Page 1

Operation, Parts, Service, Repair

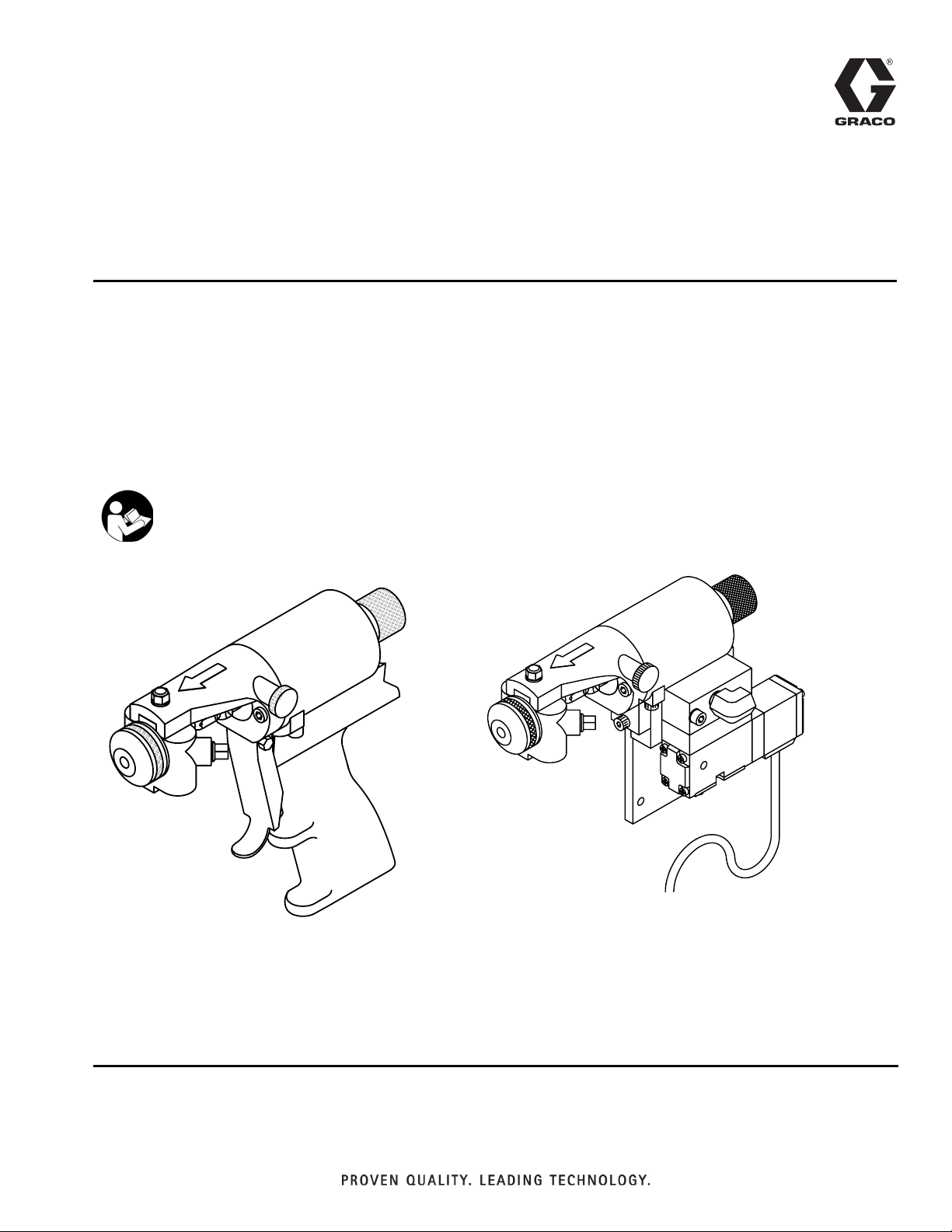

GX-8P Spray Gun

For use with non-flammable polyurethane foams, two-component coating systems

(polyureas), and some two-component epoxy systems. For professional use only.

Not for use in explosive atmospheres.

3500 psi (24 MPa, 240 bar) Maximum Working Pressure

125 psi (90 KPa, 9 bar) Maximum Air Working Pressure

Important Safety Instructions

Read all warnings and instructions

in this manual. Save these instructions.

311338J

EN

GX-8 Model 297898

GX-8P Auto Model 297860

Page 2

Models

Contents

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Important Two-Component Material Information . 5

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . 5

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 5

Keep Components A and B(R) Separate . . . . . . 5

Moisture Sensitivity of Isocyanates . . . . . . . . . . . 5

Foam Resins with 245 fa Blowing Agents . . . . . . 6

Overall View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Centerline Components . . . . . . . . . . . . . . . . . . . 8

Mixing Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation Basics . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Safety Position . . . . . . . . . . . . . . . . . . . . . . . . . 10

Air Hose Connection . . . . . . . . . . . . . . . . . . . . . 10

Coupling Block . . . . . . . . . . . . . . . . . . . . . . . . . 11

Air Inlet Configuration . . . . . . . . . . . . . . . . . . . . 12

Mixing Module and PCD Installation . . . . . . . . . 13

Valving Rod Adjustment . . . . . . . . . . . . . . . . . . 14

Initial Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Daily Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Daily Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 17

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Gun Service Kits . . . . . . . . . . . . . . . . . . . . . . . . 18

Clean Spray Gun Procedure . . . . . . . . . . . . . . . 18

Flush Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Service Screen Screw . . . . . . . . . . . . . . . . . . . . 20

Remove Check Valve . . . . . . . . . . . . . . . . . . . . 20

Remove Centerline Components . . . . . . . . . . . 21

Install Centerline Components . . . . . . . . . . . . . 21

Replace End Cap and Air Piston Assembly . . . 22

Replace Trigger Valve O-Rings . . . . . . . . . . . . . 25

Clean Mixing Module . . . . . . . . . . . . . . . . . . . . . 26

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

GX-8 Gun Final Assembly (297898) . . . . . . . . . 28

GX-8 Handle Assembly (297702) . . . . . . . . . . . 30

GX-8P Spray Gun Final Assembly (297860) . . . 32

GX-8P Auto Cylinder Assembly (297861) . . . . . 34

Auto GX-8P Optional Parts . . . . . . . . . . . . . . . . 36

Coupling Block Assembly (295383) . . . . . . . . . 37

Coupling Block (297902) . . . . . . . . . . . . . . . . . . 38

Coupling Block Assembly (24N996) . . . . . . . . . 39

Set-up Chart for GX-8P Modules . . . . . . . . . . . . . 40

GX-8P Model Specifications . . . . . . . . . . . . . . . 40

Tool Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 42

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 42

Models

Includes:

Part No. Description

Mix Module Tip Manifold

297898 ★ Gun, GX-8

297860 Gun, GX-8, Auto

24P633 ★ Gun, GX-8, with manifold 24N996 297911 296980

295338 (013) 297192 (201)

★

2 311338J

Starter

Kit

Not Included

Flushing

Kit

Page 3

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer

to procedure-specific risks. When these symbols appear in the body of this manual, refer back to

these Warnings. Product-specific hazard symbols and warnings not covered in this section may

appear throughout the body of this manual where applicable.

WARNING

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the

operating area of the equipment to help protect you from serious injury, including eye injury,

inhalation of toxic fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin,

inhaled, or swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable

guidelines.

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate

surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Engage trigger lock when not spraying.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and before

cleaning, checking, or servicing equipment.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on

skin and cause serious injury.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and before

cleaning, checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

311338J 3

Page 4

Warnings

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To

help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and

plastic drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable

fumes are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use

equipment until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated

system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical

Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine

Graco/Gusmer replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your Graco/Gusmer distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents

or fluids containing such solvents in pressurized aluminum equipment. Such use can cause

serious chemical reaction and equipment rupture, and result in death, serious injury, and property damage.

4 311338J

Page 5

Important Two-Component Material Information

Important Two-Component Material Information

Isocyanates (ISO) are catalysts used in two

component materials.

Isocyanate Conditions

Spraying or dispensing materials containing isocyanates creates potentially harmful mists,

vapors, and atomized particulates.

Read material manufacturer’s warnings and

material MSDS to know specific hazards and

precautions related to isocyanates.

Prevent inhalation of isocyanate mists, vapors,

and atomized particulates by providing sufficient

ventilation in the work area. If sufficient ventilation is not available, a supplied-air respirator is

required for everyone in the work area.

To prevent contact with isocyanates, appropriate

personal protective equipment, including chemically impermeable gloves, boots, aprons, and

goggles, is also required for everyone in the work

area.

Moisture Sensitivity of Isocyanates

Exposure to moisture (such as humidity) will

cause ISO to partially cure; forming small,

hard, abrasive crystals, which become suspended in the fluid. Eventually a film will form

on the surface and the ISO will begin to gel,

increasing in viscosity.

NOTICE

Partially cured ISO will reduce performance

and the life of all wetted parts.

• Always use a sealed container with a

desiccant dryer in the vent, or a nitrogen

atmosphere. Never store ISO in an open

container.

• Keep the ISO pump wet cup or reservoir

(if installed) filled with appropriate lubricant. The lubricant creates a barrier

between the ISO and the atmosphere.

Material Self-ignition

Some materials may become self-igniting if

applied too thick. Read material manufacturer’s

warnings and material MSDS.

