Page 1

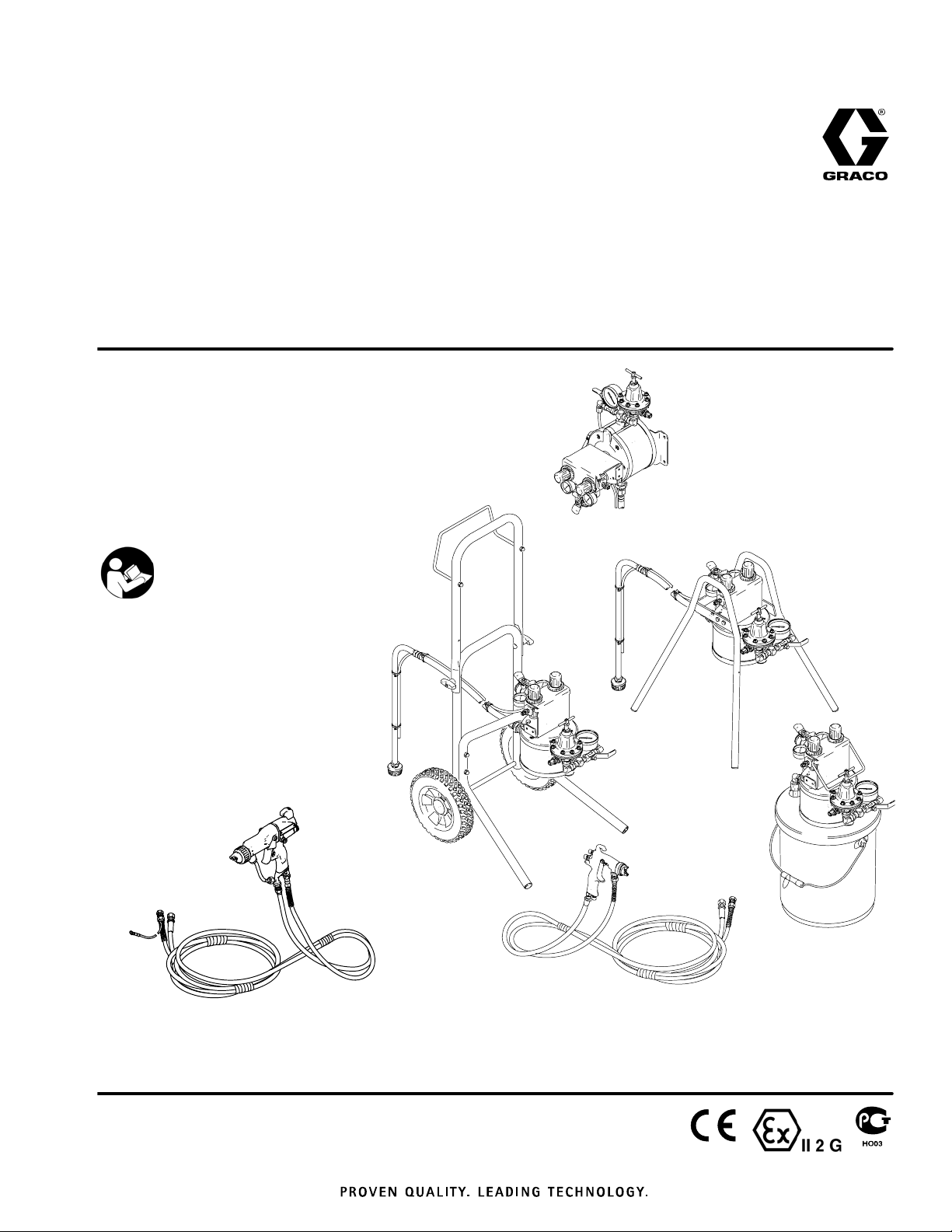

Instructions–Parts List

ALUMINUM AND STAINLESS STEEL, 1:1 RATIO

R

Triton

308

Spray Packages

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

Pail Mount Packages

Stand Mount Packages

Cart Mount Packages

Wall Mount Packages

Important Safety Instructions

Read all warnings and instructions

in this manual. Save these instructions.

See page 2 for Table of Contents

and page 3 for Models.

