Page 1

Instructions -- Parts List

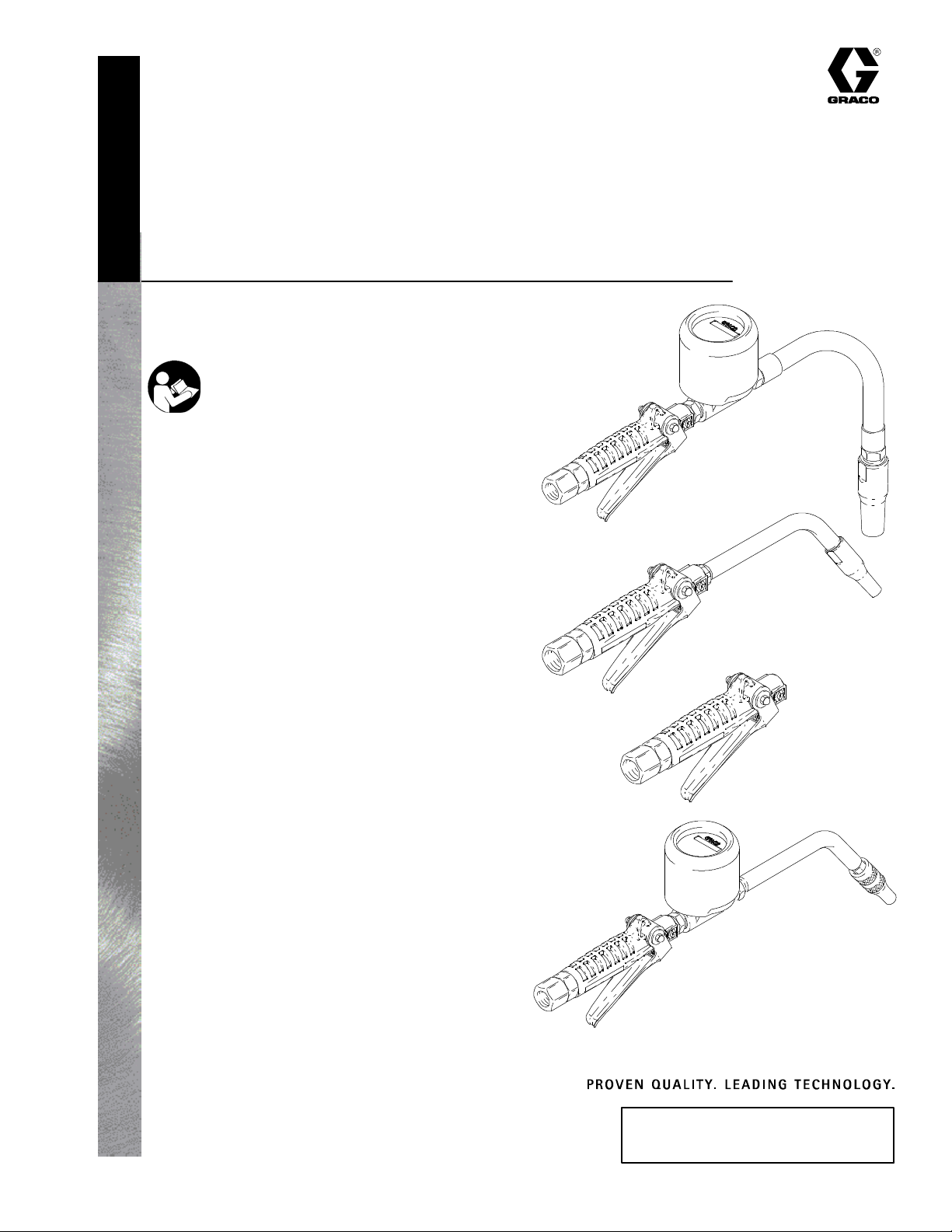

WITH OR WITHOUT ELECTRONIC METERS

V5t V12t EM6t and

EM12tDispense Valves

For dispense of petroleum and synthetic based oils.

1500 psi (10 MPa, 102 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

308642P

EN

NotesSee the list on page 3 for Model Numbers

and configurations.

See manual 307965 for information on electronic

meters 244075 and 244076.

Table of Contents

Models 3..................................

Warnings 4................................

Installation 6...............................

Operation 9...............................

Troubleshooting 10.........................

Service 11................................

Parts — EM12 and V12 Dispense Valves 12...

