Page 1

Instructions

Parts

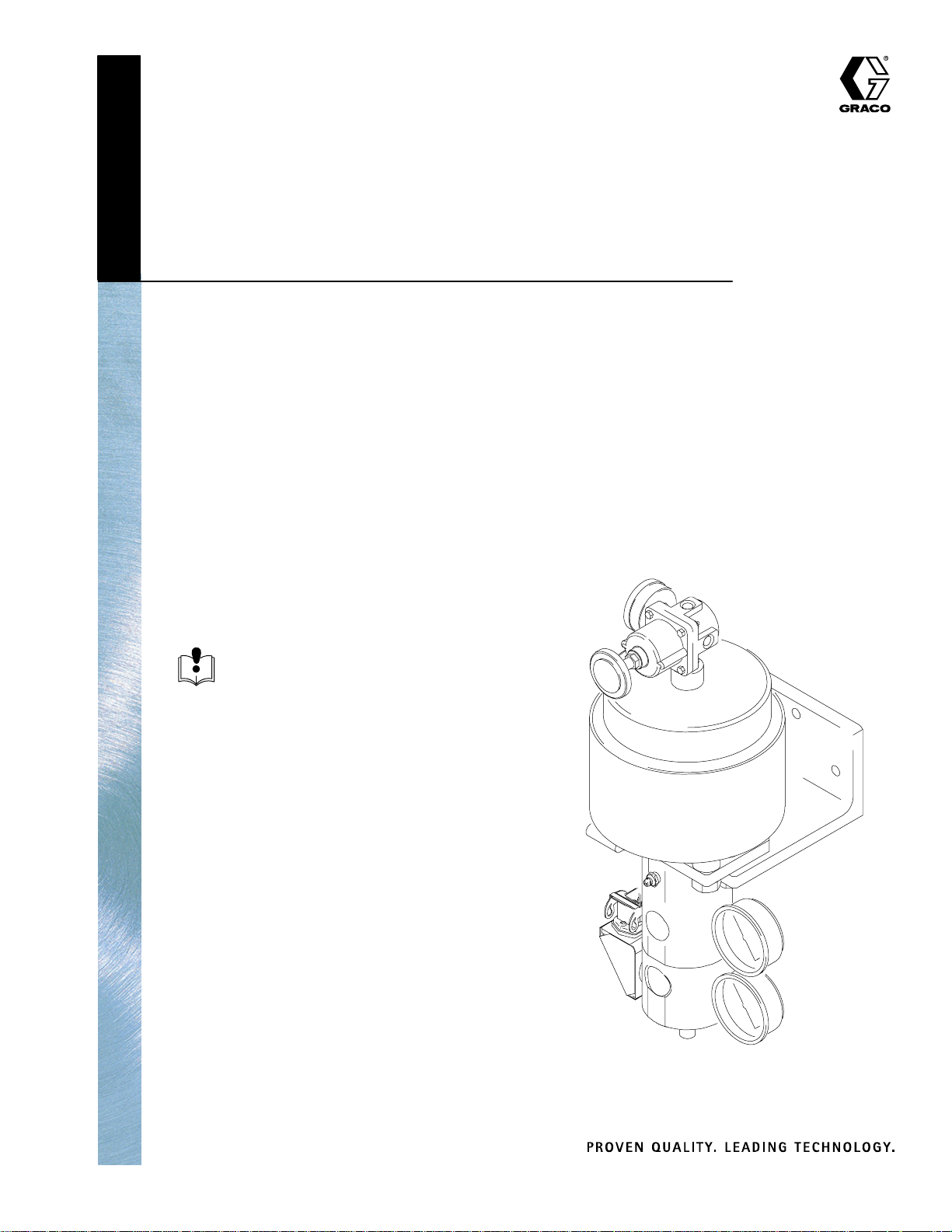

Pressure

Compensating Valve

The pressure compensating valve minimizes the effects of pressure changes from the fluid source and

reduces or eliminates material flow variances caused by piston pump changeover and unbalanced

pump lowers. Eliminating surge variations adds consistency to the application process.

The pressure compensating valve is used:

in applications requiring a consistent bead size throughout the dispense cycle.

to overcome the initial surge of material when the dispense valve is opened in a deadhead system.

with single component materials when viscosities are generally greater than 100,000 cps.

Read warnings and instructions.

See page 2 for compensator part nos., ratios,

and working pressures.

