Page 1

Instructions – Parts List

BELT-DRIVEN, STAINLESS STEEL, PNEUMATIC

Twistork Helix Mixer

with Suction Feature

For use in closed-head, bung-type, 55-gallon drums.

100 psi (0.7 MPa, 7 bar) Maximum Working Pressure

Model 236629, Series C

Standard Mixer, 0.75 HP (0.55 kW)

Model 236760, Series C

Oil-less Reversible Mixer, 0.75 HP (0.55 kW)

308345P

EN

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 20. . . . . . . . . . . . . . . . . . . . . .

Graco Information 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

03023B

0359

II 1/2 G c T3

ITS03ATEX11226

Page 2

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

Do not alter or modify this equipment.

Check equipment daily. Repair or replace worn or damaged parts immediately.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

Do not exceed the maximum working pressure of the lowest rated component in your system. This

equipment has a 100 psi (7 bar) maximum working pressure.

Use fluids and solvents that are compatible with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

Always wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid and

solvent manufacturer.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

2 308345

Page 3

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames, or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

Ground all equipment. Refer to Grounding on page 5.

If there is any static sparking or you feel an electric shock while using this equipment, shut off the

agitator immediately. Do not use the equipment until you identify and correct the problem.

Do not use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents, or

fluids containing such solvents in aluminum pumps. Such use could result in a serious chemical

reaction, with the possibility of explosion.

Do not use kerosene or other flammable solvents or combustible gases to flush the unit.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being dispensed.

Keep the dispensing area free of debris, including solvent, rags, and gasoline.

Do not smoke in the dispensing area.

Keep a fire extinguisher in the work area.

MOVING PARTS HAZARD

Moving parts, such as the rotating blades of the agitator, can pinch or amputate your fingers or other

body parts and can cause splashing in the eyes or on the skin.

Keep clear of all moving parts when starting or operating the agitator.

Always shut off the agitator and disconnect the air line before you remove the agitator from the

drum or check or repair any part of the agitator.

HAZARDOUS VAPORS

Hazardous fluids or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled. When flushing the air motor, keep your face away from the exhaust port.

308345 3

Page 4

Application

The Twistork Helix Mixer is intended to mix and maintain paints and similar fluids in closed-head, 55-gallon (200-liter) drums with 2-in. npt bung connections. The Twistork Helix Mixer provides suction porting through its siphon

tube, which allows you to siphon fluid to a pump while mixing it.

