Page 1

INSTRUCTIONS-PARTS

LIST

308–287

This

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

PRO

manual contains important

Pulse

First

choice when

quality counts.

Supersedes Rev. B

and PCN C

Electronic Volumetric Flow Meter

For use with Plural Component Precision Mixing Systems

This meter is designed to be used in a Class I, Group D hazardous environment

2800 psi (19.6 MPa, 196 bar) Maximum Working Fluid Pressure

50 psi (350 kPa, 3.5 bar) Maximum Working AirPressure

Part No. 235–402, Series A

Flow

Meter with 0.1 cc per tooth fluid volume flow

Rev. C

Model 235–403, Series A

Flow

Meter with 0.4 cc per tooth fluid volume flow

NOTE:

Optic Cables and to order the Fluid Manifold.

U.S.

See the

and Foreign Patents Pending

Accessories

section to order Fiber

-

01847

GRACO INC. P.O. BOX 1441

COPYRIGHT

Graco

Inc. is registered to I.S. EN ISO 9001

MINNEAPOLIS, MN

1993, GRACO INC.

55440–1441

Page 2

Table

of Contents

Symbols

Warnings 2.

Installation 4

Operation 6

Maintenance 7

Troubleshooting 8

Service 9

Parts 11

Dimensions 15

Technical

Warranty 16

Graco

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data

Phone Number

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

15.

16.

WARNING

INJECTION HAZARD

Spray

from hose leaks or ruptured components can inject fluid into your body and cause an extremely

serious injury

cause a serious injury

Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi

cal attention.

, including the need for amputation. Splashing fluid in the eyes or on the skin can also

.

Warning Symbol

WARNING

This

symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This

symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

corresponding instructions.

-

Do not stop or deflect fluid leaks with your hand, body

Follow the

sure; stop operation, or clean, check, or service the equipment; and install or clean the spray tip.

T

ighten all the fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily

Permanently coupled hoses cannot be repaired; replace the entire hose.

Pressure Relief Procedure

on page 6 whenever you: are instructed to relieve pres

. Replace worn, damaged, or loose parts immediately

, glove, or rag.

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

This

The meter’

equipment must only be installed by trained and qualified personnel.

s electrical chassis must be properly grounded. See

on page 5.

Do not allow water or other liquids to spill on the electrical chassis.

Do not immerse the chassis in fluids.

The air line to the electrical chassis must be turned OFF and the pressure relieved before servicing

or flushing the meter

.

Check the Electrical Grounding

-

.

308–287

Page 3

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment

in a serious injury

D

This equipment is for professional use only

D

Read all the instruction manuals, tags, and labels before operating the equipment.

D

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

D

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D

Check the equipment daily

D

Do not exceed the maximum working pressure of the lowest rated system component. This equip

ment has a

D

Use fluids that are compatible with the equipment wetted parts. See the Technical Data

all the equipment manuals. Read the fluid manufacturer’s warnings.

D

Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180

D

Comply with all applicable local, state, and national fire, electrical, and other safety regulations.

misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

.

.

. Repair or replace worn or damaged parts immediately

2800 psi (19.6 MPa, 196 bar) maximum working pressure.

_F (82_

C) or below –40

_F (–40_C).

.

