your separate

gun or tip manual.

tip.

5. Remove intake valve and clean. Check

balls and seats for nicks; replace if necessary; see pump manual 310643 or

310894. Strain paint before using to

remove particles that could clog pump.

missing or damaged seals.

7. Clean filter; see operation manual.

9. Service pump; see pump manual 310643

or 310894.

10. Replace packings; see pump manual.

Also check piston valve seat for hardened

paint or nicks and replace if necessary.

Tighten packing nut/wet-cup.

or 310894.

sure pressure control knob is properly

installed to allow full clockwise position. If

problem persists, replace pressure transducer.

13. Replace packings; see pump manual

310643 or 310894.

WHAT TO DO

311365J 11

Page 12

Troubleshooting

WHAT TO CHECK

TYPE OF PROBLEM

If check is OK, go to next check

Pump output is low 14. O-ring in pump is worn or dam-

aged

15. Intake valve ball is packed with

material

When check is not OK, refer to this column

14. Replace o-ring; see pump manual 310643

or 310894.

15. Clean intake valve; see pump manual

310643 or 310894.

WHAT TO DO

16. Pressure setting is too low 16. Increase pressure; see pump manual

310643 or 310894.

17. Large pressure drop in hose with

heavy materials

17. Use larger diameter hose and/or reduce

overall length of hose. Use of more than

100 ft of 1/4 in. hose significantly reduces

performance of sprayer. Use 3/8 in. hose

for optimum performance (50 ft minimum).

Motor runs but pump does

not stroke

1. Displacement pump pin (32)

damaged or missing; see pump

manual 310643 or 310894.

1. Replace pump pin if missing. Be sure

retainer spring (31) is fully in groove all

around connecting rod; see pump manual

310643 or 310894.

2. Connecting rod assembly (43)

damaged; see pump manual

2. Replace connecting rod assembly; see

pump manual 310643 or 310894.

310643 or 310894.

3. Gears or drive housing damaged, page 34.

3. Inspect drive housing assembly and gears

for damage and replace if necessary; see

pump manual 310643 or 310894.

Excessive paint leakage into

throat packing nut

1. Throat packing nut is loose 1. Remove throat packing nut spacer.

Tighten throat packing nut just enough to

stop leakage.

2. Throat packings are worn or

damaged

3. Displacement rod is worn or

damaged

2. Replace packings; see pump manual

310643 or 310894.

3. Replace rod; see pump manual 310643 or

310894.

Fluid is spitting from gun 1. Air in pump or hose 1. Check and tighten all fluid connections.

Reduce engine speed and cycle pump as

slowly as possible during priming.

2. Tip is partially clogged 2. Clear tip; see tip guard manual 309640.

3. Fluid supply is low or empty 3. Refill fluid supply. Prime pump; see pump

manual 310643 or 310894. Check fluid

supply often to prevent running pump dry.

Pump is difficult to prime 1. Air in pump or hose 1. Check and tighten all fluid connections.

Reduce engine speed and cycle pump as

slowly as possible during priming.

2. Intake valve is leaking 2. Clean intake valve. Be sure ball seat is not

nicked or worn and that ball seats well.

Reassemble valve.

3. Pump packings are worn 3. Replace pump packings; see pump manual 310643 or 310894.

4. Paint is too thick 4. Thin the paint according to the supplier’s

recommendations.