Keep Components A and B(R) Separate

Cross-contamination can result in cured material

in fluid lines which could cause serious injury or

damage equipment. To prevent cross-contamination:

• Never interchange component A and component B(R) wetted parts.

• Never use solvent on one side if it has been

contaminated from the other side.

• Use only moisture-proof hoses compatible with ISO.

• Never use reclaimed solvents, which

may contain moisture. Always keep solvent containers closed when not in use.

• Always lubricate threaded parts with an

appropriate lubricant when reassembling.

NOTE: The amount of film formation and rate

of crystallization varies depending on the blend

of ISO, the humidity, and the temperature.

311338J 5

Page 6

Important Two-Component Material Information

Foam Resins with 245 fa Blowing Agents

Some foam blowing agents will froth at temperatures above 90°F (33°C) when not under

pressure, especially if agitated. To reduce

frothing, minimize preheating in a circulation

system.

6 311338J

Page 7

Important Two-Component Material Information

311338J 7

Page 8

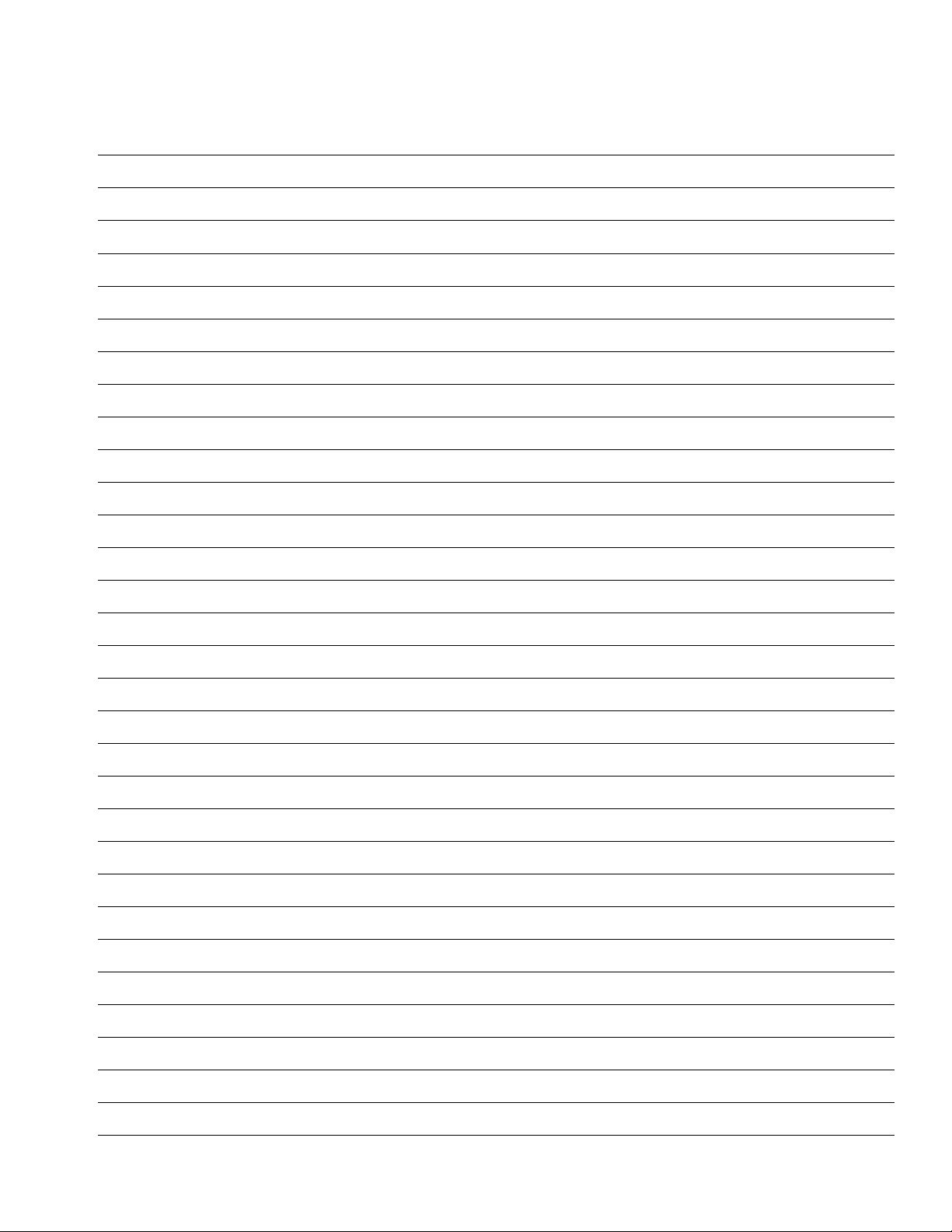

Overall View

Overall View

Gun Block

Mounting Screw

Air Cap

Gun Block

FIG. 1: GX-8P Overall View

Manual

Valves

Coupling

Block

Safety Stop

125 PSI MAX

Air Cap Air

Adjustment

Valve

Trigger

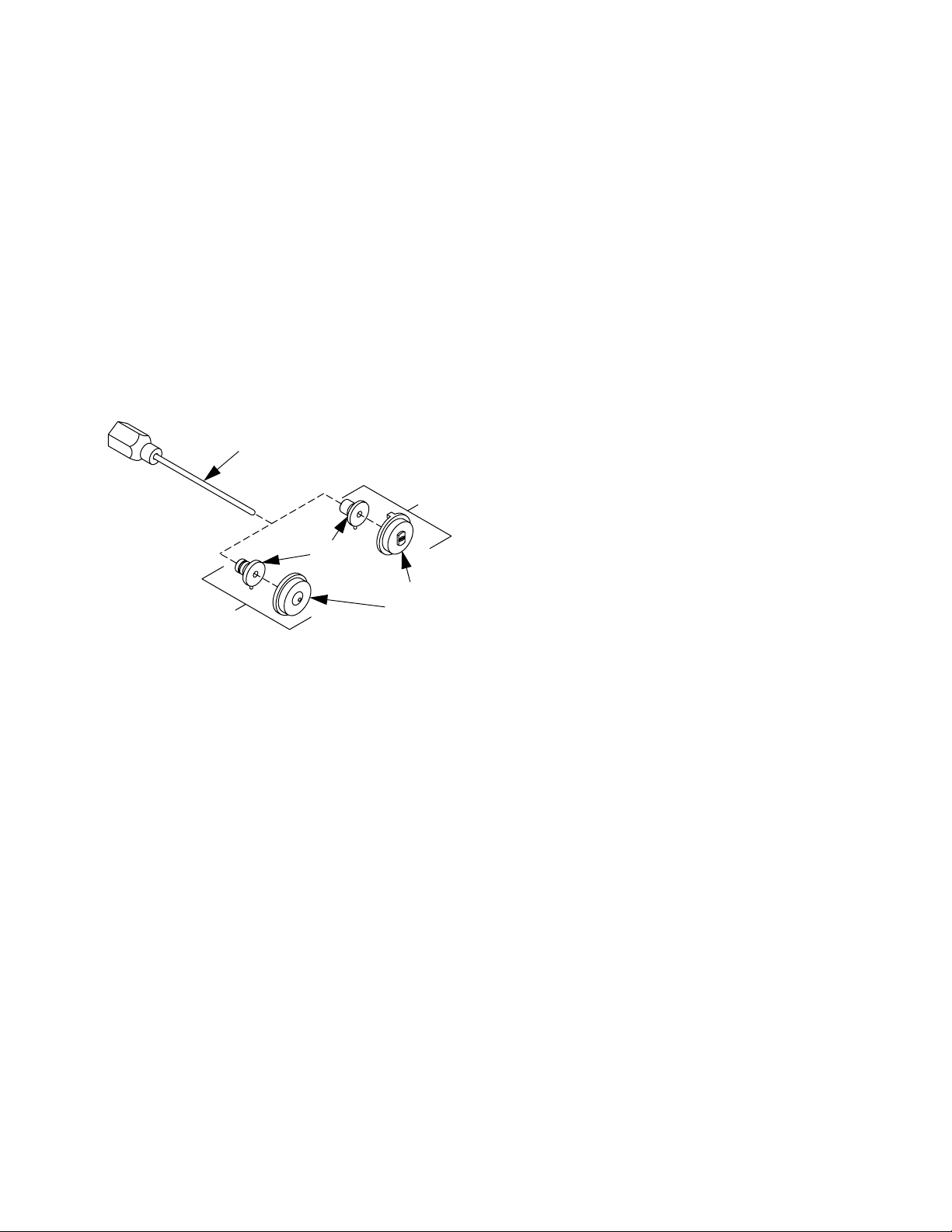

Centerline Components

B-Screen Screw

Screen

Screen

Pattern Control

Disc (PCD)

