Page 1

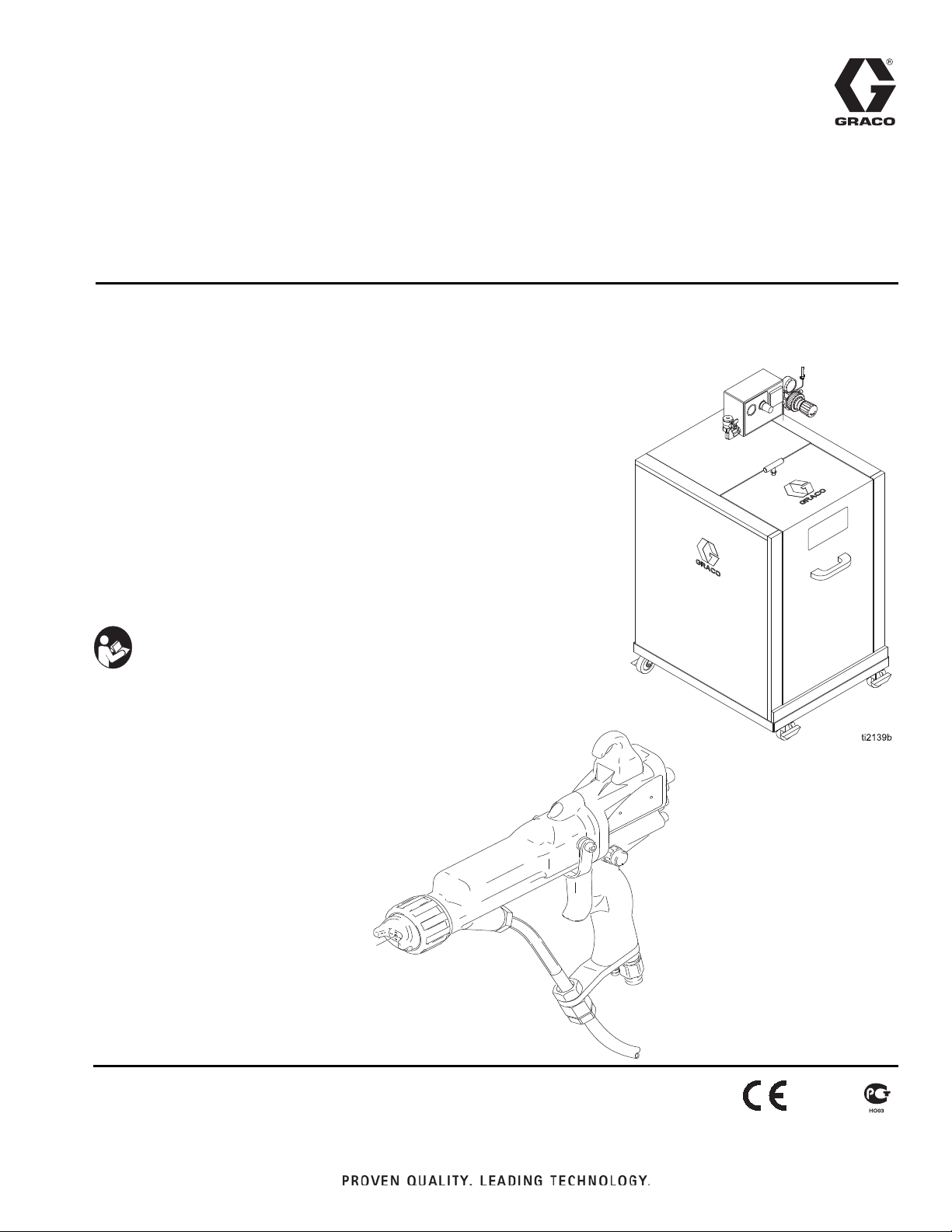

WB 100

Isolation Enclosure

PRO Xs3

Smart Gun

and Fluid

Instructions/Parts List

ELECTROSTATIC, WATERBORNE, AIR SPRAY

WB100 Isolation System and PRO™

Xs3 Spray Gun

For use when electrostatically spraying conductive, waterborne fluids that meet at least one of the

following conditions for non-flammability. For professional use only.

FM Approved

• The fluid has a flash point above 140F (60C) and a maximum

organic solvent concentration of 20%, by weight, per ASTM Standard D93.

• The fluid does not sustain burning when tested per

ASTM Standard D4206 Sustained Burn Test.

CE-EN 50059 Compliant

• Materials which cannot be ignited, in any mixture with air,

by an energy source of less than 500 mJ.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

309293N

EN

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

100 psi (0.7 MPa, 7 bar) Maximum Working Fluid Pressure

See page 3 for a List of Models

For patent information, see www.graco.com/patents.

TI1681A

Page 2

Table of Contents

List of Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warning Symbol . . . . . . . . . . . . . . . . . . . . . . . . . 4

Caution Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

How the Electrostatic Air Spray Gun Works . . . . 7

Spraying Waterborne Fluids Electrostatically . . . 7

Gun Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

System Requirements . . . . . . . . . . . . . . . . . . . . . 9

Warning Sign . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Install the System . . . . . . . . . . . . . . . . . . . . . . . . 9

Ventilate the Spray Booth . . . . . . . . . . . . . . . . . 11

Connect the Air Line . . . . . . . . . . . . . . . . . . . . . 11

Ground the Cabinet . . . . . . . . . . . . . . . . . . . . . . 11

Connect the Waterborne Fluid Hose . . . . . . . . . 11

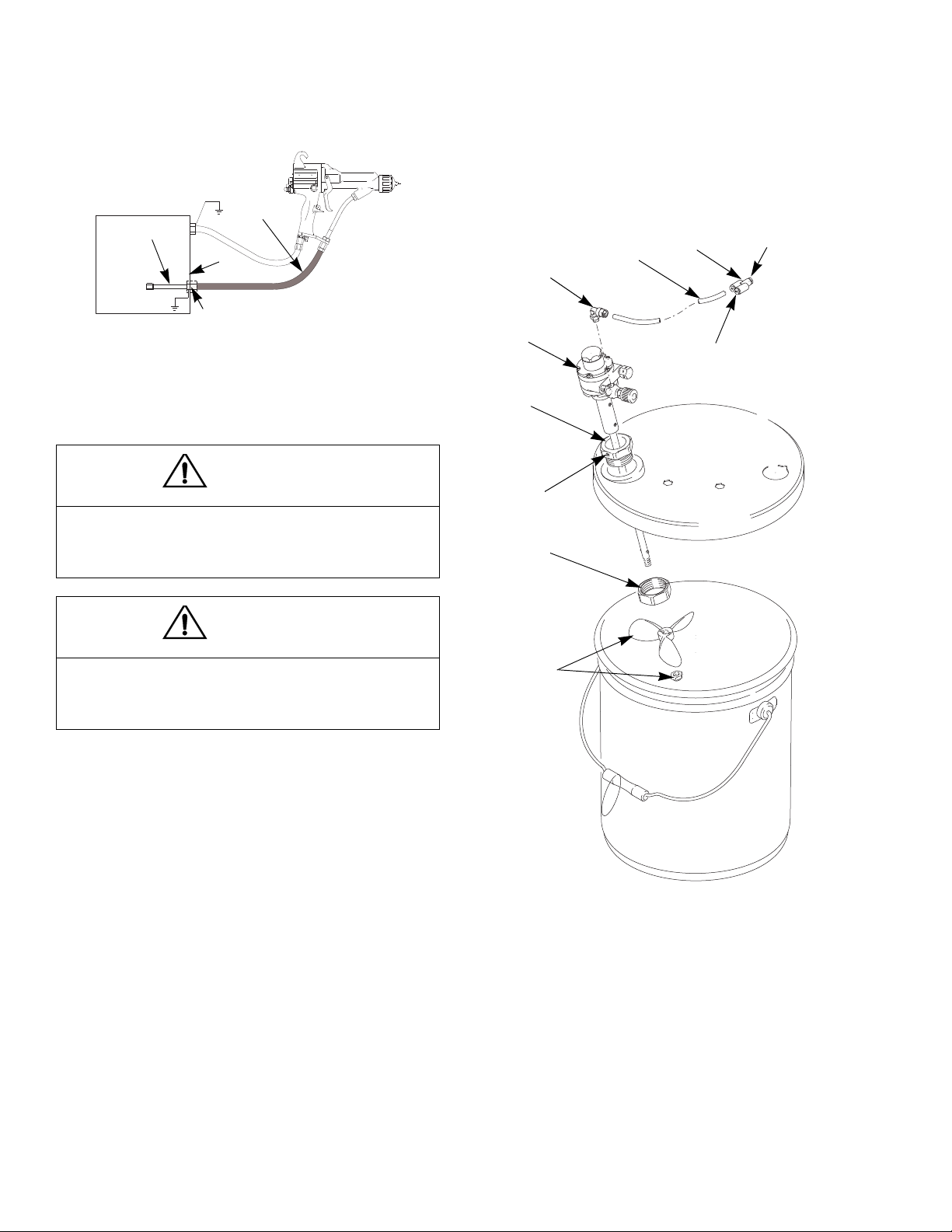

245895 Agitator Kit . . . . . . . . . . . . . . . . . . . . . . 14

245944 Fluid Regulator Kit . . . . . . . . . . . . . . . . 15

Select a Fluid Nozzle and Air Cap . . . . . . . . . . 16

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Check Electrical Grounding . . . . . . . . . . . . . . . 18

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operating Checklist . . . . . . . . . . . . . . . . . . . . . . 19

Fluid Voltage Discharge and Grounding Procedure

20

Pressure Relief Procedure . . . . . . . . . . . . . . . . 20

Fill the Fluid Supply . . . . . . . . . . . . . . . . . . . . . . 21

Adjust the Spray Pattern . . . . . . . . . . . . . . . . . . 21

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Low Voltage Adjustment (Smart Guns Only) . . 25

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Flush the Spray Gun . . . . . . . . . . . . . . . . . . . . . 26

Daily Care and Cleaning . . . . . . . . . . . . . . . . . . 27

Clean the Air Cap and Fluid Nozzle . . . . . . . . . 29

Grease Door Latch Threads . . . . . . . . . . . . . . . 29

Electrical Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Test Gun Resistance . . . . . . . . . . . . . . . . . . . . 30

Test Power Supply Resistance . . . . . . . . . . . . . 31

Test Electrode Resistance . . . . . . . . . . . . . . . . 32

Test Ground Strip Resistance . . . . . . . . . . . . . . 33

Test Cylinder Resistance . . . . . . . . . . . . . . . . . 33

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Voltage Loss Troubleshooting . . . . . . . . . . . . . . 34

Spray Pattern Troubleshooting . . . . . . . . . . . . . 37

Gun Operation Troubleshooting . . . . . . . . . . . . 38

Electrical Troubleshooting . . . . . . . . . . . . . . . . . 39

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Prepare the Gun for Service . . . . . . . . . . . . . . . 41

Air Cap/Nozzle Replacement . . . . . . . . . . . . . . 42

Electrode Replacement . . . . . . . . . . . . . . . . . . . 43

Fluid Packing Removal . . . . . . . . . . . . . . . . . . . 44

Packing Rod Repair . . . . . . . . . . . . . . . . . . . . . . 45

Barrel Removal . . . . . . . . . . . . . . . . . . . . . . . . . 46

Barrel Installation . . . . . . . . . . . . . . . . . . . . . . . . 46

Power Supply Removal and Replacement . . . . 47

Turbine Alternator Removal and Replacement . 48

Fan Air Adjustment Valve Repair . . . . . . . . . . . 49

Fluid Adjustment Valve Repair . . . . . . . . . . . . . 50

Air Valve Repair . . . . . . . . . . . . . . . . . . . . . . . . . 50

Atomizing Air Restrictor Valve Removal and

Replacement . . . . . . . . . . . . . . . . . . . . . . . . 51

ES ON/OFF Valve Repair . . . . . . . . . . . . . . . . . 51

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Air Line Accessories . . . . . . . . . . . . . . . . . . . . . 65

