Page 1

Instructions/Parts List

High Pressure

Fluid Regulators

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

309475F

II 2 G

Page 2

Contents

List of Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Flush Before First Use . . . . . . . . . . . . . . . . . . . 13

Pressure Relief Procedure . . . . . . . . . . . . . . . . 13

Adjusting the Regulator . . . . . . . . . . . . . . . . . . . 13

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Manual Conventions

Warning

WARNING

A warning alerts you to the possibility of serious injury

or death if you do not follow the instructions.

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Accessory Gauges . . . . . . . . . . . . . . . . . . . . . . . . . 25

Flow Rate Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . 26

Graco Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 28

Symbols, such as fire and explosion (shown above),

alert you to a specific hazard and direct you to read

the indicated hazard warnings (pages 4-5) for detailed

information.

Caution

CAUTION

A caution alerts you to the possibility of damage to or

destruction of equipment if you do not follow the

instructions.

2 309475F

Page 3

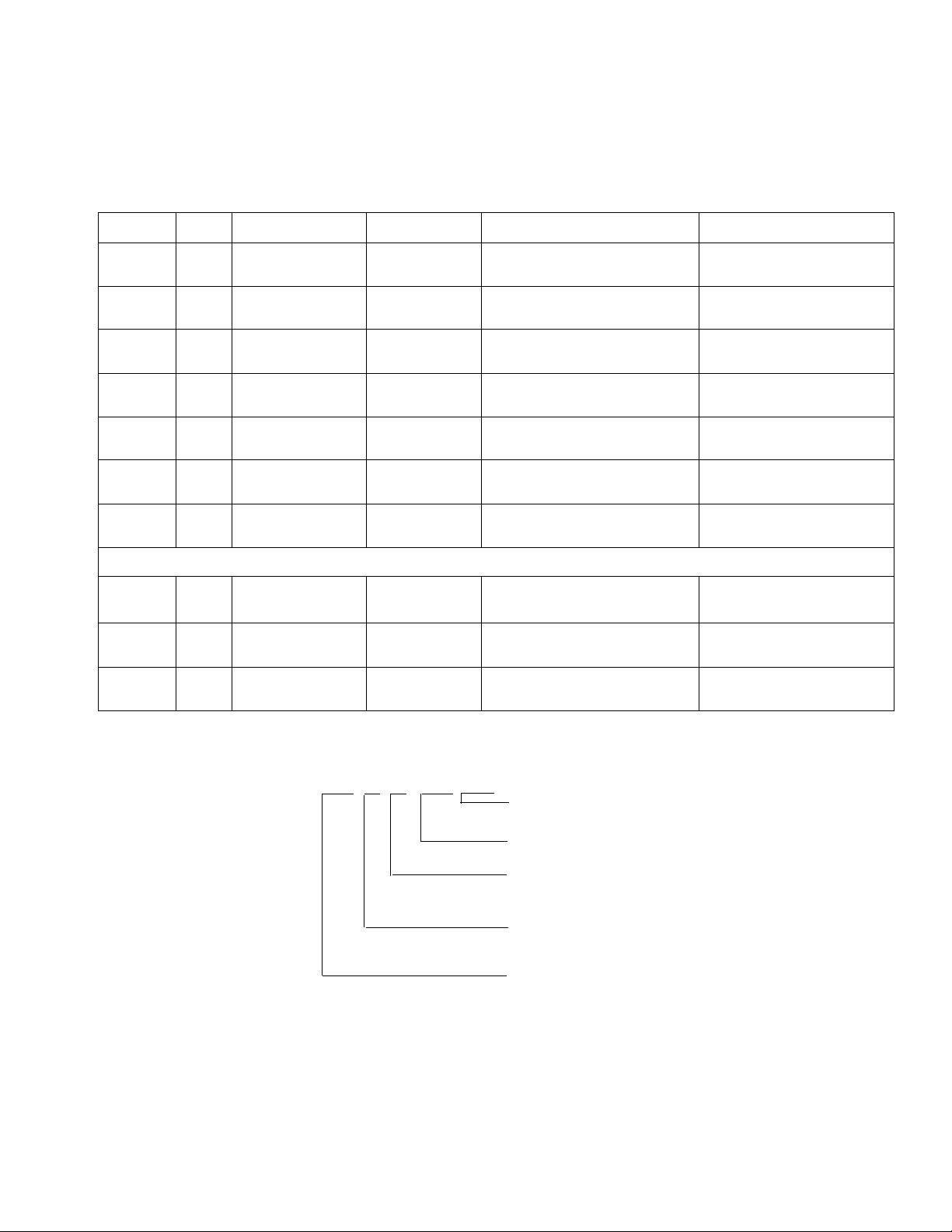

List of Models

List of Models

Part No. Series Model Type Maximum Fluid Inlet Pressure Regulated Pressure Range

233760

234266BB

233767

234264BB

233768

234265BB

233769

234270BB

233770

234271BB

233813

234259BB

233814

234260BB

Back Pressure Regulators

Part No. Series Model Type

233771

234268BB

233772

234269BB

P60-VP DN7

P60-VP DN7 npt

P200-VM

P200-VM npt

P200-VM

P200-VM npt

P150-VP DN7

P150-VP DN7 npt

P320-VP DN7

P320-VP DN7 npt

P250-VP

P250-VP npt

P100-VM

P100-VM npt

P100-RM

P100-RM npt

P200-RM

P200-RM npt

Pneumatic 5000 psi (36 MPa, 360 bar) 70-900 psi

Mechanical 5000 psi (36 MPa, 360 bar) 1300-3000 psi

Mechanical 5000 psi (36 MPa, 360 bar) 1300-4000 psi

Pneumatic 5000 psi (36 MPa, 360 bar) 300-2000 psi

Pneumatic 5000 psi (36 MPa, 360 bar) 600-4600 psi

Pneumatic 5000 psi (36 MPa, 360 bar) 600-3600 psi

Mechanical 2600 psi (18 MPa, 180 bar) 600-1500 psi

Mechanical,

back pressure

Mechanical,

back pressure

(0.5-6 MPa, 5-60 bar)

(9-20 MPa, 90-200 bar)

(9-27 MPa, 90-270 bar)

(2-15 MPa, 20-150 bar)

(4-32 MPa, 40-320 bar)

(4-25 MPa, 40-250 bar)

(4-10 MPa, 40-100 bar)

Maximum Permanent Supply

Pressure

2500 psi (17 MPa, 170 bar) 600-1500 psi

3400 psi (23.5 MPa, 235 bar) 1300-3000 psi

Regulated Pressure Range

(4-10 MPa, 40-100 bar)

(9-20 MPa, 90-200 bar)

Key to Model Designation

Pressure regulation valve e.g. P60- R M DN7 npt

npt version

Valve Seat Orifice 7mm

Operating Mode P - pneumatic

