Page 1

INSTRUCTIONS-PARTS

PTFEPTFEPTFE

LIST

308–230

This

manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

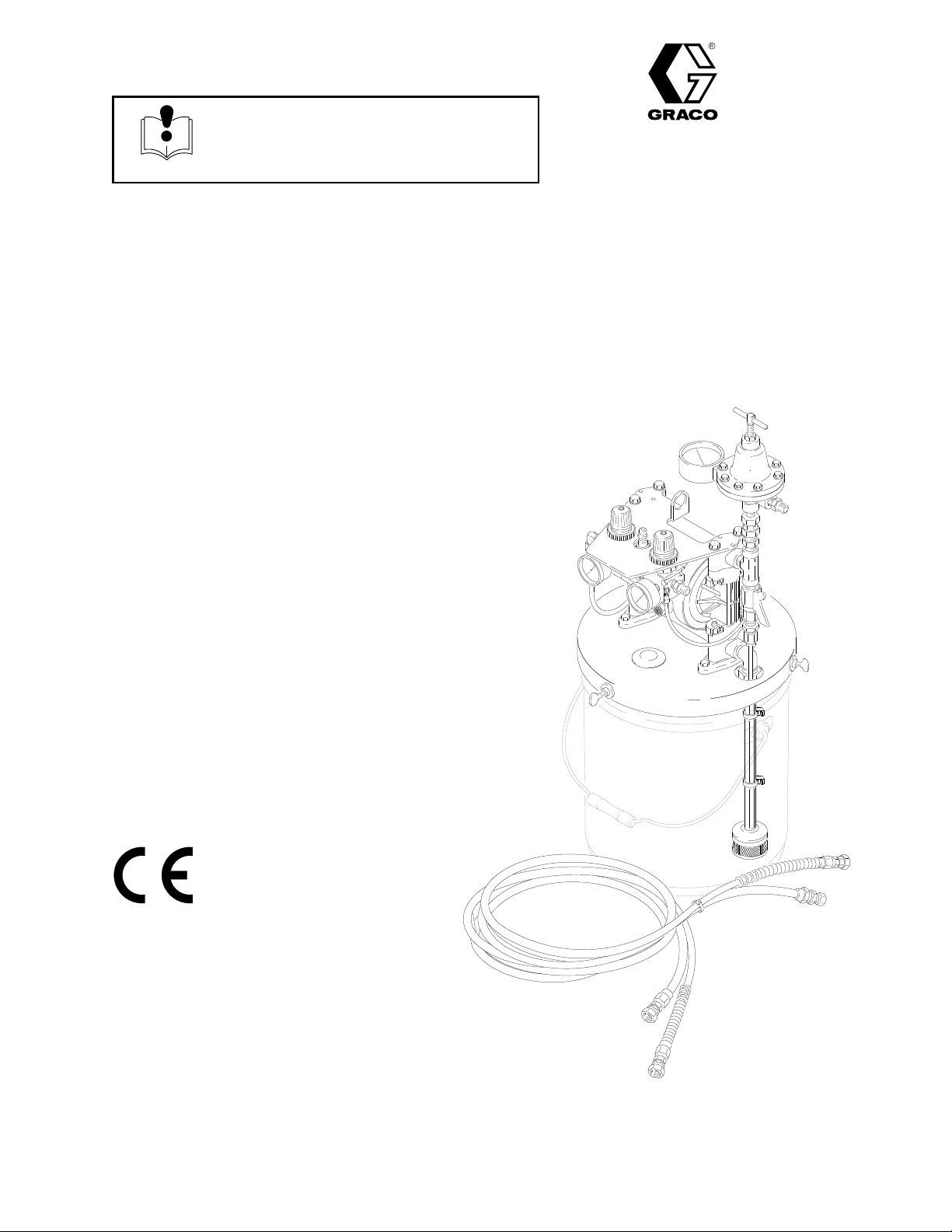

Husky

307

First

quality counts.

Air Spray/HVLP Systems

STAINLESS STEEL FLUID FITTINGS,

ACETAL PUMP WITH

0.7 MPa, 7 bar (100 psi) Maximum Fluid Working Pressure

0.7 MPa, 7 bar (100 psi) Maximum Air Input Pressure

Model 236–870, Series A

Pail

Mount Unit with Fluid Regulator

Model 224–833, Series B

Pail

Mount Unit with Fluid Regulator and Hose Kit

DIAPHRAGM

choice when

Rev. J

Supersedes Rev H

and PCN J

Model 236–412, Series A

Pail

Mount Unit with Surge T

Model 236–869, Series A

Wall

Mount Unit with Surge T

Model 236–628, Series A

Wall

Mount Unit with Surge T

Model 236–414, Series A

Wall

Mount Unit with Surge T

Model 236–868, Series A

Wall

Mount Unit with Surge T

ank and Hose Kit

ank and Suction Kit

ank and Hose Kit

ank, Suction Kit, and Hose Kit

ank

Model

224–833 Shown

(Pail is not included)

GRACO INC. P.O. BOX 1441

COPYRIGHT

Graco

Inc. is registered to I.S. EN ISO 9001

MINNEAPOLIS, MN

1992, GRACO INC.

55440–1441

Page 2

Table

of Contents

Symbols

Warnings 2.

Installation 4

Operation 10

Parts 12

Dimensions 18

Technical

Warranty Back

Graco T

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data

.

. . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

oll-Free Phone Numbers

.

. . . . . . .

Back Cover

Cover

Back Cover

WARNING

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment

This equipment is for professional use only

misuse can cause the equipment to rupture or malfunction and result in serious injury

Warning Symbol

WARNING

his

symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This

symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

.

.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are unsure about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check equipment daily

Do not exceed the maximum working pressure of the lowest rated component in your system.

