Page 1

INSTRUCTIONS–PARTS LIST 308024D

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

AIR ASSISTED AIRLESS

HIGH EFFICIENCY LOW PRESSURE SYSTEMS

AIR REGULATOR

500 psi (34 bar) MAXIMUM INLET PRESSURE

Reduced Range 0–10 psi (0–0.7 bar)

Part No. 110776

Precision regulator preset to 10 psi (0.7 bar) maximum

outlet pressure to ensure compliance to SCAQMD Air

Quality Rules 1124, 1136, 1151.

Buna–N on Dacron diaphragms.

INSTALLATION

Preparing to Install the Air Regulator

Clean the air lines to remove dirt and scale before installing the air regulator.

Apply a minimum amount of pipe compound to the air line

male threads.

CAUTION

To avoid getting compound into the air regulator

and damaging it, start with the third thread back

and work away from the end of the air line when

applying pipe compound.

CAUTION

To avoid contaminating the air supply to the air regulator, do not use an automatic air line lubricator;

lubricate the motor manually, instead.

Installing the Air Regulator

ALWAYS use an air line filter to remove harmful

dirt and moisture from your compressed air supply. Dirt and moisture will affect air regulator performance.

Install the air regulator in the air line. It can be mounted in

any position without affecting its operation.

CAUTION

The regulator has a 1/4 npt inlet and outlet, which are

labeled with arrows indicating the direction of flow. Tighten the inlet and outlet connections securely.

CAUTION

DO NOT use undersized fittings as they will limit

flow through the regulator and cause the pressure

to drop downstream.

ADJUSTMENT

Turn the knob clockwise to increase the regulated air

pressure. Turn it counterclockwise to decrease the regu-

lated air pressure. The locknut is fixed to ensure the outlet pressure does not exceed 10 psi (0.7 bar).

NOTE: If the regulator is difficult to adjust, make sure the

seal ring is lubricated.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

COPYRIGHT 1988 GRACO INC.

Page 2

MAINTENANCE

WARNING

To reduce the risk of serious bodily injury, including

splashing in the eyes or on the skin, or injury from

moving parts, ALWAYS shut off the air supply and

relieve all air and fluid pressure in the system before removing or servicing the air regulator.

The regulator does not have to be removed from the air

line to clean it. Remove the two No. 10–32 screws on the

bottom of the regulator, then pull out the inner valve

assembly.

Wash the inner valve assembly with solvent. Be careful

not to damage the diaphragm and valve facings.

CAUTION

Do not use acetone, carbon tetrachloride, trichlorethylene or similar solvents to clean the regulator. These solvents could damage regulator

parts.

