Page 1

Repair Instructions

GMax

Airless Paint Sprayer

3300 psi (227bar, 22.7 MPa) Maximum Working Pressure

See page 2 for models numbers.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Related Manuals

Operation 309408...............................

Displacement Pump 309277......................

Spray Gun 309639..............................

Spray Tip 309640................................

PC Board 309459...............................

Drain Valve Kit 308961...........................

Clutch Replacement Kit 309890...................

7900

R

309412F

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440- 1441

Copyright 2001, Graco Inc. is registered to I.S. EN ISO 9001

ti1833a

Page 2

Models

Model Series Description

233718 A Lo--Boy

233719 A Hi--Boy

233720 A Lo--Boy with RACRX tip, gun and hose

233721 A Hi--Boy with RAC X tip, gun and hose

Table of Contents

Warnings and Cautions 3.........................

Maintenance 4...................................

Troubleshooting 5................................

Repair

Rollers 8......................................

Drive Housing 9................................

Cam Follower Bearings 10......................

Engine 1 1.....................................

Pressure Control 13............................

Displacement Pump 15.........................

Parts

Pinion Assembly 17............................

Sprayers 18...................................

Pressure Control 21............................

Tip, Gun, Hose 22..............................

Dimensions 23...................................

Technical Data 23................................

Graco Warranty 24...............................

Graco Phone Number 24..........................

3094122

Page 3

Warnings and Cautions

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

Fire and explosion: Solvent and paint fumes can ignite or

explode.

To help prevent a fire and explosion:

DUse only in an extremely well ventilated area.

DEliminate all ignition sources; such as pilot lights, cigarettes and

plastic drop cloths (static arc hazard). Do not plug or unplug

power cords or turn lights on or off in spray area.

DGround Sprayer, object being sprayed, paint and solvent pails.

DHold gun firmly to side of grounded pail when triggering into pail.

DUse only conductive airless paint hose.

DDo not use 1,1,1 --trichloroethane, methylene chloride, other

halogenated hydrocarbon solvents or fluids containing such

solvents in pressurized aluminum equipment. Such use could

result in a chemical reaction, with the possibility of explosion.

DDo not fill fuel tank while engine is running or hot.

DDo not flush with gasoline.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

Fluid injection and high pressure hazard: High pressure spray or

leaks can inject fluid into the body.

To help prevent injection, always:

DEngage trigger safety latch when not spraying.

DKeep clear of nozzle and leaks.

DNever spray without a tip guard.

DDo PRESSURE RELIEF if you stop spraying or begin servicing

sprayer.

DDo not use components rated less than sprayer Maximum

Working Pressure.

DNever allow children to use this unit.

If high pressure fluid pierces your skin, the injury might look like

“just a cut”, but it is a serious wound! Get immediate medical attention.

309412 3

Page 4

Maintenance

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you:

D areinstructedtorelievethepressure,

D stop spraying,

D check or service any of the system equipment,

D or install or clean the spray tip.

Pressure Relief Procedure

1. Lock gun trigger safety .

2. Turn engine ON/OFF switch to OFF.

3. Move pressure control switch to OFF and turn

pressure control knob fully counterclockwise.

CAUTION

For detailed engine maintenance and specifications,

refer to separate Honda Engines Owner’s Manual,

supplied.

DAILY: Check engine oil level and fill as necessary.

DAILY: Check hose for wear and damage.

DAILY: Check gun safety for proper operation.

DAILY: Check pressure drain valve for proper opera-

tion.

DAILY: Check and fill the gas tank.

AFTER THE FIRST 20 HOURS OF OPERATION:

Drain engine oil and refill with clean oil. Reference

Honda Engines Owner’s Manual for correct oil viscosity.

WEEKLY: Remove air filter cover and clean element.

Replace element, if necessary. If operating in an

unusually dusty environment: check filter daily and

replace, if necessary .

4. Unlock trigger safety. Hold metal part of gun firmly

to side of grounded metal pail, and trigger gun to

relieve pressure.

5. Lock gun trigger safety .

6. Open pressure drain valve. Leave valve open until

ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, VERY SLOWLY

loosen tip guard retaining nut or hose end coupling to

relieve pressure gradually, then loosen completely.

Now clear tip or hose.

Replacement elements can be purchased from your

local HONDA dealer.

WEEKLY: Check level of TSL in displacement pump

packing nut. Fill nut, if necessary. Keep TSL in nut to

help prevent fluid buildup on piston rod and premature

wear of packings.

AFTER EACH 100 HOURS OF OPERATION:

Change engine oil. Reference Honda Engines Owner’s

Manual for correct oil viscosity.

SPARK PLUG: Use only BPR6ES (NGK) or

W20EPR--U (NIPPONDENSO) plug. Gap plug to

0.028 to 0.031 in. (0.7 to 0.8 mm). Use spark plug

wrench when installing and removing plug.

3094124

Page 5

Troubleshooting

Relieve pressure; page 4.

PROBLEM CAUSE SOLUTION

E=XX is displayed Fault condition exists Determine fault correction from table, page 14.

