Page 1

Instructions – Parts List

STAINLESS STEEL, HEAVY–DUTY

Agitators

100 psi (0.7 MPa, 7 bar) Maximum Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Tank Size

gallons (liters)

5 (19) 236661

10 (38) 236662

15 (57) 236663

For fluid viscosities above 800 cps (centipoise)

Table of Contents

Heavy–Duty

Agitator P/N

308371K

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 16. . . . . . . . . . . . . . . . . . . . . .

Graco Information 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001

0359

Model 236661

03104C

II 1/2 G T6

ITS03ATEX11226

Page 2

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Do not exceed the maximum working pressure of the lowest rated component in your system. This

equipment has a 100 psi (0.7 MPa, 7 bar) maximum working pressure.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

D Always wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid and

solvent manufacturer.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

2 308371

Page 3

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Ground the equipment and the object being sprayed. Refer to Grounding on page 4.

D If there is any static sparking or you feel an electric shock while using this equipment, stop spray-

ing immediately. Do not use the equipment until you identify and correct the problem.

D Do not use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents, or

fluids containing such solvents in aluminum pumps. Such use could result in a serious chemical

reaction, with the possibility of explosion.

D Do not use kerosene or other flammable solvents or combustible gases to flush the unit.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

D Keep the spray area free of debris, including solvent, rags, and gasoline.

D Before operating this equipment, electrically disconnect all equipment in the spray area.

D Before operating this equipment, extinguish all open flames or pilot lights in the spray area.

D Do not smoke in the spray area.

D Do not turn on or off any light switch in the spray area while spraying or while there are any fumes

in the air.

D Do not operate a gasoline engine in the spray area.

D Keep a fire extinguisher in the work area.

MOVING PARTS HAZARD

Moving parts, such as the rotating blades of the agitator, can pinch or amputate your fingers or other

body parts and can cause splashing in the eyes or on the skin.

D Keep clear of all moving parts when starting or operating the agitator.

D Always shut off the agitator and disconnect the air line before adjusting the angle of the agitator,

removing the agitator from the drum, or checking or repairing any part of the agitator.

HAZARDOUS VAPORS

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled. When flushing the air motor, keep your face away from the exhaust port.