309133C

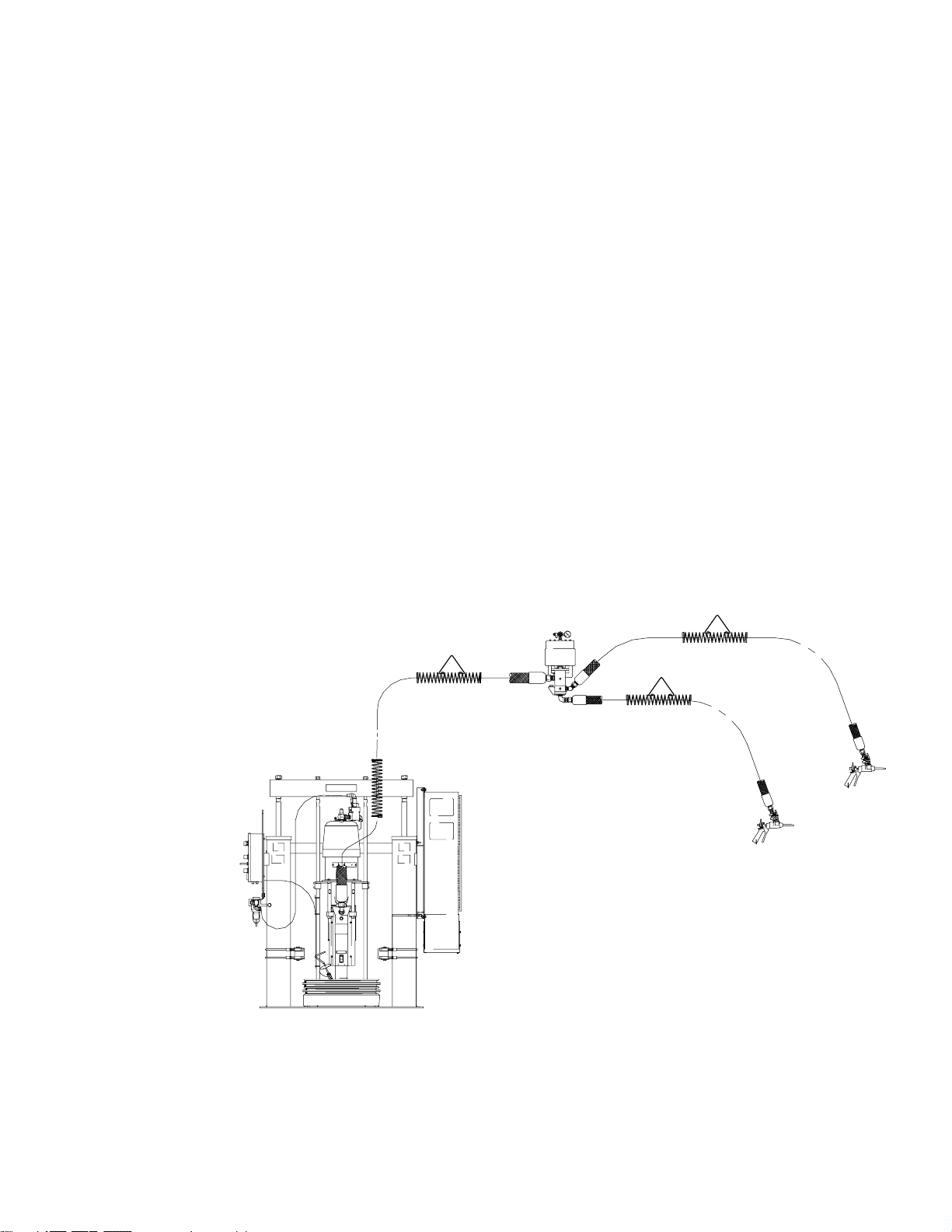

Model 243656 Shown

TI0368B

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 2000, Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Symbols 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compensator Models 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking and Repacking 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagram 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Kits and Accessories 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