PCD

Retainer

Gun Block

Air Cap

Retainer

Mixing

Module

B-Check

Valve

Coupling

Block Gasket

O-Ring

Screen

Retainer

A-Check

Valve

Coupling Block

Mounting Screw

Packing Nut

Rear Seal

Screen

Jam Nut

Valving Rod

Assembly

A-Screen

Screw

FIG. 2: GX-8P Centerline Components

8 311338J

Page 9

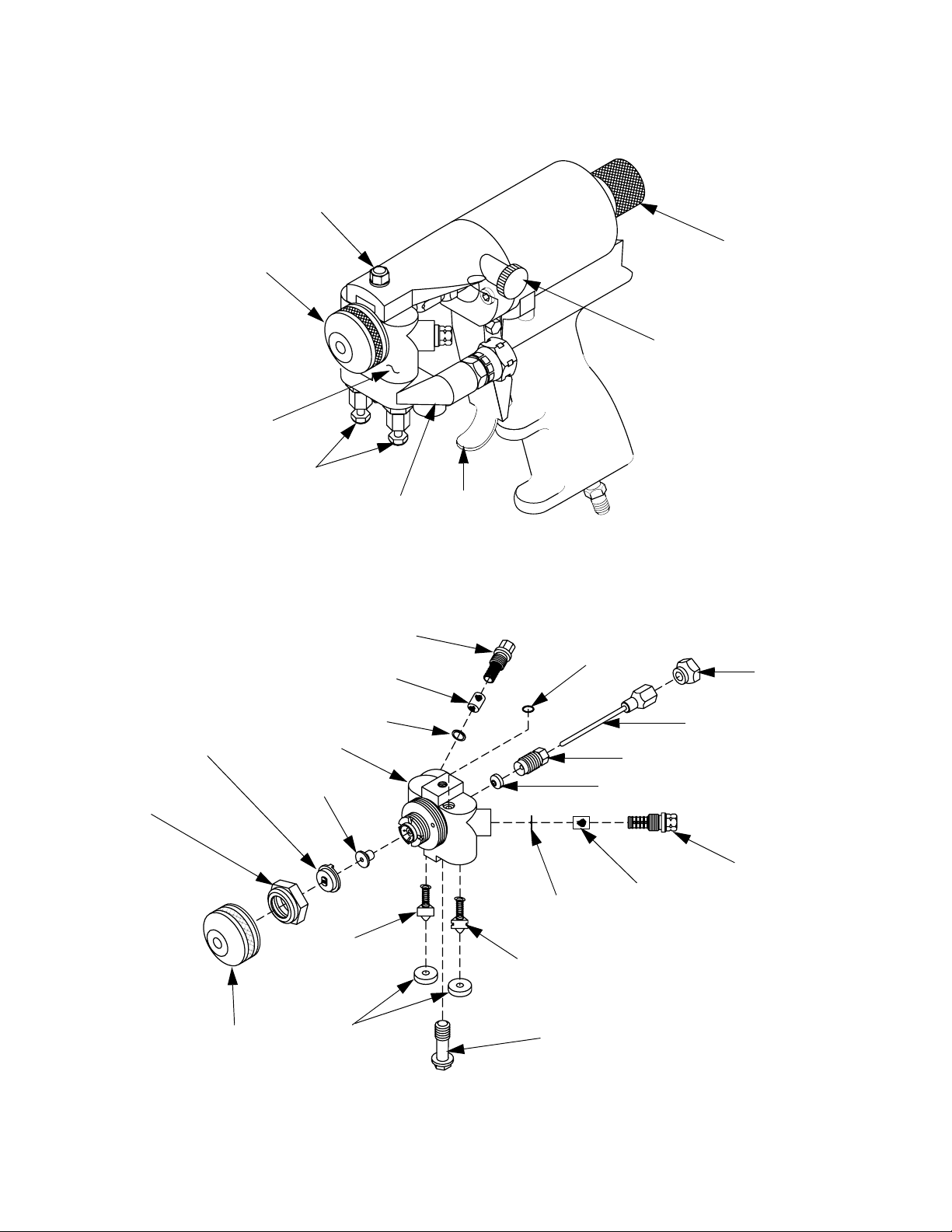

Mixing Module

Graco offers a variety of spray tip configurations to meet most applications that spray

fast-reaction chemical systems at low outputs.

GX-8P spray tip components consist of a Pattern Control Disc (PCD) and a Mixing Module

(Figure 3). Tip components are available in a

range of sizes in both round and fan spray patterns. Please contact your authorized Graco

distributor to help you determine the best configurations for your specific application.

Valving Rod

Assembly

Fan Spray

Pattern

Overall View

Mixing

Module

Round

Spray Pattern

FIG. 3: Mixing Module & PCD

Pattern

Control

Disc (PCD)

311338J 9

Page 10

Operation Basics

1

Operation Basics

To prevent accidental gun operation, always

disconnect air supply before servicing gun or

anytime gun is not in use.

Grounding

Check your local electrical code and proportioner manual for detailed grounding instructions.

Ground spray gun through connection to

Graco-approved grounded fluid supply hose.

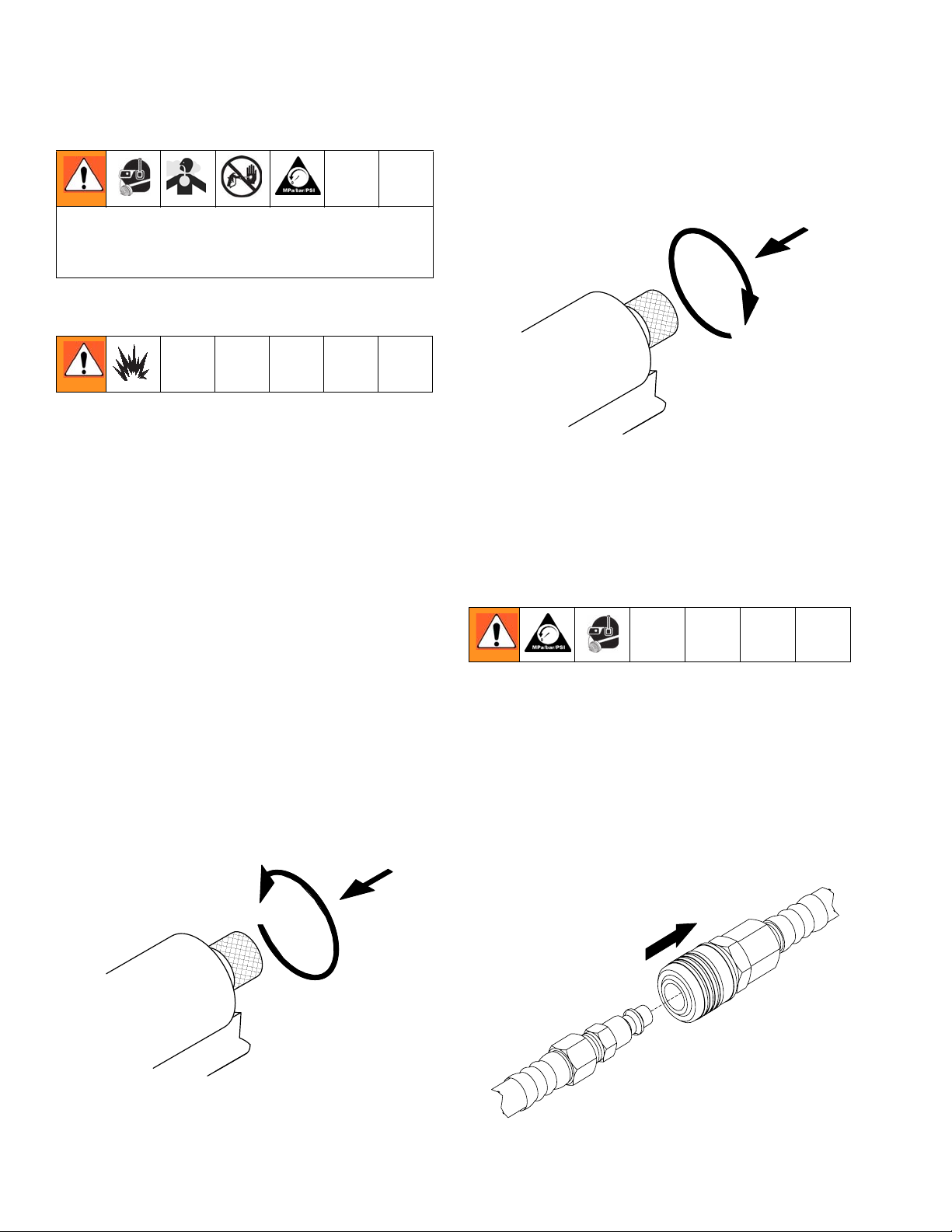

Disengage Safety Stop

To disengage safety stop, push in and turn

safety stop counterclockwise to place gun in

OPEN position.

Disengage the

Safety Stop

125 PSI MAX

FIG. 5: Safety Stop - Disengaged

Air Hose Connection

Safety Position

GX-8P guns have a two-position safety stop.

When engaged, it prevents accidental triggering of gun during servicing or down time. When

disengaged, it allows gun to dispense.

Engage Safety Stop

To engage safety stop, push in and turn safety

stop clockwise to place gun in CLOSED safety

position.

Engage the

Safety Stop

Connect Air Hoses

Pull back sleeve of female fitting, insert male

fitting and slide sleeve forward to secure connection.

Disconnect Air Hoses

Pull back sleeve of female fitting and pull out

male fitting.

Pull Sleeve

125 PSI MAX

FIG. 4: Safety Stop - Engaged

10 311338J

Page 11

Operation Basics

FIG. 6: Disconnect Air Hose

Coupling Block

Chemical hoses are joined to gun block by a

coupling block to ease installation and removal

of gun.

Manual Valves

Two manual valves located on coupling block

control flow of each chemical component to

gun.

