Page 1

INSTRUCTIONS–P

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

ARTS LIST

308–322

Rev.

A

Upgrade

For

45:1 Ratio King Sprayer 965–333

(see manual 307–666)

4050 psi (280 bar) Maximum Working Pressure

90 psi (6.3 bar) Maximum Air Inlet Pressure

For

63:1 Ratio King Sprayer 965–271

(see manual 307–666)

5000 psi (345 bar) Maximum Working Pressure

79 psi (5.4 bar) Maximum Air Inlet Pressure

Kit 949–204

GRACO INC. P.O. BOX 1441

COPYRIGHT

MINNEAPOLIS, MN

1993, GRACO INC.

55440–1441

Page 2

Installation

WARNING

Separate manuals are supplied with some compo

nents of your sprayer

instruction manuals before operating.

Never exceed the

sure

and

Maximum Air Input Pressure

sprayers, given in the Technical Data

cover

. Never exceed the maximum working pres

sure of the lowest rated component in your system.

Be sure that all fluids and solvents used are chemi

cally compatible with the wetted parts listed in your

separate component manuals.

If you are installing the kit on a previously operated

sprayer

directed in the

pump manual 307–013 (for 45:1 King Pump) or

307–663 (for 63:1 King Pump).

, be sure to relieve all system pressure, as

. Read and understand all

Maximum Fluid Working Pres

for these

on the back

WARNING

Pressure Relief Procedure

-

-

given in

2.

