Page 1

Instructions – Parts List

Parts

Mascott Equipment Co

Portland Seattle Pasco

(800) 452-5019 (800) 481-7311 (888) 450-7867

Air Filters, Lubricators,

and Kits

Maximum Temperature Range: 40–150_F (4–65_C)

Important Safety Instructions.

Read all warnings and instructions in this manual.

Save these instructions.

Air Filters

217074

106148

106149

106150

112859

110146

Air Lubricators

214847

214848

214849

237212

308169J

110148

Air Filter–Regulators–Lubricators

110150

217072

217073

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 1991, Graco Inc. is registered to I.S. EN ISO 9001

110149

Integral Filter–Regulators

15C955

246947

246948

246946

Page 2

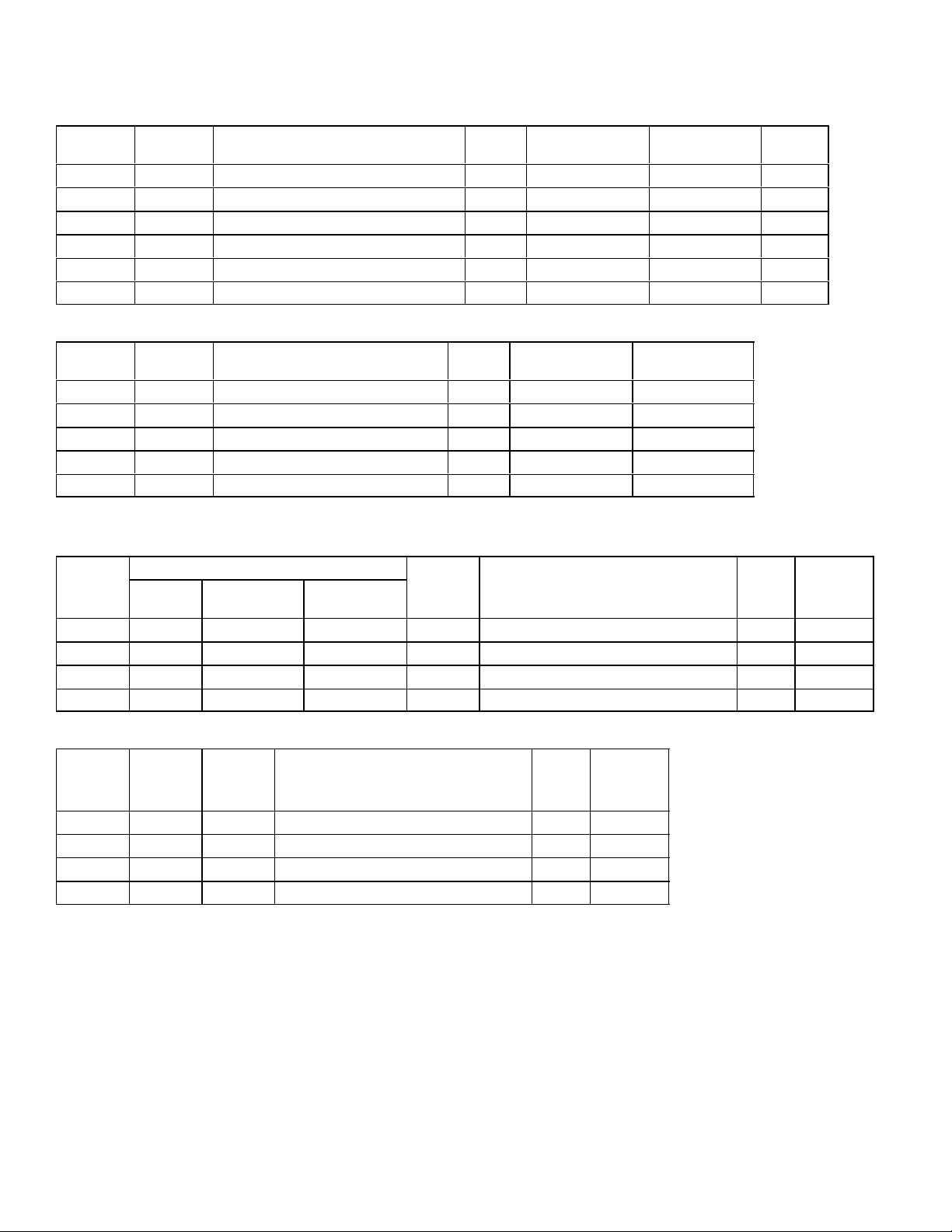

Air Filters

List of Models

Model

No.

