Page 1

Instructions – Parts List

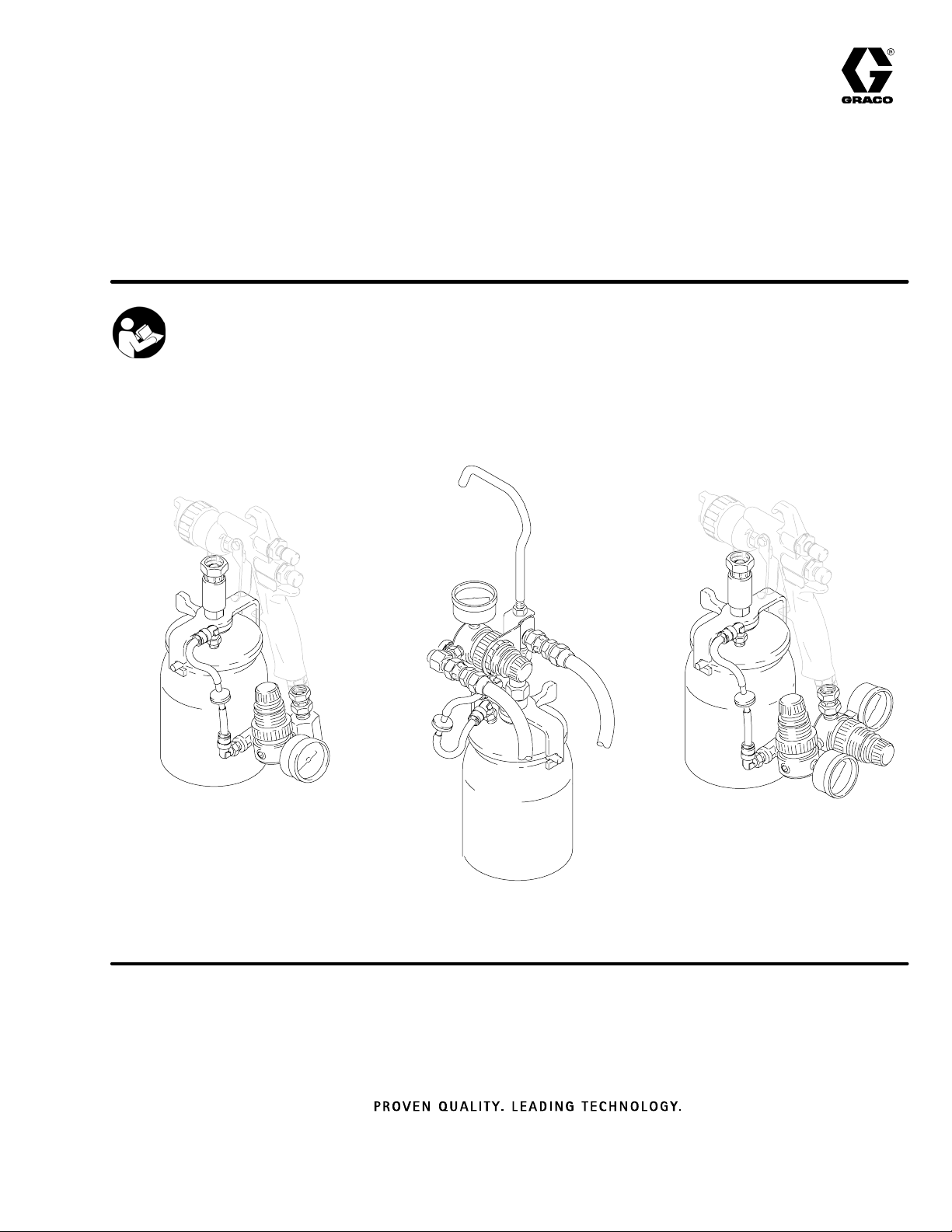

STAINLESS STEEL, ONE QUART (ONE LITER)

Air Regulated

Pressure Cups

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 10 for model numbers and maximum

working pressures.

