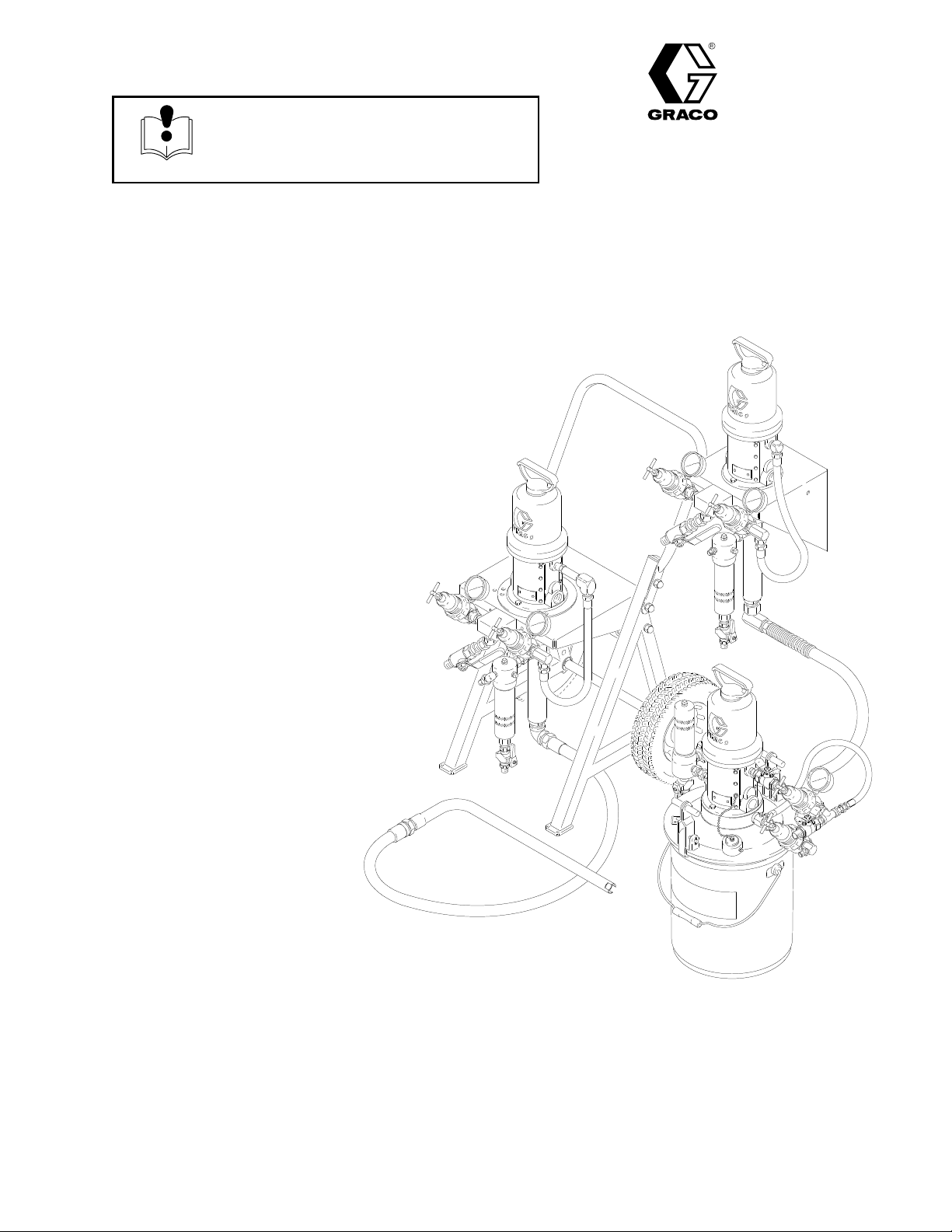

Graco 03289A, 236723, 236722, 236721, 308-367 User Manual

INSTRUCTIONS-PARTS

LIST

308–367

This

manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

23:1

RA

TIO

Monark

2760 psi (19.0 MPa, 190 bar) Maximum Fluid Working Pressure

120 psi (0.84 MPa, 8.4 bar) Maximum Air Inlet Pressure

Part No. 236–721

Cart

Mounted pump

Part No. 236–722

Pail

Mounted Pump

Part No. 236–723

Wall

Mount Pump

Sprayers

First

quality counts.

