Page 1

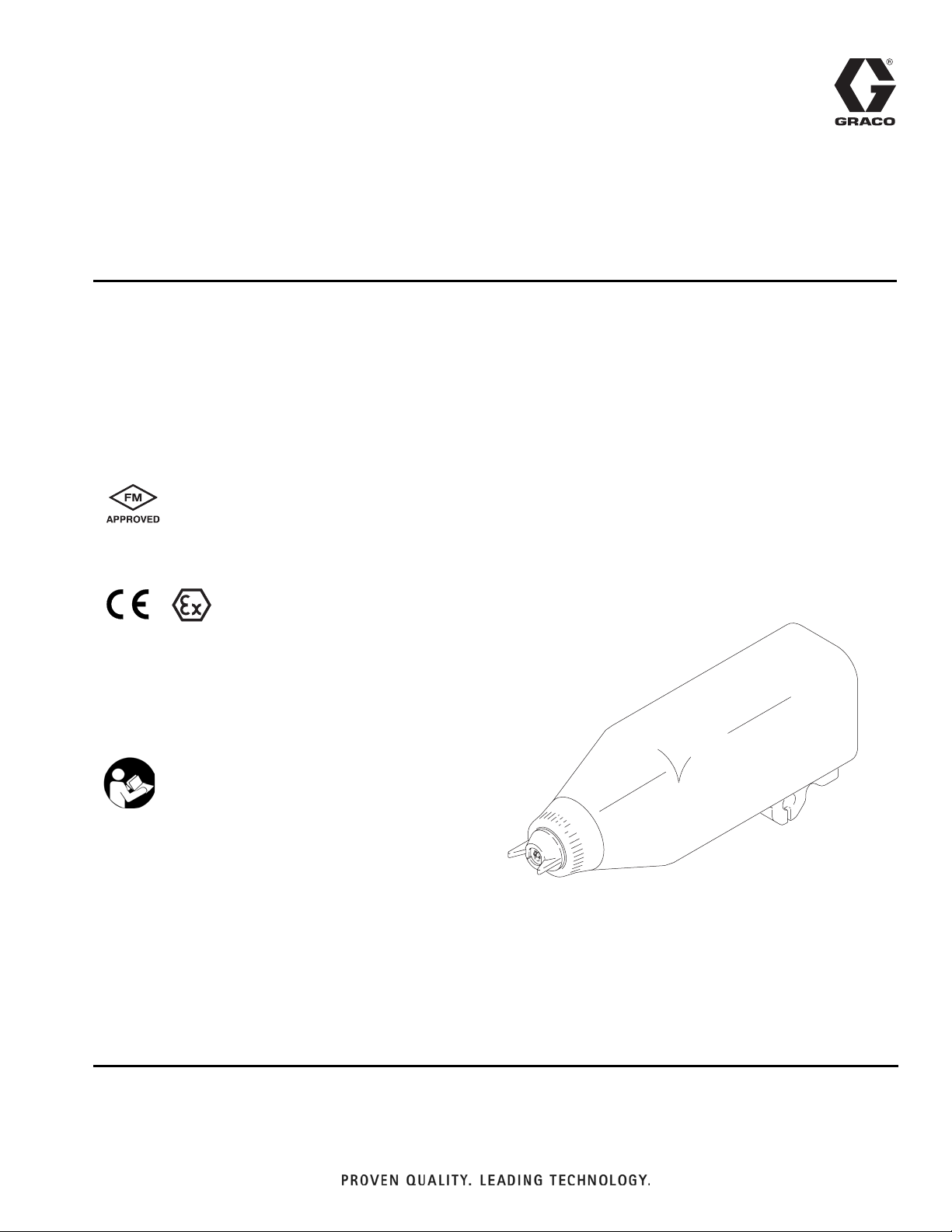

Instructions/Parts List

AUTOMATIC ELECTROSTATIC AIR-ASSISTED SPRAY GUN

™

PRO

Part No. 244592, Series A

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

3000 psi (21 MPa, 210 bar) Maximum Working Fluid Pressure

For use in Class I, Div. I hazardous locations using Group D spray materials.

#53

For use in Group II, Zone 1 areas using Group IIA spray materials.

Auto Xs AA

II 2 G EEx 0.24mJ

309298K

ENG

For Professional Use ONLY.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 2 for Table of Contents.

U.S. Patent 7,226,004

TI1713A

Page 2

Table of Contents

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warning Symbol . . . . . . . . . . . . . . . . . . . . . . . . . 3

Caution Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

How the Electrostatic AA Spray Gun Works . . . . 6

Operating the Spray Function . . . . . . . . . . . . . . . 6

Operating the Electrostatics . . . . . . . . . . . . . . . . 6

Gun Features and Options . . . . . . . . . . . . . . . . . 6

Changing the kV Setting . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Install the System . . . . . . . . . . . . . . . . . . . . . . . . 9

Warning Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Ventilate the Spray Booth . . . . . . . . . . . . . . . . . . 9

Install the Air Line Accessories . . . . . . . . . . . . . 11

Install the Fluid Line Accessories . . . . . . . . . . . 11

Install the Gun and Mounting Bracket . . . . . . . . 12

Connect the Air and Fluid Lines . . . . . . . . . . . . 13

Manifold Connections . . . . . . . . . . . . . . . . . . . . 13

Optional Fiber Optic Cable Connection . . . . . . . 14

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Check Electrical Grounding . . . . . . . . . . . . . . . . 16

Check Fluid Resistivity . . . . . . . . . . . . . . . . . . . 17

Check Fluid Viscosity . . . . . . . . . . . . . . . . . . . . 17

Install the Fabric Cover . . . . . . . . . . . . . . . . . . . 17

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pressure Relief Procedure . . . . . . . . . . . . . . . . 18

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . 18

Select a Spray Tip . . . . . . . . . . . . . . . . . . . . . . . 19

Install the Spray Tip . . . . . . . . . . . . . . . . . . . . . 19

Set the Atomization Fluid Pressure . . . . . . . . . . 20

Adjust the Electrostatics . . . . . . . . . . . . . . . . . . 21

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Triggering the Fluid Alone . . . . . . . . . . . . . . . . . 22

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Daily Care and Cleaning . . . . . . . . . . . . . . . . . . 23

Daily Care and Cleaning, continued . . . . . . . . . 24

Flush the Spray Gun . . . . . . . . . . . . . . . . . . . . . 25

Clean the Spray Gun . . . . . . . . . . . . . . . . . . . . . 26

Check for Fluid Leakage . . . . . . . . . . . . . . . . . . 28

Electrical Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Test Gun Resistance . . . . . . . . . . . . . . . . . . . . . 29

Test Power Supply Resistance . . . . . . . . . . . . . 30

Test Barrel Resistance . . . . . . . . . . . . . . . . . . . . 31

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Spray Pattern Troubleshooting . . . . . . . . . . . . . 32

Gun Operation Troubleshooting . . . . . . . . . . . . . 33

Electrical Troubleshooting . . . . . . . . . . . . . . . . . 34

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Prepare the Gun for Service . . . . . . . . . . . . . . . 35

Remove the Gun from the Manifold . . . . . . . . . . 36

Install the Gun on the Manifold . . . . . . . . . . . . . 36

Tip Guard, Air Cap, Spray Tip, or Seat Housing

Replacement . . . . . . . . . . . . . . . . . . . . . . . . 37

Electrode Replacement . . . . . . . . . . . . . . . . . . . 39

Fluid Tube Replacement . . . . . . . . . . . . . . . . . . 40

Fluid Filter Removal . . . . . . . . . . . . . . . . . . . . . . 40

Fluid Needle Replacement . . . . . . . . . . . . . . . . 41

Piston Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Adjust the Actuator Arm . . . . . . . . . . . . . . . . . . 43

Barrel Removal . . . . . . . . . . . . . . . . . . . . . . . . . 44

Barrel Installation . . . . . . . . . . . . . . . . . . . . . . . . 45

Power Supply Removal and Replacement . . . . 46

Turbine Alternator Removal and Replacement . 47

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Spray Tip Selection Chart . . . . . . . . . . . . . . . . . . . 51

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Gun Accessories . . . . . . . . . . . . . . . . . . . . . . . . 52

Air Line Accessories . . . . . . . . . . . . . . . . . . . . . 52

Fluid Line Accessories . . . . . . . . . . . . . . . . . . . 52

Miscellaneous Accessories . . . . . . . . . . . . . . . . 52

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 56

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 56

2 309

298K

Page 3

Symbols

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious injury

or death if you do not follow the instructions.

WARNING

Fire, Explosion, and Electric Shock Hazard

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help

prevent fire and explosion:

• Electrostatic equipment must be used only by trained, qualified personnel who understand the

requirements of this manual.

• Ground equipment, personnel, object being sprayed, and conductive objects in work area. See

Grounding instructions.

• Only use grounded Graco conductive air supply hoses.

• Check gun and hose resistance and electrical grounding daily.

• Use and clean equipment only in well ventilated area.

• Interlock the gun air supply to prevent operation unless ventilating fans are on.

• Use cleaning solvents with highest possible flash point when flushing or cleaning equipment.

To comply with EN50050 requirements, cleaning solvents must have a flash point at least 5°C

above ambient temperature.

• Always turn the electrostatics off when flushing, cleaning or servicing equipment.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equip-

ment until you identify and correct the problem.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths (potential static arc).

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Keep work area free of debris, including solvent, rags and gasoline.

• Keep a working fire extinguisher in the work area.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to or

destruction of equipment if you do not follow the instructions.

309298K 3

Page 4

Warning

WARNING

Skin Injection Hazard

Spray from the gun, hose leaks, or ruptured components can inject fluid into your body and cause

an extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the

skin can also cause serious injury.

• Fluid injected into the skin might look like just a cut, but is a serious injury. Get immediate

surgical treatment.

• Do not point the gun at anyone or at any part of the body. Do not put your hand or fingers over

the spray tip. Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

• Never spray without the tip guard in place.

• Follow the steps under Prepare the Gun for Service, page 35, when you stop spraying and

before cleaning, checking, or repairing equipment.

• Check the hoses and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

• Tighten all fluid connections before each use.

Toxic Fluid Hazard

Hazardous fluids or toxic fumes can cause a serious injury or death if splashed in the eyes or on

the skin, swallowed, or inhaled.

• Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

• Store hazardous fluid in an approved container. Dispose of the hazardous fluid according to all

local, state, and national guidelines.

• Wear appropriate protective clothing, gloves, eyewear, and respirator.

4 309298K

Page 5

WARNING

Equipment Misuse Hazard

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and

result in a serious injury.

• This equipment is for professional use only.

• Read all manuals, tags, and labels before operating the equipment.

• Use the equipment only for its intended purpose. If you are uncertain, call your Graco distribu-

• Do not alter or modify equipment. Use only genuine Graco parts and accessories.

• Check the equipment daily. Repair or replace worn or damaged parts immediately.

• Do not exceed the maximum working pressure of the lowest rated system component. Maxi-

• Use fluids and solvents that are compatible with the equipment wetted parts. See the Techni-

• Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

• Wear hearing protection when operating this equipment.

• Comply with all applicable local, state, and national fire, electrical, and other safety regula-

Warning

tor.

mum working fluid pressure of this equipment is 3000 psi (21 MPa, 210 bar).

cal Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

expose Graco hoses to temperatures above 180°F (82°C) or below -40°F (-40°C).

tions.

309298K 5

Page 6

Introduction

Introduction

How the Electrostatic AA Spray Gun Works

WARNING

Skin Injection Hazard

Remember, this is not an air spray gun.

For your safety, read and follow all Warnings in this manual.

The air-assisted spray gun combines airless and air

spraying concepts. The spray tip shapes the fluid into a

fan pattern, as does a conventional airless spray tip. Air

from the air cap further atomizes the fluid and completes

the atomization of the fluid tails to produce a uniform

pattern.

The high working fluid pressure of this gun provides the

power needed to atomize higher solids materials.

