Page 1

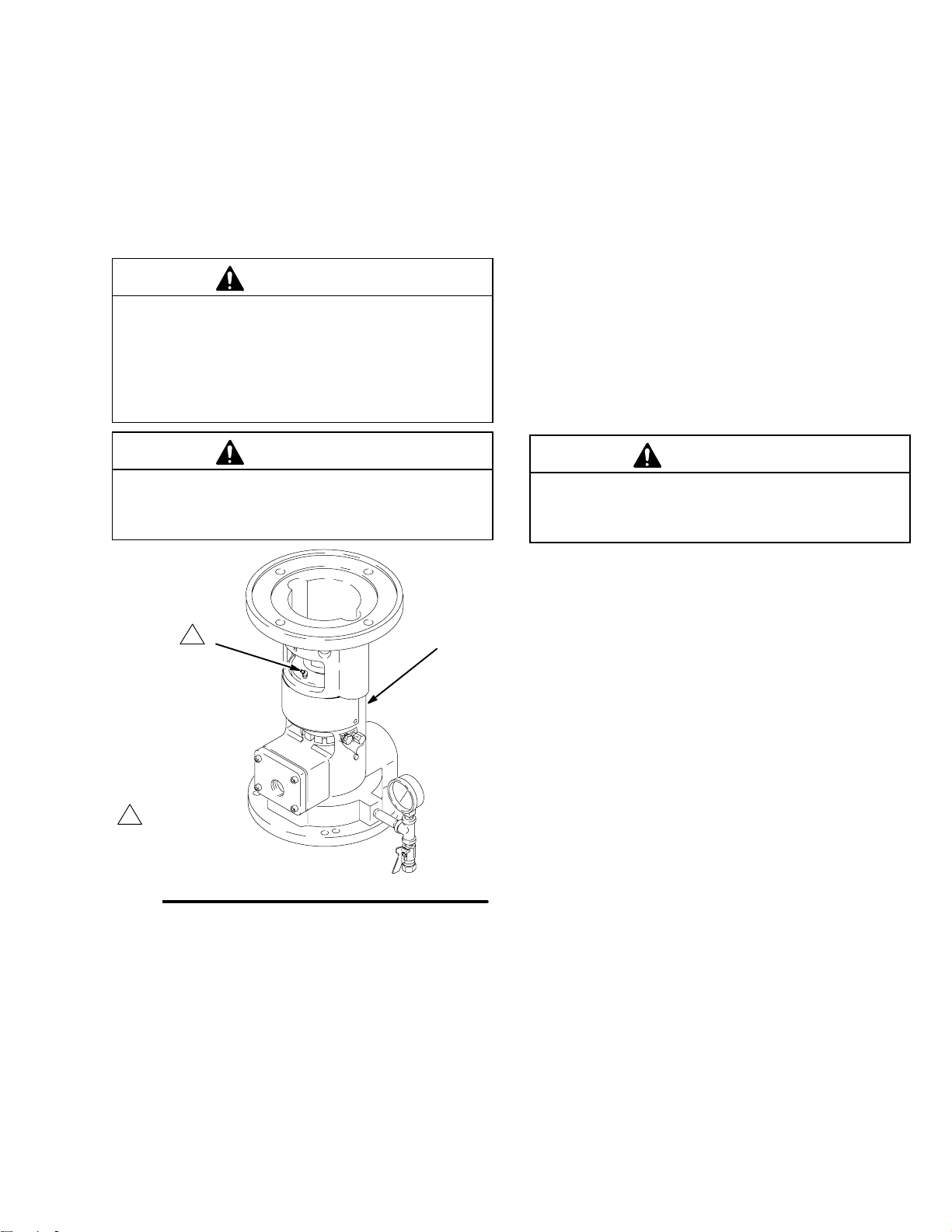

Instructions – Parts List

Parts

FREE-STANDING; CORROSION-RESISTANT OR WATERBORNE

Crown Imperial Pumps

250 psi (1.7 MPa, 17 bar) Maximum Working Pressure

Electric, Multi-Stage, Centrifugal,

Open Stand-Mounted Pumps for Circulating Systems

Read warnings and instructions.

See page 2 for table of contents and list of

models.

308059L

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 2002, Graco Inc. is registered to I.S. EN ISO 9001

Motor and Stand

Not Included

with Pump

03118

Page 2

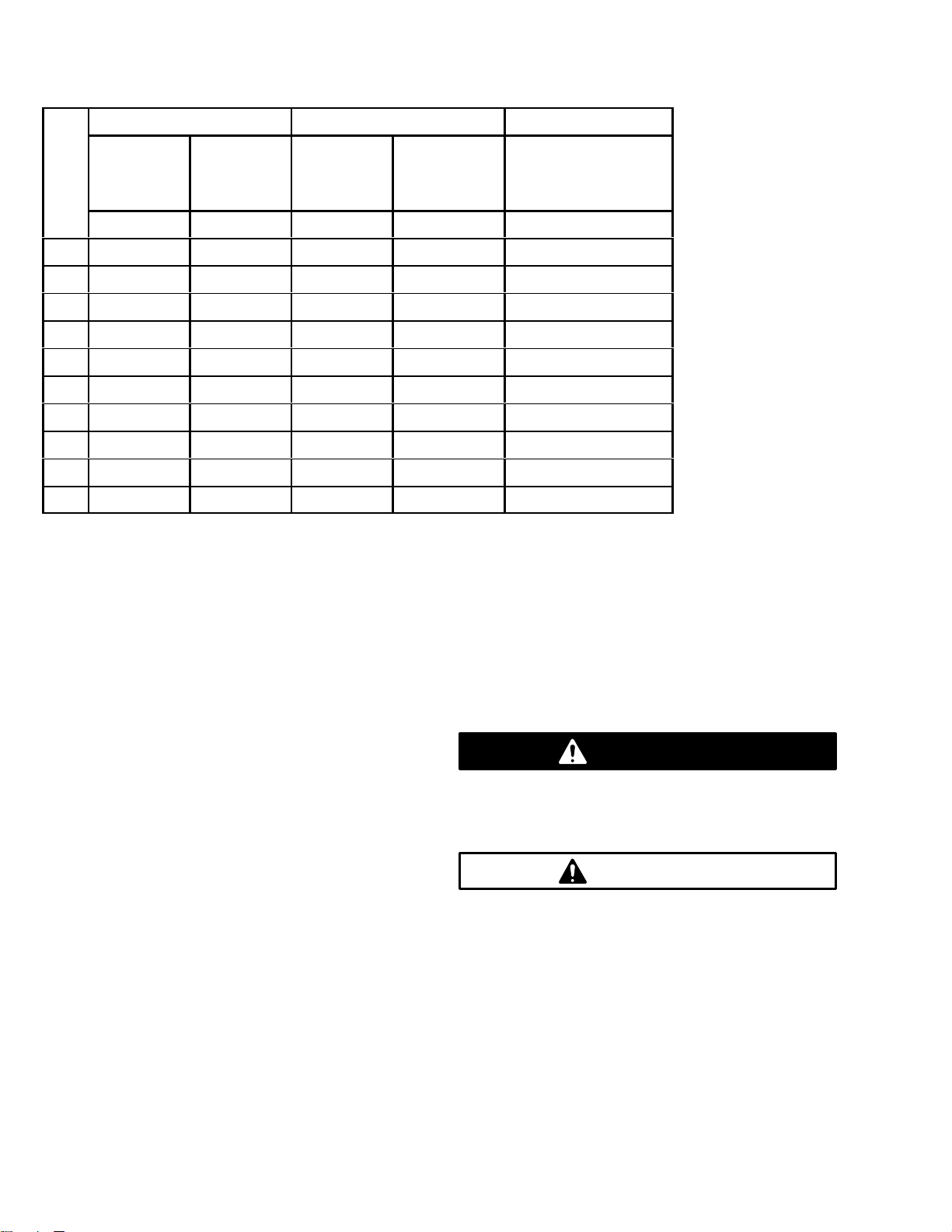

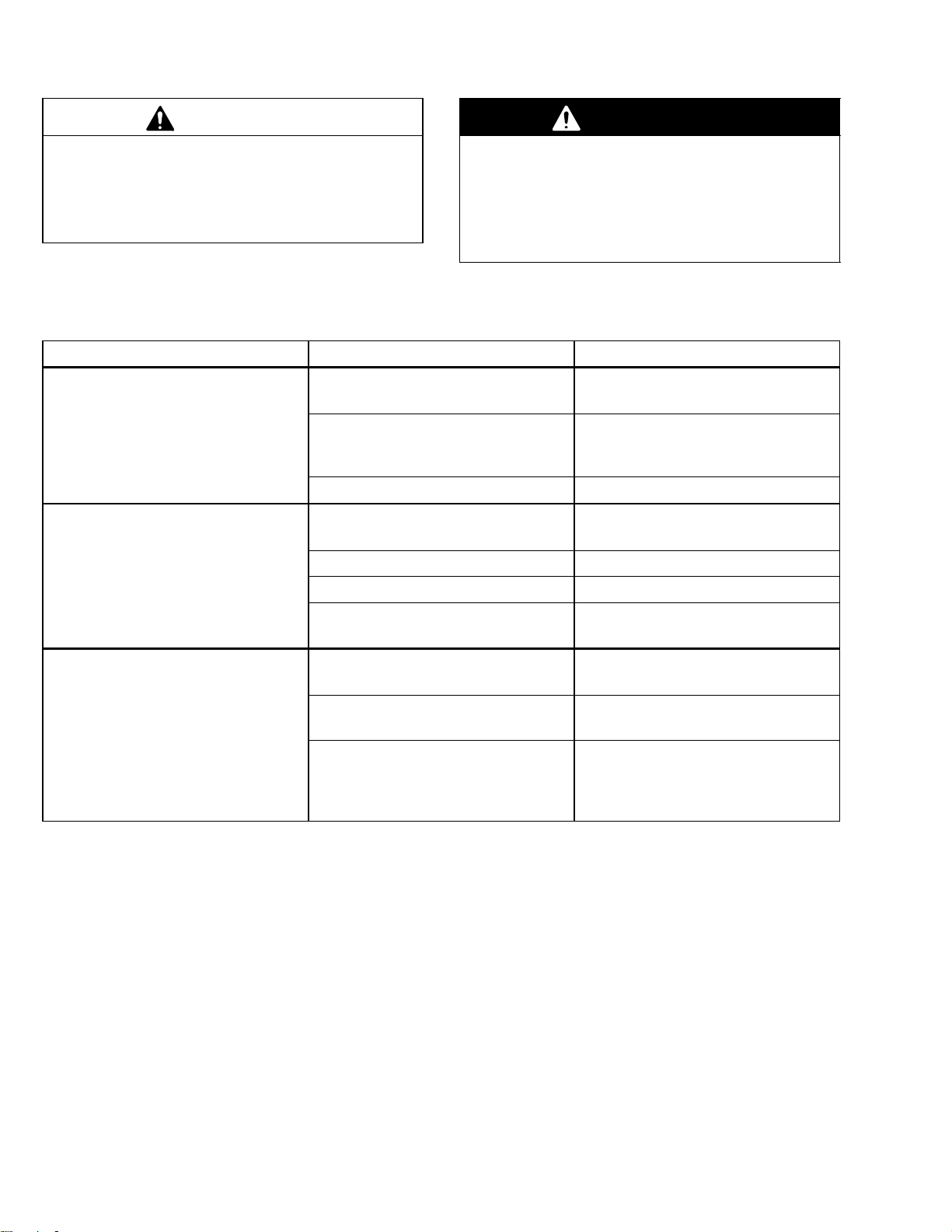

Models

CORROSION-RESISTANT WATERBORNE WATERBORNE HD

No.

of

Stag

es

10 223910 224010 224110 224210 249103

11 223911 224011 224111 224211 249104

12 223912 224012 224112 224212 249105

13 223913 224013 224113 224213 249106

14 223914 224014 224114 224214 249107

15 236615 236715 249108

Standard

Size for 60”

High Tanks

Model No. Model No. Model No. Model No. Model No.