308791E

7611A

Single Air Regulator

Pressure Cup Kit

Part No. 239802 and 245181

7613A

Remote Single Air Regulator

Pressure Cup Kit

Part No. 239804

Double Air Regulator

Pressure Cup Kit

Part No. 239803

7612A

Page 2

Table of Contents

A

Set-Up 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts

One Quart Pressure Cup 239801 7. . . . . . . . . . . . .

Single Air Reg 7

Pressure Cup Kit 239802, 245181 7. . . . . . . . . . . .

Single Air Reg. Assembly 235375, 245192 7. . . . .

Double Air Reg. Pressure Cup Kit 239803 8. . . . . .

Setup

NOTE: Tighten all fittings securely.

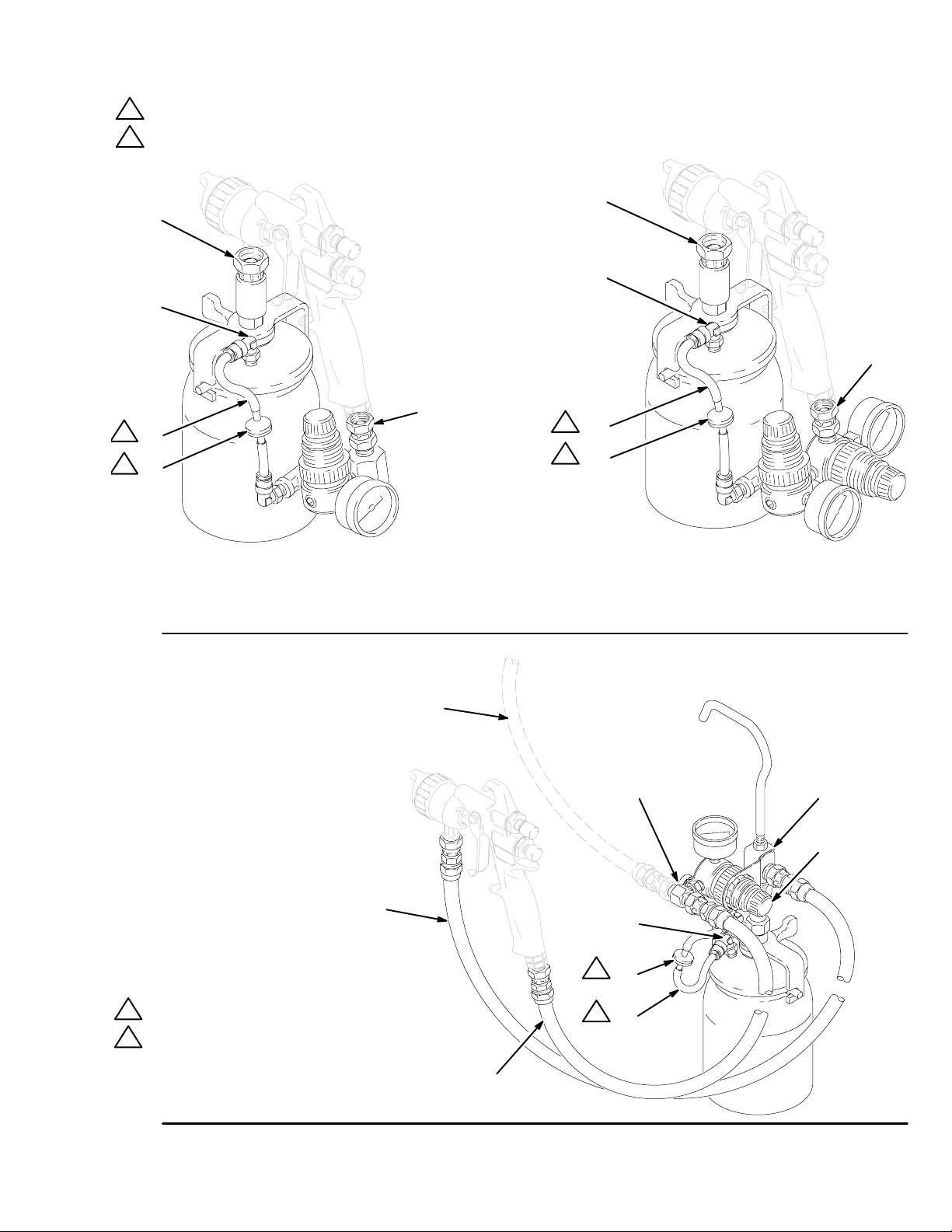

Install the Elbow Fitting and Tubing

Push the tubing (3), with the check valve (13), firmly

into the cup’s elbow fitting (D). See Fig. 2 or 3. The

tapered side of the check valve must face towards the

cup’s elbow fitting.

