Page 1

Instructions – Parts List

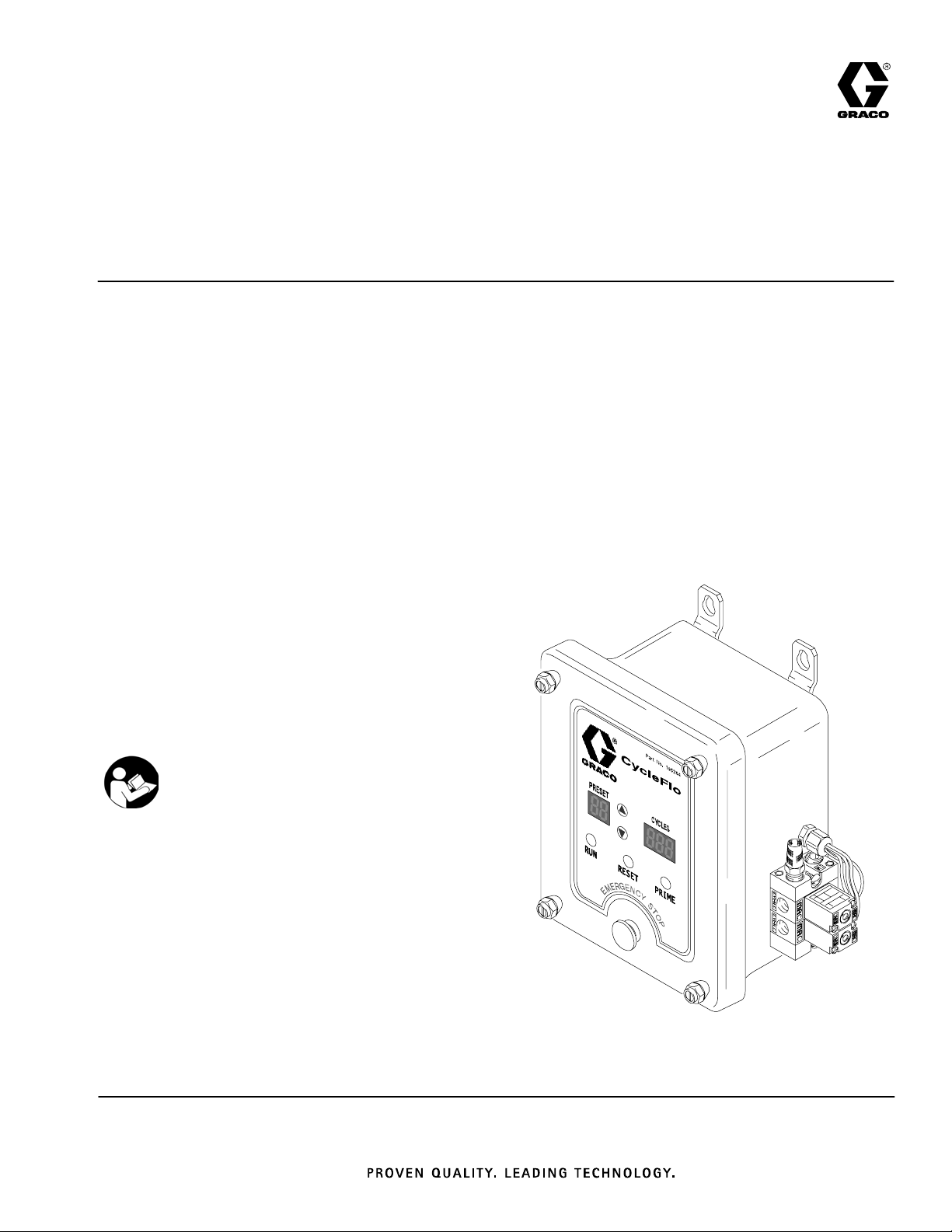

CycleFlo™ Pneumatic

309003E

Pump Controller

Controls pump speed, run time, and quantity of product delivered, for precise

batching, metering, and dosing of fluids at high or low pressures and flow rates.