6 223906 224006 224106 224206

7 223907 224007 224107 224207

8 223908 224008 224108 224208

9 223909 224009 224109 224209

High Profile

for 85” High

Tanks

Standard

Size for 60”

High Tanks

High Profile

for 85” High

Tanks

Standard Size for 60”

High Tanks

Pump mounting stands

Purchase separately.

218631 for Standard-size pump

220266 for High Profile-size pump

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preventive Maintenance 9. . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 36. . . . . . . . . . . . . . . . . . . . . .

Graco Information 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

corresponding instructions.

2 308059

Page 3

INSTRUCTIONS

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

Do not alter or modify this equipment.

Check equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

Technical Data on page 34 for the maximum working pressure of this equipment.

Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

Wear hearing protection when operating this equipment.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

Ground the equipment. Refer to Grounding on page 5.

If there is any static sparking or you feel an electric shock while using this equipment, stop spray-

ing immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

Consult the electric motor manufacturer for the proper heater-breaker requirements.

MOVING PARTS HAZARD

Moving parts in the pump housing can pinch or amputate your fingers.

Keep clear of all moving parts when starting or operating the pump.

Keep all tools, etc. away from the moving parts to reduce the risk of accidentally catching and

breaking them.

Before servicing the equipment, shut off the electric power, relieve the pressure, and drain the

pump by opening the drain valve at the pump base.

HOT SURFACE HAZARD

The pump housing and pump shaft couplers become hot during operation. To reduce the risk of

burning yourself, do not touch them until they have cooled.

3308059

Page 4

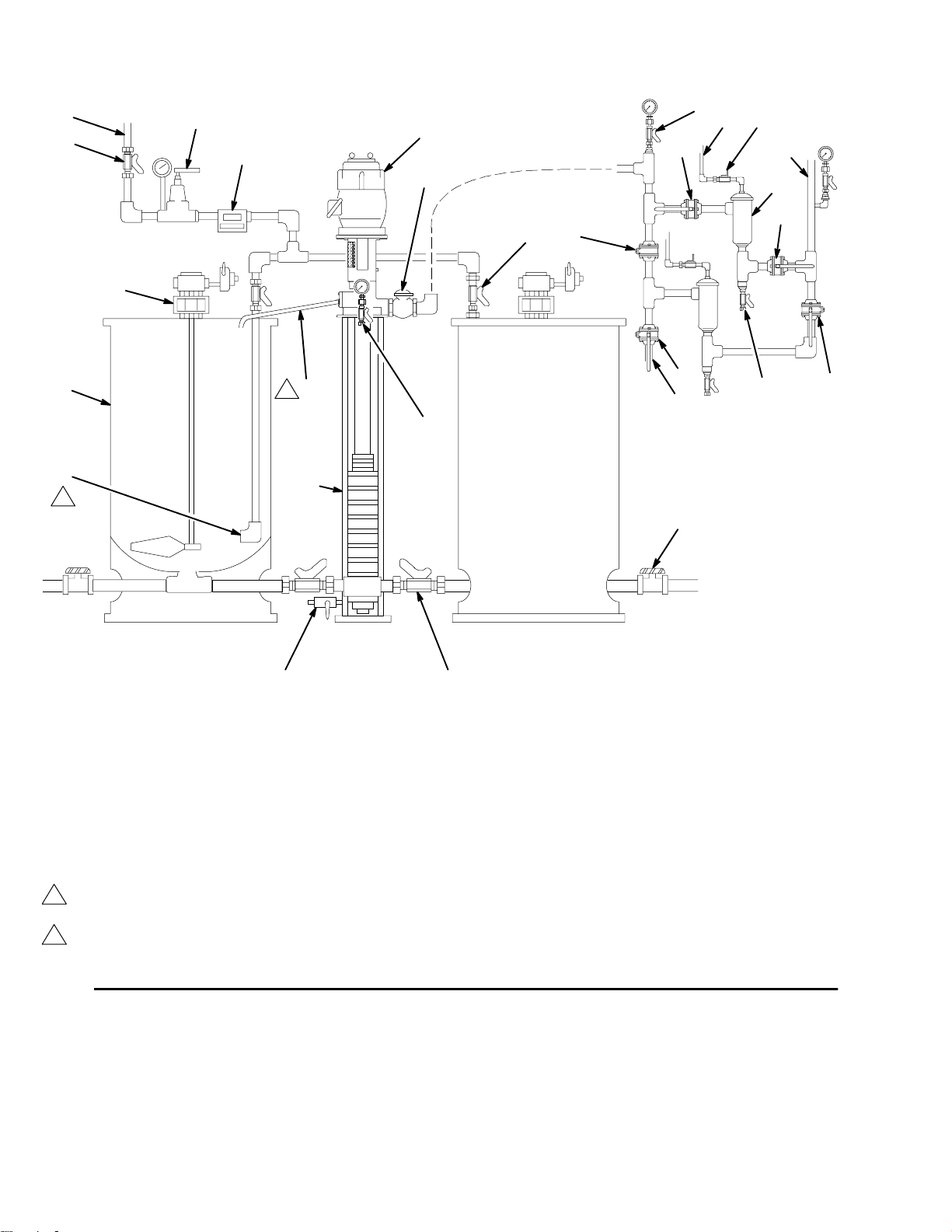

Installation

E

D

F

H

G

L

MN

Q

O

J

P

Q

KS

C

AA

B

Z

1

QR

T

U

A

2

V

X

YW

KEY

A Elbow

B Mix Tank

C Agitator

D Shutoff Valve, Return Line

E Return Line

F Back Pressure Valve

G Flow Meter

H Motor

1

Install drain tube at a maximum downward slope to the tank, with a minimum of 1/4 in. (6mm) per foot of tube.

To minimize turbulence, extend return line to bottom of tank

2

and use elbow to direct flow around perimeter of tank.

J Check Valve

K Tank Shutoff Valve

L Pressure Gauge with Pulsa-

tion Dampener and Isolation

Valve

M Open to Air

N Air Blowdown Valve

O To Spray Booth

P Fluid Filter

Q Line Isolation Valve

R Filter Drain Valve

S Standby Pump/System Blow-

down Connection Valve

T To Standby Pump

U Outlet Pressure Gauge with

Drain Valve

Fig. 1

03119

V Open Stand

W Outlet Shutoff Valve

X Tank Drain Valve

Y Pump Drain Valve

Z Drain Tube

AA Safety Isolation Valve

4 308059

Page 5

Installation

Grounding

WARNING

Ground the pump in accordance with all applicable

safety codes in your area. Proper grounding reduces the risk of shock, fire, or explosion caused

by static sparking, which can result in serious injury

and property damage.

1. Have a licensed electrician complete the electrical

hookup and wiring.

2. Consult the electric motor manufacturer for proper

heater-breaker requirements.

3. Before coupling the pump coupler to the motor

shaft coupler, check to be sure the shaft rotates in

the proper direction. Refer to Fig. 3, page 6.

System Design

The Typical Installation shown on page 4, and the

following text, is only a guide to show the relationship

of the pump to other system components. Due to the

pressure characteristics of the pump, which vary

widely with viscosity and specific gravity, professional

systems design is essential. Contact Graco (see back

page) for further information.

Return Line

Install a back pressure valve (F) to maintain proper line

pressure to all outlets. Install a flow meter (G) to

visually check the fluid flow rate.

Extend the return line (E) going into the mix tank (B) to

the bottom of the tank and end it with an elbow (A).

The elbow directs fluid around the walls of the tank to

help minimize air entrainment in the fluid.

Supply Line

Install a line check valve (J) near the 2 in. npt(f) pump

outlet.

CAUTION

The line check valve (J) is required to prevent fluid

backflow into the pump in case of a power failure or

incorrect operating procedure.

Install a pressure gauge (G) at the plugged 1/2 npt(f)

port at the left of the pump outlet. Make sure the

gauge is correctly rated for the operating pressure.

Fluid Filters

Install two fluid filters (P) with line isolation valves (Q)

on each side. This allows the system to be used while

cleaning a filter.

Pump dimensions and the mounting hole layout are

shown on page 30. The Technical Data is given on

page 32.

Fluid Lines

Line sizes depend on the flow requirements and calculated pressure drop due to the length of the run.

The pipe, tubing and fittings must be compatible with

the fluid and solvent you plan to use.

Keep in mind that sharp corners and fittings between

lengths of pipe or tubing may cause flow restrictions

and fluid breakdown. Use the longest lengths of pipe or

tubing available to minimize couplings. Use the most

direct route to the spray stations, and whenever practical, use long sweeping bends. A “holsclaw” bender is

recommended for making bends in tubing; a common

electrician’s or plumber’s bender is not satisfactory.

Remove burrs, dirt and contaminants from the ends of

the tubes before installing the fittings.

Overflow Tube

See Fig. 2. Remove the plug from the port of the

slinger cover (21). In the port; Install a minimum 3/4

in. (19 mm) ID drain tube (Z) for solvent based materials, and a minimum 1 in. (25 mm) ID drain tube for

waterborne materials. Slope the tube downward, a

minimum of .25 in. (6mm) per foot of tube and route

the tube into the mix tank.

Z

.25 in.

(6 mm)

Fig. 2

21

1 foot

(305 mm)

03120

5308059

Page 6

Installation

Mounting the Pump

Secure the pump, without the motor, in the pump

stand (V), using the bolts provided.

Be sure the pump inlet and the plumbing to the mix

tanks are at the same level. Install the necessary

plumbing, using shims as necessary. Then bolt the

pump standpipe and the tanks securely to the floor.

CAUTION

Do not flush the pump with any acid, caustic or

abrasive flush solution (line stripper) of any type. The

pump is designed to circulate automotive paint

coatings only.

After All Lines Are Installed

Flush all lines with a compatible solvent and blow out

with air. Then clean the elements of the filters (P).

Installing the Motor

Remove the protective cover and the shipping dowel

from the pump base (31). Remove the motor coupler

(29).

When wiring the motor, be sure the shaft rotates in the

direction shown on the pump base and in Fig. 3.

Place the motor coupler (29) on the motor shaft (A),

pushing it up, well beyond the end of the shaft. Lightly

snug the setscrew (B).

Lower the motor onto the pump base, making sure the

motor locating flange seats properly on the pump

base.

Loosen the motor coupler setscrew (B). Pull the coupler (29) down to engage with the pump coupler (58)

and coupling insert (6).

Adjust the motor coupler to 0.094 in. (2.39 mm) clearance. See Fig. 3. Tighten the pump coupler setscrew.

CAUTION

1. Before operating the pump, turn the motor

coupler by hand to be sure the shaft rotates

freely in the correct direction. Then recheck the

0.094 in. (2.39 mm) coupler clearance.

2. The pump is factory-set to deliver maximum

outlet pressure. Do not tamper with this adjustment as it could cause damage to the impellers

and bowls and void the warranty.

3. Never leave any contaminants, nuts, bolts, rags,

etc., in the fluid tank or supply lines as they could

seriously damage the impellers or bowls.

1

2

Fig. 3

Outlet Pressure Gauge

Direction of Rotation for Motor

B

29

6

0.094 in. (2.39 mm)

A

58

33

2

31

1

0312203121

6 308059

Page 7

Operation

CAUTION

The pump is designed for continuous operation.

Regular shutdown at night or on weekends may

cause premature bearing wear and invalidate the

warranty.

Do not let the pump run dry. Operating the pump for

more than 10 seconds without fluid circulating

through it will overheat the pump and damage it.

2. Starting the pump

(Always use this procedure to start the pump)

a. Close the isolation valves (Q) on one filter.

b. Use the valve (Q) in front of the other filter to

control the pump flow to 50 psi (3.5 bar) until

the lines are full. Then completely open the

valve.