Never open manual valve unless coupling

block is secured to gun or unless you point

gun into waste container.

Close Manual Valves

Use 5/16 in. nut driver to turn manual valve

fully clockwise.

To prevent accidental gun operation, always

set safety stop to CLOSED, close both manual valves, and disconnect air supply.

Installation and Removal

To prevent release of pressurized chemicals,

close both manual valves before coupling

block is removed.

NOTE: Triggering gun with manual valves

closed may cause crossover if any residual

chemical remains in gun ports.

Open Manual Valves

Use 5/16 in. nut driver to turn manual valve

counterclockwise approximately three full

turns.

Coupling

Block

Manual

Valves

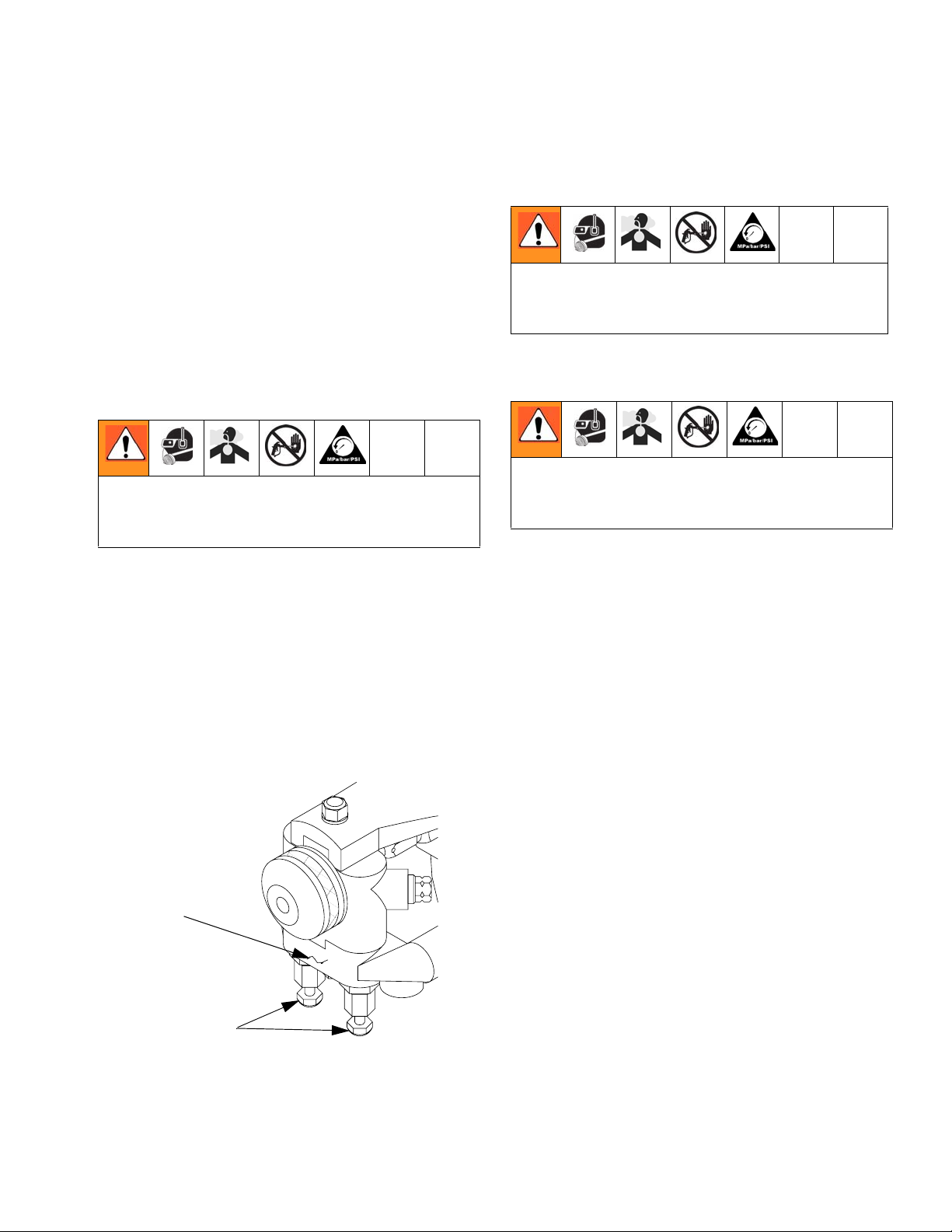

Install Coupling Block

1. Replace nicked, damaged, or worn coupling block gaskets.

2. Ensure A-(isocyanate) and B-(resin) check

valves are inserted into their proper

recesses in gun block. Isocyanate valve is

notched for easy identification.

FIG. 7: Open Manual Valves

311338J 11

Page 12

Operation Basics

3. Fit coupling block into gun block and insert

coupling block mounting screw. Use 5/16

in. nut driver to tighten to gun block.

B-Check

Valve

A-Check

Valve

Coupling Block

Gaskets

Coupling Screw

Mounting Screw

125 PSI MAX

Air Inlet Configuration

There are two configurations for the air inlet. In

the standard configuration, the air inlet is at

base of handle. In the alternate configuration,

the air inlet is at rear of gun.

Pipe Plug

125 PSI MAX

Pipe

Nipple

Optional

Pipe Plug

FIG. 8: Install Coupling Block

Remove Coupling Block

1. CLOSE safety stop.

2. Disconnect air hose.

3. Close both manual valves.

4. Remove coupling block mounting screw.

5. Separate coupling block from gun.

6. Wipe mating surfaces of gun block and

coupling block to remove residual chemicals.

7. Cover exposed openings with grease.

NOTE: To avoid accidental gun operation,

ensure coupling block manual valves are

closed before attempting to service gun, or any

time gun is not in use.

FIG. 9: Air Inlet Configuration

To change to alternate configuration:

1. Use 6 in. adjustable wrench to remove 4 in.

pipe nipple from base of gun.

2. Use 3/16 in. hex key to remove 1/8 in. pipe

plug from rear of gun.

3. Use 3/16 in. hex key to install 1/8 in. pipe

plug in location previously occupied by 4 in.

pipe nipple.

4. Use 6 in. adjustable wrench to install pipe

nipple in location previously occupied by

1/8 in. pipe plug.

12 311338J

Page 13

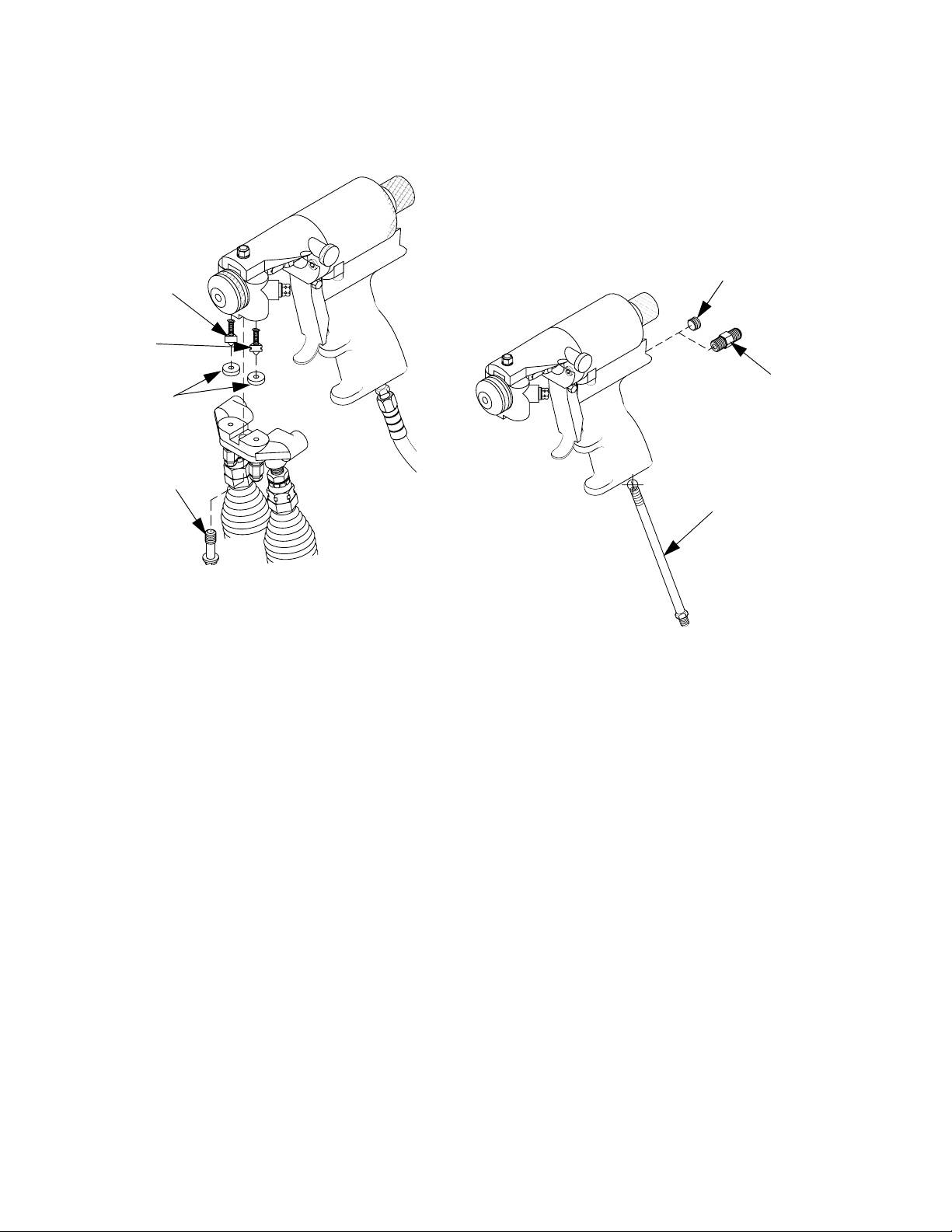

Mixing Module and PCD Installation

1. Loosen air cap by hand and remove.

2. Install mixing module:

a. Disconnect gun from coupling block.

b. Connect air supply to gun.

c. Set safety stop to OPEN.

d. Hold down trigger and place module

over tip of valving rod.

e. Align keying pin with slot in gun block

and keep gun trigger held down.