309304P

EN

TI1587b

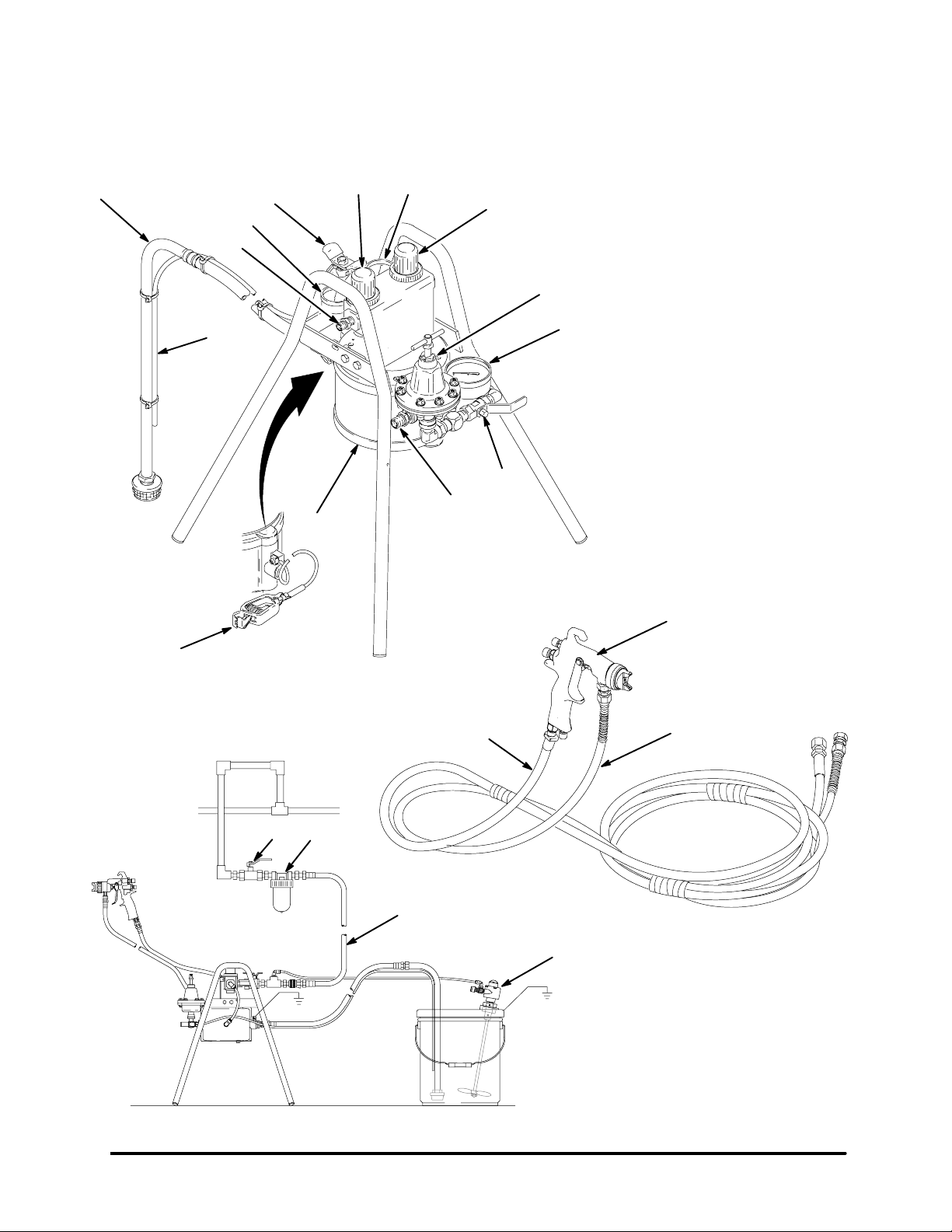

Electrostatic packages Air Spray packages and HVLP packages

TI1004b

Page 2

Table of Contents

Models 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Identification 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List and Parts Drawing

Pail Mount 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stand Mount 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cart Mount 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wall Mount 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wall Mounting Template 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Information 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3093042

Page 3

Models

Spray Package Description Pail Mount,

Series

Aluminum Pump,

No Gun

Stainless Steel Pump,

No Gun

Aluminum Pump,

AirPro Conventional Gun

Stainless Steel Pump,

AirPro Conventional Gun

Aluminum Pump,

AirPro HVLP Spray Gun

Stainless Steel Pump,

AirPro HVLP Spray Gun

Aluminum Pump,

AirPro Compliant Spray Gun

Stainless Steel Pump,

AirPro Compliant Spray Gun

Aluminum Pump,

Pro Xp 40 Electrostatic Spray Gun

Aluminum Pump,

Pro Xp 60 Electrostatic Spray Gun

Stainless Steel Pump,

AirPro HVLP Waterborne Gun

Stainless Steel Pump,

AirPro Compliant Waterborne Gun

Stainless Steel Pump,

AirPro Conventional Waterborne Gun

Stainless Steel Pump,

AirPro HVLP Stain Spray Gun

Stainless Steel Pump,

AirPro Compliant Stain Spray Gun

Stainless Steel Pump,

AirPro Conventional Stain Spray Gun

Aluminum Pump,

AirPro HVLP Stain Spray Gun

Aluminum Pump,

AirPro Compliant Stain Spray Gun

Aluminum Pump,

AirPro Conventional Stain Spray Gun

Aluminum Pump,

Pro Xp 85 Electrostatic Spray Gun

233466,

A

233467,

A

233468,

C

233469,

C

233470,

C

233471,

C

234911,

B

234912,

B

233741,

C

233742,

C

N/A N/A 289632,

N/A N/A 289633,

N/A N/A 289634,

289642,

A

289643,

A

289644,

A

289645,

A

289646,

A

289647,

A

289648,

C

Stand Mount,

Series

233473,

A

233474,

A

233475,

C

233476,

C

233477,

C

233478,

C

234913,

B

234914,

B

233743,

B

233744,

B

N/A 289635,

N/A 289636,

N/A 289637,

N/A 289638,

N/A 289639,

N/A 289640,

289649,

B

Cart Mount,

Series

233480,

A

233481,

A

233482,

C

233483,

C

233484,

C

233485,

C

234915,

B

234916,

B

233746,

C

233747,

C

A

A

A

A

A

A

A

A

A

289641,

C

Wall Mount,

Series

233487,

A

233488,

A

233489,

C

233490,

C

233491,

C

233492,

C

234917,

B

234918,

B

233748,

B

233749,

B

289622,

A

289623,

A

289624,

A

289625,

A

289626,

A

289627,

A

289628,

A

289629,

A

289630,

A

289631,

B

309304 3

Page 4

Symbols

Warning Symbol

WARNING

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

PRESSURIZED FLUID HAZARD

Spray from the gun, hose leaks, or ruptured components can splash fluid in the eyes or on the skin

and cause serious injury.

D Do not stop or deflect fluid leaks with your hand, glove, or rag.

D Follow the Pressure Relief Procedure on page 10 before cleaning, checking, or servicing the

equipment.

D Tighten all fluid connections before each use.

D Check the hoses, tubes, and couplings daily. Replace parts immediately if worn, damaged, or

loose. Permanently coupled hoses cannot be repaired.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

corresponding instructions.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in fire or explosion and serious injury.

D Ground the equipment, the object being sprayed, and all other electrically conductive objects in the

spray area. See Grounding on page 10.

D Electrostatic guns require special grounding procedures. If your package includes an electrostatic

spray gun, read and follow all grounding instructions in the gun manual 3A2494.

D If there is any static sparking while using the equipment, stop spraying immediately. Identify and

correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable vapors from the solvent or the fluid

being sprayed.

D Do not smoke in the spray area.

D Extinguish all open flames or pilot lights in the spray area.

D Do not turn on or off any light switch in the spray area.

D Electrically disconnect all equipment in the spray area.

D Keep the spray area free of debris, including solvent, rags, and gasoline.

D Do not operate a gasoline engine in the spray area.

3093044

Page 5

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in a serious injury.

D This equipment is for professional use only.

D Read all the instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check the equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated system component. This pack-

age has a 100 psi (0.7 MPa, 7 bar) maximum working pressure.