Flushing and Priming System

(See the Typical Installation and Fig. 3.)

The procedure given here is for a stand-mounted

pump, two mix tank system as shown in the Typical

Installation on page 4. Some specific instructions

may not apply to other systems; consult your plant’s

flushing procedures.

Flushing is important; it cleans all equipment and lines

of impurities. Following these instructions will help

assure satisfactory operation with quality control.

CAUTION

1. Be sure the motor rotates in the correct direction

and the drive coupler clearance is set at 0.094

in. (2.39 mm). See Fig. 3.

2. If the motor labors or the pump does not run

smoothly, check the motor for high amp draw

and check the thrust bearing for overheating.

The normal operating temperature is from 120

to 150 F (49 to 65 C). If the temperature is

higher than 150 F (65 C), consult a qualified

Graco representative after a repair check of the

drive coupler clearance.

c. Run the pump for several minutes, and then

shut off the pump.

d. Recheck the drive coupler for 0.094 in. (2.39

mm) clearance.

CAUTION

The pump coupler and bearing could move up during

shipment and then, when the pump is operated, it

could move down, leaving too much clearance. This

could damage both the coupler insert and the coupler.

3. Checking the system for leaks

a. Restart the pump and check the entire system

for leaks.

b. Tighten leaking joints as necessary.

c. Periodically check for leaks during flushing.

3. Be sure the circulating lines are flushed and

primed with fluid as instructed below. Do not

flush the pump with any acid, caustic or abrasive

flush solution (line stripper) of any type. The

pump is designed to circulate automotive paint

coatings only.

1. Preparing to flush the inside of the mix tanks

a. Close the outlet valves (W) of both tanks.

b. Pour about 100 gallons (380 liters) of the

appropriate solvent into each tank.

c. Open the outlet (W) and return valves (K) on

one tank only.

4. Continue flushing

a. Continue circulating the solvent, changing the

solvent as needed until the system is thoroughly flushed.

b. When the system is clean, stop the pump.

c. Drain all filtered residue from the filters (P).

d. Reconnect the return line (E) to the back

pressure valve (F).

7308059

Page 8

Operation

e. Close the outlet (W) and return valves (K) for

the tank being used and open the outlet and

return valves for the other tank.

f. Start the pump and circulate the solvent for at

least one hour.

g. While circulating, open the spray gun at each

drop and flush the hoses with about one gallon

(4 liters) of solvent.

5. When flushing is complete

a. Stop the pump and drain all solvent from the

tanks and lines.

b. Open the filter drain valves (R) to flush out all

filtered residue.

c. Thoroughly blow out the entire system with

clean, dry compressed air, or nitrogen, to

remove all solvent from the system.

6. Pumping paint

a. Fill a tank with paint and start the agitator (C).

b. Start the pump.

8. Flushing paint from system

Consult the paint supplier for a compatible solvent for

flushing paint from the system. Water reducible paints

should use de-ionized water and a solvent which will

keep resin in the solution. If water reducible paint has

a 20% solvent content, the flush media should also

contain approximately 20% solvent.

CAUTION

Do not flush the pump with any acid, caustic or

abrasive flush solution (line stripper) of any type. The

pump is designed to circulate automotive paint

coatings only.

CAUTION

De-ionized (D.I.) water is an aggressive, corrosive

material. It can be used on the waterborne versions

of the Imperial Pumps. Exposure of all other Imperial

Pumps to D.I. water should be minimized, and the

D.I. water should be flushed from the pump with a

non-corrosive material such as alcohol.

c. Use the filter isolation valve (Q) to control the

pump flow to 50 psi (3.5 bar) until the lines are

full, and then open the valve completely.

d. Circulate the paint until all air is removed from

the fluid lines.

e. While the paint is circulating, check and adjust

the viscosity as necessary.

7. Filling standby tank

a. Fill the other mix tank (standby tank) with paint

and start the agitator.

b. Leave the agitator running so that paint in the

standby tank will be ready for use when needed.

c. To keep air out of the system, always switch to

the standby tank before the paint supply in the

tank you have been using is completely

exhausted.

Adjusting System Pressure

Use the back pressure valve (F) to adjust the system

pressure.

Determine the line pressure required. Then, with paint

circulating in the line loop only, set the back pressure

valve so that the pressure at the last spray gun is 10

psi (0.7 bar) greater than needed.

Refer to the Typical Installation on page 4 and the

separate back pressure valve instructions.

CAUTION

The pump is set at the factory to deliver the maximum volume and outlet pressure. The pressure

cannot be increased by any adjustment of the pump.

Refer to Pump Thrust Bearing and Seal Replace-

ment, page 12, for proper adjustments.

8 308059

Page 9

Lubrication

Preventive

Lubricate the thrust bearing once a month if the pump

is operating continuously. To lubricate the bearing,

pump one or two shots (about 0.1 oz/2.8 grams) of

Chevron SRI/No. 2 NLGI grade grease through the

fitting on the top of the seal retainer. A 14 oz. tube of

this grease is supplied with the pump. See Fig. 4.

NOTE: Do not lubricate the bearing when you first

receive the pump as it is factory greased.

CAUTION

Use only Chevron SRI/No. 2 NLGI grade grease to

help prevent bearing overheating and premature

bearing failure. This green or brown-colored grease

is used for the factory pack and must not be mixed

with any other type of grease. The use of any other

type of grease will void the Graco Warranty.

CAUTION

Do not over grease the bearing, which may cause

the bearing to overheat. Remove any excess grease

after lubricating.

Maintenance

Thrust Bearing. Once a month, lubricate the thrust

bearing if pump is run continuously. Refer to thrust

bearing Lubrication instructions on this page. It is

recommended that the Imperial pump thrust bearing

assembly be replaced at least once a year.

Pump Pressure, Flow Rate, and Temperature. Once

a month, check the static discharge pressure, flow rate

of the pump, thrust bearing temperature, and coupler

clearance. Record them.

NOTE: If the operating temperature exceeds 150 F

(65 C) and normal maintenance, troubleshooting, and

service fails to reduce temperature, contact a qualified

Graco representative.

CAUTION

Blockage of the overflow tube and overflow chamber

on pump base will cause leakage through the shaft

seal and adjustment nut opening.

1

1

Grease here.

Fig. 4

Thrust Bearing Temperature Monitoring. The 3/8 in.

npt plug (54) can be removed from the pump base to

install a temperature sensor to monitor thrust bearing

temperatures. This sensor can be sourced by an

appropriate outside supplier.

54

03122

Overflow Tube. Once a month, check the overflow

tube and overflow chamber on pump base. Clean if

needed. Refer to Fig. 2 on page 5 for overflow tube

setup.

9308059

Page 10

Troubleshooting

CAUTION

When checking the pump pressure, do not leave the

check valve (J) or isolation valves (Q) closed for

more than 10 seconds while the pump is operating to

avoid overheating the pump and damaging the seals

and bearings.

NOTE: Graco offers a rebuild program on all Imperial

and Crown Imperial pumps. Contact your local sales

representative for details.

Problem Cause Solution

Pump won’t run. 1. Electric power out. 1. Check fuses; clean terminals

2. Fuses blown. 2. Check coupler clearance, re-

3. Motor inoperative. 3. Repair or replace motor.

Pump runs but pressure drops

slightly.

1. Clogged pump intake. 1. Remove and clean.

2. Increased flow rate. 2. Adjust back pressure valve.

3. Parts worn or damaged. 3. Repair pump.

4. Air entrained in fluid. 4. *Purge air. See Startup Proce-

Before removing the pump for repair, shut off the

electric power, relieve the pressure, and drain the

pump by opening the drain valve at the pump base.

This will help reduce the risk of serious injury from

electric shock, moving parts, or splashing fluid in

the eyes.

WARNING

and connections.

place fuses, repair pump (call

Graco Detroit, see back page).

dure on page 7.

Pump runs but pressure very low

or unsteady.

TROUBLESHOOTING CHART IS CONTINUED ON PAGE 11.

* Before removing the pump for cleaning, close the

check valve (J) or line isolation valves (Q) and note

the maximum pump pressure; the pressure should

be steady. Do not leave valves closed for more

than 10 seconds.

If pressure variations or pulsations are noted, the

problem could be 1.) a clogged intake, 2.) too low a

fluid level in the tanks, or 3.) restricted plumbing.

Correct the clogged condition to obtain steady

pressure.

1. Clogged pump inlet. 1. *Clean.

2. Air entrained in fluid. 2. *Purge air. See Startup Proce-

3. Problem with electric motor. 3. Check motor for proper rotation.

Low pressure can also be caused by air entrainment in

water reducible fluids. All return lines in tanks with

water reducible fluid must be routed to the bottom of

the tank.

Be careful to avoid allowing deteriorated pieces of bag

filters into the pump which can result in serious damage to the pump.

dure on page 7.

Check that RPM of motor is at

least 3750 under load.

10 308059

Page 11

Troubleshooting

Problem Cause Solution

Fluid leaking. 1. Screws or fittings loose. 1. Tighten.

2. Parts worn or damaged. 2. Repair pump.

3. Clogged bypass drain. 3. Drain.

Leakage at shaft seal (41).

(Leakage through the shaft seal/

adjustment nut opening.)

Noisy pump. 1. Improper coupler clearance. 1. Ensure 0.094 in. (2.39 mm)

Coupler insert (6) wears out prematurely.

1. Fluid viscosity is too light (especially if using solvent or other

flushing material).

2. Drain tube missing or not properly installed.

3. Drain tube blocked. 3. Clean drain tube.

2. Motor not seating properly to

pump housing.

3. Lack of grease in main thrust

bearing.

Motor not seating properly to

pump housing.

1. Seal is designed for heavier viscosity fluid, such as paint. Problem should clear up after flushing is completed.

2. Check size and slope of drain

tube; 3/4” ID and minimum

slope of 1/4” for each foot of

tube. See page 5.

clearance. See Fig. 3, page 6.

2. Loosen motor mount nuts, clean

flange and rotate motor to seat

properly; check seal for damage.

3. See Lubrication on page 9;

check for worn shaft bearings.

Loosen motor mount nuts, clean

flange and rotate motor to seat

properly; check seal for damage.

11308059

Page 12

Service

CAUTION

To avoid costly damage to the pump, follow this

service procedure carefully. Do not attempt to repair

anything that is not mentioned in this service section.

Before you start

Special tools needed for repairing the pump are mentioned in the text and described in the Accessories

section on page 32. Be sure you have all the necessary tools and repair parts on hand.