110146 22 (0.62) Husky 715, Prince, Fast–Flo, Fast–Ball 1/4 npt 300 (21) 1 (30) 20

106148 77 (2.2) President, Fire–Ball, Monark 3/8 npt 250 (17.5) 5 (150) 20

106149 106 (3.0) Bulldog, Senator, Glutton 1/2 npt 250 (17.5) 8 (240) 20

217074 106 (3.0) Bulldog, Senator, Glutton 1/2 npt 250 (17.5) 8 (240) 40

106150 250 (7.0) King 3/4 npt 250 (17.5) 16 (480) 40

112859 350 (10.0) Premier 1 npt 250 (17.5) 16 (480) 40

Max.

SCFM

Pump/System

Application

Inlet/

Outlet

Maximum WPR*

psi (bar)

Bowl Capacity

oz (ml)

Filter

Micron

Air Lubricators

Model

No.

110148 12 (0.34) Husky, Prince, Fast–Flo, Fast–Ball 1/4 npt 300 (21) 1 (30)

214847 88 (2.5) President, Fire–Ball, Monark 3/8 npt 250 (17.5) 5 (150)

214848 127 (3.6) Bulldog, Senator, Glutton 1/2 npt 250 (17.5) 8 (240)

214849 290 (8.1) King 3/4 npt 250 (17.5) 16 (480)

237212 320 (9.2) Premier 1 npt 250 (17.5) 16 (480)

Max.

SCFM

Pump/System

Application

Inlet/

Outlet

Maximum WPR*

psi (bar)

Bowl Capacity

oz (ml)

Air Filter–Regulator–Lubricator Kit

(F–R–L)

Includes Maximum

Model

No.

110149 110146 110318 110148 110319 Husky 715, Prince, Fast-Flo, Fast-Ball 1/4 npt 300 (21)

110150 106148 110234 214847 101689 President, Fire–Ball, Monark, Standard 3/8 npt 250 (17.5)

217072 106149 104266 214848 101689 Bulldog, Senator, Glutton, Husky 1030 1/2 npt 250 (17.5)

217073 106150 207755 214849 101689 King 3/4 npt 250 (17.5)

FILTER REGULATOR LUBRICATOR GAUGE Pump/System

Application

Inlet/

Outlet

WPR*

psi (bar)

Integral Filter–Regulators

Maximum

Model

No.

246946 15C956 C36260 Husky 205, 307, 515/716 1/4 npt 250 (17.5)

246947 15C955 C36260 Husky 1040, 1590, and 2150 1/2 npt 250 (17.5)

246948 15C955 C36260 Husky 3275 3/4 npt 250 (17.5)

15C955 n/a n/a n/a 1/2 npt 250 (17.5)

2 308169

FILTER GAUGE Pump/System

Application

Inlet/

Outlet

WPR*

psi (bar)