308371 3

Page 4

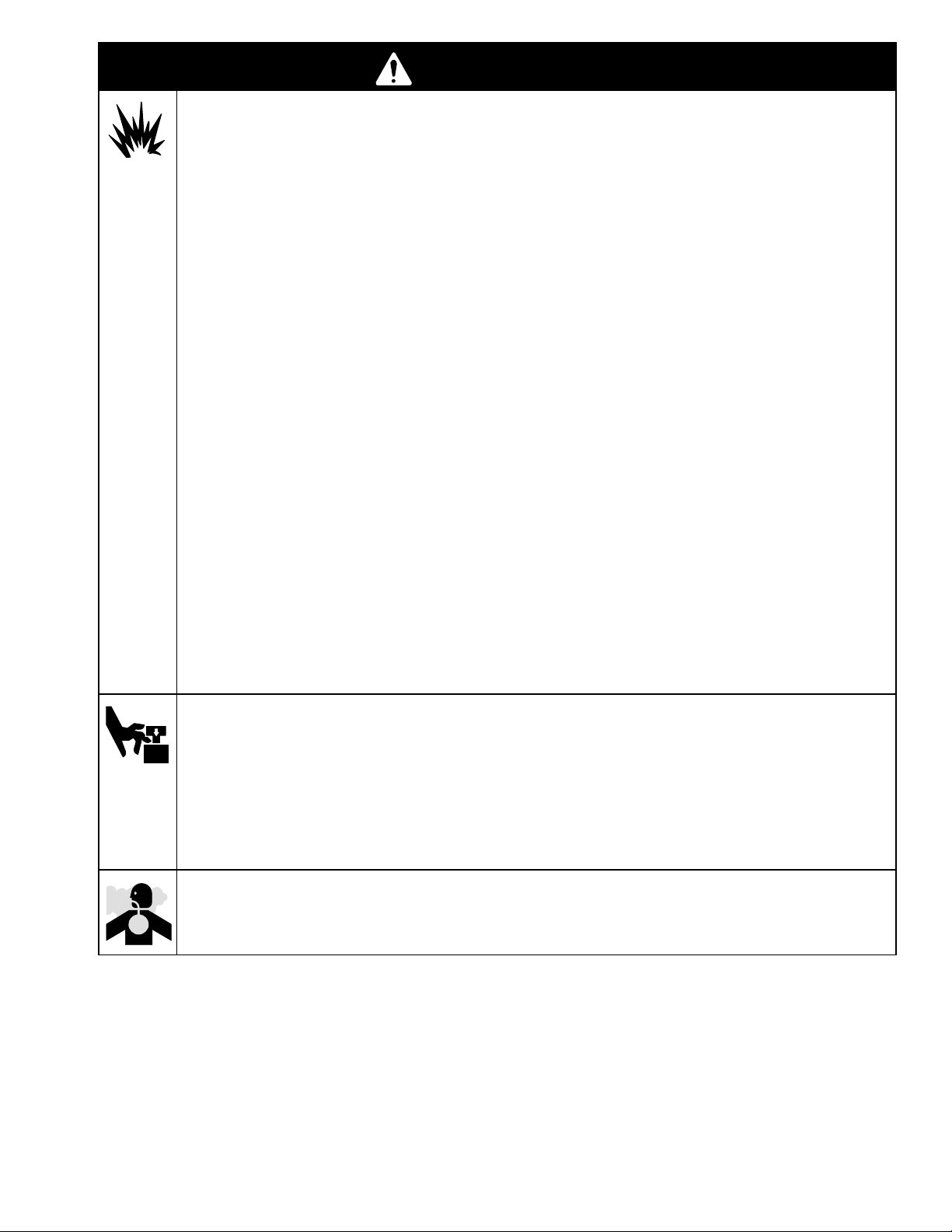

WARNING

Installation

Pressure Relief Procedure

FIRE AND EXPLOSION HAZARD

Always maintain a minimum of 1 in.

clearance between rotating agitator parts

and container to prevent sparks from contact.

Typical Installation

air line lubricator

agitator motor

air line filter

air regulator

and gauge

NOTE: Reference numbers and letters in parentheses

refer to the numbers and letters in the Figures and the

Parts Drawings.

mix tank

(reference only)

WARNING

To reduce the risk of serious bodily injury, including

splashing in the eyes or on the skin, or injury from

moving parts, which can result if the tank pressure

is not fully relieved, always follow this procedure

before opening the pressure tank cover or fill port.

1. Shut off the air supply to the tank by closing the air

inlet valve (A). Refer to Fig. 2.

2. Open the drain cock fitting (B) by turning it

counterclockwise.

3. Wait until there is no air escaping through the

fitting before removing the cover or opening the fill

port.

4. Leave the drain cock fitting open until you have

reinstalled the cover or filler cap.

Grounding

Proper grounding is an essential part of maintaining a

safe system.

To reduce the risk of static sparking, all electrically

conductive objects or devices must be properly

grounded. Check your local electrical code for detailed

grounding instructions for your area and type of

equipment.

To ground the agitator, connect one end of the

ground wire (A) to the ground connector (B) on agitator

mounting bracket. See Fig. 1. Connect the other end

of the ground wire to a true earth ground.

For a ground wire and clamp, order

Part No. 237569.

B

A

Fig. 1

4 308371

Page 5

Notes

308371 5

Page 6

Installation

If installing an agitator onto a non-agitated tank,

follow steps 1, 2, and 7 through15. If installing a

heavy-duty agitator in place of a standard agitator,

follow pages 1, 3 through 12, 14, and 15.

1. Follow the Pressure Relief Procedure above.

Then remove the pressure tank cover from the

tank.