M - mechanical

Action V - pressure regulation

R - back-pressure regulation

Regulation max 60 bar

309475F 3

Page 4

Warning

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

• This equipment is for professional use only.

• Read all instruction manuals, tags, and labels before operating the equipment.

• Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

• Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

Technical Data on page 24 for the maximum working pressure of this equipment.

• Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Techni-

cal Data section of all equipment manuals. Read the fluid and solvent manufacturer's warnings.

• Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 180°F (82°C) or below -40°F (-40°C).

• Wear hearing protection when operating this equipment.

• Never use 1,1, 1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents in pressurized aluminum equipment. Such use could result in a chemical reaction, with the possibility of explosion.

• Comply with all applicable local, state, and national fire, electrical, and safety regulations.

4 309475F

Page 5

Warning

WARNING

SKIN INJECTION HAZARD

Spray from the gun, hose leaks, or ruptured components can inject fluid into your body and cause an

extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the skin can

also cause serious injury.

• Fluid injected into the skin might look like just a cut, but is a serious injury. Get immediate surgical

treatment.

• Do not point the gun at anyone or at any part of the body. Do not put your hand or fingers over the

spray tip. Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

• Never spray without the tip guard in place.

• Follow the steps under Pressure Relief Procedure, page 13, when you stop spraying and before

cleaning, checking, or repairing equipment.

• Check the hoses and couplings daily. Replace worn, damaged, or loose parts immediately. Permanently coupled hoses cannot be repaired; replace the entire hose.

• Tighten all fluid connections before each use.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

• Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

• Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

• Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

309475F 5

Page 6

Introduction

Introduction

A fluid pressure regulator is used in air-assisted spray

systems to ensure accurate, positive control of fluid

pressure to a spray gun, dispensing valve, or atomizing

head.

A regulator installed at a circulating line take-off or pump

reduces main line pressure to maintain the desired fluid

pressure to the spray gun, dispensing valve, or atomizing head.