Engine won’t start Engine switch is OFF Turn engine switch ON

Engine is out of gas Refill gas tank. Honda Engines Owner’s Manual.

False tripping of WatchDog system. EMPTY is

displayed. Pump does

not run.

Engine operates, but

displacement pump

does not operate

Engine oil level is low Try to start engine. Replenish oil, if necessary.

Honda Engines Owner’s Manual.

Spark plug cable is disconnected or damaged Connect spark plug cable or replace spark

plug

Cold engine Use choke

Fuel shutoff lever is OFF Move lever to ON position

Oil is seeping into combustion chamber Remove spark plug. Pull starter 3 to 4 times.

Clean or replace spark plug. Start engine.

Keep sprayer upright to avoid oil seepage.

Operating conditions out of WatchDog parameters Turn pressure down. Contact Graco Technical

Assistance to adjust WatchDog parameters.

Operate without WatchDog active; Manual

309408.

Low pump output. See Troubleshooting Table, Pump Outlet Low,

page 6.

Error code displayed? Determine fault correction from table, page 14.

Pump switch is OFF TurnpumpswitchON.

Pressure setting is too low Turn pressure adjusting knob clockwise to

increase pressure.

Fluid filter (318) is dirty Clean filter. Page 20.

Tip or tip filter is clogged Clean tip or tip filter. Manual 309091.

Displacement pump piston rod is stuck due to dried

paint

Connecting rod is worn or damaged Replace connecting rod. Page 15.

Drive housing is worn or damaged Replace drive housing. Page 9.

Electrical power is not energizing clutch field Check wiring connections. Page 11.

Repair pump. Manual 309277.

Reference pressure control repair. Page 13.

Reference wiring diagram. Page 21.

With pump switch ON and pressure turned to

MAXIMUM, use a test light to check for power

between clutch test points on control board.

Remove 7--pin connector from control board

and measure resistance across clutch coil. At

70_ F, the resistance must be between 1.7

±0.2Ω ; if not, replace pinion housing.

Have pressure control checked by authorized

Graco dealer.

309412 5

Page 6

Troubleshooting

PROBLEM CAUSE SOLUTION

Clutch is worn, damaged, or incorrectly positioned Replace clutch. Manual 309890.

Pump output is low.

Pinion assembly is worn or damaged Repair or replace pinion assembly. Manual

Strainer (89) is clogged Clean strainer. Sprayer 233716 strainer is for

Piston ball (206) is not seating Service piston ball. Manual 309277.

Piston packings are worn or damaged Replace packings. Manual 309277.

O-ring (227) in displacement pump is worn or damaged

Intake valve ball is not seating properly Clean intake valve. Manual 309277.

Intake valve ball is packed with material Clean intake valve. Manual 309277. Do not

Engine speed is too low Increase throttle setting. Manual 309408.

Clutch is worn or damaged Replace clutch. Manual 309890.

Pressure setting is too low Increase pressure. Manual 309408.

Fluid filter (318), tip filter or tip is clogged or dirty Clean filter. Manual 309408 or 309091.

Large pressure drop in hose with heavy

materials

309890.

use in paint only.

Replace o-ring. Manual 309277.

leave 233716 sprayer under pressure for more

than 5 minutes when spraying texture and not

actively spraying.

Use larger diameter hose and/or reduce overall

length of hose. Use of more than 100 ft of 1/4

in. hose significantly reduces performance of

sprayer. Use 3/8 in. hose for optimum performance (50 ft minimum).

Excessive paint leakage into

throat packing nut

Fluid is spitting from gun

Pump is difficult to prime

Throat packing nut is loose Remove throat packing nut spacer. Tighten

throat packing nut just enough to stop leakage.

Throat packings are worn or damaged Replace packings. Manual 309277.

Displacement rod is worn or damaged Replace rod. Manual 309277.

Air in pump or hose Check and tighten all fluid connections. Re--

prime pump. Manual 309408.

Tip is partially clogged Clear tip. Manual 309091.

Fluid supply is low or empty Refill fluid s upply. Prime pump. Manual

309408. Check fluid supply often to prevent

running pump dry.

Air in pump or hose Check and tighten all fluid connections.

Reduce engine speed and cycle pump as

slowly as possible during priming.

Intake valve is leaking Clean intake valve. Be sure ball seat is not

nicked or worn and that ball seats well. Reassemble valve.

Pump packings are worn Replace pump packings. Manual 309277.

Paint is too thick Thin the paint according to the supplier’s

recommendations

3094126

Page 7

Troubleshooting

load

PROBLEM CAUSE SOLUTION

Engine speed is too high Decrease throttle s etting before priming pump.

Clutch squeaks each time

clutch engages

High engine speed at no

Gallon counter not working Bad sensor, broken or disconnected wire Check connections. Replace sensor or wire.

No display, sprayer operates Display damaged or has bad connection Check connections. Replace display.