D Use fluids that are compatible with the equipment wetted parts. See the Technical Data section of

all the equipment manuals. Read the fluid manufacturer’s warnings.

D Aluminum pumps only: Never use 1.1.1–trichloroethane, methylene chloride, other halogenated

hydrocarbon solvents or fluids containing such solvents in pressurized aluminum equipment. Such

use could result in a chemical reaction, with the possibility of explosion.

D Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180_F (82_C) or below –40_F (–40_C).

D Do not use the hoses to pull equipment.

D Wear hearing protection when operating this equipment.

D Comply with all applicable local, state, and national fire, electrical, and other safety regulations.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause a serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled.

D Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

D Store hazardous fluid in an approved container. Dispose of the hazardous fluid according to all

local, state, and national guidelines.

D Wear appropriate protective clothing, gloves, eyewear, and respirator.

D If the pump diaphragm fails, hazardous fluid may be exhausted along with the air.

309304 5

Page 6

Component Identification

Stand Mount HVLP Spray Package Shown

L

B

G

V

N

K

A

U

M

KEY

A TRITON 1:1 Pump

B Bleed-type master air valve

C Air supply line (not supplied)

D Air line filter (not supplied)

F

H

T

E Air line shutoff valve (not supplied)

F Pump air regulator

G Gun air regulator

H Fluid pressure regulator (HVLP and

electrostatic packages only)

J Drain/circulation valve

K Drain tube

L Suction tube

M Gun fluid hose connection

N Gun air hose connection

P Gun fluid hose

R Gun air hose

S Spray gun

T Fluid pressure gauge (HVLP and

electrostatic packages only)

U Pump air pressure gauge

V Gun air pressure gauge

W Agitator (not supplied)

Y Pump ground wire

J

S

Y

R

P

DE

C

ti1005b

W

Fig. 1

ti1006a

3093046

Page 7

Installation

CAUTION

Use a stainless steel package to spray waterborne,

acid-catalyzed, or 2-component materials. Use of

aluminum packages with these materials is not recommended. See the wetted parts in the Technical

Data section of each component manual, and your

fluid and solvent manufacturer’s compatibility information.

WARNING

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can

cause serious injury or death if splashed

in the eyes or on the skin, inhaled, or

swallowed.

Preparing the Site

D Ensure that you have an adequate compressed air

supply for the pump and gun. Refer to the separate

pump and gun manuals for air consumption data.

D Clear obstacles and debris that could cause an

unsafe operating environment.

D Have a grounded, metal pail available for use when

flushing the spray package.

D Bring an air supply line (C) from the main air supply

to the pump location. Install an accessory air filter

(D) on the compressed air line to filter dirt and

moisture from the air supply. Install a shutoff valve

(E) to isolate the filter for cleaning.

D Read TOXIC FLUID HAZARD on page 5.

D Use fluids and solvents that are compatible with

the equipment wetted parts. Refer to the Technical Data section of all equipment manuals.

Read the fluid and solvent manufacturer’s

warnings.

General Information

D Always use Genuine Graco Parts and Accessories,

available from your Graco distributor. If you supply

your own accessories, be sure they are adequately

sized and pressure rated for your system.

D Reference numbers and letters in parentheses refer

to the callouts in the Figs. and the parts lists starting on page 12.

D When the bleed-type master air valve (B) is closed

and the pump air regulator (F) and gun air regulator

(G) are opened, it relieves all air pressure to the

system components.

D Ventilate the spray booth.

WARNING

To prevent hazardous concentrations of toxic

and/or flammable vapors, spray only in a properly

ventilated spray booth. Never operate the spray

gun unless ventilation fans are operating.

Check and follow all of the national, state, and local

codes regarding air exhaust velocity requirements.

309304 7

Page 8

Installation

Pump Outlet Fluid Filter Accessories

To install a fluid filter on the pump outlet, order a filter

(AA), swivel (BB), and nipple (CC). Refer to Table 1 for

the part numbers you must order for an aluminum or a

stainless steel package.

Refer to Fig. 2. Install the fluid filter between the pump

fluid outlet and the gun fluid hose connection. If a fluid

regulator (H) is present, it must be rotated so the

gauge (T) will clear the filter.

Table 1: Installing a Fluid Filter

Fluid Filter (AA) Swivel (BB) Nipple (CC)

114361; nylon;

150 psi; 80 mesh;

for aluminum or

stainless steel

packages

235677; aluminum;

3000 psi; 60 mesh;

for aluminum

packages

223160; sst;

5000 psi; 60 mesh;

for stainless steel

packages

235207;

3/8 npt(m) x 3/8

npsm(f); sst

157705;

1/4 npt(m) x 3/8

npsm(f); cst

235207;

3/8 npt(m) x 3/8

npsm(f);

sst

166863;

1/4 npt x 3/8

npt; sst

165198;

1/4 npt x 3/8

npt; cst

166863;

1/4 npt x 3/8

npt; sst

Gun Inlet Filter

To install a filter between the hose and gun inlet, order

Filter 915921, 100 mesh, 500 psi, sst, 3/8 npsm (m x f).

Agitator Kit 245081

Part No. 245081 Agitator Kit is available for the

TRITON Sprayer Packages as an accessory. The kit

must be ordered separately. Instructions are included.

Fluid Suction Line

D The pump fluid inlet is 3/4 npt(f). Screw the suction

line (L) into the pump inlet snugly. Use a compatible liquid thread sealant on connections to prevent

air from getting into the fluid line.

D Do not pressure feed this pump.

D See the Technical Data in the pump manual

309303 for maximum suction lift.

Preparing the Operator

Anybody who operates this system should be trained

in the safe, efficient operation of all system components. At a minimum, all operators should thoroughly

read the TRITON operation manual, 309305.

Fig. 2

Related Manuals

AA

309305 TRITONt 308 Spray Package Operation

309303 TRITONt 308 Pump

BB

AA

H T

CC

ti1471a

3093048

312414 AirPro Conventional, HVLP, and

Compliant Gun

3A2494 Pro Xp Electrostatic Air Spray Guns

308325 Acetal Fluid Regulator

307212 Stainless Steel Fluid Regulator

309306 Agitator Kit

Page 9

Installation

Wall Mount Packages

NOTE: Refer to Fig. 3 and to the Wall Mounting Tem-

plate on page 21.

