Page 1

Instructions–Parts List

Coriolis Fluid Flow Meter

The meter and meter kit are intended for installation and use on a PrecisionMix II fluid

panel in non–hazardous environments only. If a Coriolis meter is installed on a

PrecisionMix II, the entire system is no longer approved for a hazardous environment.

Not approved for use in explosive atmospheres or hazardous locations.

For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual and

in your proportioner manual. Save these instructions.

5000 psi (34 MPa, 345 bar) Maximum Working Pressure

Part No. 116158 Bare Meter

.01 to 0.5 gpm (40 to 2,000 cc/min.) Flow Range.

309234H

EN

Part No. 244039 Meter Kit

Includes Part No. 116158 Bare Meter, mounting hardware, and fittings.

2300 psi (16 MPa, 160 bar) Maximum Working Pressure

Part No. 15D135 Bare Meter

.01 to 0.5 gpm (40 to 2,000 cc/min.) Flow Range.

II 2 G EEx de IIC

Part No. 15D599 Meter Kit

Includes Part No. 15D135 Bare Meter, mounting hardware, and fittings.

TI0624a

Page 2

Table of Contents

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagram 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Information 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 309234

Page 3

WARNING

SKIN INJECTION HAZARD

Spray from leaks, or ruptured components can inject fluid into your body and cause extremely serious

injury, including the need for amputation. Splashing fluid in the eyes or on the skin can also cause

serious injury.

Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate surgi-

cal treatment.

Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

Follow the Pressure Relief Procedure on page 6 whenever you: are instructed to relieve pres-

sure; stop operation; or clean, check, or service the equipment.

Tighten all the fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in fire or explosion and serious injury.

Ground the equipment as instructed in Grounding, page 5.

Never use the flow meter with an electrostatic gun isolation stand.

INSTRUCTIONS

Keep liquids away from the electronic sensor device.

Follow the material supplier recommendations when flushing or servicing the meter.

Do not service the electronic sensor. Return it to your Graco distributor for service.

If there is any static sparking while using the equipment, stop spraying immediately. Identify and

correct the problem.

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in serious injury.

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check the equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure of the lowest rated system component. See manual

cover for pressure rating.

Use fluids or solvents that are compatible with the equipment wetted parts. See the Technical

Data section of all the equipment manuals. Read the fluid and solvent manufacturer’s warnings.

Comply with all applicable local, state and national fire, electrical and other safety regulations.

309234 3

Page 4

WARNING

Installation

Mounting the Flow Meter

FIRE, EXPLOSION, AND ELECTRIC

SHOCK HAZARD

To reduce the risk of fire, explosion, or

electric shock:

All electrical equipment must only be installed

by a qualified electrician.

Understand and follow your local code and

safety regulations for hazardous location wiring

of explosion proof circuits.

Dust and Foreign Matter

Avoid having dust or foreign matter enter the flow

meter by taking the following precautions:

Thoroughly flush the fluid supply lines before

installing the flow meter.

When installing fittings, make sure that no sealing

tape overlaps into the inside of the pipe.

Installing the Flow Meter

Flow volume can only be measured at the location

where the flow meter is installed.

CAUTION

The bare meter weighs 33 lb (15 kg). Do not mount

the meter in the fluid line without proper support, to

prevent stress on the fluid inlet and outlet connections. See Fig. 1.

TI0850A

Fig. 1

No special fittings or brackets are required for mounting. External vibration will not affect the accuracy of

the meter.

The meter is safe for Class I; Division 1; Group D

hazardous indoor (NEMA 1) locations when

installed in accordance to NEC power requirements.

Refer to ANSI standards ISA-RP12.6, NEC Article

504 and the Canadian Electrical Code Appendix F.

Do not use more than 200 ft (61 m) of cable.

To prevent turbulence and cavitation in the fluid line, be

sure the line is adequately sized and contains a minimal number of restrictions (such as valves or bends).

For mounting dimensions, refer to page 10.

Continued on page 5.