section of

-

3308–287

Page 4

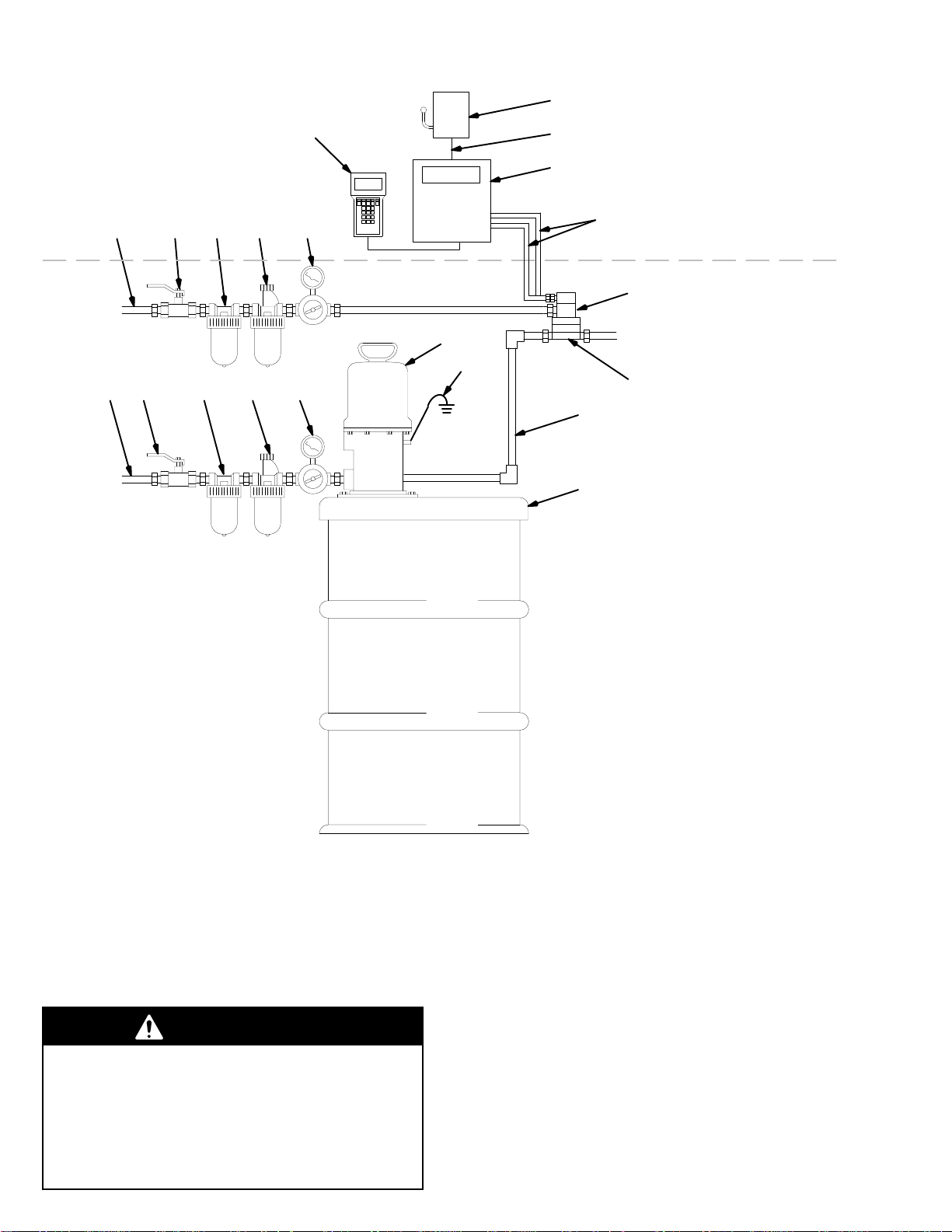

Installation

L

AB

1

A

B

KEY

A Air

Supply Line

B Bleed-T

C

D

E

F Pump

G

H

J

K

L

M Pendant

N

P

R 1

S Controller

ype Air Supply Line

Shut-of

f V

alve

Air Line Filter

Air Line Lubricator

Air Line Regulator

Fiber Optic Cable

Flow Meter

Fluid Supply Line

Fluid Supply

Main Power Switch

Pump Grounding Wire

Fluid Manifold

15V 60 Hz Electrical Supply

(required)

2

CD E

CDE

(required)

M

F

N

R

S

G

J

K

NON-HAZARDOUS

H

HAZARDOUS AREA

P

AREA

The PRO Pulse V

olumetric Flow Meter is designed to

detect the pulses induced on a magnetic sensor each

time a gear tooth passes by the sensor

. A specific

volume of fluid flows through the meter with each gear

tooth rotation. See the front cover for the specific fluid

volume flow of your meter

.