Page 3

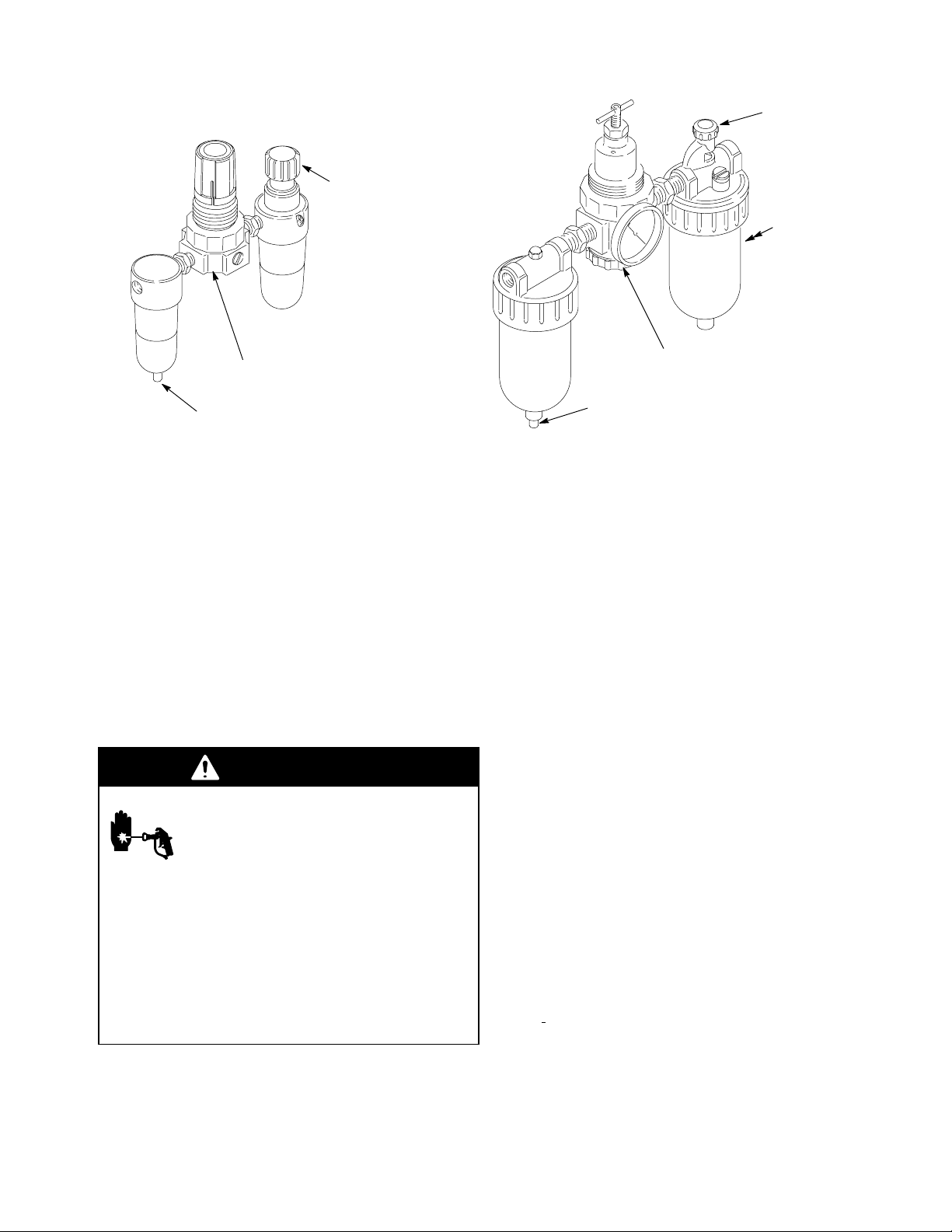

Installation

Model 110149 Model 110150

217072

217073

LUBRICATOR

ADJUSTMENT

KNOB

AIR REGULATOR

AIR FILTER DRAIN

Before installing any air line components, blow out the

pipe line to remove scale and other debris. Use pipe compound or tape sparingly and only on male threads.

Install the components in the pipe line so the flow is in the

direction of the arrow stamped on the body.

Locate the air line component(s) as close as possible to

the equipment it serves.

Install the air filter upstream from the regulator and/or lubricator.

To provide the user with a variety of assembly options, a

bleed–type master air valve is not included with FRL’s.

See Accessories on page 15 to order this valve. Another

bleed–type master air valve can be installed upstream

from the FRL to isolate it for servicing.

WARNING

Air Filter

Clean the air filter regularly to maximize filtering efficiency and to avoid excessive pressure drop. Drain contaminants from the bowl before it reaches the baffle level.

Open the drain to drain the bowl or fully relieve pressure

and remove the bowl. Use household soap and water or

denatured alcohol for cleaning. Use compressed air to

blow out the filter body. Wash the filter element and blow

it out from the inside. Clean the sight glass thoroughly. Do

not leave solvent residue in the sight glass, which may attack or weaken it. If the sight glass appears damaged by

the solvent, replace it immediately.