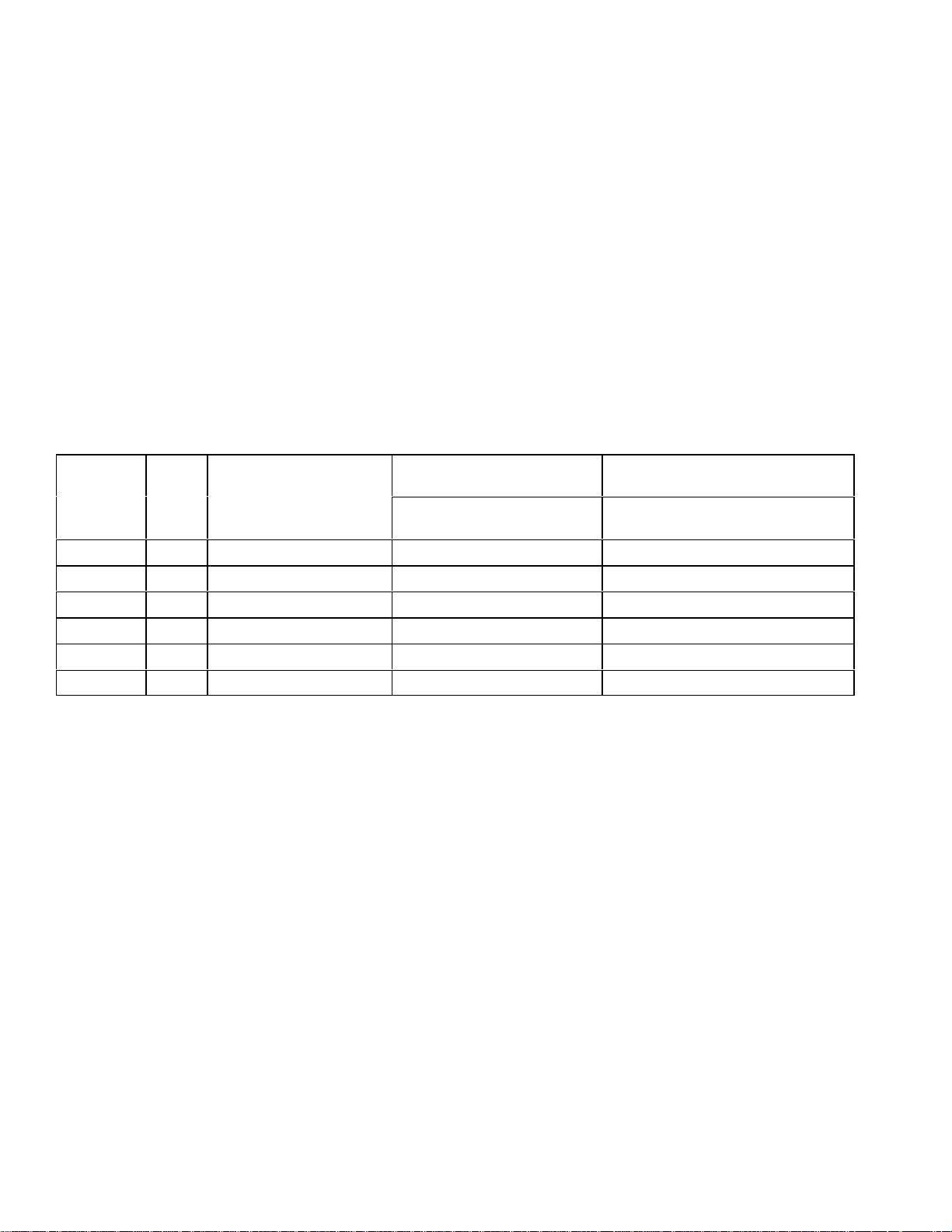

Compensator Models

Maximum Operating Air

Pressure

Ratio and Type

Part No. Series

243206 A 51:1 , Heated 120V 0.7, 7.0 (100) 23.8 , 238 (3500)

243654 A 51:1 Ambient 0.7, 7.0 (100) 23.8, 238 (3500)

243655 A 23:1 Ambient 0.7, 7.0 (100) 17.2 , 172.4 (2500)

243656 A 23:1, Heated 240 V 0.7, 7.0 (100) 17.2, 172.4 (2500)

243657 A 51:1, Heated 240 V 0.7, 7.0 (100) 23.8, 238 (3500)

243658 A 23:1, Heated 120V 0.7, 7.0 (100) 17.2, 172.4 (2500)

(parts list page)

MPa, bar (psi) MPa, bar (psi)

Maximum Operating Fluid

Pressure

2 309133

Page 3

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

Check equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure stated on the equipment or in the Technical Data

for your equipment. Do not exceed the maximum working pressure of the lowest rated component

in your system.

Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

Do not use hoses to pull equipment.

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82C (180F) or below –40C (–40F).

Wear hearing protection when operating this equipment.

Do not lift pressurized equipment.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

309133 3

Page 4

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury.

Ground the equipment and the object being sprayed. Refer to Grounding on page 8.

If there is any static sparking or you feel an electric shock while using this equipment, stop spray-

ing/dispensing immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid be-

ing sprayed/dispensed.

Keep the spray/dispense area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the spray/dispense area.

Extinguish all open flames or pilot lights in the spray/dispense area.

Do not smoke in the spray/dispense area.

Do not turn on or off any light switch in the spray/dispense area while operating or if fumes are

present.

Do not operate a gasoline engine in the spray/dispense area.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

HOT SURFACE AND FLUID HAZARD

Heated fluid can cause severe burns and can cause equipment surfaces to become very hot.

Wear protective gloves and clothing when operating this equipment in a heated system.

Do not touch the metal heat sink when the surface is hot.

Allow the equipment to cool thoroughly before servicing.

Some heated systems are designed to dispense PUR heated materials. PUR systems are supplied

with ventilation hoods, and require proper ventilation and specially designed system components.

4 309133

Page 5

WARNING

MOVING PARTS HAZARD

Moving parts, such as the air motor piston, can pinch or amputate your fingers.

Keep clear of all moving parts when starting or operating the pump.

Before servicing the equipment, follow the Pressure Relief Procedure on page 10 to prevent the

equipment from starting unexpectedly.

INJECTION HAZARD

Spray from the gun, hose leaks, or ruptured components can inject fluid into your body and cause an

extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the skin

can also cause a serious injury.

Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi-

cal attention.

Do not point the spray gun at anyone or at any part of the body.

Do not put hand or fingers over the spray tip.

Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

Do not “blow back” fluid; this is not an air spray gun.

Check the gun diffuser operation weekly.

Be sure the gun trigger safety operates before spraying.

Lock the gun trigger safety when you stop spraying.

Follow the Pressure Relief Procedure on page 10 whenever you: are instructed to relieve pres-

sure; stop spraying; clean, check, or service the equipment; or install or clean the spray tip.

Tighten all the fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

309133 5

Page 6

Unpacking and Repacking

Unpacking the Product

The pressure compensating valve was carefully packaged for shipment by Graco. When the product arrives, perform the following procedure to unpack the

unit:

1. Inspect the shipping box carefully for shipping

damage. Contact the carrier promptly if damage is

discovered.

2. Unseal the box and inspect the contents carefully.

There should not be any loose or damaged parts.

3. Compare the packing slip against all items included in the container. Any shortages or other

inspection problems should be reported immediately.

4. Store the box and packing materials in a safe

place for future use. Graco recommends that all

packing materials be saved in case the unit needs

to be shipped again.

6 309133

Page 7

Overview

Description

The purpose of the pressure compensating valve is to

provide a consistent flow of sealant and adhesive

material downstream, through a hose, to a dispense

valve and nozzle.

