Page 1

HVLP EDGE™ Gun

Models: 256855, 257092, 256856

Maximum Fluid Working Pressure: 50 psi (0.35 MPa, 3.5 bar)

Maximum Air Working Pressure: 10 psi (0.07 MPa, 0.7 bar)

Important Safety Instructions

Refer to your sprayer instruction manual for

Pressure Relief and spray instructions. Keep these

instructions.

256855

ti12761ati12761a ti12870a

257092

256856

Registered Design No. 001147813-0001

313317C

ENG

- For the application of architectural paints and coatings -

The HVLP Edge gun is not intended to be used on an external compressor

The following Warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation

point symbol alerts you to a general warning and hazard symbols refer to procedure-specific risks. Refer back to these

Warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

WARNINGS

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint

fumes, in work area can ignite or explode. To

help prevent fire and explosion:

•Use equipment only in well ventilated area.

•Eliminate all ignition sources; such as pilot lights,

cigarettes, portable electric lamps, and plastic

drop cloths (potential static arc).

• Keep work area free of debris, including solvent, rags

and gasoline.

• Do not plug or unplug power cords, or turn power or

light switches on or off when flammable fumes are

present.

• Ground all equipment in the work area. See Ground-

ing instructions.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop

operation immediately. Do not use equipment until

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

• When flammable liquid is sprayed or used for flushing

or cleaning, keep sprayer at least 20 feet (6 meters)

away from explosive vapors.

• Do not clean with materials having flash points lower

than 70° F (21° C). Use water-based materials or

mineral spirits-type material only. For complete information about your fluid, request the MSDS from the

fluid distributor or retailer.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the

influence of drugs or alcohol.

• Do not exceed the maximum working pressure or

temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with

equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your

material, request MSDS forms from distributor or

retailer.

• Check equipment daily. Repair or replace worn or

damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call

your distributor for information.

• Route hoses and cables away from traffic areas,

sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull

equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chlo-

ride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum

equipment. Such use can cause serious chemical reaction and equipment rupture, and result in death, serious

injury, and property damage.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment

when operating, servicing, or in the operating

area of the equipment to help protect you from serious

injury, including eye injury, inhalation of toxic fumes,

burns, and hearing loss. This equipment includes but is

not limited to:

• Protective eyewear and Hearing protection

• Gloves, clothing and respirator as recommended by

the fluid and solvent manufacturer

Page 2

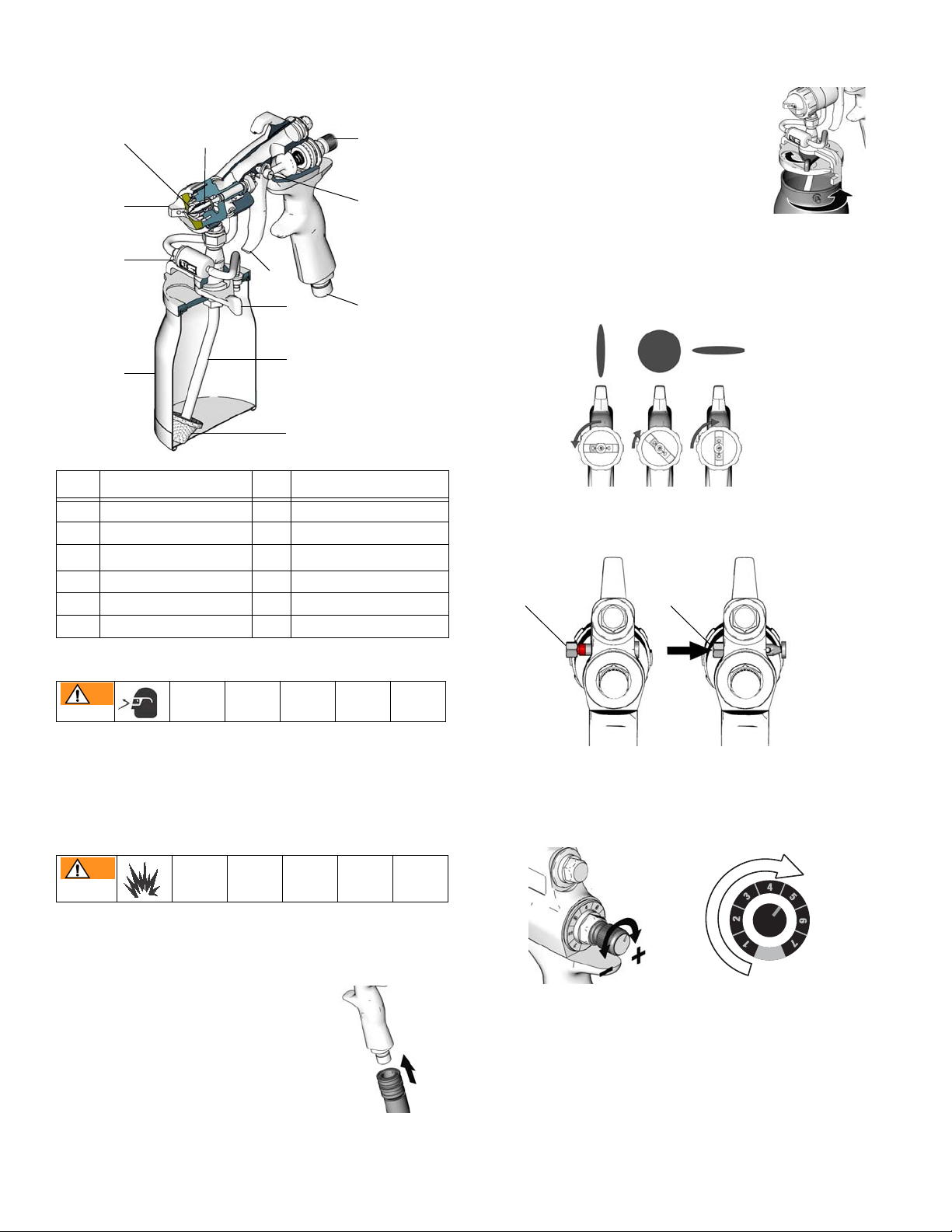

Component Identification

Component Identification

DE F

C

B

J

K

A

M

N

ID Component ID Component

A Siphon Cup G Trigger Slide

B Check Valve H Air Inlet

C Air Cap J

EasyGlide

D Air Nozzle K Latch

E Fluid Needle M Swivel Tube

F Flow Control Knob N Strainer

G

H

ti12771a

™

2. Fill cup 3/4 full. Install cover. Latch

the gun cup cover to secure it to

siphon cup.

ti12872a

Operation

Adjust Spray Pattern

1. Set air cap to position for spray pattern desired.

ti12763a

2. Verify trigger slide is in SPRAY position (E) and not

NEEDLE REMOVAL position (D).

Trigger

ED

Pressure Relief Procedure

The spray gun cup is pressurized by the gun air supply.

To reduce the risk of serious injury from pressurized fluid

or accidental spray from gun, always turn off the air supply to the gun before removing the spray gun cup. Unplug

sprayer from outlet

Setup

Make sure sprayer is turned off and unplugged from

power source. Refer to your sprayer instruction manual

for spray setup.

Connect Gun to Siphon Cup

1. Attach air hose from sprayer to

inlet fitting of gun.

ti12797a

ti12795a

Adjust Flow and Pattern Size

Flow and pattern size is determined by the flow control

knob. Set knob at 0. Increase flow to attain desired spray

pattern.

