Page 1

Instructions – Parts List

Parts

The Glutton

Pump Conversion Kits

Air Valve Conversion Kit 222054

For Pump Models 218061, 218062,

218185 & 218079

Pilot Valve Conversion Kit 221152

For Pump Models 218060, 218061, 218062,

231019, 218185 & 218079

307909B

Table of Contents

Installation 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Warranty 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Information 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read warnings and instructions.

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

Copyright 1988, Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Installation

Pressure Relief Procedure

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you:

D are instructed to relieve the pressure,

D stop spraying,

D check or service any of the system equipment,

D or install or clean the spray tips.

1. Engage the spray gun or dispensing valve safety

latch.*

2. Disengage the gun or dispensing valve safety

latch.*

3. Hold a metal part of the gun or valve firmly to a

grounded metal waste container and trigger it to

relieve the fluid pressure.*

4. Engage the safety latch again.*

5. Open the pump drain valve (required in system),

having a container ready to catch the drainage.

6. Leave the drain valve open until you are ready to

spray again.

*Applies only when using a spray gun or

dispensing valve.

7. If you suspect that the spray tip, nozzle, or hose

is completely clogged or that pressure has not

been fully relieved after following the steps above,

very slowly loosen the hose end coupling and

relieve pressure gradually, then loosen completely.

Now clear the tip, nozzle, or hose obstruction.