No display, sprayer operates 1. Display is damaged or has bad

1. Check connections. Replace display.

connection

12 311365J

Page 13

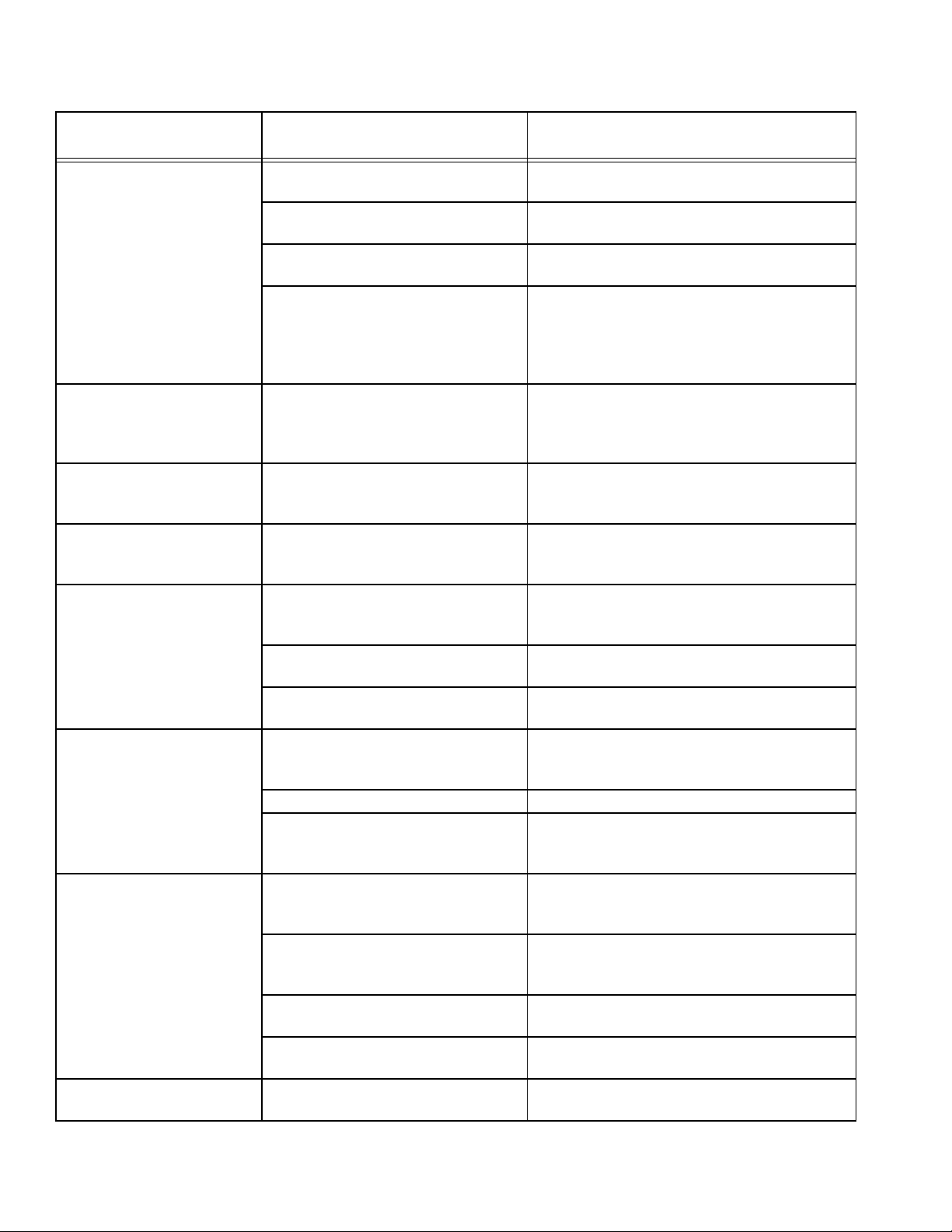

Electrical

Symptom: Sprayer does not run or stops running.

Troubleshooting

Relieve pressure; page 9.

WARNING

To avoid electrical shock or moving parts hazards when

• Plug sprayer into correct voltage, grounded outlet

• Set power switch OFF for 30 seconds and then ON

again. This ensures sprayer is in normal run mode.

• Turn pressure control knob clockwise 1/2 turn

• View digital display

covers are removed for troubleshooting, wait 30 seconds

after unplugging power cord for stored electricity to dissipate. Keep clear of electrical and moving parts during

troubleshooting procedures.

If no digital display is available, use control

board status light to troubleshoot problems: Turn ON/OFF switch OFF, remove

control cover and then turn power back

ON. Observe status light. Blinking LED total count equals digital error code i.e., two

blinks equals E=02.

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all See flow chart, page 19.

Digital display is blank

Control board status light never

lights

Sprayer does not run at all Check transducer or transducer

Digital display shows E=02

Control board status light blinks

2 times repeatedly

connections

1. Make sure there is no pressure in the system (see

Pressure Relief, page 9). Check fluid path for clogs,

such as clogged filter.

2. Use airless paint spray hose with no metal braid

1/4 in. x 50 ft minimum. Smaller hose or metal braid

hose may result in high-pressure spikes.

3. Set sprayer to OFF and disconnect power to

sprayer.

4. Check transducer and connections to control board.

5. Disconnect transducer from control board socket.

Check that transducer and control board contacts

are clean and secure.

6. Reconnect transducer to control board socket.

Connect power, set sprayer ON and control knob

1/2 turn clockwise. If sprayer does not run properly,

set sprayer to OFF and go to next step.

7. Install new transducer. Connect power, set sprayer

ON and control knob 1/2 turn clockwise. Replace

control board if sprayer does not run properly.

311365J 13

Page 14

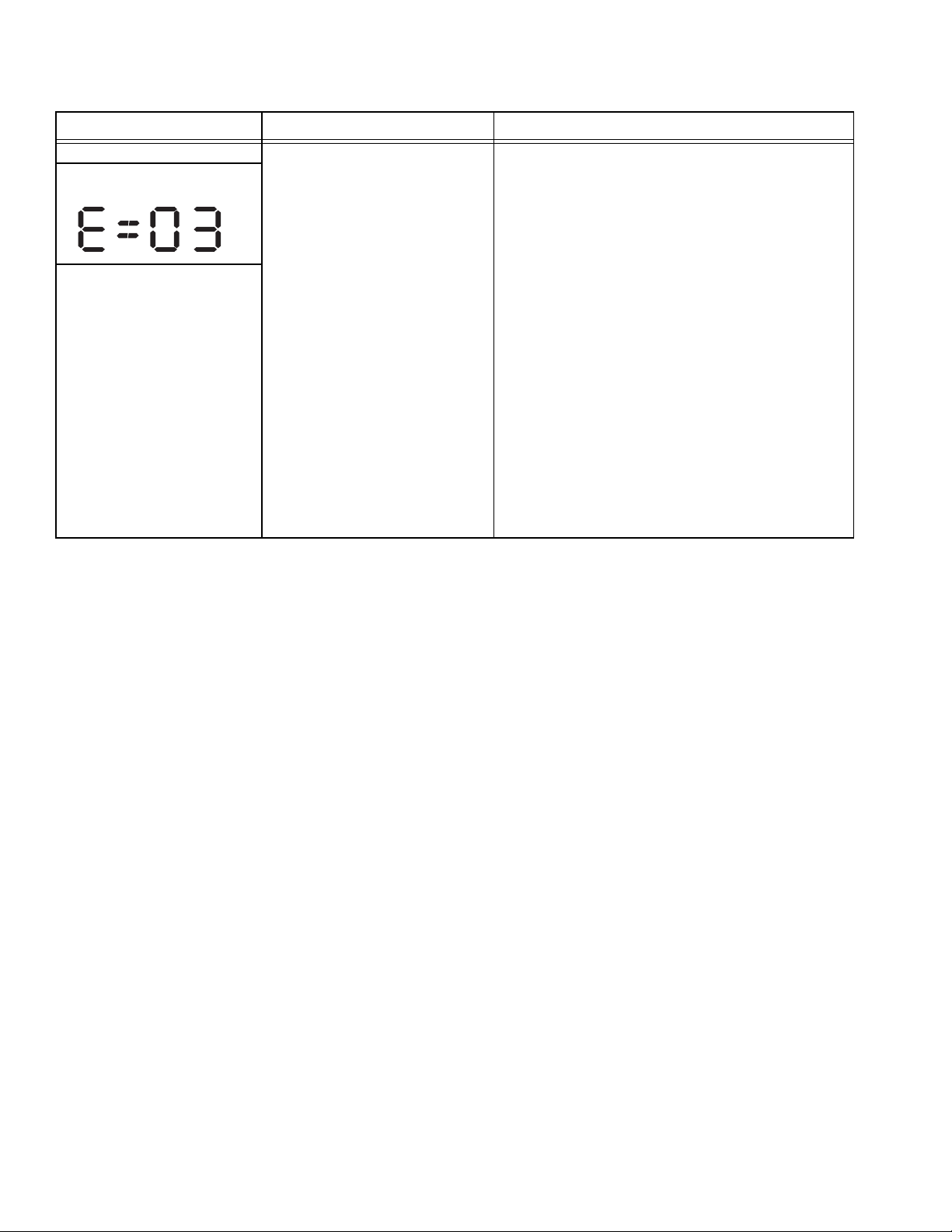

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all Check transducer or transducer

Digital display shows E=03

Control board status light blinks

3 times repeatedly

connections (control board is not

detecting a pressure signal).