NOTE: To disconnect the tubing, push down on the

fitting’s outer ring and pull on the tubing.

Part No. 239802, 239803, and 245181:

Install the Gun on the Cup

1. Tighten the cup swivel fitting (E) onto the gun fluid

inlet. See Fig. 2.

2. Tighten the air fitting (F) onto the gun air inlet.

Part No. 239804: Assemble the Remote

Single Air Regulator Pressure Cup Kit

1. Tighten the cup swivel fitting (E) onto the fluid

outlet fitting (4) of the air regulator assembly. See

Fig. 3.

2. Tighten the air supply line (G) onto the air inlet

fitting (19).

Double Air Reg. Assembly 235376 8. . . . . . . . . . . .

Remote Single Air Reg. 9. . . . . . . . . . . . . . . . . . . . .

Pressure Cup Kit 239804 9. . . . . . . . . . . . . . . . . . . .

Remote Single Air Reg. Assembly 236142 9. . . . .

Technical Data 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Information 12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

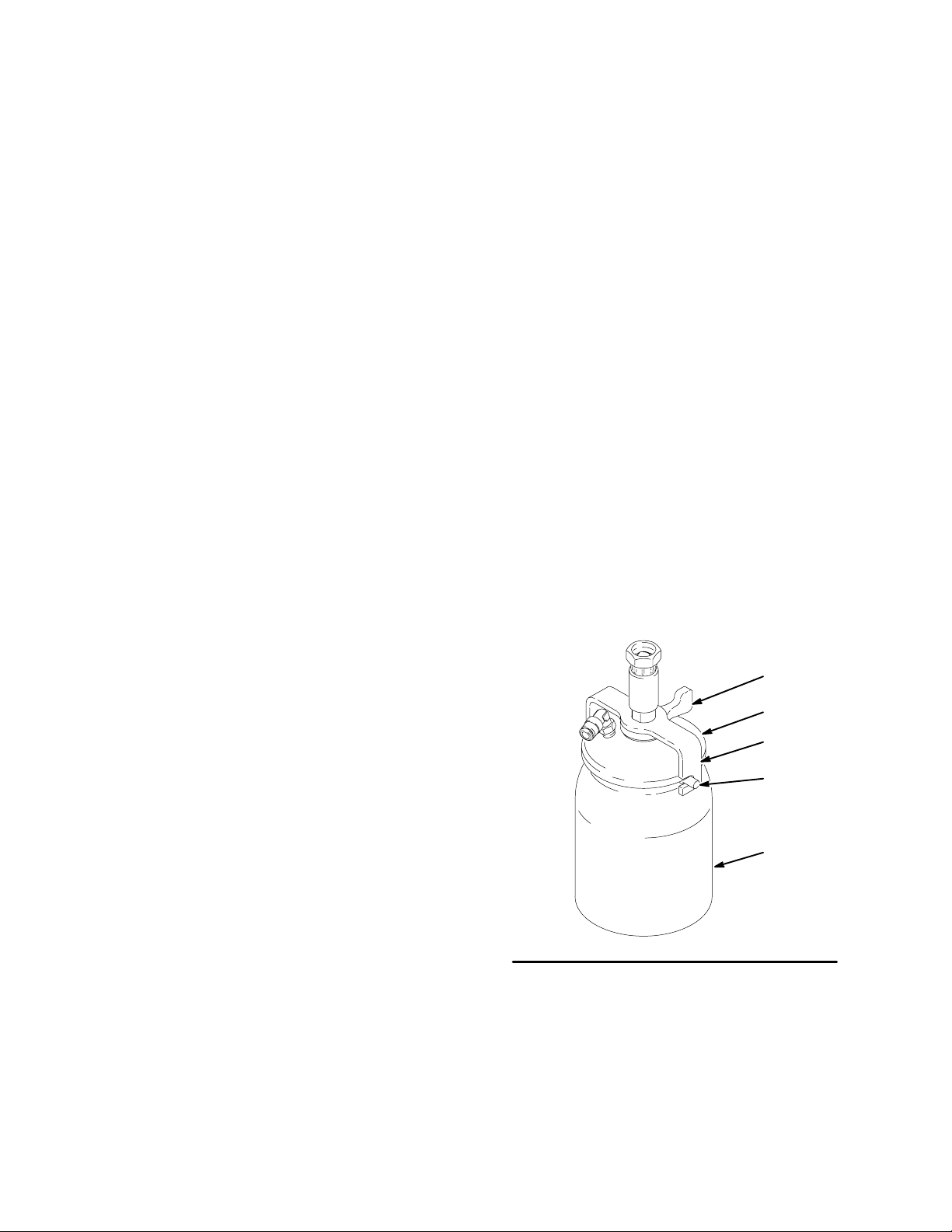

Fill the Pressure Cup

1. Push the clamp lever (A) fully to the unclamped

position, against the yoke (B). See Fig. 1.

2. Twist the cup lid (101) counterclockwise to disengage the yoke hook from the cup extended

pins (C).

3. Remove the cup lid (101) and fill the cup with fluid.

4. Twist the cup lid (101) clockwise to engage the

yoke (B) hook, then push the clamp lever (A) fully

to the clamped position. Use your thumb to force

the clamp lever into position; do not use wrenches

or tools to move it.

A

101

B

C

103

3. Tighten the air line (H) onto the gun air inlet.

4. Tighten the fluid line (J) onto the gun fluid inlet.

2 308791

Fig. 1

01961

Page 3

Setup

1

Push tube (3) fully into elbow fitting (D)

2

Tapered side of the check valve must face towards the cup’s elbow fitting

E

D

F

1

3

2

13

E

D

F

1

3

2

13

Part No. 239802 and 245181

Single Air Regulator Pressure Cup Kit

Fig. 2

Part No. 239804

Remote Single Air Regulator

Pressure Cup Kit

7612A7611A

Part No. 239803

Double Air Regulator Pressure Cup Kit

G

19 4

E

J

D

2

13

1

Push tube (3) fully into elbow fitting (D)

