Page 1

INSTRUCTIONS–PARTS LIST

309098F

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

For Automatic Lubrication Systems Only

First choice when

quality counts.t

Provides lubricant flow and pressure to operate a single line, parallel, automatic

lubrication system and vents the system to reset the injectors.

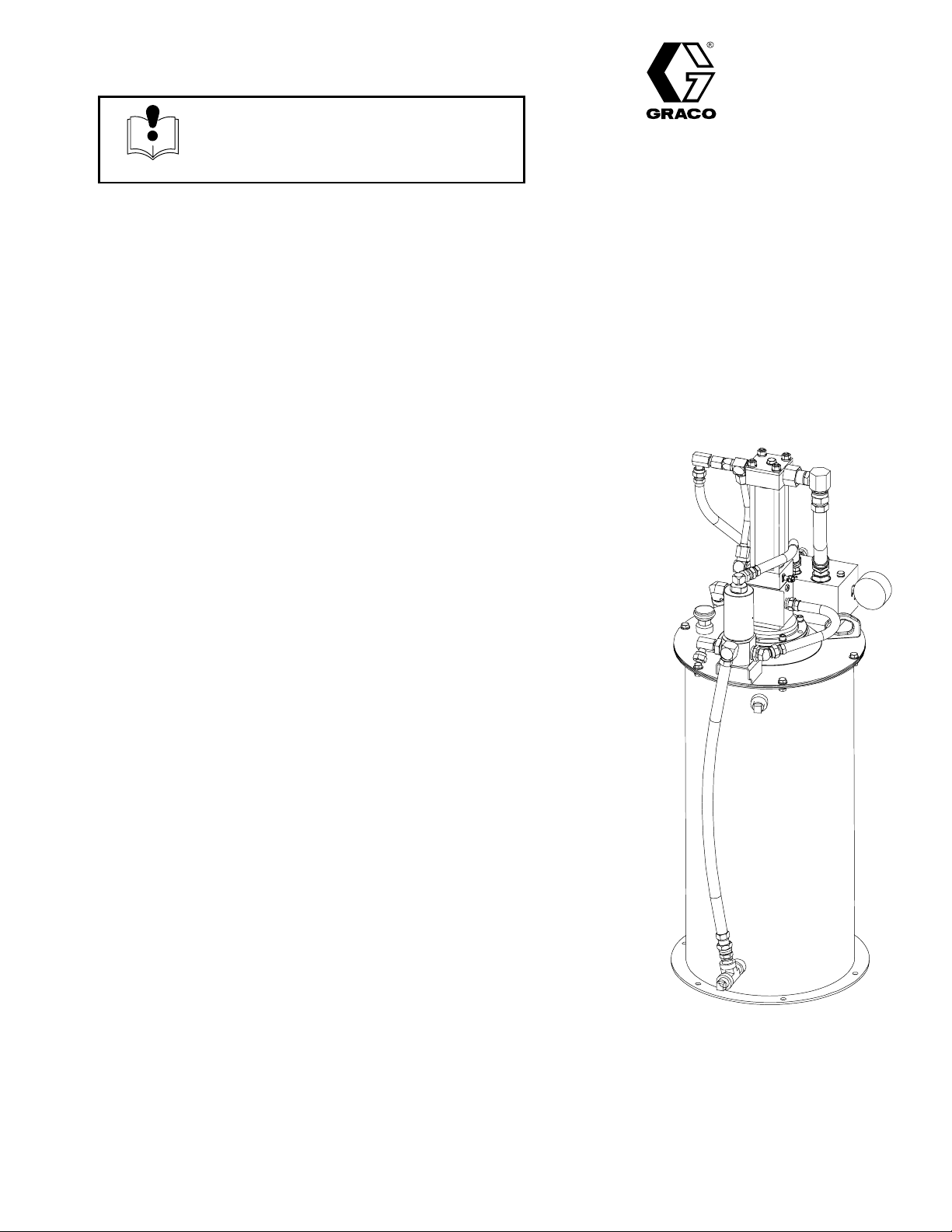

5:1 Dynastarr Pump Module

Part No. 243159, Series C

Part No. 243502 (35# Custom Tank Installation)

Part No. 243503 (120# Custom Tank Installation)

Part No. 243504 (400# Custom Tank Installation)

3500 psi (24 MPa, 240 bar) Maximum Lubricant Outlet Pressure

ENG

3500 psi (24 MPa, 240 bar) Maximum Hydraulic Fluid Input Pressure

Hydraulic Vent Valve Kit Part No. 243170

Hydraulic Control Module Kit Part No. 243501

Part No. 243159

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1999, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before you operate this equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment. Use only Graco approved repair parts.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated component in your system.