An automatic drain accessory, Part No. 106151, is available for most filters, except Model 110146. To install the

drain, fully relieve system pressure, remove the o–ring

and bowl. Remove the drain from the bowl and insert the

automatic drain in its place. Reassemble.

Skin Injection Hazard

To reduce the risk of serious bodily

injury, including skin injection, splashing

fluid in the eyes or on the skin, or injury

from the pump starting unexpectedly, be

sure your system includes a

bleed–type master air valve.Install the

air valve between the FRL outlet and the

device the FRL is serving. When

relieving system air pressure, close the

bleed–type master air valve to fully

relieve air pressure.

Mounting Air Accessories

Use a bracket to mount the air accessories to a wall or

cart. Do not hang the accessories directly off the air motor inlet, which could be damaged from the weight and

operating stress.

Regulator

The regulator reduces the air supply pressure to a specified, constant downstream pressure to maximize equipment performance. Preset pressures can be locked in.

See manual 308167 or 308168 (supplied with the FRL’s)

for complete air regulator information.

Lubricator

The lubricator meters oil into the moving air stream to lubricate air-operated motors. A manual adjustment in the

housing sets the oil drip rate into the air stream, which

can be monitored through a sight glass on most lubricators. One to two drops of oil a minute is a common adjustment. Use Graco motor oil, part no. 202659. All lubricators, except Model 110148, can be refilled with the

system pressurized. However, ALWAYS relieve the system pressure before removing the bowl for any reason.

LUBRICATOR

ADJUSTMENT

KNOB

LUBRICATOR

SIGHT

GLASS

(NOT VISIBLE FROM

THIS VIEW)