1. Set sprayer to OFF and disconnect power to

sprayer.

2. Check transducer and connections to control board.

3. Disconnect transducer from control board socket.

Check to see if transducer and control board

contacts are clean and secure.

4. Reconnect transducer to control board socket.

Connect power, set sprayer ON and control knob

to 1/2 turn clockwise. If sprayer does not run,

set sprayer to OFF and go to next step.

5. Connect a confirmed working transducer to control

board socket.

6. Set sprayer ON and control knob to 1/2 turn

clockwise. If sprayer runs, install new transducer.

Replace control board if sprayer does not run.

7. Check transducer resistance with ohmmeter (less

than 9k ohm between red and black wires and 3-6k

ohm between green and yellow wires).

Troubleshooting

14 311365J

Page 15

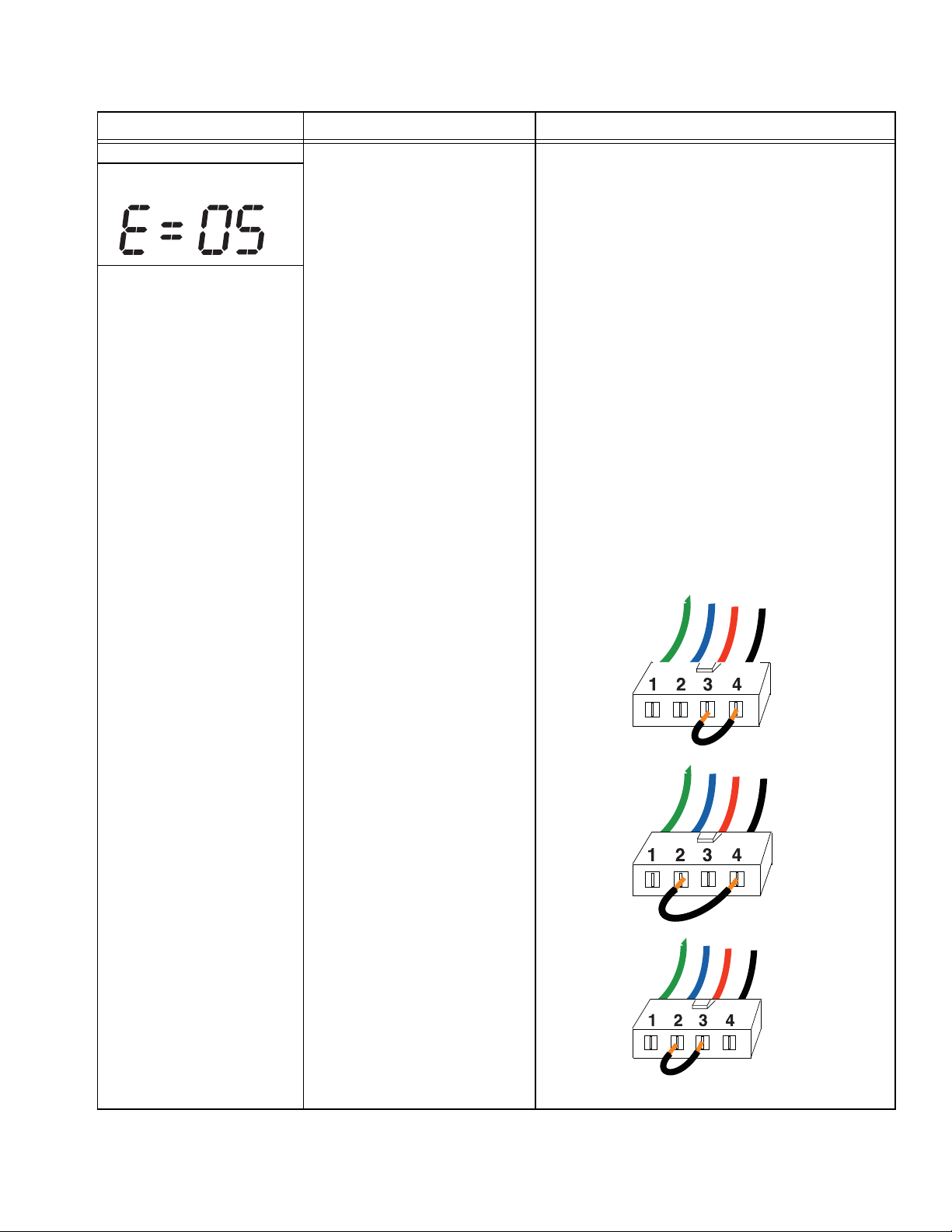

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all Control is commanding motor to run

Digital display shows E=05

Control board status light blinks

5 times repeatedly

but motor shaft does not rotate.

Possibly locked rotor condition, an

open connection exists between

motor and control, there is a

problem with motor or control board,

or motor amp draw is excessive.

1. Remove pump and try to run sprayer. If motor runs,

check for locked or frozen pump or drive train.

If sprayer does not run, continue to step 2.

2. Set sprayer to OFF and disconnect power to

sprayer.

3. Disconnect motor connector(s) from control board

socket(s). Check that motor connector and control

board contacts are clean and secure. If contacts

are clean and secure, continue to step 4.