This equipment has a

MPa, 7 bar) maximum incoming air pressure.

Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

nical Data

ings.

Do not use hoses to pull equipment.

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not ex

pose Graco hoses to temperatures above 82C (180F) or below –40C (–40

W

ear hearing protection when operating this equipment.

Do not lift pressurized equipment.

section of all equipment manuals. Read the fluid and solvent manufacturer’s warn

. Repair or replace worn or damaged parts immediately

100 psi (0.7 MPa, 7 bar) maximum working pressure at 100 psi (0.7

.

F).

Tech-

-

-

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

Page 3

TOXIC FLUID HAZARD

WARNING

WARNING

Hazardous

skin, inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container

state and national guidelines.

Always wear protective eyewear

and solvent manufacturer

Pipe and dispose of the exhaust air safely

If the diaphragm fails, the fluid is exhausted along with the air

the separate pump manual 308–553.

fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the

. Dispose of hazardous fluid according to all local,

, gloves, clothing and respirator as recommended by the fluid

.

, away from people, animals, and food handling areas.

. See

Air Exhaust V

entilation

FIRE AND EXPLOSION HAZARD

Improper

result in a fire or explosion and serious injury

grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

.

Ground the equipment. Refer to

If there is any static sparking or you feel an electric shock while using this equipment,

pumping immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being pumped.

Grounding

on page 9.

in

stop

Pipe and dispose of the exhaust air safely

fails, the fluid is exhausted along with the air

manual 308–553.

Keep the work area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the work area.

Extinguish all open flames or pilot lights in the work area.

Do not smoke in the work area.

Do not turn on or of

Do not operate a gasoline engine in the work area.

f any light switch in the work area while operating or if fumes are present.

, away from all sources of ignition. If the diaphragm

. See

Air Exhaust V

entilation

in the separate pump

Page 4

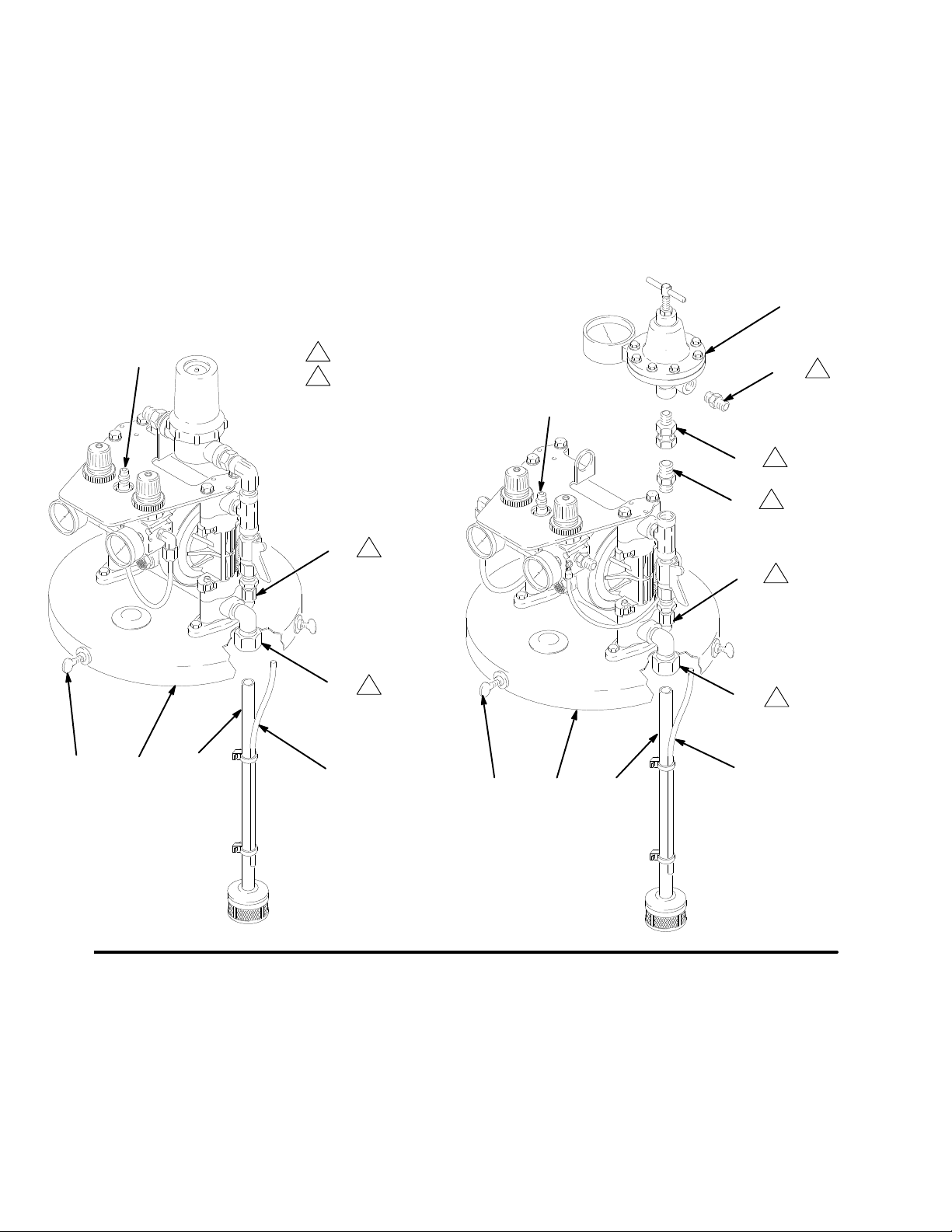

Installation

Assembling Pail Mount Units

1. Insert

2.

the suction tube (27) into the elbow (15) to

its full depth. Tighten the nut securely

. See Fig. 1.

Insert the recirculation tube (28) into the connector

(16) to its full depth. T

ighten the nut securely

3.