Installing the System

WARNING

To

help reduce the risk of serious injury

splashing in the eyes or on the skin, the bleed-type

air shut-of

f valve (B1) must be installed in the

system to relieve air trapped between this valve

and the pump after the air is shut of

can cause the pump to cycle unexpectedly

the valve close to the pump.

4 308–287

, including

f. T

rapped air

. Locate

The T

ypical Installation shown above is only a guide

for selecting and installing the flow meter

. For assis

01848

tance in designing a particular type and size system for

your application, contact your Graco representative.

Install the air line accessories in the order shown in the

T

ypical Installation, using adapters as necessary

.

Connect the air line to the Flow Meter by pressing the

front ferrule (D) and back ferrule (C) onto the tubing

(A). See Fig. 1. Press the assembly into the fitting (E)

and tighten the nut (A). Connect the fiber optic cables

by pressing the front ferrule (L) and back ferrule (K)

onto the cable (G).

The maximum fiver optic cable length is 100 ft (30.5

m) with two splices. See

Accessories

on page 14 to

order cables.

Page 5

Installation

KEY

A Tubing,

B

C

D

E

F

G

H

J

K

L

1/4” OD

Nut (nylon)

Ferrule, back (nylon)

Ferrule, front (nylon)

Air Inlet Fitting

Electrical Chassis

Fiber Optic Cables

Gear Housing Assy

Nut (aluminum)

Ferrule, back (aluminum)

Ferrule, front (aluminum)

.

K

J

G

A

Fig. 1

Check the Electrical Grounding

Fiber

Optic

Sender

F

L

1

Fiber

Sender

Optic

2

Power Indicator

Light

(Yellow)

Flow

Indicator

Light

(Green)

E

D

H

C

B

01849

Electrical

Chassis

WARNING

Proper

electrical grounding of your system is

essential when used with flammable or combustible

liquids. For you safety

FIRE, EXPLOSION, AND ELECTRIC SHOCK

HAZARD

on page 2.

Have a qualified electrician check the electrical

grounding continuity between the flow meter electrical

chassis and a true earth ground as shown in Fig. 2. If

the resistance is greater than 25 ohms, check the

mounting or add a ground strap to the chassis.

, read the warning section

Digital

Voltage

Meter

True Earth Ground

01850

Fig. 2

5308–287

Page 6

Operation

Pressure Relief Procedure

WARNING

INJECTION

Fluid under high pressure can be in

jected through the skin and cause

serious injury

injury from injection, splashing fluid, or moving

parts, follow the

whenever you:

are instructed to relieve the pressure,

stop operating,

or check or service any of the system equip

ment.

1. T

urn of

f the air supply to the meter

Allow air to exhaust out of the exhaust air port.

2.

3. T

urn of

f the fluid supply to the meter

Shut of

4.

air system.

5.

Follow the Pressure Relief Procedure for your fluid

system dispensing device.

f all electrical power to the fluid system or

HAZARD

. T

o reduce the risk of an

Pressure Relief Procedure

.

.

System Operating Checklist

Check

the following list daily

the system, to help ensure you of safe, ef

tion.

-

-

Be sure all operators are properly trained and

qualified to safely operate your system.

Be sure all operators are trained how to properly

and completely relieve system pressure according

to the

Pressure Relief Procedure

Be sure the system is thoroughly grounded. See

FIRE, EXPLOSION, AND ELECTRIC SHOCK

HAZARD

Grounding

Be sure the operator and all persons entering the

installation site are properly grounded by wearing

shoes with conductive soles or personal grounding

straps.

Be sure ventilation fans are operating properly

, page 2, and

, page 5.

, before starting to operate

ficient opera

, at left.

Check the Electrical

.

-

Operation

Operate the flow meter between 20–50 psi (140–350

kPa, 1.4–3.5 bar) air inlet pressure. The yellow flow

meter indicator light will come on when the proper air

pressure is supplied. The green flow meter indicator

light will blink on and of

f when the fluid is flowing.

6 308–287

Page 7

CAUTION

Maintenance

Flushing the Meter

Do not immerse the meter in solvent. Solvent could

damage the meter’s electrical components.