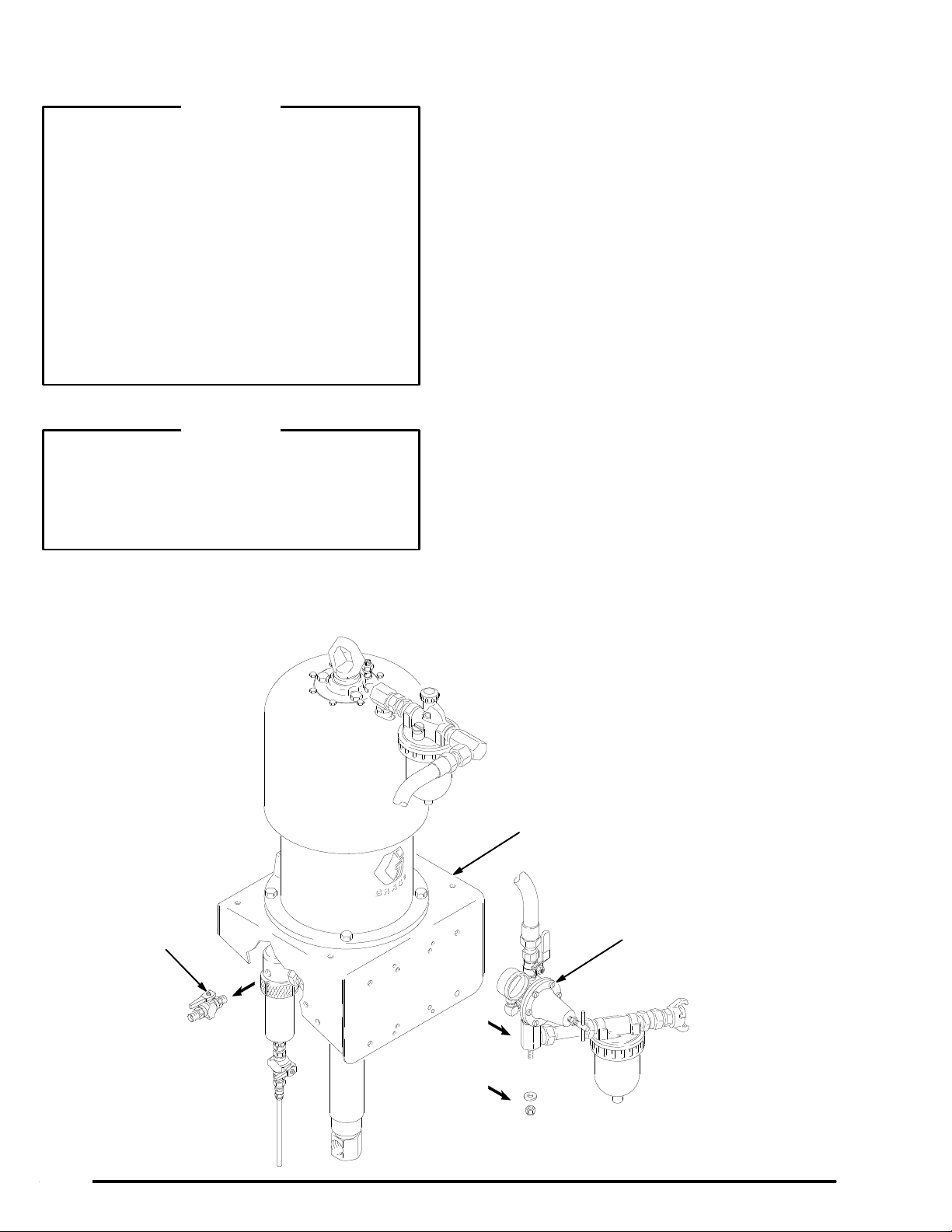

Steps a–c apply to Model 965–333 only

-

-

parts are already installed on Model 965–271.

a.

Remove the 1/4 npt and 1/8 npt pipe plugs

from the 90 air manifold (A). See Fig. 2.

b.

Screw the long nipple (10) into the 1/4 npt

port. Screw the air blow gun (1

ple. See the T

c.

Screw the nipple (12) into the 1/8 npt port.

Screw the quick disconnect coupler (13) onto

the nipple. See the T

3.

Orient the regulator bracket (6) as shown in Fig. 2

and align its holes with the two centermost holes in

the cart shelf (C). Apply thread adhesive (3) to the

two screws (7). Install the screws (7), washers (8)

and nuts (9) as shown. T

Apply thread adhesive (3) to the stud (S) of the air

4.

regulator kit (R). Install the stud in the hole of the

bracket (6) and secure with the washer (1) and nut

(2). Do not use the old nut. T

op V

iew in Fig. 2.

op V

iew in Fig. 2.

ighten securely

ighten securely

. These

1) onto the nip

.

.