1. Ensure that the wall is strong enough to support

the weight of the pump and accessories, fluid,

hoses, and stress caused during pump operation.

2. Use the Wall Mounting Template on page 21 to set

the position of the wall bracket. The top edge of

the bracket should be 4 to 5 ft (1.2 to 1.5 m) above

the floor. Verify that the dimensions are exact and

the hole locations are level before drilling the

holes.

NOTE: It is easier to mount the wall bracket (31) if the

control bracket (4) and pump (1) are removed. Disconnect the air tube (12) from the elbow (11), then loosen

the two screws (3) and lift the control bracket (4) off

the screws. To remove the pump (1), remove the

screws (3) entirely.

3. Using the template, drill four 0.38 in. (9.6 mm)

diameter holes in the wall. Attach the bracket with

anchors and screws that are long enough to keep

the bracket from vibrating during operation. Check

that the bracket is level.

Suction Kit Accessories

Suction kits are available for the wall mount packages,

as an accessory. The kits must be ordered separately.

Refer to Table 2 for information.

31

11

12

4

0.38 in.

1

3

Fig. 3

(9.6 mm)

ti1007a

Table 2: Wall Mount Suction Kits

Part No. Suction Kit Description Hose Length Tube Length

245082 Aluminum, 5 gal pail size, with strainer 4 ft (1.2 m) 17 in. (0.43 m)

245083 Stainless Steel, 5 gal pail size, with strainer 4 ft (1.2 m) 17 in. (0.43 m)

245084 Aluminum, 55 gal drum size, with bung adapter 6 ft (1.8 m) 38 in. (0.96 m)

245085 Stainless Steel, 55 gal drum size, with bung

adapter

6 ft (1.8 m) 38 in. (0.96 m)

309304 9

Page 10

Installation

Grounding

WARNING

To reduce the risk of static sparking, the entire

system must be grounded. Check your local

electrical code for detailed grounding instructions

for your area and type of equipment. Ground all of

this equipment. Also read FIRE AND EXPLOSION

HAZARD on page 4.

D Spray package: One end of the ground wire is

already connected to the pump. Connect the clamp

end of the ground wire to a true earth ground.

D Packages with Pro Xp electrostatic guns: Make

sure you read all of the grounding instructions and

warnings in your gun instruction manual 3A2494.

D Air compressor: Follow the manufacturer’s recom-

mendations.

D Object being sprayed: Follow the local code.

D Fluid supply container: Follow the local code.

D All solvent pails used when flushing: Follow the

local code. Use only metal pails, which are conductive. Do not place the pail on a non-conductive surface, such as paper or cardboard, which interrupts

the grounding continuity.

Flush Pump Before First Use

The pump was tested in lightweight oil. If the test

solution could contaminate the fluid you are pumping,

flush the pump thoroughly with a compatible solvent.

Refer to the Operation Manual 309305 for flushing

instructions.

Pressure Relief Procedure

WARNING

The system remains pressurized until pressure is

manually relieved. To reduce the risk of serious

injury from pressurized fluid, accidental spray from

the gun, or splashing of any fluid, follow this procedure whenever you

D Stop spraying

D Are instructed to relieve pressure

D Check or service any system equipment

D Install, clean, or change spray nozzles

1. Close the bleed-type master air valve (B) to relieve

the air pressure.

2. On electrostatic guns only, turn the ES ON/OFF

lever to OFF.

3. Hold the gun (B) firmly against a grounded metal

pail and trigger the gun to relieve the fluid pressure.

4. Place the drain tube (K) in a waste pail. Open the

drain/circulation valve (J) to relieve any fluid pressure trapped in the system.

30930410

Page 11

Maintenance

See the separate component instruction manuals for individual component maintenance procedures.

Daily Maintenance

Check the hoses, tubes, and couplings daily. Tighten

all fluid connections before each use.

Flushing the System

Flush the system at the following times:

D Before the first-time use

D When changing colors

D Before fluid can dry or settle out in a dormant

system

D Before storing the system

Troubleshooting

PROBLEM CAUSE SOLUTION

Pump will not run. Closed air line valve. Open valve.

Inadequate air supply, or clogged/

restricted air line.

Clogged fluid line or spray gun. Clear, service. Do not allow fluid to

Stuck or damaged pump air valve. Service pump. Use filtered air.

Ruptured diaphragm. Service pump.

Pump runs sluggishly. Worn or damaged spool o-rings. Service pump.

Pump runs erratically. Clogged suction line or inlet strainer. Clear.

Sticking or leaking check valves. Service pump.

Pump runs too fast. Exhausted fluid supply. Refill fluid supply and prime sprayer.

Increase air supply. Do not exceed

maximum air inlet pressure.

Open or clear air line.

Clean air filter.

set up in the pump and lines.

Pump cycles at stall or fails to hold

pressure at stall.

Audible air leak. Worn air valve cup or plate. Service pump.

Air bubbles in fluid. Loose suction line. Tighten. Use a compatible liquid

Poor finish or irregular spray pattern.

Worn check valves or o-rings. Service pump.

thread sealant on connections.

Incorrect fluid or air pressure at gun. See gun manual; read fluid

manufacturer’s recommendations.

Use fluid regulator.

Fluid is too thin or too thick. Adjust fluid viscosity; read fluid

manufacturer’s recommendations.

Dirty, worn, or damaged spray gun. Service gun.

Fluid is settling out. Use agitator. Order Part No. 245081

Agitator Kit.

309304 11

Page 12

Parts

Pail Mount Packages (see model descriptions on page 3)

Models 233466, 233467, 233468, 233469, 233470, 233471, 234911, 234912, 233741, 233742, 289642, 289643,

289644, 289645, 289646, 289647, and 289648.

Items 56–59 are used on Models

1

233470, 233471, 233741, 233742,

234911, 234912, 289642, 289643,

289645, 289646, and 289648 only.

5

30 11

9

37

8

1 1

57 58

30

10

3

4

12

6

7

9

31

35 (Ref)

39

22

47

12 (Ref)

11

59

1

16 (Ref)

15

1

14

2

16

35

22

33

56

45

1

32

55

34

23

36

60

ti1008b

30930412

Page 13

Parts

Pail Mount Packages (see model numbers on page 12)

Ref.