Operating the Spray Function

Applying a minimum of 50 psi (0.35 MPa, 3.5 bar) air

pressure to the gun manifold’s cylinder air fitting (CYL)

will retract the gun piston, which opens the air valves

and a short time later opens the fluid needle. This provides the proper air lead and lag when triggering the

gun. A spring returns the piston when the cylinder air is

shut off.

Operating the Electrostatics

To operate the electrostatics, apply air pressure to the

gun manifold’s turbine air fitting (TA) through a Graco

grounded air hose. The air enters the manifold and is

directed to the inlet of the power supply turbine. The air

spins the turbine, which then provides electrical power

to the internal high voltage power supply. The fluid is

charged by the spray gun electrode. The charged fluid is

attracted to the nearest grounded object, wrapping

around and evenly coating all surfaces.

The turbine air is exhausted into the shroud and out the

back of the manifold through the exhaust fitting (EXH).

The exhaust air helps keep contaminants out and helps

keep the gun clean.

Gun Features and Options

• The gun is designed for use with a reciprocator, and

can be mounted directly on a 1/2 in. (13 mm) rod.

With additional brackets, the gun can be mounted

for robotic applications.

• The gun’s quick-disconnect design enables its

removal without disconnecting the air lines to the

gun.

• Gun functions are activated from a separate control-

ler that sends the appropriate signal to the actuating

solenoids.

• The optional fiber optic readout system can be

installed to monitor the gun’s spraying voltage. A

fiber optic cable connected to the gun manifold carries the signal from the gun to a remote display

module. Part No. 224117 Display Module displays

the gun’s spraying voltage and current. Battery-operated Display Module 189762 displays the

gun’s spraying voltage only.

6 309298K

Page 7

Changing the kV Setting

Introduction

The gun’s full voltage setting is 85 kV. Three lower voltage settings are possible by actuating the KV1 and KV2

switches. Supply 50 psi (0.35 MPa, 3.5 bar) air pressure

to the KV1 and KV2 ports. Turn the air on or off as

shown in Table 1 to set the desired voltage.

The solenoid valves used to activate the KV1 and KV2

switches must bleed the air out of the lines for the

switches to draw back to the higher voltage setting.

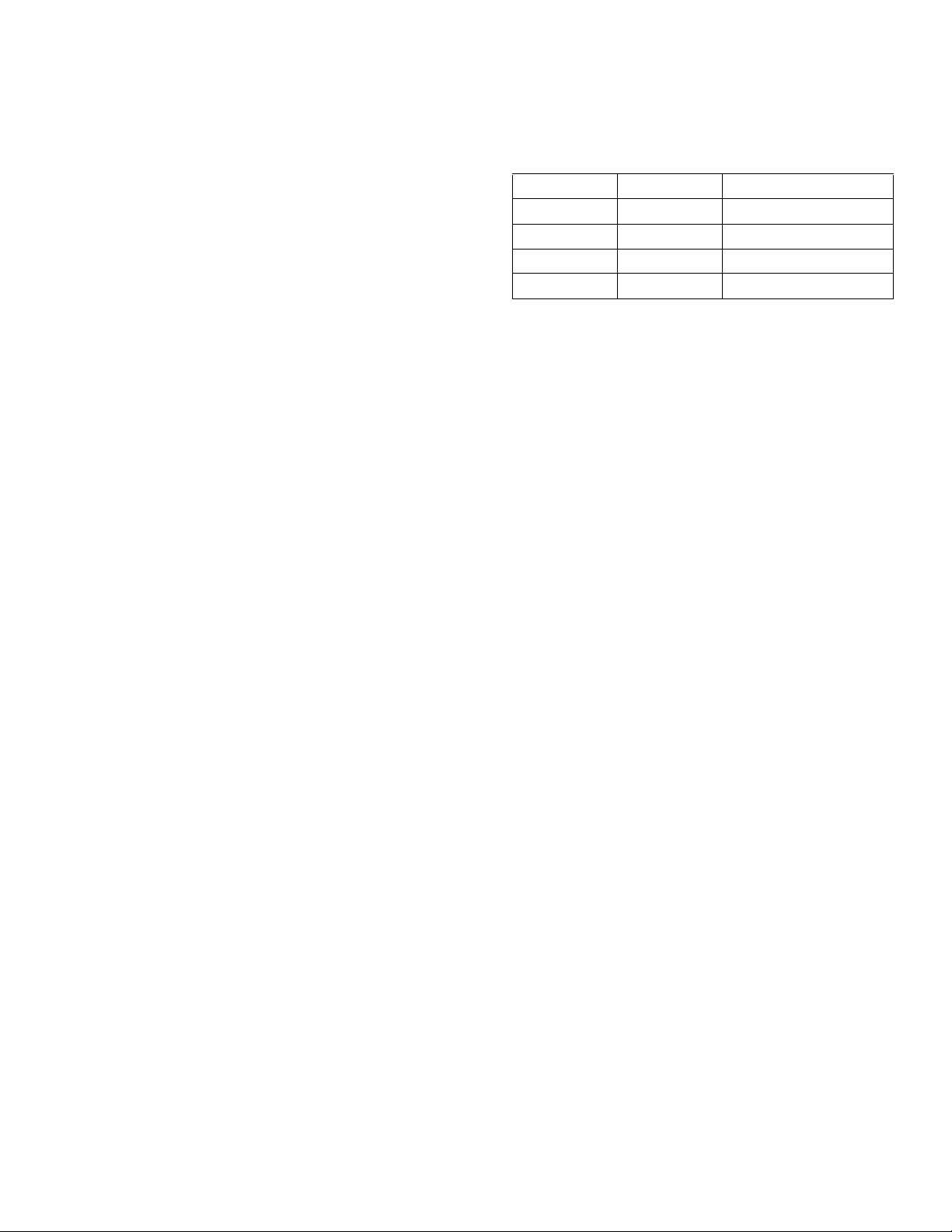

Table 1: KV1 and KV2 Switch Settings

KV1 Air KV2 Air Output Voltage (kV)

OFF OFF 85

OFF ON 70

ON OFF 60

ON ON 45

309298K 7

Page 8

Introduction

G

KV1

TA

A

CYL

C

FO

KV2

A2

P1

TI1713A

F

B

H

EXH

E

J

TI1714A

Manifold Back View

TI1739A

D

K

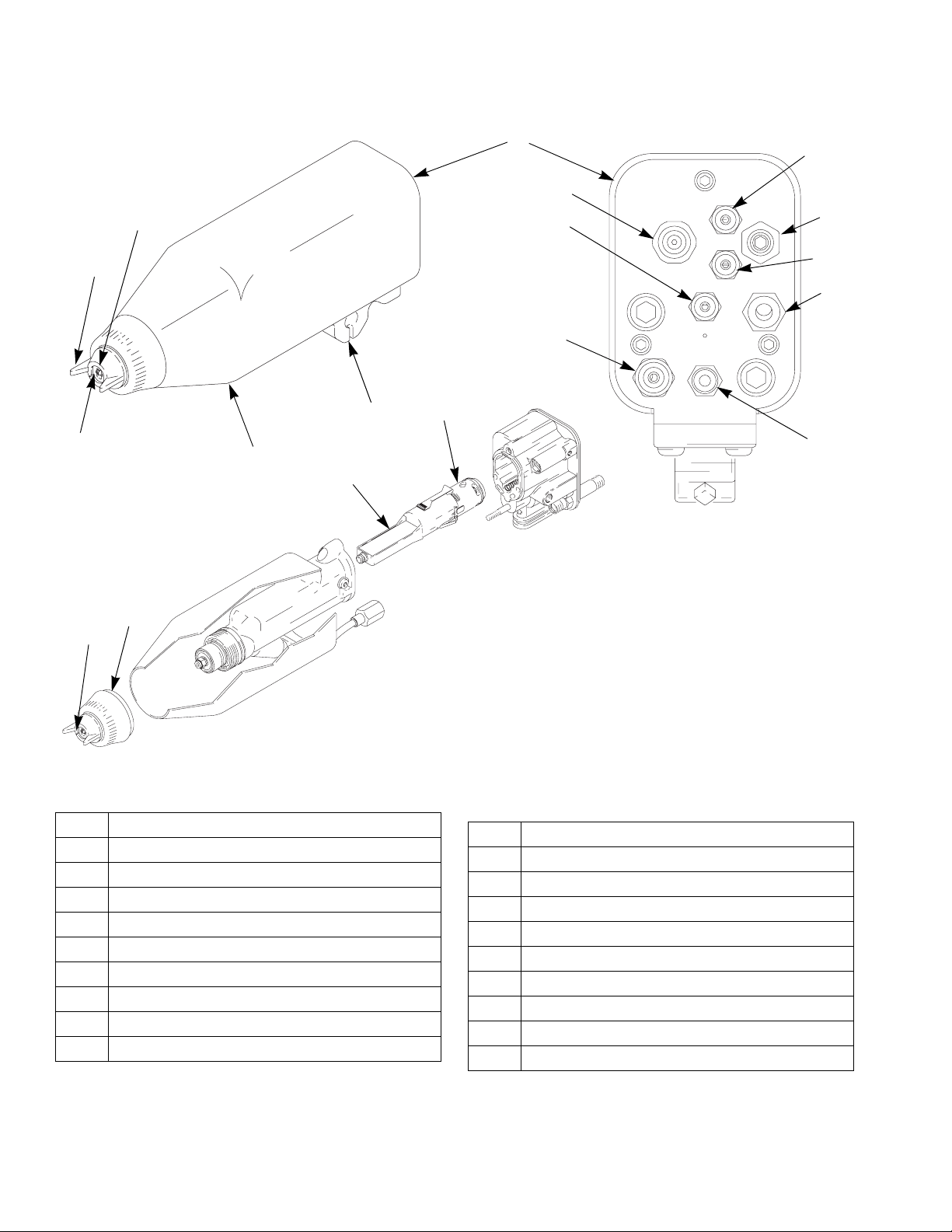

Fig. 1. Gun Overview

Key

A Air Cap

BSpray Tip

C Tip Guard

D Retaining Ring

E Shroud

F Mounting Bracket

G Manifold

H Turbine

J Power Supply

KElectrode

Manifold Markings

A1 not used

A2 Atomization Air Inlet Fitting

CYL Cylinder Air Inlet Fitting

EXH Shroud Exhaust Outlet Fitting

FO Fiber Optic Fitting

KV1 kV Switch 1 Air Inlet

KV2 kV Switch 2 Air Inlet

P1 Fluid Supply Inlet Fitting

P2 not used

TA Turbine Air Inlet Fitting

8 309298K

Page 9

Installation

Installation

Install the System

WARNING

Fire, Explosion, and Electric Shock Hazard

Installing and servicing this equipment

requires access to parts which may cause

electric shock or other serious injury if work

is not performed properly.

•Do not install or service this equipment

unless you are trained and qualified.

•Be sure your installation complies with

National, State and Local codes for the

installation of electrical apparatus in a Class

I, Div. I, Group D or a Group II,

Category 2G Hazardous Location.

•Comply with all applicable local, state, and

national fire, electrical, and other safety reg-

ulations.