Parts — EM6 Dispense Valves 13............

Parts — V5 Dispense Valves 14..............

Technical Data 15..........................

Graco Standard Warranty 16................

Graco Phone Number 16....................

EM12

Model 238641

06294A

V12

Model 238644

06292A

Bare Valve

Model 238646

8537A

EM6

Model 243599

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440--1441

Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001

TI0407

Page 2

Notes

2 308642

Page 3

Models

Non-Metered Valves

V12 -- with trigger lock

With Extension

238644 3/4 in. swivel, rigid extension

238645 3/4 in. swivel, flex extension

238651 1/2 in. swivel, rigid extension

238652 1/2 in. swivel, flex extension

V5 -- with trigger lock

With Extension

22241 1, Series C, 1/2 in. swivel, oil nozzle/extension

222412, Series C, 1/2 in. swivel, gear lube extension

222413, Series C, 1/2 in. swivel, ATF nozzle/extension

Bare Valves

Metered Valves

EM12 -- with trigger lock

English Meter

238636 3/4 in. swivel, rigid extension

238637 3/4 in. swivel, flex extension

238640 1/2 in. swivel, rigid extension

238641 1/2 in. swivel, flex extension

Metric Meter

238638 3/4 in. swivel, rigid extension

238639 3/4 in. swivel, flex extension

238642 1/2 in. swivel, rigid extension

238643 1/2 in. swivel, flex extension

EM6 -- without trigger lock

English Meter

243599 1/2 in. swivel, rigid extension

243600 1/2 in. swivel, gear lube

243601 1/2 in. swivel, flex extension

238646 3/4 in. swivel, no extension, with trigger lock

238647 1/2 in. swivel, no extension, with trigger lock

243992 1/2 in. swivel, no extension, without trigger

lock

Metric Meter

243602 1/2 in. swivel, rigid extension

243603 1/2 in. swivel, gear lube

243604 1/2 in. swivel, flex extension

308642 3

Page 4

Warnings

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before you operate this equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Do not exceed the maximum working pressure of the lowest rated system component. Refer to

the Technical Data on page 15 for the maximum working pressure of this component.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

D Do not use 1,1,1--trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids that contain such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

D Do not use hoses to pull equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180_ F(82_ C) or below --40_ F(--40_ C).

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

4 308642

Page 5

WARNING

WARNING

SKIN INJECTION HAZARD

Fluid from the dispensing valve, leaks, or ruptured components can inject fluid into your body and

cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on

the skin can also cause serious injury.

D Fluid injected into the skin may look like just a cut, but it is a serious injury. Get immediate

surgical treatment.

D Do not point the dispensing valve at anyone or at any part of the body.

D Do not put your hand or fingers over the end of the dispensing valve.

D Do not stop or deflect leaks with your hand, body, glove or rag.

D Use only extensions and nozzles that are designed for use with your dispensing valve.

D Do not use a low-pressure flexible extension with this equipment.

D Follow the Pressure Relief Procedure on page 9 before you clean, check, or service the

equipment.

D Tighten all fluid connections before you operate the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do

not repair high pressure couplings; you must replace the entire hose.

WARNING

WARNING

CALIFORNIA PROPOSITION 65

This product contains a chemical known to the State of California to cause cancer, birth defects or

other reproductive harm. Wash hands after handling.

308642 5

Page 6

Installation

See manual 307965 for electronic meters installation, operation, parts, and cautions and warnings.

NOTE: Numbers in parenthesis, for example (7), and in the Parts Drawings are reference numbers

in the Parts List on page12.

Typical Installation

Fig. 1 shows a typical installation. Additionally, these

dispense valves can be installed on a console.

CAUTION

Do not use this electronic metered dispense

valve on non-Graco consoles. Such use could

result in the trigger becoming inadvertently

pressed while the dispense valve is stowed.

J

H

L

M

KEY

DESCRIPTION

H Thermal relief kit (required) Part No. 237904

Install downstream from pump.

J Fluid shut-off valve

K Hose

L Hose reel fluid inlet hose

M Hose reel

N Metered dispense valve

The installation shown in Fig. 1 is only a guide. The

components shown are typical; however, it is not a

complete system design. Contact your Graco distributor for assistance in designing a system to suit your

particular needs.

CAUTION

To prevent line contamination, which can cause

equipment malfunction or damage, flush the lines

before you install the equipment in the system.