Clutch squeaks each time

clutch engages

Engine stalls

Clutch surfaces are not matched to each other

when new and may cause noise

Misadjusted throttle setting Reset throttle to 3700 engine rpm at no load

Worn engine governor Replace or service engine governor

Clutch surfaces are not matched to each other

when new and may cause noise

Engine speed is to slow D Increase throttle setting

Fluid filter is clogged Relieve pressure and clean filter

Too much pump friction (new pump) Reduce pressure to 3000 psi until pump wears

Spark plug wire is loose Reconnect wire

Manual 309408.

Clutch surfaces need to wear into each other.

Noise will dissipate after a day of run time.

Clutch surfaces need to wear into each other.

Noise will dissipate after a day of run time

D Adjust engine speed at no load to 3750 --

3850 rpm

in

309412 7

Page 8

Rollers

Removal

1.

2. Fig. 1. Remove six cap screws (56) lock washers

(87), clip (35), and cover assembly (13).

77

87

Fig. 1

Relieve pressure; page 4.

71

109

108

59

13

87

35

56

ti1860a

Installation

1. Install rollers (109) and dowel pins (108)

2. Install cover assembly (13) with six lock washers

(87), clip (35), and cap screws (56).

Note: A screw driver may be needed to pry off cover

assembly.

3. Remove dowel pins (108) and rollers (109)

3094128

Page 9

Drive Housing

Removal

1.

Relieve pressure; page 4.

2. Fig. 2. Disconnect gallon counting sensor.

ti1835a

Fig. 2

3. Fig. 1. Remove six cap screws (56) lock washers

(87) and cover assembly (13).

Installation

1. Liberally apply bearing grease (supplied with

replacement gear cluster) to gear cluster (102),

washers (104) and (105) and to areas called out

by note 1. Use full 0.68 pint (0.32 liter) of grease

for GMax 7900.

2. Place bronze colored washer (105) and silver

colored washer (104) onto drive housing (71).

Install gear cluster (102) through washers (105)

and (104).

3. Place bronze colored washer (71g) and silver

colored washer (71h) on shaft protruding from

large shaft of drive housing (71). Align gears and

push new drive housing straight onto pinion housing and locating pins (B).

4. Install two washers (87) and screws (59).

4. Fig. 3. Remove two screws (59) and washers (87).

5. Remove four cap screws (56) lock washers (87)

from drive housing (71).

6. Lightly tap around drive housing (71) to loosen

drive housing. Pull drive housing straight off pinion

housing. Be prepared to support gear cluster

(102), which may also come out.

56

104

87

105

21

1

71h

71g

71

71c

71b

101

87

59

8d

8e

B

102

71d

5. Install four lock washers (87) and cap screws (56)

into drive housing (71).

6. Install cover assembly (13) with six lock washers

(87) and cap screws (56).

7. Fig. 4. Reconnect gallon counting sensor.

1

Apply remaining grease to these areas

Fig. 3

71a

9046C

Fig. 4

ti1835a

309412 9

Page 10

Cam Follower Bearings

Removal

1.

2. Fig. 9. Cycle pump piston rod (222) to lowest

position. Turn engine off.

3. Fig. 5. Remove six cap screws (56), lock washers

(87) and cover assembly (13).

Note: A screw driver may be needed to pry off

cover assembly.

4. Remove four dowel pins (108) and rollers (109).

5. From front, drive out pump pin (77) with a screw

driver.

6. Remove two retainer rings (71d).

7. Remove cam follower plate (71b).

Note: Two 1/2 in. x 13 bolts may be

needed to remove cam follower plates.

8. Remove two cam follower bearings (71c).

Relieve pressure; page 4.

Installation

1. Install two cam follower bearings (71c).

2. Install cam follower plate (71b).

3. Install two retainer rings (71d).

4. Drive in pump pin (77) until it engages with pump

pin retaining clip (71a).

5. Install four rollers (109) and dowel

pins (108).

6. Install cover assembly (13) with six lock washers

(87) and cap screws (56).