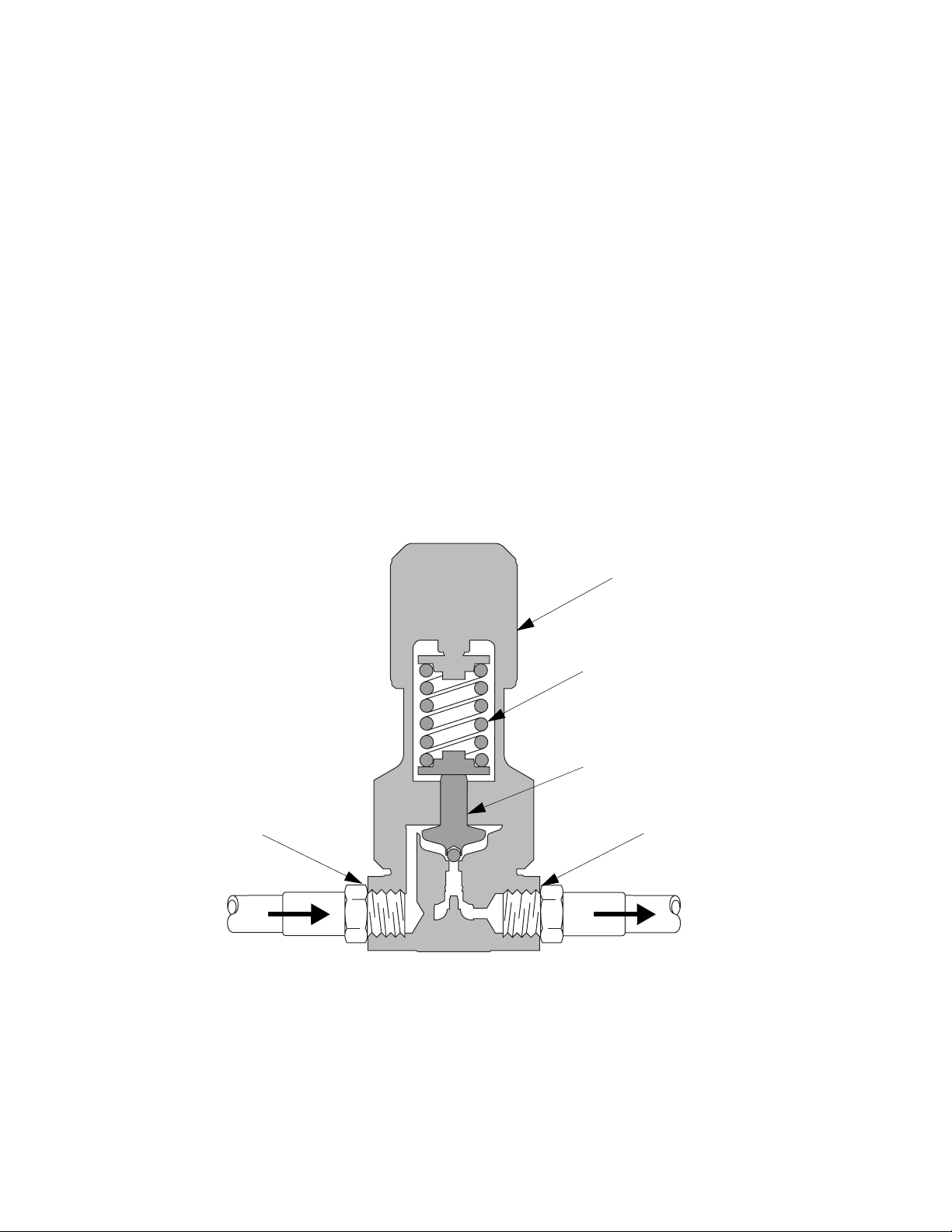

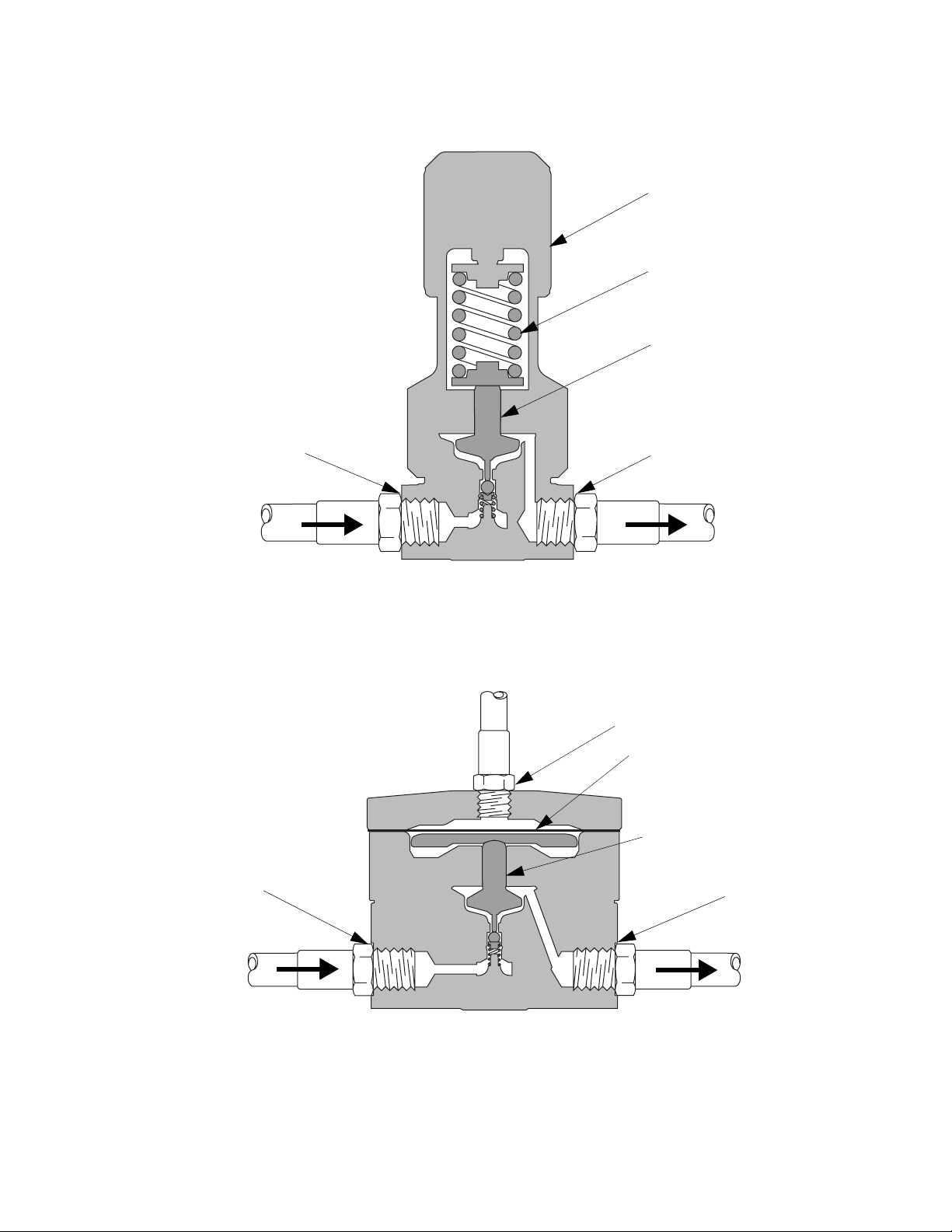

Models 233771, 233772, 234268 and 234269 (F

are mechanically operated back pressure regulators that

limit the supply pressure to a set value by opening an

outlet and guiding back excess material when the predetermined pressure has been achieved. These valves are

used in circulating systems.

IG. 1.)

Models 233767, 233814, 233768, 234260, 234264, and

234265 (F

sure regulators designed primarily for use with low to

medium viscosity fluids.

Models 233760, 233769, 233770, 233813, 234259,

234266, 234270, and 234271 (F

cally operated fluid pressure regulators designed primarily for use with highly viscous coatings.

IG. 2.) are mechanically operated fluid pres-

IG. 3.) are pneumati-

Adjustment knob

Adjustment knob

Adjustment knob

Fluid Inlet

(From gun)

Fig. 1. Cutaway of Mechanical Back Pressure Regulator

Spring

Valve plunger

Fluid Outlet

(Return line)

TI1770A

6 309475F

Page 7

Adjustment knob

Adjustment knob

Adjustment knob

Spring

Valve plunger

Introduction

Fluid inlet

(from pump)

TI1769A

Fig. 2. Cutaway of Mechanical Fluid Pressure Regulator

Fluid Inlet

(From pump)

Fluid outlet

(to gun)

TI1769A

Air Inlet

Diaphragm

Valve plunger

Fluid Outlet

(To gun)

TI1774A

Fig. 3. Cutaway of Pneumatic Fluid Pressure Regulator

309475F 7

Page 8

Installation

Installation

1. Install one regulator for each spray gun.

2. Apply thread sealant to connections as necessary.

3. Make sure that the direction of fluid flow agrees with

the flow direction markings on the regulator body.

a. Install a fluid pressure regulator upstream of the

gun: Connect the fluid line from the pump to the

inlet of the fluid regulator. Connect the fluid line

to the gun to the regulator’s outlet.

b. Install a back pressure regulator downstream of

the gun. Connect the fluid return line from the

gun to the inlet of the back pressure regulator.

Connect the fluid return line to the pump to the

regulator’s outlet.