Fig. 1

K

WARNING

N

cause volatile fumes to ignite, resulting in explosion

and fire. The dispensing system must always be

grounded. See Grounding on page 8.

04472A

FIRE AND EXPLOSION HAZARD

The movement of fluids through the

dispensing system generates static

electricity. The static electricity can

6 308642

Page 7

Installation

Pre-Installation Procedure

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 9.

2. Close the fluid shut-off valve (item J in Fig. 1).

3. Ground the hose and reel or console. See

Grounding on page 8. Do not use PTFE tape

on the pipe joints; it may cause a loss of ground

across the pipe joint.

Installation Procedure

CAUTION

If this is a new installation, or if the oil in the

lines is contaminated, flush the lines before you

install the dispensing valve.

Existing Installation

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury, whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 9.

2. Loosen and disconnect the hose from the old

dispense valve (the one that you are replacing).

For steps 3 to 5, see Fig. 2.

3. Thread the extension (26a) into the outlet of the

dispense valve, and tighten firmly.

NOTE: Do not over tighten the extension tube

assembly by using the nozzle adapter to hand turn the

nozzel. For rigid extensions, thread the extension

in at least three full turns, position the extension

for proper alignment, and tighten the sealing

nut (7). The PTFE seal on the sealing nut must

face the valve housing.

New Installation

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury, whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 9.

Steps2to6aretheFlushing Procedure.

2. Close the fluid shut-off valve (J) at each dispense

position.

3. Make sure the main fluid outlet valve at the pump

is closed, the air pressure to the pump motor is

adjusted, and the air valve is open. Slowly open

main fluid valve.

4. Place the hose end (with no dispense valve connected) into a container for waste oil. Secure the

hose in the container so it will not come out during

flushing. If you have multiple dispense positions,

first flush the dispense position farthest from the

pump, and work your way toward the pump.

4. Apply thread sealant to the male threads of the

hose fitting, thread the hose fitting into the swivel

(20), and tighten firmly.

5. Thread the new nozzle (8) or nozzle adapter onto

the extension, and tighten firmly.

6. Open all dispense position shut-off valves, and

start the pump to pressurize the syst em. See the

Operation section for proper operation.

7. For metered dispense valves, to ensure dispensing accuracy, purge all air from the fluid lines and

dispense valves before you use them.

Model shown is a V12 with

a75_ bend rigid extension.

7

26a

8

5. Slowly open the shut-off valve (J) at the dispense

position. Flush out a sufficient amount of oil to

ensure that the entire system is clean, and close

the valve.

6. Repeat step 5 at all other dispense positions.

Fig. 2

20

06292A

308642 7

Page 8

Grounding

Installation

Proper grounding is an essential part of maintaining a

safe system.

To reduce the risk of static sparking, ground all system

components per local and national electrical codes.

Refer to the user manuals for the pump and other

system components to ground the following:

D Pump: Follow manufacturer’s recommendations.

D Air and Fluid hoses: Use only grounded hoses.

D Air compressor: Follow manufacturer’s recommen-

dations.

D Fluid supply container: Follow your local code.

D To maintain grounding continuity when flushing or

relieving pressure, always hold a metal part of the

valve firmly to the side of a grounded metal pail,

then trigger the valve.

8 308642

Page 9

Operation

Pressure Relief Procedure

WARNING

PRESSURIZED EQUIPMENT HAZARD

The equipment stays pressurized until

pressure is manually relieved. To

reduce the risk of serious injury from

pressurized fluid, accidental spray from the

dispenser or splashing fluid, follow the Pressure

Relief Procedure whenever you

D Are instructed to relieve pressure

D Check, clean, or service any system equipment

D Install or clean fluid nozzles

1. Turn off the power supply to the pump.

2. Trigger the valve into a waste container to relieve

pressure.

3. Open any bleed-type master air valves and fluid

drain valves in the system.

4. Leave the drain valve open until you are ready to

pressurize the system.

If you suspect that the dispensing valve, extension, or

nozzle is clogged or that pressure has not been fully

relieved after following the steps above, very slowly

loosen a fitting on the fluid line to relieve pressure

gradually, then loosen it completely, then clear the

clog.

WARNING

To reduce the risk of a serious bodily injury, including fluid injection, never exceed the maximum

working pressure of the valve you are using or of

the lowest rated component in your system.

Dispensing Procedure

See instruction manual 307965 for electronic meter

operation.