2

Tapered side of the check valve must face

towards the cup’s elbow fitting

Fig. 3

1

3

H

7623A

308791 3

Page 4

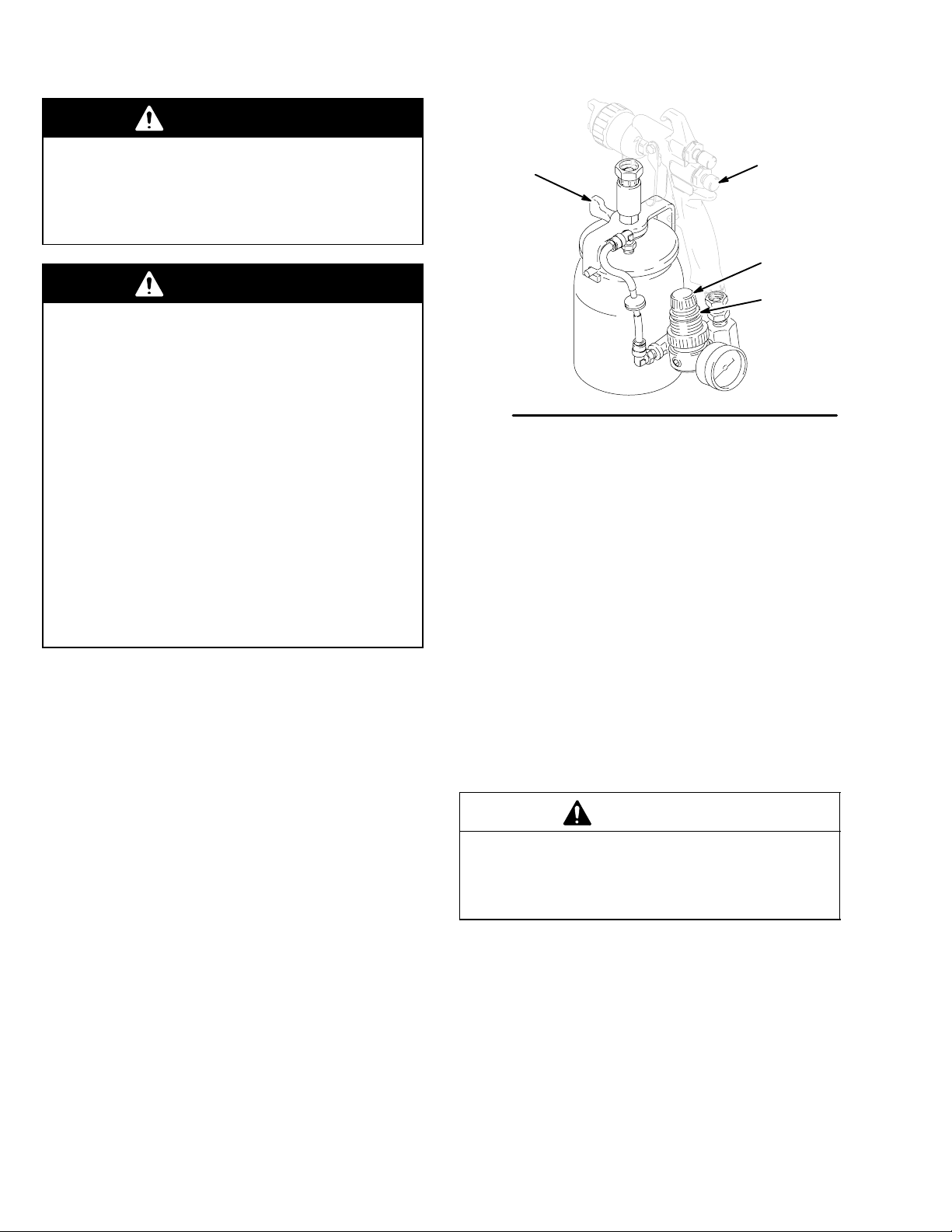

WARNING

Operation

Never exceed 20 psi (1.4 bar) static air pressure to

the cup. Exceeding the maximum working pressure

of the cup or any other system component could

cause component rupture, which could result in

serious injury and property damage.

WARNING

Pressure Relief Procedure

To reduce the risk of serious injury, including splashing in the eyes or on the skin, always follow this

procedure after you stop spraying, when checking or

servicing any part of the spray system, before disconnecting the gun, air regulator, or pressure cup

and when removing a pressure cup for refilling or

cleaning.

1. Turn off the air supply to the gun.

2. Trigger the gun into a grounded metal waste

container to relieve fluid pressure.

3. Place the cup on a table and slowly release the

clamp (A) to bleed-off any residual pressure in

the cup. See Fig. 4. Be sure to push the clamp

lever fully to the clamped position before turning

on the air supply to the gun again.

Setting the Cup Air Pressure

A

Fig. 4

M

K

L

7611A

Spraying Tips

The regulator is not self relieving so if the regulated air

pressure setting is causing excessive fluid flow, follow

these steps.

1. Pull up the cup regulator adjustment knob lock-ring

(L). See Fig. 4.

2. Turn the adjustment knob (K) counterclockwise.

3. Trigger the gun into a grounded metal waste

container until cup pressure is lowered.

1. Pull up the cup regulator adjustment knob lock-ring

(L); this allows the knob (K) to turn. See Fig. 4.

2. Set the cup pressure at zero by turning the

adjustment knob (K) fully counterclockwise.

3. Slowly turn the adjustment knob (K) clockwise to

increase the air pressure to the cup.

4. Push the adjustment knob lock-ring (L) down to

lock the cup pressure setting.

Setting the Gun Air Pressure

NOTE: Installing the gun air inlet regulator adds a

pressure drop that could limit the air cap pressure.