4. Flush and test the entire system.

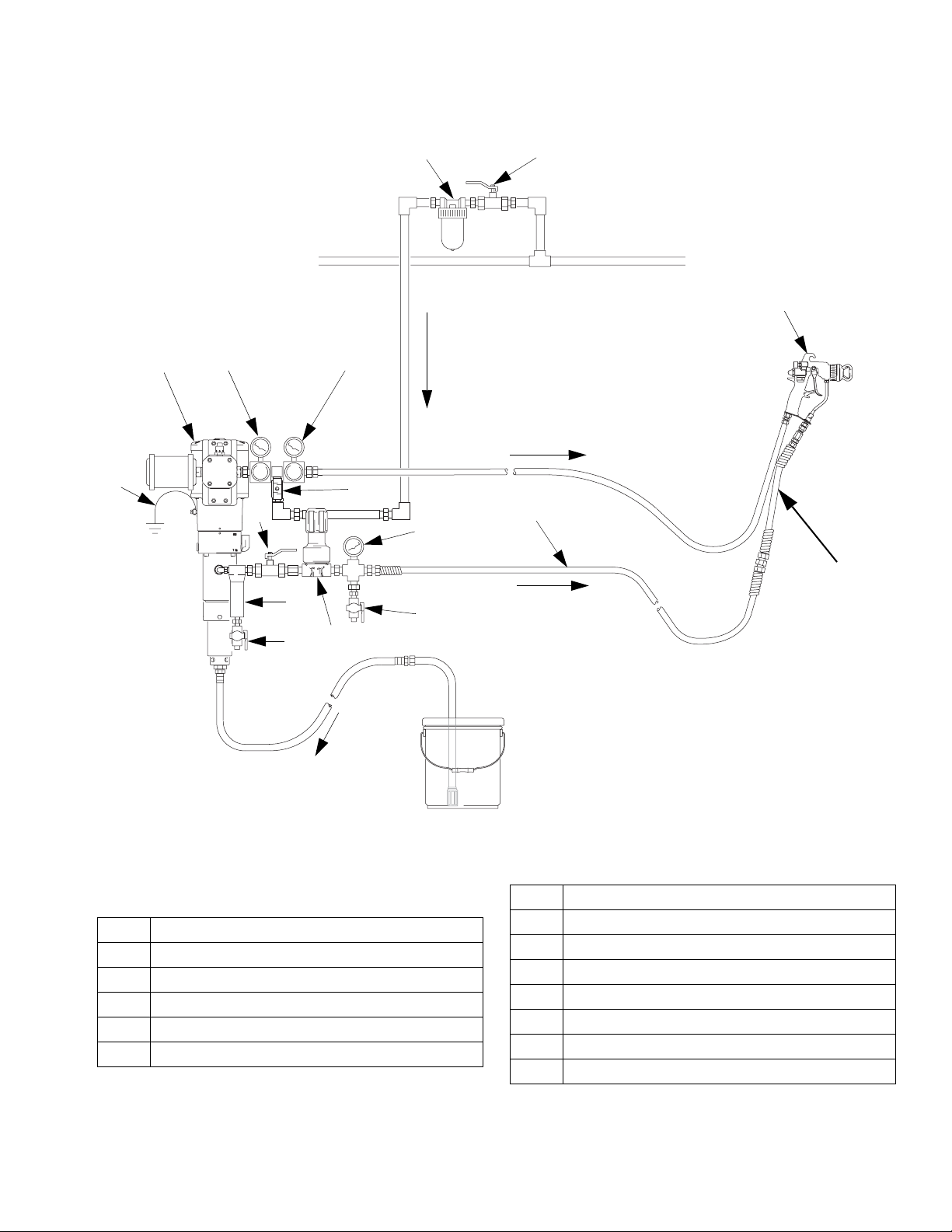

F

IG. 4., FIG. 5., and FIG. 6. show possible configurations

for installing a system. They do not depict actual system

designs. Consult your Graco distributor for assistance in

designing a system that meets your specific requirements.

8 309475F

Page 9

Installation

A

B

L

F

C

D

Air in

to pump

Air in

to gun

H

Y

H

B

E

K

Z

M

Fluid

G

J

G

Fluid in

Fig. 4. High pressure, non-circulating system, mechanical fluid regulator

Key

A Air line filter

B Bleed-type air shut-off valve

C Pump air regulator

D Gun air regulator

E Fluid hose

FPump

G Fluid drain valve

H Fluid shut-off valve

J Mechanical fluid pressure regulator

K Fluid pressure gauge

L Air-assisted spray gun

M Fluid filter

Y Pump ground wire

Z Whip hose

TI1763C

309475F 9

Page 10

Installation

A

B

A

N

B

L

Air to

Pump

Air to Fluid

D

C

F

Regulator

Air to

Gun

B

Y

K

Fluid

E

Z

H

M

J

G

G

d

i

u

l

F

Fig. 5. High pressure, non-circulating system, pneumatic fluid regulator

Key

J Pneumatic fluid regulator

A Air line filter

B Bleed-type air shut-off valve

C Pump air regulator

D Gun air regulator

E Fluid hose

FPump

K Fluid pressure gauge

LGun

M Fluid filter

N Air regulator to operate/adjust fluid regulator

Y Pump ground wire

Z Whip hose

G Fluid drain valve

H Fluid shut-off valve

TI1764C

10 309475F

Page 11

B

Installation

Air supply

D

A

H

Air to

gun

Fluid in

to gun

L

J

P

H

TI1765A

Fig. 6. High Pressure circulating system mechanical fluid regulator and back pressure regulator

Key

J Mechanical fluid regulator

A Air line filter

B Bleed-type air shut-off valve

LGun

P Mechanical back pressure regulator

D Pump air regulator

H Fluid shut-off valve

309475F 11

Page 12

Installation

12 309475F

Page 13

Operation

Operation

Flush Before First Use

Your pressure regulator has been tested in the factory

with an anti-corrosion liquid. Before using the regulator,

thoroughly flush the system with a solvent to remove

residue of this liquid as well as any contaminants that

have been introduced during assembly of the system.

Pressure Relief Procedure

WARNING

The system pressure must be manually relieved to

prevent the system from starting or spraying accidentally. To reduce the risk of an injury from accidental

spray from the gun, splashing fluid, or moving parts,

follow the Pressure Relief Procedure whenever you:

• are instructed to relieve the pressure

• stop spraying

• check or service any of the system equipment

• or install or clean the spray tip.

Adjusting the Regulator

The fluid pressure regulator controls pressure downstream from its outlet. The inlet fluid pressure should

always be higher than the outlet fluid pressure.

If you are using an accessory fluid pressure gauge, trigger the spray gun to relieve pressure in the line when

reducing the pressure, to ensure a correct gauge reading.

Adjust the pump air pressure and the fluid pressure regulator for the best spraying combination.

In a circulating system, the back pressure valve controls

the fluid pressure upstream of its inlet in the same way.

Mechanical Regulator

1. Back out the knob until there is no spring pressure.

2. Turn on the fluid supply, to admit fluid to the regulator.

3. Turn the knob clockwise to adjust fluid pressure to

the desired level.

1. Lock the gun trigger safety.

2. Close the bleed-type master air valve (required in

your system).

3. Unlock the gun trigger safety.

4. Hold a metal part of the gun firmly to the side of a

grounded metal pail and trigger the gun to relieve

pressure.

5. Lock the gun trigger safety.

6. Open the drain valve (required on your system), with

a container ready to catch the drainage.

7. Leave the drain valve open until you are ready to

spray again.

If you suspect that the spray tip or hose is completely

clogged or that pressure has not been fully relieved after

performing steps 1 through 7, very slowly loosen the tip

guard retaining nut or hose end coupling and relieve

pressure gradually. Then loosen completely and clear

the tip or hose.

