Page 1

Instructions

Parts

HYDRA-CATR VARIABLE RATIO

Proportioning Pumps

*Includes Automatic Pressure Relief Valves,

Check Valves, Pressure Gauges and Regulators

Basic Operation for Use with Configured Models

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

WARNING

309024C

Plural Component Materials Hazard

Graco Inc. does not manufacture or supply any of the

reactive chemical materials that may be used in this

equipment and is not responsible for their effects. Because of the vast number of chemicals that could be

used and their varying chemical reaction, before using this equipment the buyer and the user should determine all facts relating to the materials used, including any of the potential hazards involved. Particular

inquiry and investigation should be made into the potential dangers relating to toxic fumes, fires, explosions, reaction times, and exposure of human beings

to the individual components or their resultant mixtures. Graco assumes no responsibility for loss, damage, expense or claims for bodily injury or property

damage, direct or consequential, arising from the use

of such chemical components.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 1999, Graco Inc. is registered to I.S. EN ISO 9001

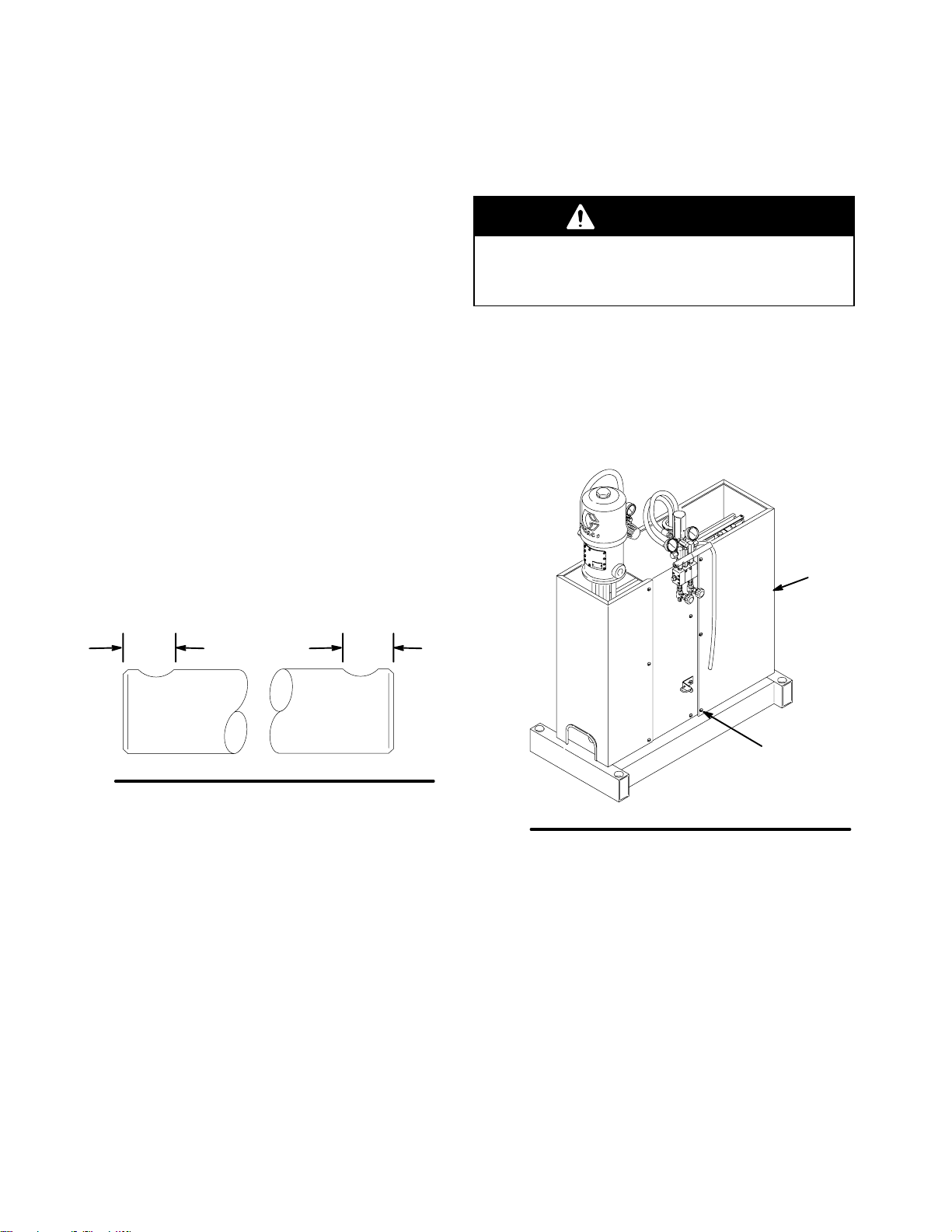

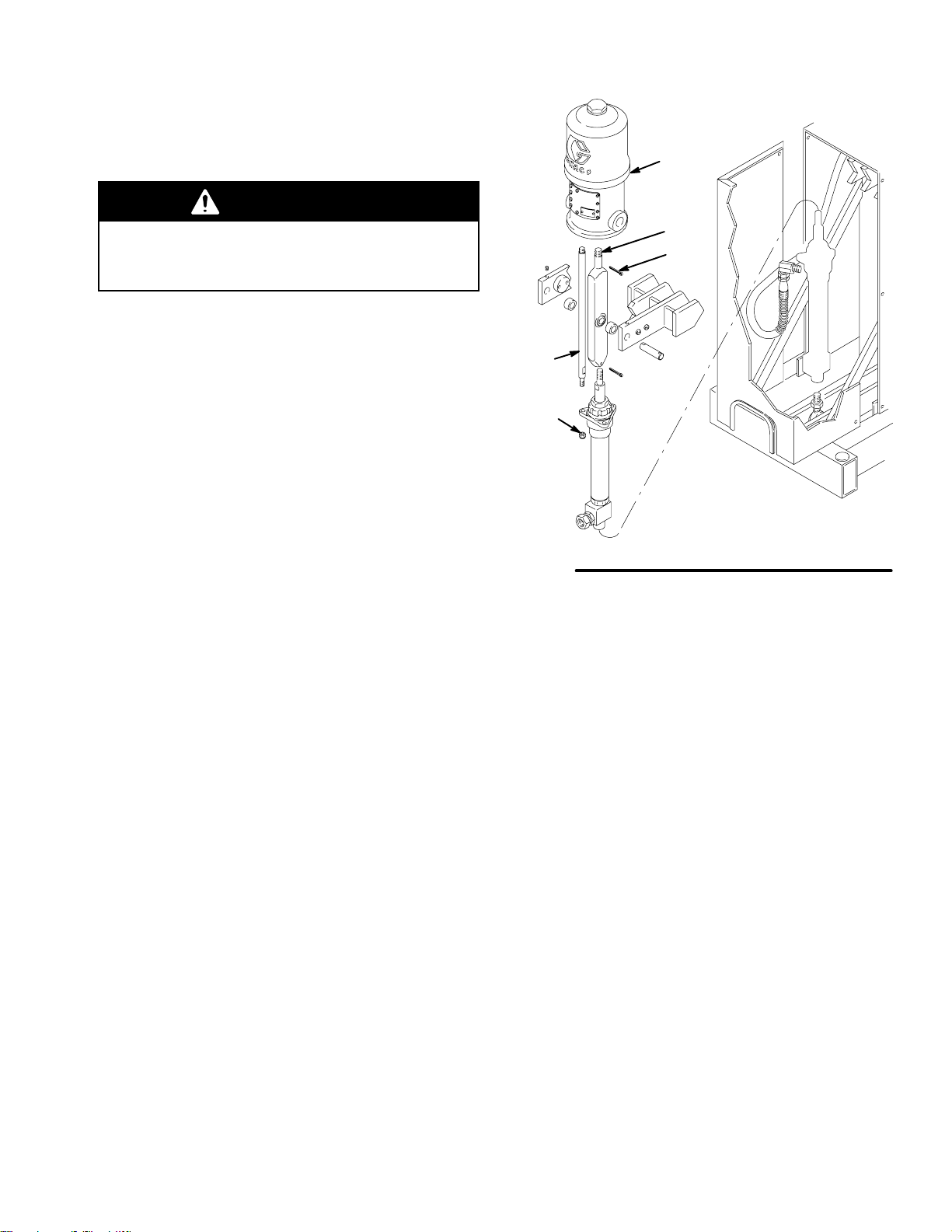

Mounting as Shown:

Monark Air Motor and

Standard Manifold Shown

Page 2

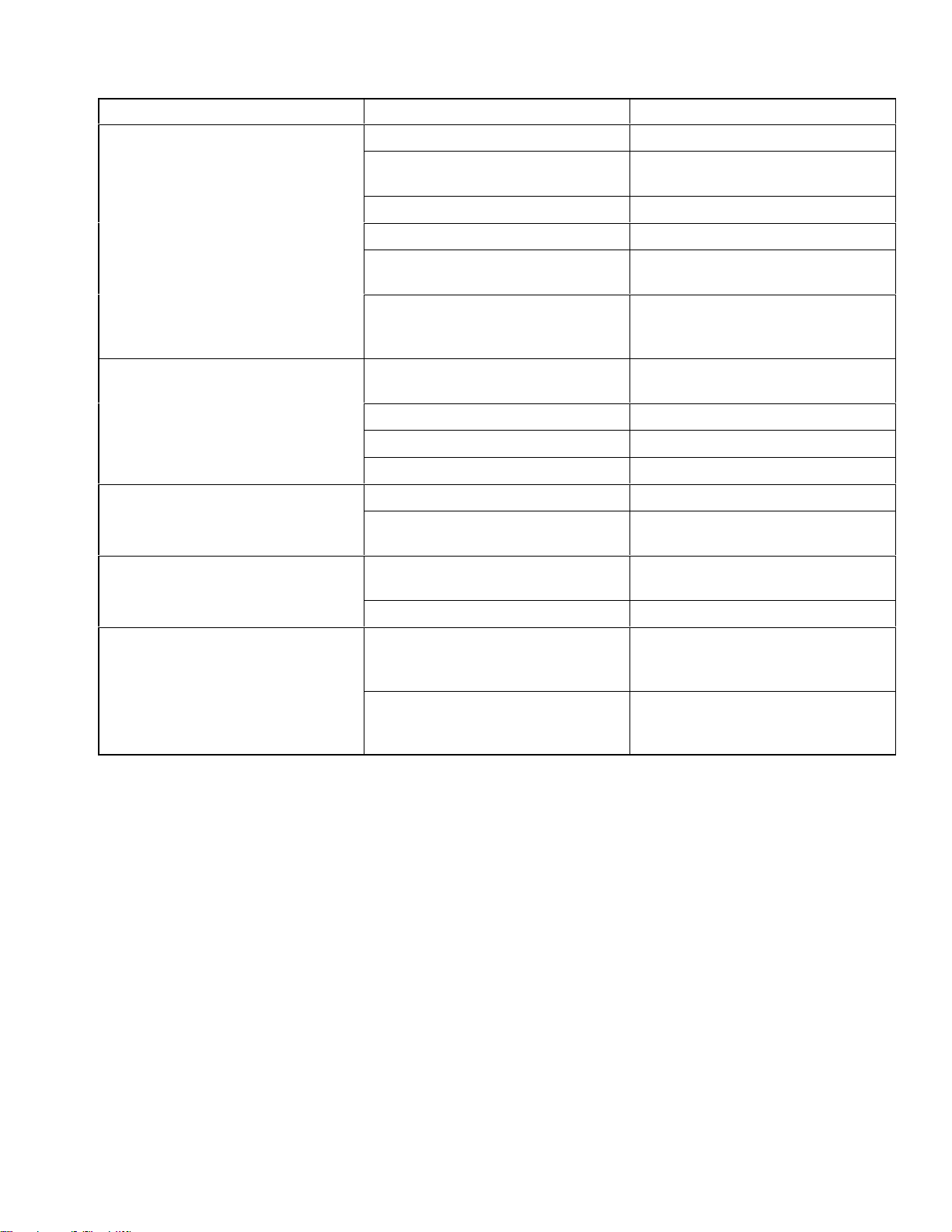

Table of Contents

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Information 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ratio Adjustment 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining the Ratio 11. . . . . . . . . . . . . . . . . . . . . . . . . .