Fig. 5

71

71c

71b

71d

109

108

13

87

56

77

9046c

30941210

Page 11

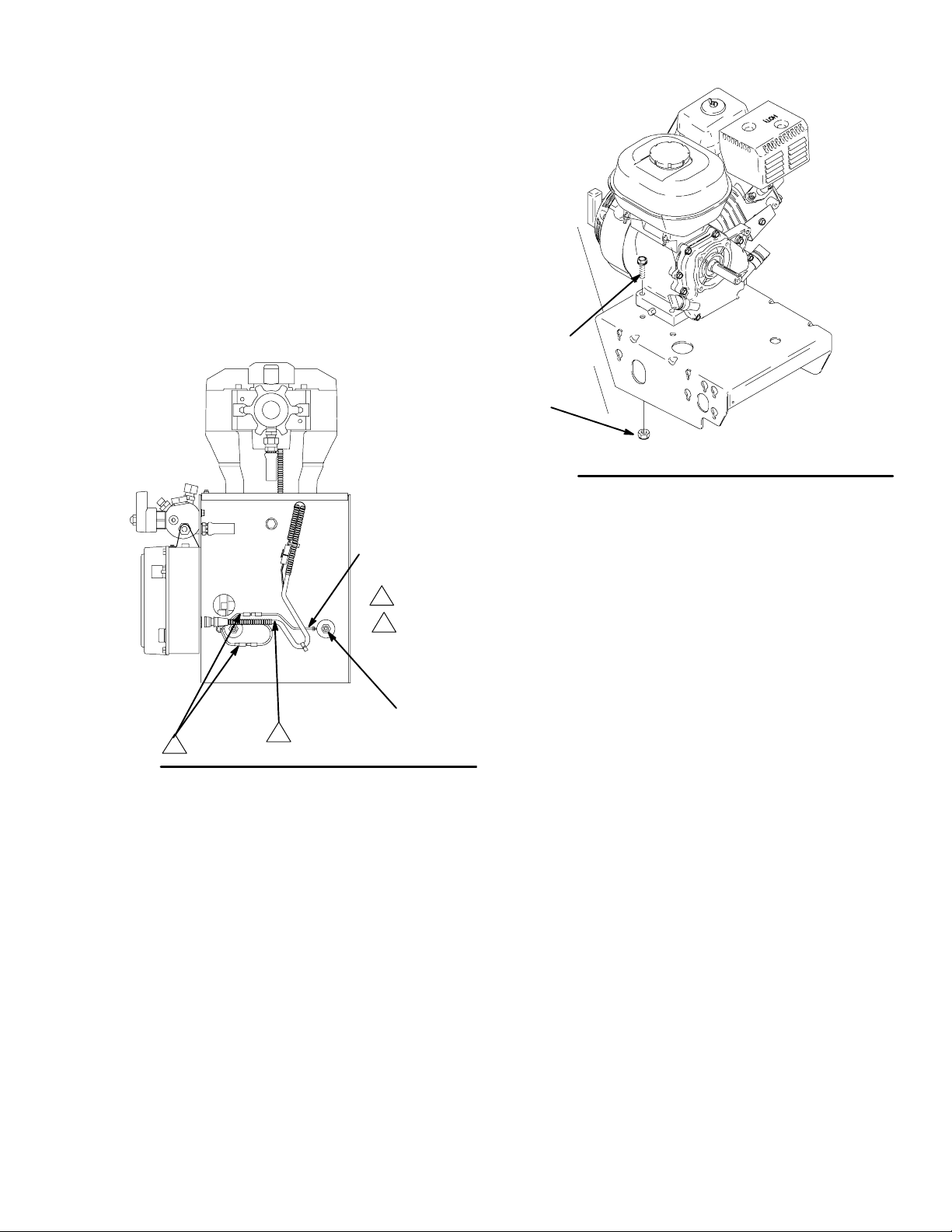

Engine

Removal

1. Remove Pinion Assembly/Rotor/Field/Pinion/

Clutch, Clamp and Clutch Housing,asin-

structed in manual 309890.

2. Fig. 6. Disconnect all necessary wiring.

3. Fig. 7. Remove two locknuts (7) and screws (6)

from base of engine.

4. Lift engine carefully and place on work bench.

NOTE: All service to the engine must be performed by

an authorized HONDA dealer.

6

Fig. 6

7

8710B

Fig. 7

Installation

Green

97

1

2

To the field

To the engine

1. Lift engine carefully and place on cart.

2. Fig. 7. Install two screws (6) in base of engine and

secure with locknuts (7). Torque to 200 in-lb (22.6

NSm).

3. Fig. 6. Connect all necessary wiring.

7

2

1

ti1835

4. Install Pinion Assembly/Rotor/Field/Pinion/

Clutch, Clamp and Clutch Housing,as

instructed in manual 309890.

309412 11

Page 12

On/Off Switch

Removal

1.

2. Fig. 8. Remove four screws (54) and

display/cover (52).

3. Pull display connector wings (A) open on PC board

and pull display connector out.

4. Disconnect ON/OFF switch connector (B) from PC

board.

5. Press in on two retaining tabs on each side of

ON/OFF switch (51) and remove switch.

52

54

Fig. 8

Relieve pressure; page 4.

122

A

139

B

51

310

50

302

122

29

Installation

1. Install new ON/OFF switch (51) so tabs of switch

snap into place on inside of pressure control

housing.

2. Connect ON/OFF switch connector (B) to PC

board.

3. Push display connector into PC board close display connector wings (A) on PC board.

4. Install display/cover (52) with four screws (54).

51

Y

Z

145

147

141

74

55

310

D

E

61a

61s

61p

61q

ti1841a

30941212

Page 13

Pressure Control

Control Board

Removal

1.

2. Fig.8. Remove four screws (54) and

display/cover (52). Pull display connector wings

(A) open on PC board and pull display connector

out.

3. Remove 2 screws (139).

4. Fig. 15. Disconnect at control board (302):

D Lead (D) from potentiometer.

D Lead (E) from transducer.

D Lead (B) from On/Off Switch connector.

