Page 1

INSTRUCTIONS-PARTS LIST

308603

Texture Flexhead and Pole Spray Guns

100 psi (7 bar) Maximum Air and Fluid Working Pressure

Model 238080, Series B

Texture Flexhead Spray Gun

Model 238807, Series B

Pole Spray Gun

WARNING

Rev. G

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including

electric shock and splashing fluid in the eyes, follow this

procedure whenever you stop spraying.

1. Shut off the pump or sprayer.

2. Trigger the gun.

3. Open the gun air valve.

4. Disconnect the power source.

Grounding

To reduce the risk of electric shock, proper electrical

grounding is essential. See your separate pump or

sprayer instruction manual, and consult your local

electrical codes for detailed grounding instructions.

The standard gun adjustment is to adjust the air

needle slightly behind the fluid tip. Fully open air valve

(3), while adjusting needle valve (5) for the minimum

air flow necessary for a good pattern.

Air bleeds from the gun nozzle whenever the gun air

valve (3) is open. Close the valve to stop the air, if

desired. Otherwise, it can stay open except during

priming.

To prevent material surge at the beginning of a spray

pattern, open valve (17) slowly while moving gun quickly.

Adjusting the spray pattern requires testing to balance

the pump pressure and the air to the gun, and using

the right tip size.

Spray Techniques

1. Test the spray pattern on cardboard. Hold the gun

18 – 30 in. (457 – 762 mm) from the surface. Use

this spraying distance for most applications.

2. Adjust fluid pressure until material flow is adequate.

3. Adjust the gun air flow valve (5) to achieve a

uniform, round spray pattern.

Working Pressure

To reduce the risk of component rupture and serious

bodily injury, never exceed 100 psi (7 bar) AIR OR

FLUID WORKING PRESSURE to this gun. Do not

exceed the maximum working pressure of any other

component in the system.

Fluid and Solvent Compatibility

Do not use 1,1,1-trichloroethane, methylene chloride,

other halogenated hydrocarbon solvents or fluids containing such solvents in this equipment, which contains

aluminum and/or zinc parts. Such use could result in a

serious chemical reaction, with the possibility of explosion, which could cause death, serious bodily injury

and/or substantial property damage.

4. Consider the size of aggregate in the material and

the coarseness of the spray pattern. Remember,

the larger the tip, the heavier the pattern.

5. Overlap each stroke 50%.

6. A circular, overlapping pattern may give the best

results, and is obtainable by grasping the flexhead

(2) and swinging the head around as the hose

flexes.

7. Use appropriate procedure for your sprayer:

a. TexSpray EXT HP, Compact HP and Twin

Tank EXT: Make sure air bleeds from the

aluminum tube when there is material pressure.

b. RTX 1500:Turn air supply off when sprayer is

not in use.

NOTE: Adjust fluid pressure to lowest pressure need-

ed to maximize efficiency of gun adjustments.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1996, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

When spraying small, confined areas, use the valve

and knob to make fine adjustments without adjusting

the pump.

