Page 1

Instructions–Parts List

Dynamic Surge Suppressor

For use with double-diaphragm pumps and low-pressure reciprocating pumps.

For professional use only.

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

308178H

EN

Model 224892, Series A

aluminum, with PTFE diaphragm

Model 224893, Series A

aluminum, with buna–N diaphragm

Model 224894, Series C

stainless steel, with PTFE diaphragm

Model 224895, Series C

stainless steel, with buna–N diaphragm

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation and Maintenance 7. . . . . . . . . . . . . . . . . . .

Troubleshooting 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Lists 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Kits 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensional Drawing 15. . . . . . . . . . . . . . . . . . . . . . .

Technical Data 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 18. . . . . . . . . . . . . . . . . . . . . . .

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

WARNING

Hazard of Using Fluids Containing Halogenated Hydrocarbons

Never use 1.1.1–trichloroethane, methylene

chloride, other halogenated hydrocarbon solvents

or fluids containing such solvents in aluminum

models 224892 or 224893. Such use could result

in a chemical reaction, with the possibility of

explosion, which could cause death, serious bodily

injury, and/or substantial property damage.

Consult your fluid suppliers to ensure that the fluids

being used are compatible with aluminum and zinc

parts.

0903

Page 2

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Do not exceed the maximum working pressure of the lowest rated component in your system.

See Technical Data on page 16.

D Use fluids and solvents that are compatible with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 82_C (180_F) or below –40_C (–40_F).

D Wear hearing protection when operating this equipment.

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

2 308178

Page 3

WARNING

WARNING

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the

skin, inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid

and solvent manufacturer.

D Graco does not manufacture or supply the reactive chemical components that may be used in

this equipment and is not responsible for injury or property loss, damage, expense or claims

(direct or consequential) that arise from the use of such chemical components.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Ground the equipment. See Grounding on page 4.

D If there is any static sparking or you feel an electric shock while using this equipment, stop

pumping immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being pumped.

D Keep the work area free of debris, including solvent, rags, and gasoline.

D Electrically disconnect all equipment in the work area.

D Extinguish all open flames or pilot lights in the work area.

D Do not smoke in the work area.

D Do not turn on or off any light switch in the work area while operating or if fumes are present.

D Do not operate a gasoline engine in the work area.

D Never use 1.1.1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

MOVING PARTS HAZARD

Moving parts, such as the air motor piston in the pump, can pinch or amputate your fingers.

D Keep clear of all moving parts when starting or operating the pump.

D Before servicing this surge tank, follow the Pressure Relief Procedure on page 4 to prevent

the equipment from starting accidentally.

United States Government safety standards have been adopted under the Occupational Safety and Health Act.

You should consult these standards––particularly the General Standards, Part 1910.

308178

3

Page 4

Installation

System Pressure

The maximum fluid working pressure of this surge

suppressor is 100 psi (0.7 MPa, 7 bar) at 100 psi

(0.7 MPa, 7 bar) incoming air pressure. Never exceed

100 psi (0.7 MPa, 7 bar) fluid or air pressure to the

surge suppressor. Do not exceed the maximum

working pressure of any component or accessory used

in the system.

Pressure Relief Procedure

WARNING

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of serious bodily injury, including

splashing fluid or solvent in the eyes or on the skin,

always follow this procedure before you check,

adjust, clean, or repair any part of the system.

1. Close the air regulator by turning counterclockwise

as far as possible.

2. Disconnect the air supply line to the surge

suppressor.

and other flammable substances, whether you are

pumping indoors or outdoors, and can cause a fire or

explosion and serious bodily injury and property

damage.

If you experience any static sparking or even a slight

shock while using this equipment, stop pumping

immediately. Do not use the system again until the

problem has been identified and corrected.

To reduce the risk of static sparking, ground the pump,

surge suppressor, and all other equipment used or

located in the pumping area. Check your local

electrical code for detailed grounding instructions for

your area and type of equipment. Ground all of this

equipment:

D Pump: See your separate pump instruction

manual.