5. Fig. 8. Remove five screws (122) from control

board and ground wire screw (122).

6. Remove connector (Y) at backside of pressure

control. Remove jam nut (Z) and control board

(302).

Relieve pressure; page 4.

Pressure Control Transducer

Removal

1.

2. Fig. 8. Remove four screws (54) and

cover (52).

3. Disconnect lead (E) from control board (302).

4. Remove two screws (141) and guard (147). Carefully pull transducer connector through rubber

grommet (145).

Relieve pressure; page 4.

Installation

When installing replacement control board, follow

instructions with control board to set model type.

1. Fig, 8. Install control board (302) and jam nut (Z).

Install connector (Y) at backside of pressure

control.

2. Install ground wire and control board (302) with

six screws (122).

3. Fig. 15. Connect to control board (302):

D Connect ON/OFF switch connector (B).

D Lead (E) to transducer.

D Lead (D) to potentiometer.

4. Fig. 8. Push display connector into PC board close

display connector wings (A) on PC board. Install

display/cover (52) with four screws (54).

5. Remove pressure control transducer (61q) and

packing o-ring (61p) from filter housing (61e).

Installation

1. Fig. 8. Install packing o-ring (61p) and pressure

control transducer (61q) in filter

housing (61e). Torque to 30--35 ft-lb.

2. Carefully feed transducer connector through

rubber grommet (145). Install guard (147) with two

screws (141).

3. Connect lead (E) to motor control board (302).

4. Install cover (52) with four screws (54).

Pressure Adjust Potentiometer

Removal

1.

2. Fig. 8. Remove four screws (54) and

cover (52) and two screws (139).

3. Disconnect lead (D) from control board (302).

4. Loosen set screws on potentiometer knob (50) and

remove knob, shaft nut, lockwasher (310) and

pressure adjust potentiometer (310).

5. Remove spacer (74) from potentiometer (310).

Relieve pressure; page 4.

Installation

1. Install spacer (74) on potentiometer (310).

2. Fig. 8. Install pressure adjust potentiometer (310),

shaft nut, lockwasher (310) and potentiometer

knob (50).

a. Turn potentiometer shaft (310) clockwise to

internal stop. Assemble potentiometer knob

(50) to strike pin on plate (29).

b. After adjustment of step a., tighten both set

screws in knob 1/4 to 3/8 turn after contact

with shaft.

3. Connect lead (D) to control board (302).

4. Install plate (29) with two screws (139).

5. Install cover (52) with four screws (54).

309412 13

Page 14

Pressure Control Repair

Digital Display Messages

Relieve pressure before repair; page 4. No display does not mean that sprayer is not pressurized.

DISPLAY SPRAYER

OPERATION

No Display Sprayer may be pressurized. Loss of power or display

not connected

Sprayer may be pressurized. Pressure less than

200 psi (14 bar, 1.4 MPa)

psi

bar

MPa

Sprayer is pressurized. Power is applied. (Pressure varies with tip size and

pressure control setting.)

Sprayer stops. Engine is running. Exceeded pressure limit Remove any filter clogs or

Sprayer stops. Engine is running. Pressure transducer faulty,

Sprayer stops. Engine is running. High clutch current 1. Check clutch 7--pin bulk-

Normal operation Spray

bad connection or broken

wire.

INDICATION ACTION

Check power source. Relieve

pressure before repair or disassembly. Verify display is

connected.

Increase pressure as needed

flow obstructions. Make sure

gun trigger is locked open if

using AutoClean valve.

Check transducer connections

and wire. Replace transducer

or control board, if necessary.

head connector. Clean

contacts.

2. 1.7 ±0.2Ω across clutch

field at 70_F

3. Replace clutch field assembly

Sprayer stops. Engine is running.

Display alternates E=06.

Sprayer stops. Engine is running. Pressure greater than

High clutch temperature 1. If clutch is new, let spray-

2000 psi (138 bar, 14 MPa)

while in Flush Timer Mode

After a fault, follow these step s to restart sprayer:

1. Correct fault condition

2. Turn sprayer OFF

3. Turn sprayer ON

30941214

er cool down and then restart

2. Inspect clutch. Replace

clutch if there is excessive

wear.

3. Remove pump pin, separate pinion housing from

clutch housing. Rotate

rotor clockwise to check

for excessive drag.

Chase paint from lines before

running in flush timer mode.

Make sure spray gun is triggered and prime valve is open

when using AutoClean

Page 15

Removal

Displacement Pump

See manual 309277 for pump repair instructions.

1. Flush pump.

2. Fig. 9. Cycle pump with piston rod (222) in lowest

position.

3.

4. Fig. 9. Remove suction tube (30) and hose (33).

33

Fig. 9

Relieve pressure; page 4.

222

9024C

30

9024B

Repair

5. Fig. 10. Use screwdriver to push out pump

pin (101).

71a

101

Detail A

Fig. 10

6. Fig. 11. Loosen locknut by hitting firmly with a

20 oz (maximum) hammer. Unscrew pump.