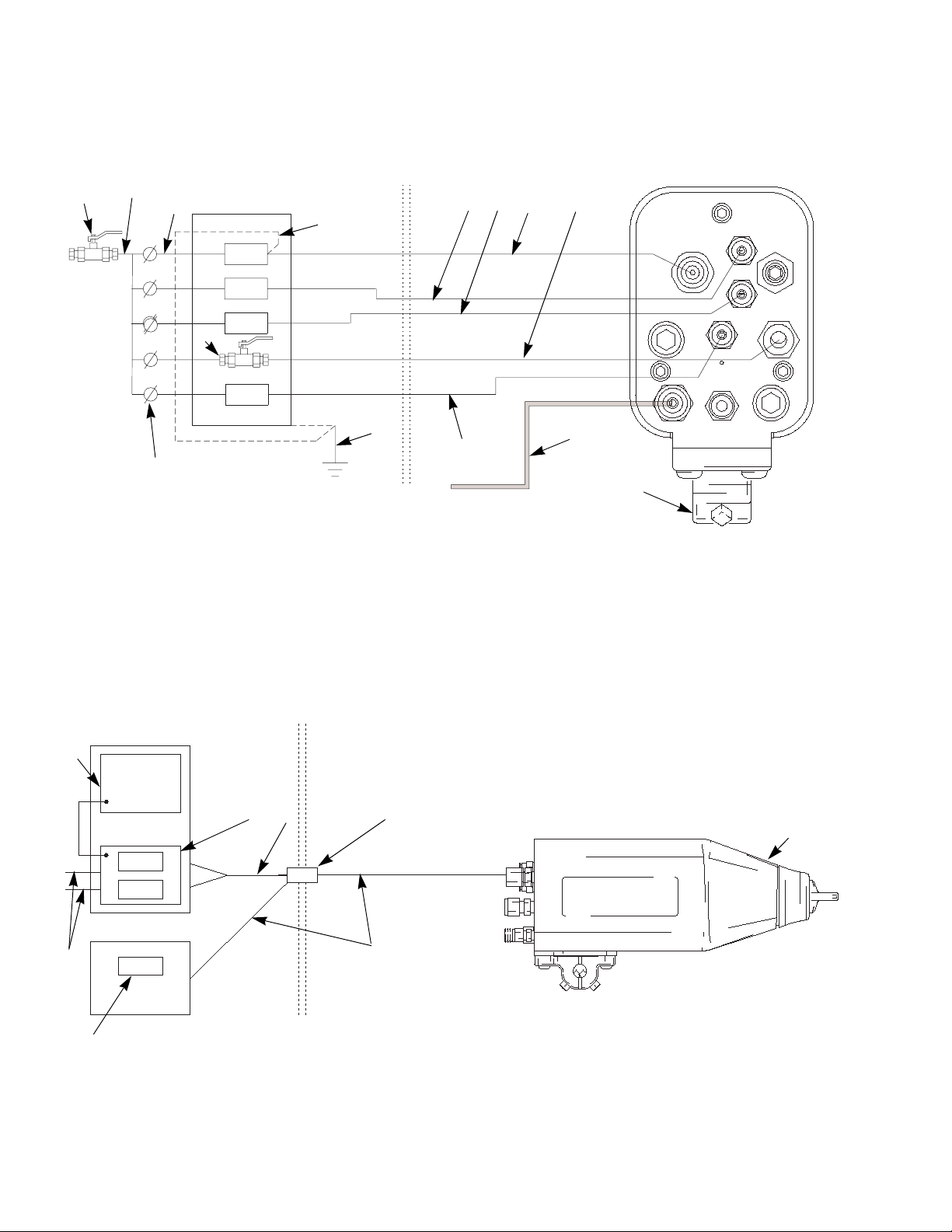

FIG. 2. shows a typical electrostatic air-assisted spray

system, and F

IG. 3. shows possible system options. It is

not an actual system design. For assistance in designing a system to suit your particular needs, contact your

Graco distributor.

Warning Signs

Mount warning signs in the spray area where they can

easily be seen and read by all operators. An English

Warning Sign is provided with the gun.

Ventilate the Spray Booth

Electrically interlock the gun turbine air supply with the

ventilators to prevent gun operation without ventilating

fans operating. Check and follow all National, State, and

Local codes regarding air exhaust velocity requirements.

High velocity air exhaust will decrease the operating efficiency of the electrostatic system. The minimum allowable air exhaust velocity is 60 ft/minute (19 linear

meters/minute).

Key to F

IG. 2. and FIG. 3.

A Air Hose Ground Wire

B Graco Grounded Turbine Air Hose (TA)

C Atomizing Air Hose, 3/8 in. (10 mm) OD (A2)

E Cylinder Air Hose, 5/32 in. (4 mm) OD (CYL)

F Fluid Hose, 1/4-18 npsm gun fluid inlet (P1)

G To Fluid Supply

H Auto PRO Xs Air-Assisted Spray Gun

J Mounting Bracket for 1/2 in. (13 mm) rod

K Solenoid Valve, requires quick exhaust port

L Bleed-Type Master Air Valve

M Air Pressure Regulator

N True Earth Ground

P 24 Volt Power Supply

Q 4-20 microampere Outputs

R Full Feature ES Display Module

S kV Only ES Display Module (battery operated)

T Fiber Optic Y Cable

U Bulkhead

V Fiber Optic Cable

W Main Air Line

kV Switch Air Hose, 5/32 in. (4 mm) OD (optional; plug KV1

X

fitting if not used)

kV Switch Air Hose, 5/32 in. (4 mm) OD (optional; plug KV2

Y

fitting if not used)

WARNING

Flammable or Toxic Vapor Hazard

Provide fresh air ventilation to avoid the buildup of

flammable or toxic vapors when spraying, flushing, or

cleaning the gun. Do not operate the gun unless ventilation fans are operating.

309298K 9

Page 10

Installation

L

W

See *

above

NOTE:

* The turbine air supply (TA) must be electrically interlocked with the spray booth ventilation fans to prevent

the power supply from operating without ventilating fans on.

X

BC

Y

A

TA

KV1

K

K

K

L

K

N

E

M

G

Non-Hazardous Area Hazardous Area

Fig. 2. Typical Installation

NOTE:

** A maximum of two splices with a total of 108 ft (33 m) of cable can be used. For the strongest

light signals, use a minimum number of bulkhead splices. See Accessories on page 52.

P

Non-Hazardous Area Hazardous Area

KV2

CYL

P1

A2

F

J

TI1741A

Manifold Back View

T

U**R

H

KV

mA

V**

Q

85.0 KV

TI1715A

S

Fig. 3. Optional Fiber Optic Connection

10 309298K

Page 11

Install the Air Line Accessories

WARNING

Component Rupture Hazard

To reduce the risk of serious injury due to

component rupture:

The pump pressure must be limited by the

pump air regulator. Do not rely on the gun

fluid regulator to limit the fluid pressure to

the gun.

Installation

WARNING

Skin Injection Hazard

Trapped air can cause the gun to spray

unexpectedly, which can result in serious

injury, including injecting fluid through the

skin. The solenoid valves (K) must have a quick

exhaust port so trapped air will be relieved between

the valve and gun when the solenoids are shut off.

The bleed-type master air valve (L) is required on the

pump air line so trapped air will be relieved between

the valve and the pump after the valves or regulator

are closed.

The fluid supply pump must be prevented from producing a fluid pressure greater than the 3000 psi (21

MPa, 210 bar) Maximum Working Fluid Pressure of

the gun. For example, the air supply pressure to a

30:1 ratio pump must not exceed 100 psi (0.7 MPa, 7

bar).

Be sure that all spray equipment and accessories

added to the spray system are properly rated to withstand the maximum working pressure of your system.

1. Install a bleed-type master air valve (L) on the main

air line (W) to shut off all air to the gun (H).

2. Install an air line filter/water separator on the gun air

line to ensure a dry, clean air supply to the gun. Dirt

and moisture can ruin the appearance of your finished workpiece and can cause the gun to malfunction.

3. Install a bleed-type air regulator (M) on each of the

air supply lines (B, C, E, X, Y) to control air pressure

to the gun.

4. Install a solenoid valve (K) on the cylinder air line (E)

to actuate the gun. The solenoid valve must have a

quick exhaust port.

5. Install a bleed-type master air valve (L) on each

pump air line to shut off all air to the pump (H).

Install the Fluid Line Accessories

1. Install a fluid filter and drain valve at the pump outlet. Filtering the fluid will help remove coarse particles and sediment that could clog the spray tip.

The gun includes an inline fluid filter (20) for additional filtration.

WARNING

Skin Injection Hazard

The fluid drain valve is required in your system to assist in relieving fluid pressure in

the displacement pump, hose and gun. Triggering the gun to relieve pressure may not be sufficient. Install a drain valve close to the pump's fluid

outlet. The drain valve reduces the risk of serious

injury, including fluid injection and splashing in the

eyes or on the skin.

2. Install a fluid regulator on the fluid line to control

fluid pressure to the gun.

309298K 11

Page 12

Installation

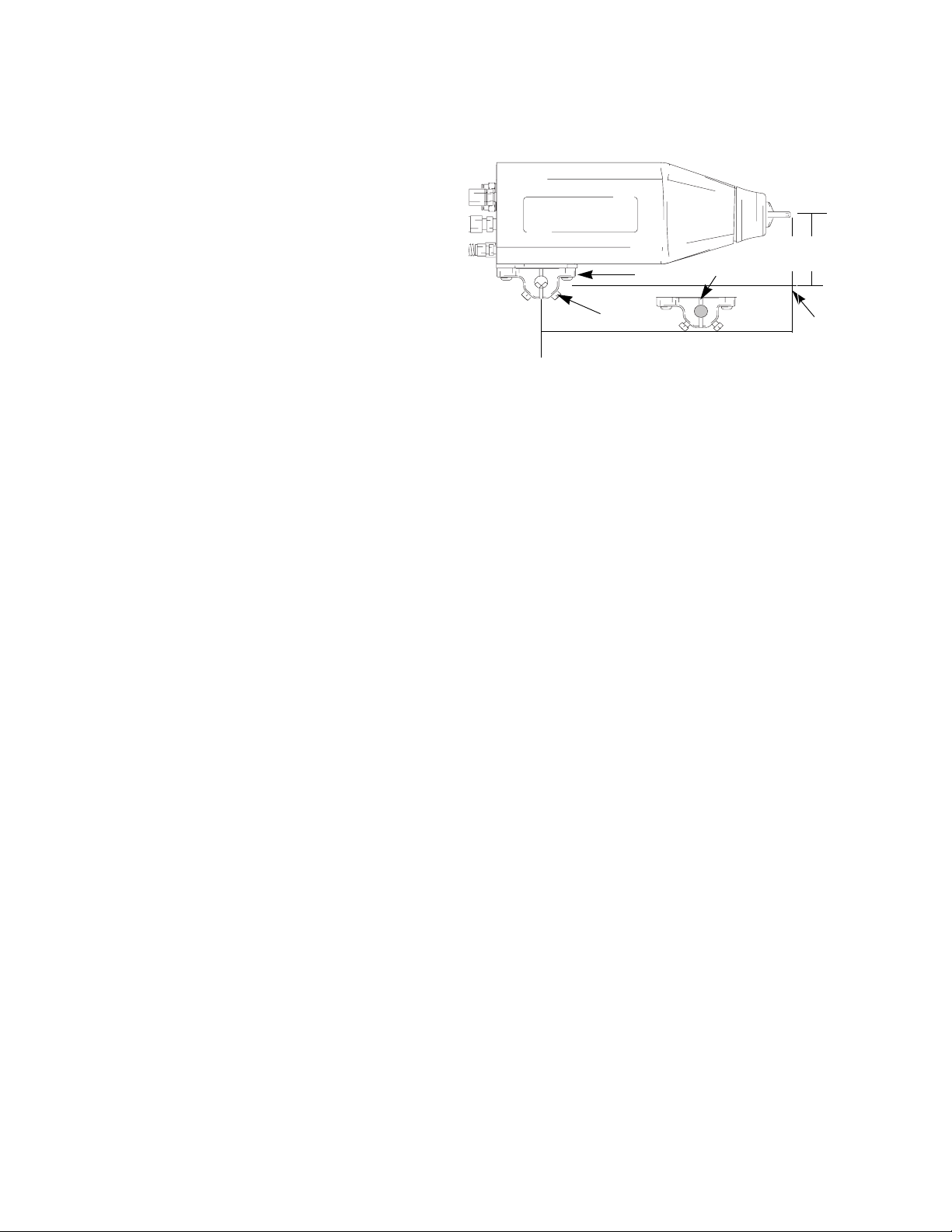

Install the Gun and Mounting Bracket

1. Loosen the mounting bracket’s two set screws (103)

and slide the bracket (102) onto a 1/2 in. (13 mm)

mounting rod. See F

2. Position the gun and tighten the two set screws.

For added positioning reliability, insert a 1/8 in. (3 mm)

locating pin into the slot (NN) in the bracket and through

a hole in the rod. See the detail in F

IG. 4..