D Use fluids and solvents that are compatible with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

D Handle hoses carefully. Do not pull on hoses to move equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 82_C (180_F) or below –40_C (–40_F).

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Be sure breather is not plugged before filling reservoir.

D Be sure unit is securely mounted before operation.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Ground the equipment and the object being dispensed to. See Grounding on page 5.

D If there is any static sparking or you feel an electric shock while using this equipment, stop

dispensing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being dispensed.

D Keep the dispensing area free of debris, including solvent, rags, and gasoline.

D Do not smoke in the dispensing area.

2 309098

Page 3

WARNING

INJECTION HAZARD

Fluid from the dispensing valve, leaks or ruptured components can inject fluid into your body and

cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on

the skin can also cause serious injury.

D Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate

surgical attention.

D Do not put your hand or fingers over the end of grease outlet.

D Do not stop or deflect leaks with your hand, body, glove or rag.

D Follow the Pressure Relief Procedure on page 9 if the injector clogs and before you clean or

service this equipment.

D Tighten all fluid connections before you operate this equipment.

D Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do

not repair high pressure couplings; you must replace the entire hose.

D Fluid hoses must have spring guards on both ends to protect them from rupture caused by kinks

or bends near the couplings.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid

and solvent manufacturer.

MOVING PARTS HAZARD

Moving parts, such as the air motor piston, can pinch or amputate your fingers.

D Do not insert fingers in overflow port when filling reservoir.

D Keep clear of all moving parts when you start or operate the pump.

D Before you service this equipment, follow the Pressure Relief Procedure on page 9 to prevent

the equipment from starting unexpectedly.

3309098

Page 4

Unpacking

Unpacking the Product

The Dynastarr pump module was carefully packaged

for shipment by Graco. When the package arrives,

perform the following procedure to unpack the units:

1. Inspect the shipping box carefully for shipping

damage. Contact the carrier promptly if damage is

discovered.

Pump Module Overview

Pump Module Capabilities

The Pump Module provides lubricant flow and pressure to operate a single line parallel automatic lubrication system. The module requires a hydraulic power

Supply and a timed signal from a lubrication controller.

Based on these signals, the pump module provides

lubricant flow and pressure to operate the injectors and

vents the injector system to reset the injectors.

2. Unseal the box and inspect the contents carefully.

There should not be any damaged parts.

3. Compare the packing slip against all items included in the box. Any shortages or other inspection problems should be reported immediately.

4. Store the box and packing materials in a safe

place for future use. Graco recommends that all

packing materials be saved in case the unit needs

to be shipped again.

Pump Module Operation

Pump Module Operation performs these cycles:

1. Upon receiving a signal from a 24 volt lubrication

controller, the 3–way solenoid valve (Fig. 3,

item F) opens, starting the pump (D) and closing

the vent valve (U).

2. The pumps builds pressure until the pressure

switch in the system sends a signal to the timer,

ending the cycle, or the pump stalls.

3. The timer terminates the 24 volt signal to the

3–way solenoid valve (F).

4. The 3–way solenoid valve (F) closes, stopping the

pump and opening the vent valve (U).

5. The system lubricant pressure bleeds back

through the vent valve (U) into the reservoir (P).

6. The pressure reducing valve (PRV) (item S) and

flow control valve (FCV) (item N) control the pump

output pressure and cycle rate.

4 309098

Page 5

Installation

Reservoir

Mount reservoir [Fig. 2, item (P)] on sturdy flat surface

with 6, 3/8 in. diameter bolts. Note location of fill port

(K), hydraulic lines, and lubricant outlet port (G) for

easy access once installed.

B

WARNING

Hydraulic system must depressurized before

connecting high pressure hydraulic supply line.