4. Set sprayer to OFF and spin motor fan 1/2 turn.

Restart sprayer. If sprayer runs, replace control

board. If sprayer does not run, continue to step 5.

5. Perform Spin Test: Test at large 4-pin motor field

connector. Disconnect fluid pump from sprayer. Test

motor by placing a jumper across pins 1 & 2. Rotate

motor fan at about 2 revolutions per second. A cogging

resistance to motion should be felt at the fan.

The motor should be replaced if no resistance is felt.

Repeat for pin combinations1&3and2&3.Pin4

(the green wire) is not used in this test. If all spin test

is positive, continue to step 6.

Troubleshooting

STEP 1:

STEP 2:

STEP 3:

Green Blue Red Black

Green Blue Red Black

Green Blue Red Black

311365J 15

Page 16

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all Control is commanding motor to run

Digital display shows E=05

but motor shaft does not rotate.

Possibly locked rotor condition,

an open connection exists between

motor and control, there is a problem

with motor or control board, or

motor amp draw is excessive.

Control board status light blinks

5 times repeatedly

6. Perform Field Short Test: Test at large 4-pin motor

field connector. There should not be continuity from

pin 4, the ground wire, and any of the remaining

3 pins. If motor field connector tests fail,

replace motor.

7. Check Motor Thermal Switch: Unplug thermal wires.

Set meter to ohms. Meter should read the proper

resistance for each model (see table below).

100k ohm

-

Troubleshooting

ti13140a

Resistance Table:

Series B Series A

695 0 ohms 100k ohms

795 2k ohms 100k ohms

1095 3.9k ohms 100k ohms

MARK V 3.9k ohms 100k ohms

16 311365J

Page 17

TYPE OF PROBLEM WHAT TO CHECK HOW TO CHECK

Sprayer does not run at all Allow sprayer to cool. If sprayer

Digital display shows E=06

runs when cool, correct cause of

overheating. Keep sprayer in cooler

location with good ventilation. Make

sure motor air intake is not blocked.

If sprayer still does not run, follow

Control board status light blinks

Step 1.

6 times repeatedly

NOTE: Motor must be cooled down for the test.

1. Check thermal device connector (yellow wires)

at control board.

2. Disconnect thermal device connector from control

board socket. Make sure contacts are clean and

secure.

3. Measure resistance of the thermal device. If reading

is not correct, replace motor.

Check Motor Thermal Switch: Unplug thermal wires.

Set meter to ohms. Meter should read the proper

resistance for each model (see table below).

100k ohm

-

Troubleshooting

Sprayer does not run at all Check the connections. Control

Digital display shows E=09

is not receiving a motor position

sensor signal

Control board status light blinks

9 times repeatedly

Sprayer does not run at all Check to see if control board is over

Digital display shows E=10

heating.

Control board status light blinks

10 times repeatedly

ti13140a

Resistance Table:

695 0 ohms

795 2k ohms

1095 3.9k ohms

MARK V 3.9k ohms

4. Reconnect thermal device connector to control

board socket. Connect power, turn sprayer ON and

control knob 1/2 turn clockwise. If sprayer does not

run, replace control board.

1. Turn power OFF.

2. Disconnect motor position sensor and inspect for

damage at connectors.

3. Reconnect sensor.

4. Turn power ON. If error continues, replace motor.

1. Make sure motor air intake is not blocked.

2. Make sure fan has not failed.

3. Make sure control board is properly connected

to back plate and that conductive thermal paste

is used on power components.

4. Replace control board.

5. Replace motor.

311365J 17

Page 18

Sprayer Will Not Shut Off

Troubleshooting

1. Relieve Pressure, page 9. Leave prime valve open

and power switch OFF.

Troubleshooting Procedure

Plumb pressure gauge into paint

hose, plug sprayer in, and turn power

switch ON. Does sprayer reach or ex-

ceed its maximum pressure?

YES

Unplug the transducer from control

board. Does motor stop running?

2. Remove control box cover so the control board

status light can be viewed if available.

NO

NO

Mechanical problem: See the proper

fluid pump manual for the sprayer for

further trouble shooting procedures.

Replace the control board.

YES

Bad transducer. Replace and test

with a new one.

18 311365J

Page 19

Sprayer Will Not Run

(See following page for steps)

Remove control box cover. Turn

sprayer ON. Observe control

board status light on control

board (see page 13).

No light

Once Normal operation

Light on

Continuously

Flashing See Error Code

Control board

commanding

motor to run

section for further

troubleshooting

See Step 1. Do

you have over

100 AC volts?

YES

NO

See Step 2. Do

you have over

100 AC volts?

YES

Replace the

ON/OFF switch.

NO

Troubleshooting

Repair or

replace

power cord.

See Step 3. Is the

proper reading present through the ther-

mal switch wires?.

YES

See step 4. Does

the motor run?

YES

NO

NO

If motor is hot, let cool and retest. If Step 4 still shows incorrect resistance, replace motor.

The motor has a defective

thermal device.

Connect a test

transducer to the

board. Does the

motor run?

YES

NO

Replace the

control board.

Replace

potentiometer.

Pressure switch.

311365J 19

Replace the

transducer

Page 20

Pressure Control Board

Pressure Control Board

100 - 120 Vac North American and Japan/Taiwan Motor Control Board

Removal

Relieve pressure; page 9. Wait 5 minutes before

servicing.

1. Remove four screws (38) and cover (96).

2. Disconnect display connector (A) from motor

control board.

3. Remove bottom two screws (39) and allow

control panel (68) to hang down freely.

4. Disconnect control board power lead(s) (D)

from ON/OFF switch (33) and motor control

board (52).

5. Disconnect potentiometer connector (C) from

motor control board.

6. Disconnect WatchDog (49) switch connector

(X) from motor control board.

7. Disconnect 15/20A switch (178) (1595 model

only).

8. Disconnect transducer connector (E) from

motor control board.

9. Disconnect motor connectors (F, G, and H)

from motor control board.