On Models 236–870 and 224–833,

assemble the

Fluid Regulator Kit (items 17, 21, 24 and 32) as

shown in Fig. 1.

4.

Attach the pail cover (2) to a pail of fluid, using the

.

thumbscrews (3). T

ighten securely

.

Model 236–412 Models 236–870

and 224–833

1

Tighten

22

2

nut securely with wrench.

Apply thread sealant to male threads.

22

16

1

15

1

32

21

16

15

17

24

2

2

2

1

1

Fig. 1

4 308-230

23

27

28

28

2723

04964

04965

Page 5

Installation

Assembling the Wall Mount Unit

Install

the wall bracket (2) 5 ft (1.52 m) above the floor

Use the mounting hole layout shown on page 18. Be

sure the wall is strong enough to support the weight of

the pump and hoses, any accessories, the fluid, and

stress caused by pump operation.

The following steps apply to Model 236–414 only:

Apply thread sealant and screw the connector (28) into

the pump’

s fluid inlet. See Fig. 2.

.

22

2

29

1

Slide the bung plug (31) onto the suction tube (33).

Push the 0.625 in. (16 mm) OD suction tube into the

elbow (30) to its full depth, then tighten the nut secure

ly with a wrench.

Push the 0.5 in. (13 mm) OD flexible tube (29) into the

elbow (30) to its full depth, then tighten the nut secure

ly with a wrench. Push the other end of the flexible

tube into the connector (28) to its full depth, then tight

en the nut securely with a wrench.

Screw the bung plug (31) into the drum bung opening.

Adjust the suction tube (33) so the end of the tube is

about 1/2 in. (13 mm) of

f the bottom of the drum, and

secure using the thumbscrew (32).

30

28

3

33

2

31

-

Insert tube (29) into connector (28)

-

1

to full depth and tighten nut

securely with wrench.

tube

Insert

2

full

securely with wrench.

3

Apply

(33) into elbow (30) to

depth and tighten nut

thread sealant to male threads.

Fig. 2

32

02773

308-230 5

Page 6

Installation

PTFEPTFEPTFE

General Information

1. The T

2.

3.

4.

ypical Installations shown on pages 7 and

8 are only a guide for selecting and installing sys

tem components. Contact your Graco distributor or

Graco T

assistance in planning a system to suit your needs.

Always use Genuine Graco Parts and Accesso

ries, available from your Graco distributor

the Product Data Sheet for the pump, Form No.

305–528. If you supply your own accessories, be

sure they are adequately sized and pressure rated

for your system.

Use a compatible, liquid thread sealant or

tape on all male threads. T

firmly to avoid air or fluid leaks.

tighten plastic threads.

Reference numbers and letters in parentheses re

fer to the callouts in the Figures and the parts lists

on pages 12–17.

echnical Assistance (see back page) for

ighten all connections

Do not over-

WARNING

T

OXIC FLUID HAZARD

Hazardous fluid or toxic fumes can

cause serious injury or death if splashed

in the eyes or on the skin, inhaled, or

swallowed.

1. Read T

OXIC FLUID HAZARD

on page 3.

-

-

. Refer to

Accessories

WARNING

A bleed-type master air valve (B) is required in

your system to relieve air trapped between this

valve and the pump. Trapped air can cause the

pump to cycle unexpectedly

serious injury

the skin, injury from moving parts, or contamination

from hazardous fluids.

A fluid drain valve (J) is required in your system to

relieve pressure in the hose if it is plugged. (The

fluid recirculation valve supplied with Models

236–870, 224–833, and 236–412 will serve this

purpose.) The drain valve reduces the risk of seri

ous injury

skin, or contamination from hazardous fluids when

-

relieving pressure. Install the valve close to the

pump’

s fluid outlet.

1.

Install the air line accessories as shown in Figs. 3

and 4. Mount these accessories on the wall or on a

bracket. Be sure the air line supplying the acces

sories is grounded.

a.

, including splashing in the eyes or on

, including splashing in the eyes or on the

Locate one bleed-type master air valve (B)

close to the pump and use it to relieve trapped

air

. See the

er master air valve (E) upstream from all air

line accessories and use it to isolate them dur

ing cleaning and repair

WARNING

, which could result in

above. Locate the oth

.

-

-

-

-

2.

Use fluids and solvents which are compatible

with the equipment wetted parts. Refer to the

T

echnical Data

als. Read the fluid and solvent manufacturer

warnings.

section of all equipment manu

b.

The air line filter (F) removes harmful dirt and

moisture from the compressed air supply

-

’s

Install an electrically conductive, flexible air hose

2.

(C) between the accessories and the pump. Use a

minimum 1/4” (6.3 mm) ID air hose. Screw an air

line quick disconnect coupler (D) onto the end of

the air hose (C). Do not connect the coupler (D) to

the air inlet fitting (22, see Figs. 1 and 2) yet.

.

Hose Connections

1. Read

2.

3.

the entire spray gun manual before connect

ing the hoses and operating the sprayer

Connect a fluid hose (N) between the pump fluid

outlet fitting and the fluid inlet of the spray gun (R).

See Figs. 3 and 4.

Connect an electrically conductive air hose (P) be

tween the outlet fitting of the gun air regulator (G)

and the air inlet of the spray gun (R).

.

-

-

6 308-230

Page 7

E

R

Y

Installation

BC

F

M

D

G

NP

L

H

A

J

K

S

Air

Spray T

ypical Installation –

Pail Mount Models with Surge Tank

KEY

A Husky

B Bleed-T

C

D

E

F

G

H

J

K

L

M

N

P

R

S

Y

NOTE:

included with the sprayer

model. Refer to the parts lists on pages

12–17 for parts included in your sprayer

307 Pump

ype Master Air V

(required for pump)

Air Supply Line

Air Line Quick Disconnect

Master Air V

Air Line Filter

Gun Air Regulator

Pump Air Regulator

Fluid Drain V

Fluid Recirculation Line

Fluid Suction Line

Surge T

Gun Fluid Supply Hose

Gun Air Supply Hose

Air Spray Gun

Pail Cover

Ground Wire (included)

See page 9 for grounding instructions.