CAUTION

Hydraulic supply must be 10μ filtered or better and

supply 0.5 – 3.0 gpm (1.9 – 11.4 lpm) at 800 psi –

3500 psi (55 bar – 241 bar, 5.5 MPa – 24 MPa).

1. Read instruction manual 308156 (included) before

installing this product.

2. Install ball valve (Fig. 2, item AA) (user provided)

in the 3/8” hydraulic supply line ( X).

3. Connect the 3/8” hydraulic supply line (X) to the

swivel (Y).

4. Connect the 3/4” hydraulic tank line (T) to the

swivel (Z).

5. Connect the 24 VDC timer controlled signal to

the 3–way solenoid valve (F).

C

D

Fig. 1

A

0720

Vent Valve Kit for Custom Tank (Part

Number 243170) Installation (See Figure 3)

1. Weld the bracket (see Fig.5 ) in place per recommended configuration for mounting the vent valve .

Paint the bracket if desired.

2. Connect the hydraulic control line (Fig. 3,

item A) to the control module vent valve hydraulic

control line (Fig. 4, item J).

3. Connect the high pressure lubricant line (Fig. 3,

item C) feeding the injector system to the lubricant

output (E).

4. Connect the vent line (F) to the lubricant reservoir.

Control Module Kit for Custom Tank (Part

Number 243501) Installation (See Figure 4)

1. Mount the control module on a flat, sturdy surface

per the recommended configuration (see Fig.2 )

6. Connect supply line (G) to the lubricant swivel (C).

7. Ground system (see Grounding below). Mount

reservoir to grounded chassis member.

Grounding (for non–mobile installation)

Loosen grounding lug locknut [Fig. 1 item (A)] and

washer (B). Insert one end of a 12 ga (1.5 mm@)

minimum ground wire (C) into slot in lug (D) and

tighten locknut securely. Connect other end of wire to

true earth ground. To order a ground wire and clamp,

order part number 222011.

2. Connect the hydraulic tank line (Fig. 4, item G) to

the pump hydraulic outlet port.

3. Connect the vent valve hydraulic control (J) connection to the hydraulic control line (Fig. 3, item A).

4. Connect the pump high pressure hydraulic line

(Fig. 4, item H) to the pump hydraulic input port.

5. Connect the high pressure hydraulic supply to the

high pressure hydraulic supply connection (L) and

the tank lines to the hydraulic tank connection (K).

6. Connect the 3–way solenoid valve (P) to the timer.

Note: Coil should always be installed with lettering

facing out.

5309098

Page 6

Installation

Typical Installation

The installation shown in Figs. 2, 4, and 5 are only a guide for selecting and installing system components. Contact

your Graco distributor for assistance in planning a system to suit your needs.

Controller

Capabilities

G

H

KEY

A High pressure hydraulic lines

B Hydraulic tank line

C Lubricant output connection

D Pump module

E Ignition switch*

F 3–Way solenoid valve

G High-pressure lubricant supply lines*

H Injector banks*

J Lubrication controller*

K Fill port

L Overflow port

M Breather

N Flow control valve (FCV)

P Reservoir

R Ground wire

S Pressure reducing valve (PRV)

T Hydraulic tank line*

U Vent valve

V Vent line

W Follower plate (optional)

X High pressure hydraulic line*

Y High pressure hydraulic connection

Z Tank hydraulic connection

AA Ball valve*

AB Level Indicator (optional)

* User provided

(for non–mobile installation)*

C

G

A

AB

M

P

W

V

K

J

E

R

D

Low Reservoir

Level Switch

(Level Indicator,

optional)

Pressure Switch

For System Control

Remote Alarm Device

(Light or Horn)

(User provided)

B

F

U

N

Y

Z

S

L

AA

T

Hydraulic

Reservoir

Return

From Hydraulic

Front Back

X

Power Supply

9649B

Fig. 2

6 309098

Page 7

A

B

Vent Valve Installation Kit (243170)

E

C

D

F

KEY

A Hydraulic control line

B Vent valve

C Pump output connection line

D Pressure relief valve

E Lubricant output

F Vent line

Fig. 3

9647A

G

H

Control Module Installation Kit (243501)