2. See Fig. 3. Unscrew and remove the hex jam nut

(C), plug (D), and O-ring (E) from the tank cover.

3. Remove the upper U-bolt (26).

4. See Fig. 4. Loosen the two set screws (13) and

remove the agitator paddle (12).

5. On 10 and 15 gallon tanks, remove the lower

U-bolt (26), loosen screws (24) and slide the baffle

(23) off the fluid tube (K).

6. Unscrew and remove the hex jam nut (C), gasket

(17), and agitator from the tank cover.

7. See Fig. 3. Place the gasket (17) on top of the

tank cover center hole. Insert the agitator drive

shaft (14) through the center hole.

B

5 Gallon Tank with Heavy-Duty Agitator

Fig. 2

A

03282A

NOTE: Position the air motor so it faces away

from the air regulator mounting as shown in Fig. 2.

8. Install the jam nut (C) below the tank cover.

Tighten the jam nut firmly to assure a seal

between the gasket (17) and tank cover.

9. Install the shaft support (11) onto the shaft housing

(9). Clamp with U-bolt (26), clamp (10), lock

washer (36) and nut (25).

10. Tighten the U-bolt at a position leaving

approximately 0.015 in. (0.006 mm) clearance gap

between the thrust washer and the top of the shaft

support. See the Parts Drawing on page 12.

11. See Fig. 4. On the 10 and 15 gallon tanks, place

the lower bearing assembly (2) and (3) on the

shaft. On the 5 gallon tank, clamp U-bolt directly to

shaft support (11). Slide the baffle (23) over the

fluid tube (K) and position the baffle about 1/2 in.

(13 mm) above the highest point on the agitator

paddle (12). Clamp in place with U-bolt (26),

washer (36), and nut (25).

D

E

C

14 (REF)

Fig. 3

14

17

10

36

25

9

F

26

11

03261B

6 308371

Page 7

Installation

12. Align the agitator paddle (12) on the agitator shaft

(14) as instructed for your model, as follows:

Models 236662 and 236663 (10 & 15 Gallon)

Align the top of the paddle hub (G) with the mark

(H) on the agitator shaft (14).

Model 236661 (5 Gallon)

If a 5 gallon pail is to be placed inside the pressure

tank (5 gallon tank only), align the top of the

paddle hub (G) with the upper mark (J) on the

agitator shaft (14). If a pail will not be placed inside

the tank, align top of hub (G) with the lower mark

(H) on the agitator shaft (14).

After the paddle (12) is properly aligned, apply low

strength sealant to the two setscrews (13) and

firmly secure the paddle with the setscrews.

13. See Fig. 5. Remove plug from air inlet manifold

(N). Remove the elbow (37) from the end of the air

hose (21) and attach to the pressure tank’s air inlet

manifold (N).

14. Connect the swivel end of the air hose (21) to the

elbow (37).

15. See Fig. 5. Remove the gear reducer’s oil level

plug (L) from the street elbow and check the oil

level in the reducer housing. The oil should never

be higher than the oil level plug. If necessary, drain

or add oil until the proper oil level is attained.

Screw the oil level plug back onto the street elbow.

J

H

1

Fig. 4

11

2 & 3

25

36

14

12

1/2”

(13 mm)

Apply low strength (cyanoacrylate) thread sealant.

25

24

26

G

1

13

11

K

23

02264

NOTE: Special high temperature synthetic gear oil is

required for the gear reducer. Use only Graco oil,

part number 204559.

308371 7

Page 8

WARNING

Operation

3. Close the tank air regulator(s) by turning the

knob(s) counterclockwise. Turn on the air supply.

To reduce the risk of serious bodily injury, which

can result if the tank pressure is not fully relieved,

always follow the Pressure Relief Procedure on

page 6 before opening the tank cover or fill port.

1. Fill the pressure tank as explained in the Pressure

Tank Instruction Manual 308369.