The pressure compensating valve applies a precisely

regulated air pressure to a rolling diaphragm to open a

valve spool. Downstream back pressure is applied to

the opposite end of the spool to push it closed. The

two opposing forces cause the spool to throttle the

material through a tapered valve seat, thereby compensating for any pressure fluctuation.

The area of the spool and the 1” (25.5 mm) stroke of

the spool cause it to displace material. When the

spool extends into the downstream end of the pressure

compensating valve it can provide up to 1.0 cu. inches

of material to compensate for the momentary loss of

supply pressure. When the spool is retracted beyond

the point of shutoff, it will withdraw material from the

downstream end. This causes a relieving effect.

The displacement of the spool is what separates it

from regulators. The inlet pressure is balanced against

the spool, thus making it immune to changes in upstream pressure. The air cylinder (rolling diaphragm)

area versus the area of the end of the spool, give the

pressure compensating valve a power ratio, just as a

reciprocating pump has a power ratio. The Pressure

Compensating Valve is available in 23:1 and 51:1

ratios, ambient or heated models.

Because the inlet pressure is balanced, a low ratio

pressure compensating valve may be used with a high

ratio pump. Optimum operation will be reached by

using the lowest ratio pressure compensating valve to

provide the required pressure.

Operation

The pressure compensating valve is installed with a

precision air regulator for the air cylinder in order to

provide accurate control. It is also installed with inlet

and outlet fluid pressure gauges. To avoid extreme

wear, when dispensing material, do not exceed 300 psi

differential across the pressure compensating valve

(the difference between the inlet and the outlet fluid

pressure gauges).

Typical Installation

309133 7

Page 8

Installation

Ground The System

WARNING

FIRE, EXPLOSION, AND ELECTRIC

SHOCK HAZARD

To reduce the risk of fire, explosion, and

serious injury, proper electrical grounding of every part of your system is

essential. Read the warning section,

FIRE AND EXPLOSION HAZARD, on

page 4 and follow the grounding instructions, below.

The following grounding instructions are minimum

requirements for a basic dispensing system. Your

system may include other equipment or objects which

must be grounded. Check your local electrical code

for detailed grounding instructions for your area and

type of equipment. Your system must be connected to

a true earth ground.

1. Pump: ground the pump by connecting a ground

wire and clamp as described in your separate

pump instruction manual.

2. Air compressors and hydraulic power

supplies: ground the equipment according to the

manufacturer’s recommendations.

7. All solvent pails used when flushing: ground

according to local code. Use only metal pails,

which are conductive. Do not place the pail on a

non–conductive surface, such as paper or

cardboard, which interrupts the grounding

continuity.

8. To maintain grounding continuity when

flushing or relieving pressure: hold a metal part

of the gun firmly to the side of a grounded metal

pail, then trigger the gun.

General Information

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in Fig. 1.

A pressure compensating valve can be used in manual

and automatic dispensing applications.

WARNING

ELECTROCUTION HAZARD

Installing and servicing this equipment

requires access to parts which could

cause an electric shock or other serious

injury. Have only qualified electricians access the

control assembly.

Location of the Pressure Compensating

Valve

3. Fluid hoses: use only ground fluid hoses with a

maximum of 500 feet (150 m) combined hose

length to ensure grounding continuity. Check the

electrical resistance of your fluid hoses at least

once a week. If your hose does not have a tag on

it which specifies the maximum electrical

resistance, contact the hose supplier or

manufacturer for the maximum resistance limits. If

the hose resistance exceeds the recommended

limits, replace it immediately.

4. Flo–gun: ground the gun by connecting it to a

properly grounded fluid hose and pump.

5. Fluid supply container: ground according to the

local code.

6. Flammable liquids in the dispensing area:

must be kept in approved, grounded containers.

Do not store more than the quantity needed for

one shift.

The pressure compensating valve should be lo-

cated between the supply pump and dispense

valve, as close to the point of disperse as possible.

CAUTION

Downstream hose lengths beyond 15 feet will start to

diminish the valve’s effectiveness in compensating

for surge.

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce risk of injury or equipment

damage:

Make sure all material hose connec-

tions are secure.

Do not pressurize the system until

you have verified the system is ready

and it is safe to do so.

8 309133

Page 9

Installation

Installing the Pressure Compensating

Valve

Before mounting the pressure compensating valve,

extra inlet/outlet plugs and insulating wrap (for heated

units only) need to be assembled. There are two inlets

and outlet ports. Decide which are to be used and

plug the others. Completely wrap the steel fluid housing with provided insulation wrap and tape.

To install the pressure compensating valve:

Mount the pressure compensating valve.

Connect the air line.

Connect the inlet and discharging hose.

Air in

37

3. Connect the material supply hose to the pressure

compensating valve’s inlet port (A) and connect

the material discharge hose to the pressure compensating valve’s outlet port (B). See Fig. 1.

NOTE: It is recommended the compensator be

isolated with shutoff valves for air and material inlet/

outlet lines.

WARNING

To reduce the risk of over–pressurizing your system, which could result in component rupture and

cause serious injury, never exceed the specified

maximum incoming air pressure to the pumps (see

the Technical Data in the pump manual).

Pressure Compensator Set Up

1. Ensure that air pressure is supplied to the ram and

pump.

2. For models with heaters, bring the system to the

operating temperature.

A

40

Material In

TI0370B

B

Material Out

Fig. 1

1. Using the attached mounting bracket (40), secure

the pressure compensating valve to a rigid support

or a wall capable of supporting 75 pounds. See

Fig. 1.