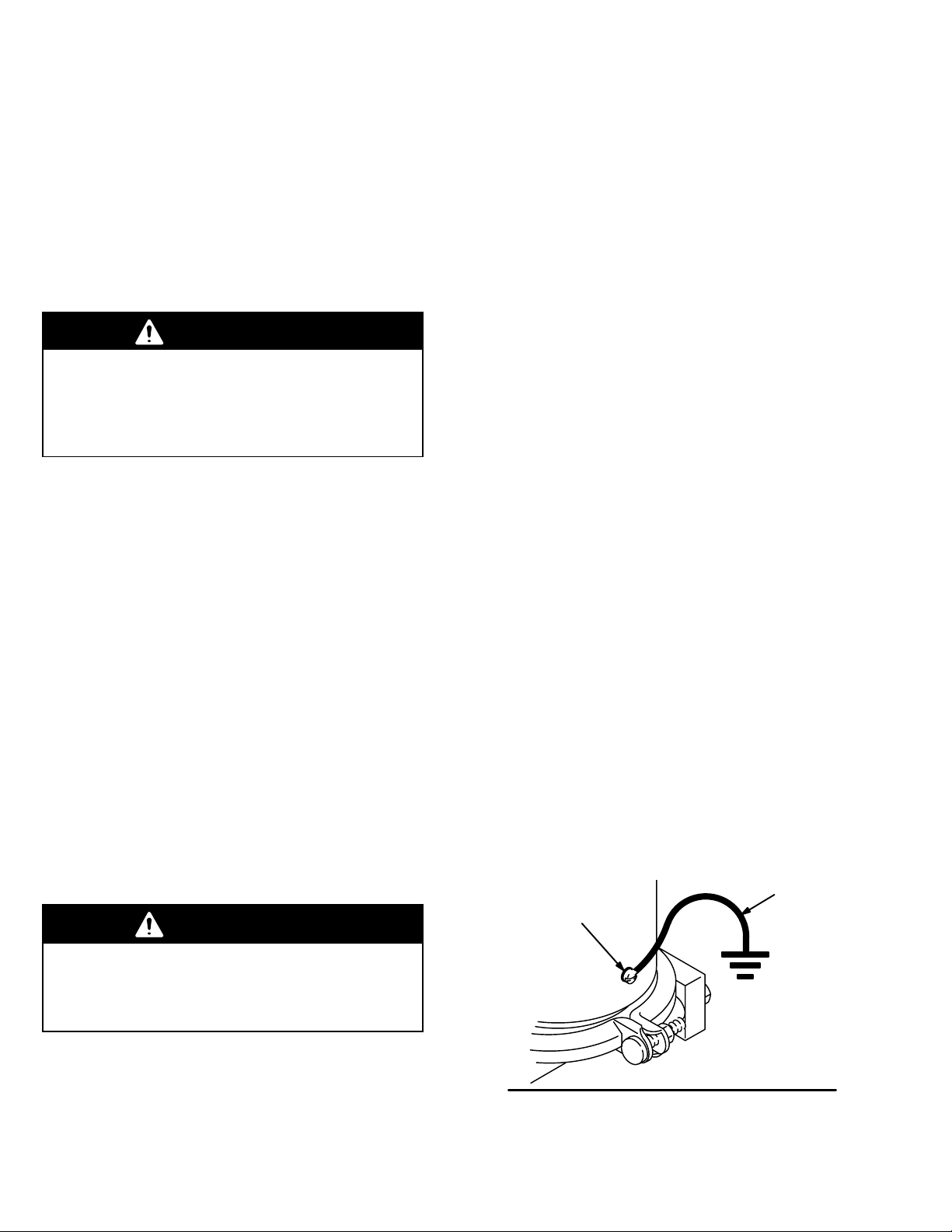

D Surge suppressor: Secure a ground wire (Y) to the

surge suppressor with the grounding screw (Z)

located on the side of the housing. See Fig. 1.

Connect the clamp end of the ground wire to a true

earth ground. To order a ground wire and clamp,

order Part No. 208950.

3. Open the dispensing valve, if used.

4. Open the fluid drain valve to relieve all fluid

pressure; have a container ready to catch the

drainage.

Fluid Compatibility

Be sure all fluids and solvents used are chemically

compatible with the wetted parts and non-wetted parts

shown in the Technical Data section on page 16.

Failure of the diaphragm may cause non-wetted parts

to be exposed to fluid. Always read the fluid and

solvent manufacturer’s literature before using them

with this equipment.

Grounding

WARNING

This equipment must be grounded. Read and

carefully follow the text of FIRE AND EXPLOSION

HAZARD on page 3 before operating the surge

suppressor.

D Air and fluid hoses: Use only grounded hoses with

a maximum of 500 ft (150 m) combined hose length

to ensure grounding continuity.

D Air compressor: Follow the manufacturer’s

recommendations.

D All solvent pails used when flushing: Follow the

local code. Use only metal pails, which are

conductive. Do not place the pail on a

nonconductive surface, such as paper or

cardboard, which interrupts the grounding

continuity.

D Fluid supply container: Follow the local code.