Fig. 11

9019B

9022A

Installation

WARNING

If pin works loose, parts could break off due to

force of pumping action. Parts could project

through the air and result in serious injury or property damage. Make sure pin (101) and retaining

clip (71a) are properly installed. See Detail A. Fig.

10.

CAUTION

If the pump locknut loosens during operation, the

threads of the bearing housing will be damaged.

Make sure locknut is properly tightened.

1. Fig. 12. Pull piston rod out 1.0 in. Screw in pump

until holes in housing plates and piston rod align.

2. Fig. 10. See Detail A. Push pin (101) into hole

until retaining clip (71a) snaps over pin.

Fig. 13. Screw jam nut down onto pump until nut

stops. Screw pump up into pump plate until it stops.

Back off pump one full turn and align pump outlet to

back. Tighten jam nut by hand, then tap 1/8 to 1/4 turn

with a 20 oz (maximum) hammer to approximately 75

±5ft--lb(102N¡m).

Fig. 13

Fig. 14. Fill packing nut with Graco TSL until fluid flows

onto the top of seal.

9021A

Fig. 12

1.0 in.

9020A

Fig. 14

9023A

309412 15

Page 16

Pump Pin Clip

Displacement Pump

Removal

1. Remove pump (85).

2. Remove two bolts (107), washers (79), pump

bracket (110), pail hook (90) and shield (113).

3. Fig. 10. Remove clip (71a).

Installation

1. Fig. 10. Install clip (71a).

2. Install shield (113), pail hook (90) and pump bracket (110) with two washers (79) and bolts (107).

Torque bolts to 40 ft-lb (54 NSm).

3. Install pump (85).

30941216

Page 17

Parts List & Drawing -- Pinion Assembly

Ref No. 8 and 71

Ref No. 8: Pinion Housing Assembly 245400 Ref No. 71: Drive Housing Assembly 245444

Ref

No. Part No. Description Qty

8a 245266 PINION HOUSING, COIL 1

8b 105489 PIN 2

8d 241114 PINION SHAFT

8e 112770 RETAINING RING, large

8e

8d

8b

56 (Ref)

87 (Ref)

8a

71h

71g

105 (Ref)

Ref

No. Part No. Description Qty

71 DRIVE HOUSING 1

71a 194060 RETAINING CLIP, pump pin 1

71b 193656 CAM FOLLOWER PLATE 1

71c 114691 CAM FOLLOWER BEARING 2

71d 114828 RETAINER CLIP 2

71g 114697 WASHER 1

71h 114698 WASHER 1

101 195523 PIN 1

71

87 (Ref)

59 (Ref)

102 (Ref)

1

104 (Ref)

71c

21 (Ref)

71b

71d

101

71a

1

Pinion housing/coil assembly (8a) includes clutch field and all bearings, pins and o-rings

9046C

309412 17

Page 18

119

64

DETAIL A

28

94

40

32

34

Parts Drawing -- Sprayers

32

88

31

4

11

70

42

95

24

36, 86

42

6

26

3

1a

23

7

42

44

42

44

1b

102

56

104

87

105

8

21

103

110

65,

66

113

69

60

*See Pinion Assembly Parts

List for more information.

*71

109

108

13

77

87

59

68

76

87

79

107

84

35

56

124

41

BOTTOM VIEW

123

132

33

100

See page 20 for parts

57

97

7

34

140

REF 49

98

85

9

37

139

38

139

39

142

92

81

49

27

27

92

DETAIL A

Ref 119

43

67

16

10

45

5

128

96

ti1831a

Ref 28

30941218

Page 19

Models 233718, 233719

Parts List

Ref.

No. Part No. Description Qty.

1 241113 CLUTCH, ASSEMBLY

includes 1a, 1b, 23, 42, 44, 88, 1

1a ARMATURE, clutch 1

1b ROTOR 1

3 193680 COLLAR, shaft 1

4 114530 ENGINE, gas, 5.5 HP, Honda 1

5 183350 WASHER 2

6 110837 SCREW, flange, hex 2

7 110838 NUT, lock 2

8 245400 PINION ASSEMBLY; Parts page 17 1

9 193682 PLUG, tube 2

10 191084 SLEEVE, cart 2

11 114271 STRAP, retaining 1

13 241536 COVER, assembly 1

16 241920 DEFLECTOR, threaded 1

21 116806 SWITCH, reed w/conn 1

24 193531 CLUTCH HOUSING 1

26 183401 KEY, parallel 1

27 246331 HOSE, drain, Lo--Boy 1

244240 HOSE, drain, Hi--Boy 1

28 245164 FRAME, cart GMAX 7900 1

31 113084 RIVET, blind 2

32 192014 PLATE, indicator 1

33 113802 SCREW 1

34 108851 WASHER 2

35 197124 CLIP 1

36 108842 SCREW 4

37 198904 SCREW, #8 2

38 114967 COUPLING, Hi--Boy only 1

39 198122 TUBE, Hi--Boy only 1

40 114678 GROMMET 1

41 104811 CAP, hub 2

42 105510 WASHER, lock, spring (hi-clr) 15

43 112827 BUTTON, snap 2

44 108803 SCREW, hex, socket head 6

45 114687 CLIP 1

49 245249 TUBE, suction, 30 gal (assembly) 1

56 101864 SCREW, cap sch 10

57 196670 LABEL, crtl box cover 1

59 114693 SCREW, cap, socket hd 2

60 290228 LABEL, caution 1

Ref.