Not for use in explosive atmospheres.

Part No. 195264 (120 VAC)

Part No. 196706 (240 VAC)

120 psi (0.8 MPa, 8 bar) Maximum Air Inlet Pressure

D Integrated Air Valves with Silenced Exhaust

D 32 Batch Presets

D 1–999 Pump Cycles per Batch Preset

D x10 Cycle Multiplier for High Volume Applications (10–9990 Cycles)

D 16 Pump Cycle Rates (10–200 CPM)

D Easy Field Programming

D Self-Test Function for Easy Troubleshooting

D Standard 120 or 240 VAC Power

ENG

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

9408B

Page 2

Table of Contents

Symbols 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pneumatic Connections 6. . . . . . . . . . . . . . . . . . . . . . .

Electrical Connections 6. . . . . . . . . . . . . . . . . . . . . . . .

Setup and Programming 8. . . . . . . . . . . . . . . . . . . . . . . .

Cycles Per Minute (CPM) Rate 8. . . . . . . . . . . . . . . . .

Presets 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Priming the Pump 9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Operation 9. . . . . . . . . . . . . . . . . . . . . . . .

Remote Operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self-Test Mode 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Installation Diagrams 13. . . . . . . . . . . . . . . . . . . .

Specifications 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Information 17. . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 18. . . . . . . . . . . . . . . . . . . . . .

Graco Information 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 309003

Page 3

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the corresponding

instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

D Read all instruction manuals, warnings, tags, and labels before operating the equipment.

D Use equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

D Other than for installation purposes, do not alter or modify this equipment. Use only genuine

Graco parts and accessories.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

corresponding instructions.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated system component.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 82° C (180° F) or below -40° C (-40° F).

D Do not lift pressurized equipment.

D Comply with all applicable local, state and national fire, electrical, and other safety regulations.

309003 3

Page 4

WARNING

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition

and result in fire or explosion and other serious injury.

D Ground the pumping equipment. Proper grounding dissipates static electricity.

D This equipment is not intended for intrinsically safe areas.

D Keep the dispense area free of debris, including solvent, rags, and gasoline.

D If there is any static sparking or you feel an electric shock while using the equipment, stop op-

erating immediately. Do not use the equipment until you have identified and corrected the

problem.

D Make sure all electrical work is performed by a qualified electrician.

D Have any checks, installation, or service to electrical equipment performed by a qualified electri-

cian only.

D Make sure all electrical equipment is installed and operated in compliance with local and appli-

cable codes.

D Make sure power is disconnected when servicing and repairing equipment.

D Keep liquids away from the electrical components.

D Disconnect electrical power at the main switch before servicing equipment.

D Never exceed maximum wattage of the supply unit.

4 309003

Page 5

General Description

The CycleFlo is a pneumatic pump controller that

allows precise control over the amount of product that

is delivered by the pump, as well as the pump speed.

The CycleFlo achieves this by operating the pump for

a preset number of cycles and then halting the pumping cycle. Up to 32 different batch sizes may be programmed into the memory of the CycleFlo for easy

delivery of different product volumes.

A batch may be initiated either from the front panel

RUN button or via a remote switch. Such a remote

switch may be connected to the trigger of a dispensing

valve so that the pump only pumps when the operator

depresses the valve trigger. Using the remote input,

the pumping cycle may also be initiated by some other

piece of equipment such as a timer or a pH controller.

The CycleFlo will halt the pumping cycle once the

preset volume of product has been dispensed.

The CycleFlo also features an adjustable pumping

rate. This allows the CycleFlo to be used with different

pump types and also to tailor the pump cycle to deliver

fluids with a variety of flow characteristics.