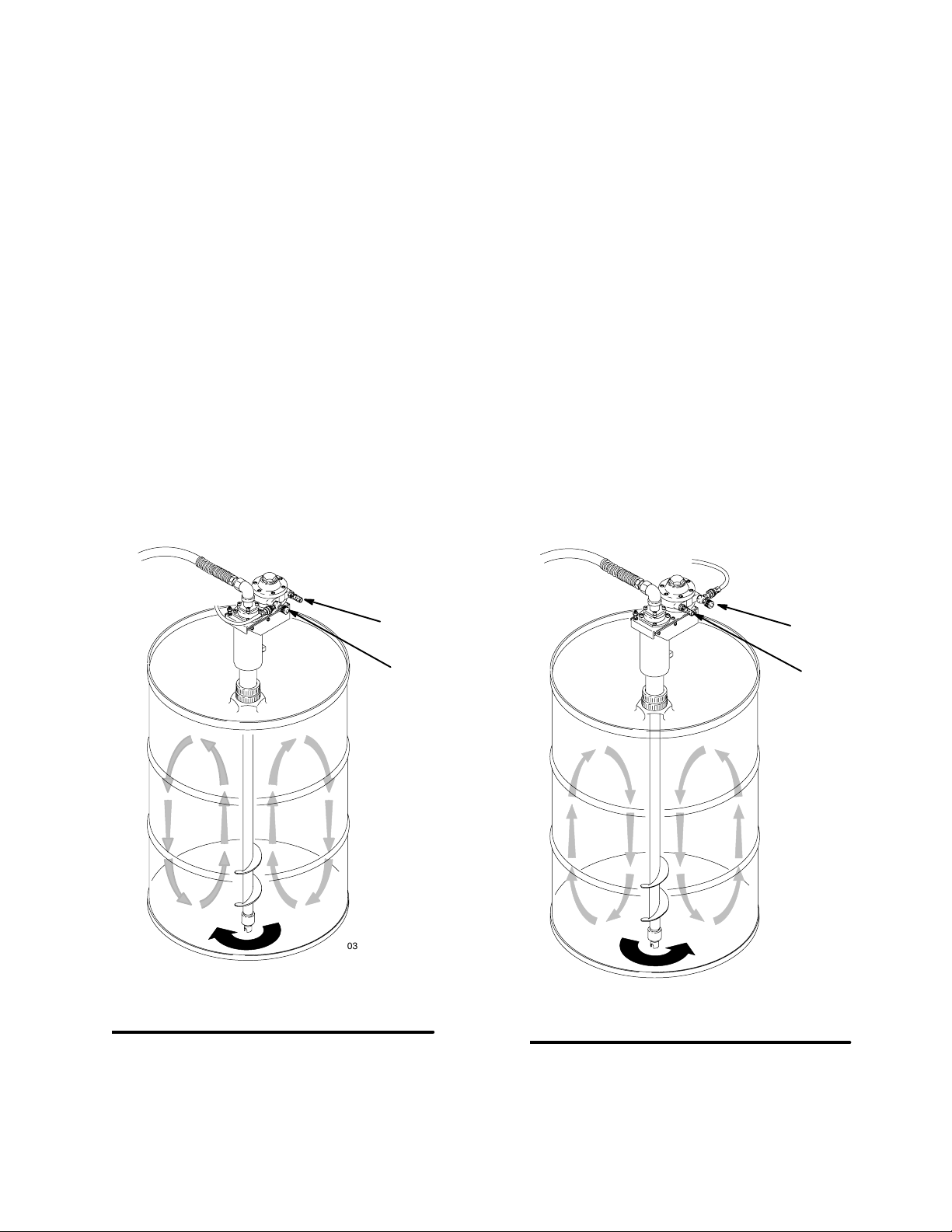

Standard Mixer, Model 236629

The standard mixer operates in a center-lift fluid rotation mode, which is preferred in most applications

because it minimizes fluid aeration. The helix rotates

counterclockwise and mixes fluid by lifting it up from

the bottom of the drum. See Fig. 1.

Standard mixer Model 236629 cannot reverse its helix

rotation.

16a

Oil-less Reversible Mixer, Model 236760

The oil-less reversible mixer operates the same as the

standard mixer, but it uses a non-lubricated air supply,

and the helix rotation can be reversed.

NOTE: Although the air motor can operate without oil,

motor life is increased when lubrication is provided.

To reverse the helix rotation on reversible mixer Model

236760, remove the air motor muffler (16a) and needle

valve (18), and switch the ports they are installed into.

See Fig. 2.

When the helix rotation is reversed, the mixer operates

in a pull-down fluid rotation mode, which can be better

for agitating fluids that are difficult to put into suspension. The helix rotates clockwise and mixes fluid by

pulling it down from the surface. See Fig. 2.

With clockwise (pull-down fluid rotation), care must be

used at high speeds to prevent cavitation, which could

be caused by air being drawn down to the siphon inlet.

18

Fig. 1

03401B

Model 236629

Standard (counterclockwise) Rotation

18

03401B

16a

03402B

Model 236760

Reversed (clockwise) Rotation

03402B

Fig. 2

4 308345

Page 5

WARNING

Installation

FIRE AND EXPLOSION HAZARD

Always maintain a minimum of 1 in.

clearance between rotating agitator parts

and container to prevent sparks from contact.