Fluid Line Accessories . . . . . . . . . . . . . . . . . . . . 65

Gun Accessories . . . . . . . . . . . . . . . . . . . . . . . . 66

Miscellaneous Accessories . . . . . . . . . . . . . . . . 66

Technical Specifications . . . . . . . . . . . . . . . . . . . . 69

California Proposition 65 . . . . . . . . . . . . . . . . . . . 69

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 70

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 70

2 309293N

Page 3

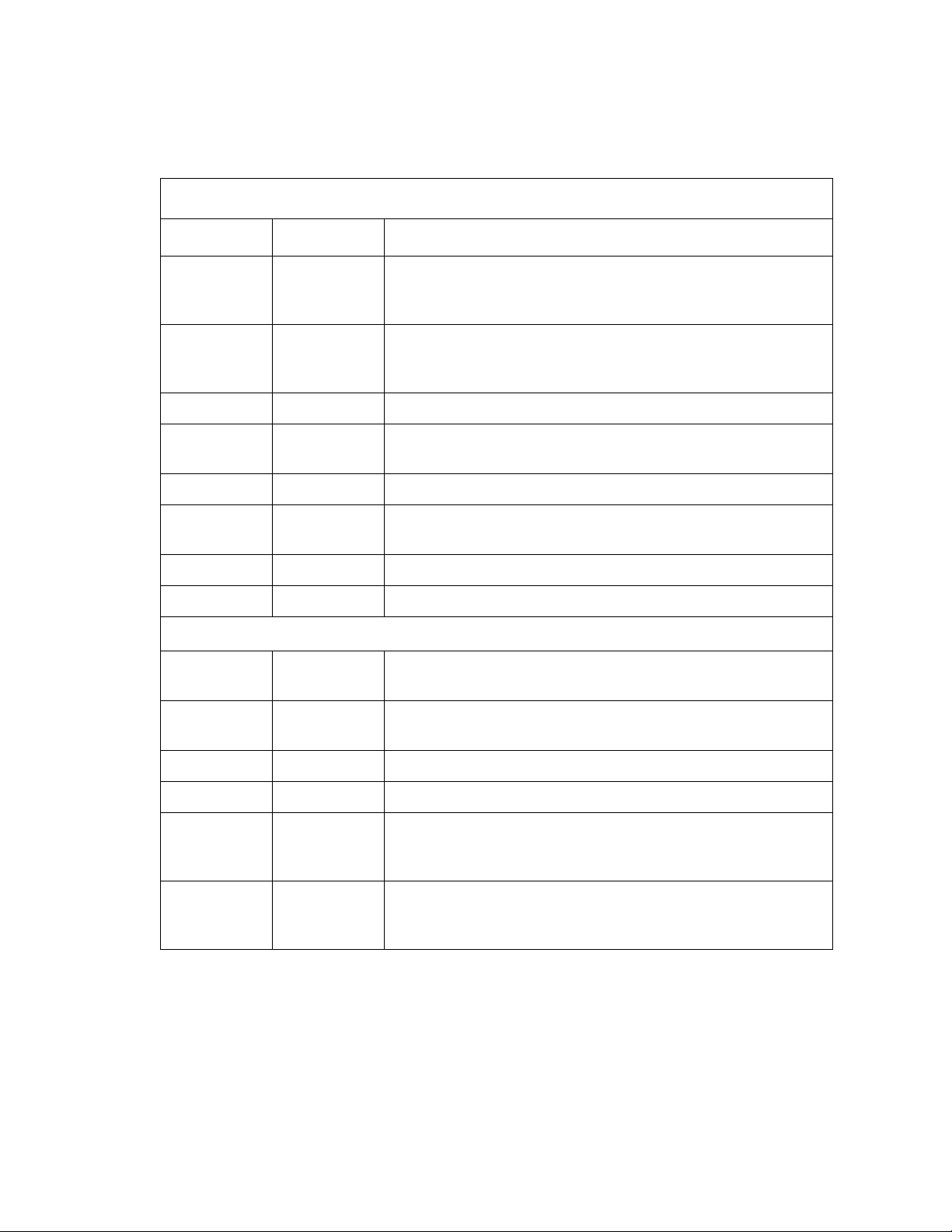

List of Models

Part No. Gun Model Description

245897 PRO Xs3 Waterborne Isolation Enclosure with standard electrostatic air

245898 PRO Xs3 Waterborne Isolation Enclosure with smart electrostatic air

233825 Waterborne Isolation Enclosure without hoses and gun.

List of Models

FM Approved

spray gun, grounded air hose, and shielded waterborne fluid

hose

spray gun, grounded air hose, and shielded waterborne fluid

hose

244581,

Series B

245301, PRO Xs3 Part No. 244581 Gun, with 25 ft (7.6 m) waterborne fluid hose

244582,

Series B

245305 PRO Xs3 Part No. 244582 Gun, with 25 ft (7.6 m) waterborne fluid hose

245252 Shielded Waterborne Fluid Hose Assembly 25 ft (7.6 m)

PRO Xs3 Standard Electrostatic Air Spray Gun, for waterborne coatings

PRO Xs3 Smart Electrostatic Air Spray Gun, for waterborne coatings,

EN 50059 Compliant

244581,

Series B

244582,

Series B

246511 Waterborne Isolat ion Enclosure, without hoses and gun

246431 PRO Xs3 Unshielded Waterborne fluid hose assembly, 25 ft (7.6 m).

246592 PRO Xs3 Waterborne Isolation Enclosure with standard electrostatic air

PRO Xs3 Standard Electrostatic Air Spray Gun, for waterborne coatings.

PRO Xs3 Smart Electrostatic Air Spray Gun, for waterborne coatings.

spray gun, grounded air hose, and unsh ielded waterborne flu id

hose

246593 PRO Xs3 Waterborne Isolation Enclosure with smart electrostatic air

spray gun, grounded air hose, and unsh ielded waterborne flu id

hose

309293N 3

Page 4

Symbols

WARNING

CAUTION

Symbols

Warning Symbol

This symbol alerts you to the possibility of serious injury

or death if you do not follow the instructions.

WARNING

Electric Shock Hazard

Improper grounding, setup, or usage of an isolated waterborne system can cause a hazardous

condition and result in electric shock or other serious injury.

• Ground the equipment, all personnel in or close to the spray area, the object being sprayed,

and all conductive objects in the spray area. See Grounding, page 17.

• The gun must be connected to a voltage isolation system that will discharge the system voltage when the gun is not in use.

• All components of the isolation system that are charged to high voltage must be contained

within an enclosure that prohibits personnel from making contact with the high voltage components before the system voltage is discharged.

Caution Symbol

This symbol alerts you to the possibility of damage to or

destruction of equipment if you do not follow the instructions.

• Follow the Fluid Voltage Discharge and Grounding Procedure on page 20 when inst ructed

to discharge the voltage; before cleaning, flushing, or servicing the system; before approaching the front of the gun; and before opening the safety enclosure for the isolated fluid supply.

• Do not touch the gun nozzle or come within 4 in. (102 mm ) of th e no zzle du rin g gu n op erat ion

or for 30 seconds after operation stops, to allow the voltage to discharge through the bleed

resistor. Place the gun in the holster (accessor y) du rin g this 30 seco nd pe rio d. Refe r to Fluid

Voltage Discharge and Grounding Procedure, page 20.

• Electrically connect a metal part of the fluid supply unit to the bleed resistor.

• The gun air supply must be interlocked with the isolat ion system to shut off the air supply any-

time the isolation system enclosure is opened.

• Use only the red-colored Graco electrically conductive gun air hose with this gun. Do not use

black or grey-colored Graco air hoses.

• Install only one continuous Graco waterborne flu id h ose bet ween the isol at ed f lu id sup ply and

the spray gun. Do not splice hoses together.

• Do not enter a high voltage or hazardous area until all high voltage equipment has been discharged.

4 309293N

Page 5

Warning

WARNING

Fire and Explosion Hazard

Improper grounding, poor air ventilation, ope n flam es, or sp ar ks can cause a hazardou s co ndit ion

and result in a fire or explosion.

• Electrostatic equipment must be used only by trained, qualified personnel who understand the

requirements in this manual.

• Ground the equipment, all personnel in or close to the spray area, the object being sprayed,

and all other electrically conductive objects in the spray area. See Grounding, page 17.

• Check gun resistance daily. See Test Gun Resistance on page 30.

• If there is any static sparking while using the equipment, st op spraying i mmediately. Identi fy

and correct the problem.

• Provide fresh air ventilation to avoid buildup of flammable or toxic vapors. See Ventilate the

Spray Booth on page 11.

• Only use this equipment to spray non-flammable, waterborne fluids, as defined on the front

cover of this manual.

• Only flush, purge, or clean the electrostatic waterborne spray system with non-flammable fluids, as defined on the front cover of this manual.

• Do not flush with the gun electrostatics turned on.

• Keep the spray area free of debris and rags. Do not store solvent and flammable fluids in the

spray area.

• Eliminate all ignition sources such as pilot lights, cigarettes, and static arcs from plastic drop

cloths. Do not plug in or unplug power cords or turn lights on or off in the spray area.

• Use only non-sparking tools to clean residue from the booth and hangers.

Toxic Fluid Hazard

Hazardous fluids or toxic fumes can cause a serious injury or death if splashed in the eyes or on

the skin, swallowed, or inhaled.

• Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

• Store hazardous fluid in an approved container. Dispo se of the hazardous fl uid according to all

local, state, and national guidelines.

• Wear appropriate protective clothing, gloves, eyewea r, and respirator.

309293N 5

Page 6

Warning

WARNING

Equipment Misuse Hazard

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and

result in a serious injury.

• This equipment is for professional use only.

• Read all manuals, tags, and labels before operating the equipment.

• Use the equipment only for its intended purpose. If you are uncertain, call your Graco distribu-

tor.

• Do not alter or modify equipment. Use only genuine Graco parts and accessories.

• Do not operate the power supply above 60 kV. Use only Graco Part No. 2 44542 Power Supply

with this gun.

• Check the equipment daily. Repair or replace worn or damaged parts immediately.

• Do not exceed the maximum working pressure of the lowest rated system component. Maxi-

mum working air and fluid pressure of this equipment is 100 psi (0.7 MPa, 7.0 bar).

• Use fluids and solvents that are compatible with the equipment wetted parts. See the Techni-

cal Specifications section of all equipment manuals. Read the fluid and solvent manufac-

turer’s warnings.

• Route the hoses away from traffic areas, sharp edges, moving parts, a nd h ot surfaces. Do no t

expose Graco hoses to temperatures above 180F (82C) or below -40F (- 40C).

• Wear hearing protection when operating this equipment.

• Comply with all applicable local, state, and national fire, electrical, and other safety regula-

tions.

Pressurized Equipment Hazard

Spray from the gun, hose leaks, or ruptured compone nts can splash fluid in the e yes or on the skin

and cause serious injury.

• Do not point the spray gun at anyone or at any par t of the body.

• Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure, page 20, when you stop spraying and before cleanin g,

checking, or repairing equipment.

• Check hoses and couplings daily. Replace worn, damaged, or loose parts immediately.

• Tighten all fluid connections before each use.

6 309293N

Page 7

Introduction

How the Electrostatic Air Spray Gun Works

Introduction

The air hose supplies air to the spray gun. Part of the ai r

operates the turbine and the rest of t he a ir a to mizes the

fluid being sprayed. The turbine generates power, which

is converted by the power cartridge to supply high voltage current to the gun’s electrode.

The fluid source supplies fluid t o the h ose a nd g un. The

gun must be connected to a voltage isolation system to

maintain voltage at the gun. In an isolation system, the

entire fluid supply is electrostatically charged. The

charged fluid is attracted to the grounded workpiece,

wrapping around and evenly coating all surfaces.

Spraying Waterborne Fluids Electrostatically

This electrostatic air spray gun is designed to spray only

waterborne fluids with a flash point above 140 F (60C)

and a maximum organic solvent concentration of 20%,

by weight, per ASTM Standard D93. Also, the fluid must

not sustain burning when tested per ASTM Standard

D4206 Sustained Burn Test.

CAUTION

The Graco warranty is void if the spray gun is connected to a non-Graco voltage isolation system or if

the gun is operated above 60 kV.

When connected to a voltage isolation system, all of the

fluid in the spray gun, fluid hose, and isolat ed fluid supply is charged to high voltage, which means that the system has more electrical energy than a solvent-based

system. Therefore, only non-flammable fluids (as

defined on the front cover of this manual) can be

sprayed with the system or be used to clean, flush, or

purge the system.

Precautions must be taken when using electrostatic

waterborne equipment to avoid potential shock haza rds.

When the spray gun charges the isolated fluid to high

voltage, it is similar to charging a capacitor or a battery.

The system will store some of the energy while spraying

and retain some of that energy after the spray gun is

shut off. It is not safe to touch the front end of the gun

until the stored energy is discharged. The amount of

time it takes to discharge the energy depends on the

system design. Follow the Fluid Voltage Discharge

and Grounding Procedure on page 20 before

approaching the front of the gun.