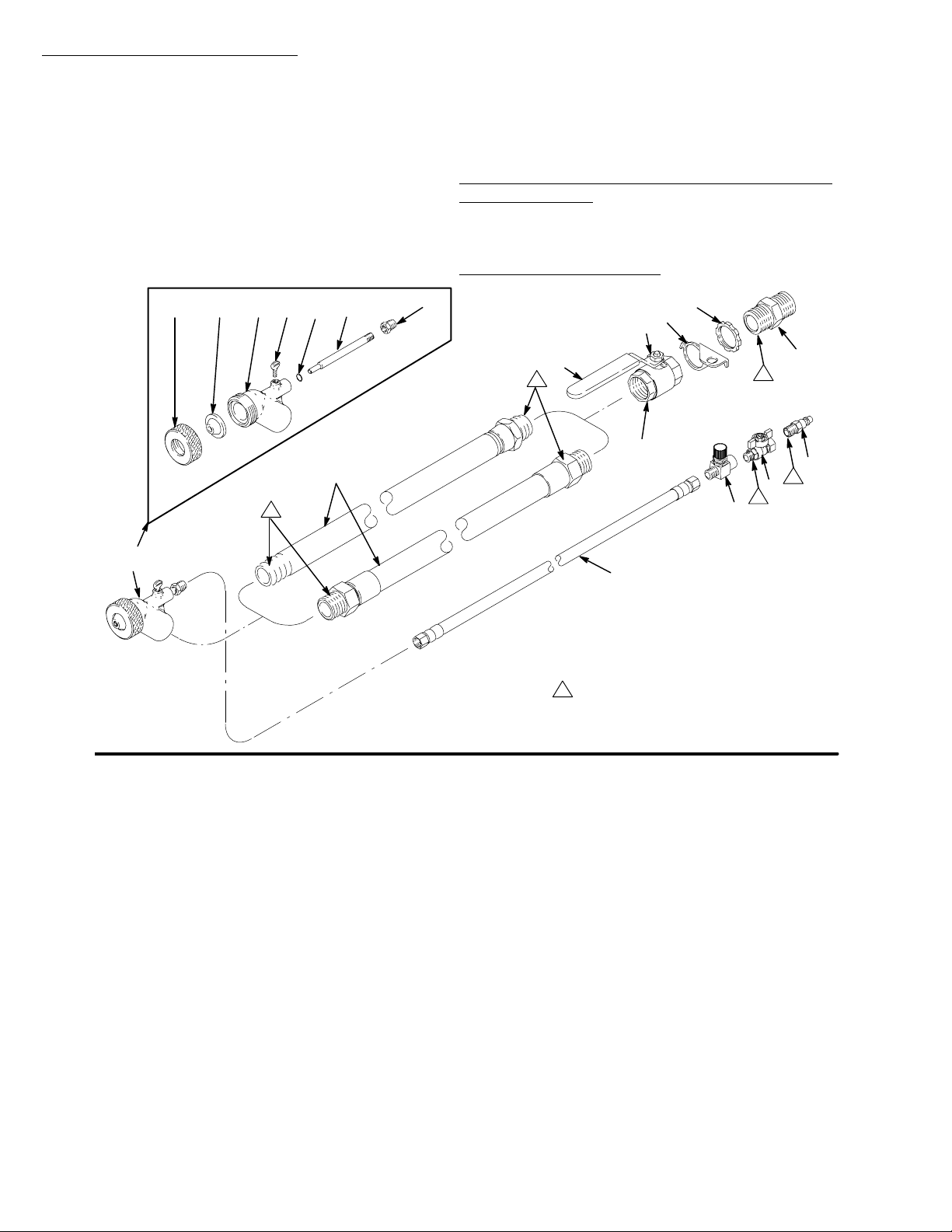

Material flow adjustments (Fig. 1)

For a lighter spray pattern, adjust the air needle (18)

closer to the fluid tip and/or reduce the fluid pressure.

For a heavier spray pattern, adjust the air needle (18)

farther back from the fluid tip and/or increase the fluid

pressure.

NOTE: Withdrawing needle valve (18) too far can force

air back into fluid hose, stopping material flow.

Air flow valve adjustment

To decrease air flow turn the valve (5) clockwise.

To increase air flow, turn the valve (5) counter clockwise.

Check and thin the material as needed to maintain the

proper consistency. The material may thicken as it sits

and slow down production or affect the spray

pattern.

Flush and dry gun thoroughly at end of each work day.

Fig. 1

12

23 22

18

212019 13 – 16

2

1

6

4

8

9

1

10

1

17

11

1

3

1

5

1

1

Apply PST sealant

05614A

Ref

No Part No. Description Qty

1 HOSE, coupled, air 1

113377 Model 238080 1

113601 Model 238807 1

2 HOSE or TUBE, fluid, with swivel 1

113378 Model 238080 (hose) 1

191633 Model 238807 (tube) 1

3 15B565 VALVE, ball, air 1

4 190807 BRACKET, valve, air 1

5 112779 VALVE, needle, air 1

6 113114 LOCKNUT, 1 in. npt 1

7 110110 SEALANT, PST (not shown) 1

8 190940 HANDLE, valve 1

9 113387 SLEEVE, handle 1

10 15E359 COUPLER, 1 in. male 1

11 119394 FITTING, air 1

This manual contains English. MM 308603

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

308603 April 1996, Revised 8/2007

Ref

No Part No. Description Qty

12 238955 SPRAY GUN, flexhead 1

(includes items 13 – 16 and 18 – 23)

13 190943 TIP, spray gun, 3/16 in. 1

14 190944 TIP, spray gun, 1/4 in. 1

15 190945 TIP, spray gun, 5/16 in. 1

16 190946 TIP, spray gun, 3/8 in. 1

17 113121 VALVE, ball, 1 in. 1

18 190947 NEEDLE, air 1

19 190948 CAP, tip retaining 1

20 190942 HOUSING, spray gun 1

21 104282 O-RING 1

22 M70895 BUSHING 1

23 100085 SCREW 1

Technical Data

Weight 67 oz (1900 grams). . . . . . . . . . . . . . . . . . . . . . . .

Loading...

Loading...