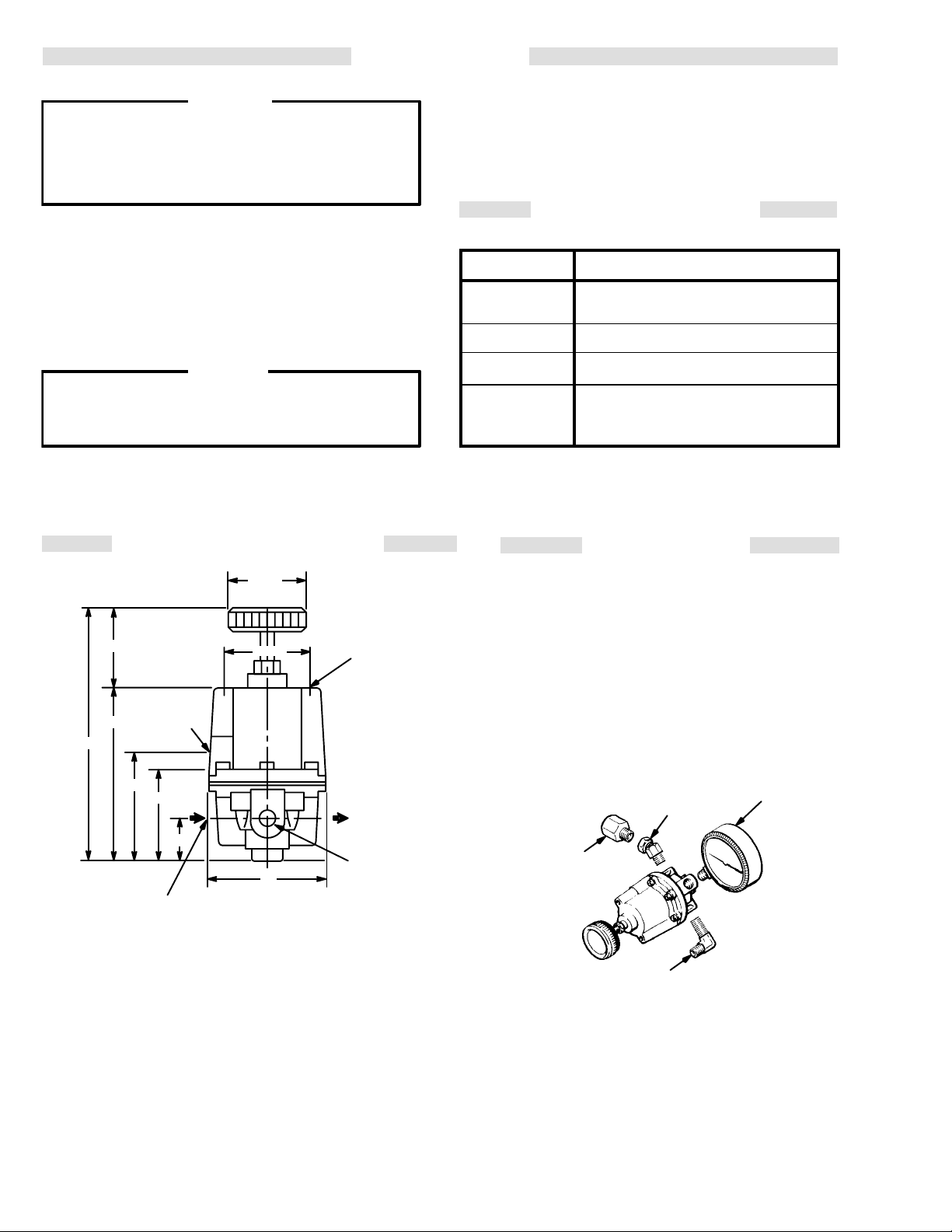

DIMENSIONAL DRAWING

Be sure the spring housing vent hole is not clogged. Keep

the vent hole clear as a slight flow of air through this hole

is necessary for the regulator to operate properly.

Lubricate the adjusting screw with petroleum jelly.

TROUBLESHOOTING

PROBLEM WHAT TO DO

High bleed rate Check relief seat & relief valve for damage

or foreign matter

Leakage Check for diaphragm damage

Valve chatter Lubricate seal rings

Air pressure

gauge reading

slowly changing

Make sure shipping plug in spring cap

vent hole is removed

ACCESSORIES

6–1/2

2–3/16

4–3/8

2–3/4

1/4 npt INLET

& OUTLET

1-7/16

VENT

INLET

1

1–7/8

2–1/4

NOTE: All measurements

in inches.

AIR PRESSURE GAUGE 185350

0–15 psi (1–103 KPa) Range

1/4 npt(m) bottom inlet

MOUNTING HOLES

1/4-20 x 0.5 deep

ADAPTER UNION 110232

1/4–18 npt(m x f) , 45 swivel

ADAPTER 159842

1/4 npt(m) x 1/2 npt(f)

ADAPTER 110249

1/4–18 npt(m), 90 elbow

OUTLET

3

1/4 npt GAGE PORT

159842

110232

110249

185350

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

308024 12–88 Revised 2/09

Loading...

Loading...