Page 1

Instructions-Parts

24G621 Agitator Speed Controller

3A1315A

Accessory

Accessory kit to control and automatically maintain the speed of an air-powered agitator.

For profess

Patent Pending

ional use only.

Important Safety Instructions

Read all warnings and instructions in this manual

and in your separate agitator manual. Save these instructions.

ENG

PROVEN QUAL ITY. LEADING TECHNOLOGY.

TI17253a

Page 2

Contents

Installation.......................................................... 3

Operation........................................................... 5

Troubleshooting.................................................. 6

Repair................................................................ 7

Kit Parts............................................................. 8

Technical Data ...................................................10

Notes ............................................................... 11

Graco Standard Warranty.................................... 12

2

3A1315A

Page 3

Installation

The agitator speed controller fits the following Graco

pneumatic rotary motors:

Motor Part No.

101140

16A871

101388

111310

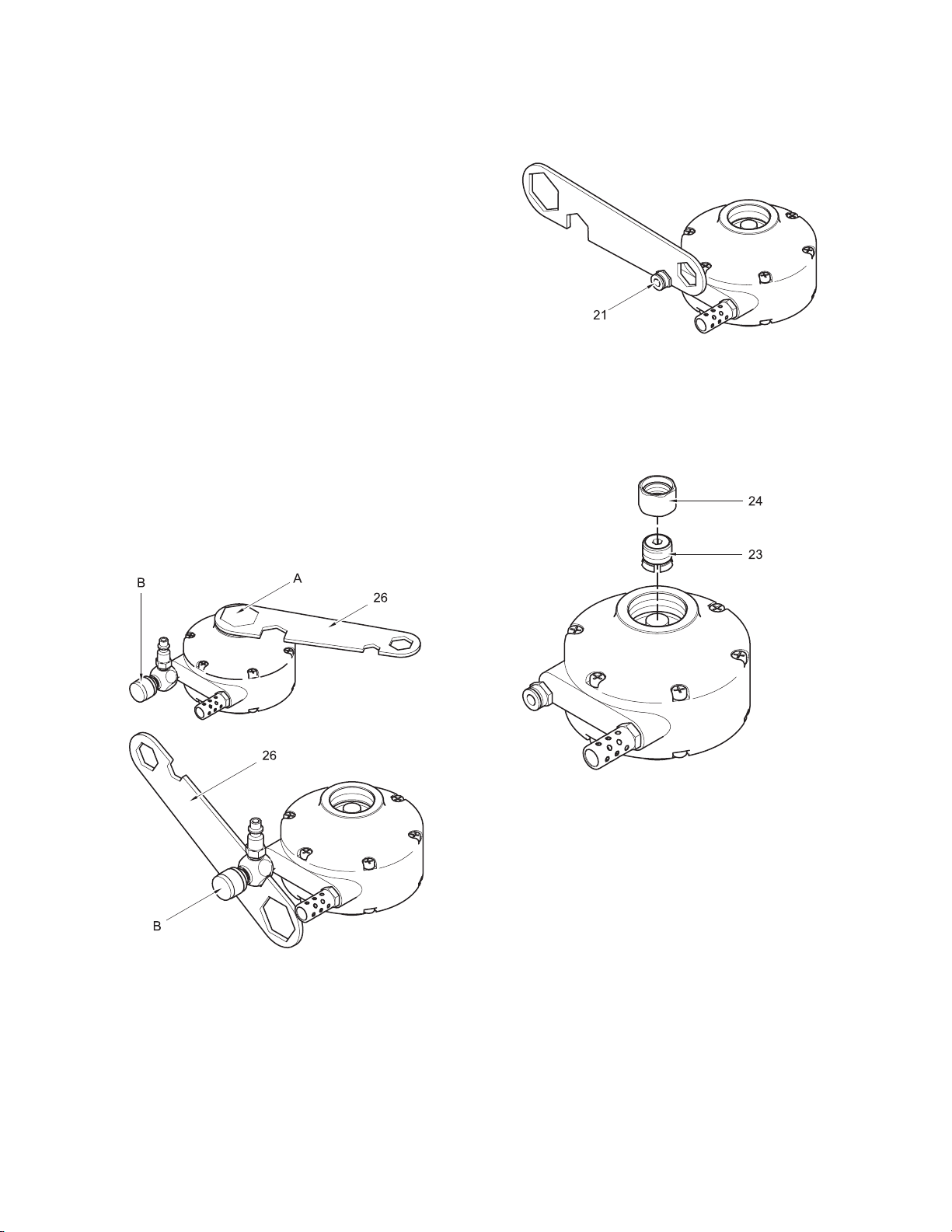

2. Install the push-to-connect air tube connector

(21) in place of the needle valve.