Set the Ratio 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculate the Ratio Setting 13. . . . . . . . . . . . . . . . . . . . .

Setting the Secondary Pump(s) 14. . . . . . . . . . . . . . . . .

Operation 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Service Tools 20. . . . . . . . . . . . . . . . . . . . .

Bearing and Pump Lubrication 20. . . . . . . . . . . . . . .

Air Lubrication 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detecting Bearing and Pin Wear 20. . . . . . . . . . . . .

Removing the Lever Arm from

the VRHC Frame 21. . . . . . . . . . . . . . . . . . . . . . . .

Determining Which Pin

and/or Bearing is Worn 22. . . . . . . . . . . . . . . . . . .

Related Manuals

Fitting the Pins into the Bearings 22. . . . . . . . . . . . .

Storage of Spare Pins and Bearings 22. . . . . . . . . .

Removing the Secondary Pump

and/or the Bearings and Pins 22. . . . . . . . . . . . . .

Replacing the Secondary Pump

and/or the Bearings and Pins 24. . . . . . . . . . . . . .

Removing the Primary Pump and/or the Lower

Bearing and Pin 25. . . . . . . . . . . . . . . . . . . . . . . . .

Replacing the Primary Pump

and/or Bearing and Pins 27. . . . . . . . . . . . . . . . . .

Replacing the Lever Arm on the Frame 28. . . . . . .

Parts 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Warranty 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Information 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual No.

President Air Motors 306982

Monark Air Motors 307043

Bulldog Air Motors 307049

Viscount I 307654

Displacement Pump 307430

Displacement Pumps 307431

Displacement Pumps 307944

Displacement Pumps 684004

Configurator Product Order Form 309025

Displacement Pumps 306936

Displacement Pumps 307862

2 309024

Page 3

Warnings

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

INSTRUCTIONS

in serious injury.

This equipment is for professional use only.

Read all instruction manuals, warnings, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

Check the equipment daily. Repair or replace worn or damaged parts immediately.

See Configurator Product Order Form 309025 for important pressure rating information. The

maximum working pressure of each model is also shown on the pump identification plate. Be sure

that all dispensing equipment and accessories are rated to withstand the maximum working pressure of your pump. Do not exceed the maximum working pressure of the lowest rated system

component.

Never operate the pump without the automatic pressure relief valves and drainage kits installed.

These valves relieve fluid pressure through a drain port at the bottom of the valve if the displacement pump pressure exceeds the working pressure.

Never exceed the recommended working pressure or the maximum air inlet pressure stated on

your pump or in the Configurator Product Order Form 309025.

Do not lift pressurized equipment.

Use only Graco approved hoses. Do not remove hose spring guards, which help protect the hose

from rupture caused by kinks or bends near the couplings.

Route the hoses away from the traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180F (82C) or below –40F (–40C).

Do not use the hoses to pull the equipment.

Use fluids and solvents that are compatible with the equipment wetted parts. See the Technical

Data section of all the equipment manuals. Read the fluid and solvent manufacturer’s warnings.

Comply with all applicable local, state and national fire, electrical and other safety regulations.

309024 3

Page 4

WARNING

SKIN INJECTION HAZARD

Spray from the spray gun, hose leaks, or ruptured components can inject fluid into your body and

cause extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the

skin can also cause serious injury.

Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi-

cal surgical treatment.

Do not point the gun/valve at anyone or at any part of the body.

Do not put your hand or fingers over the spray tip/nozzle.

Do not stop or deflect fluid leaks with your hand, body, glove, or rag.

Do not “blow back” fluid; this is not an air spray system.

Check the gun diffuser operation weekly. Refer to the gun manual.

Always have the trigger guard on the gun when dispensing.

Be sure the gun/valve trigger safety operates before dispensing.

Lock the gun/valve trigger safety when you stop dispensing.

Follow the Pressure Relief Procedure on page 15 whenever you: are instructed to relieve pres-

sure; stop spraying/dispensing; clean, check, or service the equipment; and install or clean the

spray tip/nozzle.

Tighten all fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

Do not repair high pressure couplings; you must replace the entire hose.

Fluid hoses must have spring guards on both ends, to help protect them from rupture caused by

kinks or bends near the couplings.

FIRE, EXPLOSION AND ELECTRIC SHOCK HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in fire, explosion, or electrostatic shock and other serious injury.

Ground the equipment, the object being dispensed, and all other electrically conductive objects in

the dispense area. Proper grounding dissipates static electricity generated in the equipment. Refer

to System Grounding on page 9.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvent or material.

Do not use the heater with flammable liquids, such as those having flash points below 200 F

(93 C).

Extinguish all open flames or pilot lights in the dispense area.

Do not turn on or off any light switch in the dispense area.

Do not use this equipment with flammable liquids.

Keep the dispense area free of debris, including solvent, rags, and gasoline.

4 309024

Do not smoke in the dispense area.

Do not operate a gasoline engine within the spray area.

If there is any static sparking or you feel an electric shock while using the equipment, stop dis-

pensing immediately. Do not use the equipment until you have identified and corrected the

problem.

Page 5

WARNING

MOVING PARTS HAZARD

Moving parts can pinch fingers.

Keep clear of all moving parts when starting or operating the equipment.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all

local, state and national guidelines.

Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid

and solvent manufacturer.

Avoid exposure to heated material fumes.

Provide adequate ventilation.

Graco does not manufacture or supply any of the reactive chemical components that may be

used in this equipment and is not responsible for their effects. Graco assumes no responsibility

for loss, damage, expense or claims for personal injury or property damage, direct or consequential, arising from the use of such chemical components.

System Information

This manual describes pumps designed to be part of a

Variable Ratio Hydra-Cat Pump (VRHC) dispensing

system. The VRHC proportions, mixes, and dispenses

two component fluid materials by powering two positive

displacement pump lowers from a common air motor.

This assures that the stroke rate and stroke length of

all pump lowers are proportional as set, providing

constant proportioning. The mix ratio is determined by

the movement of the outboard (slave) pump along the

arm of the machine. This movement changes the

stroke of the slave cylinder and, along with its volumetric output relationship to the master cylinder, determines the output (volumetric) ratio. The volumetric

ratio is expressed as the proportion of the volume of

fluid of the primary pump compared to the volume of

the secondary pump.

The basic proportioner includes an air motor, lower

displacement pumps, air controls, fluid inlet hardware,

fluid outlet hoses, manifold blocks and relief valve.

Additional proportioner accessories are selectable to

complete the proportioner pump (see Configurator

Product Order Form 309025).

309024 5

Page 6

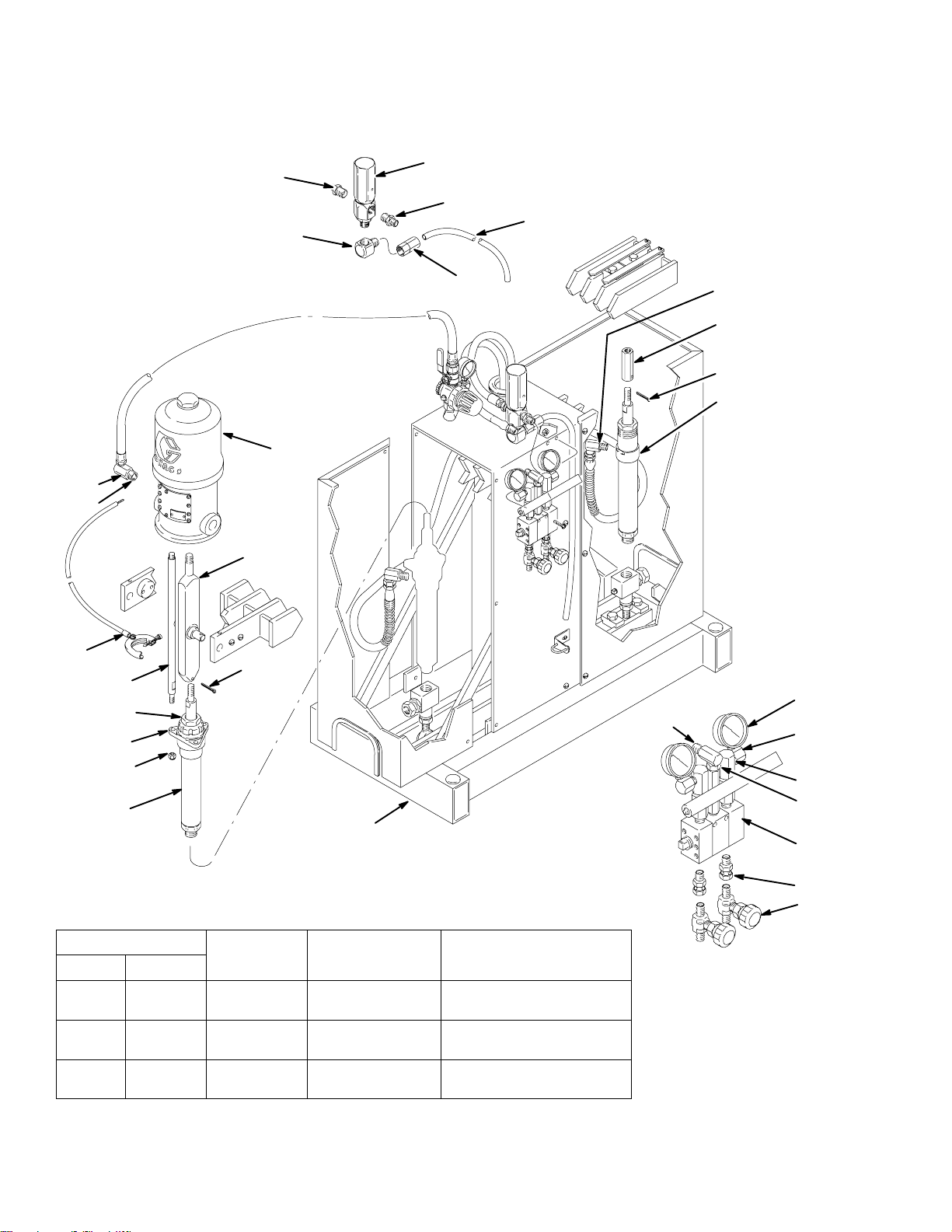

Typical Installation

About Typical Installations

The typical installations shown below and on page 7

are only guidelines to setting up a complete VRHC

system. For clarity, various components are shown in

the correct order but may not be shown in the exact

position of the installed system. For assistance in

designing your system, contact your nearest Graco

representative.