Some components shown are

alve (for accessories)

alve (required)

ank and Filter

alve

, depending on the

.

HVLP T

ypical Installation –

Pail Mount Models with Fluid Regulator

KEY

A

Husky 307 Pump

B Bleed-T

C

D

E

F

G

H

J

K

L

M

N

P

R

S

Y

NOTE:

included with the sprayer

model. Refer to the parts lists on pages

12–17 for parts included in your sprayer

ype Master Air V

(required for pump)

Air Supply Line

Air Line Quick Disconnect

Master Air V

Air Line Filter

Gun Air Regulator

Pump Air Regulator

Fluid Drain V

Fluid Recirculation Line

Fluid Suction Line

Fluid Regulator and Gauge

Gun Fluid Supply Hose

Gun Air Supply Hose

Optimiser HVLP Spray Gun

Pail Cover

Ground Wire (included)

See page 9 for grounding instructions.

Some components shown are

alve (for accessories)

alve (required)

alve

, depending on the

.

04967

E

B

F

C

M

D

G

H

A

Y

J

R

K

L

S

P

N

Fig. 3

04966

308-230 7

Page 8

Installation

Air

Spray T

Wall Mount Models with Surge Tank

F

E

R

Y

J

N

B

D

G

C

M

H

A

KEY

A Husky

B Bleed-T

(required for pump)

C

Air Supply Line

D

Air Line Quick Disconnect

E

Master Air V

F

Air Line Filter

G

Gun Air Regulator

H

Pump Air Regulator

J

Fluid Drain V

L

Fluid Suction Line

M

Surge T

N

Gun Fluid Supply Hose

P

Gun Air Supply Hose

R

Air Spray Gun

SW

all Bracket

Y

Ground Wire (included)

See page 9 for grounding instructions.

S

ypical Installation –

307 Pump

ype Master Air V

alve (for accessories)

alve (required)

ank and Filter

alve

P

NOTE:

Some components shown are

included with the sprayer

model. Refer to the parts lists on pages

12–17 for parts included in your sprayer

Fig.

4

, depending on the

L

.

04973

Page 9

Installation

Grounding

WARNING

FIRE

AND EXPLOSION HAZARD

This pump must be grounded. Before

operating the pump, ground the system

as explained below. Also read the sec

tion

FIRE OR EXPLOSION HAZARD

page 3.

T

o reduce the risk of static sparking, ground the pump

and all other equipment used or located in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of equip

ment.

Ground all of this equipment.

1.

Pump

: One end of the ground wire (Y) is con

nected to the pump grounding strip (Z). Connect

the clamp end of the ground wire to a true earth

ground.

on

-

2.

Air and fluid hoses

tive hoses.

3.

Spray gun:

are grounded with a ground wire (34) connected

between the gun air regulator and the pump

grounding strap (Z).

4.

Object being sprayed:

5.

Fluid supply container:

6.

Air compressor

mendations.

7.

-

Solvent pails used when flushing

cal code. Use only metal pails, which are conduc

tive. Do not place the pail on a non-conductive sur

face, such as paper or cardboard, which interrupts

the grounding continuity

The spray gun and the gun air hose

: Use only electrically conduc

Follow your local code.

Follow your local code.

: Follow the manufacturer’s recom

: Follow your lo

.

-

-

-

-

-

Fig. 5

Y

34

Z

04963

Page 10

Pressure Relief Procedure

PTFEPTFEPTFE

Operation

1.

Be sure the pump is properly grounded. Read

FIRE OR EXPLOSION HAZARD

on page 3.

WARNING

PRESSURIZED

The system pressure must be manually relieved to

prevent the system from starting or spraying acci

dentally. T

dental spray from the gun, splashing fluid, or mov

ing parts, follow the

whenever you:

are instructed to relieve the pressure,

stop spraying,

check or service any of the system equipment,

or install or clean the spray tips.

1.

Shut of

2. T

3.

Open the fluid drain valve to relieve all fluid pres

sure, having a container ready to catch the drain

age.

f the air to the pump.

rigger the spray gun.

Flush the Pump Before First Use

The

pump was tested in water

could contaminate the fluid you are pumping, flush the

pump thoroughly with a compatible solvent. Follow the

procedure in

EQUIPMENT HAZARD

o reduce the risk of an injury from acci

Pressure Relief Procedure

. If the test solution

Starting and Adjusting the Pump.

-

-

-

-

-

2.

Check all fittings to be sure they are tight. Be sure

to use a compatible liquid thread sealant or

tape on all male threads. T

outlet fittings snugly

into the pump.

3.

On pail mount units,

pail of fluid and attach the pail cover using the

thumbscrews. T

On wall mount units,

bung plug in the fluid supply drum as explained on

page 5.

4.

Make sure the air regulators (G and H) and bleed

valves (B and E) are closed. Open the fluid drain

valve (J).

5.

Connect the air line coupler (D) to the air inlet fit

ting.

6.

With the gun air regulator (G) closed, open the

bleed-type master air valves (B, E) and the pump

air regulator (H).

7.

Allow the pump to cycle slowly until all air is

pushed out of the recirculation line and the pump

is primed.

. Do not overtighten the fittings

ighten securely

ighten the fluid inlet and

place the suction tube in a

.

install the suction tube and

-

Starting and Adjusting the Pump

WARNING

TOXIC

Hazardous fluid or toxic fumes can

cause serious injury or death if splashed

in the eyes or on the skin, inhaled, or

swallowed. Do not lift a pump under pressure. If

dropped, the fluid section may rupture. Always fol

low the

lifting the pump.