Pneumatic Regulator

1. With the fluid supply shut off, turn on the air pressure to the regulator.

2. Turn on the fluid supply, to admit fluid to the regulator.

3. Increase the fluid inlet pressure. When the fluid outlet pressure is at the desired level, shut off the air to

the fluid regulator.

309475F 13

Page 14

Troubleshooting

Troubleshooting

Relieve the pressure (page 13) before checking or repairing the equipment.

To repair the regulator, refer to page 15.

Problem Cause Solution

Drop in fluid outlet pressure. Ruptured diaphragm (17) (pneu-

matic regulators only).

Air escaping (pneumatic regulators

only).

Worn packings. Replace packings (13).

Fluid outlet pressure increases to

level of fluid inlet pressure.

Fluid leaking from upper housing. Ruptured diaphragm (17) (pneu-

Valve ball (8) and seat (4) are worn or

stuck open.

matic regulators only).

Worn packings. Replace packings (13).

Replace diaphragm.

Check air hose and connections.

Replace packings (13).

Clean ball and seat. Replace worn or

damaged parts.

Replace diaphragm.

14 309475F

Page 15

Maintenance

Maintenance

Flushing

WARNING

The system pressure must be manually relieved to

prevent the system from starting or spraying accidentally. Fluid under high pressure can be injected

through the skin and cause serious injury. To reduce

the risk of an injury from fluid injection, splashing fluid,

or moving parts, follow the Pressure Relief Proce-

dure whenever you:

• are instructed to relieve the pressure

• stop spraying

• check or service any of the system equipment

• or install or clean the spray tip.

1. Relieve the pressure.

2. Remove the spray tip. Clean the tip and set it aside.

3. Supply solvent to the pump. Start the pump. Use the

lowest possible fluid pressure when flushing.

Do not allow paint or solvent to sit in the system for

extended periods. Fluid could dry on the plunger and

cause leakage at the plunger packings. If leakage

occurs, disassemble and clean the regulator.

Cleaning and Repair

When changing fluids or colors, the regulator should be

disassembled and cleaned. Regular cleaning and

inspection of the internal parts is necessary to keep the

fluid regulator working properly.

1. Relieve all air and fluid pressure in the system.

2. Remove the regulator from the system.

3. Disassemble the regulator (see the parts drawings

on pages 16 through 22).

4. Clean and inspect all parts.

CAUTION

Be very careful when handling the carbide balls and

seats. Damage will cause poor operation and leakage.

4. Flush the gun, spraying into a grounded metal container until clean solvent comes from the gun.

5. Relieve the pressure.

6. Reinstall the spray tip.

5. Inspect the diaphragm, packings, o-rings, and seals

for wear. Check the ball and seat for nicks, wear, or

other damage.

6. Lubricate packings, o-rings and seals when reassembling the regulator.

7. Torque as specified on the parts drawings on pages

16 through 22

309475F 15

Page 16

Parts

Parts

Mechanical Regulators

Part Nos. 233767 (shown), 233768, 233814, 234260, 234264, and 234265

26

26

24

23

21

1

20

25

16

19

14

13

12

15

9

1

6

4

5

8

7

27

3

16

10

1

11

16 309475F

Torque to 25 N•m (18.5 ft-lb).

2

Page 17

Mechanical Regulators

Part Nos. 233767 (shown), 233768, 233814, 234260, 234264, and 234265

Ref.

Part No. Description Qty

Ref.

Part No. Description Qty

No.

No.

14 15A149 GLAND, female 1

Parts

1 HOUSING, lower 1

HOUSING, lower (for npt version) 1

2 15A238 PLUG, screw 1

3 117089 SPRING, compression 1

4 245367 SEAT, valve 1

5 15Y030 O-RING 1

6 15Y031 O-RING 1

7 15A206 SUPPORT, ball 1

8 117104 BALL, 5 mm 1

9 245374 PLUNGER, valve 1

10 15A217 HOUSING, packing 1

11 117112 O-RING, slit 1

12 15A223 GLAND, male 1

13 15A142 PACKING 3

15 117125 RING, retaining, internal 1

16 15A178 PLATE, spring 2

19 117093 SPRING, compression; for

233814 and 234260

117094 SPRING, compression; for

233767, 233768, 234264, and

234265

117088 SPRING, compression; for

233768, 234265

20 15A192 HOUSING, upper 1

21 117103 SEAL, flat 1

23 15A240 SCREW, custom 1

24 15A203 CAP 1

25 117108 BALL, 8 mm 1

26 117098 SCREW, set; M6x20 2

27 15Y029 O-RING 1

1

1

1

309475F 17

Page 18

Parts

Mechanical Back Pressure Regulators

Part Nos. 233771, 233772, 234268, and 234269 (shown)

26

26

24

23

10

11

14

13

12

21

15

9

1

20

1

25

6

16

19

16

4

5

27

2

1

Torque to 25 N•m

(18.5 ft-lb).

18 309475F

Page 19

Mechanical Back Pressure Regulators

Part Nos. 233771, 233772, 234268, and 234269

Ref.

Part No. Description Qty

No.

Parts

Ref.