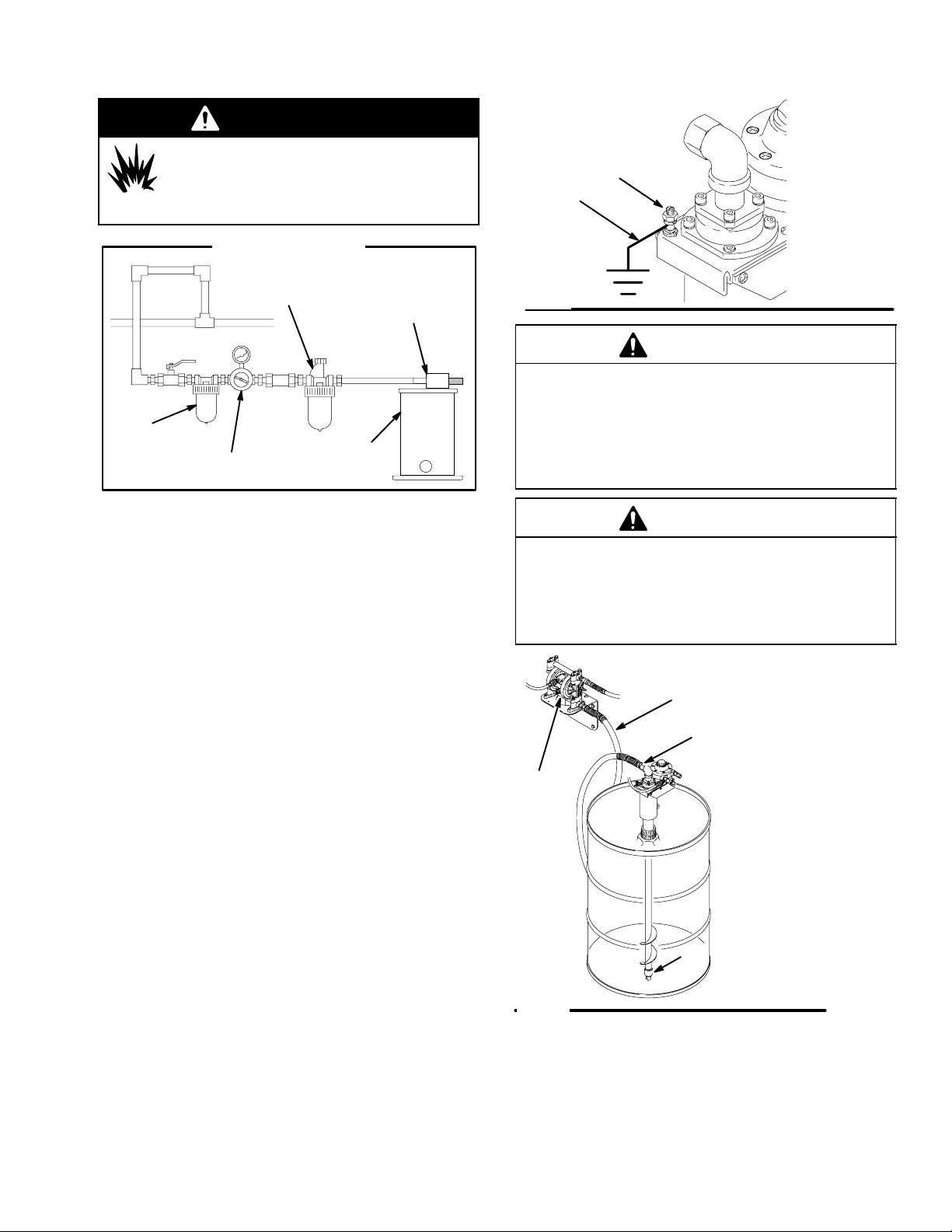

Typical Installation

air line lubricator

agitator motor

air line filter

air regulator

and gauge

mix tank

(reference only)

Grounding Instructions

Proper grounding is an essential part of maintaining a

safe system.

To reduce the risk of static sparking, all electrically

conductive objects or devices in the spray area must

be properly grounded. Check your local electrical code

for detailed grounding instructions for your area and

type of equipment.

To ground the helix mixer, connect the ground wire

(H) to the grounding lug (J) on the collar. Connect the

grounding wire clamp to a true earth ground. See

Fig. 3.

To order a ground wire and clamp, order Part No.

222011.

J

H

Fig. 3

03024

CAUTION

The bearing nut (8) is made of acetal, which is not

compatible with some of the solvents used in paints

or coatings and is not compatible with acidic fluids.

Optional Rulon bearing nut Part No. 189660 is

available. Check your material data sheet and/or

supplier for compatibility.

CAUTION

To avoid damaging the mixer, do not mount the

pump (G) directly to the mixer outlet fitting (41).

Make sure the pump is properly supported, and

install a flexible suction hose (E) between the mixer

outlet fitting and the pump, as shown in Fig. 4.

E

41

G

Fig. 4

8

03428B

308345 5

Page 6

Installation

Air Line Accessories

The following air line accessories help to increase

motor life and ease of operation.

Air Line Filter

Air line filters remove harmful dirt and moisture from

the air supply. Order one of the following:

Part No. 106148: 3/8 npt(f) air line filter

Part No. 106149: 1/2 npt(f) air line filter

Air Line Lubricator (for Model 236629 only)

CAUTION

Not lubricating the air motor will cause air motor failure.

Downstream from the filter, install an air line lubricator

for automatic air motor lubrication. Set the lubricator

feed rate at 1 drop of oil per minute for high speed or

continuous duty usage. Do not overfeed oil or exhaust

air may become contaminated. To manually lubricate

the air motor, see Lubricating the Air Motor on page

11. Order one of the following:

Part No. 214847: 3/8 npt(f) air line lubricator

Part No. 214848: 1/2 npt(f) air line lubricator

Air Line Quick-Disconnect

Install an air line quick-disconnect (F) or ball valve at

the air inlet (D). See Fig. 5. Order one of the following:

Part No. 169969: 1/8 npt(m) air line quick-disconnect

Part No. 208536: 1/4 npt(f) air line quick-disconnect

Flush the Mixer Before Using It

To prevent fluid contamination, flush the mixer with

solvent that is compatible with the fluid to be mixed.

See Flushing Instructions on page 13.

6 308345

Page 7

Installation

Installing the Mixer

The mixer weighs 24 lb (11 kg). To manually lift it in

and out of the drum, grasp the housing (3), and guide

the helix tube (7) through the drum bung. See Fig. 5.

Accessory handle Part No. 189658 is available so you

can connect a lift hook to raise and lower the mixer or

hang the mixer to store it.

CAUTION

To avoid damaging the siphon tube, lower the mixer

to the drum bottom; do not drop it.

Do not install the mixer without the bearing nut (8) in

place. See Fig. 6 on page 9. If the bearing nut is not

installed, the siphon tube (4) and helix tube (7) will

rub against each other during operation and cause

damage. Replace the bearing nut if damaged or

worn.

1. Hold the mixer by the housing (3) or by the accessory handle, and lower the helix tube (7) through

the bung until the siphon tube rests on the bottom

of the drum.