Pressure Relief Procedure

FLUID HAZARD

above before

8.

Point the spray gun (R) into a grounded metal pail,

holding a metal part of the gun firmly to the side of

the pail.

9. T

rigger the air spray gun. Open the gun air regula

tor (G) and close the fluid drain valve (J). Allow the

pump to cycle slowly until all air is pushed out of

the fluid hose and gun.

-

If you are flushing,

thoroughly clean the pump and hoses. Close the

air regulator

solvent and place it in the fluid to be pumped.

run the pump long enough to

. Remove the suction tube from the

-

10 308-230

Page 11

Operation

Pump Shutdown

WARNING

To

reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

At the end of the work shift,

on page 10.

relieve the pressure.

Flushing and Storage

WARNING

To

reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

Flush the pump when necessary to prevent the fluid

you are pumping from drying or freezing in the pump

and damaging it. Use a compatible solvent.

Before storing the pump, always flush the pump and

relieve the pressure.

on page 10.

Recirculation Line

The

recirculation tube (K, supplied with Models

236–870, 224–833, and 236–412) drains unused fluid

back into the fluid container, ensuring an even flow at

the gun. Recirculation also provides gentle fluid agita

tion. T

o recirculate fluid, open the drain valve (J) while

you are spraying. T

o stop recirculation, close the valve.

Surge Tank (Models 236–628, 236–869,

236–412, 236–868, and 236–414)

WARNING

To

reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure

The surge tank filter screen may require periodic

cleaning. First,

surge tank cover from its base and remove the filter

screen. Clean the screen with a compatible solvent

and reinstall it in the surge tank.

An optional V

tank, for use in applications where the standard EPDM

gasket is unsuitable.

relieve the pressure.

iton

gasket is supplied for the surge

on page 10.

Unscrew the

-

308-230 11

Page 12

Model 236–412, Series A

PTFEPTFEPTFE

Includes items 1–42

Parts

Ref Part

No. No. Description Qty

1 D31–331 PUMP, Husky 307; SST/ r;

See 308–553 for parts

2 235–505 COVER, pail; stainless steel 1

3 111–276 THUMBSCREW

1” (25.4 mm) long; sst

4 104–119 SCREW

0.875” (22 mm) long; sst

5 104–123 LOCKWASHER; 1/4” size; sst 4

6 102–025 NUT

7 101–754

8 103–473

9 111–813

10 108–190 GAUGE, air pressure;

11 110–209 NUT

12 111–804 REGULATOR, air;

13 111–805 BLOCK, diverter

13a 108–284 . O-RING; buna-N 3

14 111–807 ELBOW

15 111–808 ELBOW

16 111–811 CONNECT

17 111–793 T

17a 111–884 . SCREEN, 20 mesh; sst 1

17b 112–035 . GASKET

111–885 . GASKET

18 237–534 VAL

19 111–928

PLUG, pipe; 3/8 npt

TIE, recirculation tube

PLUG, button

0–100 psi (0–0.7 MPa, 0–7 bar)

0–125 psi (0–0.85 MPa, 0–8.5 bar)

pressure range

Includes item 13a

1/4 npt(m) x ferrule nut for

0.25” (6.3 mm) OD tube

3/8 npt(m) x ferrule nut for

0.625” (16 mm) OD tube

3/8 npt(m) x ferrule nut for

0.25” (6.3 mm) OD tube

Includes items 17a and 17b

TEE; 3/8 npt(f) run x

3/8 npt(m) branch; sst

, cap, hex hd; 1/4–20 unc–2a;

, hex; 1/4–20; sst

, regulator

, tube fitting, 90_; acetal;

, tube fitting, 90_; acetal;

ANK, surge; 1/2 npt(f); nylon

(alternative to EPDM; shipped loose)

VE, ball; 3/8 npt (m x f); sst

; 5/16–18 unc;

OR, tube fitting; acetal;

; EPDM (standard part)

; V

itonr;

Ref Part

No. No. Description Qty

20 112–026 ELBOW

1

21 112–027

22 169–971

23 188–077

3

24 188–380

25 188–093 BRACKET

4

26 188–107

4

1

27 188–108

3

1

28 188–115

2

2

29 181–163 HOUSING, filter

30 181–164 FIL

2

31Y 189–220

34 223–324 GROUND WIRE; 12” (300 mm);

1

35 108–290 SCREW

38 236–410 HOSE KIT

2

39 235–339 .

1

40 210–867 .

1

41 102–478 .

1

42 222–011

1

Use only GENUINE GRACO PARTS AND ACCESSORIES.

1

1

Y

Replacement Danger and W

1

are available at no cost.

NIPPLE; 1/2 npt x 3/8 npt; sst

FITTING, air line; 3/8 npt(m)

NIPPLE; 1/4–18 npt x 1/4–18.6 sf; cst

NIPPLE; 1/2 npt x 3/8–18.6 sf; sst

TUBE, inlet, air; nylon;

0.25” (6.3 mm) OD; 0.170” (4.3 mm) ID;

7.5” (191 mm) long

TUBE, suction; nylon;

0.625” (16 mm) OD x 0.5” (13 mm) ID;

12.13” (308 mm) long

TUBE, recirculation, fluid; nylon;

0.25” (6.3 mm) OD;

0.170” (4.3 mm) ID; 19” (483 mm) long

LABEL, warning

from gun air regulator to pump

8–32 x 1/4” (6.3 mm)

Includes items 39–41

GROUND WIRE; 12 gauge (1.5 mm2),

25 ft (7.6 m); with clamp

, street; 3/8 npt (m x f); sst

, air regulator

, inlet; nylon

TER, inlet; nylon

, machine;

HOSE, fluid; nylon; sst fittings;

3/8 npsm (fbe); 1/4” (6.3 mm) ID;

26 ft (7.9 m) long

HOSE, air; buna-N; cst fittings

1/4 npsm (fbe); 5/16” (7.9 mm) ID;

25 ft (7.6 m) long

TIE, hose

arning labels, tags and cards

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

13

1

12 308-230

Page 13

Model 236–412, Series A

Includes items 1–42

1

2

3

4

5

6

7

to 35–55 in–lb (4.0–6.2 N.m). Do not over-torque.