2 307909

Page 3

Installation

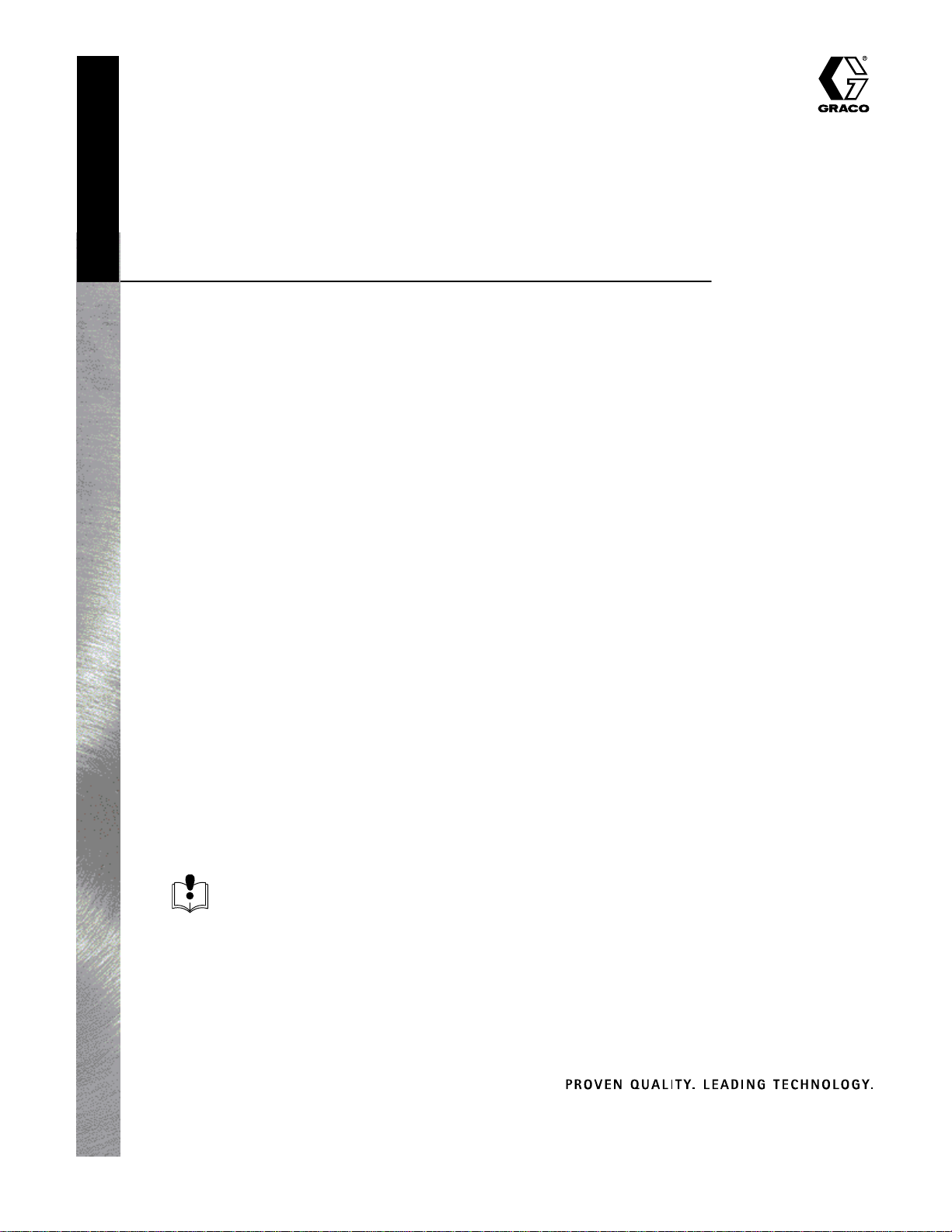

Installing the Air Valve Conversion Kit 222054

1. Follow the Pressure Relief Procedure.

2. Assemble kit as shown in Fig. 1.

3. Remove mufflers and lock rings from old air valve

and install them on new air valve. Fig. 1.

2

6

2

5

Lubricate

2

4

Torque to

27–45 in/lb (3–5 N.m)

3

(part of item 1)