IG. 4..

103

9.24 in

(234.7 mm)

Fig. 4. Mounting Bracket

102

NN

2.88 in

(73.2 mm)

To

TI1738A

Nozzle

Tip

12 309298K

Page 13

Installation

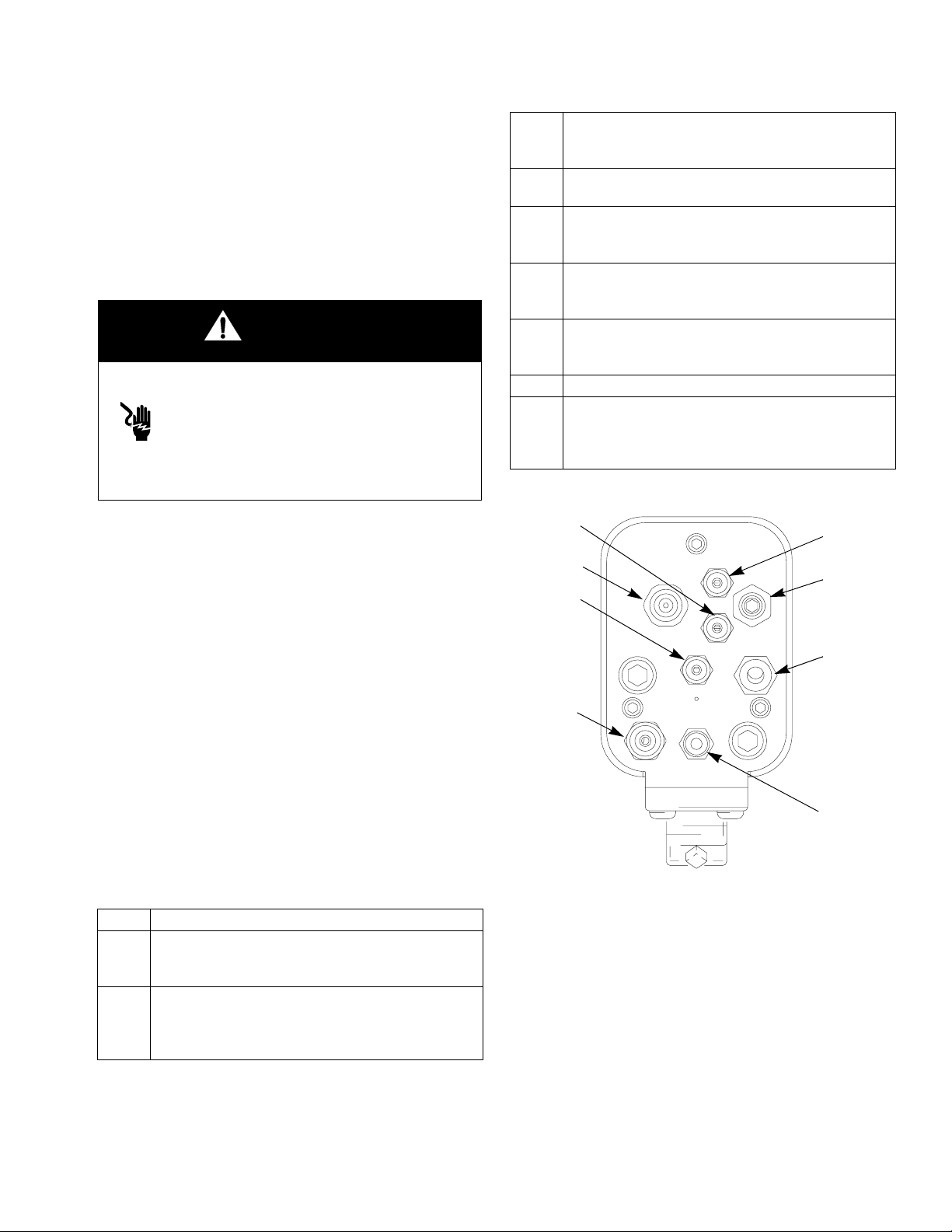

Connect the Air and Fluid Lines

FIG. 3. shows a schematic of air and fluid line connections, and F

IG. 5. shows the manifold connections. Con-

nect the air and fluid lines as instructed.

WARNING

Electric Shock Hazard

To reduce the risk of electric shock or other

serious injury, the air supply hose must be

electrically connected to a true earth

ground. Use only Graco Grounded Air

Supply Hose.

1. Connect the Graco Grounded Turbine Air Supply

Hose (B) to the gun's turbine air inlet (TA) and connect the hose ground wire (A) to a true earth ground

(N). The gun turbine air inlet fitting has a left-hand

thread to prevent connecting another type of air

hose to the turbine air inlet. See Accessories on

page 52 for further information about the hose.

EXH Shroud Exhaust Outlet Fitting

Connect a 1/4 in. (6 mm) OD x 4 ft (1.22 m) long tube to

this fitting.

FO Fiber Optic Fitting (Optional)

Connect the Graco Fiber Optic cable (see page 14).

KV1 kV Switch 1 Air Inlet Fitting

Connect a 5/32 in. (4 mm) OD tube between this fitting and

the solenoid.

KV2 kV Switch 2 Air Inlet Fitting

Connect a 5/32 in. (4 mm) OD tube between this fitting and

the solenoid.

P1 Fluid Supply Inlet Fitting

Connect a 1/4 npsm swivel fitting between this fitting and

the fluid supply.

P2 Not Used

TA Turbine Air Inlet Fitting

Connect the Graco Electrically Conductive Air Hose

between this fitting (left-hand thread) and the solenoid.

Connect the air hose ground wire to a true earth ground.

KV2

TA

CYL

KV1

FO

A2

2. Check the electrical grounding of the gun as

instructed on page 16.

3. Before connecting the fluid line (P1), blow it out with

air and flush it with solvent. Use solvent which is

compatible with the fluid to be sprayed.

Manifold Connections

A1 Not Used

A2 Atomization Air Inlet Fitting

Connect a 3/8 in. (10 mm) OD tube between this fitting and

the air supply.

CYL Cylinder Air Inlet Fitting

Connect a 5/32 in. (4 mm) OD tube between this fitting and

the solenoid. For quicker response, use the shortest hose

length possible.

P1

EXH

TI1739A

Fig. 5. Manifold Connections

309298K 13

Page 14

Installation

Optional Fiber Optic Cable Connection

An optional fiber optic fitting is shipped unassembled

with the gun. If an ES (kV) display module is used,

install the fitting in the FO port of the manifold. See F

3., page 10, for a schematic of the fiber optic connections.

1. Remove the plug (120) from the fiber optic port, and

install the fiber optic fitting (5, shipped loose with the

gun). See F

IG. 6..

5

120

IG.

2. Remove the nut (AA) from the fiber optic fitting (5)

and slide the nut over the end of the fiber optic cable

(BB). See F

IG. 7..

3. Push the cable (BB) into the fitting (5) until it bottoms out. Tighten the nut (AA) to secure the cable.

5

BB

AA

TI1581A

Fig. 7. Fiber Optic Cable

Most of the fiber optic light transmission loss occurs at

the bulkhead splices. For the strongest light signals, use

a minimum number of bulkhead splices. A maximum of

two splices, with a total of 108 ft (33 m) of cable, is recommended.

Fig. 6. Fiber Optic Fitting

TI1737A

4. See manual 308265 to install a Graco ES Display

Module.

14 309298K

Page 15

Installation

Grounding

WARNING

Fire, Explosion, and Electric Shock Hazard

When operating the electrostatic gun, any

ungrounded objects in the spray area (people, containers, tools, etc.) can become

electrically charged. Improper grounding

can result in static sparking, which can

cause a fire, explosion, or electric shock.

Follow the grounding instructions below.

The following are minimum grounding requirements for

a basic electrostatic system. Your system may include

other equipment or objects which must be grounded.

Check your local electrical code for detailed grounding

instructions. Your system must be connected to a true

earth ground.

• Pump: ground the pump by connecting a ground

wire and clamp as described in your separate pump

instruction manual.

• Electrostatic Air-Assisted Spray Gun: ground the

gun by connecting the Graco Grounded Air Hose to

the turbine air inlet and connecting the air hose

ground wire to a true earth ground. See Check

Electrical Grounding, page 16.

• Air compressors and hydraulic power supplies:

ground the equipment according to the manufacturer's recommendations.

• All air and fluid lines must be properly grounded.

• All electrical cables must be properly grounded.

• All persons entering the spray area: shoes must

have conductive soles, such as leather, or personal

grounding straps must be worn. Do not wear shoes

with non-conductive soles such as rubber or plastic.

• Object being sprayed: keep the workpiece hangers

clean and grounded at all times. Resistance must

not exceed 1 megohm.

• The floor of the spray area: must be electrically con-

ductive and grounded. Do not cover the floor with

cardboard or any non-conductive material which

would interrupt grounding continuity.

• Flammable liquids in the spray area: must be kept in

approved, grounded containers. Do not use plastic

containers. Do not store more than the quantity

needed for one shift.

• All electrically conductive objects or devices in the

spray area: including fluid containers and wash

cans, must be properly grounded.

309298K 15

Page 16

Installation

Check Electrical Grounding

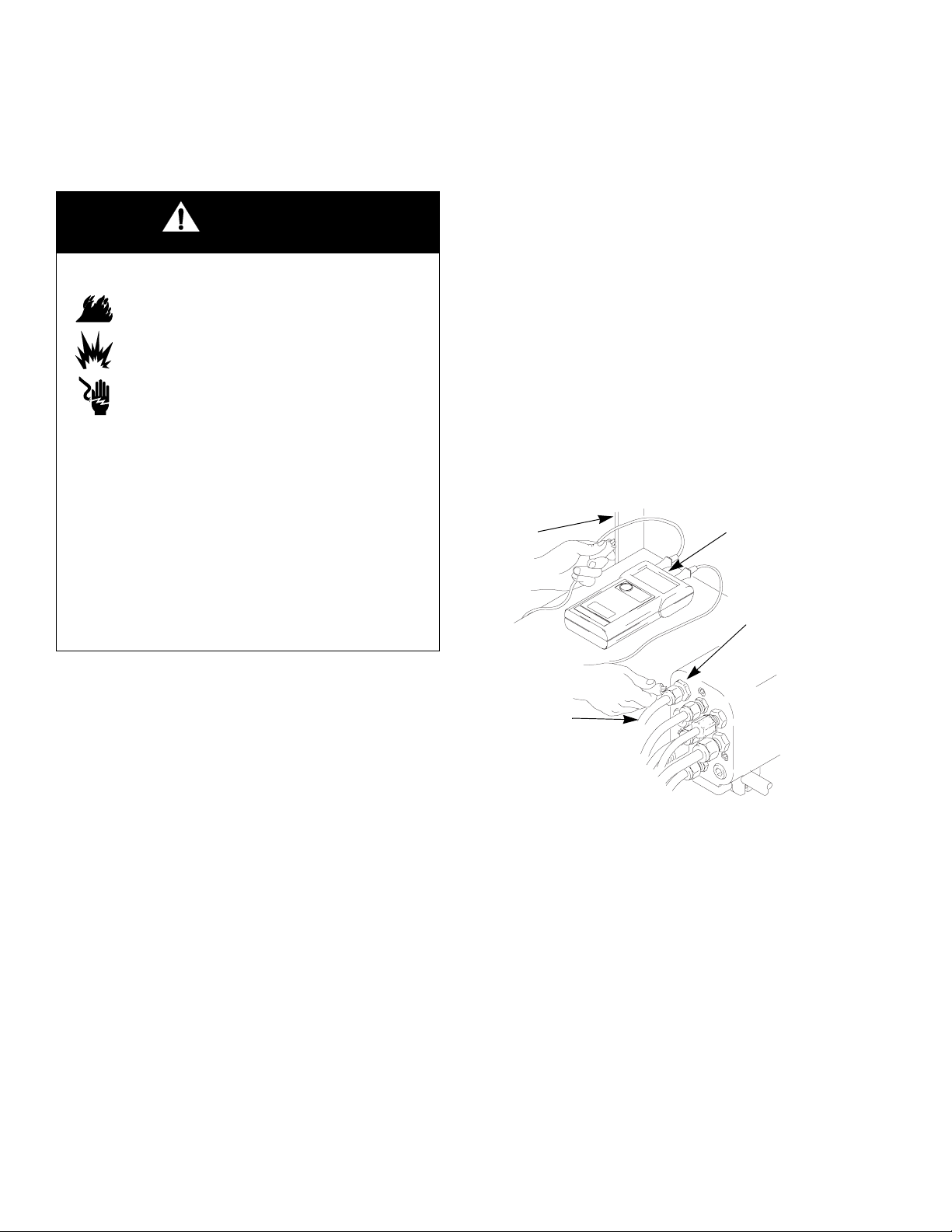

WARNING

Fire, Explosion, and Electric Shock Hazard

Megohmmeter Part No. 241079 (AA-see

F

IG. 8.) is not approved for use in a hazard-

ous area. To reduce the risk of sparking, do

not use the megohmmeter to check electrical grounding unless:

•The gun has been removed from the hazardous area;

•Or all spraying devices in the hazardous

area are turned off, ventilation fans in the

hazardous area are operating, and there

are no flammable vapors in the area (such

as open solvent containers or fumes from

spraying).