Operation Basics

3. Install PCD:

a. Hold down gun trigger and thread PCD

retainer in place by hand.

b. Use 10 in. adjustable wrench to care-

fully tighten PCD retainer until snug

enough to ensure no leak will occur.

c. Release gun trigger.

4. Install air cap and tighten by hand.

5. Adjust valving rod (see Valving Rod

Adjustment, page 14).

311338J 13

Page 14

Operation Basics

Valving Rod Adjustment

Valving rod should not require adjustment if it

was shipped from factory with mixing module

and PCD installed. Valving rod should only require adjustment when:

• Piston/rod assembly/ring is changed

• Valving rod is changed

• PCD is installed or changed

• Mixing module is installed or changed

To adjust valving rod:

1. Perform Clean Spray Gun Procedure,(see

page 18.

2. Connect air supply to gun.

3. Use 5/16 in. open-end wrench to loosen

packing nut 3 or 4 turns. This relieves pressure between seals and makes adjustment

easier.

Valving Rod

Assembly

4. Use 3/8 in. wrench on hex-shaped valving

rod shank and 1/2 in. wrench on jam nut to

loosen and back it away from valving rod by

3 or 4 full turns. Then move valving rod

toward gun cylinder. Turn valving rod shank

2 or 3 full turns clockwise.

5. Slowly turn valving rod counterclockwise to

move it toward PCD until resistance is felt.

Valving rod tip should touch inside spherical surface of PCD.

6. Carefully maintain 3/8 in. wrench in position

and tighten jam nut up against valving rod

shank to lock adjustment into place.

7. Retighten packing nut.

8. Check rear safety stop by attempting to disengage it. If knob will not turn, valving rod

is adjusted too far forward. Repeat steps 3 -

7. Make sure not to adjust valving rod past

the point resistance is felt. If safety stop disengages, proceed to step 9.

9. Trigger gun with safety stop disengaged to

confirm rear seal adjustment. Make sure

rod moves freely. If not, loosen packing nut

slightly until it does. Start to spray and

check for chemical seepage from packing

nut and retighten if necessary.

NOTE: If valving rod required adjustment as

part of initial mixing module and PCD installation on a new spray gun, proceed to Initial Set

Up, page 15.

Packing

Nut

FIG. 10: Valving Rod Adjustments

14 311338J

Jam Nut

Page 15

Operation Basics

Initial Set Up

1. Remove coupling block from gun.

2. Use two 6 in. adjustable wrenches to install

female quick disconnect fitting onto air supply hose bundled with chemical supply

hoses.

3. Use two 6 in. adjustable wrenches to connect A-isocyanate hose (red-taped) to

notched fitting on coupling block. Connect

B-resin hose (blue-taped) to fitting without

notches on coupling block.

4. Close both manual valves.

5. Pressurize A and B chemical hoses and

check for leaks (see Proportioner manual

as needed).

6. Bleed air from chemical hoses:

a. Hold coupling block with exit ports

pointed into waste container.

b. Use 5/16 in. nut driver to open each

manual valve; this allows any trapped

air to escape. Bleed each side for a

short time until chemicals leaving hoses

are free of air.

c. Close both manual valves.

7. Use cloth soaked in gun cleaner to clean

coupling block and mating surfaces.

NOTICE

Do not apply grease to mating surfaces of

coupling block to avoid accumulation of dirt

and other contaminants.

8. CLOSE safety stop.

9. Install coupling block to gun.

10.Proceed with daily start-up and shutdown

procedures as required.

311338J 15

Page 16

Operation Basics

Daily Start-up

Ensure gun is attached to coupling block and

air hose. Ensure proportioning unit is at

desired temperature and pressure. Properly

ground equipment to avoid static sparking

that may result in fire or explosion.

1. Connect air supply to gun.

2. Adjust air cap adjustment valve. Turn knob

counterclockwise to open valve and clockwise to close valve.

3. Open both manual valves.

4. OPEN safety stop.

5. Test spray on a disposable surface and

evaluate.

Daily Shutdown

NOTE: Follow daily shutdown procedure when

gun is out of service for any length of time, or

for mid- or end-of-day service. See Clean

Spray Gun Procedure, page 18.

1. CLOSE safety stop.

2. Close both manual valves.

3. Disconnect air supply from gun.

4. Shut down proportioning unit as required.

5. Clean as required (see Clean Spray Gun

Procedure, page 18).

NOTE: Disassembling gun for daily cleaning is

not recommended if gun has been operating

properly. However, if gun is removed from coupling block, it must be flushed and cleaned

thoroughly.

16 311338J

Page 17

Pressure Relief Procedure

Pressure Relief

Procedure

Relieve pressure before cleaning or repairing

gun.

1. Close both manual valves.

4. Release gun trigger, CLOSE safety stop,

and close manual valves.

If fluid in hose and proportioner is still under

pressure, follow Pressure Relief Procedure in

proportioner manual

To relieve pressure in hose after gun is

removed, place fluid manifold over containers,

facing away from you. Very carefully open

fluid valves (FIG. 13). Under high pressure,

fluid will spray sideways from fluid ports.

Manual Valves

FIG. 11: Close Manual Valves

2. OPEN safety stop.

3. Trigger gun onto cardboard or into waste

container to relieve pressure.

2

!

FIG. 13: Open Manual Valves

FIG. 12: Trigger Gun

311338J 17

Page 18

Maintenance

Maintenance

Gun Service Kits

Use either 1-Quart Gun Service Kit (296980)

or 3-Gallon Gun Service Kit (296981) to perform daily flushing of spray gun without disassembly.

FIG. 14: 1-Quart Gun Service Kit

For more information about 1-Quart Gun Service Kit, see Manual 311340.

FIG. 15: 3-Gallon Gun Service Kit

For more information about 3-Gallon Gun Service Kit, see Manual 311341.

Clean Spray Gun Procedure

To avoid static sparking that may result in fire

or explosion, ensure all equipment in cleaning

procedure is grounded. Do not clean on or

near foamed or coated surfaces or any other

flammable surfaces or objects.

Thoroughly flush gun block with gun cleaner

before removing valving rod or mixing components from gun block. Also allow chemicals in

spray gun to cool before cleaning.

This procedure makes use of the 1-Quart or

3-Gallon Gun Service Kit.

1. CLOSE safety stop.

2. Close both manual valves.

3. Remove gun from coupling block.

18 311338J

Page 19

Maintenance

4. Attach service block of gun service kit to

spray gun, and then tighten using 5/16 in.

nut driver.

5. Pressurize service kit container up to 100

psi. DO NOT EXCEED 100 psi (0.7 MPa, 7

bar).

6. Clean gun:

a. Set safety stop to OPEN.

b. Open either manual valve on service

block.

c. Trigger gun and gun service kit simulta-

neously with gun aimed into waste container.

d. Release both triggers and close manual

valves on service block.

Flush Gun

To avoid static sparking that may result in fire

or explosion, ensure all equipment in flushing

procedure is grounded. Do not flush on or

near foamed or coated surfaces.

1. CLOSE safety stop.

2. Close both manual valves.

3. Loosen B-Screen screw and then remove

by hand.

4. Use flush can to thoroughly flush screen

screw and screen screw cavity.

5. Loosen A-Screen screw and then remove

by hand.

e. Repeat procedure for other side of gun.

f. After initial cleaning, remove air cap,

PCD retainer, and PCD. Flush a second

time to ensure thorough cleaning.

7. CLOSE safety stop.

8. Disconnect air supply from gun.

9. Remove service block of gun service kit

from gun.

10.Clean screens, check valves and screen

screw (see Service Screen Screw, page

20.

NOTE: Inspect air cap, PCD, mixing module,

and gun block for build up of material and

clean as required.

6. Use flush can to thoroughly flush screen

screw and screen screw cavity.

7. Service gun, see Maintenance procedures, page 18.

Do not use metal cleaning devices to clean

plastic components.

311338J 19

Page 20

Repair

Repair

Shutdown proportioner and allow chemicals

to cool before servicing gun.

Service Screen Screw

To avoid static sparking that may result in fire

or explosion, ensure all equipment in flushing

procedure is grounded. Do not flush on or

near foamed or coated surfaces.

1. Flush gun see Clean Spray Gun Proce-

dure, page 18.

2. Unthread screen screw from gun block.

3. Remove screen screw retainer before

removing screen.