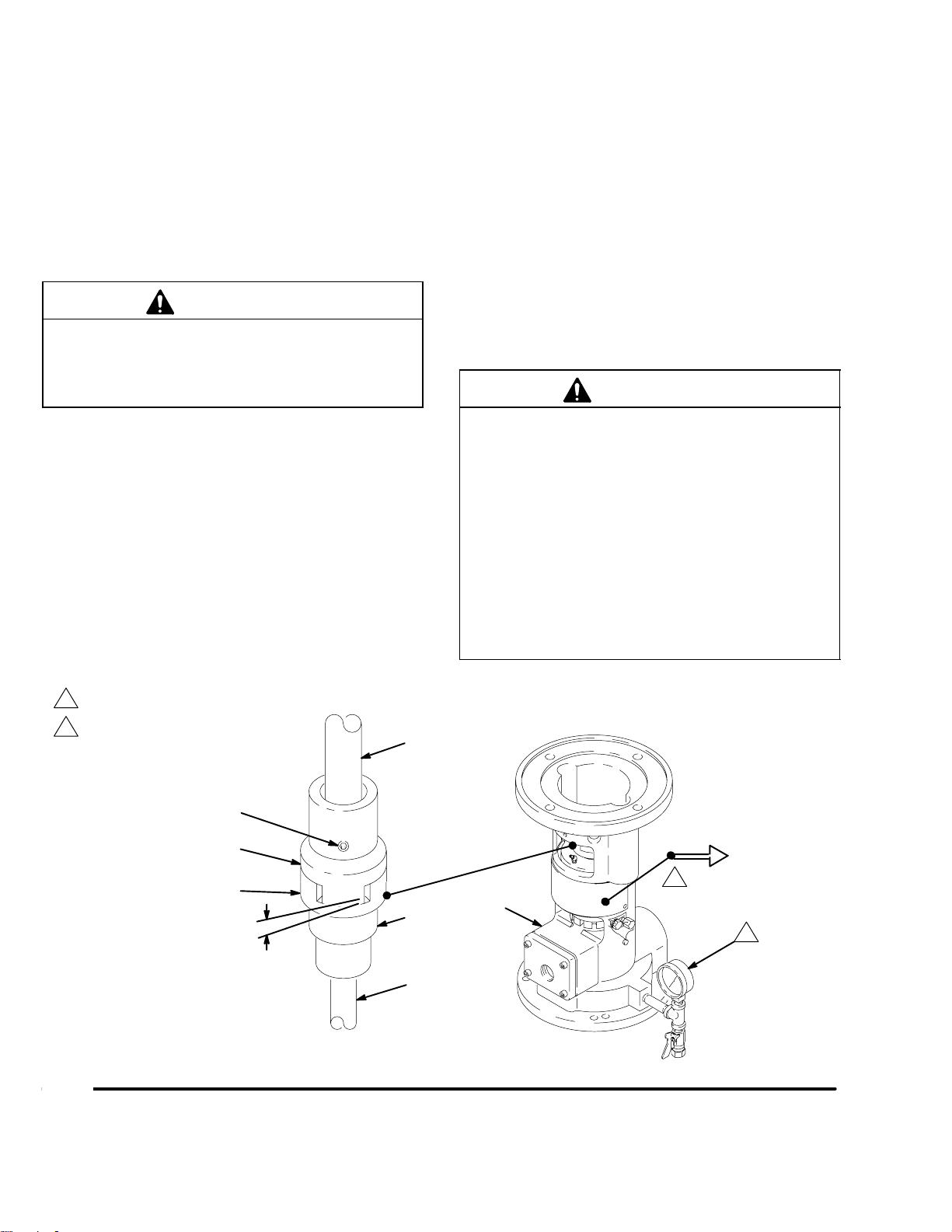

Shaft Holding

1

Tool 218634

(for standard pumps)

Shaft Holding

2

Tool 207727

(for high-profile

pumps)

36a

36b

1

2

Pump Thrust Bearing and Seal

Replacement

NOTE: It is not necessary to remove the pump from

the stand. However, if you are also repairing the lower

pump, you can install the shaft holding tool and move

the pump to the repair stand at this time. Use the tool

indicated in Fig. 5.

NOTE: Replace the pump thrust bearing (A) assembly

at least once a year. Replace the assembly if the pump

housing temperature goes over 150F (53C), which is

the first sign of bearing failure.

Disassembly

(Refer to Fig. 6, except where indicated)

1. Shut off the power to the pump. Close the check

valve (J) and/or the line isolation valves (Q). Open

the drain valve (Y) at the pump base, having a

container ready to catch the fluid. See page 4.

Remove the motor. Refer to Installing the Motor

on page 6.

2. Remove the slinger chamber screws, cover and

gasket (3, 21, 20). Inspect the chamber opening

and clean out any residue.

3. Remove the retainer plate (58c) and rubber coupling insert (6) from the pump coupling assembly

(58). Loosen the slinger (40) setscrew.

4. Hold the pump coupler (58) and screw the shaft

nut (28) off the shaft (33), using a socket wrench.

5. Remove the screws, washers and springs (10, 11,

25) and lift out the coupling assembly (58).

6. Remove the bearing support (22) and key (58b)

from the shaft (33).

03123

Fig. 5

8. Remove the three screws (13) and shaft seal

assembly (41).

NOTE: To service the lower pump section, refer to

page 15. Otherwise, continue with Step 9.

9. If the pump is mounted in a repair stand, install the

shaft holding tool. See Fig. 5.

10. Install the shaft seal assembly (41) with the three

screws (13).

11. Replace the shaft seal (8) in the adjusting nut (35).

Install the adjusting nut, engaging just one thread

in the pump base (31).

12. Position the bearing support (22) on the adjusting

nut (35) so its pin (P) and the slot in the support

align.

13. Screw the adjusting nut (35) down just until the

bearing support (22) bottoms out on the housing.

Turn the nut back 1 to 1-1/2 turns to engage

bearing support.

14. Slide the coupling assembly (58) over the shaft

(33).

15. Align the keyway and insert the key (58b) between

the coupling assembly and shaft.

16. Use the special tool, 178779, to check the shaft

location dimension. Place the tool on the face of

the coupler (58), between the coupler tabs as

shown in the detail of Fig. 7. The tabbed portion of

the tool should touch the top of the shaft (33).

Screw the adjusting nut (35) up until you attain the

0.25 in. (6.3 mm) dimension.

17. Install the shaft nut (28) using a socket wrench

and bottom it on the coupling assembly (58).

7. Remove the adjusting nut lockscrew and plug (19,

27). Then remove the adjusting nut (35).

12 308059

18. Align the hex of the nut retainer plate (58c) with

the shaft nut (28) and secure the lockwire (58d).

Page 13

58

58c

58d

58b

58a

48

29

Service

19. Install the two hold-down screws, washers, and

springs (10, 11, 25). Bottom the screws and check

the vertical travel of the retainer (A) against the

spring. If the shaft nut (28) and coupling housing

(58) are properly installed, the retainer should lift

5

6

10

11

25

28

A

0.12 to 0.19 in. (3.2 to 3.8 mm) before the springs

are solidly compressed.

20. If the pump is mounted in an assembly stand,

loosen the shaft holding tool. See Fig. 5.

Turn the bearing adjusting nut (35) two and a half

notches to the right to raise the impellers off the

bowls. Now turn the pump coupler (58) to be sure

the shaft (33) rotates freely. Check to see that the

slinger (40) is located approximately in the center

of the slinger chamber. See Fig. 7.

Fig. 6

41

31

3

22

8

P

35

13

41a

41e

41b

41c

41d

24

2

4

19

402021

27 26

If the pump is not mounted in an assembly

stand, turn the bearing adjusting nut (35) up until

the shaft (only) rotates freely. Then raise it another

two and a half notches to raise the impellers off the

bowls. See Fig. 7.

21. Install the lockscrew (19) through the pump base

and into the hole in the adjusting nut (35) without

forcing it. Install the plug (27). If necessary, turn

the adjusting nut a little, in the same direction as

pump rotation, until the plug goes in easily. Tighten

the plug securely and attach the lockwire (26) and

crimp. See Figs. 6 and 7.

22. Install the gasket, slinger chamber cover, and

screws (20, 21, 3) on the front of the pump base.

23. Install the rubber coupling insert (6) and remount

the motor. Refer to Fig. 3, page 6.

24. Remove the shaft holding tool, if installed. Install

the plug (49) and gasket (50) (see the parts

drawing). Start the pump. Use the filter isolation

valves (Q) to control the pump flow to 50 psi (3.5

bar) until the lines are full, and then completely

open the valves. Circulate the paint until all air is

removed from the fluid lines. Close the check valve

(J) or isolation valves (Q). Note the maximum

pump pressure. The pressure should be steady. If

variations or pulsations are noted, the inlet flow to

the pump is restricted, due to either a clogged

screen or restricted plumbing. Correct the clogged

condition.

CAUTION

03124

When checking the pump pressure, do not leave

the check valve (J) or isolation valves (Q) closed

for more than 10 seconds while the pump is operating to avoid overheating the pump and damaging

the seals and bearings.

13308059

Page 14

Tool 178779

58

33

Service

0.25 in. (6.3 mm)

03125

21

41a

28

58b

22

35

Notch

A

6

58

10

11

25

19

B

40

Fig. 7

14 308059

33

03126

Page 15

Service

25. Shut the pump off and recheck the coupler clearance; adjust if necessary to 0.094 in. (2.39 mm).

See Fig. 8.

26. Remove the seal chamber cover (21) and check to

be sure the slinger (40) is in the middle of the

chamber. See Fig. 7. If necessary, loosen the

setscrew (B) with a 0.19 in. hex key wrench to

readjust the slinger. Reinstall the cover, gasket and

screws (3, 20, 21).

31

29

58

0.094 in. (2.39 mm)

A

1

35

2

Repairing Shaft Bearings, Impellers,

and Seals

Disassembly

NOTE: Remove the pump from the regular stand.

1. Support the pump in a vertical position on the

accessory stand 953912, which must be bolted to

the floor for stability. Lock the pump in place. Refer

to Fig. 9.

2. Follow the disassembly procedure, Steps 1–8, on

page 12.

3. Remove the capscrews (14) at the top flange of

the riser tube (38). See Fig. 8.

NOTE: The two riser tubes used in the High Profile

pumps do not have to be disassembled.

4. Lift the pump base (31) straight up, off the shaft

(33). Avoid bending the shaft by unequal pulling

with a hoist or pry bars. Remove the capscrews

(14) at the bottom of the tube and remove the riser

tube (38). See Fig. 8.

Left –

1

Increase Pressure

Right –

2

Decrease Pressure

Torque to 30–35 ft–lb

3

(27–47 N.m)

Fig. 8

33

38

17

14

14

32

Assembly Stand

953912

3

3

03127

03128

Fig. 9

15308059

Page 16

Service

)

5. Disassemble the impeller bowls, working from the

top down.

a. Hold the first impeller with a spanner wrench

616637 and use a close fitting wrench to

loosen the impeller nut (32) 1–1 /2 turns. See

Fig. 9.

b. Place a 3/4 in. (19 mm) ID soft-steel, protect-

ing bushing, with a smooth turned end, on top

of the hex nut. Use a sharp downward blow

with a 1 foot (300 mm) length of pipe or tube

over the shaft (33) to loosen the collet (18).

See Fig. 10.

c. Remove the collet (18) and impeller (30). Do

not pry the impeller.

d. Remove all of the impeller bowl assemblies in

this way.

1 ft (300 mm)

Pipe

3/4 in. (19 mm)

ID Bushing

30

Fig. 10

37b

37a

32 18

37

33

03129

Pressing Tool

177219

0.06 in.

(1.6 mm

1

6. Inspect the shaft (33) for scoring or wear and

replace it, if needed. Check all bowls and impellers

for wear or damage and replace as needed. Install

new o-rings (9) on all impeller bowls (37b) and the

intake bowl (36a), then lubricate the o-rings in

place. Be sure the impeller nuts (32) rotate freely

on the collets.

7. To replace the bearings:

a. Use the short-nippled end of tool 177219 to

press out the bearings (37a) from all bowls

(37b) and the intake bowl (36a). See Fig. 11.

b. Use the long-nippled end of the tool to press

new bearings (36b, 37a) into the bowls. This

tool maintains the required 0.06 in. (1.6 mm)

dimensions of the impeller bowls as shown in

Fig. 11.

c. Thread the shaft holding tool into the bottom of

the intake bowl as shown in Fig. 12.

Procedure is continued on page 17.

9

Place long end down for

1

pressing new bearing

into impeller bowls.

03130

Fig. 11

Pressing Tool

177219

36a

36b

Shaft Holding Tool

1

207727 Shown

Installed (for

High Profile Pumps)

Use Shaft Holding Tool

2

218634 for Standard

Pumps

1

2

03131

Fig. 12

16 308059

Page 17

Service

d. Use the short-nippled end of tool 177219 to

press the new bearing into the intake bowl until

it bottoms against the shaft holding tool. Refer

to Fig. 11.

e. Check the bearings for concentricity. Place the

checking fixture 177218 on the bowl as shown

in Fig. 13. Drop the long end of the checking

tool 177217 into the center hole of the fixture.