4 309234

Page 5

Installation

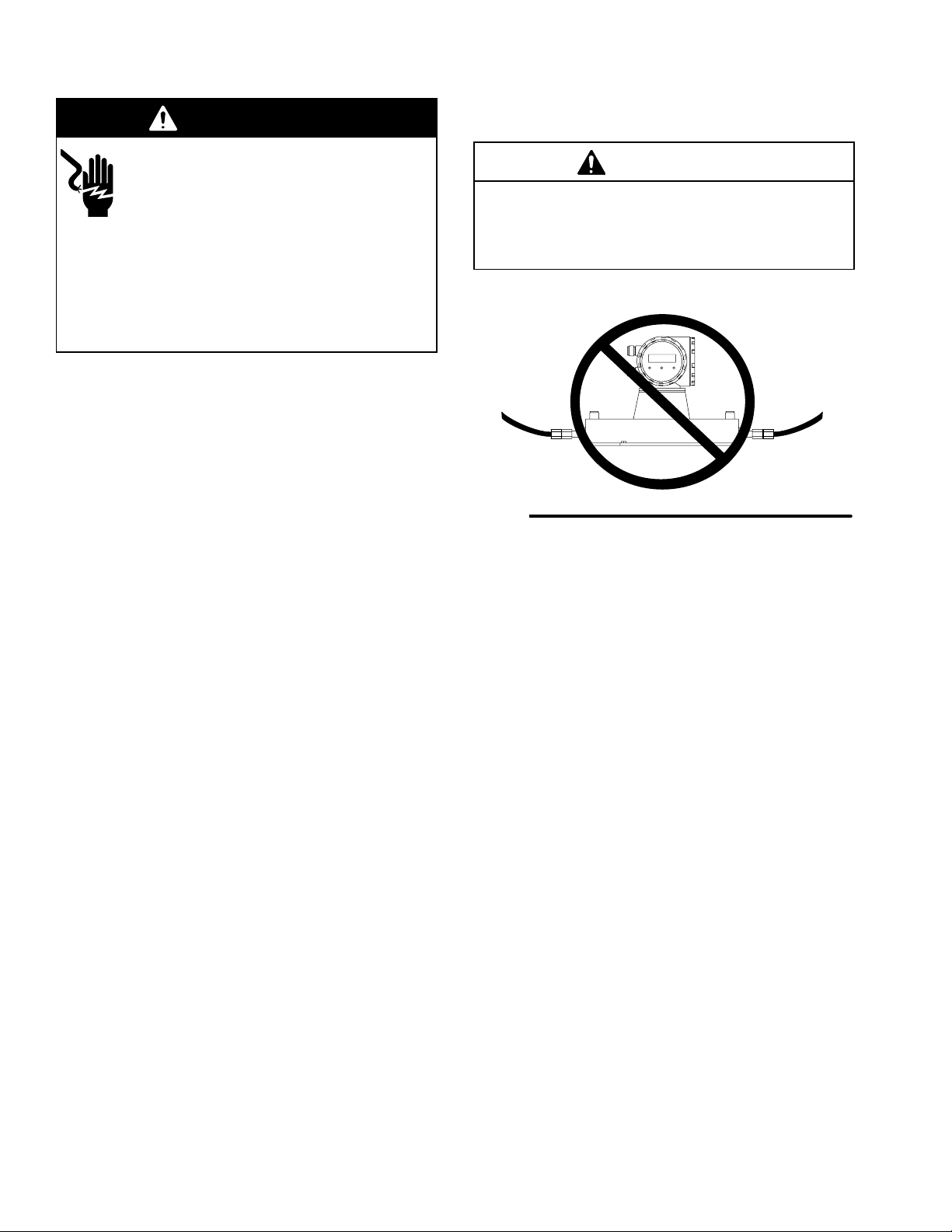

Vertical Mounting

When mounting on a vertical surface, the preferred

fluid flow is upward through the meter. See Fig. 2. This

allows solids to settle out and air to rise away from the

metering tube. This also allows thorough draining of

the meter during shutdown, to prevent fluid from drying

in the meter.

Downward flow is permitted if a check valve is installed

at the meter outlet to prevent fluid from falling through

the meter.

Do not mount the meter so the fluid line runs horizontally across the vertical mounting surface.

Grounding

WARNING

FIRE, EXPLOSION, AND ELECTRIC

SHOCK HAZARD

Proper electrical grounding of your

system is essential. For your safety,

read the warning section, FIRE, EXPLO-

SION, AND ELECTRIC SHOCK HAZARD, on

page 3.