No. Part No. Description Qty.

1 233500 PUMP, diaphragm; aluminum; 1

for 233466, 233468, 233470, 233741,

233742

233501 PUMP, diaphragm; sst; 1

for 233467, 233469, 233471

2 238909 GROUND WIRE & CLAMP ASSY 1

3 116311 SCREW, cap, hex hd; 2

5/16 unc x 5.5 in. (140 mm)

4 197126 BRACKET, control 1

5 116473 VALVE, air, bleed-type; 1/4 npt(fbe) 1

6 116393 ADAPTER; 1/4 npt (m x f) 1

7 115219 TEE; 1/4 npt(m) 1

8 116514 NUT, regulator 2

9 116513 REGULATOR, air 2

10 162453 NIPPLE; 1/4 npsm x 1/4 npt 1

11 115948 ELBOW; 1/4 npt(m) x 2

0.312 in. (8 mm) OD tubing

12 buy locally TUBE; polyethylene; 0.5 ft

0.312 in. (8 mm) OD

14 114363 VALVE, ball, fluid; sst; 3/8 npt(fbe) 1

15 116314 ELBOW; 3/8 npt(m) x 1

0.25 in. (6 mm) OD tubing

16 buy locally TUBE; polyethylene; 2.2 ft

0.25 in. (6 mm) OD

22 197449 SPACER 4

23 218798 STRAINER 1

30 110436 GAUGE, pressure, air 2

31 116315 ELBOW; 3/8 npt(m) x 1

0.5 in. (13 mm) OD tubing

32 197298 COVER, pail; cst; 1

for 233466, 233468, 233470, 233741,

233742

197216 COVER, pail; sst; 1

for 233467, 233469, 233471

33 111813 PLUG, button 1

34 116316 FITTING, straight; 1/2 npt(m) x 1

0.5 in. (13 mm) OD tubing

35 197971 TUBE, suction; polyethylene; 1

0.5 in. (13 mm) OD x 14.5 in. (368 mm)

36 101108 PAIL, 5 gal. (19 l); steel 1

37 197127 HANDLE, pail mount 1

39 104034 WASHER; 5/16 size 2

45 113786 TEE; cst; 3/8 npt(m); 1

for 233466, 233468, 233470, 233741,

233742

116400 TEE; sst; 3/8 npt(m); 1

for 233467, 233469, 233471

47 116350 BUSHING; sst; 3/4 npt(m) x 3/8 npt(f) 1

Ref.

No. Part No. Description Qty.

55 288931 GUN, AirPro Conventional; 1

for 233468, 233469;

see manual 312414

288938 GUN, AirPro HVLP spray; 1

for 233470, 233471;

see manual 312414

288945 GUN, AirPro Compliant spray; 1

for 234911, 234912;

see manual 312414

L40T10 GUN, Pro Xp 40 electrostatic; 1

for 233741;

see manual 3A2494

L60T10 GUN, Pro Xp 60 electrostatic; 1

for 233742;

see manual 3A2494

289110 GUN, AirPro HVLP Stain; 1

for 289642, 289645;

see manual 312414

289111 GUN, AirPro Compliant Stain; 1

for 289643, 289646;

see manual 312414

289109 GUN, AirPro Conventional Stain; 1

for 289644, 289647;

see manual 312414

L85T10 GUN, Pro Xp 85 electrostatic; 1

for 289648;

see manual 3A2494

56 116395 ELBOW; cst; 1/4 npt(m) x 3/8 npt(f) 1

swivel; for 233470, 233741, 233742

207123 ELBOW; sst; 3/8 npt(m) x 1

3/8 npsm(f) swivel;

for 233471

57 241976 REGULATOR, fluid, acetal; 1

0–30 psi (0–0.2 MPa, 0–2 bar) range;

includes gauge; for 233470, 233741,

233742; see manual 308325

214895 REGULATOR, fluid; sst; 1

0–100 psi (0–0.6 MPa, 0–7 bar) range;

for 233471; see manual 307212

58 187874 GAUGE, pressure, fluid; 1

sst; for 233471

59 165198 NIPPLE; cst; 1/4 npt x 3/8 npt; 1

for 233470, 233741, 233742

171195 NIPPLE; sst; 3/8 npsm x 3/8 npt; 1

for 233471

60 233499 HOSE ASSY; sst fittings; 1

3/8 npsm(f) nylon fluid hose;

1/4 npsm(f) air hose; 25 ft (7.6 m);

for 233469, 233471, 233468, 233470

240425 HOSE ASSY, electrostatic; 1

3/8 npsm(f) nylon fluid hose;

1/4 npsm(f) air hose with ground wire

and left-hand thread; 25 ft (7.6 m);

for 233741, 233742, and 289648

309304 13

Page 14

Parts

Stand Mount Packages (see model descriptions on page 3)

Models 233473, 233474, 233475, 233476, 233477, 233478, 234913, 234914, 233743, 233744, and 289649

Items 56–59 are used on Models

1

233477, 233478, 233743, 233744,

234913, 234914, and 289649 only.

30

10

16

46

23

30

5

9

11

1 1

57 58

8

12

4

67

40

9

39

22

12 (Ref)

11

59

1

16 (Ref)

48

15

47

22

1

3

56

1

14

45

55

2

31

33

60

32

ti1010b

30930414

Page 15

Parts

Stand Mount Packages (see model numbers on page 14)

Ref.

No. Part No. Description Qty.