The tool should turn freely without binding. If

the tool binds, the bearings must be replaced.

Reassembly

8. Slide the shaft (33) into the bearing in the intake

bowl (36a) and lock it in place with the shaft holding tool. See Fig. 14.

9. Clamp the intake bowl in a vise.

10. Assemble the first impeller (30), collet (18) and

impeller nut (32) onto the shaft (33). See Fig. 15.

Push downward on the impeller and hold it with the

spanner wrench, 616637, while tightening the

impeller nut to 130–150 ft-lb (175 – 205 Nm).

Refer to Fig. 16.

Shaft Holding Tool

1

207727 Shown

Installed (for

High Profile Pumps)

Use Shaft Holding Tool

2

218634 for Standard

Pumps

Fig. 14

33

36

1

2

03133

11. Install the first impeller bowl (37) and bolt it to the

intake bowl (36a) with screws (14) and lockwashers (17) and nuts (15). See Fig. 15.

NOTE: Each impeller must be bolted down tightly into

the bowl while tightening the impeller. This assures

contact with the machined face of the bowl, which will

ensure maximum pump performance.

Checking Fixture

177218

Checking

Tool

177217

37a

37b

03132

Fig. 13

37b

30

Torque to 130–150 ft–lb

1

(175–205 N.m)

Fig. 15

32

18

36a

1

14

17

15

03134

17308059

Page 18

Service

12. Remove the assembly from the vise and mount it

in the assembly stand 953912. See Fig. 16.

13. Continue assembling the bowls and impellers as in

Steps 10 and 11.

14. Install the riser tube (38) with the screws (14),

lockwashers (17) and nuts (15). See Fig. 8.

15. To replace the bearing (39) in the pump base (31),

remove the three screws and washers (7, 34),

holding the bearing from below. Press the bearing

out, using a 1.5 in. (38 mm) disc laid on the bearing and a 0.68 in. (17.3 mm) rod inserted from the

top to push it out. See Fig. 17. This bearing has a

medium-tight fit. Replace the bearing when replacing the impeller bearings.

Assembling Lower Pump Section to Base

NOTE: Be sure the pump base (31) is clean, and that

a new base bearing (39) has been installed.

1. Install the slinger (40) in the pump base with the

flange down. Use a wooden dowel, just under 0.75

in. (19 mm) diameter, to align the slinger when

assembling the pump base onto the shaft.

Torque to 130–150 ft–lb

1

(175–205 N.m)

32

1

Fig. 16

31

0.68 in.

(17.3 mm)

Rod

Spanner Wrench

616637

Assembly Stand

953912

03135

1.5 in.

(38 mm)

Flat Disc

2. Carefully lower the base (31) over the shaft (33),

passing the shaft through the bearing and slinger.

Seat the base firmly on the riser tube (38). Install

the four capscrews (14) and washers (17). Torque

to 30–35 ft-lb (27–47 Nm). Refer to Fig. 8.

3. Adjust the slinger to the center of the seal chamber opening. Tighten the slinger setscrew (B).

Refer to Fig. 7.

4. Continue assembling the pump as described in

Steps 10 to 26 on pages 12 to 15.

18 308059

34

7

39

03136

Fig. 17

Page 19

Notes

19308059

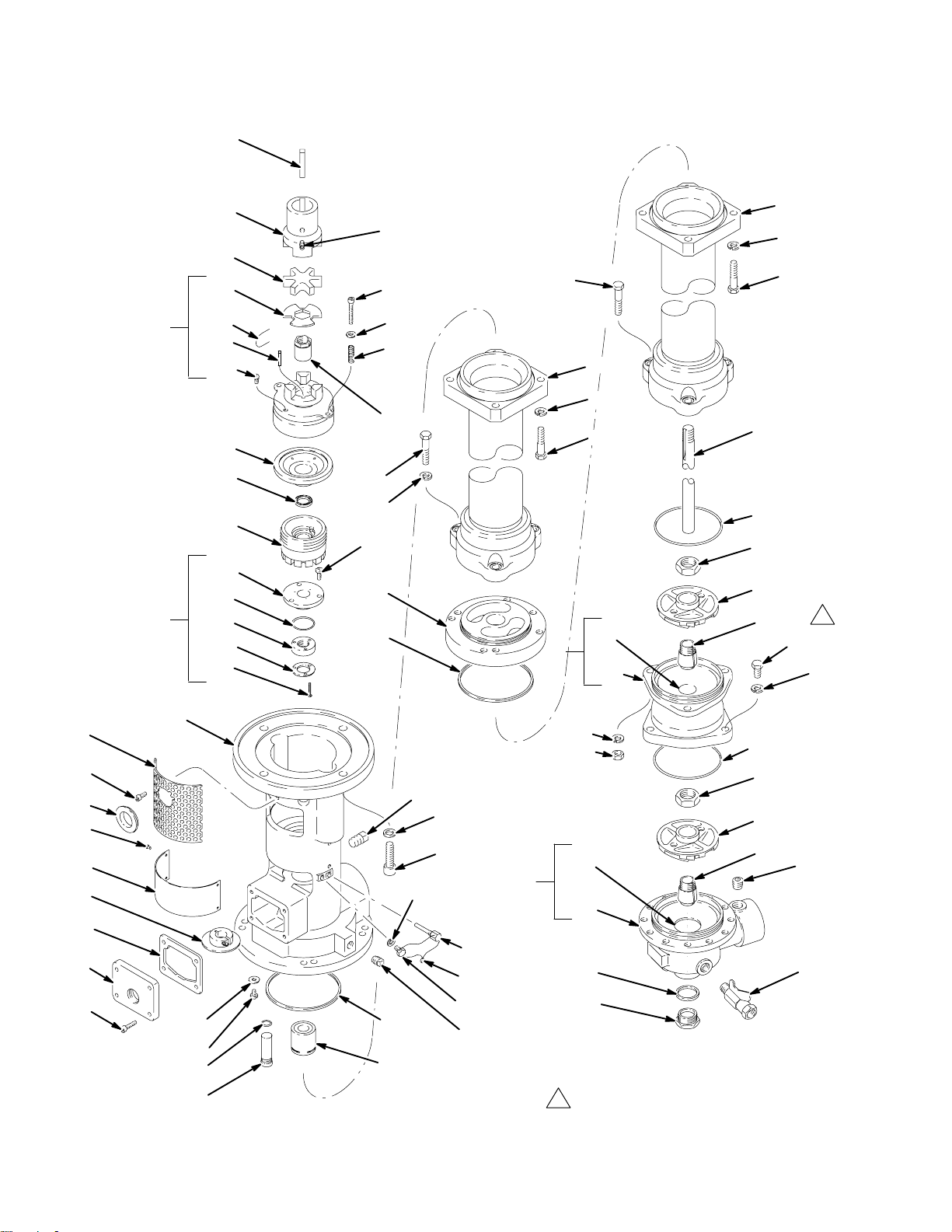

Page 20

Corrosion-Resistant, 60” Pump

48

Parts

58

41

29

58c

58d

58b

58a

22

35

41a

41e

41b

41c

38

5

6

10

11

25

28

8

13

37

14

37a

17

14

33

9

32

30

18

14 or 53

1

57

52

56

23

40

20

21

41d

31

54

1

3

34

7

63

62

12

39

24

2

4

36

19

26

27

16

37b

17

15

36b

36a

49

Use item 53 for last bowl

1

to intake only.

17

9

32

30

18

64

5150

03137

20 308059

Page 21

Parts

Corrosion-Resistant, 60” Pumps

Model Stages

223906 6

223907 7

223908 8

223909 9

223910 10

223911 11

223912 12

223913 13

223914 14

Ref

No. Part No. Description Qty

1 100055 SCREW, type “u” self tap, no. 6 x 1/4” 4

2 110343 CAPSCREW, sochd, 1/2–13 x 1–3/4” 4

3 110787 CAPSCREW, sch, 1/4–28 unf–3a x .75” 4

4 100214 LOCKWASHER,

5 100640 SCREW, cup pt slotted

headless set, 5/16 x 3/8” 1

6 102211* INSERT, coupling, rubber 1

7 110751 SCREW, mach, pnhd,

1/4–28 unf–2a x .375” 3

8 102776* SEAL,

shaft 1

9 106524* SEAL, o–ring, Viton

6 to 11 Stage Pumps 11

12 & 13 Stage Pumps 13

14 Stage Pumps 15

10 110753 CAPSCREW, sch,

1/4–28 unf–3a x 1.625” 2

11 110755 WASHER, plain, .281” ID 2

12 102848* PACKING, sq section 1

13 110752 SCREW, mach, pnhd,

1/4–28 unf–2a x .625” 3

14 103776 SCREW, hex hd, 7/16–14 x 2”

6 to 11 Stage Pumps 34

12 & 13 Stage Pumps 40

14 Stage Pumps 46

15 103777 NUT, hex, 7/16”

6 to 11 Stage Pumps 30

12 & 13 Stage Pumps 36

14 Stage Pumps 42

16 110786 PLUG,

pipe, 1/4–18 npt 1

17 103780 LOCKWASHER, spring 7/16”

6 to 11 Stage Pumps 37

12 & 13 Stage Pumps 43

14 Stage Pumps 49

18 186646* COLLET,

19 168352* SCREW, lock, adjusting nut 1

20 186117 GASKET, slinger 1

21 191401 COVER, slinger ring 1

22 168363 SUPPORT, bearing 1

23 186124 PLATE, instruction 1

24 168381 WASHER,

25 186111 SPRING, compression 2

26 104274 LOCK, wire 1

27 171711 PLUG, special 1

28 168500* NUT, shaft 1

spring, 5/16” 1

impeller 1/Stage

.53” ID 4

Ref

No. Part No. Description Qty

29 COUPLING,

motor,

170067 fits 1.38” (35 mm) motor shaft 1

169445 fits 1.12” (28.4 mm) motor shaft 1

30 170748* IMPELLER, pump 1/Stage

31 186096 BASE, pump 1

32 170770* NUT, impeller 1/Stage

33 176879 SHAFT,

impeller 1

34 170772 WASHER, plain, 1/4” 3

35 207769 NUT, adjusting 1

36 218097 INTAKE BOWL ASSEMBLY

Includes item 36a and 36b 1

36a 179909 .HOUSING, intake bowl 1

36b 176851 .BEARING,

intake bowl 1

37 218092 IMPELLER BOWL ASSEMBLY

Includes items 37a and 37b

6 to 11 Stage Pumps 10

12 & 13 Stage Pumps 12

14 Stage Pumps 14

37a 176851 .BEARING,

impeller bowl 1/bowl

37b 179774 .HOUSING, impeller bowl 1/bowl

38 TUBE, riser

218632 24.5” (622 mm)

6 to 11 Stage Pumps 1

220008 17.75” (451 mm)

12 & 13 Stage Pumps 1

220005 11” (280 mm)

14 Stage Pumps 1

39 218309 BEARING,

pump base 1

40 208846 RING, slinger 1

41 223605* SHAFT SEAL ASSEMBLY

Includes items 41a–41e 1

41a 186215 .SUPPORT, seal 1

41b 178697 .SEAL, shaft, PTFE 1

41c 170762 .RETAINER, seal 1

41d 107246 .SCREW, pan hd mach, no. 5–40 x 5/8” 3

41e 102895* .PACKING, o–ring, Viton 1

48 KEY,

parallel 1

107055 5/16”, use with coupling 170067 1

160906 1/4”, use with coupling 169445 1

49 178552 PLUG, 1–1/4 NF 1

50 178553 GASKET, plug, Delrin 1

51 237534 VALVE, ball, 3/8 npt (m x f) 1

52 110754 CAPSCREW,

sch, 1/4–28 unf–3a x .5” 1

53 110861 CAPSCREW, hex hd,

7/16–14 unc–2a x 1.5” 3

54 110762 PLUG, pipe, 3/8–18 npt 1

56 108027 GROMMET 1

57 186349 GUARD 1

58 223606 COUPLING ASSEMBLY

Includes replacement items 58a–58d 1

58a 100847 .FITTING, hydraulic, 1/4–28, 45 1

58b 168372 .KEY, 0.187” square x 1” long 1

58c 166007* .PLATE, retainer, shaft nut 1

58d 068069* .WIRE, lock 1

61 107411 GREASE,

Chevron SRI Grease–2 14 oz. 1

62 186248 PLUG, sealing, machined 2

63 102982 O–RING 2

64 101748 PLUG, 3/8 npt 1

* Recommended spare parts to keep on hand.