NOTE: Before installing, ensure that the agitator

air motor has at least 5 in. (12.7 cm) of vertical

clearance and 4 in. (10.2 cm) of horizontal clearance

in all directions around it.

NOTE: If you are using an air line lubricator, install it

in the air line upstream of the speed controller.

1. Remove the air motor top cap (A) and needle

valve (B) using the multi-function wrench (26).

Store these parts in a safe place; they will be

needed if the speed controller is ever removed.

TI17254a-1

TI17256a-1

3. Screw the compression nut (24) onto the flange

connector (23) finger-tight. Place the connector

assembly (23, 24) onto the exposed shaft of the

air motor, flange connector side down.

TI17257a-1

TI17255a-1

3A1315A 3

Page 4

4. Using the allen wrench (25) and multi-function

wrench (26), tighten the compression nut (24)

onto the flange connector at least 1/8 turn past

finger tight. This provides a firm connection to

the motor shaft.

TI17258a-1

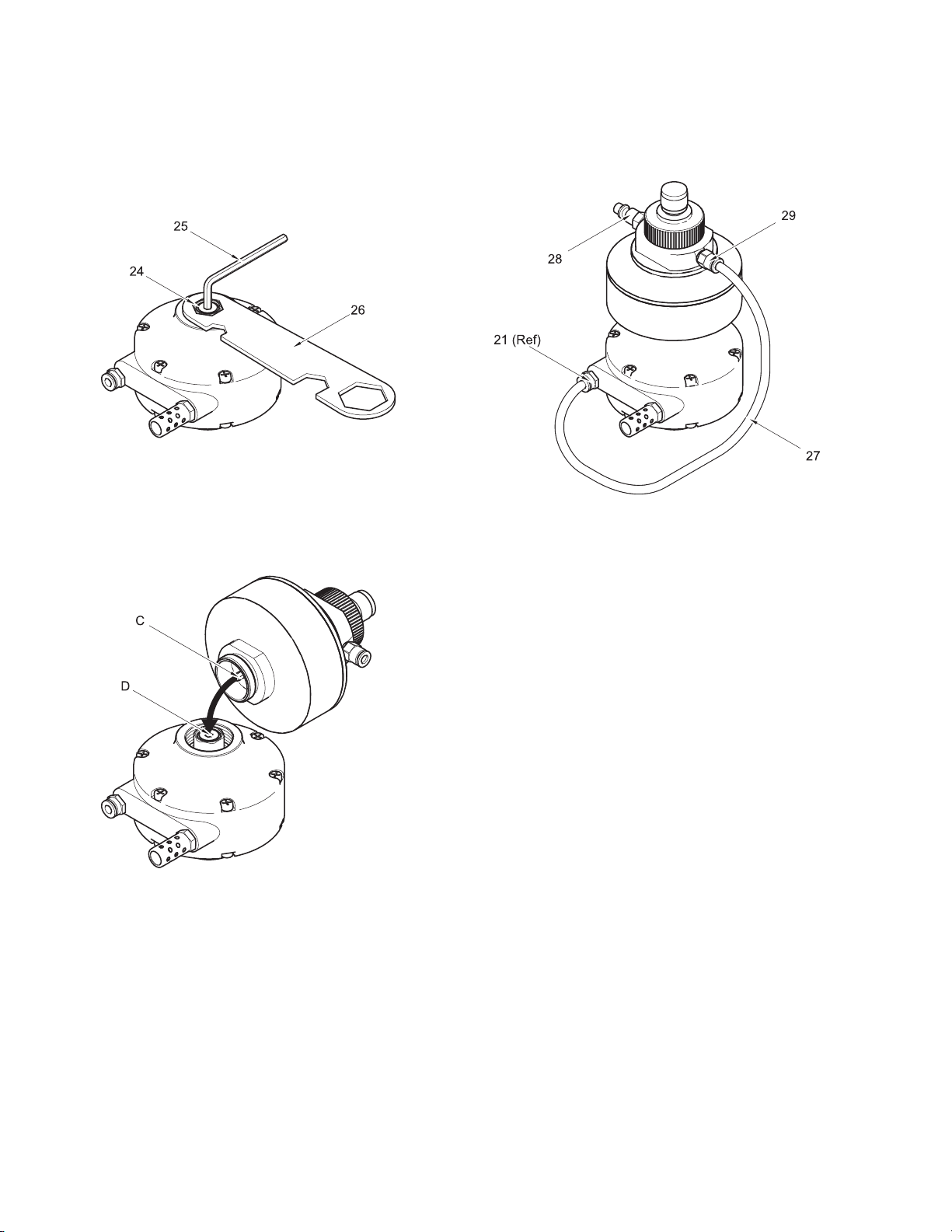

6. Connect the air tubing (27) between the speed

controller tube connector (29) and the air motor

tube connector (21).