Torque

Insert tube into connector (16) to full depth and

tighten nut securely with wrench.

Insert tube into elbow (14) to full depth and

tighten nut securely with wrench.

Insert tube into elbow (15) to full depth and

tighten nut securely with wrench.

T

orque to contact plus 1/2 turn.

Apply

thread sealant to male threads.

Pail

is not included.

11

5

12

23

6

34

35

22

13a

Parts

25

6

14

6

26

3

Part

of item 17

17a

24

6

31

17b

Part

17

21

of item 1

6

20

1

6

34 (Ref)

1

19

6

A

15

6

42

10

6

13

6

Ref.

No. 38, Hose Kit,

Includes Items 39–41.

18

6

3

7

27

2

4

14

6

26

3

7

A

4

5

9

6

16

28

6

2

8

41

29

30

40

39

04974A

308-230 13

Page 14

Model 236–870, Series A

PTFEPTFEPTFE

Includes items 1–35 and 42

Model 224–833, Series B

Includes items 1–42

Parts

Ref Part

No. No. Description Qty

1 D31–331 PUMP, Husky 307; SST/ r;

See 308–553 for parts

2 235–505 COVER, pail; stainless steel 1

3 111–276 THUMBSCREW

1” (25.4 mm) long; sst

4 104–119 SCREW

0.875” (22 mm) long; sst

5 104–123 LOCKWASHER; 1/4” size; sst 4

6 102–025 NUT

7 101–754

8 103–473

9 111–813

10 108–190 GAUGE, air pressure;

11 110–209 NUT

12 111–804 REGULATOR, air;

13 111–805 BLOCK, diverter

13a 108–284 . O-RING; buna-N 3

14 111–807 ELBOW

15 111–808 ELBOW

16 111–811 CONNECT

17{ 236–449 REGULAT

18 237–534 VAL

19 111–928

21{ 188–089

22 169–971

PLUG, pipe; 3/8 npt

TIE, recirculation tube

PLUG, button

0–100 psi (0–0.7 MPa, 0–7 bar)

0–125 psi (0–0.85 MPa, 0–8.5 bar)

pressure range

Includes item 13a

1/4 npt(m) x ferrule nut for

0.25” (6.3 mm) OD tube

3/8 npt(m) x ferrule nut for

0.625” (16 mm) OD tube

3/8 npt(m) x ferrule nut for

0.25” (6.3 mm) OD tube

3–30 psi (21–210 kPa, 0.2–2.1 bar)

pressure range

See manual 308–325

TEE; 3/8 npt(f) run x

3/8 npt(m) branch; sst

NIPPLE; 3/8 npt x 3/8–18.6 sf; sst

FITTING, air line; 3/8 npt(m)

, cap, hex hd; 1/4–20 unc–2a;

, hex; 1/4–20; sst

, regulator

, tube fitting, 90_; acetal;

, tube fitting, 90_; acetal;

VE, ball; 3/8 npt (m x f); sst

; 5/16–18 unc;

OR, tube fitting; acetal;

OR, fluid; acetal;

Ref Part

No. No. Description Qty

23 188–077

1

24{ 189–436

25 188–093 BRACKET

26 188–107

3

4

27 188–108

4

1

28 188–115

3

1

29 181–163 HOUSING, filter

2

30 181–164 FIL

2

31Y 189–220

32{ 112–497

2

34 223–324 GROUND WIRE; 12” (300 mm);

1

35 108–290 SCREW

38 236–410 HOSE KIT

2

39 235–339 .

1

40 210–867 .

1

41 102–478 .

42 222–011

Use only GENUINE GRACO PARTS AND ACCESSORIES.

1

1

{

These parts are included in Fluid Regulator Kit 235–344.

1

1

Y

Replacement Danger and W

1

are available at no cost.

NIPPLE; 1/4-18 npt x 1/4-–8.6 sf; cst

NIPPLE; 1/4-18 npt x 3/8–18.6 sf; sst

, air regulator

TUBE, inlet, air; nylon;

0.25” (6.3 mm) OD; 0.170” (4.3 mm) ID;

7.5” (191 mm) long

TUBE, suction; nylon;

0.625” (16 mm) OD x 0.5” (13 mm) ID;

12.13” (308 mm) long

TUBE, recirculation, fluid; nylon;

0.25” (6.3 mm) OD;

0.170” (4.3 mm) ID; 19” (483 mm) long

, inlet; nylon

TER, inlet; nylon

LABEL, warning

SWIVEL, union; 1/4-18 npt x

3/8–18.6 npsm

from gun air regulator to pump

, machine;

8–32 x 1/4” (6.3 mm)

Includes items 39–41

HOSE, fluid; nylon; sst fittings;

3/8 npsm (fbe); 1/4” (6.3 mm) ID;

26 ft (7.9 m) long

HOSE, air; buna-N; cst fittings;

1/4 npsm (fbe); 5/16” (7.9 mm) ID;

25 ft (7.6 m) long

TIE, hose

GROUND WIRE; 12 gauge (1.5 mm2),

25 ft (7.6 m); with clamp

arning labels, tags and cards

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

13

1

14 308-230

Page 15

Model 236–870, Series A

Includes items 1–35 and 42

Model 224–833, Series B

Includes items 1–42

1

orque to 35–55 in–lb (4.0–6.2 N.m). Do not over-torque.