2. Connect the air line to the pressure compensating

valve’s regulator (37 ). See Fig. 1.

3. Set the pressure compensating valve’s air regula-

tor to maximum (full open).

4. Place a waste container under material dispense

valve.

5. Slowly increase the supply pump pressure and fill

the entire system.

6. Once the system is fully primed, adjust the supply

pump pressure until the desired, non–regulated,

material flow rate is achieved.

7. Increase the supply pump material pressure by

300 psi.

8. Decrease the pressure compensator air regulator

until the desired flow rate is achieved.

9. Decrease the supply pump pressure until the

material flow surges, then increase the pressure

until the surge is eliminated.

10. Final material flow rate adjustments can now be

done with the pressure compensator air regulator.

11. Record all regulator and material pressures for

future reference.

NOTE: The difference between the inlet and outlet

pressure on the pressure compensating valve should

not exceed 300 psi.

309133 9

Page 10

Installation

To change the differential across the pressure

compensating valve, adjust the precision air regulator pressure up or down to bring the fluid pressure

gauges to within the 300 psi tolerance (obtain a

pressure difference as close as possible to zero

psi).

Adjust the air regulator when the material is being

dispensed.

By increasing the air pressure to the cylinder,

you increase the outlet fluid pressure.

By decreasing the air pressure you decrease

the outlet fluid pressure.

Ensure that the pressure compensating valve’s

piston always floats and does not extend to the end

of its stroke and remain there. Check this by

watching the spool between the air cylinder and the

main body of the pressure compensating valve.

The spool should move down when the supply

pump changes its stroke and move up when

the supply pump pressure is returned to normal.

If the spool does not retract, slightly reduce the

air pressure to the air cylinder. When the

dispense valve is closed the spool will retract

slightly, causing a relieving effect in the dispense hose.

Pressure Relief Procedure

This procedure is described in the instruction manual

that was supplied with your system. Please refer to

that document.

WARNING

The material and equipment will be

hot! To reduce risk of injury, wear eye

protection, gloves and protective clothing

when installing, operating, or servicing

this dispensing system.

WARNING

HIGH PRESSURES CAN CAUSE SERIOUS PERSONAL INJURY. Be sure

to OPEN THE DISPENSE VALVE

DURING SYSTEM HEATUP to allevi-

ate pressure which might occur in the system due

to material expansion.

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, moving

parts, follow the Pressure Relief Procedure

whenever you:

are instructed to relieve the pressure

stop spraying/dispensing

WARNING

MOVING PARTS HAZARD

Follow the Pressure Relief Procedure

in your separate system manual before

checking or repairing the ram or any

other part of the system and when shutting down

the system. Keep hands and fingers away from the

follower plate, fluid pump inlet, and lip of the fluid

container when raising or lowering the ram to

reduce the risk of pinching or amputating hands or

fingers.

During operation, also keep hands and fingers

away from limit switches to reduce the risk of

pinching or amputating hands or fingers.

10 309133

check or service any of the system equipment

install or clean the spray tip/nozzle

Page 11

Maintenance

Table 1 shows the preventive maintenance schedule for the Pressure Compensating Valve.

Table 1. Preventive Maintenance Schedule

Schedule Component Description

Weekly Compensator body

Remove plug to visually inspect grease. If a lot of pumped material is present, disassemble following instructions on page 13. Clean or replace components as needed.

Weekly Lubricate the components

Remove plug to visually inspect grease. If needed, lubricate with Gray Mobilith SCH220

grease.

Daily Spool floats freely

Watch the spool between the air cylinder and the main body of the pressure compensating

valve. The spool should move up and down when the supply pump pressure returns to

normal. If the spool does not retract, slightly reduce the pressure to the air cylinder.

309133 11

Page 12

Troubleshooting

Problem Cause Solution

Outlet material pressure not

consistent.

Outlet pressure builds up while

not dispensing.

Material is leaking externally. Internal seals are worn. Replace seals.

Not enough outlet pressure.

Material pressure gauge readings

do not change when the flow rate

is adjusted.

Plunger does not float Seal is worn. Replace seal.

Air regulator does not display

consistent pressure reading.

Inlet pressure is too low. Adjust inlet pressure from supply

pumps.

Internal throat seals, o–rings and/or

plunger are worn.

Internal throat seals, o–rings and/or

plunger are worn.

Material regulator is not calibrated

correctly.

Supply pumps are set too low or

turned off.

Material gauges are damaged. Replace.

Pressure adjustment range is

exceeded.

Improper regulator setting.

Regulator not functioning properly

Replace seals, inspect, and/or

replace plunger.

Replace seals, inspect, and/or

replace plunger.

See pressure compensator setup on

page 9.

Verify supply.

Calibrate the pressure in a lower

pressure range.

Replace or repair air regulator.

Air is not getting to regulator. Air hose not connected or loose. Attach or tighten air hose to regulator.

12 309133

Page 13

Service

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures and the

parts drawing on pages 16–19.

WARNING

EQUIPMENT MISUSE HAZARD

Exercise care when mounting and

handling the Pressure Compensating

Valve to prevent equipment damage or

personal injury.

Disassembly

1. Disconnect all hoses connecting the pressure

compensating valve to the gun and heating units.

2. On heated models, remove insulation wrap.

3. Remove the two bolts (41), washers (42), and nuts

(43) holding mounting bracket (40) to the mounting

plate (14).