5. When using the mixer suction feature, connect

a suction hose (E) between the mixer fluid outlet

fitting (41) and the pump. See Fig. 5. The hose

connector must have a 30 bevel to match the

fluid outlet fitting with an airtight seal. See Maxi-

mum Siphon Flow Rate on page 8.

When not using the siphon feature, plug the

fluid outlet fitting (41) to prevent excess fluid

evaporation.

The air motor exhaust can be piped out as follows:

Remove the air motor muffler (16a), and connect an

exhaust line to the exhaust port.

NOTE: Model 236629 has a1/4 npt(f) exhaust port.

Model 236760 has a 3/8 npt(f) exhaust port.

Model 236629 shown

E

41

16a

C

NOTE: The tube must rest on the bottom to evacuate the maximum amount of material from the

drum and to stabilize the mixer.

2. Make sure the gasket (46) is in place, screw the

bung adapter (44) into the bung, and tighten the

bung adapter. See Fig. 5.

3. Make sure the o-ring (20) in in place inside the

lock-ring (45), then tighten the lock-ring (45).

CAUTION

To keep the helix tube pointed straight down, make

sure the bung adapter (44) and lock ring (45) are

tight.

4. Position the air motor so the air line (C) can be

attached to the inlet (D) on the needle valve without obstructing any other system components.

3

D

F

45

20

44

7

46

03025B

Fig. 5

308345 7

Page 8

Operation

WARNING

MOVING PARTS HAZARD

To reduce the risk of serious injury,

including cuts, amputation of fingers,

and splashing in the eyes or on the skin:

Always shut off the mixer and disconnect the air

line before you check or repair the mixer.

Maximum Siphon Flow Rate

The volume of fluid that can be siphoned through the

mixer inlet is determined by the viscosity of the fluid.

The maximum flow rate is approximately 12 gpm

(45 lpm) with 100-centipoise fluid.

The maximum flow rate is approximately 1.2 gpm

(4.5 lpm) with much heavier 1000-centipoise fluid.

To prevent pump cavitation, avoid flow rates higher

than these. Check the fluid periodically for signs of

cavitation.

Operating the Mixer

See Fig. 6

CAUTION

The bearing nut (8) helps prevent excessive fluid

flow between the siphon tube (4) and helix tube (7),

but it is not intended to be a complete seal. Fluids

can pass through the bearing nut into the gap between the two tubes. Before you change colors or

coatings or store the mixer, clean the tubes as

instructed on page 10.

NOTE: Thoroughly agitate the fluid before you use the

suction feature. Agitating maximizes fluid quality and

helps avoid solids getting drawn into the siphon tube

and clogging it. A Strainer Inlet Kit 236984 is available to help prevent thick sediment from being forced

into the siphon inlet.

CAUTION

Air Requirements

For continuous use, the 0.75 HP air motor typically

requires 2.5 scfm (0.071 m/min.) of air at 400 rpm or

5.7 scfm (0.162 m3/min.) of air at 800 rpm.

Nitrogen Charging the Drum

CAUTION

If you are using nitrogen to charge the drum, use a

maximum of 0.25 psi (1.7 kPa, 0.02 bar). Such low

pressure requires special regulation equipment. Use

a passive, non-pressurized system when possible.

Higher pressure could push fluid through the shaft

seal (21) and into the top bearings (11), damaging

them. See the Parts Drawing on page 16.

Do not operate the mixer at a high speed for a long

period of time. Excessive mixer speed can cause the

fluid to foam and can cause vibration and increased

wear on parts and damage to the drum bung. Only

agitate the fluid fast enough to maintain even mixing.

You can view fluid movement through the 0.75-in.

port on the drum cover.

NOTE: If you install an air shut-off valve, the same

mixer speed is set each time it is turned on without

requiring repeated needle valve adjustments. Order

one of the following air shut-off valves:

Part No. 208390: 1/4 npt(m) x 1/4 npt(m)

Part No. 208391: 3/8 npt(m) x 3/8 npt(f)

Part No. 208392: 3/8 npt(f) x 1/4 npt(m)

Part No. 208393: 3/8 npt(m) x 3/8 npt(m)

You can also use an air line quick-disconnect (F) as a

shut-off. See Fig. 5. See Air Line Quick-Disconnect

on page 6.

8 308345

Page 9

Operation

1. Turn on the air supply to start the mixer. Regulate

the helix speed with the needle valve (18).

2. Operate the mixer continuously when supplying

paints or other fluids to the system.

Model 236629 shown

7

4

F

8

18

Shutting Down

1. To stop the mixer, close the needle valve (18), or

disconnect the quick-disconnect (F), or close the

air valve in the air supply line.

2. If you remove the mixer from the drum, remove

the bearing nut (8), and hang or tilt the mixer

upright over a container to allow it to drain. Accessory handle Part No. 189658 is available so you

can connect a lift hook to raise and lower the mixer

or hang the mixer to store it.

CAUTION

Keep the mixer upright. Do not lay it on its side or

upside down, because fluid might flow into the beltdrive area.