Airless Spray Dispensing System for

Light Viscosity Fluids

KEY

E Air Supply

F Base Supply

G Catalyst Supply

H Base Supply Pump

J Air Shutoff Valve

K Catalyst Supply Pump

L Air Line Filter

P Static Mixer

R Primary Pump Inlet

T Secondary Pump Inlet

U Solvent Pump

V Airless Spray Gun

X Grounded Fluid Hose

8 Air Pressure Gauge

NOTE: When pressure feeding the proportioning

pump, mount fluid pressure gauges (J) at the proportioning pump inlets to monitor proper adjustment of the

feed pump pressures. Never exceed 400 psi on the

inbound fluid pressure and never exceed 25% of

the Hydra-Cat pump outbound fluid pressure on

the feed supply.

13 Air Regulator

45 Bleed–type Master Air Valve

46 Pressure Relief Valve

104 Pressure Gauge

120 Mixer Manifold

123 Air Motor

124 Secondary Proportioning Pump (Slave)

H

G

E

K

LJ

123

124

F

X

U

V

45

XXTP

R

8

46

104

13

Fig. 1

6 309024

120

7117B

Page 7

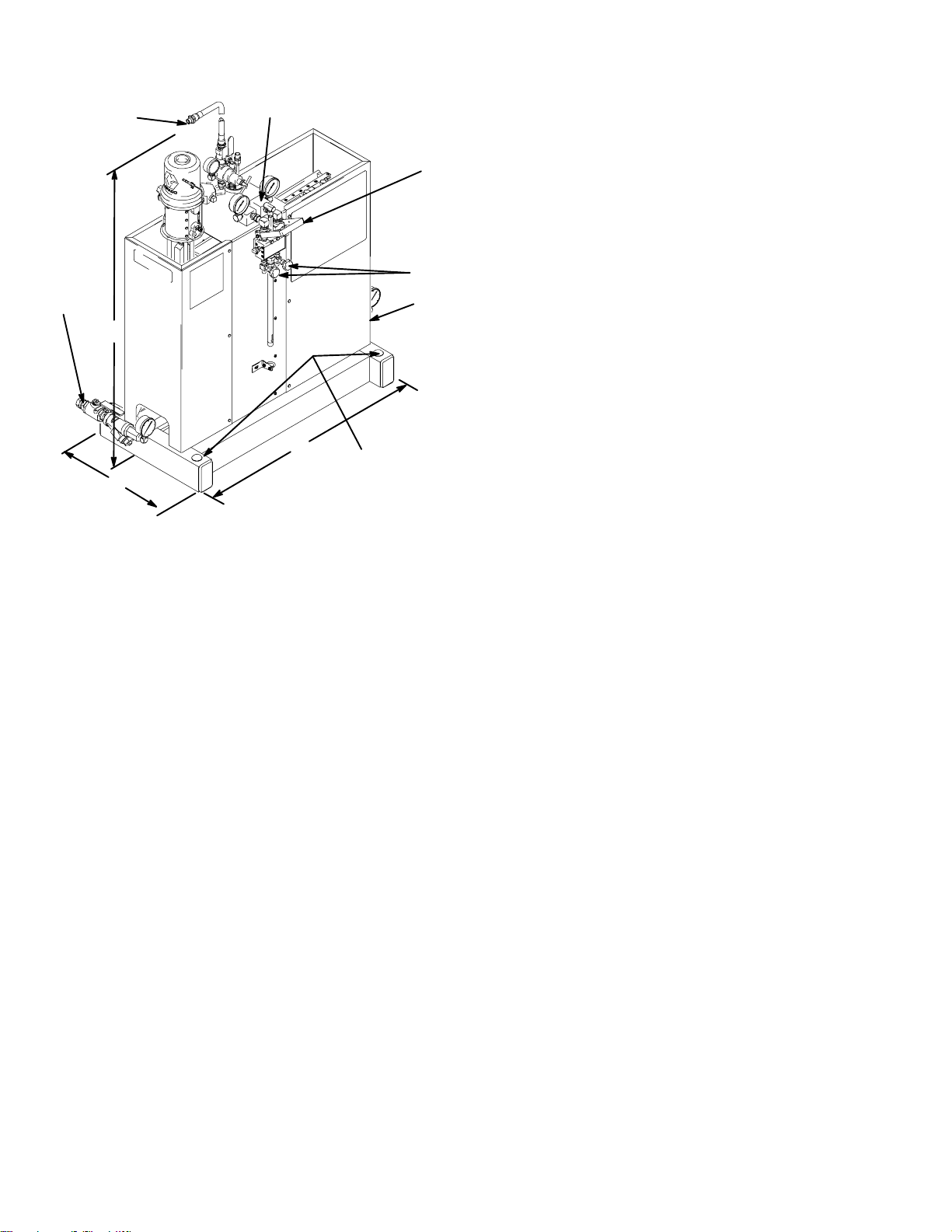

KEY

A Hydraulic Pump

B Mounting Stand

C Hydraulic Supply Line

D Hydraulic Return Line

E Drain Line (from pressure reducing valve)

F Pressure Gauge

G Flow Control Valve

H Pressure Reducing Valve

J Accumulator

K Feed Pumps

P Hydraulic Supply Line Shutoff Valve

R Hydraulic Return Line Shutoff Valve

S Hydraulic Return Line Filter

U Hydraulic Power Supply

V Fluid Hose

W Fluid Supply Line

Y Pump Ground Wire (required)

Y

A

R

F

P

D

H

K

J

K

U

B

G

E

C

V

S

W

9433A

Fig. 2

309024 7

Page 8

Installation

NOTE: Reference numbers and letters in the text refer

to Figures 1 to 18.

Location

Sit the proportioner on a flat floor positioner.

Connect the Solvent Flush Supply Line

Remove the safety panels (38,39,40). See Fig. 4 on

page 10. Connect a grounded fluid hose (X) from the

solvent flush pump to the 3/8 npt solvent flush inlet (N)

of the mixer manifold.

Connect the Fluid Supply Lines

Connect grounded fluid hoses to the 3/4 npt(f) inlet

filter fittings (R,T). If the unit will be pressure fed from

separate supply pumps, install a fluid pressure gauge

at each inlet.

NOTE: Pressurized fluid supplies must not exceed 1/4

the operating fluid pressure of the pump or 400 psi,

whichever is less. Pressure above that level will feed

through the pump and improper proportioning will

result.

System Accessories

Refer to Figures 1 and 2 and Accessories in Configu-

rator Product Order Form 309025.

NOTE: To ensure maximum pump performance, be

sure all accessories are properly sized to meet your

system requirements.

In the air line, install an air filter (L) to remove harmful

dirt and moisture from the compressed air supply.

Downstream from the air filter, the air regulator (13)

and the bleed-type master air valve (45), install an air

line lubricator to provide automatic lubrication to the

motor.

WARNING

The bleed-type master air valve (45) is required in

your system to relieve air trapped between this

valve and the pump after the pump is shut off.

Trapped air can cause the pump to cycle unexpectedly, resulting in serious injury, including amputation.

Connect the Static Mixer to the Manifold

Connect the static mixer (P) to a grounded fluid hose

and spray gun or dispensing valve to the end of the

static mixer. If multiple guns are used, connect a

manifold or pipe “T” to the bottom of the static mix tube

and connect ball valves at each outlet. Connect an

applicator fluid hose to each ball valve.

IMPORTANT: Each side must be flushed at each

application to ensure the lines do not plug with cured

material.

Tighten all fittings. Replace the safety

panels (38,39,40).

Connect the Air Supply Line

Connect a grounded air supply hose to the 1/2 npt(f)

port of the air manifold (37). Open the bleed-type

master air valve (45), and using the pressure

gauge (8), set the air regulator (13) to the desired

pressure. See Figure 1 and 2.

Pressure Relief Valve

Before operating the VRHC, make sure all components have rated working pressures of 3000 psi

(21 MPa, 207 bar) or greater. For more information

about the pressure relief valve, see Instruction Manual

308547.

8 309024

Page 9

Installation

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

Before operating the pump, ground the

system as explained below. Also read

the section FIRE AND EXPLOSION

HAZARD on page 4.

1. Pump: use the ground wire and clamp (supplied).

See Fig. 3. Loosen the grounding lug locknut (W)

and washer (X). Insert one end of the ground

wire (Y) into the slot in lug (Z) and tighten the

locknut securely. Connect the other end of the wire

to a true earth ground.

W

X

Y

Z

2. Air and fluid hoses: use only electrically conductive

hoses.

3. Air compressor: follow manufacturer’s recommendations.

4. Spray gun/dispense valve: ground through connection to a properly grounded fluid hose and pump.

5. Fluid supply container: follow your local code.

6. Object being sprayed: follow your local code.

7. Solvent pails used when flushing: follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the

pail on a nonconductive surface, such as paper or

cardboard, which interrupts the grounding continuity.

Fig. 3

0864

8. To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the spray

gun/dispense valve firmly to the side of a grounded

metal pail, then trigger the gun/valve.

309024 9

Page 10

Ratio Adjustment

Understanding the terms used with the Variable Ratio

Hydra-Cat (VRHC) System, how it functions, and

how to find and set the correct ratio(s) for your application, is the key to easier, more versatile operation of

your proportioning system.

Be sure to read and understand the following information before operating the equipment.

Terms

The ratio refers to the simultaneous output of a certain

volume of fluid by the primary and secondary pumps.

The primary pump (123) is directly under the motor; it

usually pumps the base fluid.

The secondary pump (124) is on the opposite end of

the lever arm (49). It usually pumps the catalyst. One

or two secondary pumps may be used: one for pumping catalyst and the other for reducer injection. If two

secondary pumps are used, then two ratios exist.

The ratio index clamp (30) is used to adjust the ratio

of the secondary pump(s).