1.

Clean the fluid and air line filters daily

2.

Clean the outside of the meter with a soft cloth

dampened in a compatible solvent as needed.

3.

Flush the fluid supply line and meter fluid reservoir

daily with a compatible solvent as instructed at

right.

.

WARNING

To

reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

1.

Relieve the pressure.

2.

Connect the fluid line to the solvent supply unit.

3.

Flush the meter until it is clean.

4.

Relieve the pressure

line from the solvent supply unit.

5.

Reconnect the fluid line to the fluid (paint) supply

urn on the fluid supply

6. T

Operate until the meter and fluid line are free of

7.

solvent.

on page 6.

, then disconnect the fluid

.

.

7308–287

Page 8

Troubleshooting

Y

ellow LED is of

f; no power to

WARNING

Installing and servicing this equipment requires

access to parts that may cause electric shock or

other serious injury if the work is not performed

properly

unless you are trained and qualified.

T

o reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

. Do not install or service this equipment

on page 6.

Before servicing this equipment always make sure to

relieve the pressure

.

Problem

Y

ellow LED is of

flow meter

Green LED is of

f; no power to

f

Cause Solution

Insuf

ficient air supply

T

urbine alternator not working Check for dirt or moisture in turbine.

Faulty turbine alternator

Excess moisture in air lines

T

urbine not connected to PC board

T

op PC board not connected to bot

tom PC board

Alternator shorted to chassis Check that insulating pad (2a) is in

Meter gasket (5) is damaged

Dried paint/fluid in gear track (gears

are not moving)

W

orn gears

Electronic failure

Adjust air regulator

Be sure plug is in place on back of

turbine alternator housing. Remove

and test alternator

Use filter-moisture separator

Connect 3-pin connector to square

pins.

-

T

ighten bolts to compress gasket to

0.040” (1.02 mm)

place. Replace pad if necessary

Replace gasket.

Flush fluid section of meter as

instructed in

7, or disassemble and clean the

gear housing assembly

Replace faulty gears.

Replace meter

.

.

Maintenance

.

.

.

.

on page

8 308–287

Page 9

WARNING

Service

2.

Disconnect the 3-pin connector (J) from the square

pins (H).

Installing and servicing this equipment requires

access to parts that may cause electric shock or

other serious injury if the work is not performed

properly

. Do not install or service this equipment

unless you are trained and qualified.

T

o reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

NOTE:

shooting

1.

Check all possible remedies in the

section before disassembling the meter

Relieve the pressure

on page 6.

Trouble-

and flush the meter as

described on page 7.

2.

Disconnect the fiber optic cable(s) (G) from the

electronic module (B). See Fig. 3.

3.

Disconnect the air hose fitting and remove the air

hose from the motor

. Disconnect both fluid hose

fittings and remove the fluid hose from the meter

4.

Remove the four screws (A) to separate the gear

housing (F) from the manifold.

3.

Carefully pull the alternator (4) away from the top

housing.

4.

Using an ohmmeter

alternator

. Measure the resistance between the

, test the coil in the turbine

two outer terminals of the 3-pin connector (J). The

resistance should be 3–5 ohms. If the reading

varies from this value, replace the alternator (4).

5.

Lubricate the alternator o-ring (4a) seal with petro

leum jelly

.

-

.

6.

Insert the alternator (4) into the top chassis (3).

7.

Connect the 3-pin connector (J) to the 3 square

pins (H) in the top chassis (3).

8.

Check to see that the gasket (5) is not damaged. If

damaged, replace the gasket.

9.

Snap the top and bottom chassis together

.

.

10.

Install and tighten the chassis screws (9) to 40

in-lbs (4.52 N

m).

CAUTION

Never remove the electronic module (B) from the top

gear housing (E). The electronic module is calibrated

to the gear housing assembly and will not function

properly if removed.

Torque

KEY

A Screw

Electronic Module

B

C O-Ring

D Manifold

op Gear Housing

ET

F

Gear Housing Assy

Fiber Optic Cable

G

G

.