If you use the accessory mixer handle, make sure

the mixer is loosened from the drum before you raise

it with a lift. The handle will not support the weight of

the drum.

Fig. 6

03400B

Do not let fluid from dry in the fluid tubes. See Clean-

ing the Fluid Tubes on page 10.

308345 9

Page 10

Maintenance

Prolonging the Life of the Bearing Nut

CAUTION

Use a compatible solvent to clean parts. The bearing

nut (8) is made of acetal, which is not compatible

with acidic fluids. Check your material data sheet

and/or supplier for compatibility. Avoid getting any

solvent on the air motor belt.

Replace the bearing nut (8) if it is damaged or

worn.

Do not allow fluids to dry out in the fluid section.

Dry fluid will adhere to the bearing nut (8) and could

destroy it the next time you start the mixer. Flush

the fluid section before you change colors or coatings or store the mixer.

Do not operate the mixer without fluid in the drum

as this can cause excessive bearing nut (8) wear.

5. Apply PTFE spray lubricant to the siphon tube (4)

inlet end only. Install the siphon tube through the

top of the mixer housing (3).

6. Install the two socket-head screws (24) and lockwashers (25) into the top of the siphon cover (6).

Torque the screws oppositely and evenly to 60 to

70 in-lbs (6.8 to 7.9 Nm).

7. Apply PTFE spray lubricant to the inside lip of the

bearing nut (8), and tighten it onto the helix

tube (7).

Model 236629 shown

24

1

16a

41

2

24

5

18

25

6

4

33

Cleaning the Fluid Tubes

To prevent fluid from drying on the tubes and interfering with helix rotation, clean the siphon tube (4) and

helix tube (7) when you change colors or coatings and

when the mixer is removed from the drum long enough

for the fluid to dry. Also, clean the fluid tubes for periodic maintenance as follows:

1. Remove the bearing nut (8). See Fig. 7.

2. Remove the two diagonal socket-head screws (24)

and lockwashers (25) protruding from the top of

the siphon cover (6).

3. Remove the siphon tube (4) as follows:

a. Rest the mixer on its side on the drive belt

housing so the inlet is lower than the outlet.

This orientation prevents fluid from running

into the bearing and drive belt area.

b. Pull up on the fluid outlet fitting (41) to remove

the siphon tube (4).

4. Clean the siphon tube (4), helix tube (7), and

bearing nut (8). The inside diameter of the tubes

can be cleaned by pulling a solvent-soaked rag

through them.

NOTE: Always after you mix or pump catalyzed mate-

rials that could set up between the tubes without air,

remove the siphon tube, and clean both tubes.

10 308345

4

Torque oppositely and evenly to 60 to 70 in-lbs (6.8 to 7.9 Nm).

1

Torque oppositely and evenly to 80 to 100 in-lbs (9 to 11.3 Nm).

2

Apply PTFE spray lubricant to inside lip of bearing nut before

3

you install it.

Apply PTFE spray lubricant to the siphon tube (4) inlet end

4

before you install it.

7

3

8

Fig. 7

3

03403B

03403B

Page 11

Maintenance

Lubricating the Air Motor

(Model 236629 Only)

CAUTION

Not lubricating the air motor will cause air motor failure.

If an air line lubricator is not installed, the air motor

must be manually lubricated every 8 hours. Lubricate

the agitator air motor by placing 10–20 drops of SAE

#10 light oil in the motor’s air inlet. Run the agitator for

about 30 seconds.

Cleaning the Air Intake Check Valve

The air intake check valve (33) allows make-up air to

enter the closed drum as fluid is drawn out through the

mixer outlet port. See Fig. 7. The air intake check

valve should be inspected and cleaned every 2000

operating hours or when there are any signs of the

drum beginning to collapse as fluid is drawn out.

Pump priming problems can indicate a plugged air

intake check valve. Paint overspray in the air can be

drawn into the valve and cause the ball to stick in the

closed position.

To clean the air intake check valve

1. Remove the seat (33) and ball (34). See the Parts

Drawing on page 16.

2. Clean the parts with compatible solvent, and

reassemble the valve.

3. Insert the ball (34), and tighten seat (33) until just snug.

NOTE: The seat should not be flush with

the elbow (32). Installing the seat too

tightly could jam the ball against the seat.

Correcting a Bad Suction Line Seal

Air getting pulled into the suction line makes the pump

inefficient. This can happen for the following reasons:

Cavitation is occurring, because the pump or helix

is going too fast.

Siphon hose connection is leaking.

Nylon rings (22) are not sealing. See Fig. 8.

To correct the problem (see Fig. 8)

1. Torque the four socket-head screws (24) in the

siphon fitting (5) oppositely and evenly to 80 to 100

in-lbs (9.0 to 11.3 Nm).

NOTE: If Step 1 does not correct the problem, do

Steps 2 through 5.

2. Replace the rings (22). Make sure the outer lips

face up, as shown in Fig. 8.