There are three main points to remember

when applying the use of ratios:

1. Determine the ratio required.

2. Calculate the ratio setting.

3. Set the ratio on the VRHC System.

46

DD

49

30

EE

40

EE

123

38

39

119

124

KEY

DD Manifold Lever

EE Solvent Valves

Fig. 4

10 309024

02366B

Page 11

Determining the Ratio

Determine your system conditions

If these are your conditions – one primary pump, one

secondary pump, fluids are ready-to-spray viscosity –

set the ratio as explained under Setting the

Secondary Pump(s) on page 14.

If these are your conditions – one primary pump and

one secondary pump, fluids are NOT ready-to-spray

viscosity – the ratio must be determined after the

reducer is added to the base, as instructed in

Procedure 1.

NOTE: The addition of the reducer in the base causes

changes to the ratio. To prevent reducer evaporation,

store the base in closed containers.

NOTE: Some reducers have very little ability to lubricate and may cause seals to dry out. To prolong seal

life, be sure your pump seals are compatible with the

base’s reducer. Contact your Graco distributor for the

correct seals to use.

Procedure 1: Base Is Pre-reduced

When adding reducer to the base before proportioning

with the VRHC System, determine the ratio of the

base/reducer mixture to the catalyst in order to set the

secondary pump at the correct position.

In this example, the instructions on the can say, “Mix 5

parts base to 1 part catalyst. Then reduce 3 parts of

this mixture to 1 part reducer.”

1. Add the parts of the base and catalyst to find the

parts mixture.

5 parts base

+ 1 parts catalyst

6 parts mixture

2. The next statement on the can says, “Reduce 3

parts of the mixture.” So divide the parts of the

mixture by 3 to find the parts reducer.

6 parts mixture

÷ 3 part catalyst

2 parts reducer

3. To determine the ratio of the secondary pump, add

the appropriate parts of base and reducer to find

the parts combined base/reducer.

5 parts base

+ 2 parts reducer

7 parts combined base/reducer to

1 part catalyst:

Result: The ratio of the secondary pump is 7:1.

309024 11

Page 12

Set the Ratio

Fig. 5 shows the relationship between the primary

pump and the secondary pump.

To set the secondary pump on a standard VRHC

System with only two pumps, refer to Setting the

Secondary Pump(s) on page 14.

To set the secondary pump on a non-standard VRHC

System or for an additional secondary pump, refer to

Calculate the Ratio Setting, on page 13.

NOTE: The (91) index setting provides equal primary

and secondary pump stroke lengths. 100 is 1.1 times

the primary pump stroke, allowing adjustability on both

sides of the nominal ratio setting of 91. If the same

primary and secondary pump models are used, a 91

setting will give a 1:1 ratio. If different pump models

are used, you must know the pump’s effective area to

determine the setting. The displacement pumps effective areas are listed in Configurator Product Order

Form 309025

118

20%

4

1

4

91%

123

3 3

KEY

HH Lever Arm Index

1

2

3

4

Fig. 5

100%

4

HH

2

124

02368

Primary Stroke –

4” (102 mm)

Secondary Stroke

Effective Area

Index Setting

Relationship Between Primary and

Secondary Pump

Moving the secondary pump closer to the primary

pump (to a lower index setting) reduces the secondary

stroke length, reducing its fluid output. Moving the

secondary pump further from the priming pump (to a

higher index setting) increases the secondary stroke

length, which increases its fluid output.

12 309024

Page 13

Calculate the Ratio Setting

In this example,

A 5:1 ratio of base to catalyst is required.

The base/primary pump Model (e.g. 221074);

effective area is 0.470 in.

The catalyst/secondary pump Model (e.g. 221026);

effective area is 0.278 in.

1. To determine the base to catalyst setting.

a. Multiply the primary pump’s effective area by

91 (nominal ratio setting).

0.47 primary pump’s effective area

91 nominal ratio setting

x

42.77 answer a

b. Multiply the catalyst pump’s effective area by

the ratio required.

0.278 catalyst pump’s effective area

x 5 ratio required

1.39 answer b

a. Divide answer a by answer b to determine the

index setting.

2. To make sure the index setting does not exceed

the secondary pump’s maximum stroke length:

a. Multiply the index setting by 0.044 (a constant

number).

30.8 catalyst pump setting

x 0.044 constant

1.355 catalyst pump stroke length

a. See the Pump Specifications Chart on page

12 for the pumps’ maximum stroke length. Do

not use an index setting which will exceed the

maximum stroke length for your pump model.

3. To make sure the index setting does not go below

the secondary pump minimum ratio setting, refer

to 309025 Configured Product Order Form. Do not

use a ratio higher than that specified in the maximum set position, mix ratio column for your system.

4. The number (1.355 from step 2.a.) does not

exceed the pump maximum stroke nor does it go

below the minimum ratio setting, so set the catalyst pump at the 30.8 index setting.

42.77 answer a

.

/.1.39 answer b

30.8 catalyst pump index setting

NOTE: The ratio index is only a reference point and

ratio checks must be performed to qualify the exact

ratio set desired..

309024 13

Page 14

Setting the Secondary Pump(s)

The numbers of the pump settings, calculated from the

procedures in the section, Calculate the Ratio

Setting, correspond to the scale numbers on the lever

arm (49) of the VRHC. See Fig. 6.

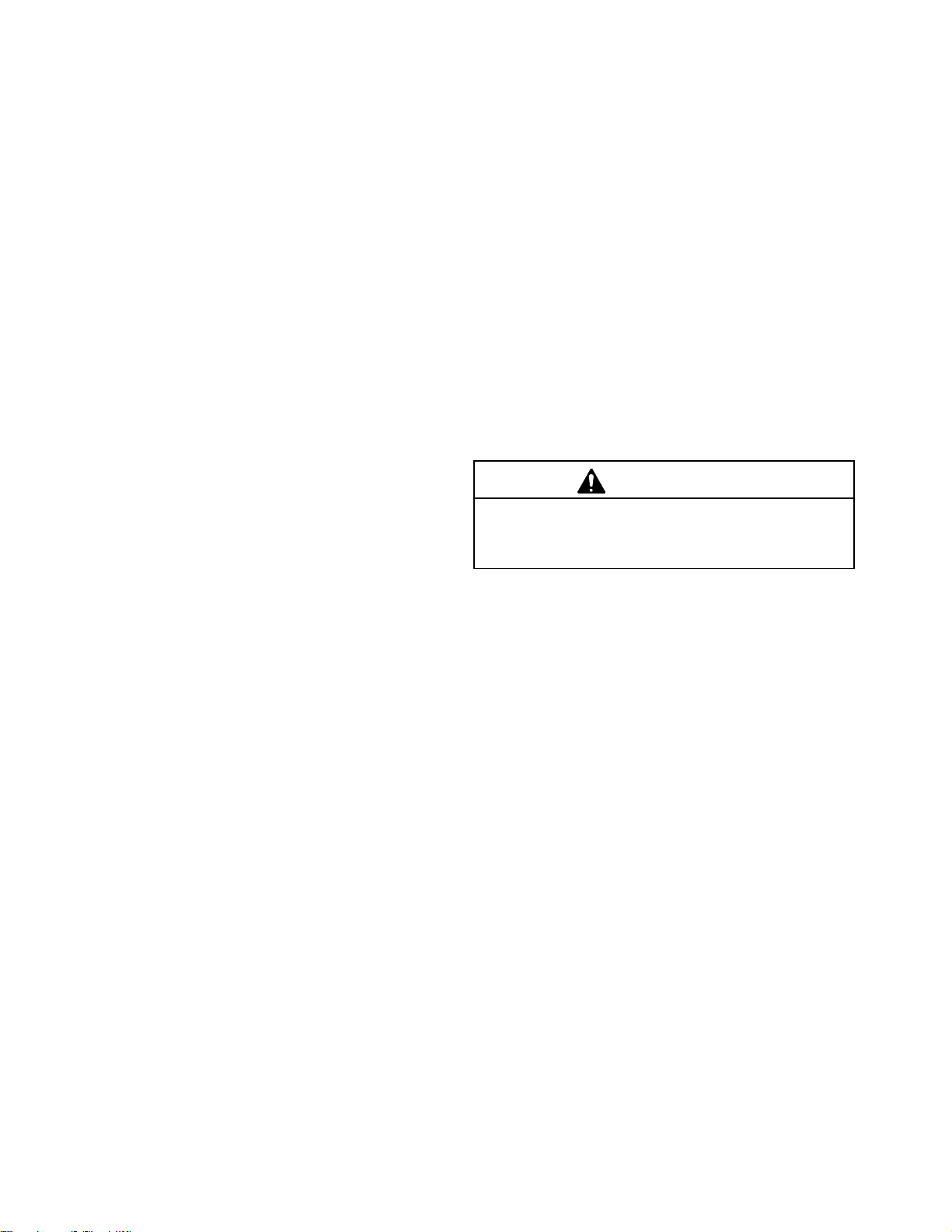

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 15.

1. Relieve the pressure.

2. Flush the unit as instructed on page 16 before

setting the pump.

16

30

26

49

3. Remove the safety panel (39). See Fig. 8 on

page 17.

4. Loosen the four capscrews (16) holding the

secondary pump(s) in place.

5. Open the fluid outlet and lift or push the lever

arm (49) to the horizontal position.

6. Move the secondary pump so that the line on the

index clamp (30) is at the desired setting on the

scale (26).

7. With the secondary pump as vertical as possible,

tighten the four screws (16) to 50 ft-lb (78 N.m).

8. Replace the safety panel (39).

16

02369

Fig. 6

14 309024

Page 15

Operation

Pressure Relief Procedure

WARNING

SKIN INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying/dispensing accidentally. Fluid under high pressure can be injected

through the skin and cause serious injury. To

reduce the risk of an injury from injection, splashing

fluid, or moving parts, follow the Pressure Relief

Procedure whenever you:

are instructed to relieve the pressure,

stop spraying/dispensing,

check or service any of the system equipment,

or install or clean the spray tip/nozzle.

1. Lock the gun/valve trigger safety.

2. Close the bleed-type master air valve (required in

your system).

3. Unlock the gun/valve trigger safety.

4. Hold a metal part of the gun/valve firmly to the side

of a grounded metal pail, and trigger the gun/valve

to relieve pressure.

5. Lock the gun/valve trigger safety.

6. Open the drain valve (required in your system),

having a container ready to catch the drainage.

7. Leave the drain valve open until you are ready to

spray/dispense again.

If you suspect that the spray tip/nozzle or hose is

completely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the tip guard retaining nut or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the tip/nozzle or hose.

309024 15

Page 16

Operation

The pumps, mixer manifold and other components

were tested with lightweight oil at the factory. Before

operating the pump, thoroughly flush the VRHC to

prevent contamination of the fluids.

System Flushing

NOTE: Flush the mixer, hose and gun/valve often

enough to prevent fluid from reacting or curing in them.

Contact your fluid manufacturer for the effective pot life

of the fluid you are using.