KEY

G Pump tank line

H Pump high pressure hydraulic line

J Vent valve hydraulic control

J

K Hydraulic tank connection

L High pressure hydraulic connection

M Pressure reducing valve

N Flow control valve

P 3–Way solenoid valve

R Regulated hydraulic pressure gauge

*

Coil should always be installed with lettering facing out

R

*

K

P

Fig. 4

M

N

L

9648A

7309098

Page 8

Vent return port

1/2” npt (f)

Vent valve bracket weld locations

18.0 Max

Installation

Pump mounting ∅ .343 or

5/16–18 (4X)

Control module ∅ .343 or

5/16–18 (2X)

5.0 5.0

Fig. 5

3.536

3.536

6.875

9653A

8 309098

Page 9

Operation

Pressure Relief Procedure

WARNING

INJECTION HAZARD

To reduce the risk of serious injury, including fluid injection or splashing in the

eyes or on the skin, always follow the

Pressure Relief Procedure whenever you

D Are instructed to relieve the pressure

D Shut off the pump

D Check, clean, or service any of the system

equipment

D Install or clean the dispensing devices

1. Disable hydraulic supply to pump (Fig. 2, item D)

by isolating it it from the high pressure hydraulic

supply using ball valve (AA).

2. Do one of the following:

D Open the pressure reducing valve to reduce

trapped hydraulic pressure,

or

D Cycle the timer to open the 3–way solenoid

valve to reduce trapped hydraulic pressure.

Note: Gage on control module should read zero

pressure after performing this step.

3. Disconnect power from Lubrication Controller (J).

WARNING

MOVING PARTS HAZARD

Do not insert finger into the overflow port

while filling a reservoir equipped with a

follower plate. Injury or amputation could

result.

Fill Reservoir

1. Connect lubricant supply hose from remote filling

station pump to fill port (Fig. 2, item K).

2. Connect automatic lube system main supply

line (G) to vent valve (U) outlet.

3. Remove plug from overflow port (L).

4. Slowly turn on supply lubricant until level of lubricant reaches overflow port.

Note: For systems with a follower plate, fill until the

follower plate reaches the overflow port.

Note: Refer to Automatic Lube System Design Guidelines Manual 309015 for instructions on priming remaining system lubricant lines and further operating

instructions.

WARNING

COMPONENT RUPTURE HAZARD

The maximum working pressure of each

component in the system may not be the

same. To reduce the risk of

overpressurizing any component in the system, be

sure you know the maximum working pressure of

each component. Never exceed the maximum

working pressure of the lowest rated component in

the system. Overpressurizing any component can

result in rupture, fire, explosion, property damage,

and serious injury.

Regulate hydraulic pressure to the pump so that no

fluid line, component, or accessory is

overpressurized.

Start-up

Prime Vent Line. The first time the reservoir is filled,

use the vent valve outlet. This removes all air from the

vent line (Fig. 2, item V).

1. Connect lubricant supply hose from remote filling

station pump unit to outlet of vent valve (U).

2. Remove plug in fill port (K) located at bottom of

reservoir.

3. Slowly turn on supply lubricant until lubricant

appears in fill port.

4. Remove lubricant supply hose from vent valve.

5. Set hydraulic pressure to pump at lowest pressure

needed [between 600 psi (41 bar, 4.1 MPa) and

1200 psi 83 bar, 8 MPa)] to get desired output

results [between 2500 psi (172 bar, 17 MPa) and

3500 psi (241 bar, 24 MPa)].

6. Set hydraulic flow rate to pump at lowest flow rate

needed to get desired results.

7. Read and follow instructions supplied with each

system component.

Note: With a primed pump and sufficient hydraulic

supply, the pump starts when the timer activates the

solenoid valve. The pump stops when the timer deactivates the solenoid valve.

9309098

Page 10

Operation

Shut Down.

CAUTION

1. For normal system shut down, disconnect power

to lubricator controller (J) by turning off the ignition

switch, and turn off hydraulic supply by closing the

ball valve (Fig. 2, item AA).

Never allow the pump to run dry of the fluid being

pumped. A dry pump will quickly accelerate to a high

speed, possibly damaging pump. If your pump

accelerates quickly, or is running too fast, stop the

pump immediately and check the fluid supply.