21308059

Page 22

Corrosion-Resistant, 85” Pump

48

Parts

58

41

29

58c

58d

58b

58a

22

35

41a

41e

41b

41c

41d

38

5

6

10

11

25

28

8

46

17

13

47

12

14

59

17

14

37a

37

37b

17

14

33

9

32

30

18

14 or 53

1

17

57

52

56

23

40

20

21

31

54

1

3

34

7

63

62

12

39

24

2

4

36

19

26

27

16

17

15

36b

36a

50

49

Use item 53 for last bowl

1

to intake only.

9

32

30

18

64

51

03022

22 308059

Page 23

Parts

Corrosion-Resistant, 85” Pump

Model Stages

224006 6

224007 7

224008 8

224009 9

224010 10

224011 11

224012 12

224013 13

224014 14

Ref

No. Part No. Description Qty

1 100055 SCREW,

2 110343 CAPSCREW, hex hd, 1/2–13 x 1–3/4” 4

3 110787 CAPSCREW, sch, 1/4–28 unf–3a x .75” 4

4 100214 LOCKWASHER, spring, 5/16” 1

5 100640 SCREW, cup pt slotted

headless set, 5/16 x 3/8” 1

6 102211* INSERT, coupling, rubber 1

7 110751 SCREW, mach, pnhd,

1/4–28 unf–2a x .375” 3

8 102776* SEAL, shaft 1

9 106524* SEAL, o–ring, Viton

10 110753 CAPSCREW, sch, 1/4–28 unf–3a

x 1.625” 2

11 110755 WASHER, plain, .281” ID 2

12 102848* PACKING,

13 110752 SCREW, mach, pnhd,

1/4–28 unf–2a x .625” 3

14 103776 SCREW, hex hd, 7/16–14 x 2”

15 103777 NUT,

16 110786 PLUG, pipe, 1/4–18 npt 1

17 103780 LOCKWASHER,

18 186646* COLLET, impeller 1/Stage

19 168352* SCREW, lock, adjusting nut 1

20 186117 GASKET,

21 191401 COVER, slinger ring 1

22 168363 SUPPORT, bearing 1

23 186124 PLATE, instruction 1

24 168381 WASHER, .53” ID 4

25 186111 SPRING, compression 2

26 104274 LOCK,

27 171711 PLUG, special 1

28 168500* NUT, shaft 1

29 COUPLING, motor

170067 fits 1.38” (35 mm) motor shaft 1

169445 fits 1.12” (28.4 mm) motor shaft 1

type “u” self tap, no. 6 x 1/4” 4

6 to 11 Stage Pumps 12

12 & 13 Stage Pumps 14

14 Stage Pumps 16

sq section 2

6 to 11 Stage Pumps 38

12 & 13 Stage Pumps 44

14 Stage Pumps 50

hex, 7/16”

6 to 11 Stage Pumps 30

12 & 13 Stage Pumps 36

14 Stage Pumps 42

spring 7/16”

6 to 11 Stage Pumps 44

12 & 13 Stage Pumps 50

14 Stage Pumps 56

slinger 1

wire 1

Ref

No. Part No. Description Qty

30 170748* IMPELLER,

31 186096 BASE,

pump 1/Stage

pump 1

32 170770* NUT, impeller 1/Stage

33 181590 SHAFT, impeller 1

34 170772 WASHER, plain, 1/4” 3

35 207769 NUT, adjusting 1

36 218097 INTAKE BOWL ASSEMBLY

Includes item 36a and 37b 1

36a 179909 .HOUSING, intake bowl 1

36b 176851 .BEARING, intake bowl 1

37 218092 IMPELLER BOWL ASSEMBLY

Includes items 37a and 37b

6 to 11 Stage Pumps 10

12 & 13 Stage Pumps 12

14 Stage Pumps 14

37a 176851 .BEARING, impeller bowl 1/bowl

37b 179774 .HOUSING, impeller bowl 1/bowl

38 218632 TUBE, riser, 24.5” (622 mm)

6 to 11 Stage Pumps 2

12 to 14 Stage Pumps 1

39 218309 BEARING, pump base 1

40 208846 RING, slinger 1

41 223605* SHAFT SEAL ASSEMBLY

Includes items 41a–41e 1

41a 186215 .SUPPORT,

seal 1

41b 178697 .SEAL, shaft, PTFE 1

41c 170762 .RETAINER, seal 1

41d 107246 .SCREW, pan hd mach, no. 5–40 x 5/8” 3

41e 102895* .PACKING, o–ring, Viton 1

46 110862 CAPSCREW, hex hd,

7/16–14 unc–2a x 1.75” 3

47 220267 PLATE, adapter

48 KEY, parallel 1

107055 5/16”, use with coupling 170067 1

160906 1/4”, use with coupling 169445 1

49 178552 PLUG, 1–1/4 NF 1

50 178553 GASKET,

plug, Delrin 1

51 237534 VALVE, ball, 3/8 npt (m x f) 1

52 110754 CAPSCREW, sch, 1/4–28 unf–3a x .5” 1

53 110861 CAPSCREW, hex hd,

7/16–14 unc–2a x 1.5” 3

54 110762 PLUG, pipe, 3/8–18 npt 1

56 108027 GROMMET 1

57 186349 GUARD 1

58 223606 COUPLING ASSEMBLY

Includes replacement items 58a–58d 1

58a 100847 .FITTING, hydraulic, 1/4–28, 45 1

58b 168372 .KEY, 0.187” square x 1” long 1

58c 166007* .PLATE,

retainer, shaft nut 1

58d 068069* .WIRE, lock 1

59 SPACER

220008 17.75” (451 mm)

12 & 13 Stage Pumps 1

220005 11” (280 mm)

14 Stage Pumps 1

61 107411 GREASE,

Chevron SRI Grease–2 14 oz. 1

62 186248 PLUG, sealing 2

63 102982 O–RING 2

64 101748 PLUG, 3/8 npt 1

* Recommended spare parts to keep on hand.

23308059

Page 24

Waterborne, 60” Pump

48

Parts

58

41

29

58c

58d

58b

58a

22

35

41a

41e

41b

41c

38

5

6

10

11

25

28

8

13

37

14

37a

17

14

33

9

32

30

18

14 or 53

1

57

52

56

23

40

20

21

41d

31

54

1

3

34

7

63

62

12

39

24

2

4

36

19

26

27

16

37b

17

15

36b

36a

49

Use item 53 for last bowl

1

to intake only.

17

9

32

30

18

64

5150

03137

24 308059

Page 25

Parts

Waterborne, 60” Pump

Model Stages

224106 6

224107 7

224108 8

224109 9

224110 10

224111 11

224112 12

224113 13

224114 14

236615 15

Ref

No. Part No. Description Qty

1 100055 SCREW,

2 110343 CAPSCREW, sochd, 1/2–13 x 1–3/4” 4

3 110787 CAPSCREW, sch, 1/4–28 unf–3a x .75” 4

4 100214 LOCKWASHER, spring, 5/16” 1

5 100640 SCREW, cup pt slotted

headless set, 5/16 x 3/8” 1

6 102211* INSERT, coupling, rubber 1

7 110751 SCREW, mach, pnhd,

1/4–28 unf–2a x .375” 3

8 102776* SEAL, shaft 1

9 106524* SEAL, o–ring, Viton

10 110753 CAPSCREW, sch,

1/4–28 unf–3a x 1.625” 2

11 110755 WASHER, plain, .281” ID 2

12 102848* PACKING,

13 110752 SCREW, mach, pnhd,

1/4–28 unf–2a x .625” 3

14 103776 SCREW, hex hd, 7/16–14 x 2”

15 103777 NUT,

16 110786 PLUG, pipe, 1/4–18 npt 1

17 103780 LOCKWASHER,

18 186646* COLLET, impeller 1/Stage

19 168352* SCREW, lock, adjusting nut 1

20 186117 GASKET,

21 191401 COVER, slinger ring 1

22 168363 SUPPORT, bearing 1

23 186124 PLATE, instruction 1

24 168381 WASHER, .53” ID 4

25 186111 SPRING, compression 2

26 104274 LOCK,

27 171711 PLUG, special 1

28 168500* NUT, shaft 1

type “u” self tap, no. 6 x 1/4” 4

6 to 11 Stage Pumps 11

12 & 13 Stage Pumps 13

14 & 15 Stage Pumps 15

sq section 1

6 to 11 Stage Pumps 34

12 & 13 Stage Pumps 40

14 & 15 Stage Pumps 46

hex, 7/16”

6 to 11 Stage Pumps 30

12 & 13 Stage Pumps 36

14 & 15 Stage Pumps 42

spring 7/16”

6 to 11 Stage Pumps 37

12 & 13 Stage Pumps 43

14 & 15 Stage Pumps 49

slinger 1

wire 1

Ref

No. Part No. Description Qty

29 COUPLING,

motor,

170067 fits 1.38” (35 mm) motor shaft 1

169445 fits 1.12” (28.4 mm) motor shaft 1

30 170748* IMPELLER,

pump 1/Stage

31 186266 BASE, pump 1

32 170770* NUT, impeller 1/Stage

33 176879 SHAFT, impeller 1

34 170772 WASHER, plain, 1/4” 3

35 207769 NUT,

adjusting 1

36 218097 INTAKE BOWL ASSEMBLY

Includes item 36a and 36b 1

36a 179909 .HOUSING, intake bowl 1

36b 176851 .BEARING, intake bowl 1

37 218092 IMPELLER BOWL ASSEMBLY

Includes items 37a and 37b

6 to 11 Stage Pumps 10

12 & 13 Stage Pumps 12

14 & 15 Stage Pumps 14

37a 176851 .BEARING, impeller bowl 1/bowl

37b 179774 .HOUSING, impeller bowl 1/bowl

38 TUBE,

riser

218632 24.5” (622 mm)

6 to 11 Stage Pumps 1

220008 17.75” (451 mm)

12 & 13 Stage Pumps 1

220005 11” (280 mm)

14 & 15 Stage Pumps 1

39 218309 BEARING,

pump base 1

40 208846 RING, slinger 1

41 223605* SHAFT SEAL ASSEMBLY

Includes items 41a–41e 1

41a 186215 .SUPPORT, seal 1

41b 178697 .SEAL,

shaft, PTFE 1

41c 170762 .RETAINER, seal 1

41d 107246 .SCREW, pan hd mach, no. 5–40 x 5/8” 3

41e 102895* .PACKING, o–ring, Viton 1

48 KEY, parallel 1

107055 5/16”, use with coupling 170067 1

160906 1/4”,

use with coupling 169445 1

49 178552 PLUG, 1–1/4 NF 1

50 178553 GASKET, plug, Delrin 1

51 237534 VALVE, ball, 3/8 npt (m x f) 1

52 110754 CAPSCREW, sch, 1/4–28 unf–3a x .5” 1

53 110861 CAPSCREW, hex hd,

7/16–14 unc–2a x 1.5” 3

54 110762 PLUG, pipe, 3/8–18 npt 1

56 108027 GROMMET 1

57 186349 GUARD 1

58 223606 COUPLING ASSEMBLY

Includes replacement items 58a–58d 1

58a 100847 .FITTING, h

ydraulic, 1/4–28, 45 1

58b 168372 .KEY, 0.187” square x 1” long 1

58c 166007* .PLATE, retainer, shaft nut 1

58d 068069* .WIRE, lock 1

61 107411 GREASE, Chevron SRI Grease–2 14 oz. 1

62 186248 PLUG, sealing, machined 2

63 102982 O–RING 2

64 101748 PLUG,

3/8 npt 1

* Recommended spare parts to keep on hand.