309293N 7

Page 8

Introduction

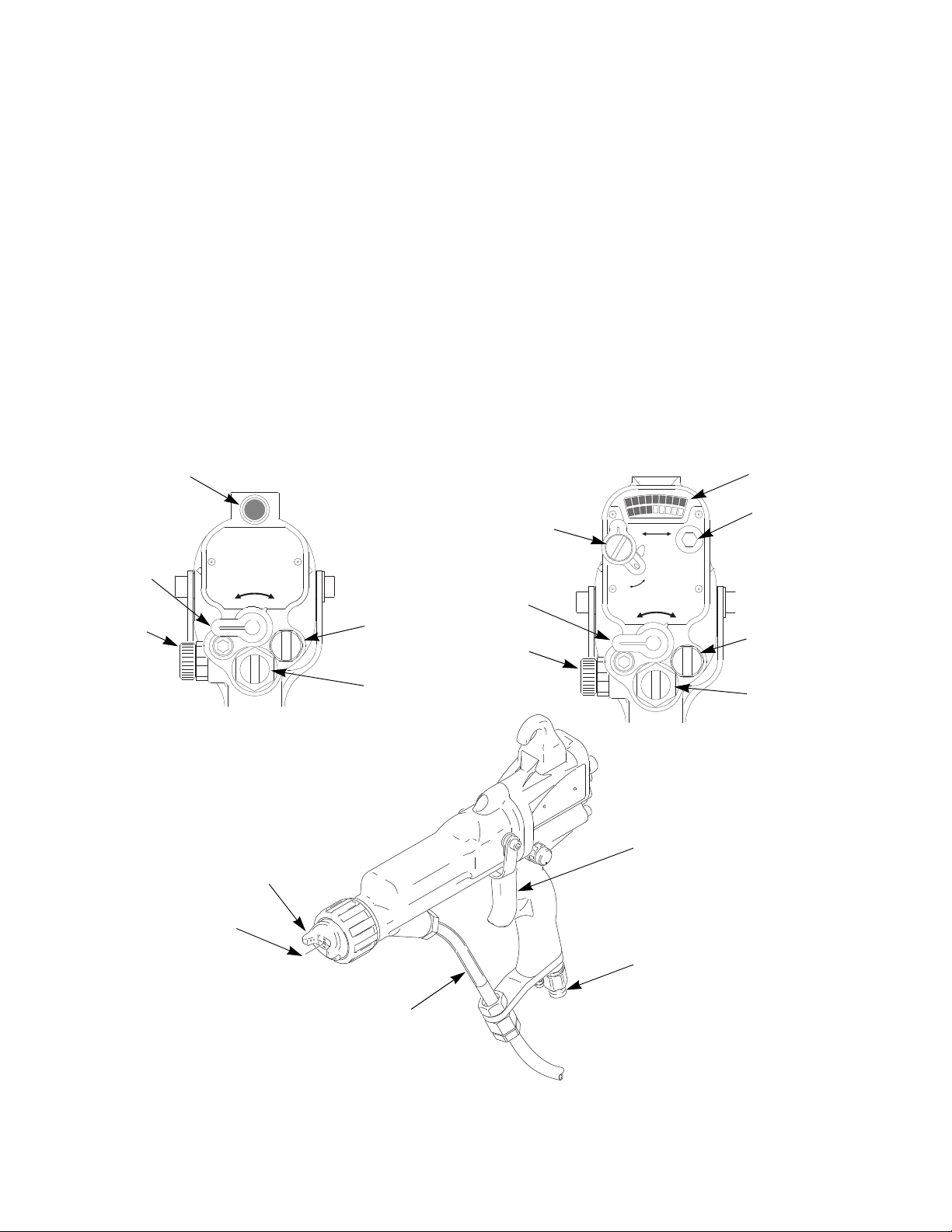

TI1681A

I O

ti1266a

I O

ES

FLUID

LO VOLTAGE

ES HI/LO

DISPLAY

ES INDICATOR

ES ON/OFF

RESTRICTOR

AIR

RESTRICTOR

FLUID

ES ON/OFF

AIR

Standard Model Smart Model

TRIGGER

AIR INLET

FLUID TUBE

AIR CAP

ELECTRODE

Gun Overview

The electrostatic gun includes the following controls

IG. 1.).

(see F

• FLUID adjustment valve. Adjusts flu id rod travel.

Use only in low flow conditions, to reduce wear.

• Fan AIR adjustment valve. Adjusts fan size and

shape.

• Atomizing air RESTRICTOR valve. Restricts

atomizing air flow. Replace with plug (included) if

desired.

• ES ON/OFF valve. Turns electrostatics ON (I) or

OFF (0).

• ES INDICATOR (standard gun only). Green when

ES is ON (I).

• Voltage/current DISPLAY (smart models only).

Shows voltage (V) and current (A). Green=spray,

yellow/red=see Electrical Troubleshooting, page

39.

• ES HI/LO switch (smart models only). Sets volt-

age to HI or LO (factory settings).

• LO VOLTAGE adjustment (smart models only).

Remove plug to adjust to four settings. Page 21.

100

%

0

KV

μα

HI

LO

ES

ES

I O

ti1253a

Fig. 1. Gun Overview

8 309293N

Page 9

Installation

Installation

System Requirements

A safe, well designed voltage isolation system should

have the following features:

• All components of the isolation system that are

charged to high voltage must be contained within an

enclosure that prohibits persons from making contact with the high voltage components before the

system voltage is discharged.

• A bleed resistor to drain off the system voltage when

the spray gun is not in use.

• The system should not have any severe arcing

occurring when the isolation mechanism opens and

closes. Severe arcing will shorten the life of the system components.

• The system must include a means for automatically

discharging the system voltage when anyone opens

the isolation enclosure.

CAUTION

Install the System

WARNING

Fire, Explosion, and Electric Shock Hazard

Installing and servicing this equipment

requires access to parts which may cause

electric shock or other serious injury if work

is not performed properly.

•Do not install or service this equipment

unless you are trained and qualified.

•Be sure your installation complies with all

National, State and Local safety and fire

codes, NFPA 33, NEC 504 and 516, and

OSHA standard 1910.107.

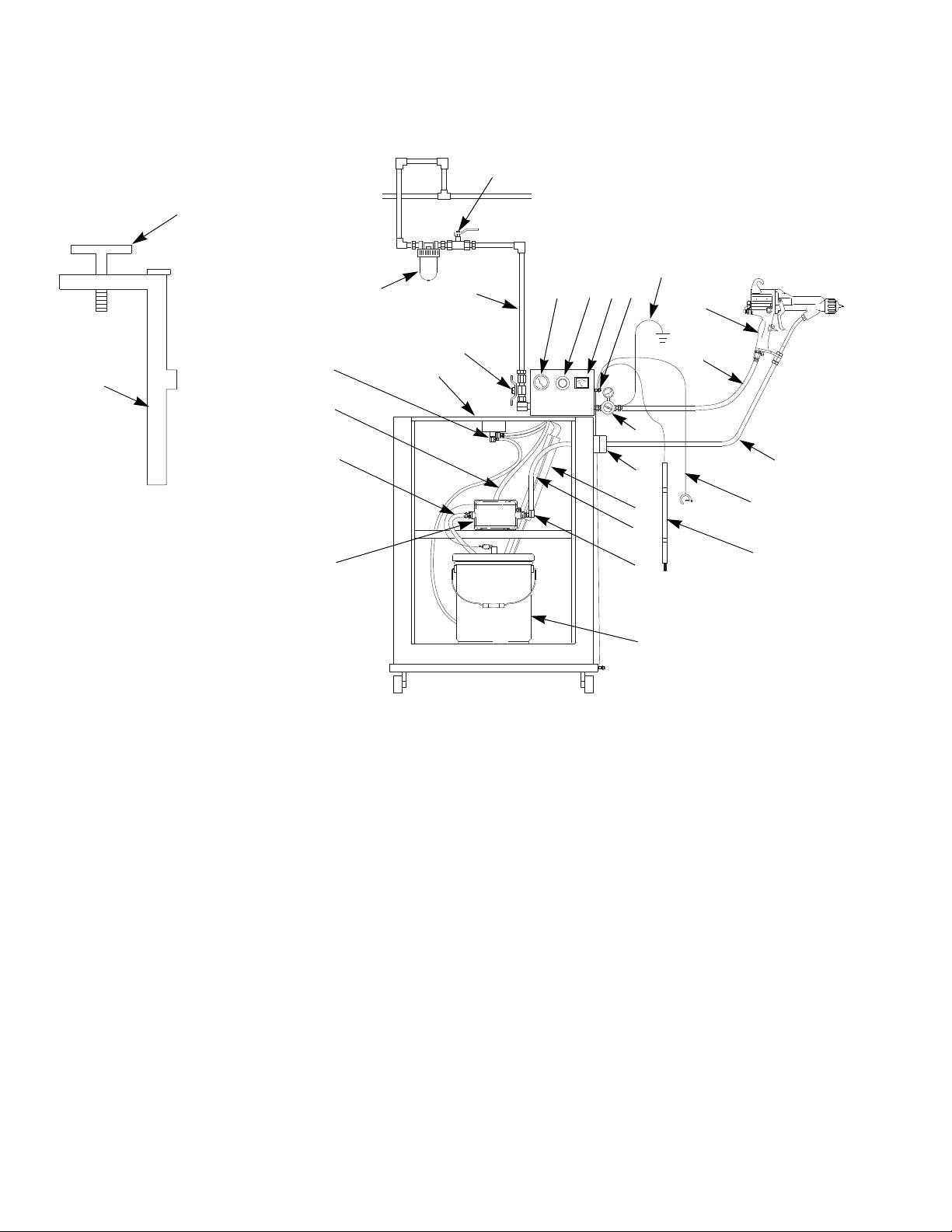

FIG. 2. on page 10 shows a PRO Xs electrostatic waterborne air spray system. For assistance in designing a

system to suit your particular needs, contact your Graco

distributor.

The Graco warranty is void if the spray gun is connected to a non-Graco voltage isolation system or if

the gun is operated above 60 kV.

Warning Sign

Mount the warning sign, Part No. 186118, in the spr ay

area where it can be seen and read by all operators.

Additional warning signs are available at no charge.

309293N 9

Page 10

Installation

A

B*

DE

F

H

J

K*

L

M

N

P*

Q*

R

S

T

U

V*

C

G

Gun ES ON/OFF valve: I is ON, 0 is OFF

B*

BB

AA

Y

Z

X

W

TI1775C

TI1896C

Fig. 2. Typical Installation: PRO Xs Waterborne System

Key

A Main Air Supply Line

B* Main Air Supply Shutoff Valve (bleed-type)

C Pump Air Pressure Gauge

D Pump Air Pressure Regulator

EkV Meter

FPump

G Pump Suction Hose

H Paint Container

J Bleed Resistor

K* Enclosure Safety Interlock

L Isolated Enclosure

M Gun Air Line Filter

N Gun Air Pressure Regulator

P* Graco Red Grounded Air Supply Hose

Q* Air Hose Ground Wire

R Graco Waterborne Fluid Hose

S Waterborne Electrostatic Air Spray Gun

T Grounding Rod

U Ground Terminal

V* Main Ground Wire

W Strain Relief/Ground Fitting

X Pump Air Supply Line

Y Grounding Cylinder

Z Pump Fluid Outlet Fitting

AA Isolated Enclosure Door

BB Enclosure T-Handle Locking Screw

* Required for safe operation. Must be purchased separately.

10 309293N

Page 11

Installation

Ventilate the Spray Booth

WARNING

Flammable or Toxic Vapor Hazard

Provide fresh air ventilation to avoid the

buildup of flammable or toxic vapors. Do not

operate the gun unless ventilation fans are

operating.

Check and follow all National, State, and Local codes

regarding air exhaust velocity requirements.

NOTE: High velocity air exhaust will decrease the operating efficiency of the electrostatic system. The minimum allowable air exhaust velocity is 60 linear ft/min

(18.3 linear meters/minute).

Connect the Air Line

4. Connect the main air supply line (A) to the

bleed-type air valve (B). The bleed valve shuts off all

air to the system. Install an additional bleed-type air

valve (B) upstream of the air filter (M) to isolate the

filter for servicing.

WARNING

Pressurized Equipment Hazard

The bleed-type air valve (B) is required in

your system to relieve air trapped between

the valve and the fluid supply unit after the

air regulator (D) is shut off. Trapped air can cause the

fluid supply unit to cycle unexpectedly, which can

result in serious injury, including splashing fluid in the

eyes or on the skin.

Ground the Cabinet

Connect the main ground wire (V) to a true earth

ground.

WARNING

Electric Shock Hazard

To reduce the risk of electric shock or other

serious injury, you must use the red-colored

Graco Electrically Conductive Air Hose for

the gun air supply hose, and you must connect the hose ground wire to a true earth ground. Do

not use the black or grey-colored Graco air hoses.

1. Install an air line filter/water separator (M) on the

main air supply line to ensure a dry, clean air supply

to the gun. Dirt and moisture can ruin the appearance of your finished workpiece and can cause the

gun to malfunction.

2. Install a bleed-type air regulator (N) on the gun air

line (P).

3. Connect the red-colored Graco Grounded Air Supply Hose (P) between the gun air regulator (N) and

the gun's air inlet. The gun air inlet fitting has a

left-hand thread. Connect the air supply hose

ground wire (Q) to a true earth ground.