2. Screw on the filler cap (F) (see Fig. 3), or if the

tank cover was removed, place the agitator and

cover on the pressure tank and secure the cover

with the c-clamp handles (M). See Fig. 5.

WARNING

Over-pressurizing the tank or accessories could

cause a part to rupture. To reduce the risk of

serious injury, including fluid injection and splashing

in the eyes or on the skin, or property damage,

never exceed the maximum air and fluid working

pressure of the lowest rated component in your

system.

4. To start the agitator, slowly open the needle valve

(20). Adjust the speed of the agitator, with the

needle valve, to about 40 to 60 rpm.

CAUTION

Do not operate the agitator at a high speed for a

long period of time. Excessive agitator speed can

cause foaming of fluid (making fluid unusable), or

vibration and increased wear on parts. Always

agitate the fluid only enough to maintain even

mixing.

5. To stop the agitator, close the needle valve (20).

L

Fig. 5

20

N

Heavy-Duty Agitator

37

M

21

03283A

8 308371

Page 9

WARNING

Service

Flushing the Air Motor

To reduce the risk of serious bodily injury, including

cuts, amputation of fingers, and splashing in the

eyes or on the skin, always follow the Pressure

Relief Procedure on page 6, shut off the agitator,

and disconnect the air line before checking or

repairing the agitator.

Lubricating the Heavy-Duty Agitator

CAUTION

Not lubricating the air motor will cause air motor failure.

Air Motor: Install an air line lubricator for automatic air

motor lubrication. Set the lubricator feed rate at 1 drop

of oil per minute for high speed or continuous duty

usage. Do not overfeed oil or exhaust air may become

contaminated. To order a 3/8 in. npt air line lubricator,

order Part No. 214847.

If an air line lubricator is not installed, the air motor

must be manually lubricated every 8 hours. Lubricate

the agitator air motor by placing 10–20 drops of SAE

#10 light oil in the motor’s air inlet. Run the agitator for

about 30 seconds.

Gear Reducer: After the first 100 hours or two weeks

of operation, remove the oil plug (T) and the oil level

plug (L), drain the oil, and thoroughly flush the housing

with light flushing oil. See Fig. 6.

WARNING

FIRE AND EXPLOSION HAZARD

Do not use kerosene or other flammable

solvents to flush the air motor. Flushing

with flammable solvents could cause fire

or explosion and result in serious injury or property

damage.

WARNING

HAZARDOUS VAPORS

Hazardous fluids or toxic fumes can

cause serious injury or death if splashed

in the eyes or on the skin, swallowed, or

inhaled. When flushing the air motor:

D Keep your face away from the exhaust port.

D Wear the appropriate protective clothing,

gloves, eyewear, and respirator.

If the motor is sluggish or inefficient, flush it with

non-flammable solvent in a well ventilated area.

The recommended solvent for air motors and

lubricated pumps is Gastr Flushing Solvent (Part No.

AH255 or AH255A) or Inhibisolr Safety Solvent.

1. Disconnect the air line and muffler.

Refill with Graco oil (part number 204559) to the

proper level.

Afterward, change the oil every six months or 2500

hours of operation (whichever occurs first) under

normal operating conditions. More frequent oil changes

are needed under severe operating conditions or in

atmospheres containing excessive moisture or

abrasives. Contact your Graco distributor.

2. Add several teaspoons of solvent or spray the

solvent directly into the motor.

3. Rotate the shaft by hand in both directions for a

few minutes.

4. Reconnect the air line, and slowly increase the air

pressure until there is no trace of solvent in the

exhaust air.

5. Re-lubricate the motor with a squirt of light-weight

oil in the chamber.

308371 9

Page 10

Service

D If the unit requires more than installation of a

service kit, it is usually quickest and easiest to send

the unit to the Graco distributor for repair or

replacement.

D If the vanes need replacing, or if foreign material is

present in the motor chamber, an experienced

mechanic may remove the end plate opposite the

drive shaft end. Do not pry with a screwdriver. It will

dent the surface of the plate and body, causing

leaks. Use a puller tool, which will remove the end

plate while maintaining the position of the shaft.