4. Measure the resistance between the turbine air inlet

fitting (TA) and a true earth ground (N).

a. If using a black or grey turbine air hose, use a

megohmmeter to measure the resistance. Use

an applied voltage of 500 minimum to 1000

volts maximum. The resistance should not

exceed 1 megohm.

b. If using a red turbine air hose, use an ohmmeter

to measure the resistance. The resistance

should not exceed 100 ohms.

3. If the resistance is greater than the maximum reading specified above for your hose, check the tightness of the ground connections and be sure the

turbine air hose ground wire is connected to a true

earth ground. If the resistance is still too high,

replace the turbine air hose.

N

AA

Failure to follow this warning could cause

fire, explosion, and electric shock and result

in serious injury and property damage.

1. Have a qualified electrician check the electrical

grounding continuity of the spray gun and turbine air

hose.

2. Make sure the turbine air hose (B) is connected and

the hose ground wire is connected to a true earth

ground.

3. Turn off the air and fluid supply to the gun.

TA

B

TI1735A

Fig. 8. Check Gun Grounding

16 309298K

Page 17

Installation

Check Fluid Resistivity

WARNING

Fire, Explosion, and Electric Shock Hazard

Check the fluid resistivity in a non-hazardous area only. Resistance Meter 722886

and Probe 722860 are not approved for use

in a hazardous area.

Failure to follow this warning could cause

fire, explosion, or electric shock and result

in serious injury and property damage.

Graco Part No. 722886 Resistance Meter and 722860

Probe are available as accessories to check that the

resistivity of the fluid being sprayed meets the requirements of an electrostatic air spray system.

Follow the instructions included with the meter and

probe. Readings of 25 megohms-cm and above provide

the best electrostatic results.

Check Fluid Viscosity

To check fluid viscosity you will need:

• a viscosity cup

• a stopwatch.

1. Completely submerge the viscosity cup in the fluid.

Lift the cup out quickly, starting the stopwatch as

soon as the cup is completely removed.

2. Watch the stream of fluid coming from the bottom of

the cup. As soon as there is a break in the stream,

shut off the stopwatch.

3. Record the fluid type, elapsed time, and size of the

viscosity cup.

4. If the viscosity is too high or too low, contact the

material supplier. Adjust as necessary.

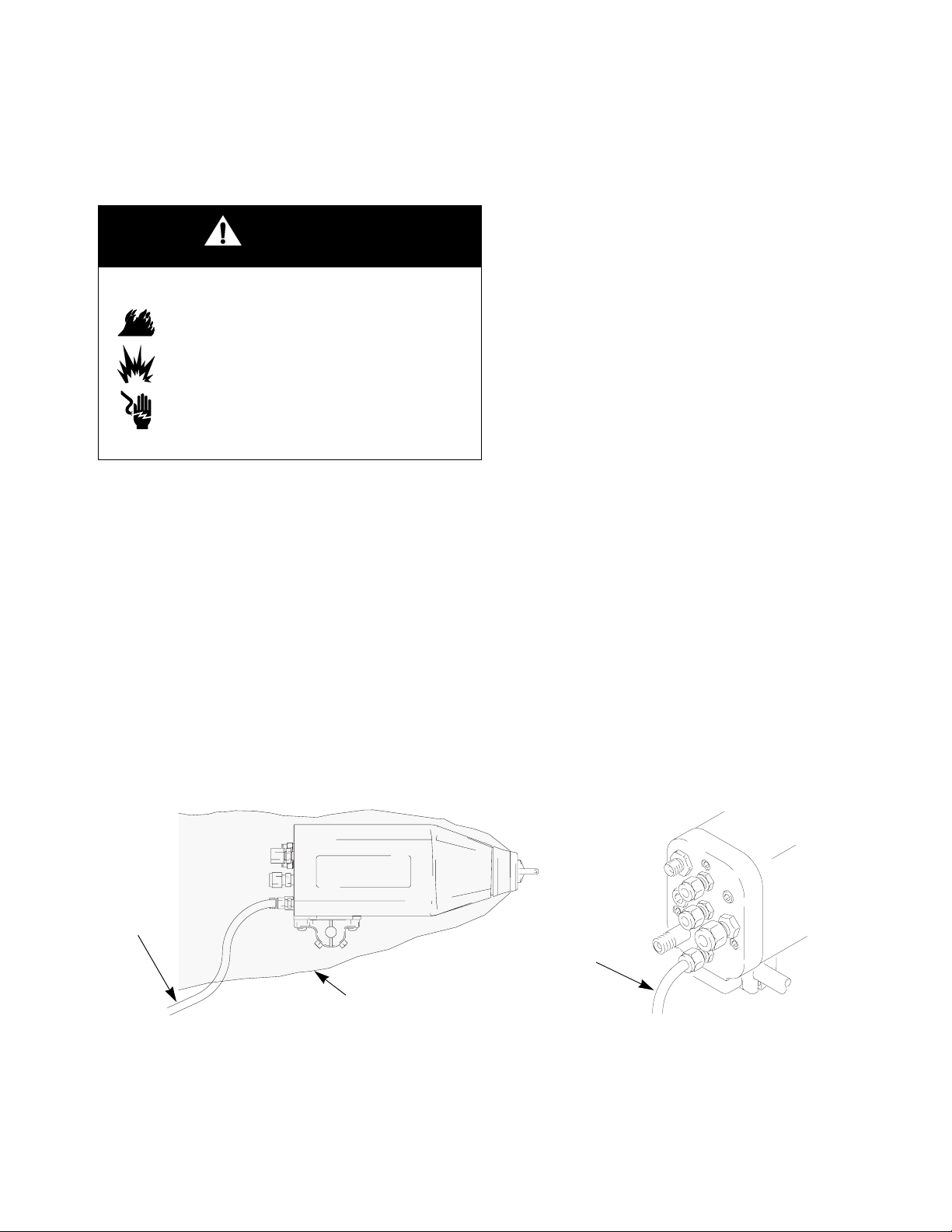

Install the Fabric Cover

1. Install a fabric cover (XX) over the front of the gun

and slide it back to cover the exposed tubing and

hoses at the back of the manifold. See F

IG. 9..

YY

Fig. 9. Fabric Cover

XX

2. Route the exhaust tube (YY) outside the cover. This

enables you to monitor the exhaust tube for the

presence of any paint or solvent. See Check for

Fluid Leakage on page 28. Strap down the exhaust

tube to prevent it from moving around.

YY

TI1736A

TI1716A

309298K 17

Page 18

Operation

Operation

Pressure Relief Procedure

WARNING

Skin Injection Hazard

The system pressure must be manually

relieved to prevent the system from starting

or spraying accidentally. Fluid under high

pressure can be injected through the skin and cause

serious injury. To reduce the risk of an injury from

fluid injection, splashing fluid, or electric shock, follow

the Pressure Relief Procedure whenever you:

• are instructed to relieve the pressure

• stop spraying

• check or service any of the system equipment

• or install or clean the spray tip.

1. Turn off all the air to the spray gun except the cylinder air, which triggers the gun.

2. Turn off the fluid supply to the gun.

3. Trigger the gun into a grounded metal waste container to relieve the fluid pressure.

7. If you suspect that the spray tip or hose is still

clogged or that pressure is not fully relieved after following the steps above, very slowly loosen the hose

end coupling and relieve pressure gradually, then

loosen completely. Now clear the tip or hose

obstruction.

Operating Checklist

Check the following list daily, before operating the system, to help ensure you of safe, efficient operation.

All operators are properly trained to safely

operate an automatic electrostatic air-assisted

spray system as instructed in this manual.

All operators are trained in the Pressure

Relief Procedure at left.

The warning sign provided with the gun is

mounted in the spray area where it can be

easily seen and read by all operators.

The system, the operator, and all persons

entering the spray area are properly

grounded. See Grounding on page 15.

The condition of the gun’s electrical components has been checked as instructed in Elec-

trical Tests on page 29.

Ventilation fans are operating properly.

Workpiece hangers are clean and grounded.

4. Open the pump drain valve and all other drain

valves in the system, having a waste container

ready to catch the drainage. Triggering the gun to

relieve pressure may not be sufficient. Leave the

drain valve open until you are ready to spray again

5. Relieve fluid pressure in the fluid supply equipment

as instructed in its instruction manual.

6. Close the bleed-type master air valve on the main

air supply line to shut off the air. Leave the valve

closed until you are ready to spray again.

18 309298K

All debris, including flammable fluids and rags,

is removed from the spray area.

All flammable fluids in the spray booth are in

approved, grounded containers.

All conductive objects in the spray area are

electrically grounded. The floor of the spray

area is electrically conductive and grounded.

The manifold exhaust tubes have been

checked for the presence of any fluid. See

Check for Fluid Leakage on page 28.

Page 19

Operation

Select a Spray Tip

The fluid output and pattern width depend on the size of

the spray tip, the fluid viscosity, and the fluid pressure.

Use the Spray Tip Selection Chart, page 51, as a

guide for selecting the appropriate spray tip for your

application.

Install the Spray Tip

WARNING

Skin Injection Hazard

To reduce the risk of a fluid injection injury,

always follow the Pressure Relief Proce-

dure on page 18, before removing or

installing the spray tip, air cap, or tip guard.

3. Install the spray tip and air cap, tip guard (3), shroud

(2), and retaining ring (1) onto the gun. Be sure the

electrode (40a) is in place. Tighten the retaining ring

firmly.

WARNING

Fire, Explosion, and Electric Shock Hazard

To reduce the risk of fire, explosion, or electric shock, never operate the gun with a

damaged electrode.

2

1. Relieve the pressure.

2. Place the spray tip (4) in the air cap (40), aligning

the tab on the tip with the groove in the air cap. Be

careful not to damage the electrode (40a).

40

01995

40a

4

Fig. 10. Install Spray Tip

40

3

1a

1

Fig. 11. Install Air Cap Assembly

TI1717A

309298K 19

Page 20

Operation

Set the Atomization Fluid Pressure

Atomization fluid pressure will vary based on the viscosity of the fluid, flow rate desired, and other system characteristics.

1. Turn off the turbine air (TA) and atomization air (A2).

2. Start the pump. Set the fluid regulator to 400 psi (2.8

MPa, 28 bar).

3. With the turbine air (TA) and atomization air (A2)

turned off, spray a test pattern, holding the gun 12

in. (305 mm) from the surface. Examine the particle

size. Do not be concerned about the presence of

tails; they will be removed in step 6.