Part No. Description Qty

No.

15 117125 RING, retaining, internal 1

1 HOUSING, lower 1

HOUSING, lower (for npt version) 1

2 15A238 PLUG, screw 1

4 245367 SEAT, valve 1

5 15Y030 O-RING 1

6 15Y031 O-RING 1

9 245376 PLUNGER, valve 1

10 15A217 HOUSING, packing 1

11 117112 O-RING, slit 1

12 15A223 GLAND, male 1

13 15A142 PACKING 3

14 15A149 GLAND, female 1

16 15A178 PLATE, spring 2

19 117093 SPRING, compression; for

233771 and 234268

117094 SPRING, compression; for

233772 and 234269

20 15A192 HOUSING, upper 1

21 117103 SEAL, flat 1

23 15A240 SCREW, custom 1

24 15A203 CAP 1

25 117108 BALL, 8 mm 1

26 117098 SCREW, set; M6x20 2

27 15Y029 O-RING 1

1

1

309475F 19

Page 20

Parts

Pneumatic Regulators

Part No. 233813 and 234259

29

30

20

26

1

Torque to 10 N•m (7.5 ft-lb).

1

9

11

11

17

16

18

14

13

12

15

1

6

4

5

8

7

27

3

2

TI1749A

20 309475F

Page 21

Pneumatic Regulators

Part No. 233813 and 234259

Ref.

Part No. Description Qty

No.

1

HOUSING, lower

HOUSING, lower (npt version only)

2 15A238 PLUG, screw

3 117089 SPRING, compression

4 245367 SEAT, valve

5 15Y030 O-RING

6 15Y031 O-RING

7 15A206 SUPPORT, ball

8 117104 BALL, 5mm, carbide

9 245375 PLUNGER, valve

11 15Y033 O-RING

Ref.

Part No. Description Qty

No.

12 15A223 GLAND, male

13 15A142 PACKING

1

14 15A149 GLAND, female

15 117125 RING, retaining, internal

1

16 15A212 PLATE, diaphragm

1

17 15A180 DIAPHRAGM

1

18 15A218 HOUSING, diaphragm

1

20 15A145 COVER, diaphragm

1

26 117128 SCREW, shcs; M8x50

1

27 15Y029

1

29 15C332

1

30 15C333

1

O-RING 1

FITTING, (npt models only) 1

WASHER, (npt models only) 1

1

Parts

1

3

1

1

1

1

1

1

6

309475F 21

Page 22

Parts

Pneumatic Regulators

Part Nos. 233760 (shown), 233769, 233770, 234266, 234270, and 234271

1

26

32

33

20

22

1

Torque to 10 N•m (7.5 ft-lb).

2

Torque to 12 N•m (8.8 ft-lb).

10

13

11

17

16

9

18

28

29

1

30

2

31

22

4

6

8

7

27

3

2

TI1745A

22 309475F

Page 23

Pneumatic Regulators

Part Nos. 233760 (shown), 233769, 233770, 234266, 234270, and 234271

Ref.

Part No. Description Qty

Ref.

Part No. Description Qty

No.

1 15A187

15C298

2 15A239 PLUG, screw

3 117091 SPRING, compression

4 245370 SEAT, valve

6 15Y031 O-RING

7 15A207 SUPPORT, ball

8 117107 BALL, 8mm, carbide

9 245377 PLUNGER, valve; for 233760,

245379 PLUNGER, valve; for 233769,

10 245364 HOUSING, plunger

11 15Y034 O-RING

13 117111 SEAL, rod

16 15A213 PLATE, diaphragm; for 233760 and

15A214 PLATE, diaphragm; for 233769 and

15A215 PLATE, diaphragm; for 233770 and

17 15A181 DIAPHRAGM; for 233760 and

15A182 DIAPHRAGM; for 233769 and

15A183 DIAPHRAGM; for 233770 and

HOUSING, lower

HOUSING, lower (for npt version)

234266,

233770, 234270, and 234271

234266

234270

234271

234266

234270

234271

No.

18 15A209 HOUSING, diaphragm; for 233760

1

1

15A210 HOUSING, diaphragm; for 233769

15A211 HOUSING, diaphragm; for 233770

1

1

20 15A146

1

1

15A147

1

1

15A148

1

22 15A220

26 117028 SCREW, shcs; M6x16

1

27 15Y032 O-RING

1

28 117018 WASHER

1

29 117030 SCREW, shcs; M6x40

1

30 117086 WASHER

1

31 117100 PLUG, threaded

32 15C332 FITTING (npt models only)

1

33 15C333 WASHER (npt models only)

1

1

1

1

Parts

and 234266

and 234270

and 234271

COVER, diaphragm; for 233760 and

234266

COVER, diaphragm; for 233769 and

234270

COVER, diaphragm; for 233770 and

234271

RING (for non-npt models only) 2

12

12

12

1

1

1

1

1

1

1

1

1

1

1

309475F 23

Page 24

Technical Data

Technical Data

Category Data

Maximum Fluid Inlet

Pressure (Fluid Pressure

Regulators)

Maximum Permanent Supply

Pressure (Back Pressure

Regulators)

Pressure Range 233760, 234266: 70-900 psi (0.5-6 MPa, 5-60 bar)