25308059

Page 26

Waterborne HD, 60” Pump

48

Parts

58

41

29

58c

58d

58b

58a

22

35

41a

41e

41b

41c

38

5

6

10

11

25

28

8

13

37

14

37a

17

14

33

9

32

30

18

14 or 53

1

57

52

56

23

40

20

21

41d

31

54

1

3

34

7

63

62

12

39

24

2

4

36

19

26

27

16

37b

17

15

36b

36a

49

Use item 53 for last bowl

1

to intake only.

17

9

32

30

18

64

5150

03137B

26 308059

Page 27

Parts

Waterborne HD, 60” Pump

Model Stages

224106 6

224107 7

224108 8

224109 9

224110 10

224111 11

224112 12

224113 13

224114 14

236615 15

Ref

No. Part No. Description Qty

1 100055 SCREW,

2 110343 CAPSCREW, sochd, 1/2–13 x 1–3/4” 4

3 110787 CAPSCREW, sch, 1/4–28 unf–3a x .75” 4

4 100214 LOCKWASHER, spring, 5/16” 1

5 100640 SCREW, cup pt slotted

headless set, 5/16 x 3/8” 1

6 102211* INSERT, coupling, rubber 1

7 110751 SCREW, mach, pnhd,

1/4–28 unf–2a x .375” 3

8 102776* SEAL, shaft 1

9 106524* SEAL, o–ring, Viton

10 110753 CAPSCREW, sch,

1/4–28 unf–3a x 1.625” 2

11 110755 WASHER, plain, .281” ID 2

12 102848* PACKING,

13 110752 SCREW, mach, pnhd,

1/4–28 unf–2a x .625” 3

14 103776 SCREW, hex hd, 7/16–14 x 2”

15 103777 NUT,

16 110786 PLUG, pipe, 1/4–18 npt 1

17 103780 LOCKWASHER,

18 186646* COLLET, impeller 1/Stage

19 168352* SCREW, lock, adjusting nut 1

20 186117 GASKET,

21 191401 COVER, slinger ring 1

22 168363 SUPPORT, bearing 1

23 186124 PLATE, instruction 1

24 168381 WASHER, .53” ID 4

25 186111 SPRING, compression 2

26 104274 LOCK,

27 171711 PLUG, special 1

28 168500* NUT, shaft 1

type “u” self tap, no. 6 x 1/4” 4

6 to 11 Stage Pumps 11

12 & 13 Stage Pumps 13

14 & 15 Stage Pumps 15

sq section 1

6 to 11 Stage Pumps 34

12 & 13 Stage Pumps 40

14 & 15 Stage Pumps 46

hex, 7/16”

6 to 11 Stage Pumps 30

12 & 13 Stage Pumps 36

14 & 15 Stage Pumps 42

spring 7/16”

6 to 11 Stage Pumps 37

12 & 13 Stage Pumps 43

14 & 15 Stage Pumps 49

slinger 1

wire 1

Ref

No. Part No. Description Qty

29 COUPLING,

motor,

170067 fits 1.38” (35 mm) motor shaft 1

169445 fits 1.12” (28.4 mm) motor shaft 1

30 170748* IMPELLER,

pump 1/Stage

31 186266 BASE, pump 1

32 170770* NUT, impeller 1/Stage

33 15E264 SHAFT, impeller 1

34 170772 WASHER, plain, 1/4” 3

35 207769 NUT,

adjusting 1

36 249110 INTAKE BOWL ASSEMBLY

Includes item 36a and 36b 1

36a 179909 .HOUSING, intake bowl 1

36b 15E310 .BEARING, intake bowl 1

37 249109 IMPELLER BOWL ASSEMBLY

Includes items 37a and 37b

6 to 11 Stage Pumps 10

12 & 13 Stage Pumps 12

14 & 15 Stage Pumps 14

37a 15E310 .BEARING, impeller bowl 1/bowl

37b 179774 .HOUSING, impeller bowl 1/bowl

38 TUBE,

riser

218632 24.5” (622 mm)

6 to 11 Stage Pumps 1

220008 17.75” (451 mm)

12 & 13 Stage Pumps 1

220005 11” (280 mm)

14 & 15 Stage Pumps 1

39 15E309 BEARING,

pump base 1

40 208846 RING, slinger 1

41 223605* SHAFT SEAL ASSEMBLY

Includes items 41a–41e 1

41a 186215 .SUPPORT, seal 1

41b 178697 .SEAL,

shaft, PTFE 1

41c 170762 .RETAINER, seal 1

41d 107246 .SCREW, pan hd mach, no. 5–40 x 5/8” 3

41e 102895* .PACKING, o–ring, Viton 1

48 KEY, parallel 1

107055 5/16”, use with coupling 170067 1

160906 1/4”,

use with coupling 169445 1

49 178552 PLUG, 1–1/4 NF 1

50 178553 GASKET, plug, Delrin 1

51 237534 VALVE, ball, 3/8 npt (m x f) 1

52 110754 CAPSCREW, sch, 1/4–28 unf–3a x .5” 1

53 110861 CAPSCREW, hex hd,

7/16–14 unc–2a x 1.5” 3

54 110762 PLUG, pipe, 3/8–18 npt 1

56 108027 GROMMET 1

57 186349 GUARD 1

58 223606 COUPLING ASSEMBLY

Includes replacement items 58a–58d 1

58a 100847 .FITTING, h

ydraulic, 1/4–28, 45 1

58b 168372 .KEY, 0.187” square x 1” long 1

58c 166007* .PLATE, retainer, shaft nut 1

58d 068069* .WIRE, lock 1

61 107411 GREASE, Chevron SRI Grease–2 14 oz. 1

62 186248 PLUG, sealing, machined 2

63 102982 O–RING 2

64 101748 PLUG,

3/8 npt 1

* Recommended spare parts to keep on hand.

27308059

Page 28

Waterborne, 85” Pump

48

Parts

58

41

29

58c

58d

58b

58a

22

35

41a

41e

41b

41c

41d

38

5

6

10

11

25

28

8

46

17

13

47

12

14

59

17

14

37a

37

37b

17

14

33

9

32

30

18

14 or 53

1

17

57

52

56

23

40

20

21

31

54

1

3

34

7

63

62

12

39

24

2

4

36

19

26

27

16

17

15

36b

36a

50

49

Use item 53 for last bowl

1

to intake only.

9

32

30

18

64

51

03022

28 308059

Page 29

Waterborne, 85” Pump

Parts

Model Stages

224206 6

224207 7

224208 8

224209 9

224210 10

224211 11

224212 12

224213 13

224214 14

236715 15

Ref

No. Part No. Description Qty

1 100055 SCREW,

type “u” self tap, no. 6 x 1/4” 4

2 110343 CAPSCREW, hex hd, 1/2–13 x 1–3/4” 4

3 110787 CAPSCREW, sch, 1/4–28 unf–3a x .75” 4

4 100214 LOCKWASHER, spring, 5/16” 1

5 100640 SCREW, cup pt slotted

headless set, 5/16 x 3/8” 1

6 102211* INSERT,

coupling, rubber 1

7 110751 SCREW, mach, pnhd,

1/4–28 unf–2a x .375” 3

8 102776* SEAL, shaft 1

9 106524* SEAL, o–ring, Viton

6 to 11 Stage Pumps 11

12 & 13 Stage Pumps 13

14 & 15 Stage Pumps 15

10 110753 CAPSCREW,

sch, 1/4–28 unf–3a x 1.625” 2

11 110755 WASHER, plain, .281” ID 2

12 102848* PACKING, sq section 2

13 110752 SCREW, mach, pnhd,

1/4–28 unf–2a x .625” 3

14 103776 SCREW, hex hd, 7/16–14 x 2”

6 to 11 Stage Pumps 38

12 & 13 Stage Pumps 44

14 & 15 Stage Pumps 50

15 103777 NUT, hex, 7/16”

6 to 11 Stage Pumps 30

12 & 13 Stage Pumps 36

14 & 15 Stage Pumps 42

16 110786 PLUG, pipe, 1/4–18 npt 1

17 103780 LOCKWASHER, spring 7/16”

6 to 11 Stage Pumps 44

12 & 13 Stage Pumps 50

14 & 15 Stage Pumps 56

18 186646* COLLET,

impeller 1/Stage

19 168352* SCREW, lock, adjusting nut 1

20 186117 GASKET, slinger 1

21 191401 COVER, slinger ring 1

22 168363 SUPPORT

, bearing 1

23 186124 PLATE, instruction 1

24 168381 WASHER, .53” ID 4

25 186111 SPRING, compression 2

26 104274 LOCK, wire 1

27 171711 PLUG, special 1

28 168500* NUT,

shaft 1

29 COUPLING, motor

170067 fits 1.38” (35 mm) motor shaft 1

169445 fits 1.12” (28.4 mm) motor shaft 1

Ref

No. Part No. Description Qty

30 170748* IMPELLER,

pump 1/Stage

31 186266 BASE, pump 1

32 170770* NUT,

impeller 1/Stage

33 181590 SHAFT, impeller 1

34 170772 WASHER, plain, 1/4” 3

35 207769 NUT, adjusting 1

36 218097 INTAKE BOWL ASSEMBLY

Includes item 36a and 36b 1

36a 179909 .HOUSING, intake bowl 1

36b 176851 .BEARING,

intake bowl 1

37 218092 IMPELLER BOWL ASSEMBLY

Includes items 37a and 37b

6 to 11 Stage Pumps 10

12 & 13 Stage Pumps 12

14 & 15 Stage Pumps 14

37a 176851 .BEARING,

impeller bowl 1/bowl

37b 179774 .HOUSING, impeller bowl 1/bowl

38 218632 TUBE, riser, 24.5” (622 mm)

6 to 11 Stage Pumps 2

12 to 15 Stage Pumps 1

39 218309 BEARING,

pump base 1

40 208846 RING, slinger 1

41 223605* SHAFT SEAL ASSEMBLY

Includes items 41a–41e 1

41a 186215 .SUPPORT, seal 1

41b 178697 .SEAL, shaft, PTFE 1

41c 170762 .RETAINER,

seal 1

41d 107246 .SCREW, pan hd mach, no. 5–40 x 5/8” 3

41e 102895* .PACKING, o–ring, Viton 1

46 110862 CAPSCREW, hex hd,

7/16–14 unc–2a x 1.75” 3

47 220267 PLATE, adapter

48 KEY,

parallel 1

107055 5/16”, use with coupling 170067 1

160906 1/4”, use with coupling 169445 1

49 178552 PLUG, 1–1/4 NF 1

50 178553 GASKET, plug, Delrin 1

51 237534 VALVE, ball, 3/8 npt (m x f) 1

52 110754 CAPSCREW,

sch, 1/4–28 unf–3a x .5” 1

53 110861 CAPSCREW, hex hd,

7/16–14 unc–2a x 1.5” 3

54 110762 PLUG, pipe, 3/8–18 npt 1

56 108027 GROMMET 1

57 186349 GUARD 1

58 223606 COUPLING ASSEMBLY

Includes replacement items 58a–58d 1

58a 100847 .FITTING, hydraulic, 1/4–28, 45 1

58b 168372 .KEY, 0.187” square x 1” long 1

58c 166007* .PLATE, retainer, shaft nut 1

58d 068069* .WIRE, lock 1

59 SPACER

220008

17.75” (451 mm)

12 & 13 Stage Pumps 1

220005 11” (280 mm)

14 Stage Pumps 1

61 107411 GREASE, Chevron SRI Grease–2 14 oz. 1

62 186248 PLUG,

sealing 2

63 102982 O–RING 2

64 101748 PLUG, 3/8 npt 1

* Recommended spare parts to keep on hand.