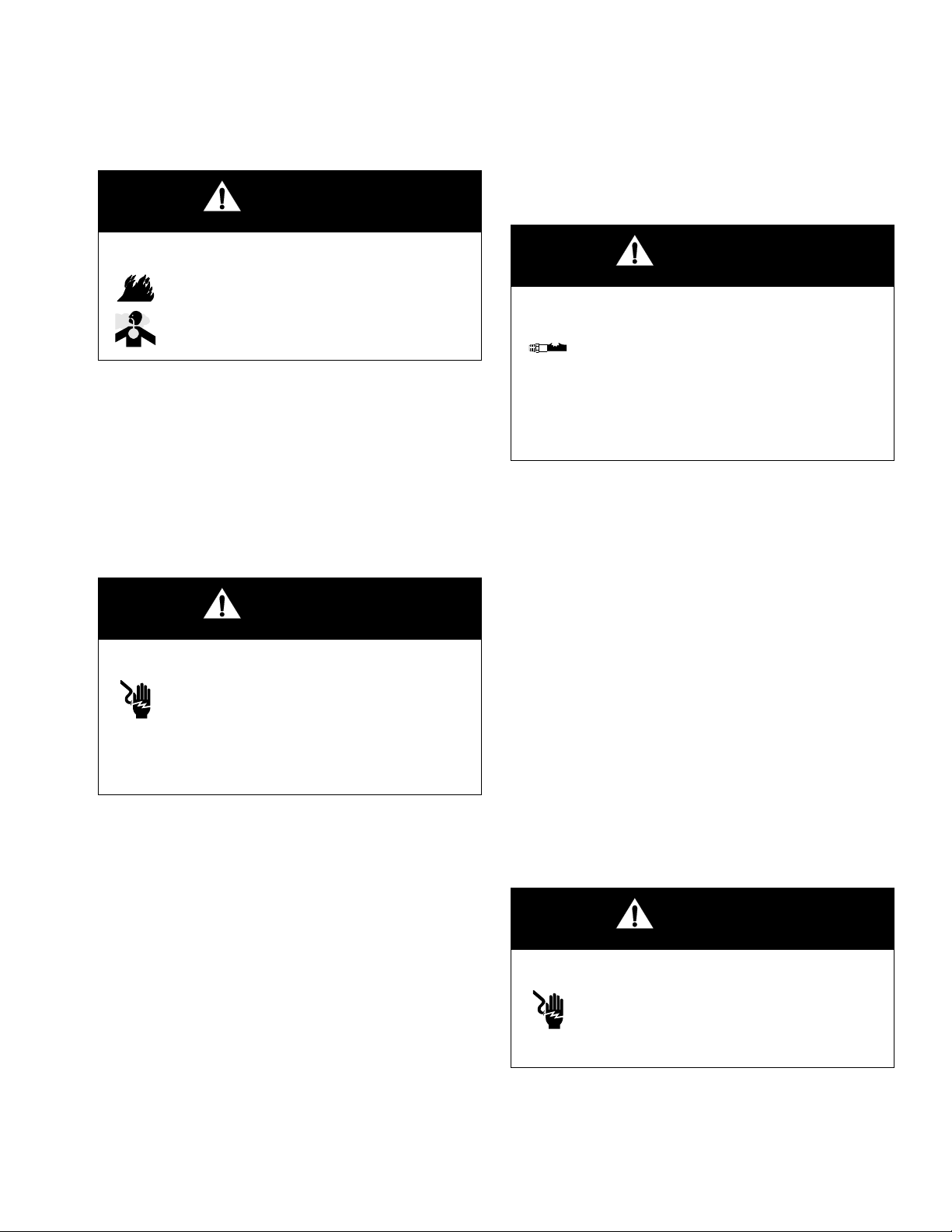

Connect the Waterborne Fluid Hose

Always use a Graco waterborne fluid hose between the

voltage isolation system fluid outlet and the gu n fluid

inlet. See F

sists of an inner PTFE tube (T) and an abrasion-resistant outer jacket (J). Shielded hose 245252 also has a

conductive layer (C), The conductive layer is con nected

to ground at the gun fitting bracket (104).

Before connecting the waterbor ne fl uid hose to t he gu n,

blow it out with air and flush with water to remove contaminants. Flush the gun before using it.

IG. 3.. The waterborne fluid hose (101) con-

WARNING

Electric Shock Hazard

To reduce the risk of electric shock, install

only one continuous Graco waterborne

hose between the isolated fluid supply and

the gun. Do not splice hoses together.

309293N 11

Page 12

Installation

35

38

39

101

102

103

104

105

107

106

108

16

A

TI2155b

TI21188a

F

T

A

B

A 7.40 in. (188 mm)

B 2.0 in. (50 mm)

C

J

Shielded Hose 245252

T

C

A 1.25 in (32 mm)

J

A

TI2742A

Unshielded

Hose 246431

1. Remove the gun air inlet fitting (35). See FIG. 3.

Fig. 3. Connect the Fluid Hose

NOTE: In a shielded hose system, if a hose failure

occurs where high voltage arcs through the inner tube,

voltage will be discharged to ground through the conductive hose layer. When properly installed, the conductive hose layer is grounded through its connection to the

grounded enclosure.

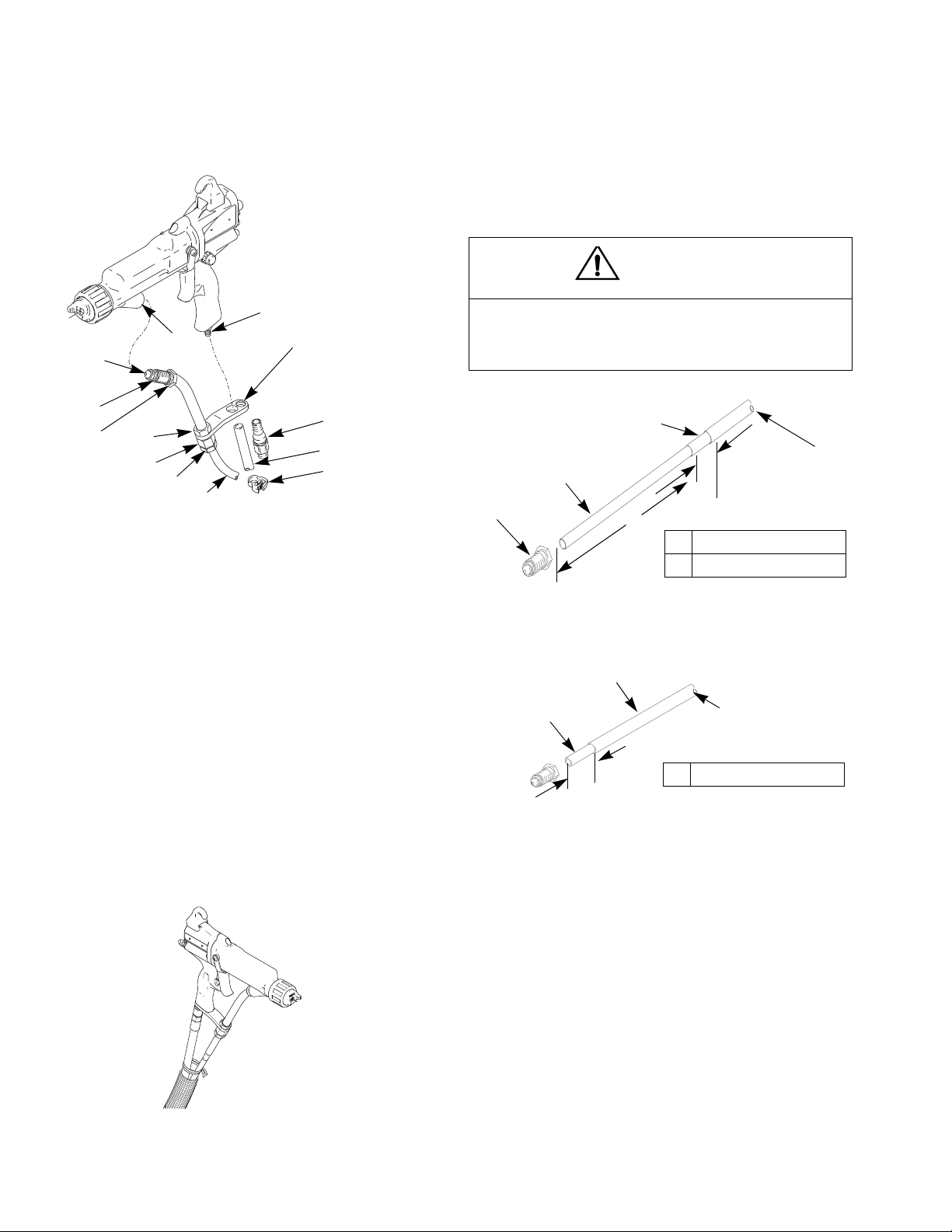

2. For the fluid hose to fit properly, it must be stripped

and assembled to the dimensions in F

IG. 5. Push

the inner tube (T) into the fitting (F) until the tube

bottoms. A new Graco waterborne fluid hose comes

fully assembled to these dimensions.

CAUTION

Be careful not to cut into the inner tube (T) of the

hose when stripping the hose. Nicks or cuts in the

PTFE tube will cause premature hose failure.

Fig. 5. Waterborne Hose Dimensions (At Gun)

Using unshielded fluid hoses minimizes the system

capacitance, resulting in faster response times and a

large reduction in the energy stored in the system, as

compared to shielded hoses. However, without the

ground shield, a weak static charge can occasionally

build up on the outer surface of the hose. To minimize

any static charge felt on the hose surface, bundle t he air

and fluid hose together, and wrap with a pr otective

cover, as shown in F

Fig. 4. Bundling the Air and Fluid Hoses

12 309293N

IG. 4.

Fig. 6.

3. Generously apply dielectric grease (40) to the o-ring

(107) and the threads of the fitting (106). Pull the fitting back 1-1/2 in. (38 mm) and apply grease to the

exposed PTFE hose to fill the area between the

hose and the fitting. Make sure the barrel inlet is

clean and dry, then screw the fitting into the fluid

inlet of the gun barrel (16). See F

IG. 3.

4. Loosen the strain relief nut (102) so the br acket can

move freely on the hose.

5. Align the bracket (104) holes with the air inlet and

exhaust outlet. Secure with the air inlet fitting (35).

Tighten the strain relief nut (102) to secure the hose.

Page 13

6. Check that the nut (105) is tightened securely to th e

T

C

A 14.5 in. (368 mm)

B 0.75 in. (19 mm)

J

A

B

TI2166A

Shielded

Hose 245252

T

C

J

W

Z

L

See Warning at right.

T

C

A 12.0 in (305 mm)

J

A

TI2743A

Unshielded

Hose 246431

T

C

J

W

Z

L

See Warning below.

TI2744

A

ferrule housing (103).

7. Press the exhaust tube (38) onto the barbed

adapter (A). Secure with the clamp (39).

8. Connect the other end of the hose to the isola ted

fluid supply as follows:

a. Graco WB100 Enclosure: Slide hose through

the strain relief fitting (W). Ensure conductive

layer (C) has passed through fitting. Tighten to

55 in-lb (6.2 N•m). Pull back on hose to check it

is secure. Comply with the requirements in

Warning at right. See F

IG. 7. and FIG. 8..

Installation

Fig. 9.

Fig. 7. Waterborne Hose Dimensions (At Graco

WB100 Enclosure)

Fig. 8. Shielded Fluid Hose Connection at Graco

WB100

309293N 13

Fig. 10. Unshielded fluid connection

WARNING

Electric Shock Hazard

For Shielded hose systems:

Conductive hose layer (C) must be

grounded through its connection to the iso-

lation system’s grounded enclosure (L) or

grounded safety fence. To maintain grounding continuity, the conductive hose layer (C) must be engag ed

in the ferrule when the strain relief nut is tightened.

Failure to properly install the hose in the strain relief

could result in an electric shock.

TI1897A

b. Non-Graco Isolated Enclosure: Connect hose

as instructed in the isolation system manual,

and comply with the requirements in the Warn-

ing at right. Refer to F

IG. 11..