T

Insert tube into connector (16) to full depth and

2

tighten nut securely with wrench.

Insert tube into elbow (14) to full depth and

3

tighten nut securely with wrench.

Insert tube into elbow (15) to full depth and

4

tighten nut securely with wrench.

5

T

orque to contact plus 1/2 turn.

6

Apply

thread sealant to male threads.

7

Pail is not included.

5

11

14

6

12

A

Parts

These

parts are included in

Fluid Regulator Kit 235–344.

of item 1

Part

31

25

1

22

6

6

14

3

26

13a

A

34 (Ref)

15

6

1

17

24

6

32

6

21

6

19

6

42

26

3

10

6

Ref. No. 38, Hose Kit,

Includes Items 39–41.

6

18

13

6

7

6

27

2

4

4

9

23

3534

7

3

6

5

6

16

28

2

8

41

29

30

40

39

04975A

308-230 15

Page 16

Model 236–628, Series A

PTFEPTFEPTFE

Includes items 1–26 and 34–42

Model 236–868, Series A

Includes items 1–26, 34–37, and 42

Model 236–869, Series A

Includes items 1–37 and 42

Model 236–414, Series A

Includes items 1–42

Parts

Ref Part

No. No. Description Qty

1 D31–331 PUMP, Husky 307; SST/ r;

See 308–553 for parts

2 224–835 WALL BRACKET KIT

Includes items 3–6

3 188–285 . BRACKET

4 104–119 . SCREW

0.875” (22 mm) long; sst

5 104–123 . LOCKWASHER; 1/4” size; sst 4

6 102–025 . NUT

7 101–754

10 108–190 GAUGE, air pressure;

11 110–209 NUT

12 111–804 REGULATOR, air;

13 111–805 BLOCK, diverter

13a 108–284 . O-RING; buna-N 3

14 111–807 ELBOW

17 111–793 T

17a 111–884 . SCREEN, 20 mesh; sst 1

17b 112–035 . GASKET

111–885 . GASKET

20 112–026 ELBOW

21 112–027

22 169–971

23 188–077

24 188–091

188–380

25 188–093 BRACKET

PLUG, pipe; 3/8 npt

0–100 psi (0–0.7 MPa, 0–7 bar)

0–125 psi (0–0.85 MPa, 0–8.5 bar)

pressure range

Includes item 13a

1/4 npt(m) x ferrule nut for

0.25” (6.3 mm) OD tube

ANK, surge; 1/2 npt(f); nylon

Includes items 17a and 17b

(alternative to EPDM; shipped loose)

NIPPLE, reducing;

1/2 npt x 3/8 npt; sst

FITTING, air line; 3/8 npt(m)

NIPPLE; 1/4–18 npt x 1/4–18.6 sf; cst

NIPPLE; 1/2 npt x 3/8–18.6 sf; cst

(Models 236–628 and 236–414 only)

NIPPLE; 1/2 npt x 3/8–18.6 sf; sst

(Model 236–869 only)

, wall

, cap, hex hd; 1/4–20 unc–2a;

, hex; 1/4–20; sst

, regulator

, tube fitting, 90_; acetal;

; EPDM (standard part)

; V

itonr;

, street; 3/8 npt (m x f); sst

, air regulator

Ref Part

No. No. Description Qty

26 188–107

1

1

27 235–500 SUCTION KIT

1

28 111–864 . CONNECT

4

29 188–173 .

4

1

30 111–863 . ELBOW

2

2

31 188–181 .

32 111–276 . THUMBSCREW

2

33 188–171 .

1

34 223–324 GROUND WIRE; 12” (300 mm);

2

35 108–290 SCREW

1

37Y 189–220

38 236–410 HOSE KIT

1

39 235–339 .

1

2

40 210–867 .

1

1

1

41 102–478 .

42 222–011

1

Use only GENUINE GRACO PARTS AND ACCESSORIES.

1

1

Replacement Danger and W

Y

are available at no cost.

TUBE, inlet, air; nylon;

0.25” (6.3 mm) OD; 0.170” (4.3 mm) ID;

7.5” (191 mm) long

Includes items 28–33

OR; acetal; 3/8 npt(m) x

0.5 in. (13 mm) tube

TUBE, flexible; nylon;

0.5 in. (13 mm) OD;

72 in. (1.83 m) long

, connector

0.625 in. (16 mm) OD tube x

0.5 in. (13 mm) OD tube

PLUG, bung; acetal

1” (25.4 mm) long; sst

TUBE, suction; acetal;

0.625 in. (16 mm) OD;

38 in. (965 mm) long

from gun air regulator to pump

, machine;

8–32 x 1/4” (6.3 mm)

LABEL, warning

Includes items 39–41

HOSE, fluid; nylon; sst fittings;

3/8 npsm (fbe); 1/4” (6.3 mm) ID;

26 ft (7.9 m) long

HOSE, air; buna-N; cst fittings

1/4 npsm (fbe); 5/16” (7.9 mm) ID;

25 ft (7.6 m) long

TIE, hose

GROUND WIRE; 12 gauge (1.5 mm2),

25 ft (7.6 m); with clamp

arning labels, tags and cards

, reducing; acetal;

; 5/16–18 unc;

1

1

1

1

1

1

1

1

1

1

1

1

1

1

13

1

16 308-230

Page 17

Model 236–628, Series A

Includes items 1–26 and 34–42

Model 236–868, Series A

Includes items 1–26, 34–37, and 42

Parts

Model 236–869, Series A

Includes items 1–37 and 42

Model 236–414, Series A

Includes items 1–42

1

2

3

4

5

6

6

to 35–55 in–lb (4.0–6.2 N.m). Do not over-torque.