3. Insert the inlet tube (4) into the bottom of the

siphon fitting (5).

4. Tap the bottom of the inlet tube (4) to make sure

the tube passes through the rings (22) and seats

on the siphon fitting (5).

5. Torque the four socket-head screws (24) in the

siphon fitting (5) oppositely and evenly to 80 to 100

in-lbs (9.0 to 11.3 Nm).

308345 11

Page 12

Torque screws oppositely and evenly to

1

80 to 100 in-lbs (9.0 to 11.3 Nm).

2

Install with outer lips facing up.

Maintenance

5

24

1

22

2

4

Fig. 8

TI0302

12 308345

Page 13

Service

WARNING

MOVING PARTS HAZARD

To reduce the risk of serious injury,

including cuts, amputation of fingers,

and splashing in the eyes or on the skin

Always shut off the mixer and disconnect the air

line before you check or repair the mixer.

Wear eye protection.

WARNING

FIRE AND EXPLOSION HAZARD

To prevent an explosive hazard, in which

injury and/or property damage can result

Do not operate the air motor with combustible

gases.

Do not use kerosene or other flammable

solvents for flushing.

WARNING

HAZARDOUS FLUIDS

Keep your face away from the exhaust

port. Foreign material exiting the air

motor can be hazardous.

Flushing Instructions

If the motor is sluggish or inefficient, flush it with nonflammable solvent in a well-ventilated area.

The recommended solvent for air motors and lubricated pumps is Gast flushing solvent (Part No.

AH255 or AH255A) or Inhibisol Safety Solvent.

1. Disconnect the air line and muffler.

2. Dump or spray several teaspoons of solvent

directly into the motor.

3. Rotate the shaft by hand in both directions for a

few minutes.

4. Reconnect the air line, and slowly increase air

pressure until there is no trace of solvent in the

exhaust air.

5. Re-lubricate the motor with a squirt of light-weight

oil in the chamber.

Servicing Guidelines

NOTE: If the motor does not operate properly after

flushing, order and install the repair kit for your air

motor. The instructions for servicing the air motor are

included with the kit. See page 17 to order the kit.

If the mixer requires more than installation of a

service kit, it is usually quickest and easiest to send

it to the Graco distributor for repair or replacement.

If the vanes need replacing or foreign material is

present in the motor chamber, an experienced

mechanic may remove the end plate opposite the

drive shaft end. Do not pry with a screwdriver. It will

dent the surface of the plate and body and cause

leaks. Use a puller tool, which will remove the end

plate while maintaining the position of the shaft.

New vanes should have the edges with cut corners

(or the notched edges, if the vanes are reversible)

pointing toward the bottom of the vane slot.

308345 13

Page 14

Service

25

24

Detail A

1

6

14a

41

14

Removing the Siphon and Helix Tubes

1. Remove the bearing nut (8). See Fig. 9.

2. Remove the two diagonal socket-head screws (24)

and lockwashers (25) protruding from the top of

the siphon cover (6).

3. Remove the siphon tube (4) as follows:

a. Rest the mixer on its side on the drive belt

housing so the inlet is lower than the outlet.

This orientation prevents fluid from running

into the bearing and drive belt area.

b. Pull up on the fluid outlet fitting (41) to remove

the siphon tube (4).

3

B

4. Remove the three hex-head screws (14a) from the

bushing (14), and install the screws into the bushing’s threaded holes as shown in Detail A of Fig.

9. Tighten the screws evenly to loosen the bushing

from the helix tube (7).

5. Pull the helix tube (7) through the bottom of the

mixer housing (3).

4

3

3

35

14

7 Ref

Detail B

Model 236629 shown

Torque oppositely and evenly to 60 to 70 in-lb (6.8 to 7.9 Nm).

1

Apply PTFE spray lubricant to inside lip of bearing nut before

2

you install it.

Apply PTFE spray lubricant to siphon tube (4) inlet end and to

3

top 6 in. (150 mm) of helix tube before you install them.

Fig. 9

14 308345

7

8

06240C

Removing the Drive Belt

NOTE: Replace the drive belt (15) if it is cracked or

worn.

WARNING

To avoid static electricity buildup and possible

sparking, which could cause fire and explosion,

replace the drive belt with a genuine ESD rated

and marked belt only (Graco Part No. 112552).

2

1. Remove the siphon tube (4) and helix tube (7) as

instructed above.

2. Remove the eight screws (27) and the drive belt

cover (2). See Fig. 10.

3. Remove the three hex-head screws (14a) and the

bushing (14).

4. Slide the drive belt (15) over the smaller pulley

(12). Then remove the larger pulley (13) and the

drive belt (15) as shown in Fig. 10.

Page 15

Service

Model 236629 shown

1

14a

14

13

2

With helix tube (7) flush with top of bushing (14), torque the

1

screws oppositely and evenly to 55 to 60 in-lbs (6.2 to 6.8 Nm).

2

Replace with a genuine ESD rated and marked belt only.