choice when

Rev. B

Supersedes Rev. A

and PCN B

GRACO INC. P.O. BOX 1441

COPYRIGHT

Graco

Inc. is registered to I.S. EN ISO 9001

MINNEAPOLIS, MN

1994, GRACO INC.

55440–1441

Table

of Contents

Symbols

Warnings 2.

Assembling

Installation 5

Operation 7

Parts 10

Technical

Warranty 16

Graco

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

the Sprayer4. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data

Phone Number

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

15.

16.

WARNING

INJECTION HAZARD

Spray

from the gun, hose leaks, or ruptured components can inject fluid into your body and cause an

extremely serious injury

can also cause a serious injury

Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi

cal attention.

, including the need for amputation. Splashing fluid in the eyes or on the skin

.

Warning Symbol

WARNING

This

symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This

symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

corresponding instructions.

-

Do not point the spray gun at anyone or at any part of the body

Do not put hand or fingers over the spray tip.

Do not stop or deflect fluid leaks with your hand, body

Always have the tip guard and the trigger guard on the spray gun when spraying.

Check the gun dif

Be sure the gun trigger safety operates before spraying.

Lock the gun trigger safety when you stop spraying.

Follow the

sure; stop spraying; clean, check, or service the equipment; and install or clean the spray tip.

T

ighten all the fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily

Permanently coupled hoses cannot be repaired; replace the entire hose.

fuser operation weekly

Pressure Relief Procedure

. Refer to the gun manual.

on page 7 whenever you: are instructed to relieve pres

. Replace worn, damaged, or loose parts immediately

, glove, or rag.

.

TOXIC FLUID HAZARD

Hazardous

skin, swallowed, or inhaled.

Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

fluids or toxic fumes can cause a serious injury or death if splashed in the eyes or on the

-

.

W

308–367

Store hazardous fluid in an approved container

local, state, and national guidelines.

ear appropriate protective clothing, gloves, eyewear

. Dispose of the hazardous fluid according to all

, and respirator

.

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment

in a serious injury

This equipment is for professional use only

Read all the instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check the equipment daily

Do not exceed the maximum working pressure of the lowest rated system component. This equip

ment has a 2760 psi (19.0 MPa, 190 bar) maximum fluid working pressure at 120 psi (0.84

MPa, 8.4 bar) incoming air pressure.

Use fluids that are compatible with the equipment wetted parts. See the Technical Data

all the equipment manuals. Read the fluid manufacturer’s warnings.

Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180

Comply with all applicable local, state, and national fire, electrical, and other safety regulations.

misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

.

.

. Repair or replace worn or damaged parts immediately

F (82

C) or below –40

F (–40C).

.

section of

FIRE AND EXPLOSION HAZARD

-

Improper

result in fire or explosion and serious injury

grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

.

Ground the equipment and object being sprayed. See

Provide fresh air ventilation avoid the buildup of flammable fumes from solvent or the fluid being

sprayed.

Extinguish all the open flames or pilot lights in the spray area.

Electrically disconnect all the equipment in the spray area.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Do not turn on or of

Do not smoke in the spray area.

Do not operate a gasoline engine in the spray area.

If there is any static sparking while using the equipment,

correct the problem.

f any light switch in the spray area while operating or if fumes or present.

Grounding

stop spraying immediately

on page 5.