NOTE: Before you begin, make sure you understand

how to unlock the trigger. Model EM6 does not have

a trigger lock.

1. Pull the trigger toward the valve body to open the

valve and begin dispensing.

2. Lock the valve open by keeping the trigger

squeezed and depressing the trigger lock button

(25intheParts Drawing). Then release the

trigger, releasing your forefinger from the trigger

lock last.

3. Pull the trigger toward the valve body to release

the trigger lock. The trigger lock disengages.

4. Release the trigger to stop dispensing.

308642 9

Page 10

Troubleshooting

Relieve the pressure before you check or repair the

dispensing valve. Be sure all other valves and controls

and the pump are operating properly.

Problem Cause Solution

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 9.

Display does not activate or is

showing unintelligent

characters.

Slow or no fluid flow Filter is clogged, or

Oil leaks from swivel.

Electronic control is malfunctioning. Replace the electronic control.

Pump pressure is low, or

Shutoff valve is not fully open, or

Foreign material is jammed in the

metering element.

Swivel is loose. Torque the swivel (20) to 15 to 20

O-ring is worn or damaged. Replace the o-ring (6), and torque the

See instruction manual 307965.

1. Relieve the pressure.

2. Clean or replace the filter (10).

See Filter Replacement on

page 11.

3. If the problem remains, contact

your Graco distributor for repair

or replacement.

ft-lb (20 to 27 N-m).

If the problem remains, contact your

Graco distributor for repair or

replacement.

swivel (20) to 15 to 20 ft-lb (20 to 27

N-m).

If the problem remains, contact your

Graco distributor for repair or

replacement.

Oil drips from nozzle. *

Valve leaks. O-rings or valve seat are worn or

Nozzle is damaged or obstructed. Inspect the nozzle for damage or

obstructions, and replace if damaged.

Replace the o-rings (15) and/or the

damaged.

valve seat (29).

See Valve Handle Repair on

page 11.

* Some fluid weepage is possible in applications where thermal expansion of fluid is possible.

10 308642

Page 11

Service

NOTE: See instruction manual 307965 for electronic meter service instructions.

Valve Handle Repair

See Fig. 3.

NOTE: The large end of the pushrod (30) fits into a

notch in the cam (21), which is part of the trigger

assembly. It is important that you know this before you

remove or install parts.

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury, when you are

instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 9.

2. If you are replacing the o-rings (15), or the cam

(21), or the push rod (30), remove the swivel (20),

and remove the internal pieces. You mu st

remove the cam in order to get the push rod

out of the outlet end of the valve handle.

3. Remove the screws (14) and washers (28), and

remove the trigger (24). Push the cam (21) out of

the valve handle (18). Replace the o-rings (15)

and/or the cam.

4. Replace any worn or broken parts.

5. Reassemble the internal pieces. The push rod

(30) must be inserted through the outlet end of

the valve handle before the cam (21) is

installed.

NOTE: For torque specifications and lubrication

instructions, see the service notes in the Parts

Drawings on pages 12, 13 and 14. EM6 models do not

have trigger lock parts 11, 25, and 27.

6. Lubricate the cam, and slide it into the valve

handle, making sure the notch is oriented as

shown in Fig. 3. Ensure that the large end of the

pushrod is resting in the notch of the cam.

7. Replace the screws (14) and washers (28), and

torquethescrewsto15to25in-lb(1.7to

2.8 N-m).

8. Replace the swivel (20), and torque to 15 to 20

ft-lb (20 to 27 N-m).

Filter Replacement

See Fig. 3.

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury, when you are

instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 9.

2. Unscrew the hose fitting from the swivel (20).

3. Remove and replace the filter (10), which is inside

the valve handle (18). Make sure the filter is

oriented as shown in Fig. 3.

4. Thread the hose fitting into the swivel (20), and

tighten. Make sure the swivel (20) is torqued to

15 to 20 ft-lb (20 to 27 N-m).