1. Ground the flow meter by connecting a grounded

cable to the sensor. Part No. 116005 Cable is

available (must be ordered separately).

Have a qualified electrician check the electrical

grounding continuity between the flow meter

sensor and a true earth ground; remove the cable

connector from the sensor and measure the resistance from the cable connector Pin A to true earth

ground. Refer to the Wiring Diagram on page 12.

Fluid Flow Fluid Flow

Fig. 2

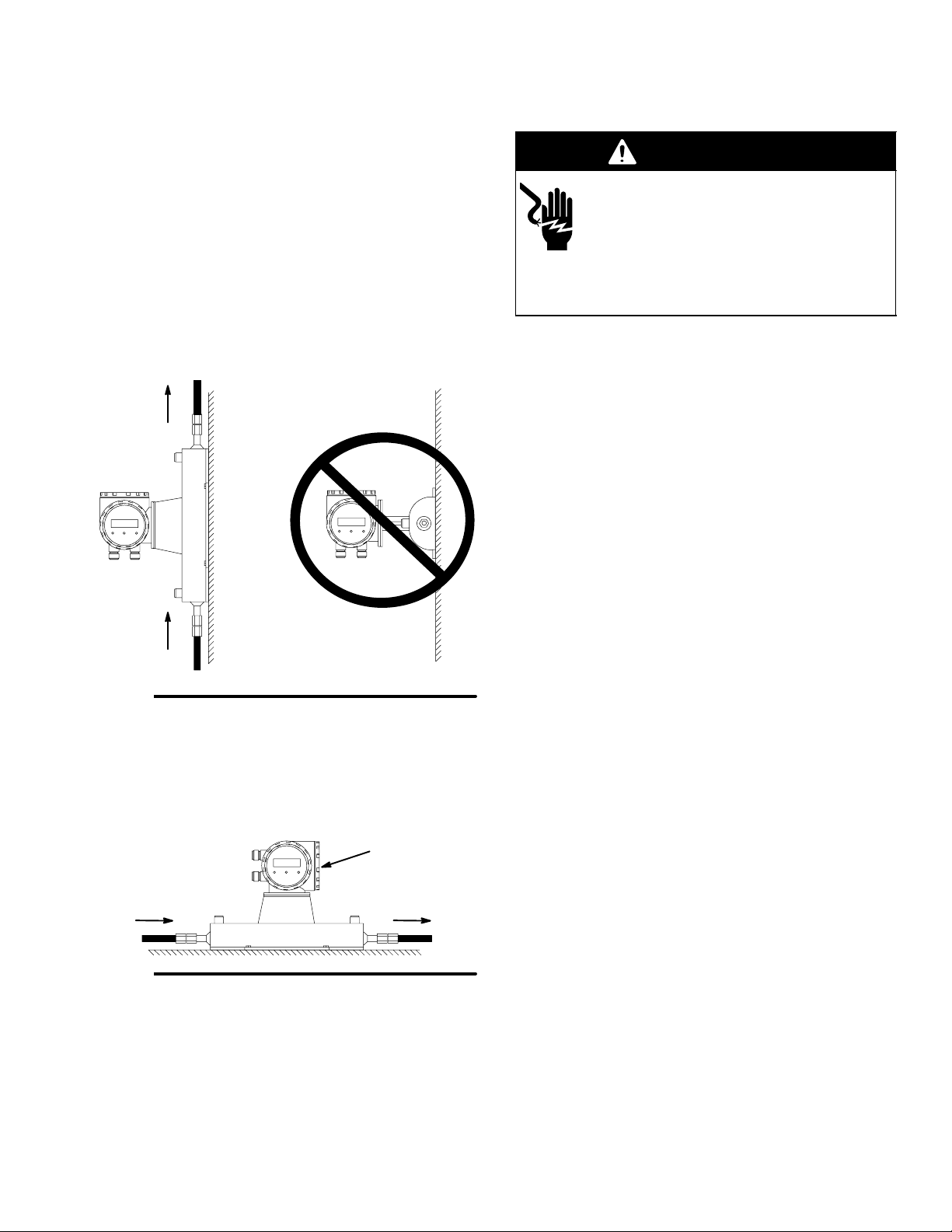

Horizontal Mounting

When mounting on a horizontal surface, the meter

transmitter must be either above or below the fluid line.