Set the gun air pressure regulator for the minimum

pressure needed to atomize your fluid. See your gun

manual for recommended settings.

4. Turn the adjustment knob (K) clockwise until you

obtain the desired lower pressure setting.

5. Push down the adjustment knob lock-ring (L).

CAUTION

Do not restrict the fluid flow by continuously spraying

with the gun’s fluid adjustment knob (M) turned in

(clockwise) as this will cause excessive abrasive

wear on the fluid needle and trigger/air valve shaft.

To restrict the fluid flow, lower the cup pressure or use

a smaller size needle/nozzle set and air cap combination.

If the cup pressure must be below 1.0 psi (0.07 bar) to

achieve the desired fluid flow, a smaller needle/nozzle

size is recommended.

4 308791

Page 5

Operation

Optional Gun Air Regulator 235119

NOTE:

D Installing the gun air inlet regulator adds a pressure

drop that could limit the air cap pressure.

D See Accessories on page 11 for air regulator

replacement parts.

1. Pull up the gun regulator adjustment knob lock-ring

(L); this allows the knob to turn. See Fig. 5.

2. Set the gun air pressure at zero by turning the

regulator adjustment knob (K) fully counterclockwise.

3. Turn on the air supply to the gun.

L

4. Turn the regulator adjustment knob (K) clockwise

to increase the air pressure to the gun.

WARNING

Never exceed 100 psi (7 bar) Maximum Working

Air Pressure to the gun. Exceeding the maxi-

mum working pressure of the gun or any other

system component could cause component

rupture, which could result in serious injury and

property damage.

5. Push the adjustment knob lock-ring (L) down to

hold the pressure setting.

Fig. 5

K

7614A

308791 5

Page 6

Maintenance

Disconnect the Gun and Air Regulator

from the Cup

1. Follow the Pressure Relief Procedure Warning

on page 4.

2. To disengage the tube grip, push down on the

outer ring of the lid elbow fitting (N), then pull the

tubing (3) out of the fitting. See Fig. 6.

3. Holding a wrench on the gun fluid inlet fitting,

disconnect the pressure cup swivel nut fitting (E).

4. Disconnect the air regulator fitting from the gun air

inlet.

5. Clean the gun as instructed in the gun manual.

CAUTION

Do not clean the air regulators in a gun washer as it

will damage the regulator diaphragm. Do not use any

cleaning method that allows solvent to enter the

regulator internally.

5. If any fluid is in the lid elbow fitting (N), flush it with

solvent but do not soak it in solvent for an

extended period.

6. If fluid is in the tubing (3) or check valve (13),

replace them. See the parts list for your cup

assembly to order parts.

E

N

3

A

101

B

102

Remove the Cup Lid

1. Push the clamp lever (A) fully to the unclamped

position, against the yoke (B). See Fig. 6.

2. Twist the cup lid (101) counterclockwise to disengage the yoke hook from the cup extended pins

(C).

3. Remove the cup lid (101).

4. Clean the cup lid (101) and cup (103).

CAUTION

When cleaning the pressure cup lid (101), avoid

prolonged exposure of the gasket (102) to solvent as

this will cause it to swell.

13

Fig. 6

C

103

3668

6 308791

Page 7

Parts

8

Use Only Genuine Graco Parts and Accessories

One Quart Pressure Cup

Part No. 239801

Includes the following parts:

Ref.

No. Part No. Description Qty.

101 236908 LID, pressure cup; Includes

item 102 1

102 189883 GASKET 1

103 239727 CUP, 1 quart (1 liter) 1

NOTE: See the Technical Data, page 10, for a list of

pressure cup materials.

101

102

Single Air Regulator Assembly

Part No. 235375, Series B

Part No. 245192

Includes the following parts:

Ref.

No. Part No. Description Qty.

