Page 1

INSTRUCTIONS-PARTS LIST

ELECTROSTATIC AIR SPRAY

309419D

Air Caps and Fluid Nozzles

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

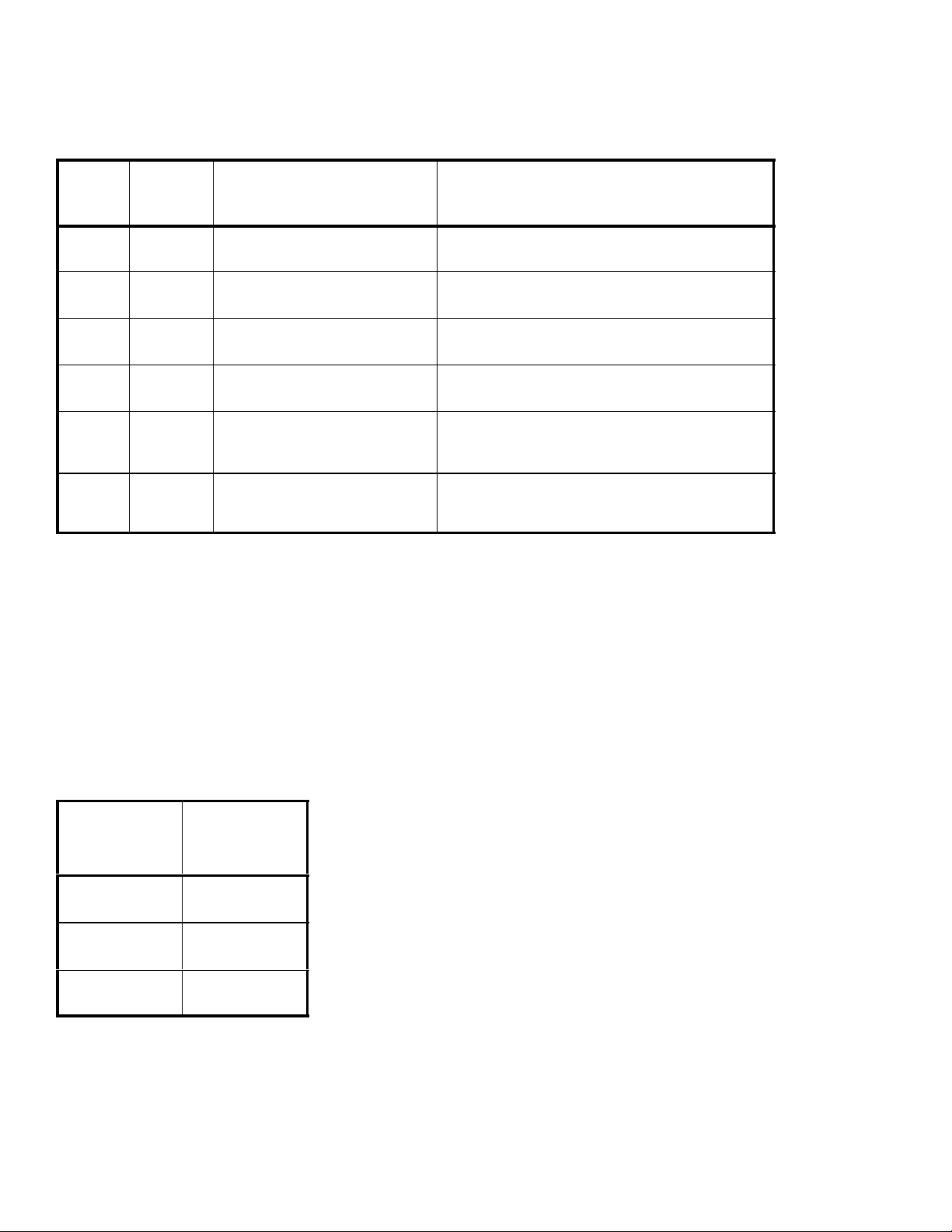

FAN PATTERN FLUID NOZZLES

PROt Xs Gun

Fluid Nozzle Part No.

197263 0.75 mm (0.030 in.)

197264 1.0 mm (0.042 in.)

197265 1.2 mm (0.047 in.)

197266 1.5 mm (0.055 in.)

197267 1.8 mm (0.070 in.)

197268♦ 2.0 mm (0.080 in.)

Fluid Nozzle

Orifice Size

ENG

249920* 0.75 mm (0.030 in.)

249921* 1.0 mm (0.042 in.)

249922* 1.2 mm (0.047 in.)

249923* 1.5 mm (0.055 in.)

249924* 1.8 mm (0.070 in.)

249925*♦ 2.0 mm (0.080 in.)

* Glass reinforced acetal construction.

♦ The 2.0 mm (0.080 in.) nozzles must be used with

air cap 24A439.

Page 2

FAN PATTERN AIR CAPS (All Models)

Air Caps

Air Cap

Part

No.