Y

Z

Static electricity is created by the fluid flowing through

the pump and hose. If the equipment is not properly

grounded, sparking may occur, and the system may

become hazardous. Sparks can ignite fumes from

solvents and the fluid being pumped, dust particles,

4 308178

Fig. 1

0942

Page 5

Installation

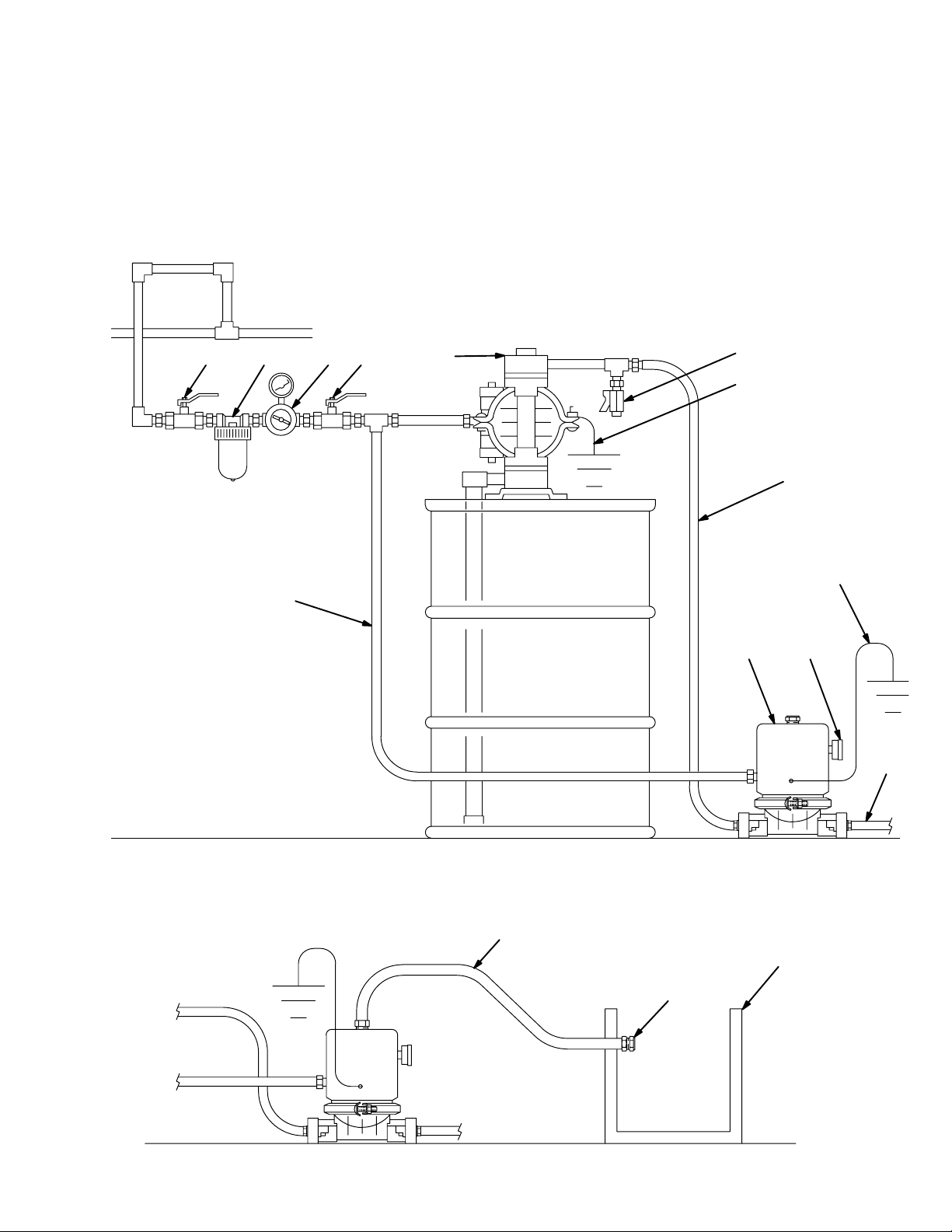

The installation shown below is only a guide for selecting and installing system components; it is not an actual

system design. Contact your Graco distributor for assistance in planning a system to suit your needs.

KEY

A Surge suppressor

B Air pressure gauge

C Fluid supply line

D Fluid outlet line

E Air supply line

F Husky 715 pump

G Fluid drain valve

H Bleed-type master air valve

(required for pump and surge

suppressor)

HJKL

F

J Air regulator

K Air Filter

L Bleed-type master air valve

(for accessories)

M Surge suppressor ground wire

(required)

N Pump ground wire

(required)