Lubricate

2

1

Fig. 1

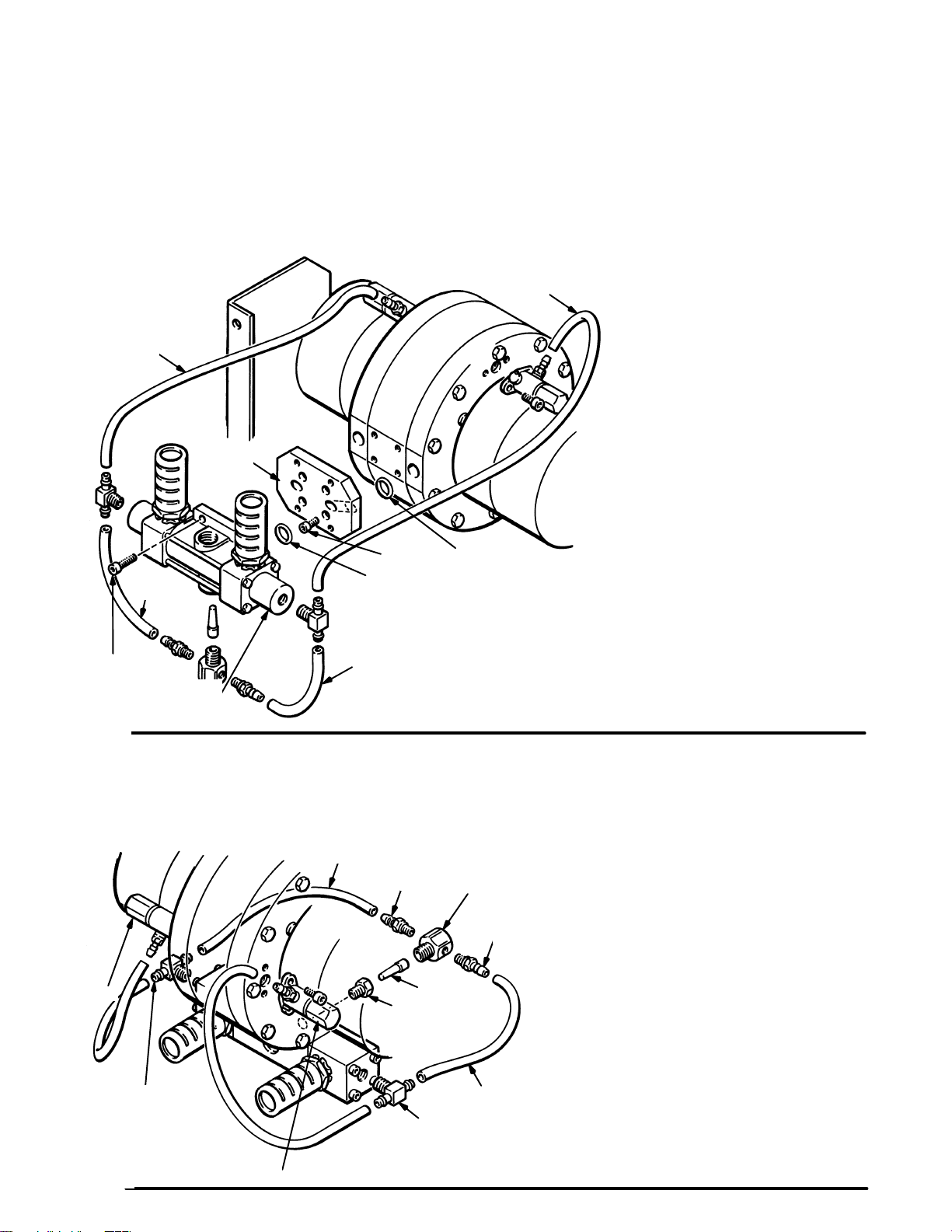

Installing the Pilot Valve Conversion Kit 221152

1. Follow the Pressure Relief Procedure.

2. Assemble kit as shown in Fig. 2.

5

2

1

6

Press fit using

3

40–60 lbs

force

7

Apply sealant

to threads

2

Fig. 2

4

Apply sealant

5

4

Apply sealant

1

307909 3

Page 4

Repair

Repairing the Air Control Valve

NOTE: An Air Valve and Pilot Valve Repair Kit is

available, page 5. Parts included in the kit are marked

with an asterisk, for example, (106*). Use all the parts

in the kit for the best results.

Disassembly

1. Follow the Pressure Relief Procedure on page

2.

2. Cut a small slit in the tube ends and disconnect

them from the pilot valve fittings, air valve tees

(113), and barb fittings (117).

3. Remove the valve end housings (102) by unscrewing the screws (111) and nuts (112). Refer to the

Parts Drawing on page 8.

4. Center the valve spools (103) in the housing (101).

Remove the spools and stem (104) by applying

opposing force with wrenches on the spool (103)

flats.

5. If the air filter (115) needs cleaning or replacement,

unscrew the filter housing (116) and remove the

filter. To clean them, soak the filter housing and the

filter in solvent until they are clean. Blow them dry

with low pressure air [under 30 psi (2.1 bar)].

Press fit the filter into the housing, using 40–60

lbs. of force. Apply sealant to the filter housing

threads and screw it into the center housing (101).

3. Replace the spools (103) if damaged. Replace the

o–ring (108*) and u–cup (109*) on each spool,

being sure to seat them in the grooves. Install the

u–cup with the lips facing towards the housing

(101).

4. Apply medium strength thread sealant to the spool

stem (104) threads. Remove the excess sealant.

CAUTION

Do not overtighten the spools (103) as this can

shear the spool threads.

5. Thread one spool (103) onto the stem (104) and

insert it into the center housing (101); be careful

not to dislodge the u–cups (110) and retainers

(105). Thread the other spool onto the stem. With

wrenches on the flats of the spools, apply opposing force and tighten until snug; 7–13 in–lb

(0.79–1.47 N.m).

6. Replace the gasket (106*) in each end housing

(102) and the o–ring (107*) on each end housing

shoulder.