4. Remove screen from screen screw. Soak in

gun cleaner or replace if clogged or dirty.

5. Clean screen screw cavity. If any particles

are visible, clean with clean out drills and

flush with gun cleaner.

NOTE: Any material left in cavity on downstream side of screen will clog mixing module.

6. Inspect screen screw seal for damage.

Replace if necessary.

7. Reinstall screen screw in gun block. Ensure

it is tight.

8. Flush gun with mixing module removed.

Remove Check Valve

To avoid static sparking that may result in fire

or explosion, ensure all equipment in flushing

procedure is grounded. Do not flush on or

near foamed or coated surfaces.

Check valves are located in cavities of gun

block under each coupling block gasket. Check

valves are triangular pieces with a spring inserted in one end. The isocyanate valve is notched

for easy identification.

To remove check valve:

1. Clean gun (see Clean Spray Gun Proce-

dure, page 18).

2. Use check valve seal removal/cleaning tool

to remove gaskets from recesses in coupling block. Inspect gaskets for damage

and replace if necessary.

3. Remove check valves. If valve does not

come out easily, insert machined end of

removal/cleaning tool over valve and rotate

it while extracting valve.

4. Clean valves and springs with gun cleaner.

Inspect for damage and replace if necessary.

5. Inspect each check valve cavity. Use cleaning tool to remove any visible particles. Use

gun cleaner to flush thoroughly.

6. Insert each check valve into its cavity

spring end first. Ensure check valve is oriented correctly. Isocyanate valve is notched

for easy identification.

7. Install coupling block gaskets.

20 311338J

Page 21

Repair

Remove Centerline Components

Refer to page 8 for diagrams of centerline

components for all gun models.

1. Flush gun (see Clean Spray Gun Proce-

dure, page 18).

2. Remove air cap (loosen by hand).

3. Use 10 in. adjustable wrench to remove

PCD.

4. Connect air supply to gun.

5. Lift PCD off nose of gun block and remove.

NOTE: To remove PCD that is stuck, set safety

stop to OPEN, depress and release gun trigger

to unseat it. CLOSE safety stop.

11.Remove and clean check valves (see

Remove Check Valve, page 20).

12.Remove valving rod:

a. Use 3/8 in. wrench on hex-shaped valv-

ing rod shank and a 1/2 in. wrench on

jam nut to loosen it and back it away

from valving rod shank by 3 or 4 full

turns.

b. Unthread valving rod from piston shaft

and remove.

13.Clean all components thoroughly before

reassembly.

14.Inspect gun block to ensure proper operation of spray gun.

6. Remove mixing module retainer.

7. OPEN safety stop. Depress and release

gun trigger to unseat it. Remove mixing

module off end of valving rod. CLOSE

safety stop.

NOTICE

Do not use sharp objects or metal tools to

remove mixing module.

8. Disconnect air supply from gun.

9. Use 5/16 in. wrench to loosen packing nut

3 or 4 turns.

10.Remove gun block:

a. Use 5/16 in. nut driver to remove gun

block retaining screw.

Install Centerline Components

Before installation, ensure all gun components

are clean and dry. Lubricate all moving parts

and threads.

1. To install valving rod, thread jam nut as far

back on piston shaft as possible. Screw

shank end of valving rod onto threaded end

of piston rod.

2. Install rear seal and packing nut if removed.

Thread packing nut into gun block by hand,

but do not tighten.

3. To install gun block, carefully slide gun

block onto valving rod towards air cylinder.

Use 5/16 in. nut driver to install gun block

onto gun block mounting bracket.

4. Connect air supply to gun.

b. Slide gun block away from valving rod

and air cylinder. If dried chemical is built

up on gun block, remove dried chemicals to make removal easier.

311338J 21

5. OPEN safety stop.

Page 22

Repair

6. To install mixing module, hold down gun

trigger and slide module over end of valving

rod. Make sure to align keypin with slot in

gun block. Keep gun trigger depressed and

proceed to step 7.

7. To install PCD, hold gun trigger in and

place PCD over mixing module. If installing

a fan tip, position PCD according to which

spray direction is needed (vertical or horizontal). Keep gun trigger depressed and

proceed to step 8.

NOTE: Parts must align properly or chemical

flow from gun block ports will not enter mixing

module when gun is triggered.

8. Install PCD retainer:

a. With gun trigger depressed, thread

PCD retainer in place by hand.

Replace End Cap and Air Piston Assembly

End Cap/Safety

Stop Assembly

Retaining

Ring

Piston

Spring

FIG. 16: End Cap and Air Piston Assembly

Piston

End Cap

O-Ring

Cylinder

Cup Seal

Piston

O-Ring

#8 Socket Head

Cap Screw

b. Use 10 in. adjustable wrench to care-

fully tighten PCD retainer until it is snug

enough to ensure no leak will occur.

c. Release gun trigger.

NOTICE

To avoid damage to module and gun block,

do not overtighten mixing module retainer.

9. Install air cap and tighten by hand.

10.Adjust valving rod (see Valving Rod

Adjustment, page 14).

1. Clean gun (see Clean Spray Gun Proce-

dure on page 18).

2. Disconnect air supply from gun.

3. Use 5/16 in. wrench to loosen packing nut

3 or 4 turns (remove nut completely if rear

seal needs to be replaced).

4. Remove gun block:

a. Use 5/16 in. nut driver to remove gun

block mounting screw.

b. Carefully slide gun block away from

valving rod and air cylinder. If dried

chemical has built up on gun block,

remove dried chemical to make removal

easier.

c. Remove valving rod and jam nut (see

Remove Check Valve, page 20):

22 311338J

Page 23

Repair

d. Use 3/8 in. wrench on hex-shaped valv-

ing rod shank and 1/2 in. wrench on jam

nut.

e. Loosen jam nut and back it away from

valving rod shank by 3 or 4 full turns.

f. Unthread valving rod and jam nut from

piston shaft.

5. OPEN safety stop.

6. Use 9/64 in. ball point hex key to remove

socket head cap screw that holds air cylinder to handle (FIG. 16).

7. Use retaining ring 45° pliers to remove

retaining ring that holds end cap in place

inside air cylinder.

8. Remove end cap/safety stop assembly and

piston spring:

a. Pull safety stop and attached end cap

out of air cylinder.

b. Remove piston spring located inside

cylinder. Be sure to retain spring for

reinstallation.

a. Remove piston/rod assembly:

Use gun block mounting screw (screw

that holds gun block to bracket) to aid in

removal of piston.

b. Look into rear of air cylinder and thread

mounting screw into center hole of piston at least 4 full turns.

c. Use 6 in. pliers to grab mounting screw

and pull piston rod assembly out of air

cylinder.

d. Inspect ring and replace if damaged.

Apply light coat of Lubriplate grease

and install new ring.

10.Inspect air cylinder cup seal. If air escapes

around piston rod during operation, remove

and replace cup seal located in front of air

cylinder. Lubricate new cup seal with Lubriplate grease and install it. Make sure cup

faces toward rear of cylinder.

11.Insert piston and rod assembly into air cylinder. Be careful not to damage cup seal in

front face of air cylinder as rod passed

though. Remove gun block mounting screw

from piston.

NOTE: Force will be required to remove end

cap because ring is tightly compressed.

9. Inspect end cap ring. Replace if damaged.

Apply light coating of Lubriplate grease and

install new end cap ring.

NOTE: Skip steps 11-13 and go to step 14 if

only end cap ring and cup seal need to be

replaced.

311338J 23

Page 24

Repair

12.Disassemble safety stop mechanism:

a. Use 5/64 in. hex key to remove two set

screws from knob.

b. Slide knob off stop pin and retain stop

pin spring.

c. Pull shaft out of end cap (FIG. 17).

13.Remove cup seal from end cap and inspect

for damage. Remove if damaged. Apply

light coat of Lubriplate grease and install

new end cap ring.

Knob

Set Screws

End Cap

Cup Seal

O-ring

Spring

Stop Pin

d. Maintain pressure on end cap. Ensure

groove remains visible.

16.Use retaining ring 45° pliers to reinstall

retaining ring into groove.

Retaining ring must seat completely into

groove to secure end cap in place when air

cylinder is pressurized. Keep clear of cap

when air pressure is applied or gun is triggered after reassembly.

17.Use 9/64 in. ball-point hex key to install and

tighten socket head cap screw, which holds

air cylinder to handle.

18.Reinstall valving rod and jam nut:

a. Thread jam nut as far as it will go onto

threaded end of piston shaft.

b. Ensure hex end of nut faces rear.

FIG. 17: End Cap/Safety Stop Assembly

14.Reassemble safety stop mechanism:

a. Insert stop pin into end cap hole.

b. Slide spring and knob onto stop pin.

c. Use 5/64 in. hex key to reinstall two set

screws into knob. Ensure knob is

secure.

15.Reinstall end cap/safety assembly and piston spring:

a. Insert piston spring and align over

raised center of piston.

b. Line up raised center of end cap with

spring and insert end cap into air cylinder.

c. Thread valving rod as far onto threaded

portion of piston rod as possible.

19.Thread packing nut into gun block by hand

but do not tighten.

20.Install gun block:

a. Ensure ring is in place in top of gun

block.

b. Carefully slide gun block onto valving

rod toward air cylinder.

c. Use 5/16 in. nut driver to install gun

block onto gun block mounting bracket.