ti12772a

ti12823a

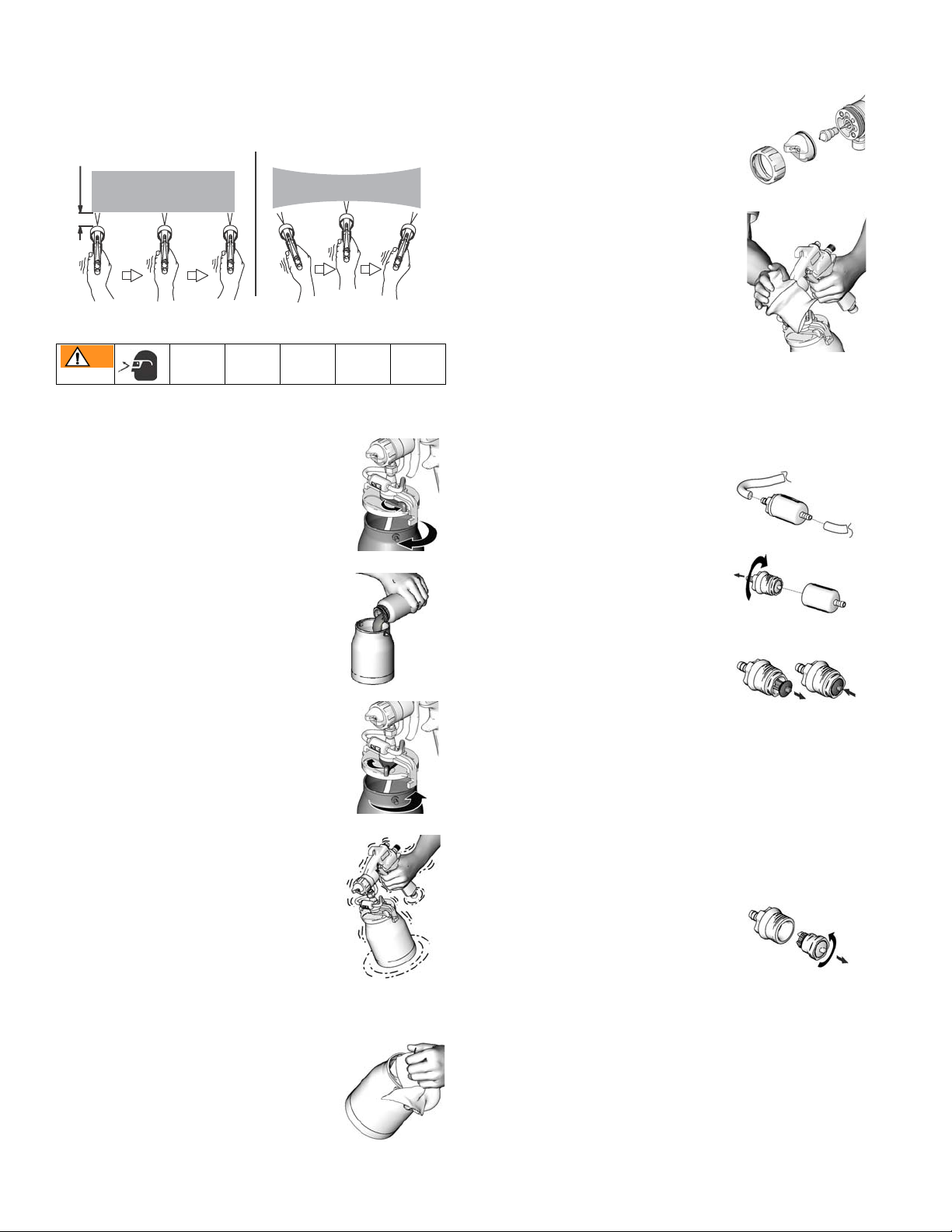

Spray

1. Keep gun perpendicular to surface and at a distance

of 6 to 8 in. (150 to 200 mm) from surface.

2 313317C

Page 3

2. Have spray gun in motion before triggering. Move

spray gun in a straight, smooth stroke. Release

trigger at end of stroke.

6 to 8 in. (150 to 200 mm)

Operation

8. Remove retaining ring, air cap

and fluid nozzle. Clean in solvent

or water. Clean face of gun with a

solvent or water dampened rag.

RIGHT

WRONG

ti12793a

Cleaning Spray Gun

Before cleaning gun, read all warnings and do Pressure

Relief Procedure.

1. Remove siphon cup. Empty spray

material from siphon cup.

ti12775a

2. Pour small amount of solvent or

water recommended by spray

material manufacturer into siphon

cup.

ti12778a

9. Assemble gun. Wipe gun with

solvent or water dampened rag.

ti12780a

Check Valve Troubleshooting

Recommended if fluid is in the check valve.

Poppet Valve Quick Clear

1. Disconnect check valve from

siphon cup air hoses.

ti13104a

2. Unscrew check valve.

ti13105a

3. Pull out on nub on poppet

valve and release.

3. Latch the gun cup cover to secure

it to siphon cup.

4. Swirl solvent or water inside of gun.

5. Spray solvent or water into waste

pail until spray appears to be clean.

6. Remove siphon cup. Empty

remaining solvent or water from

siphon cup.