Torque

Insert tube into connector (28) to full depth and

tighten nut securely with wrench.

Insert tube into elbow (14) to full depth and

tighten nut securely with wrench.

Insert tube into elbow (30) to full depth and

tighten nut securely with wrench.

T

orque to contact plus 1/2 turn.

Apply

thread sealant to male threads.

11

5

12

34

23

35

10

6

13

7

6

22

13a

6

3

14

26

Part of item 17

17a

24

6

37

17b

Part

17

of item 1

1

25

21

6

20

6

34 (Ref)

1

20

6

14

6

26

3

6

42

A

30

4

5

28

6

29

3

2

33

4

6

A

32

31

41

Ref.

No. 38, Hose Kit,

Includes Items 39–41.

33

(Ref

)

40

39

04976A

308-230 17

Page 18

Model

)

236–412

Dimensions

Models 236–870 and 224–833

13.1 in.

(332.7 mm)

Pail is not included.

Maximum pail outer diameter is 12.125 in. (308 mm).

15.1 in.

(383.5 mm)

13.1 in.

(332.7 mm)

Pail

is not included.

Maximum pail outer diameter is 12.125 in. (308 mm).

17.5

in.

(444.5 mm)

Wall

5

in.

(127

mm)

Four

0.438 in. (1

(T

o Mount Bracket T

18 308-230

Mounting

Hole Layout

9.0 in.

(228.6 mm)

(WALL

1 mm) Dia. Holes

o W

VIEW

OF

MOUNTING

BRACKET)

6.74 in.

(171.2 mm)

all)

8 in.

(203 mm

0654

Page 19

Technical

PTFEPTFEPTFE

Data

Wetted Parts

Pump

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pail

Cover (236–870, 224–833,

236–412)

Fluid Hoses

Hose

Surge

236–869)

Fluid

Fittings

Tubing

Suction

.

. . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Couplings

T

ank (236–412, 236–414, 236–628, 236–868,

Regulator (236–870, 224–833)

.

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

ube (236–414 and 236–869)

.

. . . . . . . . . . . . . . . . . . . . . .

nylon, EPDM or V

.

. . . . .

acetal,

Manual

This

manual was revised to include the changes from PCN J.

See 308–553

stainless steel

nylon

stainless steel

iton

, stainless steel

See 308–325

.

. . . . .

stainless steel

nylon

.

. . . . . . . . . .

acetal

Change Summary

Maximum

Air

Pump Air Inlet Size

Pump

* Sound

Operating Temperature Range:

* Tested to CAGI-PNEUROP–1969

Fluid W

Pressure Operating Range

Fluid Inlet and Outlet Size. 3/8 npt(f)

Data

Pump sound level at 100 psi (0.7 MPa, 7 bar), full flow

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump

sound level at 70 psi (480 kPa, 4.8 bar),

1 gpm (3.8 lpm)

is a registered trademark of the Du Pont Co.

orking Pressure

.

. . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

100 psi (0.7 MPa, 7 bar)

.

.

. . . . . . . . . . . . . .

(104–700

.

. . . . . . . . . . . . . .

40

to 150F (4.4 to 65.5

kPa, 1–7 bar)

15–100 psi

1/4 npt(f)

85 dB(A)

7

8 dB(A)

C)

308-230 19

Page 20

The

Graco

warrants all equipment listed in this manual which is manufactured by Graco and bearing its name to be free from defects in

material

any

replace

operated

This

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution

Graco

installation,

This

verification

equipment

in

transportation.

Graco’s

remedy (including, but not limited to, incidental or consequential damages for lost

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two

date

GRACO

A PARTICULAR PURPOSE IN CONNECTION WITH ACCESSORIES, EQUIPMENT

NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, gas engines,

switches,

in

In

hereunder,

breach

and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. With the exception

special extended or limited warranty published by Graco, Graco will,

any part of the equipment determined by Graco to be defective. This warranty applies only when the

and maintained in accordance with Graco’

warranty does not cover

of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

equipment with structures, accessories, equipment or materials not supplied by Graco, or the

operation or maintenance or structures, accessories, equipment or materials not supplied by Graco.

warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

material or

of sale.

making any claim for breach of these warranties.

no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor

sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

MAKES NO W

hose, etc.), are subject to the warranty

or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

of warranty

Graco Warranty and Disclaimers

for a period of twelve months from the date of sale, repair or

equipment is installed,

s written recommendations.

, and Graco shall not be liable

ARRANTY

, the negligence of Graco, or otherwise.

, AND DISCLAIMS ALL

, if any

for general wear and tear

IMPLIED W

, of their manufacturer

ARRANTIES OF MERCHANT

, or any malfunction, damage or wear caused by

improper design, manufacture,

The buyer agrees that no other

profits,

lost sales, injury to person or property

ABILITY AND FITNESS FOR

, MA

TERIALS OR COMPONENTS SOLD BUT

. Graco will provide purchaser with reasonable assistance

(2)

years of the

, and

, or any

of

FOR

GRACO CANADA CUST

The

parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent

judiciaires

TO

PLACE AN ORDER

avoir convenu que la rédaction du présente document sera en Anglais,

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procédures concernées.

OMERS

Graco

Phone Number

, contact your Graco distributor

1–800–367–4023 T

ainsi que tous documents, avis et procédures

, or call this number to identify the distributor closest to you:

oll Free.

All

written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Foreign Offices:

Sales Offices:

Belgium, Canada, England, Korea, France, Germany

GRACO INC. P.O. BOX 1441

PRINTED

IN U.S.A. 308–230 September 1992, Revised June 1997

Minneapolis, Detroit, Los Angeles

MINNEAPOLIS, MN

, Hong Kong, Japan

55440–1441

Loading...

Loading...