10. Remove motor shroud. Disconnect and remove

wiring from baffle.

11. Remove nut and screw (88) and disconnect

ground wire (87). Disconnect coil connector

(Y). Remove coil (81).

Installation

1. Use Acetone or equivalent solvent to

thoroughly remove thermal paste from the

pockets of the Powerbar.

2. Apply thermal compound:

a. For 2 capacitor boards and 6 capacitor

boards with the Powerbar shown in Figure

1 below, apply a small amount of thermal

compound 15U114 or 110009 (5) to shaded

component areas on rear of motor control

board (52).

5

52

ti17334a

Figure 1

b. For 6 capacitor boards with the Powerbar

shown in Figure 2 below, apply a small

amount of thermal compound 15U114 or

110009 (5) into both pockets of the Powerbar (69) and scrape across the pocket with

the provided scraper so an even layer is

remaining in the pocket

5

.

12. Remove top two screws (39) and control box

(61).

13. Remove six screws (27), two screws (102) and

69

control board.

ti14693a

Figure 2

NOTICE

To reduce risk of motor control board failure, do

not overtighten screws (102) which can damage

the electric components.

20 311365J

Page 21

Pressure Control Board

3. Install six screws (27), two screws (102) and

motor control board.

4. Install and torque two screws (102) to values in

illustration. Install motor control board (52) with

six screws (27). Torque to 9-11 in-lb (1.02 -

1.24 N•m).

5. Connect motor connectors, (F, G and H) to

motor control board.

6. Reconnect and install wiring in baffle. Install

motor shroud.

7. Install control box (61) with top two screws

(39).

8. Install coil (81) and tighten screw and nut (88).

Tighten ground wire screw (87) and coil

connector (Y).

9. Connect transducer connector (E) to motor

control board.

10. Connect 15/20A switch (178) (1595 model

only).

11. Connect motor control board power lead(s) (D)

to ON/OFF switch (33).

12. Connect WatchDog (49) switch connector (X)

to motor control board.

13. Connect potentiometer connector (C) to motor

control board.

14. Install control panel (68) with two screws (39).

15. Connect display connector (A) to motor control

board.

16. Install cover (96) with four screws (38).

311365J 21

Page 22

100 - 120 Vac North American

and Japan/Taiwan

Y

88

81

87

88

Tighten 2 screws

to 14-17 in-lb

102

69

27

Pressure Control Board

F

H

G

96

39

38

49

33

D

39

82

115

61

68

82

B

F

C

A

52

E

40

E

86

20

C

67

49

X

A

178

34

ti12994b

22 311365J

Page 23

240 Vac Motor Control Board

Pressure Control Board

Removal

Relieve pressure; page 9. Wait 5 minutes before

servicing.

1. Remove all four screws (38) and cover (96).

2. Disconnect display connector (A) from motor

control board (52).

3. Remove bottom two screws (39). disconnect

potentiometer connector (C) from motor control

board (52). Disconnect power cord connectors

(D) and filter board connectors (J) from

ON/OFF switch (33) and remove control panel

(68).

4. Disconnect WatchDog switch connector (X)

from motor control board.

5. Disconnect motor control board power

connectors (K) from filter board (146).

6. Remove top two screws (39) and control box

(61).

7. Disconnect transducer connector (E) from

motor control board.

8. Disconnect motor connectors (F, G and H) from

motor control board.

9. Remove motor shroud disconnect and remove

wiring from baffle.

10. Remove six screws (27), two screws (102) and

control board.

Installation

1. Use Acetone or equivalent solvent to

thoroughly remove thermal paste from the

pockets of the Powerbar.

2. Apply thermal compound:

a. For 2 capacitor boards and 6 capacitor

boards with the Powerbar shown in Figure

1 below, apply a small amount of thermal

compound 15U114 or 110009 (5) to shaded

component areas on rear of motor control

board (52).

52

ti17334a

Figure 1

b. For 6 capacitor boards with the powerbar

shown in Fig. 2 below, apply a small

amount of thermal compound 15U114 or

110009 (5) into both pockets of the Powerbar (69) and scrape across the pocket with

the provided scraper so an even layer is

remaining in the pocket

5

5

69

ti14693a

Figure 2

NOTICE

To reduce risk of motor control board failure, do

not overtighten screws (102) which can damage

the electric components.

311365J 23

Page 24

Pressure Control Board

3. Install two screws (102), six screws (27) and

control board.

4. Install and torque two screws (102) to values in

illustration on page 25. Install motor control

board (52) with six screws (27). Torque to 9-11

in-lb (1.02 - 1.24 N•m).

5. Connect motor connectors (F, G and H) to

motor control board.

6. Reconnect wiring and install onto baffle. Install

motor shroud.

7. Connect transducer connector (E) to motor

control board.

8. Connect motor control board power connectors

(K) to filter board (146).

9. Install control box (61) with top two screws

(39).

10. Connect filter board power connectors (J) and

power cord connectors (D) to ON/OFF switch

(33).

11. Connect potentiometer connector (C) to motor

control board.

12. Connect WatchDog switch (X) to motor control

board.

13. Install control panel (68) with two screws (39).

14. Connect display connector (A) to motor control

board (52).

15. Install cover (96) with four screws (38).

24 311365J

Page 25

Relieve pressure; page 9.

Pressure Control Board

240 Vac Filter Board

Removal

1. Remove four screws (38) and cover (96).

2. Disconnect display connector (A) from motor

control board (52).

3. Remove bottom two screws (39). disconnect

potentiometer connector (C) from motor control

board (52). Disconnect power cord connectors

(D) and filter board connectors (J) from

ON/OFF switch (33) and remove control panel

(68).

4. Disconnect WatchDog switch connector (X)

from motor control board.

5. Disconnect motor control board power

connectors (K) from filter board (146).

6. Remove four screws (163) from filter board

(146).

240 Vac

Tighten 2 screws

to 14-17 in-lb

(1.58-1.92 N•

102

Installation

1. Install filter board (146) with four screws (163).

2. Connect motor control board power connectors

(K) to filter board (146).