E

to 7.5

ft-lb (10 N

m)

A

B

F

C*

D

KEY

H Pins

J 3-pin

2

3T

4 Alternator

4a

5 Gasket

9 Chassis Screws

Connector

Bottom Chassis

op Chassis

Alternator O-Ring

4a

9

orque to

T

40 in-lb

(4.52 N

m)

3

H

4

J

5

2

Fig. 3

Replacing the Turbine Alternator

1. Remove

chassis (2). See Fig. 4.

the top chassis (3) from the bottom

01851

Fig. 4

0180A

9308–287

Page 10

Service

Replacing Worn Bearings

A

repair kit is available to service the bearings. An

asterisk after the description or reference letter indi

cates a part included with the repair kit. See page 1

to order the proper kit for your meter model.

CAUTION

This is a close-tolerance device. It will be damaged if

forced apart during disassembly

1.

Loosen the four screws (N). See Fig. 5. Leave

about two threads connected.

.

Install the o-ring (M*), washers (K*), and gear

3.

assemblies (L*). Be sure to install the gears on

-

1

their proper pegs. See Fig. 5.

4.

Press the gear housings together and secure them

with the four screws (N). T

ft-lbs (10 N

Install the meter back onto the adapter plate.

5.

When installing the screws (A), replace the meter

two o-rings (C*) with the o-rings from the kit.

T

orque screws to 7.5 ft-lbs (10 Nm). See Fig. 3.

m).

orque the screws to 7.5

’s

2.

The two halves of the gear housing are pegged

together and will be dif

are part of the top gear housing (E).

Hold the housing and tap the screws one at a time

in a consistent sequence and eventually the two

halves will come apart.

3.

Before removing the gears (L), note which peg the

gear is being removed from. The gears must be

installed on the same peg they were removed

from.

ficult to separate. The pegs

CAUTION

Always reinstall the gears on the peg they were

removed from to ensure proper calibration with the

electronic module.

4.

Remove the gears (L) and washers (K).

5.

Support a gear on its sides and position the bear

ing tool (T*) as shown in Fig. 6. Make sure the

gear has suf

out the bearings and spacers.

ficient clearance in the center to press

NOTE:

o-rings that match the o-rings you are replacing and

discard the others.

Kit 223–276 has two sets of o-rings. Use the

CAUTION

Never immerse a meter in solvent for cleaning. Doing

so will damage the electronics.

KEY

ET

op Gear Housing

K Washer

Gear Assembly

L

M O-Ring

N Screw

-

K*

LE

K*

6.

Press the bearing tool with an arbor press or tap it

with a soft hammer until the bearings and spacers

are removed. Repeat with the other gear

To install th

1.

Place a gear on a flat surface. Position the bear

ings (P*), spacers (R* and S*) and the bearing tool

(T*) as shown in Fig. 7.

2.

Press the bearing tool with the arbor press or tap it

with a soft hammer until bearings and spacers are

installed into the gear

10 308–287

e k

it part

s a

nd assemble the gea

. Repeat with the other gear

.

r h

ousing:

M*

Replace

disassembled

-

1b

.

Fig. 5

N

Torque

7.5 ft-lb

(10 N

m)

whenever

to

01852A

Page 11

Service

Removing Bearings Installing Bearings

KEY

L Gear

T*

V*

W Support

Assembly

Bearing T

Bearings and Spacers

ool

L

Fig.

6

*T

KEY

L Gear

*T

P* Bearing

Inner Spacer

R*

S*

Outer Spacer

T*

Bearing T

Flat Surface

U

ool

R*

P*

V

W

0968

*S

P*

L

U

0969

Fig. 7

Parts

Bearing Repair Kit 223–276

For

Meter Model 235–402,

with 0.1 cc per tooth fluid volume flow

Bearing Repair Kit 223–277

For

Meter Model 235–403,

with 0.4 cc per tooth fluid volume flow

Bearing Repair Kits include the following parts:

Ref.

Letter Description Qty.