7. Install the end housings (102) onto the center

housing (101); be careful not to move the spool

and dislodge the u–cups (110) and retainers (105).

Secure the end housings with the four screws

(111) and nuts (112), torquing them to 27–45

in–lb (3–5 N.m).

Assembly

1. Apply lithium base grease to all o–rings, u–cups,

gaskets and to the complete spool assembly

before installing them.

2. Remove the seal retainers (105) from each side of

the center housing (101). Replace the u–cup

(110*), with the lips facing into the housing. Install

the retainers with the flat side facing into the

housing.

CAUTION

If the mufflers are replaced, they must be installed

with the lock rings to avoid damage to the spool

and o–rings during operation.

8. Replace the two o–rings (108*) in the center

housing (101).

9. Install the air valve on the pump and connect the

tubing as shown in Fig. 1.

4 307909

Page 5

Repair

Repairing the Pilot Valve

NOTE: An Air Valve and Pilot Valve Repair Kit is

available. See the back cover to order. Parts included

in the kit are marked with an asterisk, for example,

(210*). Use all the parts in the kit for the best results.

Disassembly

1. Follow the Pressure Relief Procedure on page

2.

2. Unscrew the valve cap (203) from each of the

valve housings (204) and remove the parts. Clean

and inspect the parts for damage. Refer to the

Parts Drawing on page 9.

3. To replace the rod seal (210*):

a. Cut a small slit in the tube ends and discon-

nect them from the pilot valve fittings (208)

and air valve tees.

b. Unscrew the cap screws and remove the pilot

valve housings (204). Grease the rod seals

(210*) and install one on each side of the

pump.

c. Secure the pilot valve housings (204) to the

pump with the cap screws.

d. Connect the tubing to the pilot valve fittings

(208) and air valve tees as shown in Fig. 2.

Assembly

1. Apply lithium base grease to the inside and outside

of the air valve (202) and to the o–rings and seals.

2. Install the o–ring (205), being sure to completely

seat it on the flat in the valve housing (204). Install

the long end of the valve stem (201) into the

housing.

3. Install the small spring (207) over the valve stem

(201), the air valve (202) over the spring, and the

larger spring over the air valve.

4. With the copper gasket (209*) in place on the

valve cap (203), screw the cap onto each of the

valve housings (204). Torque the cap to 7.4–12.5

ft–lb (10–17 N.m).

Repair Kit

Air Valve and Pilot Valve Repair Kit 220656

Includes:

Ref

No. Part No. Description Qty

106 181464 GASKET, polyurethane 2

107 110782 O–RING, buna–n2

108 107186 O–RING, buna–n4

109 108781 U–CUP, polyurethane 2

110 108782 U–CUP, polyurethane 2

114 179861 TUBE, polyurethane,

0.25” OD; 6 in. 3

205 159589 O–RING, buna–n2

209 156766 GASKET, copper 2

210 107161 SEAL, pilot valve rod, buna–n2

183384 TUBE, polyurethane,

0.25” OD; 9.5 in. 1

108754 SEALANT, anerobic,

medium strength, 0.5 cc tube 1

307909 5

Page 6

Parts

NOTE: This air valve can be

used with the pump’s

existing pilot valves.

Connect the tubes as

shown.

2

2

2

6

3

(part of item 1)

Lubricate

5

Lubricate

4

Torque to

27–45 in/lb

(3–5 N.m)

1

Air Valve Conversion Kit 222054

For Pump Models 218061, 218062,

218185 & 218079

Includes items 1 to 6

REF

NO. PART NO. DESCRIPTION QTY

1 220902 AIR VALVE ASSY. See pages

4 & 5 for parts & service

instructions 1

2 054138 TUBE, nylon 48 in.

