Page 1

Instructions – Parts List

Parts

Huskyt 515/Huskyt 716

Drum Pump Kits and Packages

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 2 for Table of Contents.

233045

Accessory kit for pump Model No. 241565

233046

Accessory kit for pump Model Nos. 241564,

233305, 243306, 243307

233047

Accessory kit for pump Model No. 241564

233048

Accessory kit for pump Model No. D54311

233051

Drum pump package including Kit No. 233045

and pump Model No. 241565

309116D

233052*

Drum pump package including Kit No. 233047

and pump Model No. 241564

233053*

Drum pump package including Kit No. 233046

and pump Model No. 241564

233054*

Drum pump package including Kit No. 233046

and pump Model No. 243305

233055*

Drum pump package including Kit No. 233046

and pump Model No. 243306

233056*

Drum pump package including Kit No. 233046

and pump Model No. 243307

233057*

Drum pump package including Kit No. 233048

and pump Model No. D54311

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 2000, Graco Inc. is registered to I.S. EN ISO 9001

TI0108

*

TI0108

Page 2

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts

Kits and Packages 7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List and Accessory Kit Matrix 8. . . . . . . . . . . . .

Parts Drawing 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Package Matrix 10. . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 12. . . . . . . . . . . . . . . . . . . . . .

Graco Information 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING

EQUIPMENT MISUSE HAZARD

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious injury

or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to or

destruction of equipment if you do not follow the instructions.

INSTRUCTIONS

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated component in your system.

D Use fluids and solvents that are compatible with the equipment wetted parts. Refer to the Techni-

cal Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Always wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid and

solvent manufacturer.

D Wear hearing protection when operating this equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose hoses to temperatures above 180_ F (82_ C) or below –40_ F (–40_ C).

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Do not use 1.1.1–trichloroethane, Methylene chloride, other halogenated hydrocarbon solvents or

2 309116

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

Page 3

WARNING

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled. When flushing the air motor or pump, keep your face away from the

exhaust port.

D Know the specific hazards of the fluid you are using.

D Do not lift a pump under pressure. If dropped, the fluid section may rupture. Always follow the

Pressure Relief Procedure in the pump manual before lifting the pump.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state, and national guidelines.

D Always wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid and

solvent manufacturer.

D Pipe and dispose of exhaust air safely, away from people, animals, and food handling areas. If the

diaphragm fails, the fluid is exhausted along with the air. Read Exhaust Air Ventilation in instruc-

tion manual 308981.

D Never use an acetal pump to pump acids. Take precautions to avoid acid or acid fumes from

contacting the pump housing exterior. Stainless steel parts will be damaged by exposure to acid

spills and fumes.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Ground all equipment and the equipment being dispensed to. Refer to Grounding in instruction

manual 308981.

D Never use a polypropylene pump with non-conductive flammable fluids as specified by your local

fire protection code. Refer to Grounding in instruction manual 308981 for more information. Consult your fluid supplier to determine the conductivity or resistivity of your fluid.

D If you are dispensing non-conductive flammable fluids, you must use the unit with the acetal pump,

which is conductive.

D If there is any static sparking or if you feel an electric shock while using this equipment, stop

pumping immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being dispensed.

D Pipe and dispose of exhaust air safely, away from all sources of ignition. If the diaphragm fails, the

fluid is exhausted along with the air. Read Air Exhaust Ventilation in instruction manual 308981.

D Keep the work area free of debris, including solvent, rags, and gasoline.

D Electrically disconnect all equipment in the work area.

D Extinguish all open flames and pilot lights in the dispensing area.

D Do not smoke in the work area.

D Do not turn on or off any light switch in the work area while operating or if fumes are present.

D Do not operate a gasoline engine in the work area.