5. Ensure that the drive shaft hex (C) engages the

hex socket (D) in the flange connector. Screw

the base of the speed controller into the threads

at the top of the air motor until hand tight.

TI17259a-1

TI17253a-1

7. Return the unit to service. Connect the main air

line to the quick-disconnect fitting (28) on the

speed controller.

4

3A1315A

Page 5

Operation

Connect the main air line to the quick disconnect

fitting (28) on the agitator speed controller. Do not

exceed the maximum air inlet pressure of 100 psi

(0.7 MPa, 7.0 bar).

Set the agitator speed using the knob (16) on

the top of the speed controller. Turn the knob

counterclockwise (outward) to increase agitator

speed. Turn the knob clockwise (inward) to decrease

agitator speed. Once the desired agitator speed is

set, the speed controller will maintain that speed by

regulating the airflow to the air motor.

Turn knob counterclockwise

to increase speed.

28

16

Turn knob clockwise

to decrease speed.

TI17260a-1

To shut off the agitator, disconnect the air supply or

turn the speed adjustment knob clockwise until it is

fully closed.

3A1315A 5

Page 6

Troubleshooting

Problem

The speed controller does not adjust for a change in

load, or shuts off before the knob (16) is turned all

the way down.

The speed controller does not maintain a consistent

speed, or the speed rapidly fluctuates.

Upon startup, the motor runs away for a few seconds

before the speed controller slows it down.

Solution

Remove the needle (13). and liberally lubricate the

needle and o-ring (33) with multi-purpose lithium

based grease.

Replace the needle (13), u-cup (11), and o-ring (33),

using Repair Kit 24J886.

Ensure that the compression nut (24) and flange

connector (23) are securely tightened to the motor

shaft. See Installation, page 3 .

6 3A1315A

Page 7

Repair

NOTE: To repair the agitator, see your separate

agitator manual.

NOTE: Repair Kit 24J886 is available. Order the kit

separately. Kit parts are marked with an asterisk, for

example (3*). For the best results use all the parts

in the kit.

NOTE: Use multi-purpose lithium based grease

where ever lubrication is required. Order Part No.

111920.

1. Disconnect the main air line to the speed

controller.

2. Disconnect the tube (27) connecting the speed

controller and air motor.

3. Unscrew the adjustment nut (15) from the upper

housing (2). Turn the knob (16) fully clockwise

(inward) to access the o-ring (18) on the bottom

plate of the seat (14). Remove the o-ring and

replace with the new o-ring (18*). Lubricate the

o-ring.

4. Remove the large o-ring (19) on the upper

housing (2). Replace with a new o-ring (19*).

Lubricate the o-ring.

5. Unscrew the upper housing (2) from the lower

housing (1). The drive shaft (4) and cam arms (8)

may come out of the lower assembly.

6. Remove the two ball bearing assemblies (3, 20)

from the drive shaft (4). Replace with the new

ball bearing assemblies. Install the larger ball

bearing assembly (3) on the bottom of the shaft.

Install the smaller ball bearing assembly (20*) on

the top of the shaft, above the large washer (12).

NOTE: The ball bearing assemblies each consist

of one bearing and two washers. Place one

washer above the bearing and the other washer

below the bearing before installing the assembly.

7. Push the needle (13) out of the upper housing

(2) from the top. Using an o-ring pick, remove

the u-cup (11) and o-ring (33) from the upper

housing. Lubricate the new o-ring (33*) and

u-cup (11*) and install in the upper housing. The

lips of the u-cup must face up.

8. Lubricate the new needle (13*) and install in the

upper housing (2) from the bottom, being sure to

align the flat face on the needle with the mating

flat surface in the housing.

9. Ensure that the cam arms (8) align with the

groove on the bottom side of the large washer

(12). Install the drive shaft (4) and cam arm

assembly into the lower housing (1), making sure

the bearing (3*) seats fully in the recess of the

housing.

10. Screw the upper housing (2) fully onto the lower

housing (1).