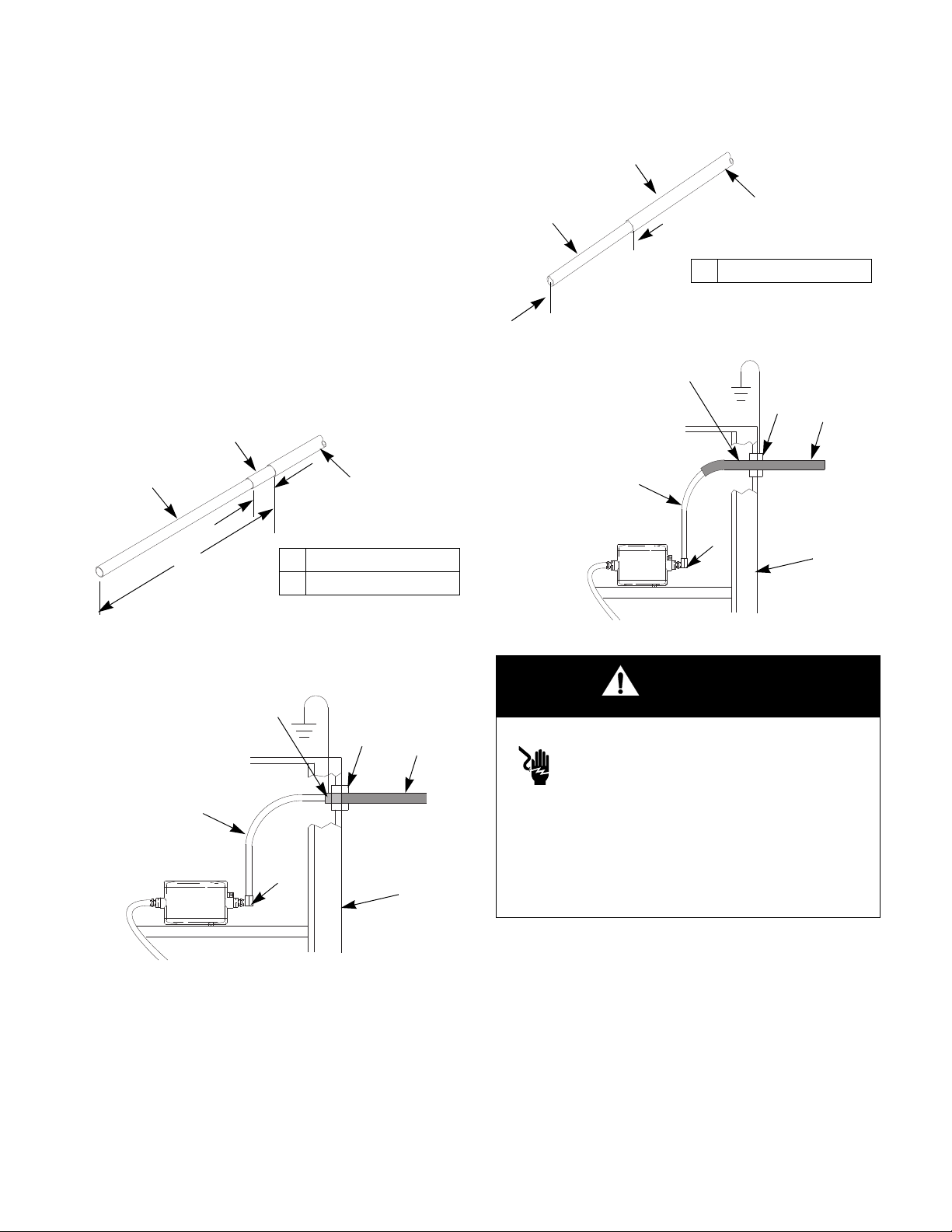

Page 14

Installation

T

J

L

C (see note above)

NOTE: Ground layer (C) of hose must

be grounded at isolation system.

401

406

403

404

406 (Ref)

407

402

TI2137A

Install tube A2 here

Connect to elbow (282)

inside control box (258)

408

TI1966A

Fig. 11. Shielded Fluid Hose Connection at Non-Graco Isolated Enclosure

c. Connect the end of the tube (T) to the pump

fluid outlet fitting (Z).

CAUTION

7. Assemble the other parts of the kit as shown.

Secure the agitator with the setscrew (408).

8. Return the system to service.

The Graco warranty is void if the spray gun is connected to a non-Graco voltage isolation system or if

the gun is operated above 60 kV.

CAUTION

Factory Mutual approval is valid only when this gun is

used with Factory Mutual approved voltage isolation

systems.

245895 Agitator Kit

To add an agitator to the Graco isolation system, order

Part No. 245895. See page 67 for the kit parts list.

1. Discharge the system voltage (page 20).

2. Relieve the pressure (page 20).

3. Open the isolated enclosure door.

Fig. 12. 245895 Agitator Kit

4. Remove the back of the control box (258).

5. Remove tube (A2) from elbow (282) at the air manifold; see the tubing diagram on page 64. Install the

Y fitting (402) into the elbow. Install tubes (A2) and

(407) into the Y fitting. See F

tor tube (407) into the cabinet.

6. Replace the back of the control box (258).

14 309293N

IG. 12.. Route the agita-

Page 15

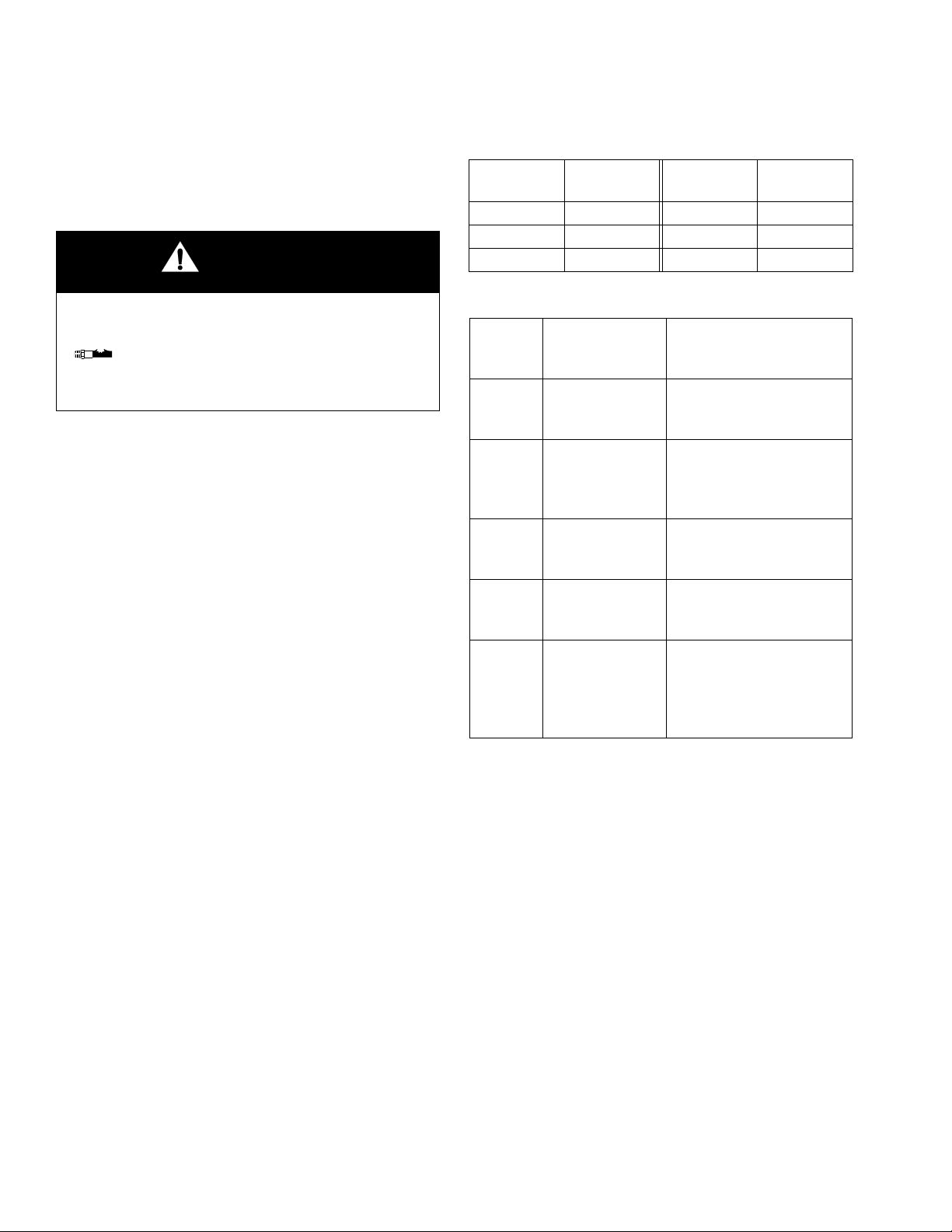

245944 Fluid Regulator Kit

TI2149A

501

502

503

504

505

506

507

Connect

tube A2

here

S

Tube A1

Connect water-

borne fluid

hose here

Connect to elbow (282) inside control

box (258)

To add a fluid regulator to the Graco isolation system,

order Part No. 245944. See page 68 for the kit parts list.

1. Discharge the system voltage (page 20).

2. Relieve the pressure (page 20).

3. Open the isolated enclosure door.

4. Remove the 1/4 OD tube (A1) from the pump air

inlet; see the tubing diagram on page 64.

5. Remove the waterborne fluid hose from the pump

fluid outlet fitting (231) and remove the fittin g.

Installation

6. Unscrew the two pump mounting screws (S, F

IG.

13.) and remove the pump from the isolation enclosure.

7. Remove the back of the control box (258).

8. Remove tube (A2) from elbow (282) at the air manifold; see page 64. Install the Y fitting (506) in the

elbow. Install tubes (A2) and (507) into the Y fitting.

Route the tube (507) into the cabinet.

9. Replace the back of the control box (258).

10. Assemble the fluid regulator kit as shown in F

IG. 13..

11. Reinstall the pump in the isolation enclosu re. U se

the two mounting holes to the left of the holes used

previously, to allow clearance for the fluid regulator.

12. Connect tube (A1) to the air inlet of fluid regulator

(504). Connect tube (507) to the pump air inlet.

13. Connect the waterborne fl uid hose to the fluid regulator outlet fitting (501).

Fig. 13. Fluid Regulator Kit

14. Return the system to service.

NOTE: The cabinet air regulator and gauge (216, 217)

will now operate the air piloted fluid regulator (504). The

pump will now operate at the inlet air pressure.

309293N 15

Page 16

Installation

Select a Fluid Nozzle and Air Cap

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on page 20

before removing or installing a fluid nozzle

and/or air cap.

The gun is supplied with Part No. 197266 Nozzle and

24A276 Air Cap. If you require a different size, refer to

Table 1 and Table 2 , and instruction manual 309419, or

consult with your Graco distributor. See Air Cap/Nozzle

Replacement on page 42.

A wide pattern kit (P/N 24A431) is included with the gun

and if installed, will provide fan air for wider spray patterns. (If pattern becomes split, use the fan air valve to

reduce the amount of fan air.)

Table 1: Fluid Nozzles

Part No.

197263 0.75 (.030) 197266 1.5 (.055)

197264 1.0 (.042) 197267 1.8 (.070)

197265 1.2 (.047) 197268 2.0 (.080)

Size,

mm (in.)

Part No.

Size,

mm (in.)

Table 2: Air Caps

Part No.

24A438

24A279

24A376*

24A274

24A439

Pattern Shape

and Length in.

(mm)

Round end;

15-17 (381-432)

Round end;

14-16 (356-406)

Tapered end;

17-19 (432-483)

Tapered end;

12-14 (305-356)

Round end;

11-13 (279-330)

Recommended Fluids and

Production Rates

Light to medium viscosity.

Up to 15 oz/min (450

cc/min)

Medium to high viscosity

and high solids.

Up to 15 oz/min (450

cc/min)

Light to medium viscosity.

Up to 15 oz/min (450

cc/min)

Light to medium viscosity.

Up to 15 oz/min (450

cc/min)

Medium to high viscosity

and high solids.

Up to 15 oz/min (450

cc/min)

For use with 2.0 mm nozzle.