21.Adjust valving rod (see Valving Rod

Adjustment on page 14).

c. Press end cap until it moves past retain-

ing ring groove in cylinder.

24 311338J

Page 25

Repair

Replace Trigger Valve O-Rings

1. Clean gun (see Clean Spray Gun Procedure, page 18).

2. Perform Pressure Relief Procedure, page

17.

3. Disconnect air supply from gun.

Refer to Parts, page 28.

1/16 in. Pipe

Plug

Spring

Seat

Valve

Liner

O-rings

03)-!8

1/8 in.

Pipe Plug

c. Apply thin coat of Lubriplate grease to

new rings and reinstall.

NOTE: Follow steps 7-14 to replace rings on

valve liner. If rings do not need to be replaced,

proceed to step 15.

7. Use 3/16 in. hex key to remove 1/8 in. rear

internal plug. This plug seals another airflow path in gun handle.

NOTE: For guns configured with air inlet at

rear of gun handle, pipe nipple replaces pipe

plug. Remove pipe nipple.

8. Use 5/32 in. hex key to remove rear internal

pipe plug (under pipe plug).

9. Use pin punch and hammer to gently tap

spring seat until it and valve liner push out

opposite end of hole.

Valve

Spring

Valve

Spool

Valve Retainer Nut

FIG. 18: Replace Trigger Valve O-Ring

Trigger Lever

Optional 1/8 in.

Pipe Nipple

Trigger Mounting

Screw

4. Use 6 in. adjustable wrench and 6 in. pliers

to remove screw and locknut that hold trigger lever in place. Remove trigger lever.

5. Use 3/8 in. wrench to loosen and remove

valve retainer nut.

6. Remove valve spool and spring:

a. Grab end of spool and pull out. Spring

will come out with spool. Do not lose

spring--it belongs in hole at end of

spool.

10.Remove rings on liner. Apply thin coat of

Lubriplate grease to new rings and install.

11.Clean valve hole. Remove any dirt and

debris. Apply thin coat of Lubriplate grease

to inside of valve hole.

12.Slide spring seat into gun handle air valve

hole, tapered end first, until it bottoms out.

13.Push valve liner in as far as it will go. Install

valve retainer nut, it will align valve liner

and spool to their proper depth.

14.Use 5/32 in. hex key to screw 1/16 in. pipe

plug back into place. Apply think coat of

pipe thread sealant to threads prior to

insertion to help prevent air leaks.

15.Apply small amount of pipe thread sealant

to 1/8 in. plug threads. Screw pipe plug in

place.

b. Remove old rings.

16.Insert valve spool into valve liner with valve

spool spring still in place. Screw in valve

retainer nut; tighten until snug.

311338J 25

Page 26

Repair

17.Use screw and locknut to reinstall trigger

lever.

Clean Mixing Module

1. Flush gun (see Clean Spray Gun Procedure, page 18).

2. Connect air supply to gun. OPEN safety

stop.

3. Remove air cap by hand.

9. Inspect valving rod for damage and replace

as required. Use cloth soaked in gun

cleaner or steel wool to clean and remove

buildup of mixed material from rod.

NOTE: If valving rod is replaced, reset forward

stop.

10.Cleanmixing module.

NOTE: Ensure cleanout tool size matches

module size used.Insert cleanout tool into pin

vise.

d. Use cleanout tool to clean module

ports. Make sure not to insert tool too

far, it will damage inside bore of module.

Use cotton swab soaked in gun cleaner

to clean bore of module.

FIG. 19: Unthread Cap from PCD Body

4. Trigger gun and hold it to relieve pressure

on PCD retainer.

5. Turn PCD retainer counterclockwise and

remove.

6. Remove PCD from mixing module retainer.

NOTE: To remove PCD that is stuck, set safety

stop to OPEN, depress and release gun trigger

to unseat it. CLOSE safety stop.

7. Remove mixing module retainer.

8. OPEN safety stop. Depress and release

gun trigger to unseat it. Remove mixing

module from end of valving rod. CLOSE

safety stop.

FIG. 20: Clean Module Ports

26 311338J

Page 27

Troubleshooting

Follow Pressure Relief Procedure, page 17,

before checking or repairing gun.

Troubleshooting

NOTICE

To prevent cross-contamination of the equipment’s wetted parts, never interchange component A (isocyanate) and component B

Use the following table to check all possible

problems and causes before disassembling

gun. See Maintenance on page 18 for referenced procedures.

(resin) parts. The gun is shipped with the A

side on the left. The gun block and the screen

screw are marked.

Problem Cause Solution

Gun does not fully actuate Safety lock engaged Disengage piston safety lock

Air not vented on open/close ports Vent open air port when closing,

vent close air port when opening

Loss of air Check air source

Fluid does not pour when gun is

fully actuated

Gun actuates slowly Loss of air pressure Check air source

Gun delays, then actuates abruptly Cured material around the purge

Gun does not actuate Air supply to gun is shut off Open air supply

Pressure imbalance Plugged orifice ports Clean orifice ports

Fluid does not shut off when fluid

valves are closed

Leak between air cylinder and fluid

housing

Material leaking out weep ports in

fluid housing near air cylinder

Closed manual valves Open valves

Plugged orifice ports Clean orifice ports

Plugged check valves Clean check valves

Safety lock engaged Disengage piston safety lock

Damaged piston o-rings Replace air piston o-rings

Inspect purge rod, mix module,

rod

Foam build-up around front tip Clean off front tip.

Plugged check valves Clean check valves

Plugged fluid screens Clean screens

Damaged fluid valves Replace

Damaged o-ring Replace

Mix module and rear seal worn Inspect and replace mix module

and orifices. Replace if necessary

and rear seal, clean fluid housing

311338J 27

Page 28

Parts

Parts

GX-8 Gun Final Assembly (297898)

12

19

23

15

22

21

17

8

11

24

10

20

11

4

3

2

9

17

16

18

13

14

03)-!8

1, 25

6

5

28 311338J

Page 29

GX-8 Gun Final Assembly (297898)

Ref. Part Description Qty.

1 15B772 HOSE, air, 1/4 in. x 23 in.

(F x F)

2 296128 GASKET, block, gasket 2

3 295623 VALVE, check, A 1

4 295624 VALVE, check, B 1

5 295596 PLUG, coupler 1

6 208536 Coupler, line, air 1

8 106560 PACKING, O-ring 1

9 295433 SCREW, mounting, block,

coupling

10 297680 NUT, seal, rear 1

11 297681 RETAINER, screen 2

12 297682 SCREW, mounting, block,

gun

13 297683 NUT, jam 1

14 297702 HANDLE, assembly 1

15 297684 RETAINER, PCD 1

16 295341 ROD, valving 1

17 297193 SCREEN, gun block, 100

mesh

18 297686 SCREW, screen, iso 1

19 297687 SCREW, screen, res 1

20 295437 PACKING, seal, rear 1

21 295338 MODULE, fan 1

22 297192 TIP, fan 1

23 297705 CAP, air 1

24 297901 BLOCK, gun 1

25 100030 Fitting 1

Parts

1

1

1

2

311338J 29

Page 30

Parts

GX-8 Handle Assembly (297702)

80

97

104

102

103

101

72

98

106

85

91

96

100

89

82

75

106

81

79

94

105

92

88

93

77

86

99

84

95

76

76

74

03)-!8

83

90

87

73

30 311338J

Page 31

GX-8 Handle Assembly (297702) GX-8 Gun Kit (297832)

Ref. Part Description Qty.

72 295435 SEAL, u-cup 1

73 295709 SCREW, cap, socket head 2

74 295662 PLUG, pipe 1

75 295732 SCREW, cap, sh, 8-32 x 1/4

LG

76 103337 PACKING, ring 3

77 106555 PACKING, ring 4

79 C02032 NUT 1

80 296627 SEAL, u-cup 1

81 295692 TRIGGER, gun, spray 1

82 116624 SCREW, set, socket head 2

83 295693 PLUG, pipe 1

84 296971 SPRING 1

85 108103 PACKING, ring 1

86 168518 PACKING, ring 1

87 295665 FITTING, nipple, pipe 1

88 295671 SCREW, mounting, trigger 1

89 296538 RING, retaining 1

90 297689 HANDLE, gun 1

91 16T691 CYLINDER, air 1

92 295686 LINER, valve 1

93 295687 SPOOL, valve 1

94 295688 NUT, retainer, valve 1

95 295689 SEAT, spring 1

96 295436 SPRING 1

97 297691 PISTON, assembly 1

98 296529 CAP, end 1

99 297693 NEEDLE, adjust, air 1

100 296530 KNOB, gap 1

101 296526 PIN, stop 1

102 295416 SPRING, piston 1

103 297694 BRACKET, assembly 1

104 114054 PACKING, ring 1

105 C20004 SCREW, cap 2

106 295685 RING 4

1

202

Ref. Part Description Qty.

201 297898 GUN 1

202 295383 BLOCK, coupling 1

203★296980 KIT, service; includes

203a-203k

203a SPRAYER, solvent, flush 1

203b VALVE, service, air 1

203c SCREW, mounting, block,

coupling

203d VALVE, manual 2

203e NIPPLE, JIC 1

203f SCREW, block, coupling 1

203g BLOCK, service 1

203h FITTING; 3/8 in. x 7/16 in. 1

203k HOSE; 3/16 ID x 3 ft 1

204★297911 KIT, starter; includes

204a-204g

204a PIN, vise 1

204b MODULE, fan, 013 1

204c TIP, round, 020 1

204d MODULE, round, 020 1

204e TIP, round, 024 1

204f TIP, fan, 201 1

204g TIP, fan, 202 1

125 PSI MAX

Parts

201

1

1

1

★ Not shown.