1 233500 PUMP, diaphragm; aluminum; 1

for 233473, 233475, 233477, 233743,

233744

233501 PUMP, diaphragm; sst; 1

for 233474, 233476, 233478

2 238909 GROUND WIRE & CLAMP ASSY 1

3 116311 SCREW, cap, hex hd; 2

5/16 unc x 5.5 in. (140 mm)

4 197126 BRACKET, control 1

5 116473 VALVE, air, bleed-type; 1/4 npt(fbe) 1

6 116393 ADAPTER; 1/4 npt (m x f) 1

7 115219 TEE; 1/4 npt(m) 1

8 116514 NUT, regulator 2

9 116513 REGULATOR, air 2

10 162453 NIPPLE; 1/4 npsm x 1/4 npt 1

11 115948 ELBOW; 1/4 npt(m) x 2

0.312 in. (8 mm) OD tubing

12 buy locally TUBE; polyethylene; 0.5 ft

0.312 in. (8 mm) OD

14 114363 VALVE, ball, fluid; sst; 3/8 npt(fbe) 1

15 116314 ELBOW; 3/8 npt(m) x 1

0.25 in. (6 mm) OD tubing

16 buy locally TUBE; polyethylene; 5.3 ft

0.25 in. (6 mm) OD

22 197449 SPACER 4

23 218798 STRAINER 1

30 110436 GAUGE, pressure, air 2

31 218743 FRAME, stand, pump 1

32 108175 PLUG, stand 4

33 100333 SCREW, cap, hex hd; 4

1/4–20 x 0.5 in. (13 mm)

39 104034 WASHER; 5/16 size 2

40 111040 NUT, lock; nylon insert; 5/16–18 2

45 113786 TEE; cst; 3/8 npt(m); 1

for 233473, 233475, 233477, 233743,

233744

116400 TEE; sst; 3/8 npt(m); 1

for 233474, 233476, 233478

46 244432 HOSE, suction; aluminum and LDPE; 1

for 233473, 233475, 233477

244433 HOSE, suction; sst; 1

for 233474, 233476, 233478, 233479

47 116350 BUSHING; sst; 3/4 npt(m) x 3/8 npt(f) 1

48 162485 NIPPLE; cst; 3/8 npsm x 3/8 npt; 1

for 233473, 233475, 233477, 233743,

233744

112100 NIPPLE; sst; 9/16–18 x 3/8 npt; 1

for 233474, 233476, 233478

Ref.

No. Part No. Description Qty.

55 288931 GUN, AirPro Conventional; 1

for 233475, 233476;

see manual 312414

288938 GUN, AirPro HVLP spray; 1

for 233477, 233478;

see manual 312414

288945 GUN, AirPro Compliant spray; 1

for 234913, 234914;

see manual 312414

L40T10 GUN, Pro Xp 40 electrostatic; 1

for 233743;

see manual 3A2494

L60T10 GUN, Pro Xp 60 electrostatic; 1

for 233744;

see manual 3A2494

L85T10 GUN, Pro Xp 85 electrostatic; 1

for 289649;

see manual 3A2494

56 116395 ELBOW; cst; 1/4 npt(m) x 3/8 npt(f) 1

swivel; for 233477, 233743, 233744

207123 ELBOW; sst; 3/8 npt(m) x 1

3/8 npsm(f) swivel;

for 233478

57 241976 REGULATOR, fluid; acetal; 1

0–30 psi (0–0.2 MPa, 0–2 bar) range;

includes gauge; for 233477, 233743,

233744; see manual 308325

214895 REGULATOR, fluid; sst; 1

0–100 psi (0–0.6 MPa, 0–7 bar) range;

for 233478;see manual 307212

58 187874 GAUGE, pressure, fluid; sst; 1

for 233478

59 165198 NIPPLE; cst; 1/4 npt x 3/8 npt; 1

for 233477, 233743, 233744

171195 NIPPLE; sst; 3/8 npsm x 3/8 npt; 1

for 233478

60 233499 HOSE ASSY; sst fittings; 1

3/8 npsm(f) nylon fluid hose;

1/4 npsm(f) air hose; 25 ft (7.6 m);

for 233476, 233478, 233475, 233477

240425 HOSE ASSY, electrostatic; 1

3/8 npsm(f) nylon fluid hose;

1/4 npsm(f) air hose with ground wire

and left-hand thread; 25 ft (7.6 m);

for 233743, 233744, and 289649

309304 15

Page 16

Parts

Cart Mount Packages (see model descriptions on page 3)

Models 233480, 233481, 233482, 233483, 233484, 233485, 234915, 234916, 233746, 233747, 289632, 289633,

289634, 289635, 289636, 289637, 289638, 289639, 289640, and 289641

31

Items 56–59 are used on Models

1

30

5

30

9

11

12

233484, 233485, 233746, 233747,

234915, 234916, 289632, 289633,

289635, 289636, 289638, 289639,

and 289641only.

16

46

23

48

47

40

39

22

79

10

7

6

9

58

8

57

11

4

1

59

77

12 (Ref)

11

55

16 (Ref)

15

60

22

14

45

1

56

1

2

3

ti1011b

30930416

Page 17

Parts

Cart Mount Packages (see model numbers on page 16)

Ref.

No. Part No. Description Qty.

1 233500 PUMP, diaphragm; aluminum; 1

for 233480, 233482, 233484, 233746,

233747

233501 PUMP, diaphragm; sst; 1

for 233481, 233483, 233485

2 238909 GROUND WIRE & CLAMP ASSY 1

3 116311 SCREW, cap, hex hd; 2

5/16 unc x 5.5 in. (140 mm)

4 197126 BRACKET, control 1

5 116473 VALVE, air, bleed-type; 1/4 npt(fbe) 1

6 116393 ADAPTER; 1/4 npt (m x f) 1

7 115219 TEE; 1/4 npt(m) 1

8 116514 NUT, regulator 2

9 116513 REGULATOR, air 2

10 162453 NIPPLE; 1/4 npsm x 1/4 npt 1

11 115948 ELBOW; 1/4 npt(m) x 2

0.312 in. (8 mm) OD tubing

12 buy locally TUBE; polyethylene;

0.312 in. (8 mm) OD 0.5 ft

14 114363 VALVE, ball, fluid; sst; 3/8 npt(fbe) 1

15 116314 ELBOW; 3/8 npt(m) x 1

0.25 in. (6 mm) OD tubing

16 buy locally TUBE; polyethylene;

0.25 in. (6 mm) OD 5.3 ft

22 197449 SPACER 4

23 218798 STRAINER 1

30 110436 GAUGE, pressure, air 2

31 233581 CART ASSEMBLY 1

39 104034 WASHER; 5/16 size 6

40 111040 NUT, lock; nylon insert; 5/16–18 2

45 113786 TEE; cst; 3/8 npt(m); 1

for 233480, 233482, 233484, 233746,

233747

116400 TEE; sst; 3/8 npt(m); 1

for 233481, 233483, 233485

46 244432 HOSE, suction; aluminum and LDPE; 1

for 233480, 233482, 233484, 233746,

233747

244433 HOSE, suction; sst; 1

for 233481, 233483, 233485

47 116350 BUSHING; sst; 3/4 npt(m) x 3/8 npt(f) 1

48 162485 NIPPLE; cst; 3/8 npsm x 3/8 npt; 1

for 233480, 233482, 233484, 233746,

233747

112100 NIPPLE; cst, 3/8 npsm x 3/8 npt;

for 233481, 233483, 233485

55 For guns L40T10, L60T10, and L85T10

see manual 3A2494

L40T10 GUN, Pro Xp 40 electrostatic; 1

for 233746

L60T10 GUN, Pro Xp 60 electrostatic; 1

for 233747

L85T10 GUN, Pro Xp 85 electrostatic; 1

for 289641

Ref.