13. Remove the two screws (19) securing the heater

cover (23) to the block outlet (11). Remove the

heater cover (23) to access the two screws (20)

securing the heating unit to the block outlet (11).

Remove the screws (20) and washers (21).

14. Carefully remove the cartridge heater (28, 57) and

RTD temperature sensor (27) from the block outlet

(11).

15. Remove the o–ring (10) and throttle adapter (17)

from the opening in the center of the lower compensator body section.

16. Remove the lip seal (9).

17. Carefully inspect the lip seals (9, 45), washers

(21), throttle adapter (17), and o–rings (6, 10) for

wear and weakness. If they are worn or damaged,

replace them.

18. Carefully inspect the piston (8). If it is damaged or

the surface scored, replace it.

4. Remove the two cap screws (25, 56) and two

spacers (13, 55).

5. Carefully remove the air cylinder (1) and the piston

(8) from the compensator body (16) and block

outlet (11).

6. Loosen the adjusting nut (2) while holding piston

(8) on the wrench flats. Remove piston (8) from

the air cylinder (1) by turning piston counterclockwise.

7. Remove the four cap screws (3) holding the

mounting plate (14) to the compensator body (16).

8. Remove the mounting plate (14).

9. Remove the bearing plunger (5) from inside the

compensator body (16).

10. Remove the o–ring (6) from the top groove on the

outside of the bearing plunger (5). Remove the lip

seal (45) located inside the bearing plunger (5).

CAUTION

Use only high temperature synthetic grease or Graco

cartridge no. 115982. Use of any other grease may

result in unit failure or system contamination.

Reassembling the Compensator

1. Generously grease lip seal (9) with high temperature synthetic grease or Graco cartridge no.

115982 (32). Carefully insert the lip seal (9), with

the lips facing down, in the opening located in the

bottom of the compensator body (16).

2. Generously grease the throttle adapter (17) with

high temperature synthetic grease or Graco cartridge no. 115982 (32). Insert the throttle adapter

(17) over the lip seal (9) in the opening on the

bottom of the compensator body (16). Place o–ring

(10) on top of throttle adapter (17).

3. Coat the heater (28, 57) and RTD temperature

sensor (27) with Lubricant Thermal Compound

(31), and insert into their proper locations in the

bottom of the compensator body (16).

11. Remove the lip seal (9) located inside the compensator body (16).

12. Turn the compensator body (16) over. Remove

the four screws (12) holding the top and bottom

halves of the compensator body together.

4. Position the heater (28, 57) and RTD temperature

sensor (27) wires in the slots located in the block

outlet (11).

Allow sufficient lead wire length to be able to

rotate the connector bracket ± 180.

309133 13

Page 14

Service

5. Carefully align the block outlet (11) and compensator body (16) and secure using the four screws

(12). Torque screws (12) to 45 ft-lb. (61 Nm).

6. Secure the heating unit to the block outlet (11)

using the two screws (20) and washers (21).

7. Replace the heater cover (23) and screws (19).

8. Turn the heater over. Generously grease the lip

seal (9) with high temperature synthetic grease or

Graco cartridge no. 115982 (32). Carefully insert

lip seal (9), with the lips facing down, in the center

opening located on the top of the compensator

body (16).

9. Generously grease o–ring (6) with high temperature synthetic grease or Graco cartridge no.

115982 (48). Position it in the groove located

around the outside of the bearing plunger (5).

10. Generously grease rod lip seal (45) with high

temperature synthetic grease or Graco cartridge

no. 115982 (32). Place the lip seal (45), with the

lips facing down, inside the bearing plunger (5).

11. Lightly grease the entire bearing plunger (5) with

high temperature synthetic grease or Graco cartridge no. 115982 (32). Carefully insert the bearing

plunger (5) in the opening on the top of the compensator body (16).

12. Attach the mounting plate (14) to the compensator

body (16) using the four cap screws (3). See Fig 1.

which shows the correct orientation of the mounting plate (14) to the compensator body (16).

13. On heated models, wrap with insulation.

14. Replace the nut (2) on the air cylinder (1).

15. Screw the piston (8) into the air cylinder and

secure with nut (2).

When the cylinder is retracted, you should have

gap of 0.44” (11.0 mm)between the base of the

air cylinder and the nut.

16. Lightly coat the piston (8) and bearing plunger (5)

with high temperature synthetic grease or Graco

cartridge no. 115982 (32). Carefully slide the

compensator body (16) over the piston (8).

17. Attach the mounting bracket (40) to the air cylinder

(1) using bolts (25, 56) and spacers (13, 55).

Torque bolts to 45 ft-lb. (61 Nm).

18. Using the grease gun (44) and high temperature

synthetic grease or Graco cartridge no. 115982

(32), slowly grease the bearing through fitting (15)

until grease is seen coming out of the opposite

side of the port.

19. Replace plug (4).

14 309133

Page 15

Notes

309133 15

Page 16

Parts List

23:1 Ratio Compensators Model Nos. 243655, 243656, & 243658

Note: The parts listed below are not used in all models.