3309116

Page 4

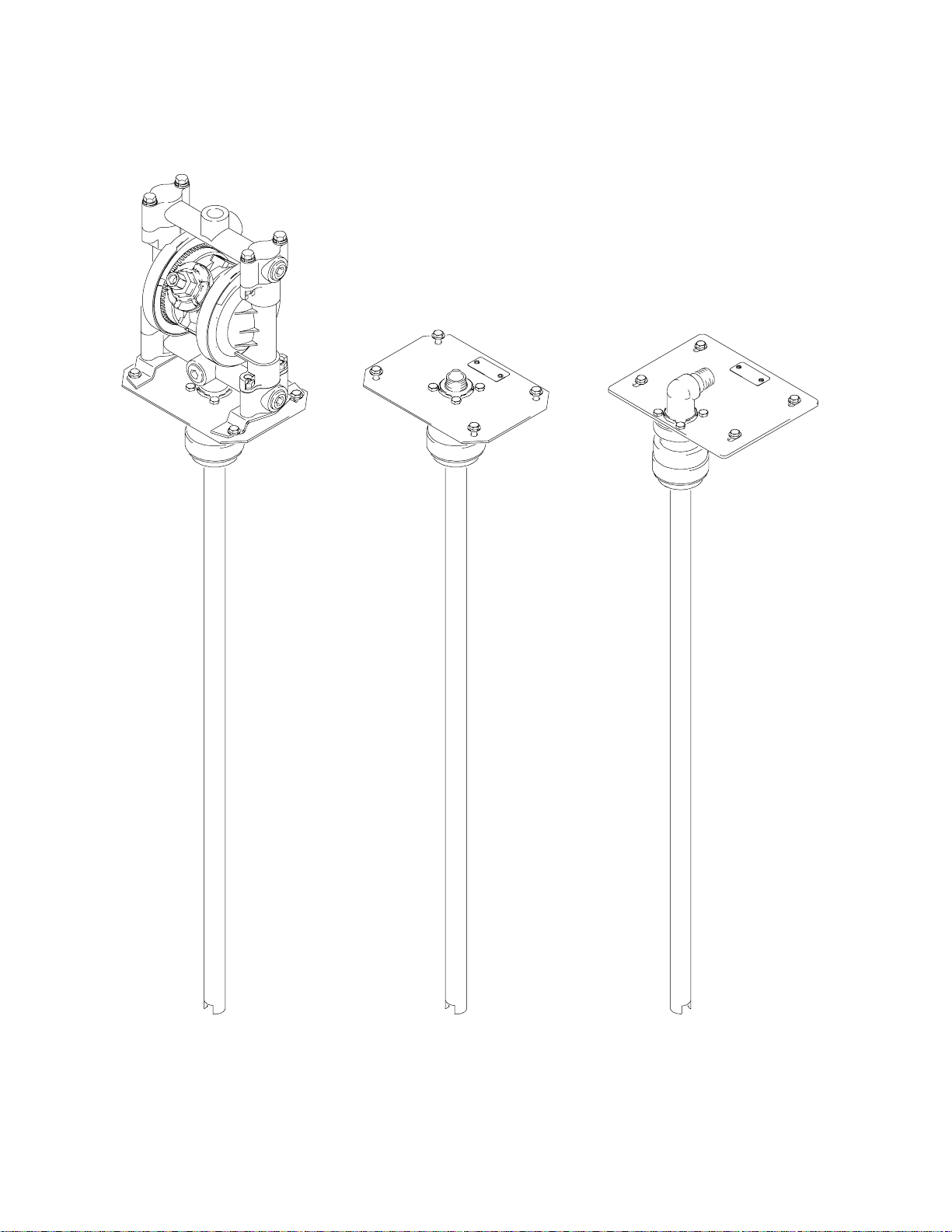

A. Representative

package with

pump mounted

B. Kit with standard

mounting plate

C. Kit No. 233048

with offset

mounting plate

4 309116

TI0108TI0108

TI0106B

Page 5

Installation

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

This unit must be grounded. Before you

operate it, ground the system as

explained in this section. Also, read Fire

and Explosion Hazard on page 3. For

further grounding information, read the

Grounding section in instruction manual

308981.

Proper grounding is an essential part of maintaining a

safe system.

To reduce the risk of static sparking, ground the pump

and all other equipment used or located in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of equipment.

Installation

NOTE: Numbers in parentheses refer to parts as de-

fined on the parts list on page 8 and the parts drawing

on page 9.

1. Remove the knurled bung adaptor (5) and the bung

gasket (2) from the bung adaptor base assembly

and install it onto the 55-gallon drum.

2. Tighten ¼ turn past hand-tight to ensure that the

bung gasket (2) engages the drum cover.