29308059

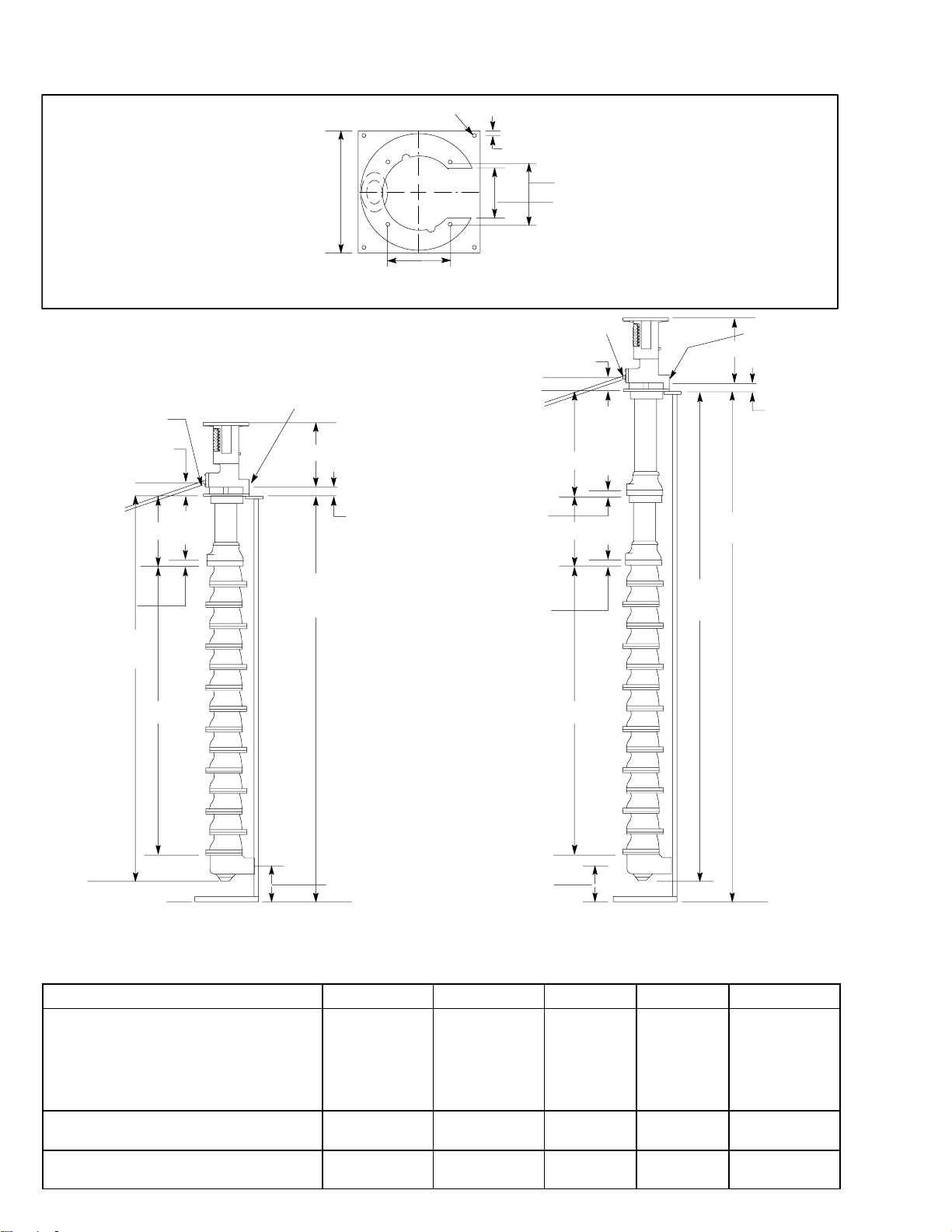

Page 30

Dimensions

Top View of

Pump Mounting Stand

Stand Weights

220266 92 lb (41.4 kg)

218631 75 lb (33.8 kg)

3/4 npt

Overflow

2.93 in. (74 mm)

B

0.53 in. (13.5 mm) Dia.

11 in.

(254 mm)

Square

Base

2 in. npt Outlet

14.68 in. (373 mm)

5.75 in.

(146 mm)

2.81 in.

(71.4 mm)

0.5 in. (12.5 mm)

2.93 in. (74 mm)

25.5 in. (0.65 m)

1 in. (25 mm)

5.75 in. (146 mm)

4.62 in. (118 mm)

3/4 npt

Overflow

B

2 in. npt Outlet

14.68 in. (373 mm)

2.81 in.

(71.4

mm)

91.5 in.

(2.3 m)

1 in. (25 mm)

62.7 in.

(1.6 m)

A

(Model 223914 Shown)

Standard Size Pumps

(for 60 in. High Tanks)

Pump No. of Stages No. of Bowls A B Weight lb (kg)

223906/224006/224106/224206

223907/224007/224107/224207

223908/224008/224108/224208

223909/224009/224109/224209

223910/224010/224110/224210

223911/224011/224111/224211

223912/224012/224112/224212

223913/224013/224113/224213

223914/224014/224114/224214

236615/236715

30 308059

66.0 in.

(1.7 m)

6.0 in.

(152 mm)

10

11

12

12

14

15

88.25 in.

1 in. (25 mm)

A

6.0 in.

(152 mm)

(Model 224014 Shown)

(2.2 m)

High Profile Size Pumps

(for 85 in. High Tanks)

6

7

8

9

10

10

10

10

10

10

12

12

14

15

33.75 in.

(857 mm)

40.5 in.

(1.03 m)

47.25 in.

(1.2 m)

24.5 in.

(622 mm)

17.75 in.

(451 mm)

11 in.

(279 mm)

210 (95)

212 (96)

214 (96)

215 (97)

217 (98)

218 (98)

220 (99)

222 (100)

223 (100)

225 (102)

03138

Page 31

Notes

31308059

Page 32

Use Only Genuine Graco Parts and Accessories

WARNING

Accessories

Back Pressure Valve 208997

180 psi (1.2 MPa, 12 bar) Controlled Working Pressure

Be sure the valves, plumbing and accessories used

in your system have a working pressure rating at

least as high as the maximum working pressure

rating of the pump.

SERVICE TOOLS

Shaft Holding Tool 207727

For High Profile Pumps.

Shaft Holding Tool 218634

For Standard Pumps.

Shaft Adjusting Tool 178779

Required for setting coupler gap.

Pressing Tool 177219

Used for pressing new bearings into bowls to maintain

proper clearance of bearings.

Checking Tool 177217

Check Fixture 177218

Used with Checking Tool 177217 to check concentricity

of new bearings pressed into impeller bowls.

Spanner Wrench 616637

For holding impellers while

torquing impeller nuts.

Chevron SRI Grease–2 107411

14 oz. Required for lubricating pump.

One tube is included with new pumps.

Assembly Stand 953912

Must be used to assemble the

pump in the proper upright

position, maintaining

alignment.

200 psi (1.4 MPa, 14 bar) Maximum Working Pressure

Stainless Steel. 0.5 in. (12.7 mm) dia. orifice.

1–1/4 in. npt inlet and outlet.

Includes 200 psi (14 bar) pressure gauge.

High Capacity Bag Filters

300 psi (2.1 MPa, 21 bar) Maximum Working Pressure

Heavy-duty, large-area perforated filter bag baskets

with 1/4 in. npt blowdown port on cover. Uses optional

wire mesh liner for dual-stage filtration. Ask your distributor to show you Form No. 300081 for part number

and ordering information.

Fluid Pressure Gauge and Pulsation Dampeners

300 psi (2.1 MPa, 21 bar) Maximum Working Pressure

1–1/4 in. npt inlet and outlet; inline.

Flow rating: 20 gpm (75 liters/min).

Calibrated at 100 centipoise, specific gravity 0.85.

208855 For use with corrosive fluids.

1/4 npt(m) inlet. 300 psi (21 bar)

Maximum Working Pressure

206171 For use with non-corrosive fluids.

1/4 npt(m) inlet. 200 psi (14 bar)

Maximum Working Pressure

Pump Mounting Stand 218631

For Standard Pump Stand

Pump Mounting Stand 220266

For High Profile Pump Stand

Standpipe, SST 223995

32 308059

Diameter: 8 in. (203 mm). Height: 61.125 in. (1.55 m)

Page 33

Accessories

Use Only Genuine Graco Parts and Accessories

Adapter Kit 213049

For 10 and 15 HP Electric Motors. Includes adapter

plate, coupling, coupling insert, and screws and

washers.

NOTE: The size of pump and motor required depends on the viscosity and specific gravity of the fluid to be

pumped, and upon the flow volume and pressure required in the user’s system. Users should contact a Graco

branch or factory office for recommendations.

Electric U–Frame Motors

Adapter Kit 916340

For 20 HP Electric Motors. Includes adapter plate,

coupling, coupling insert, and screws and washers.

Electric T–Frame Motors

Motor H.P. Voltage Rating

521470 3 230/460 Standard

521469 5 230/460 Standard

521468 7.5 230/460 Standard

521467 10 230/460 Standard

521466 15 230/460 Standard

521888 20 230/460 Standard

521455 7.5 600 Standard

51A649 3 CSA 575 Standard

51A650 5 CSA 575 Standard

51A651 7.5 CSA 575 Standard

51A652 10 CSA 575 Standard

51A653 15 CSA 575 Standard

51A654 20 CSA 575 Standard

516821 3 230/460 Premium

516732 5 230/460 Premium

516824 7.5 230/460 Premium

516825 10 230/460 Premium

516731 15 230/460 Premium

516827 20 230/460 Premium

51B297 3 CSA 575 Premium

51B298 5 CSA 575 Premium

51B299 7.5 CSA 575 Premium

51B300 10 CSA 575 Premium

51B301 15 CSA 575 Premium

51B302 20 CSA 575 Premium

114937 10 575 Inverter Duty

51B157 15 230/460 Inverter Duty

51B778 10 230/460 Inverter Duty

116228 10 380 Inverter Duty

51B673 7.5 380V/50Hz Standard

51B674 10 380V/50Hz Standard

51B675 15 380V/50Hz Standard

51B676 20 380V/50Hz Standard

51B677 7.5 380V/50Hz Premium

51B678 10 380V/50Hz Premium

51B679 15 380V/50Hz Premium

51B680 20 380V/50Hz Premium

Motor H.P. Voltage Rating

521441 3 230/460 Standard

521429 5 230/460 Standard

51B296 7.5 230/460 Standard

516826 10 230/460 Standard

521456 15 230/460 Standard

521454 20 230/460 Standard

516822 3 230/460 Premium

516823 5 230/460 Premium

516774 7.5 230/460 Premium

516775 10 230/460 Premium

516776 15 230/460 Premium

516828 20 230/460 Premium

51B681 7.5 380V/50Hz Premium

51B682 10 380V/50Hz Premium

51B683 15 380V/50Hz Premium

51B684 20 380V/50Hz Premium

General Motor Specification:

Class1, Group D, Division 1 Explosion Proof, Temp.

Code T2B, Class F Insulation, Vertical.

33308059

Page 34

Technical Data

Power Supply required 220/575 Volt AC, 3–phase, 50/60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flow Rate 0–50 gpm (0–189 liter/min). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluid Inlet and Outlet Size 2 in. npt(f). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wetted Parts Stainless Steel, PTFE, Viton, Delrin, PTFE-Coated Iron. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viton and Delrin are registered trademarks of the DuPont Co.

34 308059

Page 35

Notes

35308059

Page 36

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

International Offices: Belgium, Korea, China, Japan

Sales Office: Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

www.graco.com

PRINTED IN USA 308059 06/1990, Revised 12/2004

36 308059

Loading...