1 162453 NIPPLE 1

2 156823 SWIVEL FITTING 1

3 112699 TUBE; 1/4 in. OD X 2.38 in. 1

4 187410 AIR FITTING 1

5 111500 GAUGE; 0-15 psi (0-1 bar) range 1

6 111501 REGULATOR; 0-12 psi

(0-0.8 bar) range 1

8 112698 ELBOW FITTING; 90_ swivel;

for 1/4 in. OD tube 1

9 100168 NIPPLE 1

10 110440 TEE FITTING 1

11 112059 PRESSURE RELIEF VALVE 1

12 189557 AIR RESTRICTOR 1

13 M71256 CHECK VALVE1

14 112699 TUBE, 1/4 in. OD X 2.38 in.

(235735) 1

198527 TUBE 1/4 in. OD X 6.00 in.

(245192) 1

103

01960A

Single Air Regulator Pressure Cup Kit

Includes the following parts:

Part No. 239802

Part No. Description Qty.

235375 Single Air Regulator Assembly

See parts list at right 1

239801 Pressure Cup Assembly

See parts list above 1

195065 Air Inlet Fitting

Part No. 245181

Part No. Description Qty.

245192 Single Air Regulator Assembly

See parts list at right 1

239801 Pressure Cup Assembly

See parts list above 1

195065 Air Inlet Fitting

14

3

13

11

1

3

1

9

1

8

1

1

Apply anaerobic pipe sealant (white) to external threads

2

Press fit tightly into tee (10)

3

Tapered side of the check valve must face towards the cup’s

elbow fitting

10

2

12

1

1

65

1

2

4

1

1

0172

308791 7

Page 8

Parts

A

Use Only Genuine Graco Parts and Accessories

Double Air Regulator Pressure Cup Kit

Part No. 239803

Includes the following parts:

Part No. Description Qty.

235376 Double Air Regulator Assembly

See parts list below 1

239801 Pressure Cup Assembly

See parts list, page 7 1

195065 Air Inlet Fitting 1

Double Air Regulator Assembly

Part No. 235376, Series B

Includes the following parts:

Ref.

No. Part No. Description Qty.

2 156823 SWIVEL FITTING 1

3 112699 TUBE; nylon; 1/4 in. OD 2

4 162453 NIPPLE 1

5 111500 GAUGE; 0-15 psi (0-1 bar) range 1

6 111501 REGULATOR; 0-12 psi

(0-0.8 bar) range 1

8 112698 ELBOW FITTING; 90_ swivel;

for 1/4 in. OD tube 1

9 100168 NIPPLE 1

10 110440 TEE FITTING 1

11 112059 PRESSURE RELIEF VALVE 1

12 189557 AIR RESTRICTOR 1

13 M71256 CHECK VALVE 1

14 110436 GAUGE; 0-100 psi

(0-7 bar) range 1

15 110438 REGULATOR; 0-100 psi

(0-7 bar) range 1

3

13

11

1

1

8

1

10

2

12

1

9

1

2

1

14

15

1

4

3

8 308791

1

1

Apply anaerobic pipe sealant (white) to external threads

2

Press fit tightly into tee (10)

3

Tapered side of the check valve must face towards the cup’s

elbow fitting

1

65

01729

Page 9

Parts

Use Only Genuine Graco Parts and Accessories

Remote Single Air Regulator

Pressure Cup Kit

Part No. 239804

Includes the following parts:

Part No. Description Qty.

236142 Remote Air Regulator Assembly

See parts list below 1

239801 Pressure Cup Assembly

See parts list, page 7 1

Remote Air Regulator Assembly

Part No. 236142, Series B

Includes the following parts:

Ref.

No. Part No. Description Qty.

1 172620 HOOK 1

2 100188 HEX NUT 1

Ref.

No. Part No. Description Qty.