This ensures that solids do not collect and air does not

become trapped in the metering tube. See Fig. 3.

Transmitter

Fluid Flow

Fig. 3

Fluid Flow

TI0850A

TI0850A

If the resistance is greater than 25 ohms, check

the cable ground connection. Reconnect the

ground sheath or replace the cable. Do not operate the system until the problem is corrected.

2. Always ground the fluid supply unit, using one of

the following options:

a. Mount the meter to a grounded conductive

surface, or

b. Connect the conductive fluid hose to the meter

inlet and outlet, or

c. Connect a ground wire to the meter’s 1/4–20

unc mounting holes.

3. Never use the flow meter with an electrostatic gun

isolation stand.

309234 5

Page 6

Operation

Pressure Relief Procedure

WARNING

INJECTION HAZARD

The system pressure must be manually relieved to

prevent the system from starting or spraying accidentally. Fluid under high pressure can be injected

through the skin and cause serious injury. To

reduce the risk of an injury from injection, splashing

fluid, or moving parts, follow the Pressure Relief

Procedure whenever you:

are instructed to relieve the pressure,

stop spraying,

check or service any of the system equipment.

1. Turn off the fluid supply to the meter.

2. Shut off all electrical power to the fluid system.

3. Follow the Pressure Relief Procedure for your fluid

system dispensing device.

Flow Volume Range (60 Series)

The meter flow volume range is 0.01–0.5 gpm

(40–2,000 cc/min.).

Unscrew the meter cover to access the DIP switches.

The DIP switches must be set as shown in Fig. 4 to

ensure that the volume is 0.1 ml per pulse.

TI0851A

Fig. 4

Checking the Meter Accuracy (All)

1. To check the accuracy of the meter, turn your gun

fan and atomizing air off, then trigger the fluid into

a graduated cylinder; dispense at least 500 cc of

fluid.

2. Measure the volume of fluid in the beaker in cubiccentimeters (cc) and read the volume on the flow

meter/PrecisionMix II monitor.

Operating Mode (60 Series)

Recommended Usage

WARNING

COMPONENT RUPTURE HAZARD

Do not exceed the maximum working pressure of

your meter or any component or accessory in your

system.

See the Technical Data for fluid and ambient

temperature limits.

Only use the flow meter with fluids that are compat-

ible with the “Wetted Parts” listed in the Technical

Data.

Purge the meter housing as local codes require.

Unscrew the meter cover to access the DIP switches.

Set the ON switch to the DIP position for operation and

configuration. See Fig. 5.

DIP

Fig. 5

TI0851A

6 309234

Page 7

Operation

Using the ProMass 80A with a Graco

PrecisionMix II System

Generic Settings for Basic Installation with a

PrecisionMix II System

The function matrix is a two level construct: groups

and functions.

The groups, being the highest level, are compromised

by multiple functions. In order to select the individual

functions that will control or parameterize the measuring device, you must first select a group.

NOTE: For an overview of the functions available see

page 8.

1. Using the function matrix press to access

group options.

2. To scroll through the group options, press

or

.

3. To select a group option, press .

Once you select a group, the functions related to

that group will follow.

4. To scroll through functions, press

5. To select a function, press .

or

.

Measuring values

The following will list values per the E&H function

matrix. If a value isn’t mentioned, the the default E&H

settings will suffice.

The table below shows the minimum required settings

for use with a Graco PrecisionMix II system.

NOTE: To enable programming of the meter you will

need to enter the personal code. The factory setting is

80.

Group Parameter Value

System Units Volume Flow cc/m

Unit Volume cc

Totalizer Reset Total Yes

Current

Output

(Mass Flow)

Pulse/Freq.

Output

Process

Parameter

Assign

Current

Operation

Mode

Assign Pulse Volume

Pulse Value .119 cc/pulse

Pulse Width 1.000 ms

Output Signal Passive/Positive

On–Val.

Lf–Cut off

Off

Pulse

30.000 cc/min

6. To return back to the previous option, press

and

NOTE: Once you press , your selection is saved.

.

Maintenance

CAUTION

The fluid meter has no field-serviceable parts. Contact your Graco distributor for service.

309234 7

Page 8

Graphical Illustration of the Function Matrix

The table below shows a display of the total set values

available. The values in bold are the minimum required

setting for use with a Graco PrecisionMix II System.