3. Connect filter board power connectors (J) to

top two terminals of ON/OFF switch (33) and

power cord connectors (D) to bottom two

terminals of ON/OFF switch.

4. Connect potentiometer connector (C) to motor

control board (52).

5. Connect WatchDog switch (X) to motor control

board.

6. Install control panel (68) with two screws (39).

7. Connect display connector (A) to motor control

board (52).

8. Install cover (96) with four screws (38).

69

27

52

F

H

G

146

K

61

163

A

96

38

39

39

311365J 25

33

J

68

34

82

115

82

C

A

E

E

80

C

20

67

X

ti12995b

Page 26

110 Vac U.K. Motor Control Board

Pressure Control Board

Removal

Relieve pressure; page 9. Wait 5 minutes before

servicing.

1. Remove four screws (38) and cover (96).

2. Disconnect display connector (A) from motor

control board.

3. Remove bottom two screws (39) and allow

control panel (68) to hang down freely.

4. Disconnect control board power lead(s) (D)

from ON/OFF switch (33) and motor control

board (52).

5. Disconnect potentiometer connector (C) from

motor control board.

6. Disconnect WatchDog (49) switch connector

(X) from motor control board.

7. Disconnect 15/20A switch (178) (1595 model

only).

8. Disconnect transducer connector (E) from

motor control board.

9. Disconnect motor connectors (F, G, and H)

from motor control board.

10. Remove motor shroud. Disconnect and remove

wiring from baffle.

11. Remove nut and screw (88) and disconnect

ground wire (87). Disconnect coil connector

(Y). Remove coil (81).

Installation

1. Use Acetone or equivalent solvent to

thoroughly remove thermal paste from the

pockets of the Powerbar.

2. Apply thermal compound:

a. For 2 capacitor boards and 6 capacitor

boards with the Powerbar shown in Figure

1 below, apply a small amount of thermal

compound 15U114 or 110009 (5) to shaded

component areas on rear of motor control

board (52)

b. For 6 capacitor boards with the powerbar

shown in Fig. 2 below, apply a small

amount of thermal compound 15U114 or

110009 (5) into both pockets of the Powerbar (69) and scrape across the pocket with

the provided scraper so an even layer is

remaining in the pocket

.

52

ti17334a

Figure 1

5

5

12. Remove top two screws (39) and control box

(61).

13. Remove six screws (27), two screws (102) and

69

control board.

ti14693a

Figure 2

NOTICE

To reduce risk of motor control board failure, do

not overtighten screws (102) which can damage

the electric components.

26 311365J

Page 27

Pressure Control Board

3. Install two screws (102), six screws (27) and

control board.

4. Install and torque two screws (102) to values in

illustration. Install motor control board (52) with

six screws (27). Torque to 9-11 in-lb (1.02 -

1.24 N•m).

5. Connect motor connectors, (F, G and H) to

motor control board.

6. Reconnect and install wiring in baffle. Install

motor shroud.

7. Install control box (61) with top two screws

(39).

8. Install coil (81) and tighten screw and nut (88).

Tighten ground wire screw (87) and coil

connector (Y).

9. Connect transducer connector (E) to motor

control board.

10. Connect 15/20A switch (178) (1595 model

only).

11. Connect motor control board power lead(s) (D)

to ON/OFF switch (33).

12. Connect WatchDog (49) switch connector (X)

to motor control board.

13. Connect potentiometer connector (C) to motor

control board.

14. Install control panel (68) with two screws (39).

15. Connect display connector (A) to motor control

board.

16. Install cover (96) with four screws (38).

311365J 27

Page 28

110 Vac U.K. Filter Board

Relieve pressure; page 9. Wait 5 minutes before

servicing.

Pressure Control Board

Removal

1. Remove four screws (38) and cover (96).

2. Disconnect display connector (A) from motor

control board (52).

3. Remove bottom two screws (39). Disconnect

potentiometer connector (C) from motor control

board (52). Disconnect filter board connector

(J) and power cord connector (D) from ON/OFF

switch (33). Remove control panel (68).

4. Disconnect motor board control power

connectors (K) from filter board (146).

Disconnect filter connector (L) from power cord

connector (L).

5. Remove four screws (163) from filter board

(146).

Installation

1. Connect motor control board power connectors

(K) to filter board (146). Connect filter

connector (L) to power cord connector (L).

2. Install filter board (146) with four screws (163).

3. Connect filter board power connector (J) and

power cord connector (D) to ON/OFF switch

(33).

4. Connect potentiometer connector (C) to motor

control board (52).

5. Install control panel (68) with two screws (39).

6. Connect display connector (A) to motor control

board (52).

7. Install cover (96) with four screws (38).

28 311365J

Page 29

110 Vac U.K.

Pressure Control Board

Tighten 2 screws

to 14-17 in-lb

(1.58-1.92 N•

96

38

39

39

68

33

D

163

A

J

115

61

146

82

82

F

H

G

69

27

102

C

52

E

E

80

20

67

34

X

ti12996b

311365J 29

Page 30

Pressure Adjust Potentiometer

Pressure Control Board

Removal

Relieve pressure; page 9. Wait 5 minutes before

servicing.

1. Remove four screws (38) and cover (96).

96

38

2. Disconnect potentiometer connector (C) from

motor control board (95).

ti13493a

95

C

Installation

1. Install gasket (115), nut and potentiometer (82)

on control panel (68). Torque nut to 30-35 in-lb

(3.38 - 3.95 N•m).

68

82

115

2. Install pressure control knob (34): Check

pressure control knob alignment to

potentiometer shaft. Turn shaft fully clockwise

and attach knob in full ON position with a hex

wrench.

34

ti12998a

ti7258a

82

ti12997a

3. Remove pressure control knob (34) with a hex

wrench.

34

ti7258a

4. Remove gasket (115), nut and potentiometer

(82) from control panel (68).

68

82

115

ti12998a

82

3. Connect potentiometer connector (C) to motor

control board.