-

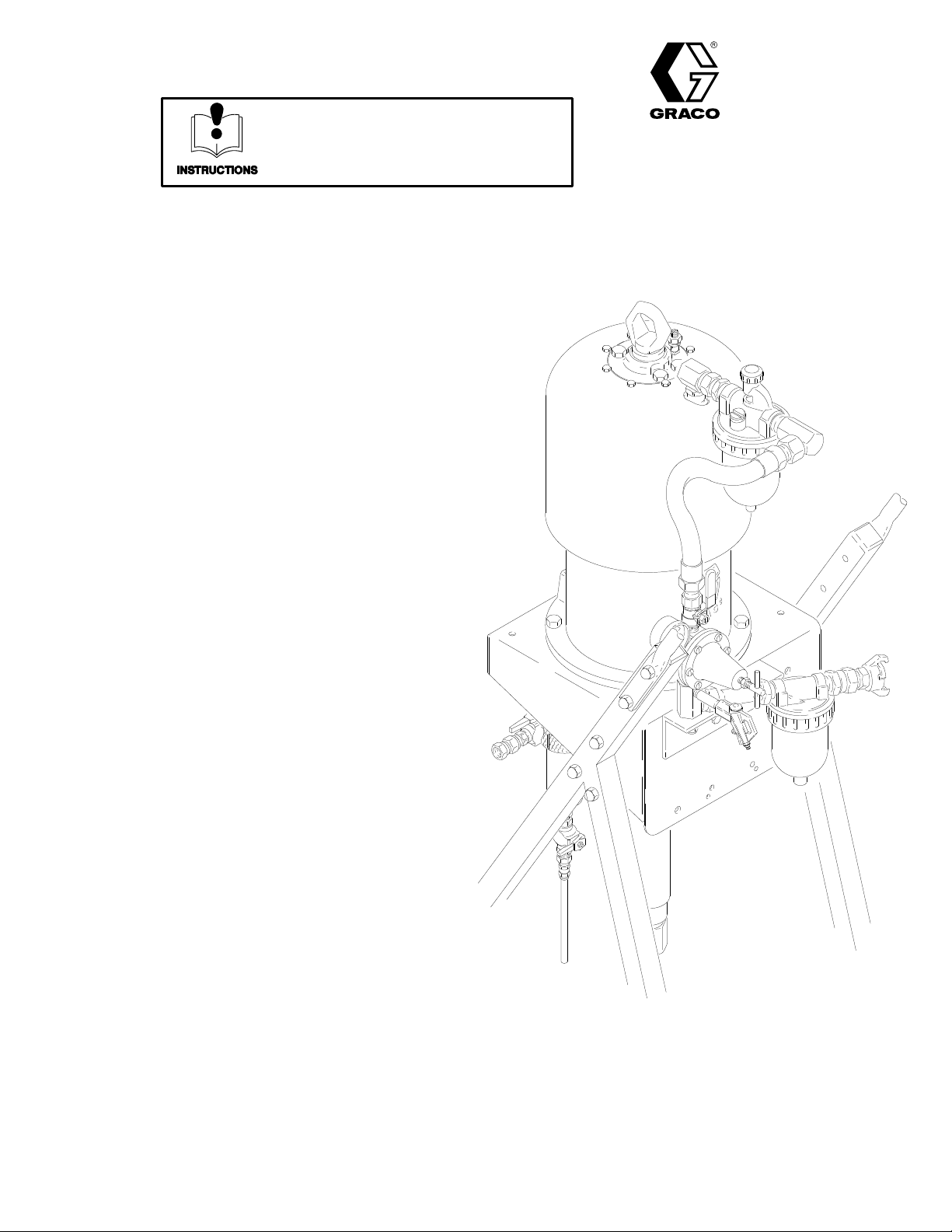

1.

Remove and discard the nut and washer holding

the air regulator kit (R) to the cart shelf (C). See

Fig. 1.

V

Remove the existing ball valve (V) from the fluid

5.

filter (F). See Fig. 1. Install the new valve (5). See

Fig. 2. Screw the rigid end of the union (4) onto

the valve.

C

R

Fig. 1

02249

Page 3

Parts

Ref.

No. Part No. Description Qty.

1 100–133 WASHER, spring lock; 3/8” 1

2 101–566 NUT

3 102–969

4 156–173 UNION, swivel;

5 210–658 VAL

6 625–710 BRACKET

7 100–450 SCREW

8 100–527 WASHER 2

9 595–757 NUT

10* 100–124

11* 208–625 GUN, air blow 1

12* 151–519

13* 208–536 COUPLER, quick disconnect;

*

These parts are included for installation on Model

965–333. These parts are already installed on Model

965–271.

, nylock; 3/8–16

ADHESIVE, thread

3/8 npt(f) x 3/8 npsm(f); carbon steel

VE, ball; 3/8 npt(mbe)

, regulator

, cap, hex hd;

5/16–18 x 1” (25 mm)

, stop

NIPPLE; 1/4 npt; 2–1/2” (64 mm)

NIPPLE, reducer; 1/4 npt x 1/8 npt

1/4 npt(f)

, King

1

1

1

1

1

2

Top View

*12

13*

A

2

1

1

1

*10

11*

A

NOTE:

Shaded parts are included in kit.