G

N

C

E

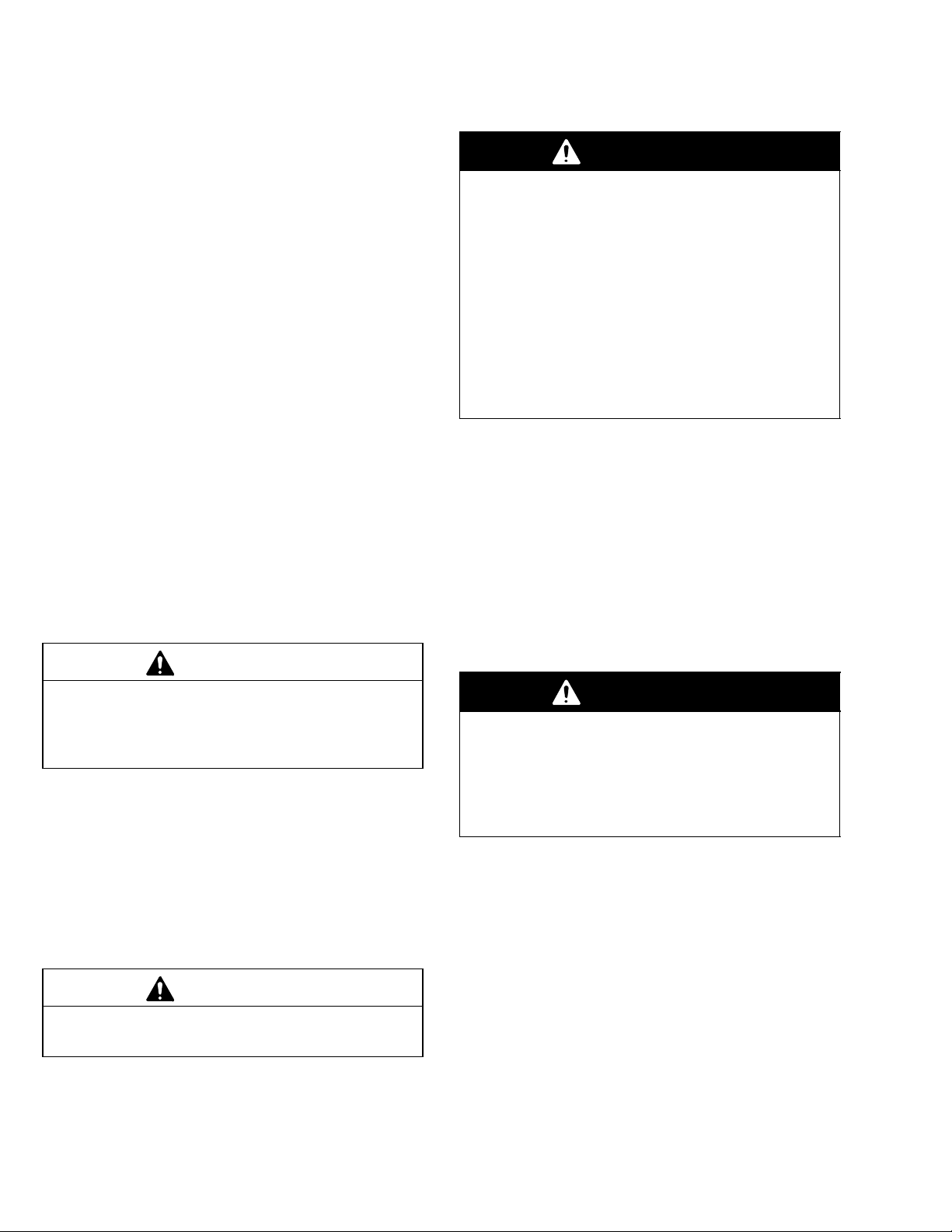

DETAIL A: Venting Exhaust Air to a Remote Container

grounded air exhaust hose

muffler

M

AB

D

container

for remote

air exhaust

308178

0906

5

Page 6

Installation

General Information

The surge suppressor uses air pressure and a

diaphragm to maintain a consistent fluid outlet

pressure from a double diaphragm or low-pressure

reciprocating pump. During normal flow, the

suppressor air pressure and fluid pressure are in

equilibrium. A sharp increase in fluid pressure causes

the air inlet port to open, increasing air pressure on the

diaphragm and returning the system to equilibrium.

Conversely, a sharp decrease in fluid pressure causes

the air exhaust port to open, decreasing air pressure

on the diaphragm and allowing the system to return to

equilibrium.

Installation

1. Read this entire manual before installing or

operating the surge suppressor.

2. The surge suppressor fluid inlet must be

connected to the pump’s fluid outlet. If the pump

is aluminum or steel, the surge suppressor may

be plumbed directly to the outlet, using 3/4 npt

fittings. If the pump is acetal or polypropylene,

place the surge suppressor on the floor or some

other solid, level surface near the pump, and

connect the surge suppressor inlet to the pump

outlet with a 3/4” ID hose and 3/4 npt fittings.

CAUTION

Air Exhaust Ventilation

WARNING

Be sure to read TOXIC FLUID HAZARD and FIRE

AND EXPLOSION HAZARD on page 3, before

operating this equipment.

Be sure the system is properly ventilated for your

type of installation. When pumping flammable or

hazardous fluids, you must vent the surge suppressor exhaust air to a safe place, away from people,

animals, food handling areas, and all sources of

ignition. If the diaphragm ruptures, the fluid will be

exhausted along with the air. Place a container at

the end of the air exhaust line to catch the fluid.

See Detail A on page 5.

The minimum size for the air exhaust hose is 3/8 in.

(10 mm) ID x 15 ft (4.6 m). If a longer hose is required,

use a larger diameter hose.

1. Remove the muffler from the surge suppressor

exhaust port. Install an exhaust hose in the

exhaust port, and connect the muffler to the other

end of the hose. Avoid sharp bends or kinks in the

hose. See Detail A on page 5.

2. Place a container at the end of the air exhaust line

to catch fluid in case the diaphragm ruptures.

Do not plumb the surge suppressor directly onto the

fluid outlet of an acetal or polypropylene pump.

Those pumps cannot support the weight of the

suppressor and will suffer damage or rupture.

3. Connect an air line from the pump’s air regulator to

the air inlet of the surge suppressor. In systems

using a 1:1 ratio pump, the air pressure supplied to

the suppressor will be the same as that supplied to

the pump.

4. Use a compatible, liquid thread sealant on all male

threads. Tighten all connections firmly to avoid air

or fluid leaks.

CAUTION

To avoid pump damage, do not overtighten the

fittings to the pump.

WARNING

Never operate the surge suppressor without the

muffler or an air exhaust line installed in the air

exhaust port. If the air exhaust port is left open and

the diaphragm shaft works loose from the bolt, the

shaft could be propelled out of the housing, causing injury.

6 308178

Page 7

Operation and Maintenance

Operating the Surge Suppressor

1. Be sure the system is properly grounded. Read

and follow FIRE AND EXPLOSION HAZARD, on

page 3.

2. Check all fittings to be sure they are tight. Be sure

to use a compatible liquid thread sealant on all

male threads, and do not overtighten the fittings

into the pump.

3. Check that the muffler or air exhaust line is

securely connected to the air exhaust port on the

top of the housing.