95

C

ti12997a

4. Install cover (96) with four screws (38).

96

38

ti13493a

30 311365J

Page 31

Pressure Control Transducer

Pressure Control Board

Removal

Relieve pressure; page 9. Wait 5 minutes before

servicing.

1. Remove four screws (38) and cover (96).

96

38

2. Disconnect transducer connector (E) from

motor control board (95).

ti13493a

E

4. Remove four screws (39) and control box (61).

Allow control panel (68) to hang down freely.

ti7458a

68

39

ti13494a

61

5. Remove grommet (40) from control box then

remove transducer (86) and o-ring (20) from

filter base (67).

ti7260a

40

67

ti12999a

95

3. Disconnect potentiometer connector (C) from

motor control board.

ti12997a

C

86

20

6. Remove grommet (40) from transducer and

save for reuse.

ti13495a

40

ti13495a

311365J 31

Page 32

Pressure Control Board

Installation

1. Install o-ring (20) and transducer (86) in filter

base (67). Torque to 35-45 ft-lb (47-61 N•m).

Install grommet onto transducer (86) and

transducer into control box.

40

67

ti7447a

86

20

2. Connect transducer connector (E) to motor

control board (95).

ti13496a

3. Install control box (61) and control panel (68)

with four screws (39).

ti7458a

39

ti13494a

61

68

4. Connect potentiometer connector (C) to motor

control board.

C

E

ti12999a

95

ti12997a

5. Install cover (96) with four screws (38).

96

38

ti13493a

32 311365J

Page 33

Notes

Notes

311365J 33

Page 34

Drive and Bearing Housing Replacement

Drive and Bearing Housing Replacement

NOTICE

Do not drop gear cluster (89) when removing

drive housing (90). Gear cluster may stay

engaged in motor front end bell or drive

housing.

Disassembly

Relieve pressure; page 9.

1. Remove screw (31), two nuts (24), pail hanger

(55) and pump rod cover (108).

2. Remove pump (91); see Displacement Pump

Replacement, page 38 (695/795) page 40

(1095/1595/Mark V).

3. Remove two screws (158) and shroud (72).

4. Remove four screws (31) and front cover (51).

5. Remove four screws (14) and washers (12) to

remove bearing housing (83) and connecting

rod (85).

6. Remove five screws (6) and pull drive housing

(90) off motor (84).

Assembly

Make sure gear (89) and thrust washers (28, 30,

90a, 36; see page 29) are in place. Brush grease

onto gear teeth.

1. Push drive housing (90) onto motor (84) and

install with five screws (6). Torque to 190-210

in-lb (21-23 N•m).

2. Install bearing housing (83) with four screws

(14) and washers (12). Torque to 25-30 ft-lb

(34-40 N•m).

3. Install front cover (51) with four screws (31).

4. Install shroud (72) with two screws (158).

5. Install pump (91); see Displacement Pump

Replacement, page 38 (695/795) page 40

(1095/1595/Mark V).

6. Install pump rod cover (108) and pail hanger

(55) with screw (31) and two nuts (24).

34 311365J

Page 35

158

Drive and Bearing Housing Replacement

72

84

90

24

83

51

6

31

85

12

14

31

108

55

91

ti13000a

311365J 35

Page 36

Motor Replacement

Motor Replacement

Removal

Relieve pressure; page 9.

1. Remove pump (91); see Displacement Pump

Replacement, page 38 (695/795) page 40

(1095/1595/Mark V).

NOTICE

Do not drop gear cluster (89) when removing

drive housing (90). Gear cluster may stay

engaged in motor front end bell or drive housing.

2. Remove drive housing (90); see Drive

Housing Replacement, page 34.

3. Remove shroud (58).

4. Remove four screws (38) and control cover

(96).

5. Remove bottom two screws (39) and allow

control panel (68) to hang down freely.

6. Disconnect all three motor connectors from

motor control board (52).

7. Disconnect motor leads.

8. Remove top two screws (39) and control

housing (61).

9. Remove strain relief (29) from motor wires and

power bar plate (69).

10. Remove motor wires from baffle 278075 and

remove baffle.

11. Remove two screws (23) and nuts (19) on side

opposite control.

12. Loosen two nuts (19) on side near control and

remove motor (84) from cart frame (62).

Installation

1. Slide new motor (84) under two screws (23) in

cart frame (62) near control.

2. Install two screws (23) and nuts (19) on motor

side opposite control.

3. Install baffle and connect motor wires.

4. Tighten all four screws (23) and nuts (19).

torque nuts to 115-135 in-lb (13-15 N•m).

5. Install strain relief (29) onto motor wires and

into power bar plate (69).

6. Install control housing (61) with top two screws

(39).

7. Connect motor leads.

8. Connect all three motor connectors to motor

control board (52).

9. Install control panel (68) with two screws (39).

10. Install control cover (96) with four screws (38).

11. Install drive housing (90); see Drive Housing

Replacement, page 34.

12. Install pump (91); see Displacement Pump

Replacement, page 38 (695/795) page 40

(1095/1595/Mark V).

36 311365J

Page 37

Motor Replacement

39

96

68

61

62

158

84

19

58

36

89

90a

30

28

90

51

6

158

12

14

31

19

90

23

6

12

14

91

ti13001a

311365J 37

Page 38

Displacement Pump Replacement for 695/795

Displacement Pump Replacement for 695/795

See pump manual 310643 or 310894 for pump

repair instructions.

See manual 311362, 311363, or 311364 for

applicable sprayer part number references.

Removal

Relieve pressure; page 9. Wait 5 minutes before

servicing.

1. Flush pump.

2. Remove screw (31) and slide pump rod shield

(108) forward.

31

OFF and unplug power cord. Push up retaining

ring (43) and push pump pin out.

44

ti7168a

43

4. Remove suction tube (76), hose (94) and any

washers and o-rings.

5. Loosen pump jam nut (56). Unscrew pump.

94

ti7167a

ti7170a

108

3. Cycle pump in JOG mode until pump pin (44) is

in position to be removed. Turn power switch

56

76

38 311365J

Page 39

Displacement Pump Replacement for 695/795

Installation

If pump pin works loose, parts could break off

due to force of pumping action. Parts could

project through the air and result in serious

injury or property damage.