4. Increase the fluid pressure in small increments.

Spray another pattern and compare the particle

size. Smaller particle size indicates improved atomization.

6. Turn on the atomization air (A2) and adjust the air

pressure until the tails disappear.

See Spray Pattern Troubleshooting on page 32 to cor-

rect spray pattern problems.

KV2

TA

CYL

KV1

A2

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, never exceed

the maximum working pressure of the lowest rated system component. Maximum

working fluid pressure of this equipment is

3000 psi (21 MPa, 210 bar).

5. Continue to increase the fluid pressure and spray

test patterns. Do not exceed 3000 psi (21 MPa, 210

bar) fluid pressure. When the particle size remains

constant, the fluid is being atomized at the lowest

possible fluid pressure.

For improved atomization at lower fluid flow rates,

change to a smaller tip orifice size.

Fig. 12. Manifold Air Connections

No Air Too Little

Air

Fig. 13. Eliminating Tails

TI1739A

Correct

Amount of Air

20 309298K

Page 21

Adjust the Electrostatics

1. Shut off the fluid supply.

1. Trigger the gun, then turn on the turbine air (TA).

See F

IG. 12..

2. Refer to Table 2 to set the proper pressure at the

turbine air hose inlet when air is flowing. Do not

exceed these pressures as there is no added benefit and turbine life could be reduced.

Operation

Table 2: Dynamic Turbine Air Pressures

Turbine Air

Hose Length

ft (m)

15 (4.6) 54 (3.8, 0.38)

25 (7.6) 55 (3.85, 0.38)

36 (11) 56 (3.9, 0.39)

50 (15.3) 57 (4.0, 0.40)

75 (22.9) 59 (4.1, 0.41)

100 (30.5) 61 (4.3, 0.43)

3. Check the voltage output of the gun using a high

voltage probe and meter or by reading the ES (kV)

Display Module.

The gun’s normal high voltage reading is 60-70 kV. If a

ball end high voltage measurement probe is used, the

gun voltage will rise to about 85 kV. This will happen

with all resistive electrostatic guns.

Air pressure at turbine air hose

inlet for full voltage

psi (bar, MPa)

See Electrical Troubleshooting on page 34 to correct

voltage problems.

309298K 21

Page 22

Operation

Spraying

WARNING

Electric Shock Hazard

To reduce the risk of electric shock, do not

touch the gun electrode or come within 4 in.

(10 cm) of the nozzle during gun operation.

1. Apply a minimum of 50 psi (3.5 bar, 0.35 MPa) air

pressure to the cylinder air fitting (CYL) to activate

the on/off sequence of atomization air (A2) and fluid

(P1). See F

2. Turn the gun functions off and on by using the air

solenoid valves on the cylinder (CYL) and turbine

(TA) air supply lines.

3. To change to a lower voltage setting, activate the

solenoids controlling the KV1 and KV2 ports. See

Changing the kV Setting on page 7.

IG. 12..

Triggering the Fluid Alone

1. Shut off and relieve the air pressure to the atomization (A2) air line, using the bleed-type air shutoff

valve.

2. Apply 50 psi (3.5 bar, 0.35 MPa) air pressure to the

cylinder air fitting (CYL) to trigger the fluid.

Shutdown

WARNING

Skin Injection Hazard

To reduce the risk of a fluid injection injury,

always follow the Pressure Relief Proce-

dure on page 18 when you stop spraying

and whenever you are instructed to relieve

the pressure.

WARNING

Fire and Explosion Hazard

If any fluid leakage from the gun is

detected, stop spraying immediately. Fluid

leakage into the gun shroud could cause

fire or explosion and result in serious injury

and property damage. See Check for Fluid

Leakage on page 28.

1. Relieve the pressure.

2. Flush and clean the equipment. See Maintenance

on page 23.

22 309298K

Page 23

Maintenance

Daily Care and Cleaning

Maintenance

CAUTION

• Clean all parts with a non-conductive, compatible

solvent. Conductive solvents can cause the gun to

malfunction.

• Do not use methylene chloride as a flushing or

cleaning solvent with this gun as it will damage

nylon components.

• Fluid in the air passages could cause the gun to

malfunction and could draw current and reduce the

electrostatic effect. Fluid in the power supply cavity

can reduce the alternator life. Whenever possible,

point the gun down when cleaning it. Do not use

any cleaning method which could allow fluid into

the gun air passages.

Do not point the gun up while cleaning it. Do not wipe the gun with a cloth that is heavily

Do not immerse the gun in fluid.

TI1742A

saturated; wring out the excess fluid.

TI1734A

309298K 23

02027A

Page 24

Maintenance

Daily Care and Cleaning, continued

WARNING

Skin Injection Hazard

To reduce the risk of a fluid injection injury,

always follow the Pressure Relief Proce-

dure on page 18 when you stop spraying

and whenever you are instructed to relieve

the pressure.

• Clean the fluid and air line filters daily.

• Clean the outside of the gun daily with a soft cloth

dampened in a compatible solvent.

• Clean the air cap, spray tip, and tip guard daily, min-

imum. Some applications require more frequent

cleaning. Replace the parts if they are damaged.

See Clean the Spray Gun, page 26.

• Check the electrode and replace if broken or damaged. See Electrode Replacement on page 39.

• Check for fluid leakage from the gun and fluid

hoses. See Check for Fluid Leakage on page 28.

Tighten fittings or replace equipment as needed.

• Check all work hangers for fluid buildup; clean if

necessary.

• Flush the gun before changing colors and whenever

you are done operating the gun.

WARNING

Fire, Explosion, and Electric Shock Hazard

To reduce the risk of fire, explosion, or electric shock, turn off the turbine air (TA) before

flushing the gun or any part of the system.

24 309298K

Page 25

Maintenance

Flush the Spray Gun

WARNING

Skin Injection Hazard

To reduce the risk of a fluid injection injury,

always follow the Pressure Relief Proce-

dure on page 18 when you stop spraying

and whenever you are instructed to relieve

the pressure.

1. Relieve the pressure.

WARNING

Fire, Explosion, and Electric Shock Hazard

To reduce the risk of fire, explosion, or electric shock, turn off the turbine air (TA) before

flushing the gun or any part of the system.

3. Remove the retaining ring (1), tip guard (3), air cap

(40), spray tip (4), and gun shroud (2). See F

Clean these parts and set them aside.

4. Turn on the solvent supply. Use the lowest possible

fluid pressure when flushing.

5. Turn on the cylinder air (CYL) to trigger the gun.

6. Flush the gun, spraying into a grounded metal container until clean solvent comes from the gun.

7. Turn off the solvent supply.

8. Relieve the pressure.

9. Install the spray tip (4) and air cap (40), tip guard

(3), shroud (2), and retaining ring (1) onto the gun.

Tighten the retaining ring firmly.

2

4a

4

40

3

1a

1

IG. 14..

TI1723A

2. Be sure the turbine air (TA) is turned off.

Fig. 14. Remove Spray Tip Before Flushing

309298K 25

Page 26

Maintenance

Clean the Spray Gun

Equipment Needed

• soft bristle brush

• compatible solvent

Procedure

WARNING

Skin Injection Hazard

To reduce the risk of a fluid injection injury,

always follow the Pressure Relief Proce-

dure on page 18 when you stop spraying

and whenever you are instructed to relieve

the pressure.

1. Relieve the pressure.

2. Be sure the turbine air (TA) is turned off.

3. Remove the retaining ring (1), tip guard (3), air cap

(40), spray tip (4), and gun shroud (2). See page 19.

4. Dip the end of a soft bristle brush into compatible

solvent. clean the front of the gun with the brush.

Avoid getting any solvent into the air passages.

Whenever possible, point the gun down when cleaning it. See F

If it appears that there is paint inside the air passages,

remove the gun from the line for servicing.

IG. 15..

TI1719A

02007

Fig. 15. Clean Front of Gun

5. Dampen a soft cloth with solvent and wring out the

excess. Wipe the exterior of the gun and shroud

clean. See F

IG. 16..

TI1720A

Fig. 16. Clean Gun Body

6. Remove the bottom fluid tube fitting (P) and fluid filter (20). See F

IG. 17.. Clean the filter in compatible

solvent.

7. Reinstall the filter (20) and fitting (P). Do not overtighten the fitting, and make sure the top fitting (Q)

remains tight.

26 309298K

Page 27

Maintenance

9. Wipe off the parts with a dry cloth. Be careful not to

damage the electrode.

WARNING

Fire, Explosion, and Electric Shock Hazard

TI1725A

Q

Fig. 17. Clean the Inline Fluid Filter

8. Clean the retaining ring (1), tip guard (3), air cap

(40), and spray tip (4) with a soft brush daily, minimum. Replace any damaged parts. Be careful not to

damage the electrode (40a).

20

P

CAUTION

Do not use metal tools to clean the

air cap or spray tip holes as this

could scratch them, and make sure

the electrode is not damaged.

Scratches in the air cap or spray tip

or a damaged electrode can distort

the spray pattern.

To reduce the risk of fire, explosion, or electric shock, never operate the gun with a

damaged electrode.

10. Check the electrode (40a). Replace if damaged.

11. Install the spray tip, page 19.

12. Install the spray tip and air cap, tip guard, shroud,

and retaining ring, page 19. Be sure the electrode

(40a) is in place.

13. Test gun resistance, page 29.

309298K 27

Page 28

Maintenance

Check for Fluid Leakage

WARNING

WARNING

Fire and Explosion Hazard

If any fluid leakage from the gun is

detected, stop spraying immediately. Fluid

leakage into the gun shroud could cause

fire or explosion and result in serious injury

and property damage.

Skin Injection Hazard

To reduce the risk of a fluid injection injury,

always follow the Pressure Relief Proce-

dure on page 18 when you stop spraying

and whenever you are instructed to relieve

the pressure.

During operation, periodically check the manifold

exhaust tube (YY) and both ends of the gun shroud (ZZ)

for the presence of fluid. See F

areas indicates leakage into the shroud, which could be

caused by leaks at the fluid tube connections or fluid

packing leakage.

If fluid is seen in these areas, stop spraying immediately.

Relieve the pressure, then remove the gun for repair.

IG. 18.. Fluid in these

YY

ZZ

Fig. 18. Check for Fluid Leakage

ZZ

YY

TI1736A

TI1716A

28 309298K

Page 29

Electrical Tests

Electrical Tests

Electrical components inside the gun affect performance

and safety. The following procedures test the condition

of the power supply (12) and barrel (6), and electrical

continuity between components.

CAUTION

The barrel resistor cartridge is part of the barrel and

is not replaceable. To avoid destroying the gun barrel,

do not attempt to remove the barrel resistor.

Use megohmmeter Part No. 241079 (AA) and an

applied voltage of 500 V. Connect the leads as shown.

WARNING

Fire, Explosion, and Electric Shock Hazard

Megohmmeter Part No. 241079 (AA-see

F

IG. 19.) is not approved for use in a haz-

ardous area. To reduce the risk of sparking,

do not use the megohmmeter to check electrical grounding unless:

•The gun has been removed from the hazardous area;

Test Gun Resistance

1. Flush and dry the fluid passage.

2. Measure resistance between the electrode needle

tip (40a) and the turbine air inlet fitting (TA); it should

be 156-180 megohms. If outside this range, relieve

pressure and remove the air cap (page 37). Inspect

the electrode (40a) and the barrel conductive ring

(6a) for damage and proper position, to ensure that

the electrode makes contact with the conductive

ring. Reinstall the air cap and repeat the measurement. If it is still outside this range, remove the gun

for service.

TA

AA

40a

TA

TI1739A

•Or all spraying devices in the hazardous

area are turned off, ventilation fans in the

hazardous area are operating, and there

are no flammable vapors in the area (such

as open solvent containers or fumes from

spraying).

Failure to follow this warning could cause

fire, explosion, and electric shock and result

in serious injury and property damage.