No. Part No. Description Qty.

For guns 288938, 288945, 244399, 288969, 288972,

288966, 289110, 289111, and 289109 see manual

312414

288938 GUN, AirPro HVLP spray; 1

for 233484, 233485

288945 GUN, AirPro Compliant spray; 1

for 234915, 234916

288969 GUN, AirPro HVLP Waterborne; 1

for 289632

288972 GUN, AirPro Compliant Waterborne; 1

for 289633

288966 GUN, AirPro Conventional Waterborne;1

for 289634

289110 GUN, AirPro HVLP Stain; 1

for 289635, 289638

289111 GUN, AirPro Compliant Stain; 1

for 289636, 289639

289109 GUN, AirPro Conventional Stain; 1

for 289637, 289640

56 116395 ELBOW; cst; 1/4 npt(m) x 3/8 npt(f) 1

swivel; for 233484, 233746, 233747

207123 ELBOW; sst; 3/8 npt(m) x 1

3/8 npsm(f) swivel;

for 233485

57 241976 REGULATOR, fluid; acetal; 1

0–30 psi (0–0.2 MPa, 0–2 bar) range;

includes gauge; for 233484, 233746,

233747; see manual 308325

214895 REGULATOR, fluid; sst 1

0–100 psi (0–0.6 MPa, 0–7 bar) range;

for 233485; see manual 307212

58 187874 GAUGE, pressure fluid; sst; 1

for 233485

59 165198 NIPPLE; cst; 1/4 npt x 3/8 npt; 1

for 233484, 233746, 233747

171195 NIPPLE; sst; 3/8 npsm x 3/8 npt; 1

for 233485

60 233499 HOSE ASSY; sst fittings; 1

3/8 npsm(f) nylon fluid hose;

1/4 npsm(f) air hose; 25 ft (7.6 m);

for 233483, 233485, 233482, 233484

240425 HOSE ASSY, electrostatic; 1

3/8 npsm(f) nylon fluid hose;

1/4 npsm(f) air hose with ground wire

and left-hand thread; 25 ft (7.6 m);

for 233746, 233747, and 289641

77 100058 SCREW, cap, hex hd; 4

1/4–20 x 1.5 in. (38 mm)

79 102040 NUT, lock; nylon insert; 1/4–20 4

309304 17

Page 18

Parts

Wall Mount Packages (see model descriptions on page 3)

Models 233487, 233488, 233489, 233490, 233491, 233492, 234917, 234918, 233748, 233749, 289622, 289623,

289624, 289625, 289626, 289627, 289628, 289629, 289630, and 289631

Items 56–59 are used on Models

1

233491, 233492, 233748, 233749,

234917, 234918, 289622, 289623,

289625, 289626, 289628, 289629,

and 289631 only.

Order suction kits separately.

2

See page 9.

8

3

12

12 (Ref)

4

16

15

11

22

14

39

47

45

58

1

57

1

59

1

56

1

1

31

22

47

48

2

11

32

30

2

7

9

9

55

10

60

6

5

32

30

ti1012b

30930418

Page 19

Parts

Wall Mount Packages (see model numbers on page 18)

Ref.

No. Part No. Description Qty.

1 233500 PUMP, diaphragm; aluminum; 1

for 233487, 233489, 233491, 233748,

233749

233501 PUMP, diaphragm; sst; 1

for 233488, 233490, 233492

2 238909 GROUND WIRE & CLAMP ASSY 1

3 116311 SCREW, cap, hex hd; 2

5/16 unc x 5.5 in. (140 mm)

4 197126 BRACKET, control 1

5 116473 VALVE, air, bleed-type; 1/4 npt(fbe) 1

6 116393 ADAPTER; 1/4 npt (m x f) 2

7 115219 TEE; 1/4 npt(m) 1

8 116514 NUT, regulator 2

9 116513 REGULATOR, air 2

10 162453 NIPPLE; 1/4 npsm x 1/4 npt 1

11 115948 ELBOW; 1/4 npt(m) x 2

0.312 in. (8 mm) OD tubing

12 buy locally TUBE; polyethylene;

0.312 in. (8 mm) OD 0.5 ft

14 114363 VALVE, ball, fluid; sst; 3/8 npt(fbe) 1

15 116314 ELBOW; 3/8 npt(m) x 1

0.25 in. (6 mm) OD tubing

16 buy locally TUBE; polyethylene;

0.25 in. (6 mm) OD 6.3 ft

22 197449 SPACER 4

30 108190 GAUGE, pressure, air 2

31 197426 BRACKET, wall mount 1

32 191892 FITTING, elbow, street; 90_ 2

39 104034 WASHER; 5/16 size 2

45 113786 TEE; cst; 3/8 npt(m); 1

for 233487, 233489, 233491, 233748,

233749

116400 TEE; sst; 3/8 npt(m); 1

for 233488, 233490, 233492

47 116350 BUSHING; sst; 3/4 npt(m) x 3/8 npt(f) 1

48 162485 NIPPLE; cst; 3/8 npsm x 3/8 npt; 1

for 233487, 233489, 233491, 233748,

233479

112100 NIPPLE; sst; 9/16–18 x 3/8 npt; 1

for 233488, 233490, 233492

55 For guns L40T10, L60T10, and L85T10

see manual 3A2494

L40T10 GUN, Pro Xp 40 electrostatic; 1

for 233748

L60T10 GUN, Pro Xp 60 electrostatic; 1

for 233749

L85T10 GUN, Pro Xp 85 electrostatic; 1

for 289631

Ref.