C O-RINGS,

K WASHER 4

M O-RING 1

P BEARINGS 4

R INNER SPACER 2

S OUTER SPACER 2

T BEARING TOOL 1

(not shown, See Fig. 3)

2 or 4

T

Gears

not

included

with Kit

K

P

R

S

P

K

M

0967

11308–287

Page 12

Parts

Part No. 235–402, Series A

0.1

cc per tooth fluid volume flow

3

30

29

28

5

16

4a

4

Part No. 235–403

with

0.4 cc per tooth fluid volume flow

8

17

15

14

Model

1a

1b

only

Model

1

9

2a

2

6

7

10

11

12

13

235–402

235–403 only

12 308–287

Page 13

Parts

Part No. 235–402, Series A

0.1

cc per tooth fluid volume flow

Part No. 235–403, Series A

0.4

cc per tooth fluid volume flow

Ref

No.

1

1a 111–073

1b 111–070

2 224–277

2a 186–924

3 224–276

4 224–603 ALTERNAT

4a 110–073

5 186–852 GASKET

6 111–157

7 186–853

8 110–420 SCREW

9 111–308 SCREW

Part No.

Description Qty.

GEAR HOUSING ASSY

information below; Includes

replaceable items 1a & 1b

. O-RING, fluid housing; PTFE

. O-RING, fluid ports; PTFE

CHASSIS ASSY

Includes item 2a

. P

AD, insulating

CHASSIS ASSY

OR; Includes item 4a

. O-RING, alternator; V

, adhesive backing

FITTING, air inlet; 1/4” tube

FLAME ARREST

, cap; 10–24 x 1.5”

, top mounting;

M4 x 0.7 x 30 mm long

; Ordering

1

2

, bottom;

, top

iton 1

OR 1

Ref

No.

10 186–922

11 107–107 W

12 186–921 BODY 1

13 101–435 BALL 1

14 108–046 SPRING 1

15 186–923 RETAINER 1

16* 187–125

17* 187–124

28 111–284 NUT

1

29 111–285

30 111–286

*

1

Graco.

1

1

Viton

1

Company.

1

To Order Gear Housing Assembly (item 1)

1

To

6

the complete flow meter assembly back to your local

Graco distributor

2

brated when a new gear housing is installed.

Part No.

Additional warning labels available at no charge from

is a registered trademark of the Du Pont

replace the Gear Housing Assembly

Description Qty.

FITTING, valve

ASHER, flow

LABEL, warning

LABEL, warning

, tube fitting; 1/4” OD

FERRULE, back; 1/4” OD

FERRULE, front; 1/4” OD

, you must send

. The flow meter needs to be recali

1

1

1

1

2

2

2

-

13308–287

Page 14

Accessories

Fiber Optic Cables

Fiber

Optic Cable Assembly

For connection between the controller and flow meter

P

ART NO.

224–690 6 ft (1.8 m)

224–691 15 ft (5 m)

224–692 25 ft (8 m)

224–693

224–694 50 ft (15 m)

224–695 75 ft (23 m)

224–696

Fiber Optic Cable Extender

For connection between the flow meter and bulkhead

connector or between two bulkhead connectors.

P

ART NO.

224–670 6 ft (1.8 m)

224–671 15 ft (5 m)

224–672 25 ft (8 m)

224–673

224–674 50 ft (15 m)

224–675 75 ft (23 m)

224–676

LENGTH

36 ft (1

100 ft (30.5 m)

LENGTH

36 ft (1

100 ft (30.5 m)

1 m)

1 m)

Bulkhead Connector 224–261

For

connection between two fiber optic cables.

Fluid Manifold

.

Contact

proper manifold.

your local Graco representative to order

0186 0187

Part

No. 223–869

Part No. 624–708

Fluid Filter 223–160

5000 psi (35.

Stainless steel bowl and polyethylene support.

NOTE:

premature flow meter wear

Order Part No. 167–026 when you order the filter

0 M

Pa

, 350 b

ar) Maximu

This filter has a 60 mesh screen. T

, use a 100 mesh screen.

m W

orkin

g P

ressure

o prevent

.