*Also available in the following colors:

24A276 - blue

24A277 - red

24A278 - green

16 309293N

Page 17

Installation

ti1259a

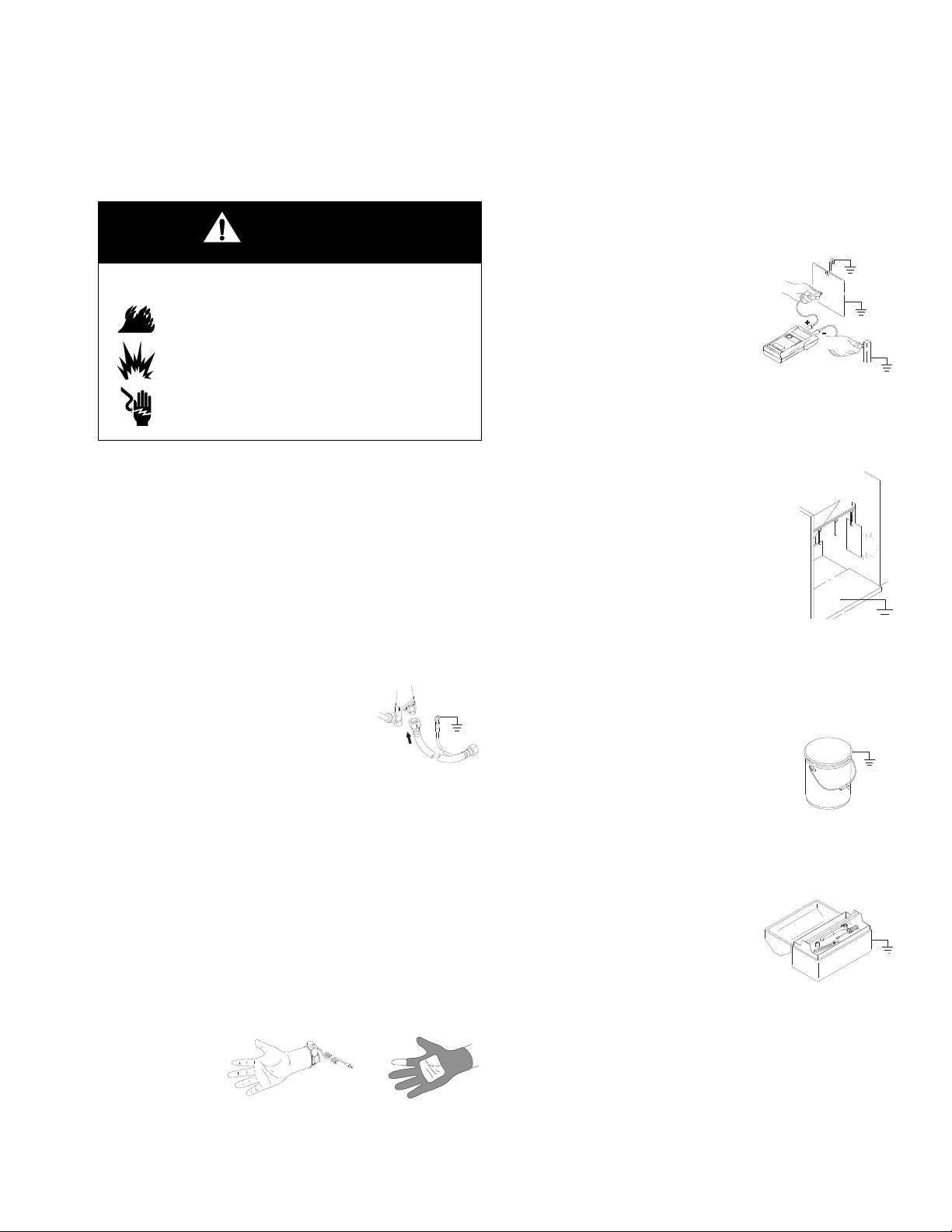

Grounding

WARNING

Fire, Explosion, and Electric Shock Hazard

When operating the electrostatic gun, any

ungrounded objects in the spray area (people, containers, tools, etc.) can become

electrically charged. Improper grounding

can result in static sparking, which can

cause a fire, explosion, or electric shock.

Follow the grounding instructions below.

The following are minimum grounding requirements for

a basic electrostatic waterborne system. Your system

may include other equipment or objects which must be

grounded. Check your local electrical code for detailed

grounding instructions. Your system mu st be co nnected

to a true earth ground.

• Voltage Isolation System: electrically connect to a

true earth ground, as instructed in the voltage isolation system manual.

• Object being sprayed: keep the workpiece hangers

clean and grounded at all times. Resistance must

not exceed 1 megohm.

• The floor of the spray area: must be electrically con-

ductive and grounded. Do not cover the floor with

cardboard or any non-conductive material which

would interrupt grounding continuity.

• Electrostatic Air Spray Gun: ground the gun by con-

necting the red-colored Graco Grounded Air Hose

and connecting the air hose ground wire to a true

earth ground. See Check Electrical Grounding,

page 18.

• Graco Waterborne Fluid Hose: the hose is gr ounded

through the conductive layer. Install the hose as

instructed on page 11.

• All persons entering the spray area: shoes must

have conductive soles, such as leather, or personal

grounding straps must be worn. Do not wear shoes

with non-conductive soles such as rubber or plastic.

If gloves are necessary, wear the condu ctive gloves

that are supplied with the gun. If non-Graco gloves

are worn, cut off fingers or palm area of glove to

ensure your hand contacts the grounded gun handle.

• All solvent pails: use only grounded metal pails,

which are conductive. Do not use plastic containers.

Do not place the pail on a non-conductive surface

such as paper or cardboard. Do no t store more than

the quantity needed for one shift.

• All electrically conductive objects or devices in the

spray area: including fluid containers, tools, and

wash cans, must be properly grounded.

309293N 17

Page 18

Installation

ti1259a

AA

BB

CC

TI2161A

TI2163A

AA

214

CC

Check Electrical Grounding

1. Have a qualified electrician check the electrical

grounding continuity of the spray gun and air hose.

2. Turn the ES ON/OFF valve OFF.

ES

I O

ti1273a

3. Turn off the air and fluid supply to th e gun. The flui d

hose must not have any fluid in it.

4. Make sure the red-colored grounded air hose (R) is

connected and the hose ground wire is connected to

a true earth ground.

7. Using an ohmmeter (AA), measure the re sist an ce

between the cabinet ground lug (214) and a true

earth ground (CC). See F

IG. 15.. The resistance

must be less than 100 ohms.

Fig. 15. Check Cabinet Grounding

5. Using an ohmmeter (AA), measure the resistance

between the gun handle (BB) and a true earth

ground (CC). The resistance should not e xceed 100

ohms. See F

IG. 14..

6. If the resistance is greater than 100 ohms, check th e

tightness of the ground connections and be sure the

air hose ground wire is connected to a true earth

ground. If the resistance is still too high, replace the

air hose.

Fig. 14. Check Gun Grounding

18 309293N

Page 19

Operation

Operation

Operating Checklist

Check the following list daily, before starting to operate the system, to help ensure you of safe, efficient operation.

All operators are properly trained to safely

operate an electrostatic waterborne air spray

system as instructed in this manual.

All operators are trained in the Pressure

Relief Procedure on page 20.

The electrostatics are turned off and properly

grounded according to the.Fluid Voltage Dis-

charge and Grounding Procedure on page

20 before any person enters the safety enclosure, before cleaning, and before performing

any maintenance or repair.

The system is thoroughly grounded and the

operator and all persons entering the spray

area are properly grounded. See Grounding

on page 17.

Fluid Hose is in good condition with no cuts or

abrasions of the PTFE layer. Replace hose if

damaged.

Ventilation fans are operating properly.

Workpiece hangers are clean and grounded.

All debris, including flammable fluids and rags,

is removed from the spray area.

Only fluids with a flash point above 140F

(60C) and a maximum organic solvent concentration of 20%, by weight, may be in the

spray area.

All conductive objects in the spray area are

electrically grounded and the floor of the spra y

area is electrically conductive and grounded.

309293N 19

Page 20

Operation

ti1289a

Fluid Voltage Discharge and Grounding Procedure

WARNING

Electric Shock Hazard

The fluid supply is charged with high voltage until the voltage is discharged. Contact

with the charged components of the isola-

tion system or spray gun electrode will

cause an electric shock. To avoid an electric shock,

follow the Fluid Voltage Discharge and Grounding

Procedure:

• whenever you are instructed to discharge the

voltage

• before cleaning, flushing, or servicing the syst em

equipment

Pressure Relief Procedure

WARNING

Pressurized Equipment Hazard

The system pressure must be manually

relieved to prevent the system from starting

or spraying accidentally. To reduce the risk

of an injury from electric shock, accidental spray from

the gun, splashing fluid, or moving parts, follow the

Pressure Relief Procedure whenever you:

• are instructed to relieve the pressu re

• stop spraying

• check or service any of the system equipment

• or install or clean the fluid nozzle.

• before approaching the front of the gun

• or before opening the safety enclosure for the

isolated fluid supply.

1. Turn the ES ON/OFF valve OFF and wait 30 seconds.

ES

I O

ti1273a

2. Remove the door T-handle locking screw. This will

shut off the air to the gun and trigger the grounding

cylinder to discharge any remaining electrical

charge.

3. Use the grounding rod to touch the pump and su pply pail. If you see any arcs, see Electrical Trouble-

shooting on page 39.

1. Turn the ES ON/OFF valve OFF.

ES

I O

ti1273a

2. Follow the Fluid Voltage Discharge and Ground-

ing Procedure at left.

3. Turn off the main air supply valve (B).

4. Trigger the gun into a grounded metal was te co ntainer to relieve the air and fluid pressure.

ti1276a

5. Relieve fluid pressure in the fluid supply unit as

instructed in your fluid supply unit manual.

20 309293N

Page 21

Fill the Fluid Supply

Operation

1. Discharge the system voltage (page 20).

2. Relieve the pressure (page 20).

ti1276a

3. Open the isolated enclosure door.

4. Remove the pail cover from the pail, holding a rag

over the suction tube strainer to prevent any fluid

from dripping into the isolated enclosure. Place the

cover and suction tube outside the enclosure.

5. Remove the supply pail from the enclosure.

CAUTION

Be sure to wipe up all fluid spills in the isolated enclosure. Fluid can create a conductive path and caus e

the system to short out.

6. Clean up any fluid spills in the enclosure, using a

soft cloth and a non-flammable, compatible solvent.

7. Fill the supply pail with fluid and return it to the

enclosure. Clean up any spills.

8. Reinstall the pail cover, holding a rag over the suction tube strainer to prevent fluid spills while you

place the pump suction tube in the pail.

WARNING

Fire and Explosion Hazard

To reduce the risk of fire and explosion, only

use this equipment with fluids that meet at

least one of the following conditions for

non-flammability:.

• The fluid has a flash point above 140F (60C)

and a maximum organic solvent concentration of

20%, by weight, per ASTM Standard D93.

• The fluid does not sustain burning when tested

per ASTM Standard D4206 Sustained Burn Test.

WARNING

Electric Shock Hazard

Contact with the charged components of

the spray gun will cause an electric shock.

Do not touch the gun nozzle or electrode or

come within 4 in. (102 mm) of the front of the gun

during operation or until performing the Fluid Voltage

Discharge and Grounding Procedure on page 20.

Follow the Fluid Voltage Discharge and Grounding

Procedure on page 20 when you stop spraying and

whenever you are instructed to discharge the volta ge.

9. Close the isolated enclosure door and fasten

securely with the T-handle locking screw.

WARNING

Adjust the Spray Pattern

Follow the steps below to establish the correct fluid flow

and air flow.

309293N 21

Component Rupture Hazard

To reduce the risk of component rupture,

which can cause serious injury, do not

exceed the maximum working pressure of

the lowest rated system component. This equip ment

has a 100 psi (0.7 MPa, 7 bar) maximum working air

and fluid pressure.

Page 22

Operation

Vertical Pattern

Horizontal Pattern

ti1269a

100

%

KV

μα

0

HI

LO

ES

I O

ES

ti1272a

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on page 20

whenever you are instructed to relieve the

pressure.

4. Fully open the fan air adjustment valve.

1. Make sure the ES ON/OFF valve is OFF.

ES

I O

ti1273a

2. Turn on the main air supply valve (B).

3. Position the air cap by loosening the air cap retaining ring, and rotating the air cap for a vertical or horizontal spray pattern. Tighten the retaining ring until

the air cap is held firmly in place; you should not be

able to rotate the air cap horns by hand.

5. Fully open the fluid adjustment valve .

0

KV

μα

HI

LO

ES

ES

I O

6. Fully open the atomizing air restrictor valve .

7. Make sure the ES ON/OFF valve is OFF.

100

%

ti1267a

22 309293N

ES

I O

ti1273a

Page 23

Operation

TI1760A

8-12 in. (200-300 mm)

TI1281A

ti1282a

8. Adjust the pump air regulator to start the f luid supply

unit. Adjust the fluid flow with the air pressure regulator until the stream from the gun travels 8-12 in.

(200-300 mm) before falling off. Typically, if fluid

pressure is below 5 psi (.04 MPa, 0.4 bar) or above

20 psi (0.14 MPa, 1.4 bar), a change of nozzle size

is recommended. Refer to instruction manual

309419 to set the fluid pressure for various fluid

flows, according to the size of the fluid no zzle be ing

used.

9. Set the gun air regulator to deliver a minimum 40 psi

(0.28 MPa, 2.8 bar) at the gun when trig gered, for

maximum transfer efficiency. See Table 3 .

10. Spray a test pattern. Check the atomization. If overatomization occurs at minimum pressure, ad just the

air atomizing restrictor valve. If atomization is inadequate, increase the air pressure.

11. Adjust the fan air adjustment valve: clockwise for a

rounder pattern, counterclockwise for a wider pattern.

Table 3: Air Regulator Settings

Air Hose Length

ft (m)

(5/16 in. [8 mm] diameter)

15 (4.6) 50 (0.35, 3.5)

25 (7.6) 60 (0.42, 4.2)

50 (15.3) 75 (0.52, 5.2)

NOTE:

• For the most efficiency, always use the lowest air

pressure possible.

• When increasing to a wide, flat pattern, it may be

necessary to increase the supply of fluid to the gun

to maintain the same amount of coverage ove r a

large area.