WARNING

Never operate the surge suppressor without the

muffler or an air exhaust line installed in the air

exhaust port. If the air exhaust port is left open and

the diaphragm shaft works loose from the bolt, the

shaft could be propelled out of the housing, causing injury.

4. Start the pump as explained in your separate

pump manual. In systems using a 1:1 ratio pump,

the air pressure supplied to the suppressor will be

the same as that supplied to the pump.

5. Allow the pump to cycle slowly until all air is

pushed out of the surge suppressor and lines, and

the pump is primed. The system is now ready for

normal operation.

WARNING

To prevent overpressurization of the surge suppressor, never exceed 100 psi (0.7 MPa, 7 bar)

fluid inlet pressure or 100 psi (0.7 MPa, 7 bar) air

inlet pressure. In systems using pumps with a ratio

greater than 1:1, reduce the air inlet pressure to

the pump as necessary to keep the fluid and air

inlet pressures to the surge suppressor within

these limits.

CAUTION

In systems using pumps with a ratio greater than 1:1,

fluid may escape into the surge suppressor air line

and contaminate the air supply if the diaphragm fails.

Installation of a check valve in the air line will prevent

fluid contamination of the air line.

Flushing the System

Flush the system regularly, using a compatible solvent.

Do not allow fluid to dry in the pump or surge

suppressor. Always flush the pump and surge

suppressor before storing them for any length of time.

Place the pump suction tube in the solvent container.

Run the pump long enough to thoroughly clean it, the

surge suppressor, hoses, and any guns or valves used

in the system. Close the pump air regulator. Remove

the suction hose from the solvent.

NOTES:

When using a pump with a ratio greater than 1:1, the

air pressure supplied to the surge suppressor and the

air pressure supplied to the pump must be at the same

ratio as the pump to prevent overpressurization of the

surge suppressor. See the following examples.

D In a system using a 2:1 ratio pump, air pressure

supplied to the surge suppressor should be twice

as high as air pressure to the pump. If the air

pressure supplied to the pump is 50 psi (0.34 MPa,

3.4 bar), you should supply 100 psi (0.7 MPa,

7 bar) air pressure to the surge suppressor.

D In a system using a 4:1 ratio pump, air pressure

supplied to the surge suppressor should be four

times as high as air pressure to the pump. If the

air pressure supplied to the pump is 25 psi

(0.17 MPa, 1.7 bar), you should supply 100 psi

(0.7 MPa, 7 bar) air pressure to the surge

suppressor.

Shutdown

Remove the suction hose from the fluid container and

run the pump until the fluid is forced out of the system.

Then shut off the air supply immediately.

308178

7

Page 8

Troubleshooting

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 4.

Relieve the pressure.

Check all possible problems and causes before

disassembling the pump or surge suppressor.

PROBLEM

Surge suppressor operates

erratically

Air bubbles in fluid Fluid supply line loose Tighten.

Fluid in exhaust air Diaphragm (13 or 21[) ruptured Replace. See page 9.

CAUSE SOLUTION

Clogged air line or air inlet Inspect; clear.

Air line connected to pressure gauge

port

Clogged fluid supply line, fluid inlet or

fluid outlet

Diaphragm (13 or 21[) ruptured Replace. See page 9.

Unbalanced air pressures between

pump and surge suppressor

Diaphragm (13 or 21[) ruptured Replace. See page 9.

Manifold o-rings (16) leaking Replace. See page 10.

Connect air line to air inlet

(see page 11).

Inspect; clear.

Ratio of air inlet pressure to surge

suppressor and air inlet pressure to

pump must be the same as pump ratio, but air pressure to surge suppressor must never exceed 100 psi

(0.7 MPa, 7 bar). See page 7.

Diaphragm plates (12 or 32) loose or

damaged

Damaged shaft (11) or shaft o-rings

(19)

Pump leaks air or fluid from cover (7) V-clamp (6) is loose Tighten V-clamp. See page 9.

[ Ref. No. 21, the PTFE diaphragm, is used only in Surge Suppressor Models 224892 and 224894.

Tighten or replace. See page 9.

Replace. See page 9.

8 308178

Page 9

Service

Servicing the Shaft O-Rings

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 4.

2. Place a container under the surge suppressor,

disconnect the hoses, and turn the surge

suppressor on end to drain the fluid.

3. Remove the v-clamp (6). See the Parts Drawing

on page 12.

4. Separate the housing (8) from the cover (7) to

expose the diaphragm and shaft assembly. Pull

the diaphragm and shaft out of the housing. See

Fig. 2.

5. Remove the three o-rings (19) from the shaft (11).

6. Lubricate the three new o-rings (19*) with

lithium-based grease and install them in the

grooves on the shaft.

Servicing the Diaphragm and Shaft

NOTE: Diaphragm Repair Kits are available. See page

14. Parts included in the kits are marked with

asterisks. The kits include some parts which are not

used on the surge suppressor. Use all the applicable

parts in the kit for the best results.

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 4.

2. Place a container under the surge suppressor,

disconnect the hoses, and turn the surge

suppressor on end to drain the fluid.

3. Remove the v-clamp (6). See the Parts Drawing

on page 12.

4. Separate the housing (8) from the cover (7) to

expose the diaphragm and shaft assembly. Pull

the diaphragm and shaft out of the housing. See

Fig. 2.