. Identify and

3308–367

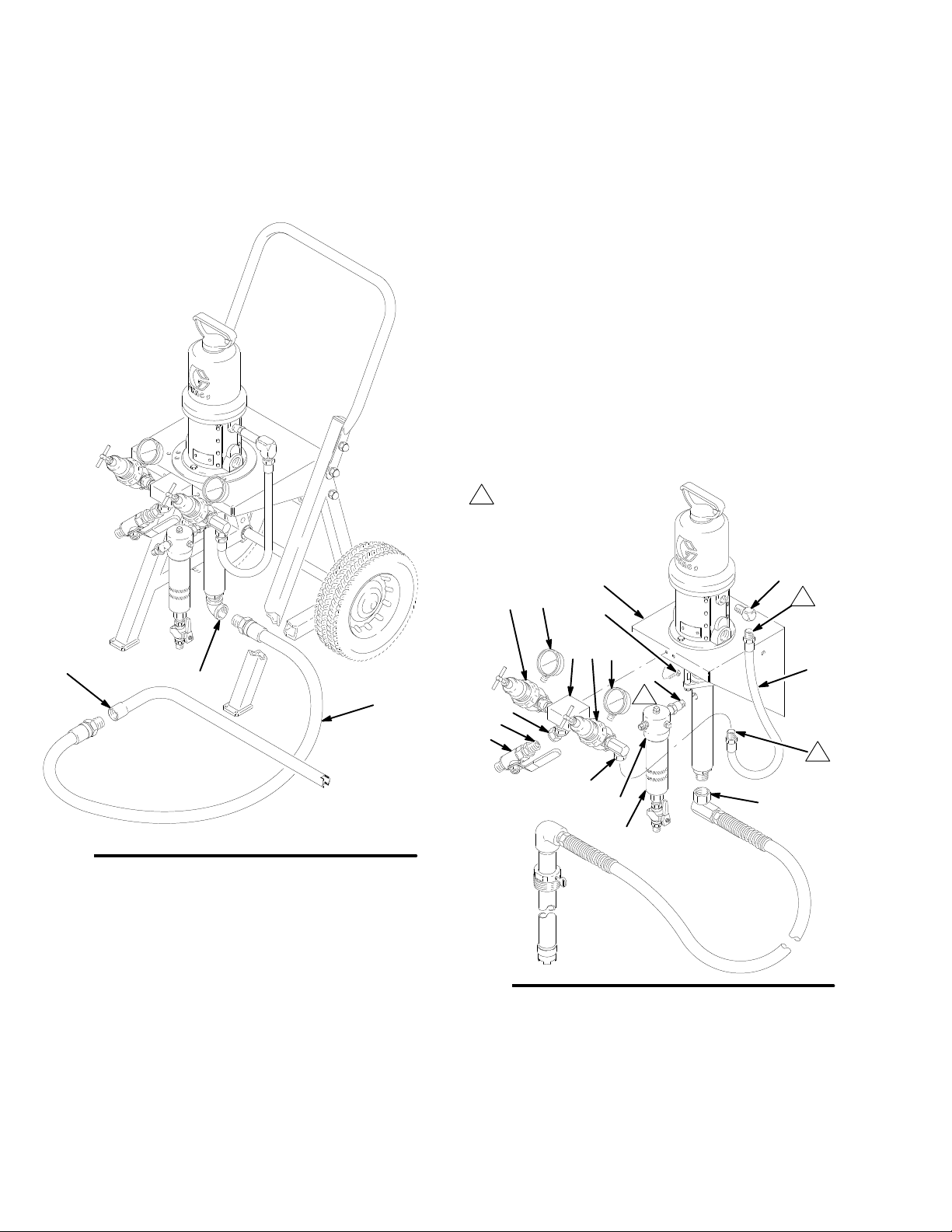

Assembling

Cart Mounted Pump

Assemble

pump intake. Screw the suction tube (7) onto the other

end of the hose. See Fig. 1.

the suction hose (6) to the elbow (5) at the

the Sprayer

4.

Screw the elbow (22) into the pump air inlet, so the

female threads face down. Apply sealant to both

ends of the hose (23). Connect one end to the

elbow (22), then connect the other end to the

swivel (24) at the pump air regulator (F).