AIR REGULATOR

AIR FILTER DRAIN

3308169

Page 4

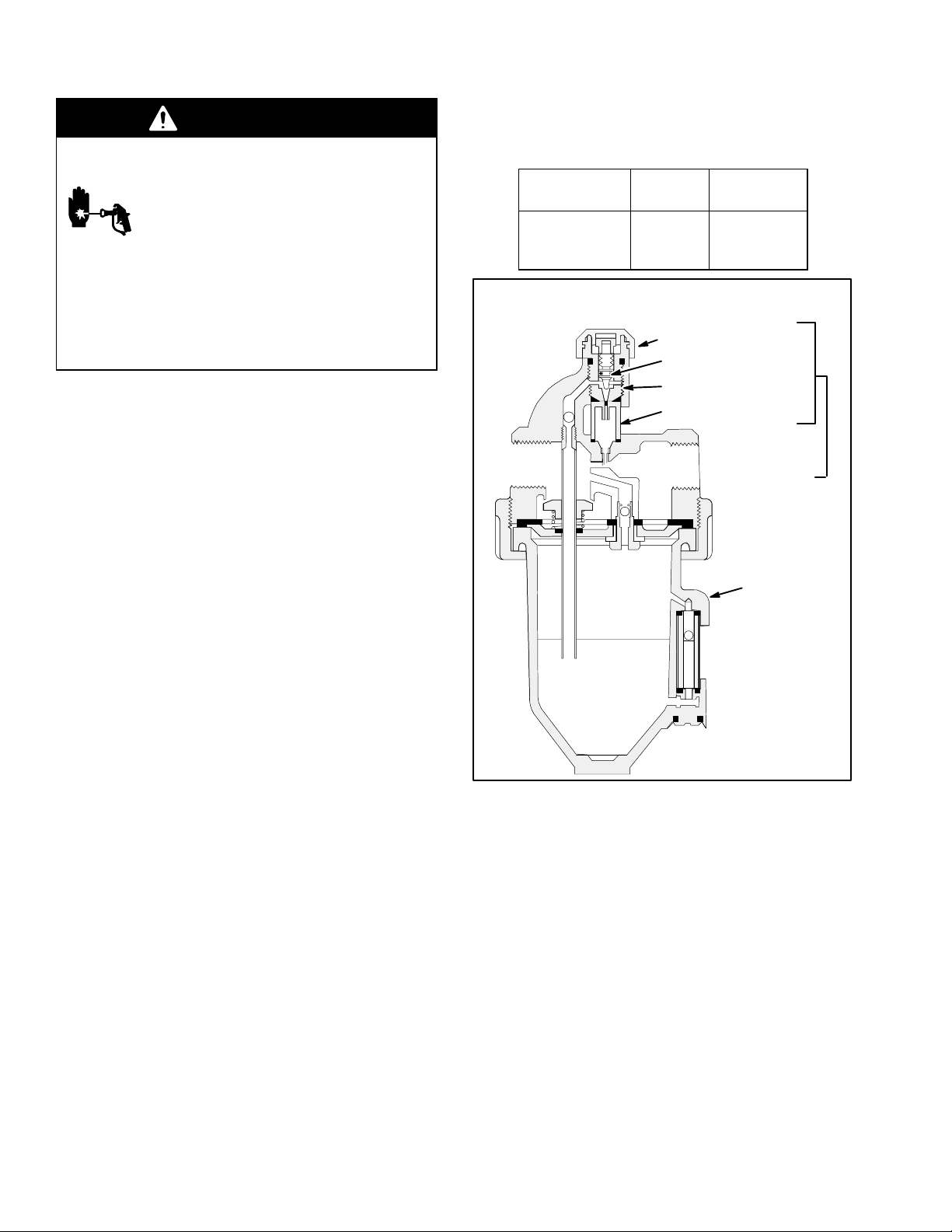

Service

WARNING

Relieve air and fluid pressure

before servicing the regulator, filter or

lubricator.

To reduce the risk of serious bodily injury, fluid injection, splashing in the eyes

or skin, injury from moving parts, ALWAYS open the bleed–type master air

valve (required) to relieve system air

pressure and trigger the gun or dispense valve and open any fluid drain

valves to relieve fluid pressure.