7. Lubricate the inner diameter of the housing (8) with

lithium-based grease. Slide the shaft and

diaphragm assembly into the housing (8). Place

the cover (7) on the housing (8).

8. Position the clamp (6) around the housing (8) and

cover (7). Apply thread lubricant to the threads of

the v-clamp, secure with the nuts, and torque to 6

to 10 ft-lb (1.4 to 13.6 N.m). See the Parts

Drawing on page 12.

5. Hold the bolt (14) steady with a wrench. Wrap a

rag around the shaft (11) to protect it, then

unscrew the shaft from the bolt using locking

pliers. Remove the nut (31), upper diaphragm

plate (32*), diaphragm (13), PTFE diaphragm

(Models 224892 and 224894 only), lower

diaphragm plate (12), and o-ring (15) from the bolt.

Clean and inspect all parts for wear or damage.

308178

9

Page 10

Service

6. Place the o-ring (15*) on the bolt (14). Install the

lower diaphragm plate (12), with the flat side facing

down.

7. Install the diaphragm (13**), making certain that

the side marked AIR SIDE is facing up on the bolt.

On Models 224892 and 224894 only, install the

PTFE diaphragm (21**) first, then the backup

diaphragm (13**).

8. Install the upper diaphragm plate (32*) with the flat

side facing up. Apply thread sealant to the bolt

(14). Hold the bolt steady with a wrench, and

screw the nut (31) onto the bolt (14). Torque to 5 to

7 ft-lb (7 to 10 N-m).

9. Wrap the shaft (11) with a rag to protect it, and use

locking pliers to screw the shaft onto the bolt (14).

Torque to 10 to 15 in-lb (1.1 to 1.7 N-m).

10. Lubricate the inner diameter of the housing (8) with

lithium-based grease. Slide the shaft and

diaphragm assembly into the housing (8). Place

the cover (7) on the housing (8).

11. Position the clamp (6) around the housing (8) and

cover (7). Apply thread lubricant to the threads of

the v-clamp, secure with the nuts, and torque to 6

to 10 ft-lb (8 to 14 N.m). See the Parts Drawing

on page 12.

Servicing the Fluid Inlet and Outlet

NOTE: Repair Kits are available to service the internal

parts of the fluid inlet and outlet. See page 14 for

ordering information. Parts included in the kits are

marked with three asterisks, for example (16***). The

kits include some parts which are not used on the

surge suppressor. Use all the applicable parts in the kit

for the best results.

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 4.

2. Place a container under the surge suppressor,

disconnect the hoses, and turn the surge

suppressor on end to drain the fluid.

3. Remove the bolts (2), lockwashers (3), and nuts

(1) holding one manifold (9) to the cover (7).

Repeat for the other side. See Fig. 2.

4. Pull the two o-rings (16), guide (18) and stop (17)

out of the cover (7). Repeat for the other side.

Clean and inspect all parts for wear or damage.

5. Push one o-ring (16***) all the way into the cavity

of the cover (7). Install the stop (17***) with the

beveled side facing inward. Install the guide (18***)

with the flat end facing inward, then install the

second o-ring (16***) around the outer edge of the

guide. Repeat for the other side.

6. Install the manifold (9) on the cover (7) with the

chamfer facing outward. Secure with the bolts (2),

lockwashers (3), and nuts (1). Torque to 3 to 6 ft-lb

(4 to 8 N.m). Repeat for the other side.

10 308178

Page 11

Service

diameter of housing

(8) with lithium-based

Fig. 2

Lubricate inner

grease

Air inlet

1/4 npt(f)

9

Chamfer

faces out

8

6

7

***16 16***

***18

Flat end

faces

inward

21**

(models

224892 and

224894 only)

17***

Beveled side

faces inward

12*

Flat side

faces down

*15**

14*

Apply sealant to

threads.

19*

Lubricate with

lithium-based grease

11

Torque to 10 to 15 in-lb

(1.1 to 1.7 N-m)

31

Torque to 5 to 7 ft-lb

(7 to 10 N-m)

32*

Flat side faces up

13**

2

1

3

Torque to

3 to 6 ft-lb

(4 to 8 N-m)

0905

308178

11

Page 12

Parts Drawing

Model 224892, Series A, aluminum surge suppressor with PTFE diaphragm

Model 224893, Series A, aluminum surge suppressor with buna–N diaphragm

Model 224894, Series C, stainless steel surge suppressor with PTFE diaphragm

Model 224895, Series C, stainless steel surge suppressor with buna–N diaphragm

10

Torque to

10 to 15 in-lb

(1.1 to 1.7 N.m)

8

6

33

Apply sealant tape to threads

30

29

Torque to 6 to 10 ft-lb

(8 to 14 N.m)

Lubricate with

lithium-base grease

Torque to

10 to 15 in-lb

(1.1 to 1.7 N.m)

Torque to

5 to 7 ft-lb

(7 to 10 N.m)

Flat side faces up

(PTFE, 183542) **13

(buna–N, 190148)

Used on Models 224892 and

(108839) **21

224894 only

Flat side faces down

(110004) *15**

Apply sealant to threads

*32

*12

*14

19

11

31

4

* The replacements for these parts are available

in Diaphragm Plate Kit 239158. See page 14.

Purchase this kit separately.