5.

Unscrew the filter bowl (T) from the top cap (U).

Apply sealant to the threads of the nipple (14) and

install the nipple and top cap in the pump outlet.

Lubricate the threads of the filter bowl (T) and

screw it into the top cap (U) tightly

6.

Mount the wall bracket 5 ft (1.5 m) above the floor

Be sure the wall is strong enough to support the

weight of the pump and accessories, fluid, hoses,

and stress caused during pump operation. Refer to

manual 306–783 for further information.

7.

Screw the suction kit swivel (13) onto the pump

intake.

Apply

1

thread sealant.

.

.

7

Fig. 1

5

Wall Mount Pump

1. Screw

2.

the gauges (25) into the air regulators (F

G). See Fig. 2.

Connect the nipple (34) and bleed valve (30) to the

swivel (36).

6

03356

,

S

24

29

7

F

25

U

T

25G

36

34

30

Fig. 2

Pail Mounted Pump

14

1

22

1

23

1

13

03357

3.

Install the air manifold assembly (S) to the wall

bracket (7) using the two screws (29).

4 308–367

The

pail mounted pump is shipped completely as

sembled.

-

Installation

Be sure that all operators read and understand this

entire manual and the separate manuals supplied with

components and accessories before using this equip

ment.

Reference numbers and letters in parentheses refer to

the figures and parts drawings.

Accessories mentioned are available from your Graco

distributor

they area adequately sized to meet your system’

requirements.

The T

example. For assistance in designing a system to meet

your particular needs, contact your Graco distributor

. If you supply your own accessories, be sure

ypical Installation shown in Fig. 4 is only an

-

s

.

System Accessories

Grounding

T

o reduce the risk of static sparking, ground the pump,

object being sprayed, and all other spray equipment

used or located in the spray area. Check you local

electrical code for detailed grounding instructions for

your area and type of equipment. Be sure to ground all

of this spray equipment.

1.