24A438 Round End 381–432 mm (15–17 in.)

24A279 Round End 356–406 mm (14–16 in.)

24A376{ Tapered

24A274 Tapered

24A439 Tapered

24A275 Tapered

Pattern

Shape

End

End

End

End

Pattern Length

with Wide Pattern Kit*

[without Wide Pattern Kit*] Recommended Fluids & Production Rates

[330–381 mm (13–15 in.)]

[330–381 mm (13–15 in.)]

432–483 mm (17–19 in.)

[330–381 mm (13–15 in.)]

305–356 mm (12–14 in.)

[330–381 mm (13–15 in.)]

279–330 mm (11–13 in.)

[254–305 mm (10–12 in.)]

356–406 mm (14 –16 in.)

[297–348 mm (12–14 in.)]

* Wide Pattern Kit – Part No. 24A431

{ Also available in the following colors:

24A276 – blue

24A277 – red

24A278 – green

Light to medium viscosity.

Up to 600 cc/min (20 oz/min).

Medium to high viscosity.

Up to 600 cc/min (20 oz/min).

Light to medium viscosity.

Up to 600 cc/min (20 oz/min).

Light to medium viscosity.

Up to 600 cc/min (20 oz/min).

For use with 2.0 mm nozzles.

Medium to high viscosity and high solids.

Up to 600 cc/min (20 oz/min).

Light to medium viscosity and high solids.

Aerospace coatings.

Up to 750 cc/min (25 oz/min).

NOTE: All air cap pattern shapes and lengths were

measured under the following conditions:

Distance to Target: 254 mm (10 in.)

Inlet Air Pressure: 3.4 bar (34 kPa, 50 psi)

Fan air: adjusted for maximum width with manual gun.

Fluid Flow Rate: 300 cc/min. (10 oz./min.)

Pattern shape and length are material–dependent.

ROUND PATTERN KITS

Light to Medium Viscosity. Light to Medium Production.

PROt Xs Gun

Kit Part No.

(Manual No.)

245217

(309447)

245219

(309447)

277851

(313223)

2 309419

Pattern

Diameter

102 to 152 mm

(4 to 6 in.)

203 to 254 mm

(8 to 10 in.)

Adjustable

Page 3

WARNING

Always turn off the power, air, and fluid supply to the gun, and trigger the gun to relieve system pressure before

installing or removing the air cap/fluid nozzle assembly. This will help reduce the risk of serious injury, including

splashing in the eyes or on the skin, or electric shock.

NOTE: Refer to your air spray gun instruction manual to install the air cap and fluid nozzle. If you do not have a

copy of the manual, copies are available at no charge from Graco Inc.

Terms

Viscosity

Light: 20 centipoise at 21_C (70_F)

Medium: 70 centipoise at 21_C (70_F)

Heavy: 160, 260 centipoise at 21_C (70_F)

High Solids: Over 360 centipoise at 21_C (70_F)

Centipoise = centistokes x fluid specific gravity.

NOTE: Refer to the Viscosity Conversion Chart on

the back cover to convert to other units of measurement.

How to Use the Fluid Nozzle Graphs

KEY

260 Centipoise Fluid

160 Centipoise Fluid

70 Centipoise Fluid

20 Centipoise Fluid

Fan Pattern Production Rate

Light Production: Fluid flow of up to 200 cc/min.

(7 oz./min.)

Medium Production: Fluid flow of up to 400 cc/min.

(14 oz./min.)

High Production: Fluid flow of up to 600 cc/min.

(20 oz./min.)

Round Pattern Production Rate

Light Production: Fluid flow of up to 150 cc/min.

(5 oz./min.)

Medium Production: Fluid flow of up to 200 cc/min.

(7 oz./min.)

2. The thick vertical line in each graph represents the

target flow rate for that nozzle size. Find the graph

that has the marked point closest to the thick

vertical line. This is the recommended nozzle size

for your application. Significantly exceeding the

target flow rate may result in lower spray performance due to excessive fluid viscosity.

Use the procedure below to select the proper fluid

nozzle for your application.

1. For each of the fluid nozzle graphs, find the point

on the graph corresponding to your desired fluid

flow rate and viscosity. Mark the point on each

graph with a pencil.

3. From the marked point, move across to the vertical

scale to find the required fluid pressure. If the

required pressure is too high, then use the next

largest nozzle size. If the fluid pressure is too low

(< 0.35 bar, 3.5 kPa, 5 psi), then use the next

smallest nozzle size.

309419 3

Page 4

Fluid Nozzle Performance Graphs

Fluid pressures are measured at the spray gun inlet.

Bar/PSI

50

3.0

45

40

2.5

2.0

35

30

25

FLUID PRESSURE

1.5

1.0

20

15

10

0.5

oz./min.

cc/min.