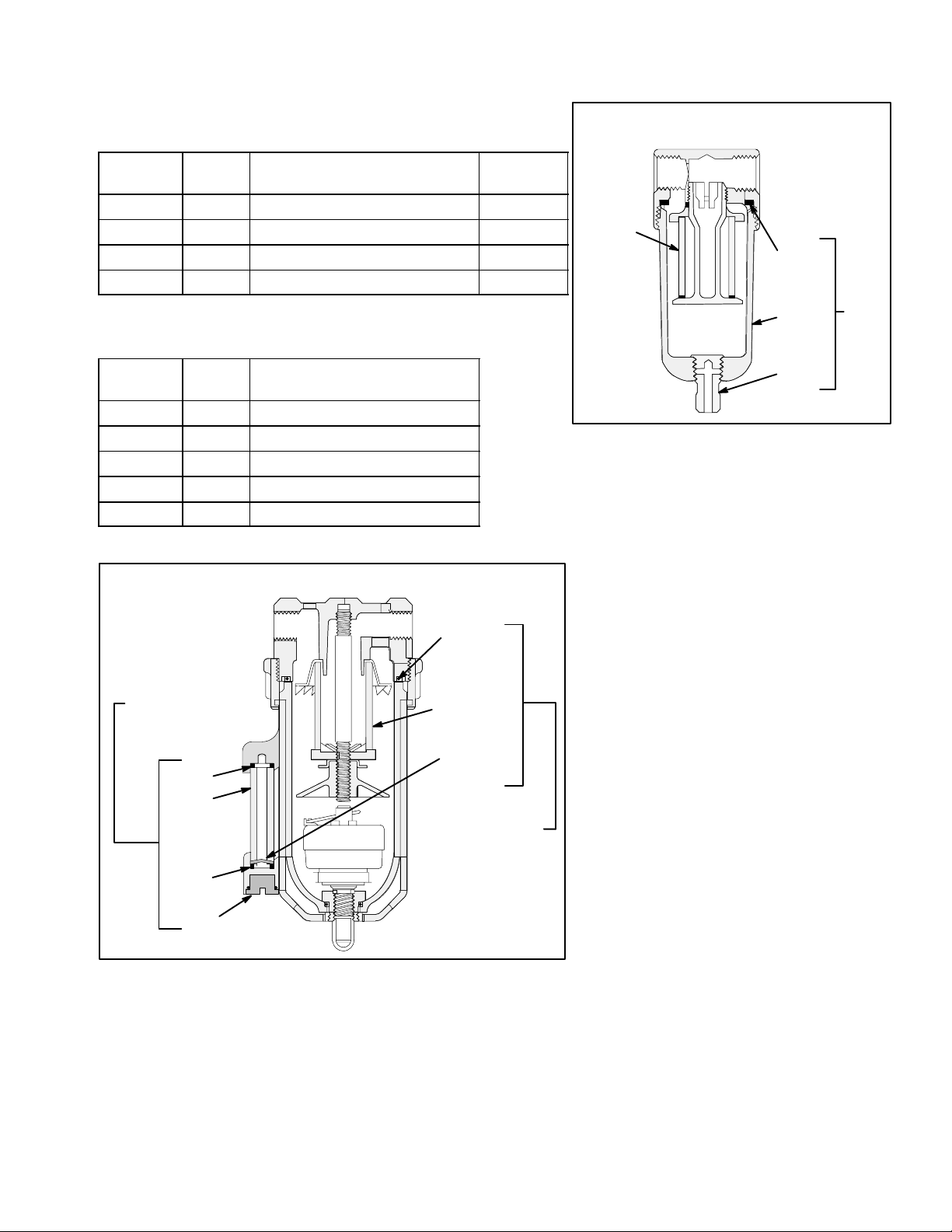

1. Disassemble the component. Refer to the illustrations on pages 4 and 5.

Repair Kits

Lubricator Repair Kits

For

Lubricator

214847

214848

214849

Lubricator 214847, 214848, 214849, 237212

Kit No. Description

102774 Repair Kit

ADJUSTABLE CAP

VALVE NEEDLE ASSY.

VALVE SEAT

FILLER PLUG

2. Use household soap and water or denatured

alcohol for cleaning. Wipe the parts clean with a

clean, soft, dry rag. Use compressed air to blow

dirt and contaminants out of the lubricator or filter

body.

3. Inspect all parts for wear or damage. Replace

damaged parts. Use all parts supplied with the kit.

NOTE: The chart identifies the available repair kits for the

air filters and lubricators covered in this manual. The cutaway drawings shown on pages 5 and 6 show the contents of the kits.

KIT 102774

BOWL

(see chart)

0940

4 308169

Page 5

Service

Filter Elements & Bowl Seals

For

Filter

Kit No. Description Bowl Seal

Part No.

106149 108035 1/2 in., 20 micron filter element 162440

106150 106204 3/4 in., 40 micron filter element 104023

112859 ––––– 1 in., 40 micron filter element –––––

110146 111690 1/4 in., 20 micron filter element N/A

Sight Glass Kits

For

Kit No. Description

Filter

106148 104991 3/8 in. sight glass

106149 104992 1/2 in. sight glass

106150 104993 3/4 in. sight glass

112859 104993 1/2 in. sight glass

217074 106197 1/2 in. sight glass

Air Filter 110146

FILTER

ELEMENT

GASKET

BOWL

DRAIN

BOWL

KIT

0939

Air Filter 106148, 106149, 106150, 112859,

217074

SIGHT GLASS KIT

104991, 104992,

104993, 106197

O-RING

SIGHT

GLASS

O-RING

PLUG

BOWL SEAL KIT

106202,106204,

106205, 106206,

108034, 108035

0938

BOWL SEAL

FILTER

ELEMENT

INDICATOR

FLOAT

5308169

Page 6

Service

Filter Bowl Replacement Kits with Seal

For

Filter

116521 116672 3/4 in. port, bowl

15C955 116672 1/2 in. port, bowl

15C956 248085 1/4 in. port, bowl

Filter Element Kit with Gasket

For

Filter

116521 116635 3/4 in. 40 micron

15C955 116635 1/2 in. 40 micron

15C956 248087 1/4 in. 40 micron

Kit No. Description

w/sight glass

w/sight glass

w/sight glass

Kit No. Description

filter element

filter element

filter element

Regulator Repair Kit

For

Filter

116521 116634 3/4 in. valve and

15C955 116634 1/2 in. valve and

15C956 248086 1/4 in. valve and

Kit No. Description

diaphragm

diaphragm

diaphragm

6 308169

Page 7

Parts

3/8 npt(f)

2

1/4 npt(f)

OUTLET

4

OUTLET

1/4 npt(f)