309003 5

Page 6

Installation

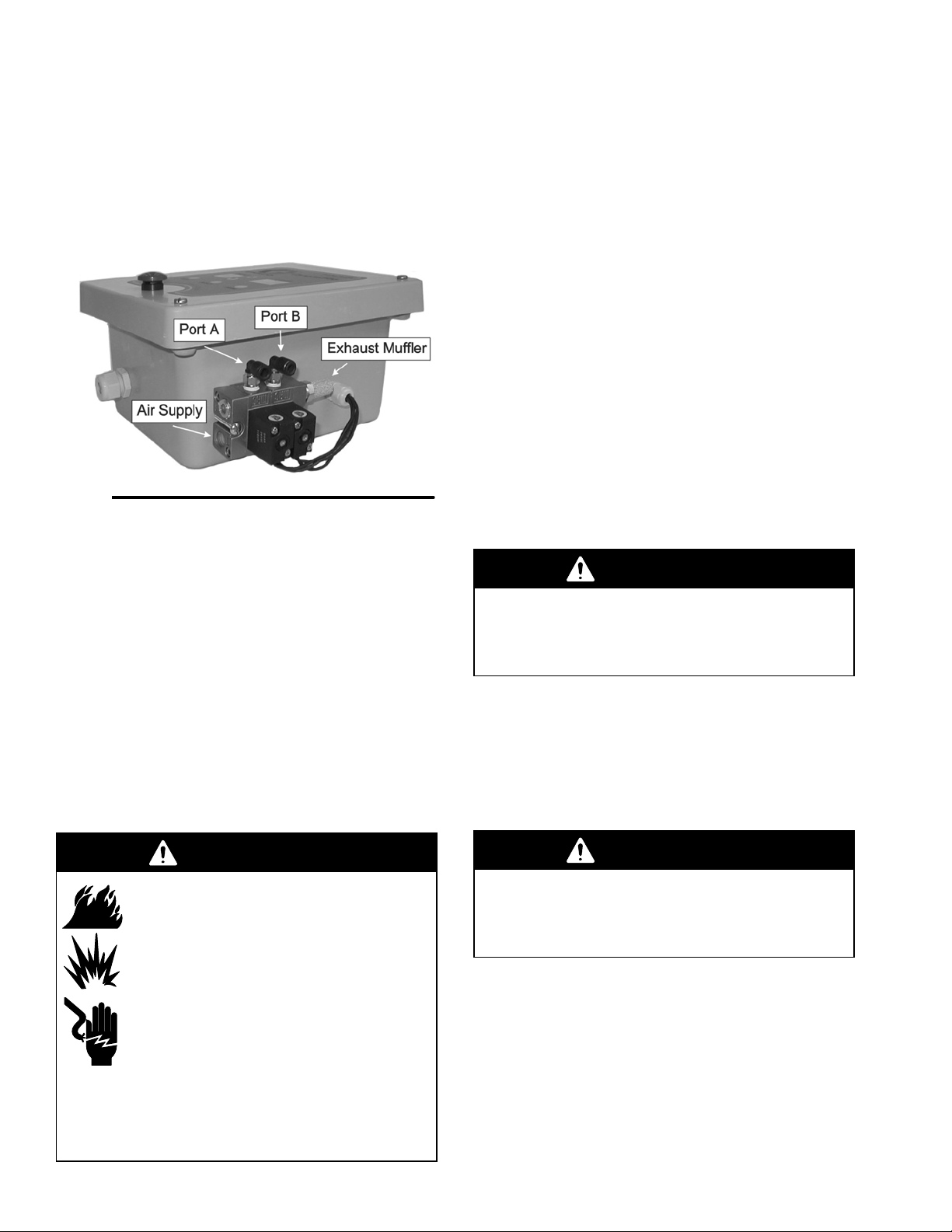

Pneumatic Connections

The integrated air valves (solenoids #1 and #2), located on the right side of the CycleFlo enclosure, have

a common air inlet (1/4 in. npt) port at the bottom and

two outlet ports (1/8 in. npt to 1/4 in. elbow tube fitting)

towards the front of the unit. The exhaust is silenced

with a muffler.