309298K 29

Fig. 19. Test Gun Resistance

TI1733B

Page 30

Electrical Tests

Test Power Supply Resistance

1. Remove the power supply (12), page 46.

2. Remove the turbine alternator (13) from the power

supply, page 47.

3. Measure resistance from the power supply's ground

strips (EE) to the spring (12b). See F

4. The resistance should be 135-150 megohms. If outside this range, replace the power supply. If in

range, proceed to the next test.

5. If you still have problems, refer to Electrical Trou-

bleshooting on page 34 for other possible causes

of poor performance, or contact your Graco distributor.

IG. 20..

6. Be sure the spring (12b) is in place before reinstalling the power supply.

12b

Fig. 20. Test Power Supply Resistance

EE

ti1599a

30 309298K

Page 31

Test Barrel Resistance

1. Insert a conductive rod (B) into the gun barrel

(removed for the power supply test) and against the

metal contact (C) in the front of the barrel.

2. Measure the resistance between the conductive rod

(B) and the barrel contact ring (6a). See F

The resistance should be 19-29 megohms. If the

resistance is incorrect, make sure the metal contact

(C) in the barrel and the barrel contact ring (6a) are

clean and undamaged.

3. If the resistance is still outside the range, remove

the barrel contact ring (6a) and measure the resistance between the conductive rod (B) and the wire

lead at the bottom of the contact ring groove.

IG. 21..

6a

Electrical Tests

C

B

ti1515b

4. If the resistance is in range, replace the contact ring

(6a) with a new one. Press the contact ring firmly

into the groove on the front of the barrel.

WARNING

Fire, Explosion, and Electric Shock Hazard

The barrel contact ring (6a) is a conductive

contact ring, not a sealing o-ring. To reduce

the risk of sparking or electric shock, do not

remove the barrel contact ring (6a) except

to replace it and never operate the gun without the contact ring in place. Do not replace

the contact ring with anything but a genuine

Graco part.

5. If the resistance is still outside the range, replace

the barrel.

Fig. 21. Test Barrel Resistance

309298K 31

Page 32

Troubleshooting

Troubleshooting

WARNING

Electric Shock Hazard

Installing and servicing this equipment

requires access to parts which may cause

an electric shock or other serious injury if

the work is not performed properly. Do not install or

repair this equipment unless you are trained and

qualified.

Skin Injection Hazard

To reduce the risk of a fluid injection injury,

always follow the Pressure Relief Proce-

dure on page 18 before doing any maintenance or service on this gun or system.

Check all possible remedies in the Troubleshooting

Chart before disassembling the gun.

WARNING

Spray Pattern Troubleshooting

Some spray pattern problems are caused by the improper balance between air and fluid.

Problem Cause Solution

Fluttering or spitting spray. No fluid. Refill supply.

Air in fluid supply. Check fluid source. Refill.

Irregular pattern. Fluid buildup; partially plugged tip. Clean. See page 26.

Worn/damaged tip or air cap holes. Clean or replace.

Pattern pushed to one side; air cap

gets dirty.

Tails in pattern. Atomization air pressure too low. Increase atomization air pressure.

Fluid buildup on air cap/tip guard. Atomization air pressure too high. Decrease.

Air cap holes plugged. Clean. See page 26.

Fluid pressure too low. Increase.

Fluid pressure too low. Increase.

32 309298K

Page 33

Troubleshooting

Gun Operation Troubleshooting

Problem Cause Solution

Excessive spray fog. Atomization air pressure too high. Decrease air pressure as low as pos-

sible.

Fluid too thin. Increase viscosity.

“Orange Peel” finish. Atomization air pressure too low. Increase air pressure; use lowest

pressure necessary.

Spray tip (4) too large. Use smaller tip; see page 51.

Poorly mixed or filtered fluid. Remix or refilter fluid.

Fluid too thick. Reduce viscosity.

Fluid leaks from the fluid packing

area

Air leaks from the air cap Worn piston stem o-rings (34e, 34f). Replace; see page 42.

Fluid leakage from the front of the

gun

Gun does not spray Low fluid supply. Add fluid if necessary.

Paint buildup on air cap Atomization air pressure too high. Reduce.

Air leaks from manifold Manifold is not tight. Tighten manifold screws (106).

Fluid doesn’t shut off properly. Seat housing (5) too tight. Replace; see page 37.

Worn fluid needle packings or shaft. Replace fluid needle assembly (8);

see page 41.

Worn or damaged fluid needle (8). Replace; see page 41

Worn fluid seat housing (5). Replace; see page 37.

Loose spray tip (4). Tighten retaining ring (1); see page

37.

Damaged tip seal (4a). Replace; see page 37.

Dirty or clogged spray tip (4). Clean; see page 37.

Damaged spray tip (4). Replace; see page 37.

Damaged fluid needle (8). Replace; see page 41.

Piston (34) not actuating. Check cylinder air. Check piston

u-cup (34d); see page 48.

Actuator arm (29) is out of position. Check actuator arm and nuts. See

page 43.

Dirty air cap. Clean; see page 37.

Worn or missing o-rings. Replace o-rings. See page 43.

Fluid buildup on fluid needle (8). Replace needle; see page 41.

Piston sticking. Clean or replace o-rings. See page

43.

309298K 33

Page 34

Troubleshooting

Electrical Troubleshooting

Problem Cause Solution

Poor wrap. Turbine air is not turned on. Turn on.

Booth exhaust velocity is too high. Reduce velocity to within code limits.

Atomization air pressure too high. Decrease.

Fluid pressure too high. Decrease.

Incorrect distance from gun to part. Should be 8-12 in. (200-300 mm).

Poorly grounded parts. Resistance must be 1 megohm or

less. Clean workpiece hangers.

Faulty gun resistance. See Test Gun Resistance on page

29.

Low fluid resistivity. Check fluid resistivity, page 17.

Fluid leaks from the packing (8d) and

causes a short.

Faulty turbine alternator. Be sure the plug is in place on the

The KV switch is stuck on low. Check the switch actuation; replace if

No power. Replace power supply. See page 46.

No voltage or low voltage reading on

the gun ES display module

Operator gets mild shock. Operator not grounded or is near

Operator gets shock from workpiece. Workpiece not grounded. Resistance must be 1 megohm or

Damaged fiber optic cable or connection.

Turbine air is not turned on. Turn on.

Poor wrap. See causes and solutions under Poor

ungrounded object.

Gun not grounded. See Check Electrical Grounding on

Clean the packing rod cavity.

Replace the packing rod. See page

41.

back of the turbine alternator housing. Remove and test the turbine

alternator. See page 47.

needed.

Check; replace damaged parts.

Wrap, above.

See Grounding on page 15.

page 16 and Test Gun Resistance

on page 29.

less. Clean workpiece hangers.

34 309298K

Page 35

Repair

Prepare the Gun for Service

Repair

• Check all possible remedies in Troubleshooting

before disassembling the gun.

WARNING

Electric Shock Hazard

Installing and repairing this equipment

requires access to parts that may cause

electric shock or other serious injury if the

work is not performed properly. Do not install or service this equipment unless you are trained and qualified.

WARNING

Skin Injection Hazard

To reduce the risk of a fluid injection injury,

always follow the Pressure Relief Proce-

dure on page 18 when you stop spraying,

before servicing the gun, and whenever you

are instructed to relieve the pressure.

• Use a vise with padded jaws to prevent damage to

plastic parts.

• Lubricate the power supply o-ring (12a), some fluid

needle parts (8), and certain fluid fittings with Part

No. 116553 Dielectric Grease, as specified in the

text.

• Lightly lubricate o-rings and seals with non-silicone

grease. Order Part No. 111265 Lubricant. Do not

over-lubricate.

• Only use genuine Graco parts. Do not mix or use

parts from other PRO Gun models.

1. Flush and clean the gun, page 23.

2. Relieve the pressure, page 18.

3. Remove the gun from the manifold, page 36.

4. Remove the gun from the worksite. Repair area

must be clean.

309298K 35

Page 36

Repair

Remove the Gun from the Manifold

1. Remove the fluid supply hose from the fluid fitting

(22).

2. Loosen the bottom gun screw (31) until the gun sits

loosely in the mounting bracket slot (A). See F

22..

IG.

CAUTION

The piston return spring (105) is compressed

between the manifold and the gun body when they

are assembled. To avoid sudden movement of the

gun, loosen the bottom gun screw (31) before loosening the three manifold screws (106). This allows the

gun to move forward gradually as the manifold

screws are loosened. Hold the gun firmly in hand

while loosening the manifold screws.

106

112

105

A

TI1721A

102

22

Fig. 22. Remove Gun from Manifold

Install the Gun on the Manifold

3. Holding the gun firmly in hand, loosen the three

screws (106) from the back of the manifold.

4. Remove the gun from the manifold and take it to the

service area.

1. Make sure the gasket (112) and spring (105) are in

place on the manifold. See F

parts for damage and replace them as needed.

2. Secure the gun to the manifold by tightening the

three screws (106).

3. Secure the gun to the mounting bracket (102) by

tightening the bottom screw (31).

IG. 22.. Inspect the

36 309298K

Page 37

Tip Guard, Air Cap, Spray Tip, or Seat Housing Replacement

1. Prepare gun for service, page 35.

2. Remove the retaining ring (1), tip guard (3), air cap

(40), spray tip (4), and shroud (2). You may have to

turn the air cap with the tip guard to remove it. See

F

IG. 23..

3. Remove the seat housing (5) with the tool (37) provided. See F

3

1a

1

40

IG. 24..

2

4a

4

TI1723A

Repair

WARNING

Fire, Explosion, and Electric Shock Hazard

The barrel contact ring (6a) is a conductive

contact ring, not a sealing o-ring. To reduce

the risk of sparking or electric shock, do not

remove the barrel contact ring (6a) except

to replace it and never operate the gun without the contact ring in place. Do not replace

the contact ring with anything but a genuine

Graco part.

37

B

Fig. 23. Tip Guard, Air Cap, and Spray Tip Replacement

CAUTION

The barrel resistor cartridge (B) is part of the barrel

and is not replaceable. To avoid destroying the gun

barrel, do not attempt to remove the barrel resistor.

Fig. 24. Seat Housing Replacement

WARNING

Fire, Explosion, and Electric Shock Hazard

To reduce the risk of fire, explosion, or electric shock, never operate the gun with a

missing or damaged electrode.

4. Make sure the electrode (40a) is not damaged or

missing. See page 39 to install the electrode.

309298K 37

Page 38

Repair

5. Install the seat housing (5) with the tool (14) provided. Tighten until snug, then 1/4 turn more; do not

overtighten. See F

IG. 24..

CAUTION

To avoid damaging the seat housing and gun barrel,

never overtighten the seat housing. Overtightening

may affect the fluid shutoff.

6. Place the spray tip (4) in the air cap (40). Align the

tab of the tip with the groove in the air cap. Be careful not to damage the electrode (40a).

7. Slide the shroud (2) onto the gun.

8. Install the spray tip (4) and air cap (40), tip guard

(3), shroud (2), and retaining ring (1) onto the gun.

Make sure the u-cup (1a) is in place on the retaining

ring (1). The lips must face forward. Tighten the

retaining ring until the air cap is held firmly in place;

you should not be able to rotate the air cap horns by

hand.

9. Test gun resistance, page 29.

10. Install the gun onto the manifold and bracket. See

page 36.

38 309298K

Page 39

Repair

Electrode Replacement

WARNING

Electric Shock Hazard

To reduce the risk of fire, explosion, or electric shock, do not operate the spray gun

without the electrode installed in the air cap.

1. Prepare the gun for service, page 35.

2. Remove the air cap assembly, page 37.

3. Pull the electrode (40a) out of the back of the air

cap, using a needle-nose pliers.

4. Push the new electrode through the air cap hole.

Make sure the short end (BB) of the electrode

engages the hole (CC) in the back of the air cap.

Press the electrode in place firmly with your fingers.

See F

IG. 25..