WARNING

TIPPING HAZARD

When mounting the stainless steel pump

(D54311), ensure that the offset mounting plate

(7) is positioned so that the pump is mounted

over the drum to prevent tipping when the fluid

level in the drum is low.

These units should be used only on drums

positioned on a flat, level surface. Uneven or

slanted surfaces could cause the drum to tip

over.

Do not relocate a drum with the unit mounted in

the bung hole. When the unit is mounted, the

center of gravity is too high for stability when

moving the drum.

CAUTION

The bung adaptor (8) has 2.5 in. of adjustment to

accommodate slight variances in drum size. To ensure

that the bung adaptor does not come out of the retainer, do not allow the bottom of the larger diameter of

the bung adaptor to extend more than 2.5 in. from the

retainer (6).

9. Tighten the retainer (6) ¼ turn past hand-tight to

ensure the PTFE o-ring (3) seals against the bung

adaptor base assembly.

10. Ground the pump and the system. Refer to instruction manual 308981.

TOXIC FLUID HAZARD

3. If an air-tight seal is required, place the white foam

gasket (9) in the recess on top of the bung adaptor

(8).

4. Loosely attach the pump to the mounting plate with

the 4 washers (4) and 4 screws (1) provided.

5. Apply sealant to the threads of the suction tube

(101).

6. Insert the threaded end of the suction tube (101)

through the bottom of the bung adaptor base assembly and tighten it into the inlet manifold of the

pump.

7. Tighten the four screws (1) that attach the pump to

the mounting plate (7).

8. Insert the assembly into the drum through the bung

adaptor (5) installed on the drum.

Read the Toxic Fluid Hazard

information on page 3.

11. Follow the installation procedure in instruction

manual 308981 to complete the installation of the air

and fluid lines to and from the pump.

12. Open the second hole in the drum cover to

introduce make-up air or inert gas. The bung adaptor and bung adaptor base seal against the drum.

Failure to provide make-up air or inert gas could

cause the drum to collapse. If necessary, take

applicable steps to ensure the make-up air is dry

and that dangerous gases do not escape from the

drum.

13. To operate the pump, follow the procedures in

instruction manual 308981.

5309116

Page 6

Dimensional Drawing

Adjustable from

2.6 in. (66 mm) to

5.1 in. (130 mm)

8.5 in.

(216 mm)

6.8 in.

(173 mm)

Adjustable from 31.5 in. (800 mm)

to 34.0 in. (864 mm)

8.5 in.

(216 mm)

6.9 in.

(175 mm)

TI0108 TI0106B

6 309116

Page 7

Service

For service instructions specific to the pump, see instruction manual 308981.

Parts

Kits

Pump Accessory Kit 233045

Includes polypropylene bung base 233073 and

polypropylene suction tube 196096.

Pump Accessory Kit 233046

Includes acetal bung base 233074 and aluminum

suction tube 196095.

Pump Accessory Kit 233047

Includes acetal bung base 233074 and stainless steel

suction tube 196094.

Pump Accessory Kit 233048

Includes stainless steel bung base 233076 and stainless

steel suction tube 196094.

Pumps

Part

No.

241564 PUMP, Husky 515

241565 PUMP, Husky 515

243305 PUMP, Husky 716

243306 PUMP, Husky 716

243307 PUMP, Husky 716

D54311 PUMP, Husky 716

Description Qty.

1

Fluid section: acetal (groundable)

Guides: acetal

Balls: PTFE

Diaphragms: PTFE

1

Fluid section: polypropylene

Guides: polypropylene

Balls: PTFE

Diaphragms: PTFE

1

Fluid section: aluminum

Guides: acetal

Balls: SantopreneR

Diaphragms: SantopreneR

1

Fluid section: aluminum

Guides: acetal

Balls: buna-N

Diaphragms: buna-N

1

Fluid section: aluminum

Guides: acetal

Balls: PTFE

Diaphragms: PTFE

1

Fluid section: stainless steel

Guides: stainless steel

Balls: PTFE

Diaphragms: PTFE

Packages

Drum Pump Package 233051

Includes pump 241565 and Kit No. 233045

Drum Pump Package 233052

Includes pump 241564 and Kit No. 233047

Drum Pump Package 233053

Includes pump 241564 and Kit No. 233046

Drum Pump Package 233054

Includes pump 243305 and Kit No. 233046

Drum Pump Package 233055

Includes pump 243306 and Kit No. 233046

Drum Pump Package 233056

Includes pump 243307 and Kit No. 233046

Drum Pump Package 233057

Includes pump D54311 and Kit No. 233048

7309116

Page 8

Parts List and Accessory Kit Matrix

7

Kits

Ref.