INLET

3

1

5

Model 110149, Series A

Includes items 1–5

Ref

No. Part No. Description Qty

1 110146 FILTER 1

2 110318 REGULATOR (see 308167) 1

3 110148 LUBRICATOR 1

4 110321 MOUNTING BRACKET 1

5 110319 1/8 in. GAUGE 1

3/8 npt(f)

INLET

0926

4

2

1

Model 110150, Series B

Includes items 1–5

Ref

No. Part No. Description Qty

1 106148 FILTER 1

2 110234 REGULATOR (see 308167) 1

3 214847 LUBRICATOR 1

4 101689 1/4 in. GAUGE 1

3

7308169

Page 8

Parts

4

1/2 npt(f)

OUTLET

1/2 npt(f)

INLET

5

0926

2

1

Model 217072, Series A

Includes items 1–5

Ref

No. Part No. Description Qty

1 106149 FILTER 1

2 104266 REGULATOR (see 308167) 1

3 214848 LUBRICATOR 1

4 106145 MOUNTING BRACKET 2

5 101689 GAUGE 1

4

3/4 npt(f)

OUTLET

3/4 npt(f)

INLET

3

5

2

0926

3

1

Model 217073, Series A

Includes items 1–5

Ref

No. Part No. Description Qty

1 106150 FILTER 1

2 207755 REGULATOR (see 308167) 1

3 214849 LUBRICATOR 1

4 106145 MOUNTING BRACKET 2

5 101689 GAUGE 1

8 308169

Page 9

Parts

2

2

1

1

Model 15C955, 246947, and 246948

Model 246946

Ref

No. Part No. Description Qty

1 15C956 REGULATOR, filter, air; 1/4 npt 1

2 C36260 GAUGE, pressure, air 1

Ref

No. Part No. Description Qty

1 15C955 REGULATOR, filter, air 1/2 npt 1

Model 246947

116521 REGULATOR, filter, air 3/4 npt 1

Model 246948

2 C36260 GAUGE, pressure, air 1

Models 246947 and 246948 only

9308169

Page 10

Dimensions

Air Filter

Model

No.

110146 1/4 npt 1.6 (40) 4.0 (102) 3.6 (91)

106148 3/8 npt 2.5 (64) 6.0 (143) 3.1 (79)

106149 1/2 npt 3.3 (83) 6.8 (174 ) 6.3 (159)

217074 1/2 npt 3.0 (76) 7.5 (191) 6.6 (168)

106150 3/4 npt 4.0 (102) 8.8 (222) 7.8 (198)

112859 1 npt 4.5 (114) 8.8 (222) 7.9 (201)

Model 110146

B

C

A

Inlet/

Outlet

Width (A)

in. (mm)

Model 106148

106149

106150

112859

A

B

C

Height (B)

in. (mm)

Height (C)

in. (mm)

Model 217074

B

C

Lubricators

Model

No.

110148 1/4 npt 1.5 (39) 5.0 (126) 3.0 (76)

214847 3/8 npt 2.5 (64) 7.2 (182) 4.8 (122)

214848 1/2 npt 3.3 (83) 7.9 (201) 5.6 (142)

214849 3/4 npt 4.0 (103) 9.9 (251) 7.3 (184)

237212 1 npt 4.0 (103) 9.9 (251) 7.3 (184)

A

0929

0930

0932

Inlet/

Outlet

Width (A)

in. (mm)

Model 110148

B

C

Height (B)

in. (mm)

Height (C)

in. (mm)

Model 214847

214848

214849

237212

A

A

B

C

0934

0935

Integral Filter–Regulators

Model

No.

246946 1/4 npt 2–3/8

246947 1/2 npt 3.375

246948 3/4 npt 3.375

B

C

Models 15C955,

246947, 246948

A

Inlet/

Outlet

Width (A)

in. (mm)

(60.32)

(85.73)

(85.73)

Height (B)

in. (mm)

9.563

(242.87)

11.375

(288.93)

11.375

(288.93)

B

C

Model 246946

Height (C)

in. (mm)

4.938

(125.41)

6.5 (165)

6.5 (165)

A

TI3969

TI3970

10 308169

Page 11

Filter–Regulator–Lubricators

Dimensions

Model

No.