7. Clean inside of siphon cup with a

clean rag.

ti12775a

ti12872a

ti12906a

ti12905a

ti13106a

4. Assemble check valve. Install

on air hoses.

5. Try spraying again to see if

spraying is normal.

Check Valve Cleaning

1. Do steps 1 and 2 of Poppet Valve Quick Clean.

2. Unscrew poppet valve from

check valve.

3. Clean all parts in solvent recommended by spray material

manufacturer.

4. After all parts are dry apply a light coat of petroleum

jelly all over o-ring.

5. Assemble check valve. Install on air hoses.

ti13107a

313317C 3

Page 4

Needle Replacement

Needle Replacement

Removal

1. Relieve pressure.

2. Remove air cap (1).

3. Push trigger slide (4) over to NEEDLE REMOVAL

position (D) shown on page 2.

4. Remove fluid nozzle (2).

5. Pull needle (3) out.

Installation

1. Insert needle (3).

2. Install fluid nozzle (2).

3. Push trigger slide (4) over to SPRAY position (E)

shown on page 2.

4. Install air cap.

Material / Fluid Set Selection Guide

Material Fluid Set #2

256946

Dye

Ink

Non-Wiping Stain

Automotive Finish

Lacquer

Stain

Enamel

Epoxy

Urethane

Var nis h

Primer

Industrial Finishes

Latex

Multi-Spec

Butyrate

Nitrate Dope

Oil Wall Paint

Fluid Set #3

256947

Fluid Set #4

256948

Fluid Set #5

256949

Fluid Set #6

256950

6

3

4

2

1

5

ti12766a

Selecting Fluid Sets:

Grooves at end of fluid needle indicate

size of fluid set. Example: Needle with 2

grooves on end goes with #2 fluid set.

#2

ti13753a

Swivel Tube Adjustment

The adjustable swivel tube allows the gun to be held in

any position while spraying.

Optional Artisan Air Valve (256927)

Installation

1. Remove air plug housing.

To adjust the position of the tube in the cup:

1. Loose nut (F). Rotate cup to desired spray position.

2. Install Artisan air valve.

2. Tighten nut (F).

F

ti12776a

4 313317C

ti12777a

ti12910a

Page 5

Troubleshooting

Problem Cause Solution

Orange peel finish - Paint

surface not smooth

Blushing - clear coatings

appear milky

Fish eyes - small pools on

painted surface that will not

fill

Runs and sags Applying too much paint per pass for

Solvent pops or bubbles Sprayed surface drying before sol-

Pain droplets too large • Maintain proper spraying distance, page 2.

Paint droplets drying too fast to properly flow out of gun

Cold weather spraying Keep fluid and object being sprayed as close to

Moisture condensation is trapped in

lacquer when spraying in hot, humid

conditions

Silicone contamination from lubricants, grease, polish, or waxes on

the surface being sprayed

the drying conditions

vent gas can be released

Troubleshooting

• Keep turbine air filters clean to allow full air

flow.

• Do not use an air hose that is too long to

provide sufficient atomization pressure.

• If droplets are still too large, reduce fluid.

Keep object being sprayed out of direct sunlight.

When spraying in warmer temperatures, use a

slower evaporating solvent or a reducer.

room temperature as possible. When spraying

on a cold surface, most paints will become too

thick to flow properly.

• Allow turbine to warm up a few minutes

before spraying.

• Store lacquer off concrete floors, at room

temperature.

• Apply lighter coats and allow for proper drying time.

• Use a slower evaporating solvent or

reducer.

• Do not spray in windy conditions.

Clean all parts with a cleaning solvent; wipe with

a solvent rag and a clean rag. Replace rags as

needed. If problem persists, use a fish eye eliminator.

• Move gun faster or decrease fluid flow.

• Maintain proper spraying distance, page 2.

• Reduce amount of thinner or use a faster

drying thinner.

• Apply fluid in lighter coats to allow for proper

evaporation.

• Use the recommended thinners.

• Follow the solutions for Orange Peel Finish,

Paint Droplets Too Large in this Troubleshooting Table.