Fig. 10

12 22715

03027B

Assembling the Mixer

1. Make sure the spacer (10) is in place (see Parts

Drawing on page 16). With its larger-I.D. taper

facing up, install the larger pulley (13) and the

drive belt (15) through the mixer housing. See

Fig. 10.

2. Slide the other end of the drive belt over the

smaller pulley (12). The drive belt should not be

tight after it is installed. Make sure the pulleys are

aligned, then secure the small pulley (12) by

tightening its setscrew. Torque setscrew to

45 to 55 in–lbs (5.1 to 6.2 Nm).

3. Place the bushing (14) into the larger pulley (13).

4. Install the screws (14a) in the non-threaded holes

in the bushing (14); do not tighten the screws yet.

5. Place the installation tool (B) on the end of the

helix tube. See Fig. 9.

NOTE: The installation tool (B) is included with

Shaft Seal Kit 236762.

CAUTION

Use the installation tool (B) to insert the helix tube (7)

through the shaft seal (21) without damaging the seal

lip. See Fig. 9. See the Parts Drawing on page 16

for the location of the seal.

6. Apply PTFE spray lubricant to the top 6 in.

(150 mm) of the helix tube (7). While holding the

pulley (13) down, push the helix tube and tool (B)

up through the bottom of the mixer housing (3)

until the tube is flush with the top of the bushing

(14). Then remove the installation tool.

Wedge a screwdriver blade into the gap of the

bushing (14) to spread the bushing while inserting

tube (7).

7. Torque the three hex-head screws (14a) oppositely

and evenly to 55 to 60 in-lbs (6.2 to 6.8 Nm). See

Fig. 10.

8. Install the thrust washer (35) flush to the bushing

(14) as shown in Detail B of Fig. 9.

9. Secure the drive belt cover (2) with the eight

screws (27).

10. Apply PTFE spray lubricant to the siphon tube (4)

inlet end only. Install the siphon tube through the

top of the mixer housing (3). See Fig. 9.

11. Install the two socket-head screws (24) and lockwashers (25) into the top of the siphon cover (6).

Torque the screws oppositely and evenly to 60 to

70 in-lbs (6.8 to 7.9 Nm).

NOTE: The helix tube (7) should move up and

down about 0.05 inch (1.3 mm). If it does not, the

bearings (11) are not fully seated. Push the bearings in until they are fully seated. See the Parts

Drawing on page 16 for the location of the bearings.

12. Apply PTFE spray lubricant to the inside lip of the

bearing nut (8), and tighten it onto the helix

tube (7).

308345 15

Page 16

Parts Drawing

Press into place; lips face down.

1

Apply high-strength thread sealant

2

to threads.

10

25

28

31

30

35

4

9

25

11

27

29

24

41

3

5

3

24

39

13

22

6

32

3

34

4

16 or 17

51

3

30

16a

3

26

3

7

1

18

See Detail

50

45

20

33

44

3

2

27

46

7

14a

12a

12

5

Apply anaerobic PTFE pipe sealant

3

to threads.

With helix tube (7) flush with top of

4

bushing (14), torque oppositely and

evenly to 55 to 60 in-lbs (6.2 to 6.8

Nm).

Tighten after you align pulleys

5

(12 and 13). Torque setscrew to

45 to 55 in–lbs (5.1 to 6.2 Nm).

6

Drive belt must not be tight after it is

installed.

7

Bend washer tab up to lock.

Apply PTFE spray lubricant to

8

inside lip of bearing nut before you

install it.

Torque oppositely and evenly to 80

9

to 100 in-lbs (9 to 11.3 Nm).

Torque oppositely and evenly to 60 to

10

70 in-lbs (6.8 to 7.9 Nm).

Apply PTFE spray lubricant to siphon

11

tube (4) inlet end and to top 6 in.

(150 mm) of helix tube (7) before you

install them.

Install flush with top of nut (8), and

12

torque to 40 to 45 in-lb (4.5 to 5.1

Nm).

Install with outer lips facing up. See

13

Fig. 8 on page 12.

14

13

10

2

11

9

11

1

21

16 308345

15

6

11

Needle Valve (Ref. No. 18) Detail

18e

18f

18d

51

3

18a

18b

18c

Includes items 18a to 18e

8

8

56

12

TI0301B

0911B

Page 17

Parts List

Model 236629 Standard Mixer

Includes items 1 to 16 and 18 to 50, 57–58

Model 236760 Oil-less Reversible Mixer

Includes items 1 to 15 and 17 to 58

Ref.

No. Part No. Description Qty.

1 236720 BRACKET 1

2 189648 COVER, belt drive 1

3 189649 HOUSING, mixer 1

4 189651 TUBE, siphon 1

5 189653 FITTING, siphon 1

6 189654 COVER, siphon 1

7 236719 TUBE, helix 1

8 189655 NUT, bearing; acetal AF 1

9 189656 SPACER, bearing 1

10 189657 SPACER, pulley 1

11 112548 BEARING, ball 2

12 112549 PULLEY (small), drive belt

Includes item 12a 1

12a – SETSCREW, pulley;

1/4 x 20 x 3/16 in.