Fig. 1

The A and B outlet ports are to be connected to the A

and B ports, respectively, on the Huskyt 205, or to

the two air valve control ports located on the air motors

of pumps larger than the Husky 205. The unit comes

equipped with 1/4 in. OD push-in tube fittings installed

in the A and B ports.

On pumps larger than the Husky 205, a three-way

solenoid valve (Graco Part No. 115605 or equivalent)

should be installed on the main air supply to the pump.

This ensures that pressure is not generated by the

pump when the controller is not operating. The air

supply valve signal output on the CycleFlo controller is

designed to control this valve.

An access hole with a strain relief installed has been

provided for the external power connection. Due to the

unique requirements of each installation, access holes

have not been provided for other optional external

wiring connections. Access holes will need to be added

for the external Air Supply Valve Signal and/or Remote

Run options. Have a qualified electrician determine the

proper strain relief, wire type, and wire size for your

particular application. When positioning or adding

access holes, be careful not to damage any internal

components. Failure to use the proper strain relief,

wire type, and wire size can cause damage to internal

components or personal injury.

The 24 Volt DC Air Supply Valve Signal output is used

to control a three-way valve (Graco Part No. 115605 or

equivalent) on the main air supply of pumps larger than

the Husky 205. This ensures that pressure is not

generated by the pump when the controller is not

operating. Failure to use this valve can cause damage

to the unit and possible personal injury.

WARNING

Failure to use the recommended valve can cause

damage to the unit and possible personal injury.

Follow the pressure relief procedure in the pump

manual before moving or servicing the pump.

The CycleFlo requires 120/240 VAC, 50/60 Hz to

operate. The power input is fuse-protected with a 160

mA fuse for 120 Volt service and an 80 mA fuse for

240 Volt service (see Fig. 2).

Electrical Connections

WARNING

FIRE, EXPLOSION, AND ELECTRIC

SHOCK HAZARD

To reduce the risk of fire, explosion, or

electric shock:

D The power source conduit is not an

adequate ground for the system. The

unit must be grounded to a true earth

ground.

D A qualified electrician must complete

all grounding and wiring connections

and check the resistance.

D Refer to your local code for the requirements for

a “true earth ground” in your area.

6 309003

WARNING

When replacing the fuse, make sure to replace it

only with one of equivalent rating. Failure to do so

may cause damage to the unit and possible personal injury.

Connect power to the unit as described. Always have a

qualified electrician perform wiring connections. Connect Line (L) and Neutral (N) wires to the terminal

block as shown in Fig. 2. The Ground wire (GND) must

be attached to the #10–32 ground stud. A crimp-on

ground wire lug comes attached to the ground stud.

Remove the lug and attach to the ground wire. Replace the lug assembly back onto the stud and fasten

down with the kepsnut provided.

Page 7

26

Installation

1

2

CPM Rate

3

4

5 x10 CPM Multiplier

6 Program Mode

7 Test Mode

8 Remote Run Test

24 VDC, 6W max.

SW1

DIp Switch

25

24 VDC, 6W max.

24 VDC, 6W max.

2

1

24 VDC, 6W max.

Micro Processor

+

Remote Run

Input

–

Air Supply

+

Valve Signal

–

Output

+

Solenoid

–

Valve #1

+

Solenoid

–

Valve #2

160 mA or 80 mA

Fuse

Transformer

J2

J1

Terminal

Block

L

N

Power

(120 VAC

or

240 VAC)

L

N

GRND

Fig. 2

The Remote Run input is an external switch input. A

switch connected to this input should be a potential

free contact.

The Air Supply Line Valve Signal is a 24 VDC output

signal. This signal drives the external 6W solenoid

valve (Graco Part No. 115605), which controls the

main air supply (required for pumps larger than the

Husky 205).