5. Install the air cap assembly, page 37.

6. Test gun resistance, page 29.

40a

CC

BB

Fig. 25. Electrode Replacement

02013

309298K 39

Page 40

Repair

Fluid Tube Replacement

There are no replaceable parts in the fluid tube assembly. Only remove when necessary.

1. Prepare the gun for service, page 35.

2. Remove the air cap assembly, page 37. Remove the

shroud (2).

C

E

D

20

3. Disconnect the bottom fluid tube nut (C). See F

26..

4. Carefully unscrew the top fluid tube nut (D).

IG.

CAUTION

Be careful not to damage the fluid tube assembly (19)

when cleaning or installing it, especially the sealing

surface (E). If the sealing surface is damaged, the

entire fluid tube assembly must be replaced.

5. Apply Part No. 116553 dielectric grease to the entire

length of the plastic extension on the end of the fluid

tube (19).

6. Apply low strength thread sealant to the fluid tube

nut threads.

ti1524a

Fig. 26. Fluid Tube Replacement

Fluid Filter Removal

1. Prepare the gun for service, page 35.

2. Remove the air cap assembly, page 37. Remove the

shroud (2).

3. Disconnect the bottom fluid tube nut (C).

4. Remove the fluid filter (20). Clean or replace the filter, as needed.

Replacement filters are available in 100 mesh (standard) or 60 mesh sizes. See page 52.

5. Install the fluid filter. Tighten the bottom nut (C) onto

the fitting (22) and torque to 20-30 in-lb (2.3-3.4

N•m). Make sure the top nut (D) remains tight.

7. Install the fluid tube into the gun barrel and tighten

the top nut (D) hand-tight, then 1/4 to 1/2 turn with a

wrench. There will be a gap between the nut and

barrel. Do not overtighten the nut.

CAUTION

8. Make sure the fluid filter (20) is in place. Tighten the

bottom nut (C) onto the fitting (22) and torque to

20-30 in-lb (2.3-3.4 N•m). Make sure the top nut

remains tight.

9. Reinstall the shroud and air cap assembly, page 37.

10. Test gun resistance, page 29.

40 309298K

Be sure the fluid tube (19) is not twisted after tightening the bottom nut (C).

6. Reinstall the shroud and air cap assembly, page 37.

7. Test gun resistance, page 29.

Page 41

Fluid Needle Replacement

1. Prepare the gun for service, page 35.

Repair

2. Remove the air cap assembly and seat housing,

page 37.

3. Remove the barrel (6), page 44.

4. Remove the spring cap (45) and the spring (8a)

from the barrel. See F

5. Be sure the seat housing (5) is removed. Place the

2 mm ball end wrench (44) in the back of the fluid

needle assembly. Push the tool in and turn it counterclockwise about 12 full turns to unthread the needle.

6. Using the multi-tool (37), pull back on the packing

nut (N) to remove the fluid needle assembly. See

F

IG. 28..

7. Install the fluid needle assembly in the gun barrel.

Push in on the needle with the 2 mm ball end

wrench (44) and tighten. See F

8. Install the spring (8a).

IG. 27..

IG. 29..

25

45

8a

Fig. 27. Spring Cap and Springs

N

37

9. Install the spring cap (45), making sure the grounding spring (25) is in place. Tighten until snug. Do

not overtighten.

10. Install the barrel (6), page 45.

CAUTION

To avoid damaging the seat housing and gun barrel,

never overtighten the seat housing. Overtightening

may result in improper fluid shutoff.

11. Install the seat housing and air cap, page 37.

12. Test gun resistance, page 29.

Fig. 28. Fluid Needle Removal

Fig. 29. Fluid Needle Replacement

309298K 41

Page 42

Repair

Piston Repair

1. Prepare the gun for service, page 35.

2. Remove the air cap, page 37. Remove the gun

shroud (2).

Table 3: Piston O-Rings

Description Function

Shaft O-Ring

(34g)

Seals cylinder air along the piston rod

(34b). Replace if air leaks along rod.

3. Remove the jam nut (28), actuator arm (29), and

adjustment nut (30). See F

28

29

IG. 30..

30

34b

TI1732A

Fig. 30. Actuator Arm

4. Push on the piston rod (34b) to push the piston out

the back of the gun.

5. Inspect the o-rings (34e, 34f, 34g) and u-cup packing (34d) for damage. See Table 3 and F

IG. 31..

6. Lubricate the o-rings (34e, 34f, 34g) and u-cup

packing (34d) with non-silicone grease, Part No.

111265. Do not over-lubricate.

Front O-Ring

(34e)

Back O-Ring

(34f)

U-Cup (34d) Replace if air leaks from small vent hole

Air shutoff seal. Replace if air leaks from

air cap when gun is de-triggered.

Separates cylinder air from atomizing air.

at back of manifold when gun is triggered.

34a

34d

34c

34f

34e

TI1575A

34b

34d

34g

34f

7. Align the two stems (34c) with the holes in the gun

34e

body and press the piston assembly into the back of

the gun until it bottoms.

8. Install and adjust the actuator arm, page 43.

34g

TI1576A

Fig. 31. Piston O-Rings

42 309298K

Page 43

Repair

Adjust the Actuator Arm

1. Install the adjustment nut (30), actuator arm (29),

and jam nut (28) onto the piston rod (34b). Note that

the jam nut (28) has a slightly larger hex and a thinner profile than the adjustment nut (30). See F

30. on page 42.

2. Position the parts so there is a 0.125 in. (3 mm) gap

between the actuator arm (29) and the fluid packing

rod nut (U), which allows the atomizing air to actuate

before the fluid. See F

IG. 32..

3. Tighten the adjustment nut (30) against the actuator

arm (29). Check that the 0.125 in. (3 mm) gap has

been maintained. See F

IG. 32..

4. Test gun resistance, page 29.

IG.

5. Install the gun shroud (2) and air cap, page 37.

6. Install the gun onto the manifold and bracket. See

page 36.

0.125 in. (3 mm) gap

U

29

TI1567A

28

30

34b

Fig. 32. Actuator Arm Adjustment

309298K 43

Page 44

Repair

Barrel Removal

1. Prepare the gun for service, page 35.

2. Remove the air cap, page 37. Remove the gun

shroud (2).

3. Disconnect the fluid tube nut (C).

4. Remove the jam nut (28) and actuator arm (29). See

page 42.

5. Loosen the three screws (10, 33). See F

IG. 33..

CAUTION

To avoid damaging the power supply (12), pull the

gun barrel (6) straight away from the gun body (32). If

necessary, gently move the gun barrel from side to

side to free it from the gun body.

6. Hold the gun body (32) with one hand and pull the

barrel (6) straight off the body. See F

C

33

Fig. 33. Barrel Removal

IG. 33..

6

10

32

TI1728A

Fig. 34. Disconnect Fluid Tube

32

6

29

30

28

19

TI1732A

C

44 309298K

Page 45

Repair

Barrel Installation

1. Be sure the gasket (11) and grounding spring (25)

are in place. Make sure the air holes are aligned

properly. Replace if damaged. See F

2. Place the barrel (6) over the power supply (12) and

onto the gun body (32).

3. Tighten the three screws (10, 33) oppositely and

evenly (about a half turn past snug).

IG. 35..

CAUTION

Do not over-tighten the screws (10, 33).

4. Make sure the fluid filter (20) is in place. Tighten the

bottom nut (C) onto the fitting (22) and torque to

20-30 in-lb (2.3-3.4 N•m). Make sure the top nut (D)

remains tight.

5. Install and adjust the actuator arm (29) and jam nut

(28). See page 43.

6. Test gun resistance, page 29.

7. Install the gun shroud (2) and air cap, page 37.

8. Install the gun onto the manifold and bracket. See

page 36.

32

Fig. 35. Barrel Installation

12

11

10

9

22

29

25

28

20

D

19

C

TI1729A

309298K 45

Page 46

Repair

Power Supply Removal and Replacement

• Inspect the gun body power supply cavity for dirt or

moisture. Clean with a clean, dry rag.

• Do not expose gasket (11) to solvents.

1. Prepare gun for service, page 35.

2. Remove the barrel (9), page 44.

CAUTION

Be careful when handling the power supply (12) to

avoid damaging it.

3. Grasp the power supply (12) with your hand. With a

gentle side to side motion, free the power supply/alternator assembly from the gun body (32),

then carefully pull it straight out. Disconnect the flexible circuit (23) from the socket at the top of the body

(32). See F

IG. 36..

5. Check the power supply resistance, page 30.

Replace if necessary.

Before installing the power supply, make sure the

o-rings (12a, 13a), spring (12b), and pads (13e) are in

place.

6. Connect the 6-pin flexible circuit (23) to the power

supply.

7. Connect the 3-wire connector (GG). Slide the alternator (13) down onto the power supply (12).

8. Lubricate the alternator o-ring (13a) with non-silicone grease, Part No. 111265. Do not over-lubricate.

9. Lubricate the power supply o-ring (12a) with dielectric grease.

10. Insert the power supply/alternator assembly in the

gun body (32). Make sure the ground strips make

contact with the body. Connect the flexible circuit

(23) to the socket at the top of the body. Push the

6-pin connector into the socket to ensure it is properly connected.

11. Install the barrel (6), page 45.

12. Test gun resistance, page 29.

4. Disconnect the 3-wire connector (GG) from the

power supply. Slide the alternator up and off the

power supply. Inspect the power supply and alternator for damage. Disconnect the 6-pin flexible circuit

(23) from the power supply.

46 309298K

Page 47

12

23

11

Fig. 36. Power Supply

12a

12b

13a

13

13e

GG

Turbine Alternator Removal and Replacement

Replace turbine alternator bearings after 2000 hours of

operation. Order Part No. 223688 Bearing Kit.

1. Prepare gun for service, page 35.

2. Remove the power supply/alternator assembly,

page 46.

3. Disconnect the alternator from the power supply,

page 46.

32

TI1730A

4. Measure resistance between the two outer terminals of the 3-wire connector (GG); it should be

2.5-3.5 ohms. If outside this range, replace the

alternator coil.

5. Follow the bearing replacement procedure in the

bearing kit manual 308034.

6. Install the alternator on the power supply, page 46.

7. Install the power supply/alternator assembly, page

46.

Page 48

Parts

Parts

Part No. 244592 PRO Auto Xs AA Electrostatic Gun, Series A

10

6

6a

5

1

12a

1a

12b

3

12

40

26

19

35

4

25

11

4a

13e

13

13a

40a

34e

34f

34a

34d

34c

34b

2

23

27

29

8

30

28

19 (Ref)

ti1722

48 309298K

8a

45

20

22

32

31

33

34g

14

37

44

Ref. No. 13: Alternator Detail

13b

13b

13e

13d

13c

13a*

TI1481a

Page 49

Part No. 244592 PRO Auto Xs AA Electrostatic Gun, Series A

Parts

Ref.

No.

1 244950 RING, retaining, air cap; includes

1a*† 198307 . U-CUP 1

2 197916 SHROUD 1

3 276767 TIP GUARD 1

4 GG3XXX SPRAY TIP (customer’s choice);

4a 183459 . SEAL, spray tip 1

5 245280 HOUSING, seat 1

6 244531 BARREL, gun; includes item 6a 1

6a 197486 . O-RING; conductive 1

8 244714 NEEDLE, fluid; includes item 8a 1

8a 112691 . SPRING, compression 1

10 197518 SCREW; socket-hd; 10-24 x 3/4

11*† 197517 GASKET, barrel 1

12 244541 POWER SUPPLY, 85 kV; includes

12a*† 103337 . O-RING; fluoroelastomer 1

12b 197624 . SPRING, compression 1

13 244555 TURBINE, alternator; includes

13a*† 110073 . O-RING; fluoroelastomer 1

13b 223688 . BEARING KIT; includes front

13c 244577 . COIL 1

13d 111745 . RING, retaining 1

13e 198821 . PAD, pressure 2

14 107460 WRENCH, ball end; 4 mm 1

15 179791 TAG, warning (not shown);

16 180060 SIGN, warning (not shown);