Used on model 243655 only

Used on model 243658 only

Used on model 243656 only

Used on models 243656 and 243658 only

Ref Part

No. No. Description Qty

2 C07179 ADJUSTING Nut 1

3 C38372 SCREW, cap, hex head 4

4 C19252 PLUG, flush 1/8” 1

5 195647 BEARING, plunger 1

6 106258 O–RING, packing viton 1

8 C07131 PISTON 1

9 C07124 SEAL, PTFE 2

10 C20138 O–RING, packing viton 2

11 195646 BLOCk, outlet 1

12 C19834 SCREW, cap socket 3/8” x 1.25” 4

13 C07135 SPACER 2

14 C07111 MOUNTING PLATE 1

15 C07113 FITTING, lubricant 1

16 195645 COMPENSATOR, body 1

17 C07133 ADAPTER, throttle 1

18 C78480 CONNECTOR, AMPH, 6–Pin, 16 GA 1

19 C19269 SCREW 2

20 112166 SCREW, cap, 1/4”–20 x .75” 2

21 C19197 WASHER, plain, USS 3/16” 2

22 C34043 BRACKET 1

23 C34040 COVER 1

24 C06323 GAUGE, fluid 2

25 C19794 SCREW, cap, 3/4”–10 x 2.5 2

27 C32255 RTD TEMPERATURE SENSOR 7.8” 1

28 115864 CARTRIDGE HEATER, 120 volt 1

29 C34137 INSULATOR, fiberglass 100”

30 C33049 TAPE, adhesive, fiberglass 100”

31 073019 LUBRICANT, thermal compound

See 120 volt wiring diagram on page 20

See 240 volt wiring diagram on page 20

Part not shown

Ref Part

No. No. Description Qty

32 115982 LUBRICANT, synthetic 1

33 102794 NUT, hex 4

34 C19950 SCREW, cap, SCH 4

36 C07536 TUBE, heat shrink 3”

37 C06101 REGULATOR, 1/4 npt, 1.75” 1

39 C36260 GAUGE, air 1

40 C52578 BRACKET, mounting 1

41 100003 BOLT, hexagon 3/8”–16 x 1.5” 2

42 100133 WASHER, lock 2

43 100307 HEX, nut, 3/8”–16 2

44 551189 GREASE GUN, 3 oz. cartridge 1

45 115751 SEAL, rod 1

46 189930 LABEL, caution 1

47 290228 LABEL, caution 1

51 C34045 SPACER 1

53 C07166 AIR CYLINDER 1

54 156971 FITTING, reducing 3/8” x 1/4” npt 1

55 C07208 SPACER 2

56 C19075 SCREW, cap, hex head 5/8” X 2.5 2

57 115863 CARTRIDGE HEATER 240 volt 1

58100171 SCREW, machine 2

59 115860 INSERTS, female, crimp terminal 1

60 115862 CONNECTOR, male, crimp 7

61 115861 BULKHEAD, housing 1

62 C07569 WIRE, lead 6”

63 112144 SCREW 1

64 101674 TERMINAL RING, ground 1

16 309133

Page 17

Parts

23:1 Ratio Models: 243655, 243656, and 253658

Torque to 45 ft lbs

1

Generously lubricate using high temperature synthetic grease

2

or Graco cartridge no. 115982 only.

When the cylinder is fully retracted there should be a gap of

3

.44” between the base of the air cylinder and the nut.

Lips face down

4

Lips face up

5

† Used on model 243655 only

z Used on model 243658 only

Used on model 243656 only

* Used on models 243656 and 243658 only

1

2

39

37

39

54

53

33z

18z

34z

28z/57

19*

23*

27*

58

61

20*

21*

60

59

22*

51*

45

2

4

2

6

13/55

2

5

3

9

2

4

8

2

41

42

1

14

4

25†/56

1

16

15

2

40

2

9

5

2

17

2

11

10

24

25/56

43

1

TI0369B

12

1

309133 17

Page 18

Parts List

51:1 Ratio Compensators Model Nos. 243206, 243654 & 243657

Note: The parts listed below are not used in all models.