J3

Solenoid Valve #1 and #2 Signals (24 VDC output

signals) are pre-connected to the air valves on the

right side of the CycleFlo.

Power Connections

Connect Line (L), Neutral (N), and Ground (GND) as

shown in Fig. 2. Ground wire must be attached to the

ground stud and fastened down with the nut provided.

309003 7

Page 8

Setup and Programming

An 8-position DIP switch (SW1) (see Fig. 1 for location) is used to set the cycle rate and cycles multiplier.

It is also used to invoke the various test modes.

Before the CycleFlo can be put into operation, the

parameters in Fig. 3 must be programmed for each

particular application.

OFF ON

1

2

3

4

5

6

7

8

SW1

Fig. 3

CPM Rate

See Fig. 4

x10 Cycles Multiplier

Program Mode

Test Mode

Remote Run Test

Cycles Per Minute (CPM) Rate

The pump cycle rate is adjustable to accommodate

different pump sizes, varying product viscosity, and

product delivery speed. The pump cycle rate is measured in cycles per minute (CPM), which is the number

of times the pump performs a pump cycle in one

minute. One pump cycle consists of a momentary

pressurization of each one of the two diaphragms.

The CPM Rate Table in Fig. 4 shows the settings for

the first four switches of SW1 and the resulting CPM

rate.

SW1 CPM Rate Table

10

CPM

152520

30

35

40

45

625088

75

100

125

150

1

2

3

4

Presets

The CycleFlo has 32 programmable presets to easily

switch between amounts of fluid delivered by the pump

during a RUN cycle. Each preset is programmed with

the number of times the pump will be cycled. Use the

Y and B buttons on the front panel to step through

the presets. The PRESET display will indicate the

selected PRESET program number and the CYCLES

display will show the associated number of pump

cycles.

NOTE: SW1–5 is the x10 Cycle Multiplier. If SW1–5 is

in the ON position, the actual number of pump cycles

will be 10 times that of the CYCLES display.

To change the number of cycles associated with a

programmed preset, do the following:

1. Place the CycleFlo into Program Mode by moving

SW1–6 to ON. The PRESET display will blink to

indicate that the Program Mode is active.

2. Use the BY buttons to select the PRESET to be

changed.

3. Press and hold the RUN button, then use the B

and Y buttons to adjust the 100’s digit of the

CYCLES display.

4. Press and hold the RESET button, then use the B

and Y buttons to adjust the 10’s digit of the

CYCLES display.

5. Press and hold the PRIME button, then use the B

and Y buttons to adjust the 1’s digit of the

CYCLES display.

6. Once the correct number of cycles is displayed,

use the B and Y buttons to move to another

PRESET and then back to the current one to verify

that the new cycle count was stored correctly.

200

NOTE: Either the B or Y button must be pressed for

the new cycle count to be programmed into the CycleFlo’s memory.

7. Repeat for the next PRESET, as needed.

Fig. 4

8 309003

Denotes Switch is ON

8. When finished, switch SW1–6 to the OFF position

to place the CycleFlo into Normal Operating mode.

Page 9

Operation

Priming the Pump

A priming feature allows for the temporary operation of

the pump for priming purposes. The pump cycle rate

during priming is controlled by the 8-position DIP

switch (SW1).

Pressing the PRIME button on the front panel will start

the pump cycling while the button is held. Once

primed, release the button to stop pump operation.

Front Panel Operation

The B and Y buttons (see Fig. 5) select the desired

PRESET pump cycle. The pump cycle count for each

PRESET is displayed in the CYCLES display.

B Decrease Y Increase

Cycles

Preset

Pressing the RUN button on the front panel starts the

pump cycling for the number of cycles indicated by the

CYCLES display. The CYCLES display will count down

from its current count every time the pump performs a

complete cycle (both diaphragms alternately activated). When all cycles have been performed, the

pump will stop and the CYCLES display will automatically be reset to the full cycle count for the current

PRESET. The unit is then ready for another dispense

cycle.