233814, 234260: 2600 psi (18 MPa, 180 bar)

233760, 233767, 233768, 233769, 233770, 233813, 234259, 234264, 234265,

234266, 234270, and 234271: 5000 psi (36 MPa, 360 bar)

233771, 234268: 2500 psi (17 MPa, 170 bar)

233772, 234269: 3400 psi (23.5 MPa, 235 bar)

233767, 233772, 234264, 234269: 1300-3000 psi (9-20 MPa, 90-200 bar)

233768, 234265: 1300-4000 psi (9-27 MPa, 90-270 bar)

233769, 234270: 300-2000 psi (2-15 MPa, 20-150 bar)

233770, 234271: 600-4600 psi (4-32 MPa, 40-320 bar)

233771, 233814, 234268, 234260: 600-1500 psi (4-10 MPa, 40-100 bar)

233813, 234259: 600-3600 psi (4-25 MPa, 40-250 bar)

Maximum Operating Air

Pressure (Pneumatic

Regulators Only)

Maximum Flow Rate See chart on page 26.

Temperature Range 233767, 233768, 233771, 233772, 233813, 233814, 234259, 234260, 234264,

Fluid inlet and outlet 233767, 233768, 233771, 233772, 233813, 233814, : 3/8 BSPP(F)

Air inlet 233760, 233769, 233770, 233813: 1/4 BSPP(F)

*Gauge port 233760, 233769, 233770, 234266, 234270, 234271: 1/4 BSPP(F)

Wetted Parts 233767, 233768, 233771, 233772, 233813, 233814, 234259, 234260, 234264,

233760, 233770, 233813, 234259, 234266, 234271: : 85 psi (0.6 MPa, 6 bar)

233769, 234270: 75 psi (0.5 MPa, 5 bar)

234265, 234268, 234269: 32-194°F (0-90°C)

233760, 233769, 233770, 234266, 234270, 234271: 50-176°F (10-80°C)

234259, 234260, 234264, 234265, 234268, 234269: 3/8 npt(F)

233760, 233769, 233770: 3/4 BSPP(F)

234266, 234270, 234271: 3/4 npt(F)

234259, 234266, 234270, 234271: 1/4 npt(M)

234265, 234268, 234269: Stainless steel, tungsten carbide, PTFE, chemically

resistant fluoroelastomer

233760, 233769, 233770, 234266, 234270, 234271: UHMWPE, Stainless steel,

acetal, tungsten carbide, PTFE, chemically resistant fluoroelastomer

*Accessory Gauges Available

24 309475F

Page 25

Accessory Gauges

Model Gauge

233760 118340

234266 118340

233769 118341

234270 118341

234770 118341

234271 118341

Accessory Gauges

309475F 25

Page 26

Flow Rate Data

Flow Rate Data

Maximum fluid flow with 10 weight oil, regulator wide open and no downstream restrictions.

Part No. Inlet Fluid Test Pressure Inlet/Outlet Size Fluid Flow

233760

234266

233767

234264

233768

234265

233769

234270

233770

234271

233771

234268

233772

234269

233813

234259

233814

234260

5000 psi (36 MPa, 360 bar) 3/4 BSPP(F)

3/4 npt(F)

3000 psi (21 MPa, 210 bar) 3/8 BSPP(F)

3/8npt(F)

3660 psi (25 MPa, 256 bar) 3/8 BSPP(F)

3/8npt(F)

4000 psi (28 MPa, 280 bar) 3/4 BSPP(F)

3/4npt(F)

3800 psi (26 MPa, 266 bar) 3/4 BSPP(F)

3/4npt(F)

2500 psi (17 MPa, 170 bar) 3/8 BSPP(F)

3/8npt(F)

3400 psi (23.5 MPa, 235 bar) 3/8 BSPP(F)

3/8npt(F)

3800 psi (26 MPa, 266 bar) 3/8 BSPP(F)

3/8npt(F)

2500 psi (17 MPa, 170 bar) 3/8 BSPP(F)

3/8npt(F)

11.3 gpm (42.9 lpm)

8.2 gpm (31.2 lpm)

9.2 gpm (35.0 lpm)

11.7 gpm (44.5 lpm)

12.3 gpm (46.7 lpm)

10.2 gpm (38.8 lpm)

13.1 gpm (49.8 lpm)

10.6 gpm (40.3 lpm)

8.1 gpm (30.8 lpm)

Mounting Dimensions

A

Part No. Thread Dimension A

233760

234266

233767

234264

M6 36 mm (1.42 in.)

M5 28 mm (1.10 in.)

Part No. Thread Dimension A

233768

234265

233769

234270

233770

234271

233771

234268

233772

234269

233813

234259

233814

234260

M5 28 mm (1.10 in.)

M6 36 mm (1.42 in.)

M6 36 mm (1.42 in.)

M5 28 mm (1.10 in.)

M5 28 mm (1.10 in.)

M5 28 mm (1.10 in.)

M5 28 mm (1.10 in.)

26 309475F

03/2006

Page 27

Mounting Dimensions

309475F 27

Page 28

Graco Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in material

and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by

Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance

of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1-800-328-0211 Toll Free

612-623-6921

612-378-3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 309475

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2002, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 2/2009

Loading...

Loading...