Troubleshooting

Problem Cause Solution

System does not build sufficient

pressure

Pump malfunction

Pump turned off too soon

Refer to manual 308156

Increase timer “pump on” setting

Increase hydraulic flow rate to pump

Solenoid malfunction

Too low or no hydraulic supply

Vent valve seal failure

Vent valve needle/seat failure

Reservoir out of grease

Broken or leaky supply/branch line

Injector failure

Pressure in tank line too high due to

restrictions in tank line or plumbing

too small

Lubricant dispensed from pressure relief valve

Pump runs too fast Reservoir out of lubricant

Lubricant coming out of breather Reservoir overfilled Drain lubricant until overflow stops

Pump will not start No hydraulic supply

System pressure set too high Decrease hydraulic pressure to pump

Pump cavitation

Leak in distribution system

Repair or replace

Turn pressure up or supply on

Replace seal

Replace needle and seat

Fill reservoir

Tighten connections and/or replace

line(s)

Repair or replace

Remove tank line restrictions

Use larger plumbing

Fill reservoir

Install a follower plate

Repair leak

Verify/check hydraulic supply

10 309098

Solenoid malfunction

No electrical supply to lubrication

controller

Lubrication controller malfunction

Pump malfunction

Replace solenoid

Turn on electrical supply

Refer to controller manual 308950

Refer to pump manual 308156

Page 11

Parts Drawing

Pump hydraulic outlet

1

Pump lubricant outlet

Pump hydraulic inlet

3e

3h

3f

3c

7

5

8

3d

3i

3a

3g

9652B

11309098

Page 12

Parts Drawing

To pump hydraulic inlet

4n

4d

4a

4c

4e

4b

4m

4q

6

5

4g

4j

To pump hydraulic outlet

To pump

lubricant outlet

4r

4f

2p

2e

4h

2c

2i

2k

4p

4k

2h

2n

2g

2b

2f

2a

2j

2d

Item 4a: Torque to 40–43 ft lbs (54–58 Nm) (lubricate o–ring with oil before installation)

Item 4c: Torque to 15–20 ft lbs (20–27 Nm) (lubricate o–ring with oil before installation)

Item 4d: Torque to 20–25 ft lbs (27–34 Nm) (lubricate o–ring with oil before installation)

Item 4e: Torque to 15–20 ft lbs (20–27 Nm) (lubricate o–ring with oil before installation)

Item 4f: Torque to 68–75 ft lbs (92–102 Nm) (lubricate o–ring with oil before installation)

Item 4g: Torque to 22–24 ft lbs (30–33 Nm) (lubricate o–ring with oil before installation)

Item 4h: Torque to 40–43 ft lbs (54–58 Nm) (lubricate o–ring with oil before installation)

2m

2q

3b

3a

9652B

12 309098

Page 13

Parts List

Model 243159, Dynastar Pump Module

includes items 1 – 8

*Model 243502, 35# Dynastar Pump Module

Installation Kit includes items 1, 2, 4 and 8

*Model 243503, 120# Dynastar Pump

Module Installation Kit includes items 1, 2, 4

and 8

*Model 243504, 400# Dynastar Pump

Module Installation Kit includes items 1, 2, 4

and 8

Ref.

No. Part No. Description Qty.

1 224751 PUMP (used on Model 243159

and Model 243503) 1

See manual 308156

224912 PUMP, 35# Dynastar 1

(used on Model 243502)

See manual 308156

224752 PUMP, 400# Dynastar 1

(used on Model 243504)

See manual 308156

2 243170 KIT, installation, vent valve 1

2a 100505 . BUSHING, pipe 1

2b 100840 . ELBOW, street 1

2c 100896 . FITTING, bushing, pipe 1

2d 111801 . SCREW, cap, hex hd 2

2e 115122 . VALVE, pressure relief 1

(see manual 308954)

2f 161889 . UNION, adapter 1

2g 157705 . UNION, swivel 1

2h 158212 . BUSHING 1

2i 115470 . UNION, union, swivel, 90_ 1

2j 162667 . ELBOW, street, pipe 1

2k 194867 . BRACKET, vent valve 1

2m 194995 . HOSE, vent; 1/2 in. 1

2n 238370 . HOSE 2

2p 242063 . VALVE, vent 1

(see manual 309099)

2q 156684 . UNION, adapter 1

Ref.