NOTICE

If the pump jam nut loosens during operation,

the threads of the drive housing will be

damaged.

1. Extend pump piston rod 1.5 in. Apply grease to

top of pump rod at (A) or inside connecting rod.

2. Install pump pin (44). Verify retaining spring

(43) is in groove of connecting rod (85).

3. Push pump up until pump threads engage.

4. Screw in pump until threads are flush with drive

housing opening. Align pump outlet to back.

5. Install washers, o-rings and suction tube (76)

and hose (94).

6. Screw jam nut (56) up onto pump until nut

stops. Tighten jam nut by hand, then tap 1/8 to

1/4 turn with a 20 oz (maximum) hammer to

approximately 75± 5 ft-lb (102 N•m).

7. Install pump rod shield (108) with screw (31).

8. Fill packing nut with Graco TSL until fluid flows

onto top of seal.

ti7171a

1.5 in.

A

ti7169a

311365J 39

Page 40

Displacement Pump Replacement 1095/1595/Mark V

Displacement Pump Replacement 1095/1595/Mark V

Removal

See Skin Injection Hazard; page 6.

1. Flush pump.

2. Stop pump with piston rod in its lowest position.

3. Do Pressure Relief, page 9.

4. Separate drain hose from sprayer.

ti7326a

7. Ratchet open pump door.

a. Ratchet pump door forward.

ti6373a

b. Twist latch u-bolt out of pump door recess.

c. Place u-bolt on pump door outer edge.

d. If pump door is stuck, do steps e, f, and 8,

otherwise go to step 9.

e. Twist latch u-bolt back from pump door

outer edge

ti6374a

.

5. Disconnect paint hose from pump.

ti6300a

6. Raise latch lock. Push latch open.

ti6369a

ti6370a

f.

Place u-bolt on pump door protrusion.

ti6375a

40 311365J

Page 41

Displacement Pump Replacement 1095/1595/Mark V

8. Ratchet pump door forward.

ti6377a

9. Open pump door.

ti7331a

Installation

1. Adjust piston rod with pin holder to pull out

piston rod. Tap piston rod on hard surface to

push in piston rod.

2. Push pump collar flush with bearing housing

ledge to be able to close pump door.

ti6325a

ti5492a

3. Slide pump into connecting rod. Push pump pin

until it is fully retained.

Note: Pin will snap into position.

10. Pull out pump pin and place in pin holder.

ti7327a

ti6378a

ti7328a

311365J 41

Page 42

Displacement Pump Replacement 1095/1595/Mark V

4. Close pump door and rotate latch into position.

Do not tighten latch.

ti7329a

ti6313a

5. Rotate pump to align with paint hose. Connect

paint hose and hand tighten to 70 in-lb.

ti6299a

6. Tighten latch and rotate latch lock into locked

position.

ti6204a

TI6312a

7. Attach drain hose to sprayer.

ti7330a

8. Fill pump with Graco TSL until fluid flows onto

top of seal.

ti5493a

42 311365J

Page 43

Wiring Diagram

695/795 Lo-Boy Series B; 695 Hi-Boy Series D;

795 Hi-Boy Series C; 1095/1595/Mark V Series B

Wiring Diagram

Power Plug

ON/OFF

Switch

Black +

Motor

white

green/ground

ti7346a

green/ground

Digital Display

Black

Pressure

Transducer

14A 10A

Switch

1595/MARK V

Potentiometer

Watchdog

311365J 43

Page 44

Wiring Diagram

695/795 Lo-Boy Series B; 695 Hi-Boy Series D;

795 Hi-Boy Series C; 1095/1595/Mark V Series B

Digital Display

Wiring Diagram

Motor

Potentiometer

Pressure

Transducer

Black

ON

Dip Switch

Watchdog

20A 15A

1595 Switch

ti12980a

green/ground

ON/OFF

Black

white

Black +

Switch

Power Plug

green/ground

44 311365J

Page 45

Wiring Diagram

UltraMax II: 695/795 Lo-Boy Series B; 695 Hi-Boy Series D;

795 Hi-Boy Series C; 1095/Mark V Series B

(Models with only TWO large capacitors on control board)

Wiring Diagram

ON/OFF

Switch

Power Plug

Japan/Taiwan

Models

Black +

Motor

white

green/ground

Potentiometer

Watchdog

green/ground

Blue

Black

ti7523a

Digital Display

Pressure

Transducer

Motor

ti7347a

green/ground

175

Blue

UK

Brown

ON/OFF

Switch

Brown +

Blue

green/ground

Black

Digital Display

Pressure

Transducer

Models

Watchdog

Power Plug

311365J 45

Page 46

Wiring Diagram

UltraMax II: 695/795 Lo-Boy Series B; 695 Hi-Boy Series D;

795 Hi-Boy Series C, 1095/Mark V Series B

(Models with SIX large capacitors on control board)

Wiring Diagram

Thermal

Switch

Motor

Motor

Leads

Motor

Sensor

Leads

green/ground

ti13484a

Japan/Taiwan Models

Digital Display

white

green/ground

Black

Potentiometer

Black

ON

Pressure

Transducer

Black +

Dip Switch

AutoClean

Watchdog

ON/OFF

Switch

Power Plug

Motor

Thermal

Switch

Digital Display

Potentiometer

Pressure

Transducer

Black

Dip Switch

Motor

Leads

UK Models

Motor

Sensor

Leads

Black

ON

Blue

Blue

AutoClean

Watchdog

ti13485a

green/ground

Brown

ON/OFF

Switch

Brown +

Blue

Power Plug

46 311365J

Page 47

Notes

Notes

311365J 47

Page 48

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

2ULJLQDOLQVWUXFWLRQV This manual contains English. MM 311365

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2005, Graco Inc. is registered to ISO 9001

www.graco.com

Revised J August 2014

Loading...

Loading...