1. Put the pump intake hoses of the feed pumps into

5 gallon (20 liter) containers of compatible solvent.

Refer to the fluid manufacturer’s recommendations.

2. Start the pump as explained below.

3. Do not install the spray tip/nozzle yet. Hold a metal

part of the gun/valve firmly to the side of a

grounded metal pail. Using the lowest possible

fluid pressure, trigger the gun/valve into the pail.

Starting the Pump

NOTE: To open the mixer manifold (120), put the

handle in the down position. To close the mixer

manifold, put the handle in the up position. See Fig. 7.

CAUTION

Never exceed 25% of the normal proportioner output

pressure with the feed system.

1. Start feed pump supplies and ensure fluid pressure is at least 25 psi at each pump outlet.

2. Close the bleed-type master air valve. Turn the air

regulator knob all the way out (counterclockwise).

3. Turn on the main air supply.

4. Open the mixer manifold handle, trigger the gun/

valve, slowly open the bleed-type master air valve,

and turn the air regulator knob clockwise until the

pump starts.

4. When clean solvent comes from the gun/valve,

release the trigger and carefully check all connections in the system for leaks.

5. Take the hoses out of the solvent and trigger the

gun/valve until all solvent has been pumped out of

the hoses.

Solvent

Handle Up,

Mixer

Base Catalyst

Closed

Solvent

valve

shown

open

5. Allow the pump to cycle slowly until all the air is

pushed out of the lines. Release the trigger – the

pump will stall against the pressure.

6. The manifold handle controls fluid flow. When the

manifold is open, base and catalyst are supplied to

the gun/valve. To stop the flow, close the handle.

Solvent

Base Catalyst

Solvent

valve

shown

closed

Fig. 7

16 309024

Handle

Down,

Mixer

Open

Solvent Out

02370

Page 17

Operation

NOTE: To open the mixer manifold (120), put the

handle in the down position. To close the mixer

manifold, put the handle in the up position. See Fig. 7

on page 16.

Standard Operating Flushing

1. Use the solvent valves to flush contaminants and

mixed fluids from the mixer manifold, hose and

gun/valve. Follow the procedure below.

a. Start the solvent pump. Close the mixer

manifold.

b. Open one of the solvent valves (EE).

c. Trigger the gun/valve into the metal pail until

the solvent valve is thoroughly flushed.

Release the trigger.

d. Close the open solvent valve. Open the other

solvent valve. Repeat step c

e. With both solvent valves open, flush until all

contaminants and fluids are removed. Release

the trigger.

40

Fig. 8

46

49

30

EE

120

39

119

02366A

2. To flush the sampling valves (119), place a

grounded metal pail under them. Turn the valve

handle to the open position. Flush until all contaminants and fluids are removed. Close the sampling

valves and solvent valves. The solvent valves

should be finger tight only, but must be tight

enough to prevent solvent from mixing with the

fluid during operation.

3. Trigger the gun/valve to relieve pressure.

Checking the Ratio

1. Open the mixer manifold (120).

2. Set the operating pressure. After determining the

operating pressure, release the gun/valve trigger

and lock the trigger safety.

3. Close the mixer manifold.

4. Open the sample valve (119) on the secondary

pump side approximately three turns. Open the

sampling valve on the primary pump side just one

turn. This prevents the pressure from building up

on the secondary pump, which would cause the

relief valve (46) to open.

5. Place a grounded metal pail under the sampling

valves.

6. Open the mixer manifold. Use the sampling valves

to adjust the pressures to your normal operating

pressure.

NOTE: The pressure must be within 20% of your

normal operating pressure to get a useable sample.

7. Close the mixer manifold. Put the sampling

containers under the sampling valves.

8. Open the mixer manifold. Check the ratio. Make

sure the pressure is within 20% of the normal

operating pressure. Close the mixer manifold when

enough fluid has been dispensed into the sampling

containers.

NOTE: If the pressure is not within 20% of the normal

operating pressure, follow the flushing procedure on

page 16, and then take another sample. If the sample

ratio is incorrect, there is a problem with the sample

valves, secondary pump setting or the pump operation.

Check the pump setting or service the sampling valves

or pump.

309024 17

Page 18

Troubleshooting

Troubleshooting Techniques

Because the pumps are mechanically linked, the action

of one pump can affect the readings of the second

pump. Therefore, the key to successful troubleshooting

is to be sure to isolate the problem.

For example, the secondary pump pressure, as read

on the gauge, is low and sluggish during pump

changeover. The most likely problem is a binding

primary pump.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 15.

To isolate the pump:

WARNING

Use very low air pressure to the air motor when

making these checks. This system can produce

very high fluid pressure, which can cause serious

injury, including injection, splashing in the eyes or

on the skin, and injury from moving parts. Follow

the Pressure Relief Procedure on page 15.

WARNING

To reduce the risk of injuring or amputating a hand,

fingers or other body parts, never place your hands

or any part of your body or any tools inside the

safety panel at any time, for any reason, while the

unit is operating.

Refer to the manuals listed below to repair

the VRHC components.

1. Relieve the pressure.

2. Disconnect the index clamp (30) from the

secondary pump and lean the pump out of the way

of the lever arm (49). Now you can verify the

operation of the primary pump alone.

3. Use the sampling valves (119) at the mixer

manifold (120).

a. Check the outlet ratio for the primary side.

b. With the sampling valves closed, check for

pump stalling on both the up and down

strokes.

c. Check for rapid gauge response during pump

changeover.

4. When the operation of the primary side has been

verified, reconnect the lever arm (49) to the

secondary pump. Let the primary pump run freely

in a pail of fluid and repeat the checks in Step 3 on

the secondary side.

Component Ref. No. Manual No.

President Motor 207352 306982

Bulldog Motor 20835 307049

Monark Motor 205997 307043

Viscount I

Hydraulic Motor

Pump Lower 215932 307430

Pump Lower 215930 307431

Pump Lower 217339 307430

Pump Lower 222012 307944

Pump Lower 239388 307944

Pump Lower 222015 307944

Pump Lower 222017 307944

Pump Lower 222019 307944

Pump Lower 217529 306936

Pump Lower 901878 307862

Pump Lower 948640 684004

Pump Lower 948641 684004

Pump Lower 948195 307944

Pump Lower 948197 307944

948699

307654

18 309024

Page 19

Problem Cause Solution

System won’t run or stops while

running

Troubleshooting

Air pressure or volume too low Increase, check air compressor.

Closed or restricted air line or air

valve

Fluid valves closed Open fluid valves.

Clogged fluid hose Replace fluid hose.

Air motor worn or damaged Service air motor; see manual

Displacement pump stuck Service displacement pump. See

Open or clean as required.

306982.

manuals listed in the chart on

page 18.

Fluids not mixing properly

System speeds up or runs

erratically

Squeaking or knocking noise is

heard

System stops running on the end

of a stroke

Clogged filter in fluid line Clean; replace element if neces-

sary.

Manifold problems Refer to manual 307400.

Check ratio Check; replace pump.

Clogged fluid hose Replace fluid hose.

Fluid containers are empty Check often – keep filled.

Displacement pump parts worn or

damaged

Bearing(s) dry or worn Lubricate; replace bearing(s) if

Pump bottoming out See below.

Secondary displacement pump

bottomed out because ratio index

clamp was set too far out

Secondary displacement pump

bottomed out because top pivot

bearings are set too high

Service displacement pump. See

manuals listed in the chart below.

necessary.

Adjust ratio index clamp.

Adjust bearings. See Removing

the Lever Arm from the VRHC

Frame on page 21.

309024 19

Page 20

Service

Required Service Tools

Tool Use for

3/32”–90 or

T-handle hex key

3/4” open end wrench Clamp bolts and fluid

1” open end wrench Locknuts on capscrews

9/16” open end wrench Tie rod nuts

1/2” open end wrench Loosening tie rods from

1–1/8” open end wrench Pivot bearing locknuts

Adjustable open end

wrench

Needle nose pliers Bending and pulling

Medium slotted

screwdriver

Small hammer and 6”

punch

All setscrews

hose on pump outlet

motor base

Tightening connecting

rod to pumps

cotter pins

Removing shields

Tapping out pins

Air Lubrication (Air Operated Motors Only)

If your air supply is very dry, install air line lubricators

between the air regulators and pumps for automatic air

motor lubrication. See Accessories in Configurator

Product Order Form 309025 for a lubricator.

Lubricate periodically with

1

Graco Gear Reducer Oil

1

1

1

Bearing and Pump Lubrication

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 15.

1. Relieve the pressure.

2. Insert one end of the nylon hose (52) into the

wet-cup.

3. Pour Throat Seal Liquid (44) into the hose until the

wet-cup is full.

4. Lubricate the VRHC periodically with Graco Gear

Reducer Oil (43). If the pump is operating continuously at 60 cycles/min., lubricate at the points

shown in Fig. 9 once every five days.

Service instructions are in the manuals for the separate components. See the chart on page 18.

1

Fig. 9

02371A

Detecting Bearing and Pin Wear

Audio Detection

When a bearing fails, it makes a knocking noise each

time the pump changes stroke. Shut off the system

immediately to avoid serious damage. Replace the

bearing(s).

Visual Detection

Check the movement of the lever arm (49) by watching

it through the opening in the safety panel (39). If it

bounces, shut off the system immediately to avoid

serious damage. Replace the bearing pin.