No. Part No. Description Qty.

64Y 194126 LABEL, warning 1

65Y 194127 LABEL, warning 1

66Y 194317 LABEL, danger, English 1

67Y 195119 LABEL, warning tag 1

68Y 195519 LABEL, caution 1

69Y 192840 LABEL, warning 1

70 100644 SCREW, cap, sch 5

71 245444 DRIVE HOUSING; Parts page 17 1

76 198653 LABEL, identification 1

77 195523 PIN, PUMP 1

79 100018 WASHER, lock, spring 2

81 196723 CLIP, spring, Lo -- Boy only 1

84 193394 NUT, retaining 1

85 246257 DISPLACEMENT PUMP;

Manual 309277 1

86 100214 WASHER, lock 4

87 104008 WASHER, lock, spring 12

88 101682 SCREW, cap, sch 4

92 189920 STRAINER 1

94 237686 CLAMP, grounding assy 1

95 112798 SCREW, thread form, hex hd 1

96 108795 SCREW, mach, pnh 4

97 240997 CONDUCTOR, ground 4

98 162485 FITTING, nipple, adapter 3

100 114984 SCREW, tapping, phil pan hd 2

102 241539 GEAR, combination 1

103 241540 REPAIR KIT, HOOK, PAIL

(includes item 113) 1

104 114699 WASHER, thrust 1

105 114672 WASHER, thrust 1

107 110343 SCREW, cap, sch. 2

108 114695 PIN, dowel 4

109 241322 ROLLER, assembly 4

110 194118 BRACKET, pump 1

113 195377 SHIELD, paint 1

119 245245 HANDLE, cart 1

123 198720 WHEEL, semi-pneumatic 12 in. 2

124 198723 AXLE, clip 2

128 108068 PIN, spring straight 2

132 116891 WASHER 2

139 112774 SCREW, machine 1

140 198847 HOSE, coupled 1

141 109575 SCREW, threadforming 2

Y Replacement Danger and Warning labels, tags, and cards

are available at no cost.

309412 19

Page 20

Parts Drawing -- Sprayer

Ref 70

139

302a

151

52

51

150

55

122

61a

61b

61c

139

51

29

50

54

310

74

310

152

302

147

141

61n

145

61m

61h

61g

61k

61e

61f

61d

61j

61p

61q

61r

ti1838a

22

143

61s

30941220

Page 21

Parts List -- Sprayer

REF

NO. PART NO. DESCRIPTION QTY

22 162485 ADAPTER 2

29 198553 PANEL, control 1

50 116167 KNOB, potentiometer 1

51 116752 SWITCH, rocker, (spst) 1

52 245393 DIGITAL DISPLAY 1

Includes 54, 57, 151, 152

53 198534 PLA TE, control 1

54 116252 SCREW, #8 taptite, phil 4

55 198548 HOUSING, control 1

FILTER, fluid 1

61 245396 KIT , repair, filter 1

(includes 61a--61s)

61a 196675 BOWL, filter 1

61b 104361 O-RING 1

61c 244067 STRAINER, mesh, 60 1

61d 196786 TUBE, diffuser 1

61e 245401 KIT, repair, filter base 1

61f 193710 SEAL, valve 1

61g 193709 SEAT, valve 1

61h 1 14797 GASKET 1

61j 245103* VALVE 1

61k 114708 SPRING, compression 1

61m 194102 HANDLE, valve 1

61n 1 14688 NUT, cap, hex hd 1

61p 1 11457 O-RING 1

REF

NO. PART NO. DESCRIPTION QTY

61q 243222 TRANSDUCER, pressure control 1

61r 197055 GASKET, plug 1

61s 196781 PLUG, AutoClean 1

74 198650 SP ACER, shaft 1

122 1 14331 SCREW, pnhd 6--32 6

133 109575 SCREW, threadformer 2

139 1 12774 SCREW, mach 4

143 245475 PLUG, packless 1

145 1 14296 BUSHING, step 1

147 198994 GUARD, transducer 1

Y 189246 LABEL, warning 1

150

151 198884 LABEL, instruction, GMax 1

152 198648 LABEL, GMax, LCD 1

302 245394 BOARD, PC 1

302a NUT, nylon 1

310 241443 POTENTIOMETER, pressure control 1

* Drain valve replacement kit 245103 includes 61f, 61g, 61h,

61k, 61m, and 61n.