No. Part No. Description Qty.

3 241486 KIT, reservoir, 90 # grease 1

3a 100737 . PLUG, pipe 2

3b 108126 . TEE, pipe 1

3c 110996 . NUT, flanged, hex 6

3d 111800 . SCREW, cap, flange head 4

3e 115254 . BREATHER 1

3f 194868 . GASKET, cover 1

3g 194907 . PAIL, reservoir 1

3h 247448 . COVER, reservoir 1

3i 104663 . PLUG, pipe 1

4 243501 KIT, installation control module 1

4a 112581 . ADAPTER, male 1

4b 115746 . MODULE, hydraulic control 1

4c 115775 .. VALVE, 3–way solenoid 1

4d 115773 .. VALVE, flow regulating 1

4e 115774 .. VALVE, pressure reducing 1

4f 115757 . ADAPTER, straight thread 1

4g 115758 . ADAPTER, straight thread 1

4h 115760 . ADAPTER, straight thread 1

4j 115763 . ADAPTER, straight thread 1

4k 115776 . HOSE, 3/4”X3/4” NPT 1

4m 115829 . UNION, swivel, 90 degree 1

4n 160327 . UNION, adapter, 90 degree 1

4p 207648 . UNION, adapter, 90 degree 1

4q 238370 HOSE, coupled, 1 ft. 1

4r 802072 . GAUGE, pressure 1

5 100214 WASHER, lock 6

6 110384 SCREW, cap, hex hd 2

7 101864 SCREW, cap 4

8 15M442 GASKET, pump 1

* Installation kits for custom user provided lubricant reservoirs not shown

13309098

Page 14

Technical Data

Maximum hydraulic input pressure 3500 psi (241 bar, 24 MPa. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump wetted parts See manual 308156. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vent valve wetted parts See manuals 309099. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reservoir wetted parts steel, buna–n rubber. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum delivery 66 oz/min (119 in

Hydraulic pressure operating range 800 to 1200 psi (5.5 to 8 MPa, 55 to 83 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic flow rate operating range 0.5 to 3.0 gpm (1.9 to 11.4 liter/ min). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricant outlet pressure range 2500 to 3500 psi (17 to 24 MPa, 172 to 241 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reservoir overflow port size

Reservoir fill port size

Hydraulic inlet port size 3/8” nps swivel (Figure 3, item T). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic tank line size 3/4” nps swivel (Figure 3, item X). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubricant outlet port size

Grease capacity 90 lb. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting holes for pump module Six 7/16” holes on 13 7/8” bolt circle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reservoir diameter 12 3/4” (324 mm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump module height 37 3/4” (959 mm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical requirements Timed 24 VDC signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical power requirements 14.7 Watts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filtration (hydraulic fluid) 10μ (microns) or better. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sound pressure* 77 dB (A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

*Sound pressure reading taken with pump operating at 66 cycles per minute.

*Sound pressure measured per CAGI–PNEUROP, 1971.

3

/min, 1952 cm3/min) at 3 gpm hydraulic flow rate. . . . . . . . . . . . . . . . . . . . . . . . . .

1

/2 npt (Figure 3, item L). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

/2 npt (Figure 3, item K). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

/2 nps swivel (Figure 3, item G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic tank

3/4” nps swivel

42.75 in.

(1086 mm)

Hydraulic high

pressure inlet

3/8” nps swivel

Lubricant outlet

1/2” npt swivel

Dimensions

Overflow port

1/2” npt

Mounting Diagram

17.5 in.

(444.5 mm)

∅15.0 in.

(381 mm)

14 309098

15.0 in.

(381 mm)

6x 7/16” holes

13 7/8” bolt circle

Fill port 1/2 in. npt

9650A

Page 15

Hydraulic Control Module Circuit: 243501

Does not include pump and pump valve kit.

15309098

Page 16

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Phone Number

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

Minneapolis Local: 612–623–6928; Toll Free: 1–800–533–9655; or FAX: 612–378–3590

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

16 309098

Original instructions. This manual contains English. MM 309098

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

GRACO INC. is registered to ISO9001

www.graco.com

PRINTED IN USA January 2000, Revised October 2010

Loading...

Loading...