20 309024

Page 21

Service

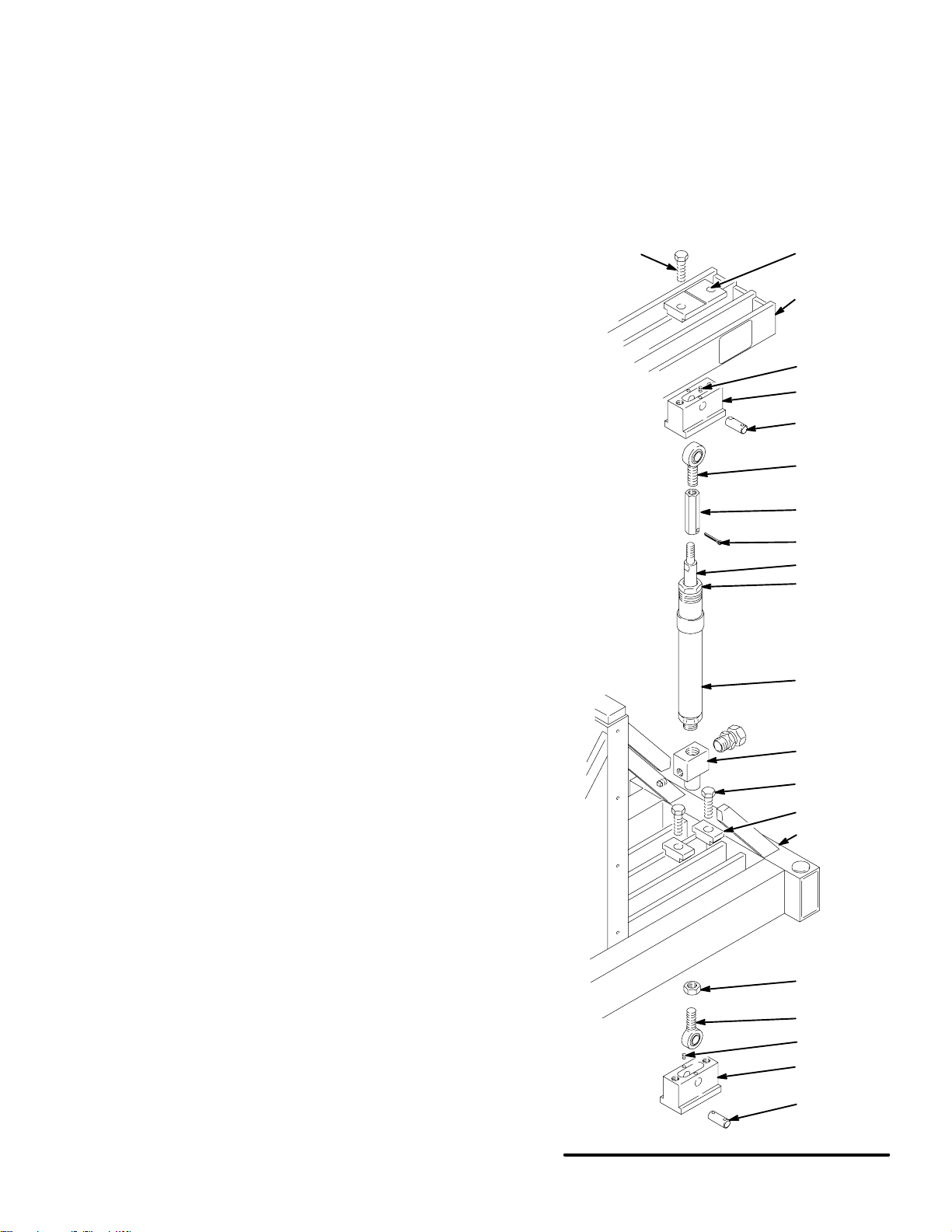

Removing the Lever Arm from the VRHC

Frame

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 15.

1. Flush the entire system with a solvent which is

compatible with the fluid being pumped. Disconnect the air line and relieve the pressure.

2. Remove the safety panels (38,39,40). See Fig. 10.

3. Loosen the two setscrews (59) holding the primary

displacement pump pin (35c) in the lever arm (49).

See Fig. 11. The setscrews must be backed out far

enough to clear the countersinks of the pin. Tap

the pump pin out of the lever arm and bearing.

4. Slide the primary pump out of the lever arm (49)

slot and save the two nylon spacers (27c).

11. Remove the punch and lift the lever arm (49) off

the VRHC frame.

12. Loosen the two pivot bearing locknuts (2) and turn

the bearings (15) out of the housing (122). The

bearings should be only hand tight. If they are

tighter, use a wrench on the flats of the bearing

(15) to unscrew the bearing from the frame.

49

39

40

5. Slowly lower the pump to the floor until it supports

itself with the lower bearing (14d). See Fig. 17 on

page 27.

6. Push down on the secondary displacement pump

end of the lever arm (49) at point (JJ) until it is at

the bottom of the stroke. See Fig. 11.

7. Remove the two top capscrews (16a) from the

index clamp (30).

8. Raise the lever arm (49) slowly. Lower the

secondary pump to the floor until it supports itself

with the lower bearing.

9. Loosen the two setscrews (17) located above the

ends of the frame pin (33). The setscrews must be

turned out far enough to clear the countersinks of

the pin.

10. Using a long punch and hammer, gently drive the

frame pin (33) out from one end until it can be

pulled out.

CAUTION

Fig. 10

121

59

35c

27c

33

49

1

12

38

1

15

2

02366A

16a

30

JJ

17

31

34a

Do not drop the pin; dents will make reassembly difficult.

Fig. 11

02372

309024 21

Page 22

Service

Determining Which Pin and/or Bearing is

Worn

1. Disassemble the VRHC. After the pins and bearings are removed, wipe them off with a clean rag.

2. Visually inspect the pins for scoring, lines, grooves

and scratches on the area in contact with the

bearing. Then feel the surface of the pin for rough

areas or a difference in size. If these signs of wear

are detected, replace both the pin and bearing.

3. To check the bearings, hold the threaded part of

the bearing in one hand and use the other hand to

move the balls inside the bearing up and down. If

there is any noticeable movement, replace the

bearings. Also check the bearings for roundness. If

a bearing appears to be out of round (eggshaped), replace it.

Fitting the Pins into the Bearings

Tolerances between the surface of the pin and the

bearings are very close. Never force the pin into the

bearing. If the pin does not fit, sand it from the end to

just past the countersinks with 500 grit sandpaper. See

Fig. 12. If the pin still does not fit, return it to the

factory for replacement. If the pin needs replacement,

replace the bearing also.

Removing the Secondary Pump and/or the

Bearings and Pins

1. Flush the entire system with a compatible solvent.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 15.

2. Relieve the pressure.

3. Remove the safety panel (39). See Fig. 13.

Disconnect the inlet and outlet fluid hoses of the

secondary displacement pump (124).

39

Fig. 12

02373

Storage of Spare Pins and Bearings

Completely coat spare pins and bearings with Graco

Gear Reducer Oil (43) or the equivalent when storing

these parts. Never use grease.

22 309024

1

02366A

Fig. 13

Continued on page 23.

Page 23

Service

NOTE: Refer to Fig. 14 for steps 4 to 10.

4. Push down on the lever arm (49) until the wrench

flats (KK) on the secondary pump (124) are just

above the wet-cup (LL). Remove the ratio index

clamp capscrews (16a) and the index clamp (30).

NOTE: Some fluid will drip from the pump when you

are removing the ratio index clamp.

5. Raise the lever arm (49) off the pivot pin

support (31a).

6. Remove the connecting rod cotter pin (102), if the

pump has one. Unscrew the connecting rod

assembly (117, 14a, 34a, 31a) in one piece from

the pump.

7. If you are removing only the pump, remove it from

the inlet manifold (32). If the secondary pump(s)

need repair, follow the instructions in its manual.

8. If you are removing the bearings and pins, tilt the

secondary pump (124) forward until it rests on the

floor. Then follow Steps 9 and/or 10.

9. If you are removing the upper bearing (14a) and

support pin:

d. Raise the VRHC lower frame (50) and remove

the support (31b).

e. Gently tap the support pin (34b) out with a

hammer and punch.

f. Replace the pin and bearing.

16a

30

49

17a

31a

34a

14a

117

102

KK

LL

a. Loosen the two setscrews (17a). Back out the

setscrews far enough to clear the countersinks

of the support pin (34a).

b. Place the support (31a) in a vise. Unscrew the

connecting rod (117) from the bearing (14a).

The connecting rod and bearing are sealed

with thread sealant and may be difficult to

unscrew.

c. Remove the support (31a) from the vise.

Gently tap the support pin (34a) out with a

hammer and punch.

d. Replace the support pin and bearing.

10. If removing the lower bearing (14b) and support

pin (34b):

a. Remove one of the lower clamps (28) and

capscrews (16b).

b. Loosen the locknut (3) and screw the pump

manifold (32) off the bearing (14b) to remove

the secondary displacement pump (124).

c. Remove the remaining clamp (28) and cap-

screw (16b) from the lower support (31b).

124

32

16b

28

50

3

14b

17b

31b

34b

02374

Fig. 14

309024 23

Page 24

Service

Replacing the Secondary Pump and/or the

Bearings and Pins

NOTE: Refer to Fig. 14 for Steps 1 to 3.

1. If only the secondary pump is being replaced:

a. Screw the secondary pump (124) into the inlet

manifold (32). The manifold must face the end

of the VRHC as shown in Fig. 14. If it does

not, rotate the secondary displacement pump

until it does, and tighten the locknut (3) against

the inlet manifold. Torque the locknut to 60 ft-lb

(81 N.m).

b. Replace the connecting rod assembly (117,

14a, 34a, 31a) onto the displacement rod, and

line up the cotter pin holes. Insert the cotter

pin (102).

c. Raise the lever arm (49) and place the

support (31a) under the proper slot.

d. Push down the lever arm until the support fits

into the slot. If the support does not line up

with the slot, rotate it clockwise until it does.

e. Place the ratio index clamp (30) over the top of

the support (31a). Insert the capscrews (16a).

f. Set the index clamp (30) for the proper ratio

and tighten the capscrews (16a).

2. If replacing the lower bearing (14b) and support

pin (34b):

a. Place a generous amount of Graco Gear

Reducer Oil (43) on the inside of the lower

bearing (14b) and the surface of the support

pin (34b).

b. Screw the locknut (3) onto the bearing (14b)

threads until the locknut bottoms out.

c. Slide the bearing into the slot in the

support (31b). Insert the pin (34b) into place

with the countersinks under the setscrew (17)

holes. Tighten the setscrews to 35 in-lb (4

N.m). These are 10–32 self-locking setscrews.

If no drag is felt while turning, replace the

setscrew.

d. Screw the secondary displacement

pump (124) and manifold (32) onto the

bearing (14b) until it bottoms out. Be sure it is

not resting against the locknut (3).

e. Align and loosely install the two clamps (28)

and capscrews (16b).

3. If replacing the upper bearing (14a) and support

pin (34a):

a. Place a generous amount of Graco Gear

Reducer Oil (43) on the inside of the upper

bearing (14a) and the surface of the support

pin (34a).

b. Slide the support (31a) onto the bearing (14a).

Insert the support pin (34a) with the countersinks in place under the setscrew (17a) holes.

CAUTION

Do not force the pin into place. Check for burrs on

the pin or in the VRHC frame if the pin does not slide

into place.

c. Tighten the setscrews (17a) to 35 in-lb

(4 N.m). These are 10–32 self-locking screws.

If no drag is felt while turning, replace the

setscrews.

d. Place the support (31a) in a vise and screw

the connecting rod (117) onto the bearing

(14a). The connecting rod and the bearing can

be disassembled and then reused one time

before needing replacement. Be sure to seal

the connecting rod and the bearing with thread

sealant such as Loctite No. 27105 or the

equivalent. Apply 3 drops of the sealant to the

threads of the bearing.

e. Screw the connecting rod (117) onto the

pump (124) until the cotter pin holes line up (if

the displacement pump has them). Install the

cotter pin (102) and tighten the connecting rod

against the piston shoulder of the displacement rod.

f. Follow steps 1.c to 1.f at left.

g. Tighten the capscrews (16b) at the bottom of

the secondary displacement pump (124).