Used on model 243206 only

Used on model 243657 only

Used on models 243206 and 243657 only

Used on all models except 243654

Ref Part

No. No. Description Qty

1 C07109 AIR CYLINDER 1

2 C07179 ADJUSTING Nut 1

3 C38372 SCREW, cap, hex head 4

4 C19252 PLUG, flush 1/8” 1

5 195647 BEARING, plunger 1

6 106258 O–RING, packing viton 1

8 C07131 PISTON 1

9 C07124 SEAL, PTFE 2

10 C20138 O–RING, packing viton 2

11 195646 BLOCk, outlet 1

12 C19834 SCREW, cap socket 3/8” x 1.25” 4

13 C07135 SPACER 2

14 C07111 MOUNTING PLATE 1

15 C07113 FITTING, lubricant 1

16 195645 COMPENSATOR, body 1

17 C07133 ADAPTER, throttle 1

18 C78480 CONNECTOR, AMPH, 6–Pin, 16 GA 1

19 C19269 SCREW 2

20 112166 SCREW, cap, 1/4”–20 x .75” 2

21 C19197 WASHER, plain, USS 3/16” 2

22 C34043 BRACKET 1

23 C34040 COVER 1

24 C06323 GAUGE, fluid 2

25 C19794 SCREW, cap, 3/4”–10 x 2.5 2

27 C32255 RTD TEMPERATURE SENSOR 7.8” 1

28 115864 CARTRIDGE HEATER, 120 volt 1

29 C34137 INSULATOR, fiberglass 100”

30 C33049 TAPE, adhesive, fiberglass 100”

31 073019 LUBRICANT, thermal compound

Used on model 243654 only

See 120 volt wiring diagram on page 20

See 240 volt wiring diagram on page 20

Part not shown

Ref Part

No. No. Description Qty

32 115982 LUBRICANT, synthetic 1

33 102794 NUT, hex 4

34 C19950 SCREW, cap, SCH 4

35 C19254 PLUG, pipe, flush, 1/4” 1

36 C07536 TUBE, heat shrink 3”

37 C06101 REGULATOR, 1/4 npt, 1.75” 1

38 164856 FITTING, reducing, 3/8” x 1/4 npt (m) 1

39 C36260 GAUGE, air 1

40 C52578 BRACKET, mounting 1

41 100003 BOLT, hexagon 3/8”–16 x 1.5” 2

42 100133 WASHER, lock 2

43 100307 HEX, nut, 3/8”–16 2

44 551189 GREASE GUN, 3 oz. cartridge 1

45 115751 SEAL, rod 1

46 189930 LABEL, caution 1

47 290228 LABEL, caution 1

51 C34045 SPACER 1

52 C19254 PLUG, pipe flush 1

57 115863 CARTRIDGE HEATER 240 volt 1

58100171 SCREW, machine 2

59 115860 INSERTS, female, crimp terminal 1

60 115862 CONNECTOR, male, crimp 7

61 115861 BULKHEAD, housing 1

62 C07569 WIRE, lead 6”

63 112144 SCREW 1

64 101674 TERMINAL RING, ground 1

18 309133

Page 19

Parts

51:1 Ratio Models: 243206, 243654, and 253657

Torque to 45 ft lbs

1

Generously lubricate using high temperature synthetic grease

2

or Graco cartridge no. 115982 only.

When the cylinder is fully retracted there should be a gap of

3

.44” between the base of the air cylinder and the nut.

Lips face down

4

Lips face up

5

z Used on model 243206 only

Used on model 243657 only

Used on models 243206 and 243657 only

*

1

2

45

2

4

39

37

39

38

1

33z

18z

34z

28z/57

19*

23*

27*

58

61

21*

60

20*

59

22*

51*

2

6

13

2

5

3

9

2

4

8

2

41

42

1

14

4

25

1

16

15

2

40

2

9

5

2

17

2

10

24

25

43

1

TI0369B

11

12

1

309133 19

Page 20

120 Volt Models

Wiring Diagram

27

18, 36

28

240 Volt Models

57

27

62

6364

20 309133

Page 21

Repair Kits and Accessories

Use Only Genuine Graco Parts and Accessories

Compensating Valve Repair Kit 233082

For all 23:1 and 51:1 models ordered after May 2000.

Ref.

No. Part No. Description Qty.

6 106258 O–RING, packing viton 1

9 C07124 SEAL, PTFE 2

10 C20138 PACKING, O–RING 1

29 C34137 SHEET FIBERGLASS 100”

30 C33049 TAPE, high temperature 100”

45 115751 SEAL, rod 1

Compensating Valve Upgrade Kit 243464

For all 19:1 compensating valves with aluminum fluid

sections ordered before May 2000.

Ref.

No. Part No. Description Qty.

111178 O–RING, air cap 2

C07189 SEAL 2

C20135 O–RING 2

195633 BEARING 1

115750 SEAL 1

195634 WASHER 1

To repair a 19:1 Compensating Valve that has been

upgraded with Kit 243464, order each of the following:

Ref.

No. Part No. Description Qty.

C07199 REPAIR KIT 1

(Includes 111178, C07189, and C20135)

115750 SEAL 1

Connector Accessory Kit

Used to mate the Graco Pressure Compensating Valve

to a non–Graco heating controller. NOTE: The control

end connector is provided and wired by customer.

Ref.

No. Part No. Description Qty.

244021 KIT, loft (3 m); cable and valve end

connector 1

Grease Gun

For all models.

Ref.

No. Part No. Description Qty.

44 551189 GREASE GUN 1

Grease Cartridge

For use with Grease Gun Part No. 551189.

Ref.

No. Part No. Description Qty.

32 115982 GREASE CARTRIDGE, high

temperature grease 1

309133 21

Page 22

Technical Data

gq ( )

Category Data

Fluid Inlet 1 npt(f)

Fluid Outlet 1 npt (f)

Air Inlets 1/4 npt (f)

Voltage Required (heated models)

Output Wattage 400 watts

Maximum recommended pressure drop 300 psi

Maximum air inlet pressure 250 psi ( 1.70 MPa, 17.0 bar)

Maximum operating pressure 100 psi (0.7 MPa, 7.0 bar)

Maximum Temperature 400F (C)

Weight 23:1 ratio pumps 48 pounds, 51:1 ratio pumps 62 pounds

Dimensions 26.5” x 14” x 14”

120 volts for models 243206 and 243658

240 volts for models 243656 and 243657

22 309133

Page 23

Dimensions

51:1 pumps: 10.5 in.

23:1 pumps: 9.5 in.

51:1 pumps: 9 in.

23:1 pumps: 7 in.

1.5 in.

51:1 pumps: 17 in.

23:1 pumps: 15 in.

2 in.

Side View Back View

309133 23

Page 24

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Phone Numbers

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–367–4023 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

International Offices: Belgium, Korea, Hong Kong, Japan

Sales Offices: Minneapolis, Detroit

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

www.graco.com

PRINTED IN USA 309133 July 2000, Revised November 2001

24 309133

Loading...

Loading...