Part No. Description

No.

1 102023 SCREW, cap

2 106537 GASKET, bung

3 112553 PACKING, O-ring

4 115814 WASHER, flat, SST

5 178575 ADAPTOR, bung

6 178576 RETAINER, O-ring

196092 PLATE, mounting, offset

196093 PLATE, mounting

196097 ADAPTOR, bung, polypropylene

196098 ADAPTOR, bung, acetal

8

196099 ADAPTOR, bung, stainless steel

9 196103 GASKET

10 111183 RIVET, pop

11 290045 PLATE, designation

12 115813 FITTING, street elbow

233045

233046

233047

8 8 8 8

1 1 1 1

1 1 1 1

4 4 4 8

1 1 1 1

1 1 1 1

1 1 1

1

1 1

1 1 1 1

2 2 2 2

1 1 1 1

233048

1

1

1

13 101324 NUT, hex, jam

14 102025 NUT, full, hex, regular

196094 TUBE, suction, stainless steel

196095 TUBE, suction, aluminum

101

196096 TUBE, suction, polypropylene

4

4

1 1

1

1

8 309116

Page 9

Parts Drawing

Offset mounting plate and street elbow for use

with stainless steel pump, model D54311.

10

1

11

1

4

12

9

8

101

7

6

3

5

2

7 offset

4

13

14

TI0116B

TI0116B

9309116

Page 10

Pump Package Matrix

Pump Bung Base Tube

Package

Part No.

233051

233052

233053

233054

233055 Aluminum/buna-N n n

233056

233057

See the Parts Drawing on page 9.

Description

Polypropylene/PTFE

with polypropylene tube

Acetal/PTFE with stainless steel tube

Acetal/PTFE with aluminum tube

Aluminum/Santoprene

with aluminum tube

Aluminum/PTFE with

aluminum tube

Stainless steel/Stainless

steel with stainless steel

tube

241565

PP-PP-TE-TE

241564

AC-AC-TE-TE

243305

AL-AC-SA-SA

243306

AL-AC-BU-BU

243307

AL-AC-TE-TE

D54311

SS-SS-TE-TE

n n

n n

n n

n n

n n

n n

233045

PP/PP

233046

AC/AL

233047

AC/SS

233048

SS/SS

196094SS196095AL196096

n

n

n

n

n

n

n

PP

10 309116

Page 11

Technical Data

Husky 515/716

Maximum fluid working pressure 100 psi (0.7 MPa, 7 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air pressure operating range 30 –100 psi (0.2–0.7 MPa, 2.1–7 bar). . . . . . . . . . . . . . . . . . . .

Weight

233045 4.0 lb (1.8 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

233046 4.5 lb (2.0 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

233047 6.5 lb (2.9 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

233048 9.5 lb (4.3 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts

233045 polypropylene. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

233046 aluminum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

233047 stainless steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

233048 stainless steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Non-wetted parts (materials vary depending on kit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

epoxy-coated steel, stainless steel, PTFE, nickel-plated steel,

polyethylene, polypropylene, aluminum, zinc-plated steel

Santoprener is a registered trademark of the Monsanto Company.

For additional technical data specific to the pump, refer to instruction manual 308981.

11309116

Page 12

Graco Warranties

Graco Standard Husky Pump Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of five years from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within six years of the date

of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Extended Product Warranty

Graco warrants all Husky 205, 307, 515, 716, 1040, 1590, 2150, and 3275 air valve center sections to be free from defects in material

and workmanship for a period of fifteen years from date installed in service by the original purchaser. Normal wear of items such as

packings or seals are not considered to be defects in material and workmanship.

Five years Graco will provide parts and labor.

Six to Fifteen years Graco will replace defective parts only.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

MM 309116

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

www.graco.com

PRINTED IN USA 01/2000 Revised 06/2006

12 309116

Loading...

Loading...