Pressing the RESET button during a RUN operation

stops the pumping cycle. The CYCLES display will

blink to indicate that the RUN mode was interrupted.

Once in this mode, there are two possible actions:

pressing the RUN button will resume the pump cycling

where it was interrupted or pressing the RESET button

again will reset the CYCLES to the full count for the

current PRESET.

Remote Operation

The B and Y buttons select the desired PRESET

number of pump cycles. Pump cycles for each PRESET are displayed in the CYCLES display.

Closing the REMOTE RUN contact starts the pump

cycling for the number of cycles indicated by the

CYCLES display. The CYCLES display will count down

from its current count every time the pump performs a

complete cycle (both the diaphragms alternately activated). When all cycles have been performed, the

pump will stop and the CYCLES display will automatically be reset to the full cycle count for the current

RESET.

Run

Emergency Stop

Fig. 5

Reset

Prime

9408B

Opening the REMOTE RUN contact stops the pump

cycling. The CYCLES display will blink to indicate that

the RUN mode was interrupted. Once in this mode,

there are two possible actions: closing the REMOTE

RUN contact again will resume the pump cycling

where it was interrupted or pressing the RESET button

on the front panel will reset the CYCLES to the full

count for the current PRESET.

When all cycles have been performed, the pump will

stop and the CYCLES display will show 000 until the

REMOTE RUN contact is opened. The CYCLES

display will then automatically be reset to the full cycle

count for the current PRESET.

309003 9

Page 10

Troubleshooting

p

The following is a list of possible problems and their causes. The CycleFlo also has a built-in self-test mode that

allows dynamic testing of all components.

Troubleshooting Guide

Problem

No operation at all

LED display shows incomplete

digits

Front panel button(s) don’t work

Pump won’t operate when RUN

button is pressed

Pump won’t operate (cycles count

down and valve driver LED’s

blink)

Pump won’t operate (CYCLES

count down but no valve driver

LED’s)

Cause Solution

Blown fuse. Check fuse and replace with 250 V

1/4A type.

Emergency Stop switch OFF. Press switch.

Poor ribbon cable connection. Turn power off and unplug then re-

plug ribbon cable on main board and

display board.

Damaged display board. Replace board.

Poor ribbon cable connection. Turn power off and unplug then re-

plug ribbon cable on main board and

display board.

Loose mounting screw. Make sure mounting screws on dis-

play board are securely tightened.

Damaged display board. Replace board.

Incorrect operating mode. Make sure SW1–6, 7, 8 are all in the

OFF position.

No or low air supply. Check air supply to make sure there

is sufficient pressure and air avail-

able.

Bad solenoid wire connections. Turn off power and check wire con-

nections from solenoid valve #1 and

#2 to make sure they are all con-

nected and seated properly.

Bad solenoid valve(s). Turn off air supply and listen for

“clicking” on solenoid valves; replace

valves if no “clicking” is audible.

Bad valve drivers on main board. Replace main board.

10 309003

Page 11

Self-Test Mode

CAUTION

During this test, the solenoid valves may be activated. This will activate a connected pump. To

prevent inadvertent pumping, disconnect the air

supply to the solenoid valves or remove the air lines

to the pump.

TEST MODE (SW1–7)

The CycleFlo has a built-in test program that allows for

dynamic testing of all internal and external components.

Once activated, the self-test mode will do the following

continuously until the test mode is de-activated:

D All display digits count from 0–9 in unison. This is

used to determine if any of the displays are faulty.

Replace the display board if segments of the display fail to activate during the self-test.

D Each of the five front panel buttons activates a

decimal point on the LED displays. Replace the

display board if a button fails to activate a decimal

point.

Position SW1–7 to the ON position to activate the

self-test mode. Position SW1–7 to the OFF position to

de-activate the self-test mode.