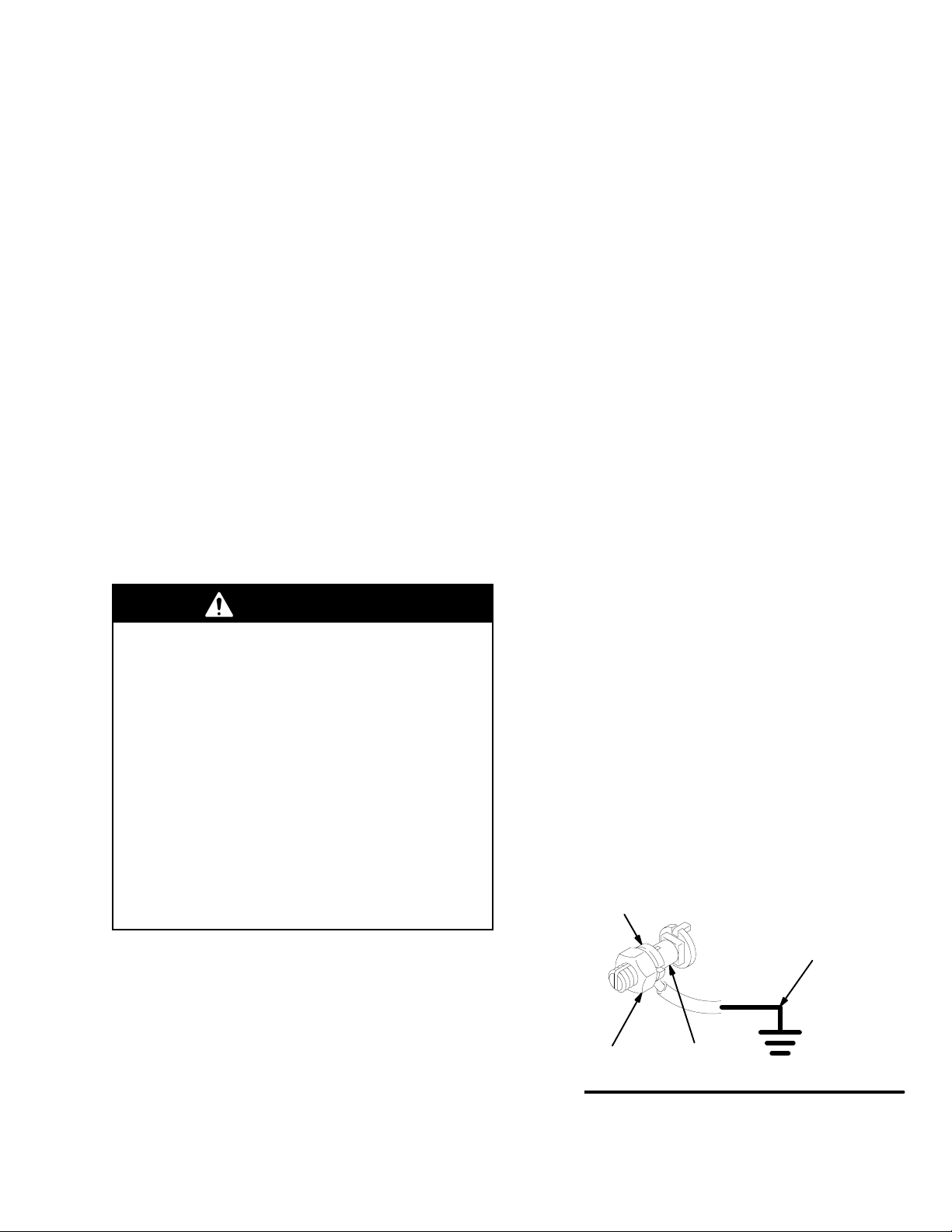

Pump:

loosen the grounding lug locknut (W) and

washer (X). Insert one end of a 1.5 mm2 (12 ga)

minimum ground wire (Y) into the slot in lug (Z)

and tighten the locknut securely

nect the other end of the ground wire to a true

earth ground.

2.

Air hoses:

3.

Fluid hoses:

4.

Air compressor:

dations.

5.

Spray gun:

tion to a properly grounded fluid hose and pump.

6.

Fluid supply container:

code.

use only grounded air hoses.

use only grounded fluid hoses.

follow manufacturer’s recommen

grounding is obtained through connec

according to your local

. See Fig. 3. Con

-

-

-

WARNING

Two

required components are supplied with your

pump, to help reduce the risk of serious injury

including fluid injection, splashing in the eyes or on

the skin, or injury from moving parts if you are

adjusting or repairing the pump.

The

bleed-type master air valve (B)

trapped between this valve and the pump. T

air can cause the pump to cycle unexpectedly. To

bleed air from the pump, the pump air regulator

(F) must be open when you close this valve.

The

fluid drain valve (H)

pressure in the displacement pump, hose, and gun;

triggering the gun to relieve pressure may not be

sufficient.

Install an air line filter (E) in the main air line, to re

move harmful dirt and moisture from the compressed

air supply

motor

the pump air regulator (F). Install a second master air

valve (D) in the main air line, to isolate the accessories

for servicing.

. T

o provide automatic lubrication of the air

, install an air line lubricator (P) downstream from

assists in relieving fluid

relieves air

rapped

-

7.

Object being sprayed:

code.

8.

All solvent pails used when flushing,

local code. Use only metal pails, which are con

ductive, placed on a grounded surface. Do not

place the pail on a non-conductive surface, such

as paper or cardboard, which interrupts the

grounding continuity

9.

T

o maintain grounding continuity when flushing or

relieving pressure

spray gun firmly to the side of a grounded metal

pail, then trigger the spray gun.

X

W

Fig. 3

according to your local

according to

.

, always hold a metal part of the

Y

Z

-

5308–367

Loading...

Loading...