14

28

27

11

notch

30

15

15

28

Fig. 3

20

10

24

18

25

14

21

308642 11

7854B

Page 12

Parts — EM12 and V12 Dispense Valves

EM12 Models: 238636 to 238643 -- with trigger lock

(with electronic meter and extension)

V12 Models: 238644, 238645, 238651,

and 238652 -- with trigger lock

(no meter, includes extension)

Bare Valves: 238646 and 238647 -- with trigger lock

(no meter, no extension)

Includes items 6, 10--25, and 27--30

36

7

26a

8

1

5

14

2

30

28

18

29

12

16

10

6

4

20

1

3

Ref

No. Part No. Description Qty

6 111137 O--RING, valve/swivel

For Models 238636 to 238645,

238651, and 238652 2

For Models 238646 and 238647 1

7 112841 NUT, seal; 1/2--14 npt

For Models 238636, 238638,

238640, 238642, 238644, and

238651 1

8 238400 NOZZLE, oil

For Models 238636 to 238645,

238651, and 238652 1

10 185416 FILTER 1

11 113924 SPRING, compression 1

12 113493 SPRING, compression 1

14 110637 SCREW, machine 2

15 113574 SEAL, o-ring 2

16 113627 WASHER, plain 1

18 191074 HANDLE, valve 1

20 238398 SWIVEL; 3/4--14 npt

For Models 238636 to 238639

and 238644 to 238646 1

238399 SWIVEL; 1/2--14 npt

For Models 238640 to 238643,

238647, 238651 and 238652 1

27

11

25

24

35

4

15

21

4

15

28

14

2

1

Torque to 15 to 20 ft-lb (20 to 27 N-m).

2

Torque to 15 to 25 in-lb (1.7 to 2.8 N-m).

Apply lubricant to threads when reassembling.

3

Apply lubricant to packings and sealing

4

surfaces when reassembling.

Apply thread sealant when reassembling.

5

Ref

No. Part No. Description Qty

21 191315 CAM 1

24 191320 TRIGGER 1

25 191321 TRIGGER LOCK 1

26a 191403 TUBE, 75_ bend; 1/2 npt

For Models 238636, 238638,

238640, 238642, 238644, and

238651 1

26b 238401 HOSE, flexible; 1/2 npt

For Models 238637, 238639,

238641, 238643, 238645,

and 238652 1

27 192106 GUIDE, spring 1

28 191552 WASHER, flat 2

29 191313 SEAT, valve 1

30 192501 ROD, push 1

35 158491 NIPPLE

For Models 238636 to 238643 1

36 244075 METER, electronic; English

For Models 238636, 238637,

238640, and 238641 1

244076 METER, electronic; metric

For Models 238638, 238639,

238642, and 238643 1

26b

8

1

06293C

12 308642

Page 13

Parts—EM6DispenseValves

EM6 Models: 243599 to 243604 -- without trigger lock

(with electronic meter and extension)

Bare Valve: 243992 bare valve -- without trigger lock

(no meter, no extension)

Includes items 6, 10--23, and 25--27

33

28c

28b

7

28a

29c

5

32

2

13

25

27

14

17

26

11

15

10

6

4

1 3

18

Ref

No. Part No. Description Qty

6 111137 O--RING, valve/swivel

For Models 243599 to 243604, 2

For Model 243992 1

7 112841 NUT, seal; 1/2--14 npt

For Models 243599 to 243604, 1

10 185416 FILTER 1

11 113493 SPRING, compression 1

13 110637 SCREW, machine 2

14 113574 SEAL, quad ring 2

15 113627 WASHER, plain 1

17 191074 HANDLE, valve 1

18 238399 SWIVEL; 1/2--14 npt 1

20 191315 CAM 1

23 191320 TRIGGER 1

28 203265 NOZZLE, rigid extension

For Models 243599, and 243602

Includes items 28a--28c 1

28a 100081 . BUSHING; 1/2 npt(m) x 3/8 npt(f) 1

28b 159246 . TUBE, nozzle 1

28c 203655 . NOZZLE, non--drip 1

23

29b

29a

4

20

14

4

30a

25

2

13

Torque to 15 to 20 ft-lb (20 to 27 N-m).

1

Torque to 15 to 25 in-lb (1.7 to 2.8 N-m).

2

Apply lubricant to threads when reassembling.

3

Apply lubricant to packings and sealing

4

surfaces when reassembling.

Apply thread sealant when reassembling.