UNIT PRESS URE

UNIT LENGTH

UNIT TEMPERATURE

UNIT DENSITY

TEST DISP LAY

CONTRAST LCD

DISPLAY DAMPING

FORMAT

ACTUAL FREQ.

FAILSA FE VALUE

VALUE SIM. CURR.

FAILS AFE MO DE

SIMULATION CURR.

FAILSAFE MODE

TIME CONSTANT

ACTUAL CURRENT

FAILS AF E MO DE

FAILS AF E MO DE

OUTPUT SIGN AL

VALU E F H IGH

TIME CONS TANT

RESET TOTAL

VAL. SIM. SWIT. PNT

SIM. SWITCH PO INT

OUTPUT SIGNAL

ACTUAL STATUS

PULSE WIDTH

VAL. SIM. STAT. IN

DEVICE ID

MANUFACTURER ID

WRITE PROTECTIO N

MEASURE FLUID

DENSITY SET VALUE

ZERO POINT A DJUST

EPD RESPO NSETIME

EPD VALUE HIGH

EPD VALUE LOW

DENSITY COE F. C 1

DENSITY CO EF. C 0

CAL. COEF. KD 2

CAL. COEF. KD 1

TEMP. COEF. KT

FLOW DAMPING

TEMP. COE F. KM 2

MAX. TEMP. CARR.

MIN. TEMP. CARR.

MAX. TEMP. MEAS.

MIN. TEMP. MEAS.

TROUBLESHOOTING

SYSTEM RESET

ALARM DELAY

ERROR CATEGORY

ASSIGN PRO C. ERR.

TEMPERATURE

DENSITY

VOLUME FLOW

MASS FLOW

MEASURING VALUES

8 309234

UNIT VOLUME

UNIT VOLUME

FLOW

UNIT MASS

UNIT MASS FLOW

SETUP COM MISSION

QUICK SETUP

SYSTEM

UNITS

100% VALUE

STAT US ACCESS

100% VALUE

DEF. PRIVAT E CODE

ASSIGN LINE 2

ACCESS CODE

LANGUAGE

ASSIGN LINE 1

OPERATION

USER INTERFACE

UNIT TOTALIZER

OVERFLOW

SUM

ASSIGN TOTALIZER

TOTALIZER

VALU E 20 m A

VAL UE F L OW

VALUE 0_4 mA

END VALUE FREQ.

CURRENT SPAN

ASSIGN FREQ UENCY

ASSIGN

CURRENT

OPERATION

CURRENT

OUTPUT

PULSE/FREQ.

PULSE VALUE

ASSIGN PULSE

VALUE SIM. FREQ.

MODE

SIMULATION FREQ.

OUT.

SIM. STATU S IN

TIME CONSTANT

OFF–VALUE

ON–VALUE

ASSIGN STATUS

STATUS OUTPUT

HART PROTOCOL

BUS ADD RESS

MIN. PULSE WIDTH

ACTIVE LEVEL

TAG DESCRIPT ION

TAG N AM E

ASSIGN STATUS IN

STATUS INPUT

COMMUNICATION

PRESSURE

EMPTY PIPE DET.

PRESSUR E MODE

OFF–VAL. LF–CUT OFF

ON–VAL

LF–OUT OFF

RESTORE ORIGINA L

DENSITY A DJUST

ASSIGN LF–CUT OFF

PROCESS

PARAM.

DENSITY DAMPING

POS. ZERO RETURN

MEASURING MODE

INSTL. DIR. SENS OR

SYSTEM PARAMETER

TEMP. COEF. KM

NOMINAL DIAMETER

ZERO POINT

K–FACTOR

SENSOR DATA

DENSITY COEF. C 5

DENSITY C OEF. C 4

DENSITY CO EF. C 3

DENSITY CO EF. C 2

ERROR CATEGORY

SW–REV. I/O

SW–REV. S–DAT

VALUE SIM. MEAS.

ASSIGN SY S. ERROR

SENSOR TY PE

PREV. SYS. COND

SIM. MEASURA ND

ACTUAL SYS. COND.

SIM. FAILSAFE MODE

SUPERVISION

SIMULAT. SYSTEM

I/O MO DUL TYPE

SW–REV. AMP.