3 172680 ELBOW FITTING 1

4 172682 HOSE ADAPTER 1

5 111500 GAUGE; 0-15 psi (0-1 bar) range 1

6 111501 REGULATOR; 0-12 psi

(0-0.8 bar) range 1

7 112698 CONNECTOR; for 1/4 in. OD tube 1

9 112699 TUBE; nylon; 1/4 in. OD 2

10 110440 TEE FITTING 1

11 112059 PRESSURE RELIEF VALVE 1

12 189557 AIR RESTRICTOR 1

13 M71256 CHECK VALVE 1

14 103656 HEX NIPPLE 1

15 212005 AIR HOSE; buna-n; 1/4 npsm;

6 ft. (1.83 m) long 1

16 212006 FLUID HOSE; nylon; 3/8 npsm;

6.5 ft. (1.98 m) long 1

17 188770 MOUNTING BRACKET 1

18 112308 PANEL NUT 1

19 183696 TEE FITTING 1

1

5

1

14

1

11

19

15

1

10

1

Apply anaerobic pipe sealant (white) to external threads

2

Press fit tightly into tee (10)

1

6

17

18

1

2

3

4

4

16

2

12

1

7

9

3

13

3

Tapered side of the check valve must face towards the cup’s

elbow fitting

4

Apply high strength anaerobic pipe sealant (green) to external

threads.

01963A

308791 9

Page 10

Technical Data

Single Air Regulator Pressure Cup Kit, Part No. 239802 and 245181

Maximum Outlet Pressure 12 psi (0.8 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Inlet Pressure 100 psi (7 bar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Double Air Regulator Pressure Cup Kit, Part No. 239803

Cup Regulator Maximum Outlet Pressure 12 psi (0.8 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gun Regulator Maximum Outlet Pressure 100 psi (7 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Inlet Pressure 100 psi (7 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Single Air Regulator Pressure Cup Kit, Part No. 239804

Maximum Outlet Pressure 12 psi (0.8 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Inlet Pressure 100 psi (7 bar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

One Quart Pressure Cup, Part No. 239801

Maximum Working Pressure 20 psi (1.4 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Size 1 quart (1 liter). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Material

Cup, Tube, Seat, and Nut 304 Stainless Steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lid Glass–Filled Nylon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sleeve, Clamp Arm Electroless Nickel Plated Aluminum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Yoke Electroless Nickel Plated Steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cup Gasket Polyethylene Foam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cup Fluid Nut Thread 3/8–18 npsm; R3/8–19 compound thread. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulator Swivel Nut Thread 1/4–18 npsm; R1/4–19 compound thread. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight

Pressure Cup Only 1 lb. 7 oz. (646 g). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cup with Single Air Regulator* 2 lb. 4 oz. (1007 g). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cup with Double Air Regulator* 2 lb. 8 oz. (1113 g). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Cup with Air Regulator Assembly* 2 lb. 9 oz. (1130 g). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Cup with Air Regulator Assembly and Hoses* 4 lb. 1 oz. (1816 g). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gun Air Regulator* 8 oz. (224 g). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

* Weight without gun

10 308791

Page 11

Accessories

Spray Gun Air Regulator Assembly 235119

100 psi (7 bar) Maximum Outlet Pressure

150 psi (10 bar) Maximum Inlet Pressure

For use on a spray gun with a 1/4–18 npsm air fitting.

Includes the following parts:

Ref.

No. Part No. Description Qty.

1 162453 NIPPLE; 1/4 npt x 1/4 npsm 1

2 156823 SWIVEL UNION; 1/4 npt 1

3 110436 GAUGE; 0-100 psi

(0-7 bar) range 1

4 110438 REGULATOR; 0-100 psi

(0-7 bar) range 1

NOTE: Installing the gun air inlet regulator adds a

pressure drop that could limit the air cap pressure.

3

1

2

Quick Disconnect Coupler 208536

1/4 npt(f), zinc-plated brass

NOTE: Installing the coupler adds a pressure drop that

could limit the air cap pressure.

Quick Disconnect Pin 169970

1/4 npt(m), zinc-plated steel

169970

Replaces nipple 162453,

item 1, at left

208536

0697

One Quart Pressure Cup Liners 112490

Box of 20 special blend polyethylene liners.

Use to line cup for easy clean-up. Graco Standard

4

01730

Warranty

308791 11

Page 12

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 308791

International Offices: Belgium, China, Japan, Korea

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Graco Headquarters: Minneapolis

Copyright 1977, Graco Inc. is registered to I.S. EN ISO 9001

www.graco.com

Revised March 2008

12 308791

Loading...

Loading...