REMOTE RUN TEST (SW1–8)

Position SW1–8 (the REMOTE RUN test) to the ON

position to activate the AIR SUPPLY VALVE signal and

cycle the solenoid valves at the CPM rate set by

SW1–1, 2, 3, 4. The Remote Run Test (SW1–8) performs the same function as closing the Remote Run

Switch input, and therefore, is used to test the functionality of the Remote Run Switch input. Follow the

Troubleshooting Guide on page 10 if either fails to

operate.

309003 11

Page 12

Parts

Display

Board

Enclosure

Ribbon Cable

Main Board

Air

Valve

Parts

Part No. Description

195264 CycleFlo Pneumatic Pump Controller Unit (120 VAC)

196706 CycleFlo Pneumatic Pump Controller Unit (240 VAC)

––––– Enclosure

––––– Emblem (not shown – located on front of unit) (120 VAC)

––––– Emblem (not shown – located on front of unit) (240 VAC)

115381 Main Board (120 VAC)

116111 Main Board (240 VAC)

115380 Display Board

115382 Ribbon Cable

115383 Air Valve (NOTE: two valves are required per controller)

Optional Accessories

Part No. Description

102518 Cord Set, Electrical

115988 Tube, Nylon, 50 ft

115605 Valve, Solenoid, 24 VDC, 6W

––––– Not sold separately.

12 309003

Page 13

Typical Installation Diagrams

A

120 or 240 VAC

CycleFlo

Remote Run Input

Diaphragm Pump

(Husky 205 shown)

PH Controller, Flow

Controller, Timer, etc.

Sends on/off signal to

CycleFlo Controller

Controller

Compressed Air In

9409

309003 13

Page 14

Typical Installation Diagrams

CycleFlo Controller

Chemical Injector

Flow Controller sends

on/off signal to the

CycleFlo Controllers*

Flow

Sensors*

Remote Run Input

In

Solenoid

Valve #1

CycleFlo

Controller

Solenoid

Valve #2

Husky 1040

Metering Pump

120 or 240 VAC

Air Supply Valve Signal (24 VDC)

Compressed Air

Air Supply

Solenoid Valve

Out

Inline

Mixers*

*Provided by others

14 309003

Page 15

Typical Installation Diagrams

CycleFlo Controller

Water Neutralization

CycleFlo

Controller

Flow

Sensor*

Remote Run Input

Flow

Meter

Chemical

Injector

Husky 1040

In

Remote Pump

Solenoid

Valve #1

Solenoid

Valve #2

120 or 240 VAC

Air Supply Valve Signal (24 VDC)

Compressed Air In

Air Supply

Solenoid Valve

Out

*Sends on/off signal to CycleFlo Controller

Husky 1040–3275

Transfer Pump

309003 15

Page 16

Typical Installation Diagrams

CycleFlo Controller

Water Treatment

Air Supply

Solenoid Valve

Air Supply Valve

Cooling Coils*

Signal (24 VDC)

120 or

240 VAC

Compressed Air In

CycleFlo

Controller

Remote Run Input

Corrosion

Inhibitor

Chemicals

* Provided by others

In

Solenoid

Valve #1

Solenoid

Valve #2

Out

Husky 1040

Metering Pump

PH Controller –

sends on/off signal to

CycleFlo Controller*

Centrifugal Pump*

(water circulating)

16 309003

Page 17

Specifications

Power Requirements:

120 VAC, 50/60 Hz, 160 mA

240 VAC, 50/60 Hz, 80 mA

Air Supply:

120 psi (0.8 MPa, 8 bar) Maximum

Mounting Information

4 in.

(102 mm)

8 7/8 in.

(225 mm)

9438A

309003 17

Page 18

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor, or call to identify the distributor closest to you:

Phone: 612–623–6921 or Toll Free: 1–800–328–0211 Fax: 612–378–3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 309003

International Offices: Belgium, China, Japan, Korea

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

18 309003

Graco Headquarters: Minneapolis

Copyright 1999, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 09/2009

Loading...

Loading...