D New vanes should have the edges with cut corners

(or the notched edges, if the vanes are reversible)

pointing toward the bottom of the vane slot.

Cleaning the Shaft

Each week, clean any dried fluid from around the

bearing (38) area of the shaft (14).

Replacing the Heavy-Duty Air Motor

(See Fig. 6)

Removing the Heavy-Duty Air Motor

1. Disconnect the air hose (21).

2. Loosen the two setscrews (32) on the collar (2)

and remove the air motor (1).

Installing the Heavy-Duty Air Motor

1. Place one-half of the coupling (3a) on the air motor

shaft (S), flush with the end of the shaft. Tighten

the coupling setscrew against the flat on the shaft.

2. Install the load cushion (P) on the gear reducer

coupling half. Slide the clamp (2) onto the collar

(4).

3. Align the two coupling halves (3a), and push the

air motor hub into the collar (4) until it bottoms out,

then back it out 0.015 in. (0.38 mm). Make sure

the air motor inlet and outlet face up.

4. Apply Loctiter No. 222 to the two clamp setscrews

(32). Align the setscrews to one side of the slots

on the collar (4), and tighten them.

5. Apply pipe thread sealant to the inlet (20) and

outlet (22) fittings, and install them in the air motor.

T

L

2

2

P

22

2

4

1

32

Fig. 6

3a

1

Apply Loctite No. 222.

Apply low-strength thread sealant.

2

S

1

2266B

Replacing the Heavy-Duty Gear Reducer

(See Fig. 7)

1. Do not attempt to repair the gear reducer (5)

yourself. Contact your Graco distributor.

2. When replacing the gear reducer, turn it upside

down and remove the cap screws (33) and

washers (40) from the bottom of the old gear

reducer. Remove the top coupling half (19a) from

the old gear reducer, and install the coupling half

on the new gear reducer. Wipe the screw holes

clean with a rag.

3. Apply Loctite No. 271, or equivalent, to the four

cap screws (33). Install them with the washers (40)

through the bracket (6) and into the gear reducer.

Make sure the three hole pattern on the bottom of

the bracket (6) is orientated in relation to the gear

reducer (5) as shown in Fig. 7. Run the agitator

to let the bracket (6) center itself. Torque the

screws to 160 in-lb (18 NSm). Leave the gear

reducer upside down for 30 minutes to allow the

Loctite to cure. Set the coupling as instructed

under Setting the Agitator Shaft Coupling, on

page 11.

21

20

10 308371

CAUTION

Do not use the four screws supplied with the new

gear reducer to secure it; those screws will not

properly secure the gear reducer. Use the cap

screws and washers (33 and 40) removed from the

old gear reducer. Be careful not to spill any oil from

the gear reducer.

Page 11

Service

Servicing the Agitator Shaft and

Couplings (See Fig. 7)

Setting the Agitator Shaft Coupling

1. With the agitator shaft (14) pushed up against the

washer (15a), secure the lower portion of the

coupling half (19b) to the shaft by tightening the

coupling setscrew against the flat on the shaft.

Leave about a 0.015 in. gap between the coupling

half and washer (15b).

2. Secure the upper coupling half (19a) to the gear

reducer shaft by tightening the coupling setscrew

into the keyway. Leave about a 0.015 in. gap

between each of the coupling halves (19a, 19b)

and the load cushion (R).

Replacing the Agitator Shaft

1. Remove the agitator paddle. Remove the setscrew

from the lower coupling (19b). Pull out the agitator

shaft (14) and install the new shaft. Replace the

agitator paddle.

2. With the agitator shaft (14) pushed up against the

washer (15a), secure the lower portion of the

coupling half (19b) to the shaft by tightening the

coupling setscrew against the flat on the shaft.

Leave about a 0.015 in. gap between the coupling

half and washer (15b).