No. Part No. Description Qty.

For guns 288931, 288945, 288945, 288969, 288972,

288966, 289110, 289111, and 289109 see manual

312414

288969 GUN, AirPro HVLP Waterborne; 1

for 289622

288972 GUN, AirPro Compliant Waterborne; 1

for 289623

288966 GUN, AirPro Conventional Waterborne;1

for 289624

289110 GUN, AirPro HVLP Stain; 1

for 289625, 289628;

see manual 312414

289111 GUN, AirPro Compliant Stain; 1

for 289626, 289629

289109 GUN, AirPro Conventional Stain; 1

for 289627, 289630

56 116395 ELBOW; cst; 1/4 npt(m) x 3/8 npt(f) 1

swivel; for 233491, 233748, 233749

207123 ELBOW; sst; 3/8 npt(m) x 1

3/8 npsm(f) swivel;

for 233492

57 241976 REGULATOR, fluid; acetal; 1

0–30 psi (0–0.2 MPa, 0–2 bar) range;

includes gauge; for 233491, 233748,

233749; see manual 308325

214895 REGULATOR, fluid; sst 1

0–100 psi (0–0.6 MPa, 0–7 bar) range;

for 233492; see manual 307212

58 187874 GAUGE, pressure, fluid; sst; 1

for 233492

59 165198 NIPPLE; cst; 1/4 npt x 3/8 npt; 1

for 233491, 233748, 233749

171195 NIPPLE; sst; 3/8 npsm x 3/8 npt; 1

for 233492

60 233499 HOSE ASSY; sst fittings; 1

3/8 npsm(f) nylon fluid hose;

1/4 npsm(f) air hose; 25 ft (7.6 m);

for 233490, 233492, 233489, 233491

240425 HOSE ASSY, electrostatic; 1

3/8 npsm(f) nylon fluid hose;

1/4 npsm(f) air hose with ground wire

and left-hand thread; 25 ft (7.6 m);

for 233748, 233749, and 289631

309304 19

Page 20

Technical Data

Category Data

Maximum fluid working pressure 100 psi (0.7 MPa, 7 bar)

Maximum incoming air pressure 100 psi (0.7 MPa, 7 bar)

Maximum operating temperature 120_ F (49_ C)

Wetted Parts:

Pump See pump instruction manual 309303.

Gun See gun instruction manuals 312414 or 3A2494.

Fluid pressure regulator See regulator instruction manuals 307212 or 308325.

Fluid hoses, aluminum packages nylon, nickel-plated carbon steel (cst), LDPE/rubber blend (suction

hose), aluminum

Fluid hoses, stainless steel packages nylon, stainless steel (sst), LDPE/rubber blend (suction hose)

Fluid hoses, electrostatic packages nylon, nickel-chrome plated carbon steel (cst), LDPE/rubber blend

(suction hose)

Fluid fittings, aluminum packages Zinc-plated carbon steel (cst), stainless steel (sst), polypropylene,

polyethylene

Fluid fittings, stainless steel packages Stainless steel (sst), polypropylene, polyethylene

Pail cover, aluminum packages Zinc-plated carbon steel (cst)

Pail cover, stainless steel packages Stainless steel (sst)

Weight (without hoses or gun):

Pail mount packages Aluminum: 22 lb (10 kg)

Stainless Steel: 28 lb (12.7 kg)

Stand mount packages Aluminum: 20 lb (9.1 kg)

Stainless Steel: 27 lb (12.3 kg)

Cart mount packages Aluminum: 30 lb (13.6 kg)

Stainless Steel: 36 lb (16.4 kg)

Wall mount packages Aluminum: 19 lb (8.6 kg)

Stainless Steel: 24 lb (10.9 kg)

Sound Pressure Levels in dB(A)* (measured at 1 m from unit)

Input Air Pressures Sound Pressure

Pump: 20 psi (0.14 MPa, 1.4 bar), Fluid Regulator: 5 psi (0.035 MPa, 0.35 bar) 64.7

Pump: 40 psi (0.28 MPa, 2.8 bar), Fluid Regulator: 15 psi (0.105 MPa, 1.05 bar) 68.5

Pump: 40 psi (0.28 MPa, 2.8 bar), No Fluid Regulator 69.1

Pump: 40 psi (0.28 MPa, 2.8 bar), Circulation Mode 69.2

Pump: 60 psi (0.42 MPa, 4.2 bar), No Fluid Regulator 72.1

Sound Power Levels in dB(A)* (tested in accordance with ISO 3744)

Input Air Pressures Sound Power

Pump: 20 psi (0.14 MPa, 1.4 bar), Fluid Regulator: 5 psi (0.035 MPa, 0.35 bar) 76.3

Pump: 40 psi (0.28 MPa, 2.8 bar), Fluid Regulator: 15 psi (0.105 MPa, 1.05 bar) 80.1

Pump: 40 psi (0.28 MPa, 2.8 bar), No Fluid Regulator 80.8

Pump: 40 psi (0.28 MPa, 2.8 bar), Circulation Mode 80.8

Pump: 60 psi (0.42 MPa, 4.2 bar), No Fluid Regulator 83.7

* Sound readings are for bare packages only. Refer to the separate gun manual for gun sound data.

30930420

Page 21

Wall Mounting Template

Use this drawing as a template to drill mounting holes in the wall.

Verify that the dimensions are exact and the hole locations are level before drilling the holes.

Drill four 0.38 in. (9.6 mm) diameter mounting holes

7.00 in. (178 mm)

8.00 in. (203 mm)

4.50 in. (114 mm)3.50 in. (89 mm)

4.10 in. (104 mm)

For mounting pump to bracket

309304 21

Page 22

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of thirty-six months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within four (4) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the distributor closest to you:

Phone: 612–623–6921 or Toll Free: 1–800–328–0211 Fax: 612–378–3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 309304

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES S P.O. BOX 1441 S MINNEAPOLIS MN 55440–1441 S USA

Graco Headquarters: Minneapolis

Copyright 2001, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revised October 2012

30930422

Loading...

Loading...