5

012345678910

ORIFICE SIZE: 0.75 mm (0.030 in.)

60 120 180 240 300

FLUID FLOW

Bar/PSI

50

3.0

45

40

2.5

2.0

35

30

25

FLUID PRESSURE

1.5

1.0

20

15

10

0.5

oz./min.

cc/min.

5

0 5 10 15 20 25 30

ORIFICE SIZE: 1.2 mm (0.047 in.)

200 400 600 800

FLUID FLOW

Bar/PSI

50

3.0

45

40

2.5

2.0

35

30

25

FLUID PRESSURE

1.5

1.0

20

15

10

0.5

oz./min.

cc/min.

5

0 5 10 15 20 25 30

ORIFICE SIZE: 1.0 mm (0.040 in.)

200 400 600 800

FLUID FLOW

Bar/PSI

50

3.0

45

40

2.5

2.0

35

30

25

FLUID PRESSURE

1.5

1.0

20

15

10

0.5

oz./min.

cc/min.

5

0 5 10 15 20 25 30

ORIFICE SIZE: 1.5 mm (0.059 in.)

200 400 600 800

FLUID FLOW

Performance Graphs are continued on page 5.

4 309419

Page 5

Fluid Nozzle Performance Graphs

Fluid pressures are measured at the spray gun inlet.

Bar/PSI

50

3.0

45

40

2.5

2.0

35

30

25

FLUID PRESSURE

1.5

1.0

20

15

10

0.5

oz./min.

cc/min.

5

0 5 10 15 20 25 30

ORIFICE SIZE: 1.8 mm (0.070 in.)

200 400 600 800

FLUID FLOW

Bar/PSI

1.4

20

18

1.2

16

1.0

14

12

0.8

10

FLUID PRESSURE

0.6

0.4

8

6

4

0.2

2

oz./min.

0 5 10 15 20 25 30

cc/min.

ORIFICE SIZE: 2.0 mm (0.080 in.)

200 400 600 800

FLUID FLOW

Viscosity Conversion Chart

Measurement Light Medium Heavy

Poise 0.2 0.7 2.6 3.6

Centipoise 20 70 260 360

Du Pont Parlin 7 32

Du Pont Parlin 10 13 20

Fisher 1 30

Fisher 2 15 33

Ford Cup 3 12 36

Ford Cup 4 10 28 68

Krebs Units KU 35 58 62

Saybolt Universal

SSU

Shell 2 40

Shell 3 15 48

Shell 4 22

100 370 1280 1730

High

Solids

Measurement Light Medium Heavy

Zahn 1 37

Zahn 2 18 30

Zahn 3 30 41

Zahn 4 21 28

Zahn 5 13 18

Sears Craftsman Cup 23

Redwood No. 1 Sec. 98 286 1060 1465

Redwood No. 2 Sec. 30.05 105.6 149

Engler Degrees 2.9 9.4 34.65 47.75

Saybolt Furol Sec. 35 124.5 171.5

High

Solids

309419 5

Page 6

Air Cap Comparison

Air Cap

Part No.

24A438 Grey Round End Better Best Good

24A279 Grey Round End Better Better Good

24A376* Grey Tapered End Best Better Better

24A276* Blue Tapered End Best Better Better

24A377* Red Tapered End Best Better Better

24A378* Green Tapered End Best Better Better

24A274 Grey Tapered End Good Good Best

24A439 Grey Tapered End Good Best Better

24A275 Grey Tapered End Best Good Best

* Identical except color

Air Cap

Color

Pattern

Shape

Transfer

Efficiency Atomization Cleanliness

Air Cap Compatibility Chart

Recommended

Part No.

Replacement

197477 24A438

197478 24A376

197479 24A274

197480 24A279

197481 24A439

6 309419

Page 7

Air Consumption Charts

24A438

25

20

15

10

Air Consuption (SCFM)

5

0

1520253035404550556065707580

Wall Pressure (psi)

24A376, 24A276,

24A277, 24A278

25

20

5/16 in. x 25 ft hose

5/16 in. x 50 ft hose

Test Conditions

D Fan valve adjusted full open

D PRO Xs4 Gun

24A279

25

20

15

10

Air Consuption (SCFM)

5

0

1520253035404550556065707580

Wall Pressure (psi)

24A274

25

20

15

10

Air Consuption (SCFM)

5

0

1520253035404550556065707580

Wall Pressure (psi)

24A439

25

20

15

10

Air Consuption (SCFM)

5

15

10

Air Consuption (SCFM)

5

0

1520253035404550556065707580

Wall Pressure (psi)

24A275

25

20

15

10

Air Consuption (SCFM)

5

0

1520253035404550556065707580

Wall Pressure (psi)

0

1520253035404550556065707580

Wall Pressure (psi)

309419 7

Page 8

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Phone Number

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 309419

8 309419

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 2001, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 12/2009

Loading...

Loading...