SERIAL NUMB ER

SENSOR VER SION

AMP. HW VERSION

Page 9

Parts

Use Only Genuine Graco Parts and Accessories

Part No. 244039 and 15D599

Coriolis Meter Kit, for solvent-borne materials (0.8–2000 cps)

Ref.

No.

1 116158 METER, Coriolis; for solvent

2 196805 BRACKET, mounting 1

3 111647 CABLE, 4 conductor;

4 514030 CONNECTOR, cable 1

5 100643 SCREW, cap, socket head;

6 100021 SCREW, cap, hex head;

Part No. Description Qty.

and water-borne materials

that cannot be handled

through a gear meter

(244039 only)

15D135 METER, Coriolis; same as

above (15D599 only)

10 ft (3.05 m)

1/4–20 x 1 in. (25 mm)

1/4–20 x 1 in. (25 mm)

2

Ref.

No.

1

1

4

4

7 100015 NUT, hex; 1/4–20 4

8 105510 WASHER, lock, spring;

9 501687 VALVE, check 1

10 24N345 HOSE, fluid; PTFE;

11 115571 FITTING, adapter,

12 166846 FITTING, connector;

13 552269 FITTING, adapter;

Keep these spare parts on hand to reduce down

Part No. Description Qty.

4

1/4 in.

1

1/4 npsm(f)

1

1/4 bsp(m) x 1/4 npt(f)

2

1/4 npt x 1/4 npsm

2

1/4 npt x 1/4 #4 FAC

time.

12

13

3

5

7

8

6

9

NOTE: When fluid flow is downward through the meter,

a check valve (9) must be installed at the fluid outlet.

4

1

13

10

12

11

TI0623a

309234 9

Page 10

Dimensions

D

R

N

P

J

C

H

A

Dia

E

G

K

F

B

M

L

S

Four 0.26 in.

(6.6 mm) holes

Diameter

(ANSI)

1/8 in. 0.138 in.

J K L M N P R S T Weight

6.16 in.

(156 mm)

Dia. A B C D E F G H

(3.5 mm)

9.45 in.

(240 mm)

1.26 in.

(32 mm)

22.4 in.

(569 mm)

7.88 in.

(200 mm)

17.1 in.

(434 mm)

11.0 in.

(279 mm)

7.50 in.

(191 mm)

8.23 in.

(209 mm)

6.73 in.

(171 mm)

5.90 in.

(150 mm)

7.26 in.

(184 mm)

6.89 in.

(175 mm)

3.86 in.

(98 mm)

8.66 in.

(220 mm)

4.34 in.

(110 mm)

T

TI0852A

12.3 in.

(312 mm)

33 lb

(15 kg)

10 309234

Page 11

Technical Data for Bare Meter

Category Data

Maximum Working

Fluid Pressure

Flow Range 0.01–0.5 gpm

Fluid Temperature

Range

Maximum Ambient

Temperature

Fluid Viscosity Range 0.8–2000 cps

Maximum Cable

Length

Model 116158: 5000 psi

(34 MPa, 345 bar)

Model 15D135: 2300 psi

(16 MPa, 160 bar)

(40–2,000 cc/min)

40–180 F (4–80 C)

180 F (80 C)

200 ft (61 m)

Category Data

Flow Meter

Inlet/Outlet

Resolution ≈ 0.119 cc/pulse

Accuracy + 0.5 %*

Supply Voltage 24 Vdc

Wetted Parts 303 and 440C Stainless

* For most commonly used coatings, the flow meter reading

will be accurate to within +

low viscosities and low flow rates.

1/4 npt(f)

Steel, PTFE

0.5%. Accuracy will diminish at

309234 11

Page 12

Wiring Diagram for

PrecisionMix II and PrecisionMix II 3K

60 Series Meter Wiring Detail

1082

2021

1082

2021

A–4251, B–4271, C–4291

80 Series Meter Wiring Detail

1082

TI0625a

1082

2021

1082

2021

A–4251, B–4271, C–4291

12 309234

1082

TI0625a

Page 13

Notes

309234 13

Page 14

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 309234

GRACO INC. AND SUBSIDIARIES S P.O. BOX 1441 S MINNEAPOLIS, MN 55440–1441 S USA

14 309234

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

Copyright 2001, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

www.graco.com

Revised September 2012

Loading...

Loading...