Air Regulator Setting

psi (MPa, bar)

(with gun triggered)

WARNING

Electric Shock Hazard

When the ES ON/OFF switch is turned ON,

the fluid supply is charged with high voltage

until the voltage is discharged. Contact with

the charged components of the spray gun

will cause an electric shock. Do not touch the gun

nozzle or electrode or come within 4 in. (102 mm) of

the front of the gun during operation.

12. Turn the ES ON/OFF switch ON (I).

ES

I O

ti1283a

ti1284a

309293N 23

Page 24

Operation

ti1253a

100

%

KV

μα

0

HI

LO

ES

I OI O

ES

ti1285a

13. Check that the ES indicator or display is lit , or check

that the kV indicator on the isolated enclosure reads

45-55 kV. If not, see Electrical Troubleshooting on

page 39 for possible problems.

ES

I O

ti1266a

14. Check the kV meter on the isolated enclosure;

45-55 kV is normal.

15. Spray a test piece. Examine the edges f or coverage.

If wrap is poor, see Spray Pattern Troubleshoot-

ing on page 37.

16. When you finish spraying, perform the Shutdown

procedure on page 25.

24 309293N

Page 25

Operation

ti1288a

100

%

KV

μα

0

ti1529a

53

12

ON

OFF

Shutdown

1. Discharge the system voltage (page 20).

2. Flush the spray gun. See page 26.

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on whenever

you are instructed to relieve the pressure.

3. Relieve the pressure (page 20).

ti1276a

2. Remove the LO VOLTAGE adjustment plug (53). Set

the desired voltage, using a small screwdriver to

slide switches 1 and 2 ON or OFF, according to

Table 4 . Also see F

IG. 16..

Fig. 16. Low Voltage Adjustment Switches

Table 4: Low Voltage Adjustment

12kV

ON ON 50

Factory Setting >ON OFF 40

OFF ON 35

OFF OFF 30

ti1276a

4. Hang the gun from its hook or place it in the accessory holster, with the nozzle pointing down. Be sure

to keep the gun from grounding out.

Low Voltage Adjustment (Smart Guns Only)

The ES HI/LO switch enables you to switch between full

voltage and a lower voltage output. The lower voltage is

factory set, but can be adjusted.

1. Set the ES HI/LO switch to LO.

309293N 25

Page 26

Maintenance

ti1288a

Maintenance

Flush the Spray Gun

Flush the gun before changing colors, at the end of the

day, before storing, and before repairing the gun.

WARNING

Fire, Explosion, and Electric Shock Hazard

To reduce the risk of fire, explosion, or electric shock, turn the ES ON/OFF valve OFF

before flushing the gun.

Follow the Fluid Voltage Discharge and

Grounding Procedure on page 20 before

flushing.

Only flush, purge, or clean the gun with fluids that

meet at least one of the following conditions for

non-flammability:

1. Turn the ES ON/OFF valve OFF and wait 30 seconds for the voltage to bleed off.

ES

I O

ti1273a

2. Discharge the system voltage (page 20).

3. Relieve the pressure (page 20).

ti1276a

4. Change the fluid source to solvent.

5. Point the gun into a grounded metal pail. Flush until

clean solvent flows from the gun.

• The fluid has a flash point above 140F (60C)

and a maximum organic solvent concentration of

20%, by weight, per ASTM Standard D93.

• The fluid does not sustain burning when tested

per ASTM Standard D4206 Sustained Burn Test.

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on page 20

whenever you are instructed to relieve the

pressure.

ti1276a

6. Relieve the pressure.

ti1276a

7. Open the isolated enclosure door. Leave the flushing fluid in the system until you are ready to spray

again.

8. Hang the gun from its hook, with the nozzle po inting

down. Be sure to keep the gun from grounding out.

9. Before using the system electrostatically again,

make sure no flammable vapors are present.

26 309293N

Page 27

Daily Care and Cleaning

ti1295a

Maintenance

CAUTION

• Clean the outside of the gun daily with a soft cloth

dampened with a non-flammable solven t, as

defined on page 26.

• Check for fluid leaks. Tighten all fittings.

• Clean the air cap and fluid nozzle daily, minimum.

See page 29. Some applications require more frequent cleaning.

• Fluid in the air passages could cause the gun to

malfunction and could draw current and reduce the

electrostatic effect. Fluid in the power supply cavity

can reduce the alternator life. Do not use any

cleaning method which could allow fluid into the

gun air passages.

• Hang the gun with its nozzle pointing down when it

is not being used.

• Clean the workpiece hangers with non-sparking

tools.

• Clean the fluid and air line filters daily.

Do not immerse the gun in fluid.

ti1294a

• Check the movement of the trigger and valves.

Lubricate if necessary.

Do not point the gun up while cleaning it. Do not wipe the gun with a cloth that is heavily satu-

rated; wring out the excess fluid.

ti1293a

309293N 27

Page 28

Maintenance

240

• Inspect the cabinet and clean up any spilled paint.

Conductive paint residue allowed to contact

grounded parts may short out the electrostatics.

• Keep the inside of the cabinet clean, for proper

operation.

• Visually inspect the ground strip (240) for damage.

Replace if needed. Measure the resistance weekly.

See page 33.

CAUTION

28 309293N

Page 29

Maintenance

ti1297a

9

27

29

7

Clean the Air Cap and Fluid Nozzle

Equipment Needed

• soft bristle brush

• non-flammable solvent

Procedure

1. Turn the ES ON/OFF valve OFF. Wait 30 seconds.

ES

I O

ti1273a

2. Discharge the system voltage (page 20).

3. Relieve the pressure (page 20).

NOTE: If it appears that there is paint inside the fluid

nozzle (7) air passages, remove the gun from the line for

servicing.

7. Carefully install the air cap (9). Be sure to insert the

electrode (29) through the ce nter hole of the air cap.

Rotate the air cap to the desired position.

8. Tighten the retaining ring (27) until the air cap is

held firmly in place; you should not be able to rotate

the air cap horns by hand.

9. Test gun resistance, page 30.

ti1276a

4. Remove the retaining ring (27) and air cap (9 ). See

IG. 17..

F

CAUTION

Do not use metal tools to clean the

air cap or fluid nozzle holes as this

could scratch them, and make sure

the electrode is not damaged.

Scratches in the air cap or nozzle or

a damaged electrode can distort the

spray pattern.

5. Clean the air cap (9) with the soft bristle brush and

non-flammable solvent or submerge the air cap in

solvent and wipe it clean.

6. With the gun pointing down, clean the fluid nozzle

(7) and the front of the gun with a soft brush dampened with non-flammable solvent.

Fig. 17. Clean Air Cap and Fluid Nozzle

Grease Door Latch Threads

Inspect the door T-handle locking screw regularly, to

ensure the threads are well greased. Apply silicone-free

grease to the threads when necessary.

309293N 29

Page 30

Electrical Tests

TI1688B

AA

35

29

Electrical Tests

Electrical components inside the gun af fect performance

and safety. The following procedures test the condition

of the power supply (18) and electrode (29), and electrical continuity between components.

Use megohmmeter Part No. 241079 (AA) and an

applied voltage of 500 V. Connect the leads as shown.

WARNING

Fire, Explosion, and Electric Shock Hazard

Megohmmeter Part No. 241079 (AA-see

F

IG. 18.) is not approved for use in a haz-

ardous area. To reduce the risk of sparking,

do not use the megohmmeter to check electrical grounding unless:

•The gun has been removed from the hazardous area;

•Or all spraying devices in the hazardous

area are turned off, ventilation fans in the

hazardous area are operating, and there

are no flammable vapors in the area

(such as open solvent containers or

fumes from spraying).

Failure to follow this warning could cause

fire, explosion, and electric shock and r esult

in serious injury and property damage.

Test Gun Resistance

1. Prepare the gun for service as instructed on page

41.

2. Measure resistance between the electrode needle

tip (29) and the air swivel (35); it should be 117-137

megohms. If outside this range, go to the next test. If

you still have problems, refer to Voltage Loss Trou-

bleshooting on page 34 for other possible causes

of poor performance, or contact your Graco distr ibutor.

Fig. 18. Test Gun Resistance

30 309293N

Page 31

Test Power Supply Resistance

EE

18b

1. Prepare the gun for service as instructed on page

41.

2. Remove the power supply (18), page 46.

3. Remove the turbine alternator (19) f rom the power

supply, page 47.

4. Measure resistance from the power supply's ground

strips (EE) to the spring (18b). See F

5. The resistance should be 95-105 megohms. If outside this range, replace the power supply. If in

range, proceed to the next test.

6. Be sure the spring (18b) is in place before reinstalling the power supply.

IG. 19..

Electrical Tests

ti1599a

Fig. 19. Test Power Supply Resistance

309293N 31

Page 32

Electrical Tests

ti1499a

B

29

C

ti1548a

F29E

7a

Test Electrode Resistance

1. Prepare the gun for service as instructed on page

41.

2. Insert a conductive rod (B) into the gun barrel

(removed for the power supply test) and aga inst the

metal contact (C) in the front of the barrel.

3. Measure the resistance between the conductive rod

(B) and the electrode (29). The resist ance should be

20-30 megohms. See F

4. If in range, refer to Electrical Troubleshooting on

page 39 for other possible causes of poor performance, or contact your Graco distributor.

IG. 20..

5. Remove the electrode (29), page 43. Measure the

resistance between the contact (E) and the electrode wire (F). The resistance should be 20-30 megohms. If out of range, replace the electrode. See

IG. 21..

F

6. Make sure the metal contact (C) in the barrel, the

nozzle contact ring (7a, F

IG. 22.), and the electrode

contact (E) are clean and undamaged.

Fig. 21. Electrode

ti1513a

Fig. 22. Nozzle Conductive O-Ring

Fig. 20. Test Electrode Resistance

32 309293N

Page 33

Test Ground Strip Resistance

206

214

209

214

See FIG. 23.. Using an ohmmeter, measure the resistance between the latch housing (206) and the ground

lug (214). The ground strip is groun de d t hroug h t he ca rt

back to the ground lug. Resistance must be less than

100 ohms. If greater than 100 ohms, re place the groun d

strip (240).

Electrical Tests

Fig. 24. Test Cylinder Resistance

Fig. 23. Test Ground Strip Resistance

Test Cylinder Resistance

See FIG. 24.. Remove the enclosure door. Usin g an

ohmmeter, measure the resistance from the pump (209)

to the ground lug (214). Resistance must be less than

100 ohms. If greater than 100 ohms, re place the

grounding cylinder.

309293N 33

Page 34

Troubleshooting

Troubleshooting

Spray Gun

• Fluid leakage

WARNING

Electric Shock Hazard

Installing and servicing this equipment

requires access to parts which may cause

an electric shock or other serious injury if

the work is not performed properly. Do not install or

repair this equipment unless you are trained and

qualified.

Follow the Fluid Voltage Discharge and Grounding

Procedure on page 20 before checking or servicing

the system and whenever you are instructed to discharge the voltage.

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on page 20

before checking or servicing any part of the

system and whenever you are instructed to

relieve the pressure.

• Dielectric breakdown at the fluid hose connect ion or

fluid packings

• Not enough air pressure for the turbine

• Faulty power supply

• Excessive overspray on gun surfaces

• Fluid in the air passages

Waterborne Fluid Hose

• Dielectric failure of hose (pin-hole leak through

PTFE layer)

• Air gap in the fluid column between the gun and isolated fluid supply, causing a low voltage reading on

the isolation system voltage meter.

Voltage Isolation System

• Fluid leakage

• Dirty interior

Voltage Loss Troubleshooting

Normal spraying voltage for a system using the waterborne gun is 45-55 kV. The system voltage is lower due

to spraying current demands and voltage isolation system losses.

A loss of spraying voltage can be caused by a problem

with the spray gun, fluid hose, or voltage isolation system, since all of the system components are electrically

connected through the conductive, water b or ne fluid .

Before troubleshooting or servicing the voltage isolation

system itself, you need to determine which comp o nent

in the system is most likely causing a problem. Possible

causes include the following:

34 309293N

Page 35

Troubleshooting

Visual Check

First, check the system for any visible faults or errors to

help isolate whether the spray gun, fluid hose or voltag e

isolation system has failed. A voltage probe and meter,

part no. 236003, is helpful for diagnosing voltage problems and is required for some of the troubleshooting

tests that follow.

1. Check that all of the air and fluid tubes and hoses

are properly connected.

2. Check that the voltage isolation system valves and

controls are properly set for operation.

3. Check that the interior of the isolated enclosure is

clean.

4. Check that the spray gun and voltage isolation system have sufficient air pressure.

5. Check that the gun ES ON/OFF valve is in the ON

position and that the gun ES indicator light is on. If

the ES indicator light is not on, remove the spray

gun for service and complete the electrical test s on

pages 30- 32.