5

19a

6

40

1

33

18

7

8

15b

9a

2

R

19b

14 (REF)

9

9b

2

Replacing the Coupling

1. Remove the three cap screws (18), washers (7)

and spacers (8) from the mounting bracket (6). Lift

the air motor and gearbox off the tank cover.

Remove the two coupling halves (19a, 19b) from

the shaft ends.

2. Install the new coupling halves on the shaft ends.

Replace the air motor/bracket assembly and the

three cap screws (18), washers (7) and spacers

(8) to fasten the mounting bracket.

Replacing the Shaft Seals

1. Remove the three cap screws (18), washers (7),

and spacers (8) from mounting bracket (6), and

move the air motor assembly.

2. With air motor assembly removed, remove the

setscrew from the lower coupling half (19b). Pull

out the agitator shaft (14).

3. Remove the hex nut (16) and remove the shaft

housing (9). Remove the seals (9a, 9b) from the

shaft housing, and install the new seals.

4. Reinstall the shaft housing and shaft. Use

installation steps listed in Setting the Agitator

Shaft Coupling.

1

Apply Loctite No. 271.

Torque to 160 in-lbs (18 N-m)

2

Install seals with open spring-loaded

side toward tank

Fig. 7

16

15a

14

2267C

308371 11

Page 12

19

27

29

40

18

14

Parts Drawing

Stainless Steel, Heavy-Duty Agitators

5

28

37

3

1

4

35

22

6

32

2

2

3

7

33

3

19

8

30

41 42

Model No. 236661, 5-gallon size

Model No. 236662, 10-gallon size

Model No. 236663, 15-gallon size

21

20

1

9a

15

9

9b

17

20c

20b

16

20a

20d

20f

20e

10

36

25

26

15

REF NO. 20

Needle Valve

includes items 20a through 20f

14

4

11

39

5

38

25

23

24

1

Orient collar (4) with slots facing up and down.

Orient screws (32) on collar (2) to either side of

2

slots on mounting collar (4).

Remove original bolts, and replace with (33).

3

Torque to 160 in-lbs (18 N-m).

25

36

14

12 308371

26

12

13

3103C

Locate the bottom shoulder of shaft (14) against

4

washer (15) when assembling coupler (19).

Items (38) and (39) are not used on the 5-gallon

5

model. Attach item (26) to (11) for this model.

Apply low-strength (cyanoacrylate) thread

6

6

sealant.

03103B

Page 13

Parts List

Stainless Steel, Heavy-Duty Agitators

Model No. 236661, 5-gallon size

Model No. 236662, 10-gallon size

Model No. 236663, 15-gallon size

Ref Part

No. No. Description Qty.

1 162425 MOTOR, air 1

2 181849 COLLAR 1

3 100828 COUPLING, flexible 1

4 220416 COLLAR, mounting;

Includes items 4a & 4b 1

4a 181848 SLEEVE, mounting, air motor 1

4b 170751 PLATE, mounting 1

5 181794 REDUCER, gear 1

6 181749 BRACKET, mounting 1

7 100020 WASHER, lock 3

8 108462 SPACER 3

9 236092 HOUSING, shaft;

Includes replaceable items 9a & 9b 1

9a 103553 · SEAL, shaft 1

9b 104431 · SEAL, shaft 1

10 112533 CLAMP, plate, sst 1

11 210576 SUPPORT, shaft;

Includes replaceable item 38 1

12* 236098 PADDLE, agitator; plastic 1

13 112230 SCREW, set, sch, 1/4–20 x 0.5 in.