100 Mesh Filter Screen 167–026

For

use with Fluid Filter 223–160.

Bleed-type Master Air Valve 107–142

Grounding Clamp and Wire 222–011

12

ga, 25 ft (7.6 m) wire

300

psi (2.1 MPa, 21 bar) Maximum Working Pressure

Relieves air trapped in the air line between the pump

air inlet and this valve when closed. 1/2” npt

14 308–287

Page 15

DIM. C

DIM. A

Dimensions

DIM. B

Part

No.

235–402

235–403

Dim. A Dim. B Dim. C

4.25 in

(108 mm)

4.25 in

(108 mm)

4.10 in.

(104 mm)

4.25 in.

(108 mm)

4.44 in.

(113 mm)

4.50 in.

(114 mm)

01847

Technical

Category Data

Maximum Working Fluid Pressure

Maximum W

Fluid Pressure Operating Range

Air Pressure Operating Range

Air Inlet

Maximum Fiber Optic Cable Length

W

etted Parts

orking Air Pressure

Manual

This

manual was revised to include the changes from PCN C.

2800 psi (19.6 MPa, 196 bar)

50 psi (350 kPa, 3.5 bar)

0–2800 psi (0–19.6 MPa, 0–196 bar)

20–50 psi (140–350 kPa, 1.4–3.5 bar)

1/4 inch OD tube

100 ft (30.5 m) with two splices

Stainless Steel, PTFE

Change Summary

Data

15308–287

Page 16

The

Graco

warrants all equipment listed in this manual which is manufactured by Graco and bearing its name to be free from defects in

material

any

replace

operated

This

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution

Graco

installation,

This

verification

equipment

in

transportation.

Graco’s

remedy (including, but not limited to, incidental or consequential damages for lost

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two

date

GRACO

A PARTICULAR PURPOSE IN CONNECTION WITH ACCESSORIES, EQUIPMENT

NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, gas engines,

switches,

in

In

hereunder,

breach

and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. With the exception

special extended or limited warranty published by Graco, Graco will,

any part of the equipment determined by Graco to be defective. This warranty applies only when the

and maintained in accordance with Graco’

warranty does not cover

of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

equipment with structures, accessories, equipment or materials not supplied by Graco, or the

operation or maintenance or structures, accessories, equipment or materials not supplied by Graco.

warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

material or

of sale.

making any claim for breach of these warranties.

no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor

sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

MAKES NO W

hose, etc.), are subject to the warranty

or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

of warranty

, the negligence of Graco, or otherwise.

, and Graco shall not be liable

ARRANTY

, AND DISCLAIMS ALL

Graco W

s written recommendations.

for general wear and tear

IMPLIED W

, if any

, of their manufacturer

ARRANTIES OF MERCHANT

arranty

of

for a period of twelve months from the date of sale, repair or

equipment is installed,

, or any malfunction, damage or wear caused by

improper design, manufacture,

, and

The buyer agrees that no other

profits,

lost sales, injury to person or property

(2)

ABILITY AND FITNESS FOR

, MA

TERIALS OR COMPONENTS SOLD BUT

. Graco will provide purchaser with reasonable assistance

, or any

years of the

FOR

GRACO CANADA CUST

The

parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent

judiciaires

TO

PLACE AN ORDER

avoir convenu que la rédaction du présente document sera en Anglais,

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procédures concernées.

OMERS

Graco

Phone Number

, contact your Graco distributor

1–800–367–4023 T

ainsi que tous documents, avis et procédures

, or call this number to identify the distributor closest to you:

oll Free.

All

written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Foreign Offices:

Sales Offices:

Belgium, Canada, England, Korea, France, Germany

GRACO INC. P.O. BOX 1441

PRINTED

IN U.S.A. 308–287 February 1993, Revised July 1997

Minneapolis, Detroit, Los Angeles

MINNEAPOLIS, MN

, Hong Kong, Japan

55440–1441

16 308–287

Loading...

Loading...