9

8

R

6

5

4

Fig. 2

3

A

7

S

1

C

2

Page 4

Technical

Data

Ratio

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum fluid working pressure

Maximum air input pressure

W

etted parts See separate component manuals

The

Graco Warranty and Disclaimers

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 965–333:

Model

965–271:

Model 965–333:

Model

Model

Model

4050 psi (280 bar)

5000 psi (345 bar)

965–271:

90 psi (6.3 bar)

79 psi (5.4 bar)

965–333:

965–271:

45:1

63:1

WARRANTY

Graco

warrants all equipment manufactured by it and bearing its name to be free from defects in material and workman

ship on the date of sale by an authorized Graco distributor to the

for

breach of this warranty

, Graco will, for

a period of twelve months from the date of sale, repair or replace any part of the

equipment proven defective. This warranty applies only when the equipment is installed, operated

accordance with Graco’

This

warranty does not cover

misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

lation,

substitution

of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the

s written recommendations.

, and Graco shall not be liable for

incompatibility with Graco equipment of structures, accessories,

improper

als

This

design, manufacture, installation, operation or maintenance of

not supplied by Graco.

warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco

original

purchaser for use. As purchaser’s sole remedy

and maintained in

, any malfunction, damage or wear caused by faulty instal

equipment or materials not supplied by Graco, or the

structures, accessories, equipment or materi

distributor for verification of the claim. If the claimed defect is verified, Graco will repair or replace free of charge any

defective parts. The equipment will be returned to the original purchaser transportation prepaid. If inspection of the

does

equipment

charges

may include the costs of parts, labor and transportation.

not disclose any defect in material or workmanship, repairs will be made at a reasonable charge, which

-

-

-

DISCLAIMERS AND LIMIT

THE

TERMS OF THIS W

RANTIES

POSE,

EVERY

NO

BE

(EXPRESS OR IMPLIED), INCLUDING W

AND OF ANY NON–CONTRACTUAL LIABILITIES, INCLUDING PRODUCT LIABILITIES, BASED

FORM OF

CASE SHALL GRACO’S LIABILITY EXCEED THE AMOUNT OF THE PURCHASE PRICE. ANY ACTION FOR BREACH OF W

BROUGHT WITHIN TWO (2) YEARS OF THE DA

EQUIPMENT

GRACO

MAKES NO W

PURPOSE,

These

WITH RESPECT T

items sold, but not manufactured by Graco (such as electric motor

ARRANTY CONSTITUTE

LIABILITY FOR DIRECT

NOT COVERED BY GRACO W

ARRANTY

ATIONS

PURCHASER’S SOLE AND EXCLUSIVE REMEDY AND ARE IN LIEU OF ANY OTHER W

ARRANTY OF MERCHANT

, SPECIAL OR CONSEQUENTIAL DAMAGES OR LOSS IS EXPRESSL

TE OF SALE.

ARRANTY

, AND DISCLAIMS ALL IMPLIED W

O ACCESSORIES, EQUIPMENT

ABILITY OR W

ARRANTIES OF MERCHANT

, MA

TERIALS, OR COMPONENTS SOLD BUT NOT MANUF

ARRANTY OF FITNESS FOR A PARTICULAR PUR

ON NEGLIGENCE OR STRICT LIABILITY

ABILITY AND FITNESS FOR A P

, switches, hose, etc.) are subject to the war

AR-

Y EXCLUDED AND DENIED. IN

ARRANTY MUST

ARTICULAR

ACTURED BY GRACO.

ranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for

breach

TO

utor

closest to you:

of these warranties.

PLACE AN ORDER

Graco

, contact your Graco distrib

Phone Numbers

, or call this number to identify the distributor

1–800–367–4023 T

oll Free

-

FOR TECHNICAL ASSIST

ANCE,

service repair

information or assistance regarding the application of

Graco equipment:

1–800–543–0339 T

oll Free

.

-

4 308-322

Sales

Foreign Offices:

Offices:

Atlanta, Chicago, Dallas, Detroit, Los Angeles, Mt. Arlington (N.J.)

Canada; England; Korea; Switzerland; France; Germany; Hong Kong; Japan

GRACO INC. P.O. BOX 1441

PRINTED

MINNEAPOLIS, MN

IN U.S.A.

308–322 8/93

55440–1441

Loading...

Loading...