(13 mm) 2

14 188886 SHAFT, agitator, 15 in., 5 gal size

(18.9 liters); sst 1

14 188887 SHAFT, agitator, 20.75 in., 10 gal size

(37.8 liters); sst 1

14 188888 SHAFT, agitator, 31 in., 15 gal size

(56.7 liters); sst 1

15 104373 WASHER, thrust; 1/2 in. ID x 1 in. OD 2

16 188784 NUT, jam, hex; 1–1/2 in.–12;

stainless steel 1

17 196309 GASKET, LDPE foam 1

18 102598 SCREW, cap, socket head;

10–32 x 0.5 in. (13 mm) 3

19 108463 COUPLING, flexible 1

* Stainless steel agitator paddle 186517, 304 stainless

steel welded construction, replaces plastic agitator paddle

236098.

Ref Part

No. No. Description Qty.

20 206264 VALVE, needle;

Includes items 20a to 20f 1

20a 166529 · NEEDLE, valve 1

20b 166532 · NUT, packing 1

20c 164698 · KNOB, packing 1

20d 157628 · O-RING; buna-N 1

20e 165722 · BODY, valve 1

20f 166531 · WASHER, nylon 1

21 160023 HOSE, coupled; 400 psi

(2.8 MPa, 28 bar)

maximum working pressure 1

22 156969 MUFFLER, exhaust 1

23 171989 BAFFLE, agitator, sst 1

24 112222 SCREW, cap, socket head;

1/4-20 x 1 in., (25 mm) sst 2

25 112223 NUT, hex, regular; 1/4–20, (19 mm)

sst 6

26 110278 U-BOLT, clamp; sst 2

27 111593 SCREW, grounding 1

28 157021 WASHER, lock, internal 1

29 186620 LABEL, grounding symbol 1

30 Y 290152 LABEL, warning 1

32 101118 SCREW, set, sch; 10–24 x 0.25 in.

(6 mm) long 2

33 110298 SCREW, cap, sch; 1/4–20 x .875 in.

(22 mm) long 4

35 116940 SCREW, cap; 5/16–18 x 1/2 in.

(13 mm) long 2

36 104123 WASHER, lock, sst 4

37 112307 ELBOW, street; 90_ x 1/8–27 npt(f)

1/8–27 npt(m) 1

38 171970 BEARING PTFE; Included with

Models 236662 and 236663 only 1

39 187324 HOUSING, bearing; Included with

Models 236662 and 236663 only;

sst 1

40 170772 WASHER, flat; 0.26 x 0.69 dia;

sst 4

41 194701 GUARD 1

42 100078 SCREW, #8–32x3/8 in. 1

Y Extra warning labels are available for free.

308371 13

Page 14

Technical Data

Heavy-Duty Models 236661, 236662, and 236663

For fluid viscosity above 800 cps (centipoise)

Air motor: air driven, gear reduced,

1/2 HP (373 W)

Air pressure: 100 psi (0.7 MPa, 7 bar) maximum

Gear ratio: reduced 20:1

shaft rpm is 1/20 of air motor rpm

Wetted parts: 304 and 316 stainless steel, PTFE,

Zytelr, and bronze

Weight : 21.0 lb (9.5 kg)

*Sound data:

Sound pressure

At no load at maximum rpm: 83.4 dB(A)

Under load at 50 rpm: 64.0 dB(A)

Sound power

At no load at maximum rpm: 96.6 dB(A)

Under load at 50 rpm: 77.2 dB(A)