3 104092 SCREW, cap, sch;

10–24 x 0.625 4

4 101888 SCREW, cap, sch

10–24 x 0.875 4

2

REF

NO. PART NO. DESCRIPTION QTY

5 107186 O–RING, buna–n2

6 183745 PLATE, adapter 1

6 307909

Page 7

Parts

5

2

7

Apply sealant

to threads

2

3

6

Press fit using

40–60 lbs force

5

1

4

Apply sealant

4

Apply sealant

1

Pilot Valve Conversion Kit 221152

For Pump Models 218060, 218061, 218062, 231019, 218185 & 218079

Includes items 1 to 7

REF

NO. PART NO. DESCRIPTION QTY

1 221133 PILOT VALVE ASSY.

See pages 6 & 7 for parts

& service instructions 2

2 108383 FITTING, seal, o–ring 2

3 159840 BUSHING; 1/4–18 npt(f)

x 1/8–27 npt(m) 1

REF

NO. PART NO. DESCRIPTION QTY

4 107191 TEE, barbed 2

5 054138 TUBE, polyurethane 48 in.

6 160736 FILTER, air 1

7 183620 HOUSING, filter, air 1

307909 7

Page 8

Air Control Valve 220902

Includes items 101 to 117

Parts

116

Apply sealant to threads

117

112

101

*110

115

Press fit

105

104

114*

108*

Lubricate

*109

Lubricate

Apply medium strength

sealant to threads.

Torque to 7–13 in/lb

(0.79–1.47 N.m)

103

*108

Lubricate

*106

Lubricate

Torque to

27–45 in/lb

(3–5 N.m)

111

*107

Lubricate

Air Control Valve 220902

Includes items 101 to 117

REF

NO. PART NO. DESCRIPTION QTY

101 183370 HOUSING, valve center 1

102 183369 HOUSING, valve end 2

103 183368 SPOOL, differential 2

104 183367 STEM, spool 1

105 183366 RETAINER, seal 2

106* 181464 GASKET, polyurethane 2

107* 110782 O–RING, buna–n2

108* 107186 O–RING, buna–n4

109* 108781 U–CUP, polyurethane 2

110* 108782 U–CUP, polyurethane 2

8 307909

REF

NO. PART NO. DESCRIPTION QTY

111 108780 SCREW, cap, hex hd;

112 100179 NUT, full hex; 10–24 UNC–2A 4

113 107191 TEE, barbed 2

114* 179861 TUBE, polyurethane; 0.25”

115 160736 FILTER, air 1

116 183620 HOUSING, air filter 1

117 108383 FITTING, barbed,

*Included in Repair Kit 220656 on page 5

102

Lubricate

113

Apply sealant

M5 x 0.8 x 150 4

(6.35 mm) O.D. 2

with buna–n o–ring 2

Page 9

Pilot Valve 221133

Includes items 201 to 210

Parts

210*

Lubricate

208

Torque to 27–45 in/lb

(3–5 N.m)

204

205*

Lubricate

201

207

202

Lubricate ID & OD

206

209*

203

Torque to 7.4–12.5 ft/lb

(10–17 N.m)

Pilot Valve 221133

Includes items 201 to 210

REF

NO. PART NO. DESCRIPTION QTY

201 183604 STEM, valve 1

202 183603 VALVE, air 1

203 183605 CAP, valve 1

204 183606 HOUSING, valve 1

205* 159589 O–RING, buna–n1

206 108961 SPRING, compression 1

REF

NO. PART NO. DESCRIPTION QTY

207 108960 SPRING, compression 1

208 108383 FITTING, barbed, buna–n o–ring

209* 156766 GASKET, copper 1

210* 107161 SEAL, pilot valve rod, buna–n1

*Included in Repair Kit 220656 on page 5.

seal;10–32 UNF–2A 1

307909 9

Page 10

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–367–4023 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

International Offices: Belgium, Korea, Hong Kong, Japan

Sales Offices: Minneapolis, Detroit

www.graco.com

PRINTED IN USA 307909 04/1988, Revised 08/2002

10 307909

Loading...

Loading...