311338J 31

Page 32

Parts

GX-8P Spray Gun Final Assembly (297860)

120

127

130

129

131

125

114

126

116

121

119

122

118

113

107

128

109

123

124

117

110

108

115

FIG. 21: GX-8P Spray Gun Final Assembly

111

112

32 311338J

Page 33

GX-8P Spray Gun Final Assembly (297860)

Ref. Part Description Qty.

107 15B772 HOSE, air, 1/4 X 23 in. (F X F) 1

108 296128 GASKET, block, gasket 2

109 295623 VALVE, check, A 1

110 295624 VALVE, check, B 1

111 295596 PLUG, coupler 1

112 208536 COUPLER, line, air 1

113 191872 FITTING, pipe, hex 1

114 106560 PACKING, o-ring 1

115 295433 SCREW, mounting, block,

coupling

116 297680 NUT, seal, rear 1

117 297681 RETAINER, screen 2

118 297682 SCREW, mounting, block, gun 1

119 297683 NUT, jam 1

120 297684 RETAINER, pod 1

121 295341 ROD, valving 1

122 297861 CYLINDER, GX-8P, auto 1

123 297193 SCREEN, gun block,

100 mesh

124 297686 SCREW, screen, iso 1

125 297687 SCREW, screen, res 1

126 295437 PACKING, seal, rear 1

127 297705 AIR, cap 1

128 112307 ELBOW, street 1

129 297901 BLOCK, gun 1

130 297192 TIP, fan 1

131 295338 MODULE, fan 1

1

2

Parts

311338J 33

Page 34

Parts

GX-8P Auto Cylinder Assembly (297861)

51

47

49

26

52

58

59

48

45

36

38

35

60

30

39

53

50

61

27

37

46

28

31

61

32

54

32

57

33

34

44

43

29

60

33

56

40

42

41

FIG. 22: GX-8P Auto Cylinder Assembly

34 311338J

Page 35

GX-8P Auto Cylinder (297861)

Ref. Part Description Qty.

26 295435 SEAL, u-cup 1

27 295709 SCREW, cap, socket head 4

28 295732 SCREW, cap, sh,

8-32 X 1/4 LG

29 104376 SCREW, cap, sch 2

30 297743 TIE, cable, #6 1

31 C20988 PACKING, o-ring 2

32 103337 PACKING, o-ring 4

33 297253 WASHER, helical, .188 in.

diameter

34 104705 SCREW, cap, sch 2

35 296627 SEAL, u-cup 1

36 116624 SCREW, set, socket head 2

37 297862 SCREW, cap, flat head 1

38 108103 PACKING, o-ring 1

39 168518 PACKING, o-ring 1

40 297863 SCREW, cap, socket head 3

41 297975 WASHER, lock 3

42 297881 VALVE, control 1

43 297882 MANIFOLD, air valve 1

44 297883 GASKET 1

45 296538 RING, retaining 1

46 297690 CYLINDER, air 1

47 295436 SPRING 1

48 297691 PISTON, assembly 1

49 296529 CAP, end 1

50 297884 NEEDLE, air adjust 1

51 296530 KNOB, gap 1

52 296526 PIN, stop 1

53 297885 BRACKET 1

54 297886 BLOCK, valve mount 1

56 297888 PLATE, mounting, gun 1

57 297889 PLATE, cover, manifold 1

58 295416 SPRING, piston 1

59 114054 PACKING, o-ring 1

60 C20004 SCREW, cap 4

61 295685 O-RING 4

Parts

1

4

311338J 35

Page 36

Parts

Auto GX-8P Optional Parts

8

7

1

2,3,4

2,3,4

5

Ref. Part Description

1 297899 KIT, auto, GX-8 Gun

2 298752 WIRE, 10 ft, extension har-

ness

3 298753 WIRE, 25 ft, extension har-

ness

4 298754 WIRE, 50 ft, extension har-

ness

5 298611 ENCODER, assembly

6 299083 CABLE, VMU, extension 25 ft

7 297730 CABLE, encoder, assembly

8 297741 CONTROL BOX, TX50 pro-

cessor

6

Qty.

1

1

1

1

1

1

1

1

36 311338J

Page 37

Coupling Block Assembly (295383)

62

63

Parts

66

62

65

Ref. Part Description Qty.

62 295662 Pipe plug, flush seal, 1/8 in. 2

63 295888 B-swivel fitting 1

64 295889 A-swivel fitting 1

65 295693 Pipe plug, flush seal, 1/16 in. 2

66 296970 Manual valve assembly 2

67 296215 Coupling block 1

67

64

311338J 37

Page 38

Parts

Coupling Block (297902)

70

67

71

Ref. Part Description

67 295662 PLUG, pipe

70 296626 VALVE, assembly, manual

71 260810 Block, coupling

Qty.

2

2

1

38 311338J

Page 39

Coupling Block Assembly (24N996)

Parts

308

306

302

305

305

301

307

305

Apply pipe sealant to all male threads

prior to assembly. Torque fittings to

120-130 in-lb (14-15 N•m)

Ref. Part Description

301 296215 BLOCK, coupling, ss 1

302 295430 VALVE, manual 2

303 104071 PLUG, pipe 2

304 112307 FITTING, street elbow 2

305 C20895 FITTING, bushing, 1/4 x 1/8 4

306 117506 FITTING, swivel, 1/4 npt x #6 jic 1

307 122722 ADAPTER, jic06x1/4npt, mm, ms, 6k 1

308 122963 ADAPTER, swvl, jic05x1/4npt, fm, ms, 6 1

309 117455 FITTING, nipple, 1/4 npt x #5 jic 1

ti19795a

Qty.

309

305

304

303

304

311338J 39

Page 40

Set-up Chart for GX-8P Modules

Set-up Chart for GX-8P Modules

Pres-

sure

(psi)

2500 1.0 4.0 295377 .013 1 .013 1 295339 (020)

2500 1.4 5.0 295377 .013 1 .013 1 295428 (024)

2500 1.0 6 295338 .013 1 .013 1 297192 (201)

2500 1.4 7 295338 .013 1 .013 1 297841 (202)

Output

(lbs/min)

Pattern

✖Dia.

(inches)

Module Part

No.

Round Spray Pattern

Resin

Port

Size

Fan Spray Pattern

No.

Orifices

Iso Port

Size

No.

Orifices Tip

✖ At 18-24 in. above substrate

GX-8P Model Specifications

Module/Tip Data for Chemical Sprayed at 2500 PSI

❄Output

✖Module Kit Cleanout Drill Tip ❄Pattern

(lbs/min)

Fan Spray Pattern

295338

(.098 diameter)

295377

(.098 diameter)

297914

(.013 diameter)

297914

(.018 diameter)

297192 (201) 6 in. wide 1.0

297841 (202) 7 in. wide 1.4

Round Spray Pattern

295339 (020) 4 in. diameter 1.0

295428 (024) 5 in. diameter 1.4

❄ Actual results may vary due to chemical system characteristics, temperature, pressure,

and ratio.

Tool Kits

297966 GX-8P Tool Kit

✖ Includes appropriate cleanout drills.

40 311338J

Page 41

Technical Data

Category Data

Air Supply 100-125 psi (7-9 bars)

Maximum Operating Pressure 3500 psi (24 MPa, 240 bar)

Maximum Output ❄ 0.4 gallons/min. (1.52 liters/min.)

Minimum Output ❄ 0.1 gallons/min. (0.38 liters/min.)

Maximum sound pressure*† 78.7 db(A) 100 psi (0.7 MPa, 7 bar)

Maximum sound power**† 85.7 db(A) 100 psi (0.7 MPa, 7 bar)

Height 7 in. (17.8 cm)

Length 7.5 in. (19 cm)

Width 2.5 in. (6.25 cm)

Technical Data

Weight

Mixing Internal impingement, airless atomization, sol-

Wetted Parts Stainless Steel, Carbon Steel, HDPE, Acetal

❄ Theoretical: actual results will vary with operating conditions.

† Measured at typical operating conditions (clean-off valve on gun is a half turn open).

* Sound pressure measured 3 feet (1 meter) from equipment.

** Sound power measured per ISO-9416-2.

3.5 lbs. (1.59 kg)

vent-free, mechanically self cleaning

311338J 41

Page 42

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from

defects in material and workmanship on the date of sale to the original purchaser for use. With the exception of any special,

extended, or limited warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace

any part of the equipment determined by Graco to be defective. This warranty applies only when the equipment is installed,

operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused

by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering,

or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the

incompatibility of Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper

design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by

Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor

for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts.

The equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose

any defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts,

labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING

BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no

other remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or

property, or any other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within

two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS

SOLD BUT NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors,

switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable

assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying

equipment hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach

of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal

proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les

parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et

procédures judiciaires exécutés, donnés ou intentés, à la suite de ou en rapport, directement ou indirectement, avec les

procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211, Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2006, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 311338

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised October 2012

Loading...

Loading...