24 309024

Page 25

Service

Removing the Primary Pump and/or the

Lower Bearing and Pin

1. Flush the entire system with a compatible solvent.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 15.

2. Relieve the pressure.

3. Remove the safety panels (39,40). Disconnect the

inlet and outlet hoses on the primary displacement

pump (123).

NOTE: Refer to Fig. 15 for Steps 4 to 6.

4. Remove the three tie rod locknuts (103) and push

up on the air motor (118) until the tie rods (116)

clear the mounting holes of the displacement

pump. See Fig. 15.

5. Using a wrench on the flats of the tie rods,

unscrew them from the air motor base.

6. Remove the upper cotter pin (102c) and unscrew

the air motor from the connecting rod (121).

116

103

Fig. 15

Continued on page 26.

118

121

102c

02375A

309024 25

Page 26

Service

NOTE: If only the motor needs repair, follow the

instructions in the appropriate manual.

NOTE: Refer to Fig. 16 for Steps 7 to 15.

7. Remove the lower cotter pin (102d) from the

connecting rod (121) (if the pump has one) and

loosen the two setscrews (59). The setscrews

must be backed out far enough to clear the countersink of the bearing support pin (35c).

8. Hold the connecting rod (121) and gently tap out

the support pin (35c) with a hammer and punch.

9. Slowly pull the connecting rod (121) away from the

lever arm (49) and tilt the pump (123) forward until

it rests on the frame. Save the two nylon

spacers (27c).

10. Unscrew the connecting rod (121) from the

displacement pump (123). If necessary, replace

the connecting rod.

11. If removing the pump only, remove it from the

manifold (32). If the primary pump needs repair,

follow the instructions in the separate pump

manual.

12. If removing the lower bearing (14d) and pin (35d),

tilt the primary pump (123) forward until it rests on

the floor. Then follow steps 13 to 15.

13. Loosen the lower rod end locknut (3) and unscrew

the pump manifold (32) to remove the primary

pump (123).

14. Loosen the two setscrews (17b). The setscrews

must be backed out far enough to clear the countersinks of the support pin (35d).

15. Remove the pin (35d) and save the two nylon

spacers (27d) and the bearing (14d).

35d

17b

35c

27c

59

121

32

49

3

118

121

102c

02376

116

102d

14d

27d

103

123

Fig. 16

26 309024

02377

02375A

Page 27

Service

Replacing the Primary Pump and/or

Bearing and Pins

NOTE: Refer to Fig. 17 for Steps 1 to 9 except where

noted.

1. Screw the displacement pump (123) into the inlet

manifold (32) so the outlet is facing the back.

2. Screw the connecting rod (121) onto the primary

displacement pump until the cotter pin holes line

up. Install the cotter pin (102d) if the pump has

one; if not, bottom out the connecting rod on the

displacement pump.

3. Pull the connecting rod upward until the displacement pump stops.

4. Screw the air motor (118) onto the connecting rod

until the cotter pin holes line up. Install the cotter

pin (102c).

5. Rotate the air motor until the air inlet port is on the

same side as the air inlet manifold (37).

7. Push down the air motor and place the tie rods into

the displacement pump tie plate. Tighten the tie

rod locknuts (103).

8. To install the support pin (35c) into the upper

bearing:

a. Remove the two capscrews (16a) from the

support (31a) on the secondary pump (124).

b. Move the lever arm (49) until you can place

the nylon spacers (27c) and support pin (35c)

in line with the bearing in the connecting rod

(121).

c. Lubricate the support pin with Gear Reducer

Oil (43) and tap it into the upper bearing with

the countersinks facing up.

CAUTION

Do not force the pin into place. Check for burrs on

the pin or in the VRHC frame if the pin does not slide

into place. Sand with 500 grit sandpaper between the

countersinks.

6. Screw the three tie rods (116) into the air motor

base and torque to 35–50 ft-lb (47–68 N.m).

NOTE: One of the tie rods will run through the lever

arm slot.

118

121

59

27c

116

103

102c

49

35c

102d

d. Torque the two setscrews (59) to 35 in-lb

(4 N.m). See Fig. 18 on page 29.

e. Move the lever arm (49) back into place and

reinstall the two capscrews (16a) onto the

support (31a) of the secondary pump.

1

3

35d

27d

17b

2

14d

02430

123

32

02375A

1

Torque to 60 ft-lb (81 N.m)

2

Torque to 35 in-lb (4 N.m)

309024 27

Page 28

Service

9. If replacing the lower bearing (14d) and pin (35d):

a. Thread the locknut (3) all the way onto the

bearing.

b. Screw the inlet manifold (32) onto the bearing

twelve turns and tighten the locknut up to the

inlet manifold. Torque to 60 ft-lb (81 N.m).

c. Lubricate the support pin (35d) with Gear

Reducer Oil (43). Install the pin with the countersinks facing up, into one side of the frame

base (50). Place one nylon spacer (27d) on

the end of the support pin.

d. Install the bearing (14d) and manifold (32) and

align them with the support pin (35d).

e. Tap the pin in flush with the opposite side of

the frame. Align the second nylon spacer with

the support pin, and tap the pin all the way into

the side of the frame base (50).

f. Tighten the two setscrews (17b) onto the

support pin (35d). Torque to 35 in-lb (4 N.m).

g. Follow the procedure for replacing the primary

pump on page 27.

Replacing the Lever Arm on the Frame

CAUTION

Tolerances between the surface of the frame and

bearing are very close. Do not force the pin into

place. Check for burrs on the pin or in the VRHC

frame if the pin does not slide into place. Sand with

500 grit sandpaper between the countersinks.

NOTE: Refer to Fig. 18 for Steps 1 to 5.

1. Screw the locknuts (2) onto the pivot bearing (15).

2. Screw the pivot bearing into the frame base (50).

Adjust the distance from the top of the support

pin (33) to the bottom of the frame (50) to 26.125”

(664 mm).

3. With the bearings at the correct height and parallel

to each other, torque the locknuts (2) to

60 ft-lb (81 N.m).

4. Place a generous amount of lubricant (43) onto the

support pin, and place the lever arm (49) over the

bearings (15).

5. Slide the support pin, with the countersinks up,

through the lever arm and bearings. Torque the

two setscrews (17) to 35 in–lb (4 N.m).

NOTE: If no drag is felt while turning the setscrews,

replace them.

28 309024

Page 29

Service

35

16

17

30

59

1

15

31

26.125”

(664 mm)

2

2

35d

27d

121

124

32

50

15

33

50

123

Torque to 35 in-lb (4 N.m)

1

Torque to 60 ft-lb (81 N.m)

2

02378

Fig. 18

02371A

309024 29

Page 30

For Monark Options A01, M01, and Q01

125

128

Parts

126

127

130

107

118

121

129

117

107

or

111

124

116

102

103

123

30 309024

02434A

108

110

120

122

106

115

105

109

119

Page 31

For Monark Options A01, M01, and Q01

Parts

Ref.

No. Part No. Description Qty.

102 100103 PIN, cotter 3

103 101566 LOCKNUT, 3/8–16 3

Ref.

No. Part No. Description Qty.

119 108233 SAMPLE VALVE, needle 2

120 215626 MANIFOLD 1

104 104088 RIVET 2

105 100139 PLUG, pipe, 1/8 npt 2

121 215693 CONNECTING ROD 1

106 105770 FLUID PRESSURE GAUGE, 2

1000 psi (70 bar), 1/4 npt(m)

122 215925 UNIT FRAME 1

107 155494 UNION, 3/8 npt(m) x 3/8 npt(f) 1

108 155541 SWIVEL UNION, 90,1

123 215932 PRIMARY DISPL. PUMP 1

1/4 npt(m) x 1/4 npsm(f)

109 156823 UNION, 1/4 npt(m x f) 2

124 222015 SECONDARY DISPL. PUMP 1

110 158962 ELBOW, street, 2

1/4 npt(f) x 1/8 npt(m)

111 161037 SWIVEL UNION, 1/2 npt(m) x

3/8 npsm (f) 1

114 172446 PLATE, designation 1

115 177088 SWIVEL UNION, 3/8 npt(f) x 2

3/8 npsm(f), two 1/8 npt(f) ports

116 177109 TIE ROD, 15.81 inch (401.6 mm) 3

shoulder–to–shoulder

117 177114 CONNECTING ROD, 1

2.535 inch (64.4 mm) long

used in A01 Option

177113 CONNECTING ROD 1

2.62 inch (66.5 mm) long

used in M0I and Q01 Options

118 205997 AIR MOTOR, Monark 1

See parts in manual 308043

125 162449 NIPPLE, 1/2 x 1/4 1

126 237060 RELIEF VALVE 1

127 159239 NIPPLE, 3/8 x 1/2 1

128 158683 ELBOW 90, 1/2 x 1/2 1

129 113187 CONNECTOR, female, tube 1

130 190738 TUBE, nylon 1

See parts in manual 307400

12.67 inch (321.8 mm) long

see parts on pages 32 to 35

See parts in manual 307430

Used in M01 Option

See parts in manual 307431

215932 SECONDARY DISPL. PUMP 1

Used in A01 Option

See parts in manual 307430

222019 SECONDARY DISPL. PUMP 1

Used in Q01 Option

See parts in manual 307431

475 (33) to 575 (400) psi (bar)

working pressure

309024 31

Page 32

Unit Frame All Options

Torque to 35 in–lb (4 N.m)

1

Torque to 60 ft–lb (81 N.m)

2

12

Parts

16

42

12

26

25

1

53

59

35

27

36

33

32

25

17

49

1

31

34

15

53

2

14

5

32

16

5

2

28

9

32 309024

3

2

3

2

60

50

14

17

1

31

34

02432A

Page 33

Unit Frame All Options

Parts

Ref.

No. Part No. Description Qty.

2 100071 LOCKNUT, hex, 3/4–16 2

3 100155 NUT, 5/8–18 2

5 100509 PLUG, pipe, 1/4 npt 3

9 101747 PLUG, bottom, 1/4 npt(m) 4

12 103836 SCREW, slotted head,

10–32 x 3/4 in. (19 mm) 12

14 105751 BEARING, rod end 3

15 105752 BEARING, rod end 2

16 100060 CAPSCREW, hex head,

1/2–13 x 1–3/4 inch (44 mm) 4

17 105762 SETSCREW, 10–32 8

25 159463 SPACER 4

26 177042 GAUGE, designation 2

27 177086 SPACER, 1/4, nylon 4

28 177089 CLAMP, lower 2

30 177099 CLAMP, top, index 1

31 177100 SUPPORT, pivot pin 2

Ref.

No. Part No. Description Qty.

32 177101 MANIFOLD, inlet 2

33 177105 PIN, pivot, frame 1

34 177106 PIN, pivot, housing 2

35 177107 PIN, pivot, pump 2

36 177108 PLATE, wear 2

42 177144 LABEL, WARNING 4

44 206994 THROAT SEAL LIQUID

(not shown) 8 ounces

49 215664 ARM, lever 1

50 215665 FRAME BASE, VRHC 1

52 061135 HOSE, nylon (not shown) 1.5 feet

53 102790 SCREW, 10–24 4

59 108038 SETSCREW, 10–32 2

60 189559 CAP, end 4

Replacement Danger and Warning labels, tags and

cards are available at no cost.