** The replacements for these parts are available

in Diaphragm Repair Kits D05001 and D05007.

See page 14. Purchase the applicable kit

separately.

*** The replacements for these parts are available

in Repair Kits D05210, D05310, and D05270.

See page 14. Purchase the applicable kit

separately.

18*** (acetal, 186692)

(sst, 187243)

17*** (acetal, 186691)

(sst, 187242)

2

Torque to

3 to 6 ft-lb

(4 to 8 N.m)

3

9

16*** (110636)

Chamfer

faces out

12 308178

1

7

05476

Page 13

Parts Lists

Model 224892, Series A

aluminum surge suppressor with PTFE diaphragm

Model 224893, Series A

aluminum surge suppressor with buna–N

diaphragm

Ref Part

No. No. Description Qty

1 100307 NUT, hex; 3/8–16 unc–2b 4

2 100003 BOLT, cap, hex hd;

3/8–16 unc–2a x 1.5” long 4

3 111203 LOCKWASHER; 3/8” size 4

4 112499 NUT, hex; 5/16 18–8;

silver-plate sst 1

6 189540 V-CLAMP; sst 1

7 185622 COVER; aluminum 1

8 187476 HOUSING; aluminum 1

9 187477 MANIFOLD; aluminum 2

10 111530 MUFFLER 1

11 187475 SHAFT; acetal 1

12 191837* PLATE, diaphragm, fluid side; sst 1

13 183542** DIAPHRAGM, backup;

polyurethane;

used on Model 224892 only 1

190148** DIAPHRAGM; buna–N;

used on Model 224893 only 1

14 113901* SCREW, cap, hex hd;

1/4–20 unc–2a x 1.25” long; sst 1

15 *110004** O-RING; PTFE 1

16 110636*** O-RING; PTFE;

used on Model 224892 only 4

110636*** O-RING; buna–N;

used on Model 224893 only 4

17 186692*** STOP, ball; acetal 2

18 186691*** GUIDE, ball; acetal 2

19 111532 O-RING; buna–N 3

21 108839** DIAPHRAGM; PTFE;

used on Model 224892 only 1

29 100264 SCREW, machine, pan hd;

10–24 unc–2a x 5/16” long 1

30 100718 LOCKWASHER, int tooth; no. 10 1

31 102025 NUT, hex; 1/4–20; sst 1

32 191741* PLATE, diaphragm, air side; SST 1

33 100721 PLUG, pipe, headless; 1/4 npt 1

* The replacements for these parts are available in

Diaphragm Plate Kit 239158. See page 14. Purchase the

kit separately.

** The replacements for these parts are available in

Diaphragm Repair Kits D05001 and D05007. See page 14.

Purchase the applicable kit separately.

*** The replacements for these parts are available in Repair

Kits D05210, D05310, and D05270. See page 14.

Purchase the applicable kit separately.

Model 224894, Series C

stainless steel surge suppressor with PTFE

diaphragm

Model 224895, Series C

stainless steel surge suppressor with buna–N

diaphragm

Ref Part

No. No. Description Qty

1 100307 NUT, hex; 3/8–16 unc–2b 4

2 100003 BOLT, cap, hex hd;

3/8–16 unc–2a x 1.5” long 4

3 111203 LOCKWASHER; 3/8” size 4

4 112499 NUT, hex; 5/16 18–8;

silver-plate sst 1

6 189540 V-CLAMP; sst 1

7 187241 COVER; stainless steel 1

8 187476 HOUSING; aluminum 1

9 187564 MANIFOLD; stainless steel 2

10 111530 MUFFLER 1

11 187475 SHAFT; acetal 1

12 16M908* PLATE, diaphragm, fluid side;

sst machined 1

13 183542** DIAPHRAGM, backup;

polyurethane;

used on Model 224894 only 1

190148** DIAPHRAGM; buna–N;

used on Model 224895 only 1

14 113901* SCREW, cap, hex hd;

1/4–20 unc–2a x 1.25” long; sst 1

15 *110004** O-RING; PTFE 1

16 110636*** O-RING; PTFE;

used on Model 224894 only 4

110636*** O-RING; buna–N;

used on Model 224895 only 4

17 187243*** STOP, ball; stainless steel 2

18 187242*** GUIDE, ball; stainless steel 2

19 111532 O-RING; buna–N 3

21 108839** DIAPHRAGM; PTFE;

used on Model 224894 only 1

29 100264 SCREW, machine, pan hd;

10–24 unc–2a x 5/16” long 1

30 100718 LOCKWASHER, int tooth; no. 10 1

31 102025 NUT, hex; 1/4–20; sst 1

32 191741* PLATE, diaphragm, air side; SST 1

33 100721 PLUG, pipe, headless; 1/4 npt 1

* The replacements for these parts are available in

Diaphragm Plate Kit 239158. See page 14. Purchase the

kit separately.

** The replacements for these parts are available in

Diaphragm Repair Kits D05001 and D05007. See page 14.

Purchase the applicable kit separately.

*** The replacements for these parts are available in Repair

Kits D05210, D05310, and D05270. See page 14.

Purchase the applicable kit separately.

308178

13

Page 14

Repair Kits

Repair Kits must be purchased separately.

Use only genuine Graco parts and accessories.