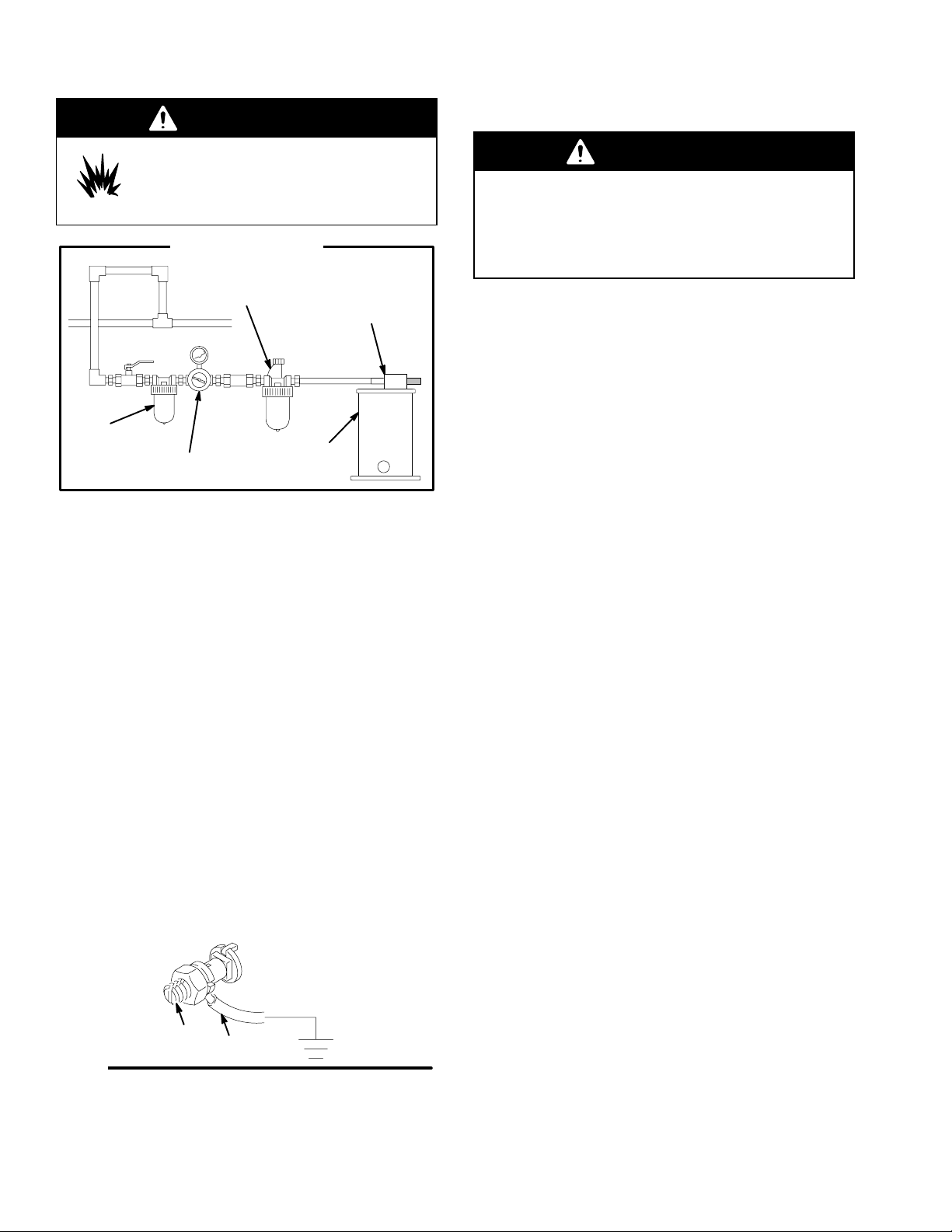

Air Consumption Chart

30

A 20 psi (0.14 MPa, 1.4 bar)

B 40 psi (0.28 MPa, 2.8 bar)

C 60 psi (0.41 MPa, 4.1 bar)

25

D 80 psi (0.55 MPa, 5.5 bar)

E 100 psi (0.7 MPa, 7 bar)

* Sound level measurements taken at 1 meter per

CAGI-PNEUROP, 1971.

Loctiter is a registered trademark of the Loctite

Corporation

Zytelr is a registered trademark of the DuPont

Company.

Gastr is a registered trademark of Gast

Manufacturing.

Inhibisolr is a registered trademark of Penetone Corp.

E

20

15

CFM (Free Air) Consumption

10

5

0

0 500 1000 1500 2000 2500 3000

D

C

B

A

Speed–RPM (Output)

14 308371

Page 15

Notes

308371 15

Page 16

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

16 308371

This manual contains English. MM 308371

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

www.graco.com

308371 07/1994, Revised 07/2007

Loading...

Loading...