309024 33

Page 34

Unit Frame All Options

24

Parts

47

22

45

8

7

13

37

6

60

48

42

40

11

51

19

4

38

1

56

57

55

58

12

29

39

61

Ref. 60

21

02433A

34 309024

Page 35

Unit Frame All Options

Parts

Ref.

No. Part No. Description Qty.

1 108036 STUD, fastener 12

4 100377 SCREW, slotted head,

1/4–20 x 5/8 in. (16 mm) 2

6 100737 PLUG, pipe, 1/2 npt 4

7 100840 ELBOW, street, 1/4 npt (m x f) 1

8 100960 GAUGE, air pressure, 0–200 psi

(0–14 bar) 1

11 108037 NUT, sheet spring, 10–24 12

12 103836 SCREW, slotted head,

10–32 x 3/4 in. (19 mm) 12

13 104267 AIR REGULATOR, 1/2 npt(f) inlet

and outlet, 1/4 npt(f) gauge ports

0–125 psi (0–8 bar) range.

See manual 307204 1

19 155470 SWIVEL UNION, 90, 1/2 npt(m)

x 1/2 npsm(f) swivel 1

21 157785 SWIVEL UNION, straight,

3/4 npt(m) x 1/2 npsm(f) swivel 2

22 100081 BUSHING, 3/8 npt(f) x 1/2 npt(m) 1

23 158244 GROMMET 1

24 158491 NIPPLE, 1/2 npt 1

29 177096 LABEL, WARNING 1

37 177117 MANIFOLD, air 1

Ref.

No. Part No. Description Qty.

38 177118 PANEL, safety 1

39 177119 PANEL, safety 1

40 177120 PANEL, safety 1

42 177144 LABEL, WARNING 4

45 107142 AIR VALVE, bleed–type master 1

47 214652 HOSE, buna–s, 1/2 in. (13 mm)

ID, coupled 3/8 npt(mbe),

1.5 ft (0.45 m) long 1

48 H53806 HOSE, nylon; 3/8 (10 mm) ID;

3/8 npsm(fbe); 6 ft (1.8 m) long 1

51 062035 MOLDING, rubber 1.8 feet

55 180673 BRACKET 1

56 100179 NUT, 10–24 2

57 100718 WASHER, no. 10 2

58 180674 U–BOLT, 10–24 1

60 223778 HOSE, PTFE, 1/4 in. (6 mm)

ID, coupled 1/4 npsm(fbe),

5 ft (1.8 m) long 1

61 164672 ADAPTER, 3/8 npt x

1/4 npsm(mbe) 1

Replacement Danger and Warning labels, tags and

cards are available at no cost.

309024 35

Page 36

All President Options

B

Parts

130

129

131

134

132

127

128

135

116

126

125

121

102

118

133

107

111 or 127

117

102

124

104

110

103

123

122

Displacement Pump Combinations for Other Proportion Ratios

See page 38 for adjustment ratio.

Pump Combinations

Primary Secondary

222012 222015 1.2:1 to 5.6:1 1.10 to 0.70

222012 222017 1.4:1 to 6.7:1 1.10 to 0.70

222012 222019 1.9:1 to 9.0:1 1.10 to 0.70

Maximum to minimum ranges.

NOTE: Output pressure decreases as volume output increases.

Based on pump speed of 40 cycles per minute using No. 10 oil test media.

Proportion

Ratio

36 309024

Volume Output

gpm (l/min.)

(4.2 to 2.6)

(4.2 to 2.6)

(4.2 to 2.6)

At 100 psi (0.7 MPa, 7 bar)

psi (MPa, bar)

1300 to 2200

(9 to 15, 90 to 152)

1400 to 2200

(9.7 to 15, 97 to 152)

1600 to 2300

(11 to 16, 110 to 159)

115

106

120

108

119

02380

Page 37

All President Options

Ref

Part No. Description Qty Options

No.

102 100103 PIN, cotter 3 A04

A06

1 All

Others

103 101566 LOCKNUT, sst, 3/8–16 3 All

104 102814 GAUGE, pressure,

5000 psi (34 MPa, 350

bar), 1/4 npt(m)

106 100139 PLUG, pipe, 1/8 npt 2 All

107 155541 UNION, swivel, 90

1/4 npt(m) x 1/4

npsm(f)

108 156823 UNION, 1/4 pt(m) x 1/4

npt(f)

110 158962 ELBOW, street, 1/4

npt(f) x 1/8 npt(m)

111 161037 UNION, swivel, 1/2

npt(f) x 3/8 npsm(f)

115 177088 UNION, swivel, 3/8

npt(f) x 3/8 npsm(f)

116 177111 TIE ROD, 16” (407

mm) shoulder to

shoulder

177112 TIE ROD, 15.2” (385

mm) shoulder to

shoulder

177471 TIE ROD, 16.9” (429

mm) shoulder to

shoulder

117 177113 CONNECTING ROD,

2.62”(66.5 mm) long

177114 CONNECTING ROD,

2.5” (64.4 mm) long

177115 CONNECTING ROD,

3.39” (88.1 mm) long

118 207352 MOTOR, President

119 108233 SAMPLING VALVE,

needle

120 215626 MANIFOLD

4

121 215691 CONNECTING ROD,

13.5”(342 mm)

215692 CONNECTING ROD,

11.8” (300 mm)

215693 CONNECTING ROD,

12.7” (321 mm)

,

5

2 All

1 All

2 All

2 All

2 A04

A06

2 All

3

A09

A12

A14

D02

F06

686632

3 A04

3 A06

1 A09

A12

A14

D02

F06

686632

1 A04

1 A06

1 All

2 All

1 All

1 A06

1 A09

A12

A14

D02

F06

686632

1 A04

Parts

Ref

No.

122 215925 HOUSING, VRHC 1 All

123 215932 PRIM. DISPL. PUMP

124 215932 SEC. DISPL. PUMP

125 215690 MOUNTING PLATE 1 A09

126 164417 LOCKNUT 1 A09

127 155494 UNION, 3/8 npt(mxf) 1 A04

128 158212 BUSHING, 1/2 npt(m) x

129 162449 NIPPLE, 1/2 x 1/4 npt 1 All

130 237063 VALVE, relief, 2900 to

131 159239 NIPPLE, 3/8 x 1/2 npt 1 All

132 158683 ELBOW, 90, steel 1 All

133 113187 CONNECTOR, female,

134 190738 TUBE, nylon 1 All

135 237569 WIRE, ground 1 All

1

See manual 307430 for parts.

2

See manual 307431 for parts.

3

See manual 307944 for parts.

4

See manual 307400 for parts.

5

See manual 306982 for parts

Part No. Description Qty Options

1

1 A04

215930 PRIM. DISPL. PUMP

222012 PRIM. DISPL. PUMP

222015 PRIM. DISPL. PUMP

222017 PRIM. DISPL. PUMP

222017 PRIM. DISPL. PUMP

222015 PRIM. DISPL. PUMP

215930 SEC. DISPL. PUMP

222012 SEC. DISPL. PUMP

222015 SEC. DISPL. PUMP

222017 SEC. DISPL. PUMP

222019 SEC. DISPL. PUMP

222019 SEC. DISPL. PUMP

2

3

3

3

3

3

1

2

3

3

3

3

3

1 A06

1 A09

1 A12

1 A14

1 D02

1 F06

1 A04

1 A06

1 A09

1 A12

1 A14

1 D02

1 F06

A12

A14

D02

F06

686632

A12

A14

D02

F06

686632

A06

3 All

others

1 All

3/8 npt(f)

1 All

3600 psi (20 to 24.8

MPa, 200 to 248 bar)

1 All

tube

309024 37

Page 38

Dimensions

D

E

A

C

F

H

E

02366A

B

Four sockets

for casters.

See

Accessories

A Height

President 48.5” (1232 mm). . . . . . . . . . . . . . . . . . .

Viscount 48.5” (1232 mm). . . . . . . . . . . . . . . . . . . .

G

Monark 45.6” (1156 mm). . . . . . . . . . . . . . . . . . . . .

Bulldog 55.5” (1410 mm). . . . . . . . . . . . . . . . . . . . .

B Length 35” (889 mm). . . . . . . . . . . . . . . . . . . . . . . . .

C Width 18” (457 mm). . . . . . . . . . . . . . . . . . . . . . . . . .

D Air Inlet 1/2 npt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . .

has four 1/4 npt(f) plugged outlets

E Fluid Inlets Two 3/4 npsm(f) swivel,. . . . . . . . . . . . .

has 1/4 npt(f) plugged cleanout port

F Solvent Inlets 1/2 npt(m). . . . . . . . . . . . . . . . . . . . . .

G Fluid Outlet 1/2 npt(m). . . . . . . . . . . . . . . . . . . . . . . .

H Valve Outlets Two 1/4 npt(m). . . . . . . . . . . . . . . . . . .

38 309024

Page 39

Technical Data

Motor Weight

19 lb

President

Monark

Bulldog

Viscount I

(8.6 kg)

13 lb

(5.9 kg)

78 lb

(35.1 kg)

18.5 lb

(83 kg)

Stroke

Length

4 in

(102 mm)

3 in

(6 mm)

4.75 in

(121 mm)

4 in

(102 mm)

Effective

Area

14.19 Sq in

91.55 cm

7.0 Sq in

2

45 cm

7.07 Sq in

45.61 cm

7.07 Sq in

45.61 cm

Wetted Parts – See Configurator Product

Order Form 309025

Maximum Fluid Working Pressure Maximum Pump Air Input Pres-

Pump Model

sure

President 250 bar, 25.0 MPa (3600 psi) 12.5 bar, 1.25 MPa (180 psi)

Monark 125 bar, 12.5 MPa (1800 psi) 12.5 bar, 1.25 MPa (180 psi)

Bulldog 347 bar, 34.7 MPa (4950 psi) 6.3 bar, 0.63 MPa (90 psi)

Air Pressure of Sound Tests

Pump Model

(25 cycles/min)

President 12.5 bar, 1.25 MPa

* Sound Pressure

Level

** Sound Power

Level

98 dBa 113 dBa

(180 psi)

Monark 12.5 bar, 1.25 MPa

96 dBa 112 dBa

(180 psi)

Bulldog 7 bar, 0.7 MPa

94 dBa 109 dBa

(100 psi)

* Sound pressure was measured in accordance with Cagi Pneurop, 1969.

** Sound power was measured in accordance with ISO 3744, 1981.

309024 39

Page 40

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

40 309024

MM 309024

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

www.graco.com

PRINTED IN USA 309024 July 1999 Rev. 02/2006

Loading...

Loading...