11. Turn the adjustment knob (16) all the way

counterclockwise (outward). Screw the

adjustment nut (15) fully onto the upper housing

(2).

12. Connect the air tubing (27) between the speed

controller tube connector (29) and the air motor

tube connector (21).

13. Return the unit to service. Connect the main air

line to the quick-disconnect fitting (28) on the

speed controller.

ti17005a

3A1315A

7

Page 8

Kit Parts

The kit contains all necessary parts and tools to

install the agitator speed controller.

Ref.

No.

1

2

3* BALL BEARING

4 SHAFT, drive 1

5

Description

HOUSING, lower, speed controller

HOUSING, upper, speed controller

BAR, mounting 2

Qty

1

1

1

Ref.

Description

No.

27

TUBE, nylon; 1/4 in. (6 mm) OD; 2

ft (0.6 m)

28

FITTING, quick-disconnect, air; 1/8

npt(m)

29

CONNECTOR; 1/8 npt(m) x 1/4 in.

(6 mm) OD tube

33* O-RING; buna-N; 0.375 in. (9.5

mm) OD

* These parts are included in Repair Kit 24J886.

Qty

1

1

1

1

6

SCREW, machine, pan-head; 8–32

1

x3/4in. (19mm)

7

NUT, hex; 8–32 1

8ARM,cam 2

9

BEARING, sleeve; bronze

2

10 PIN 2

11* PACKING, u-cup; UHMWPE

1

12 WASHER, speed controller 1

13*

14

NEEDLE, speed controller 1

SEAT, needle

1

15 NUT, adjustment 1

16

KNOB, adjusting

18* O-RING; chemically resistant

1

1

fluoroelastomer; 0.816 in. (20.7

mm) OD

19* O-RING; chemically resistant

1

fluoroelastomer; 1.5 in. (38 mm) OD

20* BALL BEARING

21

CONNECTOR; 1/4 npt(m) x 1/4 in.

1

1

(6 mm) OD tube

TI17004a-1

22

O-RING; chemically resistant

1

fluoroelastomer; 0.441 in. (11.2

mm) OD

23

CONNECTOR, flange; 3/16 hex

1

socket

24 NUT, compression 1

25

26

WRENCH, allen; 3/16 hex

WRENCH, multi-function

1

1

TI17253a-1

8 3A1315A

Page 9

ti17005a

3A1315A 9

Page 10

Technical Data

Maximum air supply pressure

Minimum air supply pressure

Maximum speed 1000 rpm

Maximum speed controller air temperature

Main air inlet size

Speed control range

Diameter

Height (installed) 4.5 in. (114 mm)

Weight 1.4 lb (0.64 kg)

100 psi (0.7 MPa, 7 bar)

70 psi (0.5 MPa, 4.9 bar)

130°F (55°C)

1/8 npt quick-disconnect fitting

100–1000 rpm

4in. (102mm)

10 3A1315A

Page 11

Notes

3A1315A

11

Page 12

Graco Standar

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its

name to be free from defects in material and workmanship on the date of sale to the original purchaser for

use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a

period of twelve months from the date of sale, repair or replace any part of the equipment determined

by Graco to be defective. This warranty applies only when the equipment is installed, operated and

maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper

maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall

Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment

with structures, accessories, equipment or materials not supplied by Graco, or the improper design,

manufacture, installation, operation or maintenance of structures, accessories, equipment or materials

not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimedtobedefectivetoan

authorized Graco distributor for verification of the claimed defect. If the claimed defect is verified, Graco

will repair or replace free of charge any defective parts. The equipment will be returned to the original

purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material

or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of

parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obli

The buyer agrees that no other remedy (including, but not limited to, incidental or consequential damages

for lost profits, lost sales, injury to person or property, or any other incidental or consequential loss) shall

be available. A

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH

ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT MANUFACTURED BY

GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.),

are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable

assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from

Graco supplying equipment hereunder, or the furnishing, performance, or use of any products or other

goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or

otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents,

notices and legal proceedings entered into, given or instituted pursuant hereto or relating directly or

indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du

présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés,

donnés ou intentés, à la suite de ou en rapport, directement ou indirectement, avec les procédures

concernées.

gation and buyer’s sole remedy for any breach of warranty shall be as set forth above.

ny action for breach of warranty must be brought within two (2) years of the date of sale.

d Warranty

Graco Information

To place an order, contact your Graco Distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original Instructions. This manual contains English, MM 3A1315

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2011, Graco Inc. is registered to ISO 9001

www.graco.com

Loading...

Loading...