(not a replacement part) 1

13 112550 PULLEY (large), drive belt 1

14 112551 BUSHING, QD taper lock;

includes items 14a 1

14a – SCREW, hex head; #10–24 x 1 in.

(not a replacement part) 3

15 112552 BELT, drive; ESD rated / marked 1

16* 101140 AIR MOTOR, standard; 0.75 HP

Model 236629 only

Includes item 16a 1

16a 113779 MUFFLER, exhaust; 1/4 npt 1

17** 112723 AIR MOTOR, reversible, oil-less;

0.75 HP Model 236760 only;

Includes item 16a 1

18 206264 VALVE, needle

Includes items 18a to 18f 1

18a 166529 .VALVE, needle 1

18b 166532 .NUT, packing 1

18c 164698 .KNOB, adjusting 1

18d 157628 .O–RING, packing 1

18e 165722 .BODY, valve 1

18f 166531 .WASHER 1

20 112553 O-RING; PTFE 1

21 112555 SEAL, shaft; graphite-filled PTFE 1

22 195045 RING, seal, tube support; Nylon 3

24 112556 SCREW, socket-head; M6 x 16 8

25 108050 LOCKWASHER, spring; M6 8

Ref.

No. Part No. Description Qty.

26 112557 SCREW, set; M6 1

27 106084 SCREW, pan-head; M5 x 10 10

28 104029 LUG, grounding 1

29 104582 WASHER, tab 1

30 105332 LOCK NUT, hex 3

31 100718 LOCKWASHER; #10 1

32 100839 ELBOW, street; 1/8 npt 1

33 189659 SEAT, check valve 1

34 105691 BALL; 1/4 in. diameter; SST 1

35 189662 WASHER, thrust 1

39 189527 LABEL, warning 1

41 112572 UNION, swivel; 90

44 178575 ADAPTER, bung 1

45 178576 RETAINER, o-ring 1

46 106537 GASKET; polyethylene 1

50 189650 TUBE, housing 1

51 159841 ADAPTER;

3/8 npt(m) x 1/4 npt(f);

Model 236760 only 2

56 110980 CLAMP, hose

Model 236760 only 1

57 15A722 LABEL, warning 1

58 16A614 LABEL, warning 1

* A repair kit is available. Order Repair Kit 207335 for

standard air motor (Part No. 101140).

** A repair kit is available. Order Repair Kit 236996 for

reversible oil-less air motor (Part No. 112723). You

must also order two adapters (Part No. 159841), to

adapt the needle valve and muffler.

This part is included in Repair Kit 236762, which

may be purchased separately. The kit also includes

an installation tool, which is needed to insert the

helix tube through the shaft seal without damaging

the seal lip.

An optional Rulon bearing nut is available. Order

Part No. 189660.

Keep these spare parts on hand to reduce down

time.

Replacement Danger and Warning labels, tags, and

cards are available at no cost.

308345 17

Page 18

Technical Data

Maximum working pressure 100 psi (0.7 MPa, 7 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum recommended helix speed 800 rpm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum siphon flow rate

with 100 centipoise material approximately 12 gpm (45 lpm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

with 1000 centipoise material approximately 1.2 gpm (4.5 lpm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air consumption

at 400 rpm 2.5 scfm (0.071 m/min). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

at 800 rpm 5.7 scfm (0.162 m3/min). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Noise level at 400 to 800 rpm (tested to CAGI-PNEUROP–1969) < 70 dBA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Weight 24 lb (11 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts 304 and 316 stainless steel, graphite-filled PTFE, acetal AF, Rulon LR. . . . . . . . . . . . . . . . . . . . . . . . . .

External parts that may come in contact with fluid

Bung adapter (Ref. No. 44) carbon steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air check valve elbow (Ref. No. 32) carbon steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Housing (Ref. No. 3) aluminum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rulon is a registered trademark of Dixon, a division of Furon.

Gast is a registered trademark of Gast Manufacturing.

Inhibisol is a registered trademark of Penetone Corp.

18 308345

Page 19

Dimensions

3/4–14 npt(f)

fluid outlet

7.4 in.

(18.8 cm)

1/8 npt(f)

air inlet

NOTE: The bung adapter

adjusts the depth of the

mixer to a minimum of 32 in.

(81.3 cm) and a maximum of

35-1/8 in. (89.2 cm).

32 in. (81.3 cm) minimum

35-1/8 in. (89.2 cm) maximum

48.6 in.

(123.4 cm)

2 npt

bung adapter

03023B

308345 19

Page 20

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor, or call to identify the nearest distributor:

Phone: 612–623–6921 or Toll Free: 1–800–328–0211 Fax: 612–378–3505

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

20 308345

Original instructions. This manual contains English. MM 308345

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES

Copyright 1994, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco Headquarters: Minneapolis

P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441 USA

www.graco.com

Revision P – December 2012

Loading...

Loading...