110149 1/4 npt 5.1 (130) 5.1 (130) 3.5 (89) 1.6 (40)

110150 3/8 npt 8.8 (222) 9.6 (244) 5.4 (137) 4.1 (105)

217072 1/2 npt 8.1 (206) 10.4 (263) 5.8 (146) 4.0 (105)

217073 3/4 npt 15.8 (400) 13 (330) 7.8 (197) 5.0 (127)

Model 110149

B

Inlet/

Outlet

C

Width (A)

in. (mm)

A

Height (B)

in. (mm)

D

Height (C)

in. (mm)

Depth (D)

in. (mm)

Models 110150, 217072, 217073

B

C

A

D

0926

0924

11308169

Page 12

Air Filter Flow Curves

Model 110146

5

4

3

2

1

PRESSURE DROP – psi (bar)

0

0 5 10 15 20 25

Model 106149

5

4

3

2

Inlet Pressure

Air Flow (SCFM)

Inlet Pressure Inlet Pressure

Model 106148

5

4

3

2

1

PRESSURE DROP – psi (bar)

0

0 1020304050

Model 217074

5

4

3

2

Inlet Pressure

Air Flow (SCFM)

1

PRESSURE DROP – psi (bar)

0

0 102030405060708090100110

Model 110148

5

4

3

2

1

PRESSURE DROP – psi (bar)

0

0 102030405060

Air Flow (SCFM)

Inlet Pressure

Air Flow (SCFM)

1

PRESSURE DROP – psi (bar)

0

0 20406080100120

Air Flow (SCFM)

Model 106150 Inlet Pressure

5

4

3

2

1

0

PRESSURE DROP – psi (bar)

0 40 80 120 160 200 240 280

Air Flow (SCFM)

12 308169

Page 13

Air Filter Flow Curves

Model 112859 Inlet Pressure

6

5

4

3

2

1

PRESSURE DROP – psi (bar)

0

0 40 80 120 160 200 240 280 320 360 400

25

PSIG

Air Flow (SCFM)

100

PSIG

Model 246946

100

80

60

40

20

Reduced Pressure (PSIG)

–02

–03

–04

Air Flow (SCFM)

Models 246947 and 246948

Standard 40 Micron Element Supply Pressure 100 psig

80

10080604020

3/8”

3/4”& 1”

1/2”

60

1/4”

3/4”& 1”

40

20

PRESSURE DROP – psi (bar)

0

0

1/4”

3/8”

1/4”

3/8”

Air Flow (SCFM)

1/2”

1/2”

3/4”& 1”

25020015010050

13308169

Page 14

Notes

14 308169

Page 15

Accessories

Gauges

Model Air Pressure

Range

160430 0–100 psi (7 bar) 1/4 npt Black 2 in. (51 mm) 1 102019

101689 0–200 psi (14 bar) 1/4 npt Black 2 in. (51 mm) 1 102019

101180 0–200 psi (14 bar) 1/4 npt Chrome 2 in. (51 mm) 1 102019

101689 0–200 psi (14 bar) 1/4 npt Chrome 2 in. (51 mm) 2 102019

Inlet Type of

Case

Dial Dia. Style Glass

P/N

Bleed Type Master Air Valve

Part No. Description

107141 3/4 npt (m x f)

107142 1/2 in. npt (m x f)

110223 1/4–18 npt (fbe)

110224 3/8–18 npt (fbe)

110225 1/2–14 npt (fbe)

110226 3/4–14 npt (fbe)

Style 1 (Bottom Inlet)

Style 2 (Back Inlet)

106151 AUTOMATIC DRAIN

Installs in place of standard drain

for automatic drain. For all models except 110146.

202659 AIR MOTOR OIL

For use in lubricators.

114598 MOUNTING BRACKET

Includes two brackets and is

used for 1 in. pipe.

15308169

Page 16

Graco Standard Warranty

u

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–328–0211 Toll Free

1–612–623–6921

1–612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of p

Graco reserves the right to make changes at any time without notice.

16 308169

MM 308169

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

www.graco.com

PRINTED IN USA 308169 12/2003 Rev. 02/2006

Loading...

Loading...