The Ref. No. shown in the kits below correspond to the reference numbers used in the Parts List on page 13. For the

best results, use all the parts in the kit, even if the old parts still look good.

PTFE Diaphragm Kit D05001

For Models 224892 and 224894. Includes enough parts

to service the surge suppressor twice.

Ref

No. Part No. Description Qty.

13 183542 DIAPHRAGM, backup;

polyurethane 2

15 110004 PACKING, o-ring 2

16 110636 PACKING, o-ring 8

] 191779 BEARING; acetal 2

] 113704 PACKING, o-ring; FKM 2

21 108839 DIAPHRAGM; PTFE 2

] These parts are not used with the surge suppressor.

Buna-N Diaphragm Kit D05007

For Models 224893 and 224895. Includes enough parts

to service the surge suppressor twice.

Ref

No. Part No. Description Qty.

13 190148 DIAPHRAGM; buna–N 2

15 110004 PACKING, o-ring 2

16 110636 PACKING, o-ring 8

] 191779 BEARING; acetal 2

] 113704 PACKING, o-ring; FKM 2

] These parts are not used with the surge suppressor.

PTFE Ball Repair Kit D05210

For Model 224892 only. Includes enough parts to service

the surge suppressor twice.

Ref

No. Part No. Description Qty.

15 110004 PACKING, o-ring 2

16 110636 O-RING; PTFE 8

17 186691 GUIDE, ball; black acetal 4

18 186692 STOP, ball; black acetal 4

] 108639 BALL; 0.75”; PTFE 4

] These parts are not used with the surge suppressor.

Buna-N Ball Repair Kit D05270

For Model 224893 only. Includes enough parts to service

the surge suppressor twice.

Ref

No. Part No. Description Qty.

15 110004 PACKING, o-ring 2

16 110636 PACKING, o-ring 8

17 186691 GUIDE, ball; black acetal 4

18 186692 STOP, ball; black acetal 4

] 108944 BALL; 0.75”; buna–N 4

] These parts are not used with the surge suppressor.

PTFE Ball Repair Kit D05310

For Model 224894 only. Includes enough parts to service

the surge suppressor twice.

Ref

No. Part No. Description Qty.

15 110004 PACKING, o-ring 2

16 110636 O-RING; PTFE 8

17 187242 GUIDE, ball; stainless steel 4

18 187243 STOP, ball; stainless steel 4

] 108639 BALL; 0.75”; PTFE 4

] These parts are not used with the surge suppressor.

Buna-N Ball Repair Kit D05370

For Model 224895 only. Includes enough parts to service

the surge suppressor twice.

Ref

No. Part No. Description Qty.

15 110004 PACKING, o-ring 2

16 110636 PACKING, o-ring 8

17 187242 GUIDE, ball; stainless steel 4

18 187243 STOP, ball; stainless steel 4

] 108944 BALL; 0.75”; buna–N 4

] These parts are not used with the surge suppressor.

] These parts are not used with the surge suppressor.

Diaphragm Plate Kit 239158

For all models.

Ref

No. Part No. Description Qty.

12 16M908 PLATE, diaphragm, fluid,

sst machined 1

14 113901 SCREW, flange, hex-head;

1/4–20 x 1.25 1

15 110004 PACKING, o-ring; PTFE 1

32 191741 PLATE, diaphragm, air side 1

14 308178

Page 15

Dimensional Drawing

air exhaust muffler: 1/2 npt

air inlet:

1/4 npt(f)

height:

8.78 in.

(223 mm)

fluid outlet:

3/4 npt(f)

width across clamp:

7.38 in. (187.5 mm)

fluid inlet:

3/4 npt(f)

inlet-to-outlet length:

7.74 in. (196.6 mm)

total length:

8.40 in. (213.4 mm)

0903

308178

15

Page 16

Technical Data

Maximum fluid working pressure 100 psi (0.7 MPa, 7 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air pressure operating range 25 to 100 psi (0.18 to 0.7 MPa, 1.75 to 7 bar). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum free flow delivery 16 gpm (60 l/min). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air inlet 1/4 npt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air exhaust 1/2 npt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid inlet. 3/4 npt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid outlet 3/4 npt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted parts Model 224892: acetal, aluminum, PTFE,. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

316 stainless steel

Model 224893: acetal, aluminum, PTFE,

buna–N, 316 stainless steel

Model 224894: 316 stainless steel, PTFE

Model 224895: 316 stainless steel, buna–N, PTFE

Non-wetted Parts Models 224892 and 224894:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

acetal, aluminum, buna–N,

polyurethane, bronze, plated steel,

polyester (labels)

Models 224893 and 224895:

acetal, aluminum, buna–N,

bronze, plated steel, polyester (labels)

Weight Models 224892 and 224893: 10 lb (4.6 kg). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 224894 and 224895: 14 lb (6.4 kg)

16 308178

Page 17

Notes

308178

17

Page 18

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the distributor closest to you:

Phone: 612–623–6921 or Toll Free: 1–800–328–0211 Fax: 612–378–3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

18 308178

Original Instructions. This manual contains English. MM 308178

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES

Copyright 1991, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco Headquarters: Minneapolis

S P.O. BOX 1441 S MINNEAPOLIS, MN 55440-1441 S USA

www.graco.com

Revised 1/2012

Loading...

Loading...