10. Inspect the entire system for any visible fluid leakage and repair any fluid leaks that are found. Pay

special attention to the following areas:

• Packing area of the spray gun

• Fluid hose: check for leakage or any bulges in the

outer cover, which may indicate an internal leak

• Internal voltage isolation system components

Tests

If you still have no voltage, separate the spray gun and

hose from the voltage isolation system and check

whether the gun and hose alone will hold voltage with

the following test.

1. Flush the system with water and leave the lines

filled with water.

2. Discharge the system voltage (page 20).

3. Relieve the pressure (page 20).

4. Disconnect the fluid hose from the voltage isolation

system.

6. Check that the voltage isolation system's enclosure

door is closed and that any safety interlocks are

engaged and working properly.

7. Make sure the voltage isolation system is in the “isolate” mode, where it is isolating the fluid voltage

from ground.

8. To eliminate air gaps in the fluid column, spray

enough fluid to purge the air out between the voltage isolation system and the spray gun. An air gap

in the fluid hose can break the electrical continuity

between the spray gun and the isolated fluid supply

and cause a low voltage reading on a voltage meter

connected to the isolated fluid supply.

9. Check the spray gun cover and barrel for accumu lated overspray. Excessive overspray can create a

conductive path back to the grounded gun handle.

Install a new gun cover and clean the exterior of the

gun.

NOTE: Avoid allowing any water to leak out of the fluid

hose as that could cause a significant air gap in the flui d

column up to the gun electrode, which can break the

conductivity path and conceal a potential failure area.

5. Position the end of the hose as far as possible away

from any grounded surface. The end of the h ose

must be at least 1 ft. (0.3 m) from any ground. Make

sure that no one is within 3 ft. (0.9 m) of the end of

the hose.

6. Turn the ES ON/OFF valve to ON and trigger the

gun just enough to turn on the air to the gun but not

the fluid. Measure the voltage at the gun electrode

with a voltage probe and meter.

7. Discharge the system voltage by waiting 30 seconds and then touching the gun electrode with a

grounded rod.

8. If the meter reading is 45 to 55 kV, the gun and fl uid

hose are okay, and the problem is in the voltage isolation system.

If the reading is below 45 kV, the problem is in the

gun or fluid hose.

309293N 35

Page 36

Troubleshooting

9. Flush the fluid hose and gun with enough air to dry

out the fluid passages.

10. Turn the ES ON/OFF valve to ON and trigger the

gun. Measure the voltage at the gun electrode with

a voltage probe and meter.

11. If the meter reading is 45-55 kV, the gun power supply is okay, and there is probably a dielectric breakdown somewhere in the fluid hose or gun. Continue

with step 12.

If the reading is below 45 kV, do the electrical tests

on page 30 to check the gun and power supply

resistance. If those tests show the gun and power

supply are okay, continue with step 12.

12. A dielectric breakdown is most likely in one of the

following three areas. Repair or replace the component that is failing.

• Fluid hose

Check for leakage or any bulges in the outer cover,

which may indicate a pin-hole leak through the

PTFE layer. Disconnect the fluid hose from th e gun,

and look for signs of fluid contamination on the outside of the PTFE portion of the fluid tube.

13. Before reassembling the gun, clean and dry the gun

fluid inlet tube. Repack the inner spacer of the fluid

packing rod with dielectric grease and reassemble

the gun.

14. Reconnect the fluid hose.

15. Check the gun voltage with the voltage probe and

meter before filling the gun with fluid.

Inspect the end of the hose connected to the voltage isolation system. Look for cuts or nicks.

Make sure the hose is properly stripped (see step 2

on page 12). Restrip or replace the hose.

• Fluid packings

Remove the packing assembly from the gun as

instructed on page 44, and look for signs of fluid

leakage or any blackened areas, which would indicate arcing is occurring along the packing rod.

• Fluid hose connection joint to the spra y gun

A breakdown at the fluid hose connection joint

would be caused by fluid leaking past the o-ring

seals on the end of the hose. Remove the hose at

the gun connection and look for signs of fluid leakage along the PTFE tube.

36 309293N

Page 37

Spray Pattern Troubleshooting

NOTE: Check all possible remedies in the Troubleshooting Chart before disassembling the gun.

NOTE: Some spray pattern problems are caused by the improper balance between air and fluid.

Problem Cause Solution

Fluttering or spitting spray. No fluid. Refill supply.

Loose, dirty, damaged nozzle/seat. Clean or replace nozzle, page 42.

Air in fluid supply. Check fluid source. Refill.

Improper spray pattern. Damaged nozzle or air cap. Replace, page 42.

Fluid buildup on air cap or nozzle. Clean. See page 29.

Troubleshooting

Fan air pressure too high. Decrease.

Fluid too thin. Increase viscosity.

Fluid pressure too low. Increase.

Fan air pressure too low. Increase.

Fluid too thick. Reduce viscosity.

Too much fluid. Decrease flow.

Streaks. Did not apply 50% overlap. Overlap strokes 50%.

Dirty or damaged air cap. Clean or replace, page 42.

309293N 37

Page 38

Troubleshooting

Gun Operation Troubleshooting

Problem Cause Solution

Excessive spray fog. Atomizing air pressure too high. Close restrictor valve some, or

decrease air pressure as low as possible; minimum 40 psi (0.28 MPa, 2.8

bar) needed at gun for full voltage.

Fluid too thin. Increase viscosity.

“Orange Peel” finish. Atomizing air pressure too low. Open atomizing air valve more or

increase gun air inlet pressure; use

lowest air pressure necessary.

Poorly mixed or filtered fluid. Remix or refilter fluid.

Fluid too thick. Reduce viscosity.

Fluid leaks from the fluid packing

area

Air leaks from the front of the gun Air valve (21) is not seating properly. Clean and service air valve; see

Fluid leakage from the front of the

gun

Gun does not spray Low fluid supply. Add fluid if necessary.

Dirty air cap Misaligned air cap (9) and fluid noz-

Worn packings or rod. Replace packings or rod; see page

45.

page 50.

Worn or damaged packing rod (26). Replace; see page 45

Worn fluid seat. Replace fluid nozzle and/or electrode

needle; see pages 42 to 43.

Loose fluid nozzle (7). Tighten; see page 42.

Damaged nozzle o-ring (7b). Replac e; see page 42.

Damaged air cap (9). Replace; see page 42.

Dirty or clogged fluid nozzle (7). Clean; see page 42.

Damaged fluid nozzle (7). Replace; see page 42.

Damaged fluid adjustment valve (25). Replace; see page 50.

Clean fluid buildup off air cap and

zle (7).

fluid nozzle seat; see page 29.

38 309293N

Page 39

Electrical Troubleshooting

Problem Cause Solution

Voltage still present at gun after following the Fluid Voltage Discharge

and Grounding Procedure

Poor wrap. ES ON/OFF valve OFF (0).* Turn ON (I).

ES ON/OFF valve is not turned OFF. Turn OFF.

Did not wait long enough for voltage

to discharge.

Air pocket in fluid line leaves fluid

near gun isolated.

Voltage isolation system failed. Service voltage isolation system.

Grounding cylinder not operating. Check resistance of grounding cylin-

Gun air pressure too low. Check air pressure to gun; minimum

Atomizing air pressure too high. Decrease.

Fluid pressure too high. Decrease.

Incorrect distance from gun to part. Should be 8-12 in. (200-300 mm).

Poorly grounded parts. Resistance must be 1 megohm or

Faulty gun resistance. See Test Gun Resistance on page

Fluid leaks from the packing (26d)

and causes a short.

Faulty turbine alternator. Be sure the plug is in place on the

The KV HI-LO lever is on LO. Check the lever actuation; replace if

Spilled paint, dried paint, or other

contaminants inside WB100 enclosure, causing a short circuit.

Wait longer before touching electrode

with grounded rod. Check for bleed

resistor failure.

Determine cause and correct. Purge

air from fluid line.

der, page 33. Replace if needed.

40 psi (0.28 MPa, 2.8 bar) needed at

gun for full voltage.

less. Clean workpiece hangers.

30.

Clean the packing rod cavity.

Replace the packing rod. See page

45.

back of the turbine alternator housing. Remove and test the turbine

alternator. See page 48.

needed.

Clean interior of enclosure.

Troubleshooting

309293N 39

Page 40

Troubleshooting

Problem Cause Solution

ES indicator or voltage/current dis-

ES ON/OFF valve OFF (0).* Turn ON (I).

play is not lit.

No power. Replace power supply. See page 47.

Voltage/current display stays red

Gun too close to part. Should be 8-12 in. (200-300 mm).

(smart guns only).

Check fluid resistivity. See Operation on page 19.

Dirty gun. Clean. See page 27.

Operator gets mild shock. Operator not grounded or is near

See Grounding on page 17.

ungrounded object.

Gun not grounded. See Check Electrical Grounding on

page 18 and Test Gun Resistance

on page 30.

A weak static charge has built up on

the surface of an unshielded fluid

hose. This is a charge on the hose

Bundle and wrap the air and fluid

hoses together. See Connect the

Waterborne Fluid Hose, page 11.

surface, not a failure of the hose insulation.

Operator gets shock from workpiece. Workpiece not grounded. Resistance must be 1 megohm or

less. Clean workpiece hangers.

* ES indicator light is off when the gun is triggered.

40 309293N

Page 41

Repair

Repair

Prepare the Gun for Service

WARNING

Fire, Explosion, and Electric Shock Hazard

To reduce the risk of a fire, explosion, or

electric shock:

•Follow the Fluid Voltage Discharge and

Grounding Procedure on page 20 and

be sure the ES ON/OFF valve is OFF

before flushing, checking, or servicing

the system and whenever you are

instructed to discharge the voltage.

•Clean all parts with a non-flammable fluid

as defined on the front cover of this manual.

•Do not service this equipment unless you

are trained and qualified.

• Check all possible remedies in Troubleshooting

before disassembling the gun.

• Use a vise with padded jaws to prevent damage to

plastic parts.

• Lubricate the power supply o-ring (18a), some packing rod parts (26), and certain fluid fittings with

dielectric grease (40), as specified in the text.

• Lightly lubricate o-rings and seals with non-silicone

grease. Order Part No. 111265 Lubricant. Do not

over-lubricate.

• Only use genuine Graco parts. Do not mix or use

parts from other PRO Gun models.

• Air Seal Repair Kit 244781 is available. The kit must

be purchased separately. Kit parts are marked with

an asterisk, for example (6*).

• Fluid Seal Repair Kit 244911 is available. The kit

must be purchased separately. Kit parts are marked

with a double asterisk, for example (26a**).

•Do not touch the gun nozzle or come within

4 in. (102 mm) of the nozzle during gun

operation or until you perform the Fluid

Voltage Discharge and Grounding

Procedure on page 20.

WARNING

Pressurized Equipment Hazard

To reduce the risk of injury, follow the Pressure Relief Procedure on page 20 before

checking or servicing any part of the system

and whenever you are instructed to relieve the pressure.

NOTE:

1. Follow the Fluid Voltage Discharge and Grounding Procedure on page 20.

2. Flush the gun, page 26.

3. Blow the fluid lines dry with air.

4. Relieve the pressure, page 20.

5. Disconnect the gun air and fluid lines at the isolation

system.

6. Remove the gun from the worksite. Repa ir area

must be clean.

309293N 41

Page 42

Repair

27

9

7

7a

7b

27a*

37

Air Cap/Nozzle Replacement

WARNING

CAUTION

Hold the front end of the gun up and trigger the gun

while removing the nozzle to help drain the gun and

prevent any paint or solvent left in the gun from entering the air passages.

1. Prepare gun for service, page 41.

2. Remove the retaining ring (27) and air cap (9 ). See

IG. 25..

F

3. Point gun up and squeeze trigger while removing

the fluid nozzle (7) assembly with the multi-tool (37).

Fire, Explosion, and Electric Shock Hazard

The nozzle contact ring (7a) is a conductive

contact ring, not a sealing o-ring. To reduce

the risk of sparking or electric shock, do not

remove the nozzle contact ring (7a) except

to replace it and never operate the gun with out the contact ring in place. Do not repla ce

the contact ring with anything but a genuin e

Graco part.

NOTE: Use non-silicone grease, Part No. 111265, on

the small o-ring (7b). Do not over-lubricate. Do not lubricate the contact ring (7a).

4. Lightly lubricate the o-ring (7b). Install it and th e

contact ring (7a) on the nozzle (7).

NOTE: Make sure the electrode needle (29) is fingertight (page 43).

5. Trigger gun while installing the fluid nozzle (7) with

the multi-tool (37). Tighten until the fluid no zzle

seats in the gun barrel (1/8 to 1/4 turn past

hand-tight).

6. Install the air cap (9) and retaining ring (27). Make

sure the u-cup (27a*) is in place with the lips facing

forward.

7. Test gun resistance, page 30.

ti1501a

Fig. 25. Air Cap/Nozzle Replacement

42 309293N

Page 43

Electrode Replacement

37

1. Prepare the gun for service, page 41.

2. Remove the air cap and nozzle, page 42.