313317C 5

Page 6

Problem Cause Solution

No or slow fluid flow, intermittent spray, or fluttering spray

Fluid leaks at fluid nozzle

after trigger is released

Poor spray pattern Air cap horn hole and/or fluid nozzle

Wrong size fluid set being used Select proper fluid set for fluid being sprayed,

Gun fluid nozzle blocked by dried

paint or damaged

Cup or pressure pot cover not tight

enough or gasket damaged

Cup or pressure pot fluid tubes

blocked by dried paint or damaged

Air flow to cup blocked To check, remove cup (leave cover connected).

Needle packings not properly

adjusted.

Note: Fluid loss through packings

affects fluid pressure and causes a

fluid leak from gun body.

Plugged inlet strainer Replace strainer if plugged or remove strainer if

Needle not seating in fluid nozzle Check for a loose fluid nozzle or a bent nozzle

plugged

Technical Data

page 4

Clean or replace fluid nozzle

Tighten cover or replace gasket

Clean or replace fluid tubes

Trigger gun and check air flow out of check

valve. If air is not flowing freely, clean or replace

check valve.

Clean gun body with solvent and brush provided. Adjust needle packings.

material is high viscous.

or needle; tighten nozzle or replace parts as

needed.

Soak air cap and/or fluid nozzle in solvent.

Clean air cap horn holes with non-metallic item

to avoid permanently damaging them.

Technical Data

Maximum inlet fluid pressure 50 psi (0.35 MPa, 3.5 bar)

Maximum inlet air pressure 10 psi (0.07 MPa, 0.7 bar)

Air inlet Quick-disconnect

Fluid inlet 3/8 nps

Sound levels per ISO 3744

Sound power level less than 65.0 dB(A)

Sound pressure level less than 65.0 dB(A)

Wetted parts

Bare spray gun stainless steel, aluminum

Spray gun cups aluminum, polyethylene

1-quart optional remote cup aluminum, polyethylene

6 313317C

Page 7

Parts

Parts

22a

22b

10

3

21

22

37

9

44

14

8a

8c

8b

8d

8

15

7

45

29

29c

29b

29a

24

29d

23

1

25

13

12

32

2

19

17

Ref Part Description Qty

1 256858 BODY, gun 1

2 188493 PACKING, u-cup, gun 1

3 257108 HOUSING, nozzle 1

7 192348 NUT, head 1

8 256960 KIT, includes 8a, 8b, 8c, 8d 1

8a SPREADER, u-cup 1

8b PACKING, u-cup 1

8c SPACER, packing 1

8d NUT, head 1

9 256951 HOUSING, air, cap 1

10 256861 RING, retaining, cap, air 1

12 257087 VALVE, air 1

13 15V846 TRIGGER 1

14 280545 PIN, slide, trigger, w/ball 1

15 15V848 NUT, slide, trigger, pin 1

17 257086 VALVE, fluid 1

19 114069 SPRING, compression 1

21 196468 FITTING, adapter 1

22 244130 CUP, 1qt, under (includes 22a, 22b) 1

Translated Manuals

ti12764a

Ref Part Description Qty

22a M70424 CUP, gasket 1

22b 244132 CUP, bottom 1

23 196463 TUBE, handle 1

24 277950 HANDLE, gun 1

25 196464 COUPLER, male 1

29 256957 CHECK VALVE, complete, includes

29a, 29b*, 29c, 29d

29a FITTING, adapter 1

29b* POPPET, check valve assembly 1

29c FITTING, air 1

29d TUBE, air, cup 2

32 15V844 HOUSING, plug, fluid 1

37 193218 STRAINER 1

44 See Material / Fluid Set Selection

Guide table, page 4,

45 M70394 STEM, air pressure 1

▲ Replacement Danger and Warning labels, tags, and cards

are available at no cost.

* Three-pack Check Valve Repair Kit 256956 is available

1

English - 313317 Spanish - 313339 French - 313325 Korean - 313617 Chinese - 313618

313317C 7

Page 8

Graco Standard Warranty

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in material

and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by

Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective.

This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco

component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance of structures,

accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of the

claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned to the

original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will be made

at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO

WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY

GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their

manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or the

furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of

Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite de

ou en rapport, directement ou indirectement, avec les procédures concernées.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty Program”.

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

or call 1-800-690-2894 to identify the nearest distributor.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 313317

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

www.graco.com

12/2008, Revised 09/2009

8 313317C

Loading...

Loading...