Y Replacement Danger and Warning labels, tags, and cards

are available at no cost.

includes 61p

Includes 302a

71

Pressure Control Wiring Diagram

52

8

51

302

61q

VIEW A

VIEW A

Fig. 15

97

310

ti1834a

309412 21

Page 22

Parts List/Drawing -- Sprayers with RAC 5

Tip, Gun & Hose

Models 233720, 233721

Includes items 201 to 204

Ref

No. Part No. Description Qty

201 233719 Hi-Boy Sprayer 1

See parts list on page 19

233718 Lo-Boy Sprayer 1

See parts list on page 19

202 240797 HOSE, grounded, nylon; 3/8 in. ID; 1

cpld 3/8 npsm(fbe); 50 foot (15 m);

spring guards both ends

3300 psi (227 bar, 27.7 MPa)

203 238358 HOSE, grounded, nylon; 3/16 in. ID;

cpld 1/4 npsm(m) x 1/4 npsm(f) swivel;

3 foot (0.9 m); spring guards both ends 1

204 246220 CONTRACTOR SPRAY GUN

Includes RAC X 517--size SwitchTip

and HandTitet Guard

See 309639 for parts 1

205 159841 ADAPTER 1

t

202

204

205

203

0160

Accessories

DANGER LABELS

An English language DANGER label is on your

sprayer. If you have painters who do not read English, order one of the following labels to apply to

your sprayer. The drawing shows the best placement of these labels for good visibility.

Order the labels from your Graco distributor.

Apply other

language here

French 194931

Spanish 194932

German 194933

Greek 194934

Korean 194935

English 194125

Displacement Pump Repair Kits

Packing repair kits.

GMax 7900 240916

03497A

30941222

Page 23

Technical Data

Honda GX160 Engine

Power Rating @ 3700 rpm

ANSI 5.5 Horsepower.......................

DIN 6270B/DIN 6271

NA 2.9 Kw -- 4.0 Ps......................

NB 3.6 Kw -- 4.9 Ps......................

Maximum working pressure 3300 psi...............

(227 bar, 22.7 MPa)

Noise Level

Sound power 105 dBa.........................

per ISO 3744

Sound pressure 96 dBa........................

measured at 3.1 feet (1 m)

Cycles/gallon (liter) 69 (18)........................

Dimensions

Model 233718, 233720

Lo-Boy Cart without hose or gun

Maximum delivery rating 2.1 gpm (7.9 liter/min)......

Maximum tip size 1 gun with 0. 046 in. tip..........

2 guns with 0.033 in. tip

3 guns with 0. 026 in. tip

4 guns with 0. 022 in. tip

Inlet paint strainer 16 mesh (1190 micron)...........

stainless steel screen, reusable

Outlet paint filter 60 mesh (250 micron).............

stainless steel screen, reusable

Pump inlet size 3/4 in. npt (m)......................

Fluid outlet size 3/8 npsm from fluid filter............

Wetted parts zinc-plated carbon steel,..............

PTFE, Nylon, UHMW polyethylene,

Viton

r,Delrinr, leather, aluminum, tungsten carbide,

nickel and zinc-plated carbon steel, stainless steel,

chrome plating, PEEK

NOTE: Delrinr,PTFE,Vitonr are trademarks of the DuPont

Company.

Model 233719, 233721

Hi-Boy without hose or gun

Weight (dry, without packaging) 180 lb (82.1 kg).....

Height 41 in. (104.1 cm)..........................

Length 39 in. (99.1 cm)...........................

Width 22 in. (55.9 cm)............................

Weight (dry, without packaging) 175 lb (79.4 kg).....

Height 41 in. (104.1 cm)..........................

Length 39 in. (99.1 cm)...........................

Width 22 in. (55.9 cm)............................

309412 23

Page 24

Graco Standard Warranty

Graco warrants all equipment manufactured byGraco and bearingits nameto befree from defects in material and workmanship onthe

date of saleby an authorized Gracodistributorto the originalpurchaser for use. With theexception of any special, extended, orlimited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repairor replaceany partof theequipment

determined by Graco to be defective. This warranty applies only when the equipmentis installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, orany malfunction, damage or wear caused by

faultyinstallation, misapplication,abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non--Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipmentwill be returnedto the original purchaser transportationprepaid. If inspection ofthe equipment doesnot disclose anydefect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’ssole obligation andbuyer’s sole remedyfor any breach of warranty shall be as set forth above. The buyer agrees thatno other

remedy (including, but not limited to, incidental orconsequential damages for lost profits, lost sales,injury to person or property,or any

other incidental orconsequential loss) shall be available. Any action forbreach of warrantymust bebrought within two (2)years ofthe

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment,materialsor components sold but notmanufactured by Graco. These items sold,but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUST

The parties acknowledge that they have required that the present document,as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly orindirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsique tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

OMERS

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty

Program”.

Graco Phone Number

TO PLACE AN ORDER, contact your Graco distributor, or call 1--800--690--2894 to identify your closest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

MM 309412

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440--1441

www.graco.com

30941224

PRINTED IN USA 309412E 1/2002 Rev. 08/2009

Loading...

Loading...