5

Ref

No. Part No. Description Qty

29 201701 NOZZLE, gear lube

For Models 243600 and 243603

Includes items 29a--29c 1

29a 100206 . BUSHING; 1/2 npt(m) x 1/4 npt(f) 1

29b 187046 . TUBE, nozzle 1

29c 201540 . NOZZLE, non--drip

30 203687 NOZZLE, flexible extension

For Models 243601 and 243604

Includes items 30a --30b 1

30a 109160 . HOSE, coupled; 1 ft (0.3 m);

1/2-- 14 npt(m) x 1/4-- 18 npt(f) 1

30b 203655 . NOZZLE, non--drip 1

25 191552 WASHER, flat 1

26 191313 SEAT, valve 1

27 192501 ROD, push 1

32 158491 NIPPLE

For Models 243599 to 243604 1

33 244075 METER, electronic; English

For Models 243599, 243600,

and 243601 1

244076 METER, electronic; metric

For Models 243602, 243603,

and 243604 1

30b

TI0408

308642 13

Page 14

Parts — V5 Dispense Valves

2

3

1

Model 238647 ---- Bare Valve, with trigger lock

4

7853A

Model 238647 ---- Bare Valve

Ref

No. Part No. Description Qty

1* 238647 VALVE 1

Model 222411, Series C ---- For Oil

Ref

No. Part No. Description Qty

1* 238647 VALVE 1

2 203265 NOZZLE, oil 1

See parts list on page 13.

Model 222412, Series C -- -- For Gear Lube

Ref

No. Part No. Description Qty

1* 238647 VALVE 1

3 201701 NOZZLE, gear lube 1

See parts list on page 13.

Model 222413, Series C -- -- For A.T.F.

Ref

No. Part No. Description Qty

1* 238647 VALVE 1

4 203687 NOZZLE, A.T.F. 1

See parts list on page 13.

* See parts below.

Ref

No. Part No. Description Qty

6 111137 O-RING, valve/swivel 1

10 185416 FILTER 1

11 113924 SPRING, compression 1

12 113493 SPRING, compression 1

14 110637 SCREW, machine 2

15 113574 SEAL, o-ring 2

16 113627 WASHER, plain 1

18 191074 HANDLE, valve 1

20 238399 SWIVEL; 1/2--14 npt 1

21 191315 CAM 1

24 191320 TRIGGER 1

25 191321 TRIGGER LOCK 1

27 192106 GUIDE, spring 1

28 191552 WASHER, flat 2

29 191313 SEAT, valve 1

30 192501 ROD, push 1

29

12

16

10

143

20

1

Torque to 15 to 20 ft-lb (20 to 27 N-m).

2

Torque to 15 to 25 in-lb (1.7 to 2.8 N-m).

Apply lubricant to threads when reassembling.

3

Apply lubricant to packings and sealing

4

surfaces when reassembling.

14

2

28

27

11

25

18

15

24

30

4

21

15

14

4

28

2

14 308642

6

7854B

Page 15

Technical Data

NOTE: See instruction manual 307965 for electronic meter Technical Data.

Recommended maximum flow rate*

V5 dispense valves 5.0 gpm (18.9 lpm)...................................................................

EM6 dispense valves 6.0 gpm (23.0 lpm).................................................................

V12 and EM12 dispense valves 12.0 gpm (45.4 lpm)......................................................

Maximum operating pressure 1500 psi...................................................................

(10 MPa, 102 bar)

Weight (without meter) 0.4 lb (0.18 kg)...................................................................

Operating temperature range --4_ to 130_ F(--20_ to 55_ C)................................................

Storage temperature range --40_ to 140_ F(--40_ to 60_ C).................................................

Inlet sizes 1/2 npt and 3/4 npt...........................................................................

See page 3 for model numbers and configurations.

Outlet size 1/2 npt.....................................................................................

Wetted parts aluminum, stainless steel,..................................................................

carbon steel, acetal, nitrile rubber, Geolastt

* Under normal operating conditions

Geolastt is a trademark of Advanced Elastomer Systems.

308642 15

Page 16

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free fromdefects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,damage or wear caused by

faultyinstallation, misapplication, abrasion, corrosion,inadequate or impropermaintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipmentwill be returned to the originalpurchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’ssole obligation and buyer’ssole remedy for any breach of warrantyshall be as set forth above. The buyer agrees that no other

remedy (including,but not limited to, incidental or consequential damages forlost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUST

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

OMERS

Graco Phone Numbers

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1--800--533--9655 Toll Free

612--623--6928

612--378--3590 Fax

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 308642

For patent information: www.graco.com/patents

16 308642

International Offices: Belgium, Korea, China, Japan

Graco Headquarters: Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440--1441

www.graco.com

02/1997, Revised December 2014

Loading...

Loading...