Page 1

Instructions

Model 24F531

Model 24F947

Diesel Exhaust

3A1189G

Fluid (DEF) System

For pumping diesel exhaust fluid. Not approved for use in European explosive atmosphere

locations. For professional use only.

50 psi (0.3 MPa, 3.4 bar) Maximum Fluid Working Pressure

50 psi (0.3 MPa, 3.4 bar) Maximum Air Input Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

Model No. 24F531

Wall mounted with meter

Model No. 24F878

Wall mounted without meter

Model No. 24F947

Drum mounted without meter

Model No. 24M499

Drum mounted with meter

Related Manuals:

313048 Meter

308981 Husky Pump

Page 2

Warnings

Warnings

The following general warnings are for the setup, use, grounding, maintenance, and repair of this equipment. Additional, more specific warnings may be found throughout the body of this manual where applicable. Symbols appear-

ing in the body of the manual refer to these general warnings. When these symbols appear throughout the manual,

refer back to these pages for a description of the specific hazard.

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Route exhaust away from work area. If diaphragm ruptures, fluid may be exhausted into the air.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

2 3A1189G

Page 3

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about

your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure. Turn off all equipment

and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area

of the equipment to help protect you from serious injury, including eye injury, hearing loss, inhalation of

toxic fumes, and burns. This equipment includes but is not limited to:

• Protective eye wear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

Pressure Relief Procedure

Follow this Pressure Relief Procedure whenever you:

• Are instructed to relieve pressure.

• Stop dispensing.

• Check, clean or service any system equipment.

• Install or clean fluid nozzles.

1. Turn OFF air supply to pump (F

2. Open the nozzle.

3. Be sure you have a container ready to catch drainage.

IG. 1).

3A1189G 3

Page 4

Installation

K

B

G

D

J

H

C

A

F

E

L

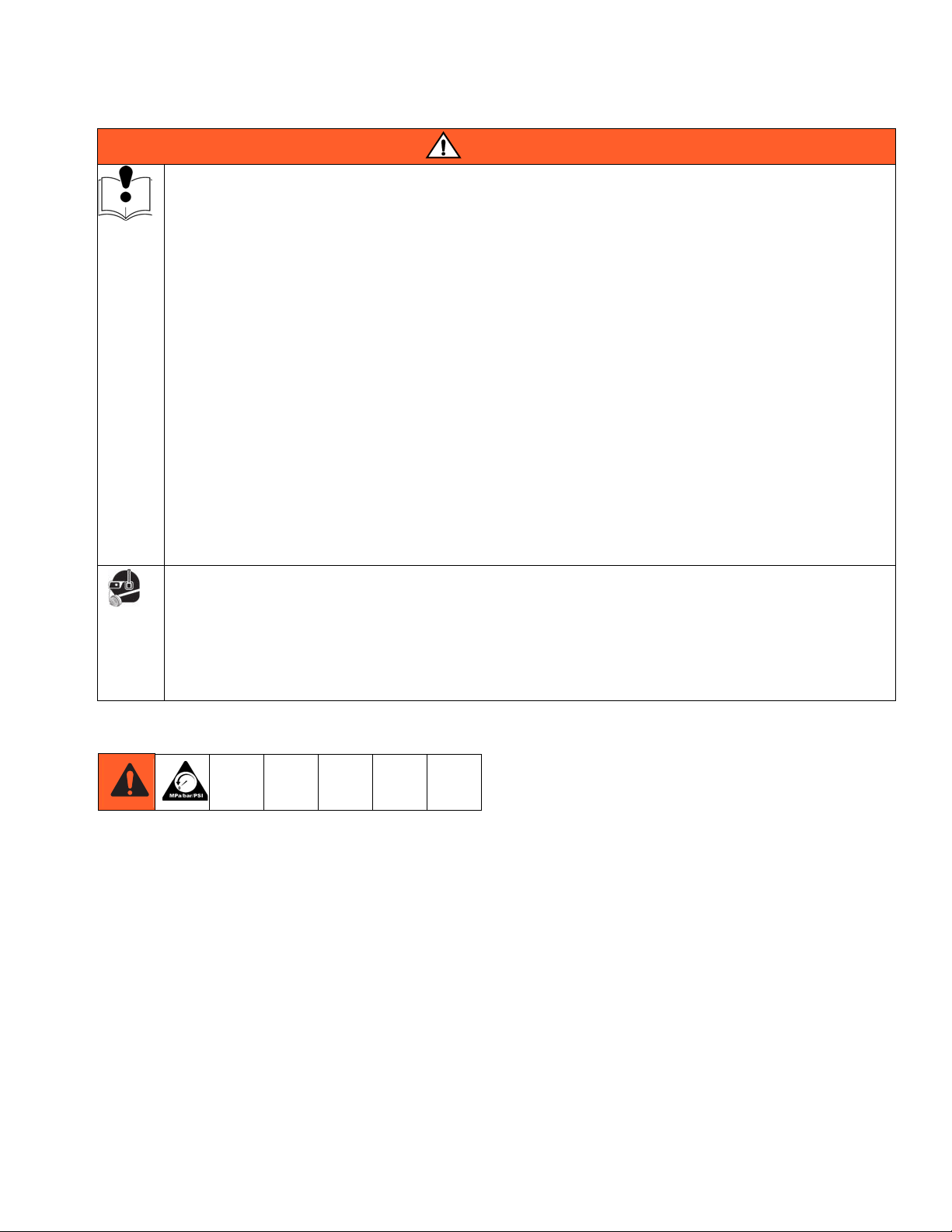

Installation

Typical Installations

Model 24F531 - Wall Mounted, with Meter

Model 24F878 - Wall Mounted, no Meter

FIG. 1

Key

APump

B Bleed-type master air valve (required for pump)

C Air supply line

D Pump air regulator

E Fluid supply hose

F Suction kit

G Wall mounting bracket

H Fluid nozzle

JMeter

K Nozzle bracket and bath

L Safety valve - set to 50 psi (3.4 bar, 0.34 MPa)

4 3A1189G

Page 5

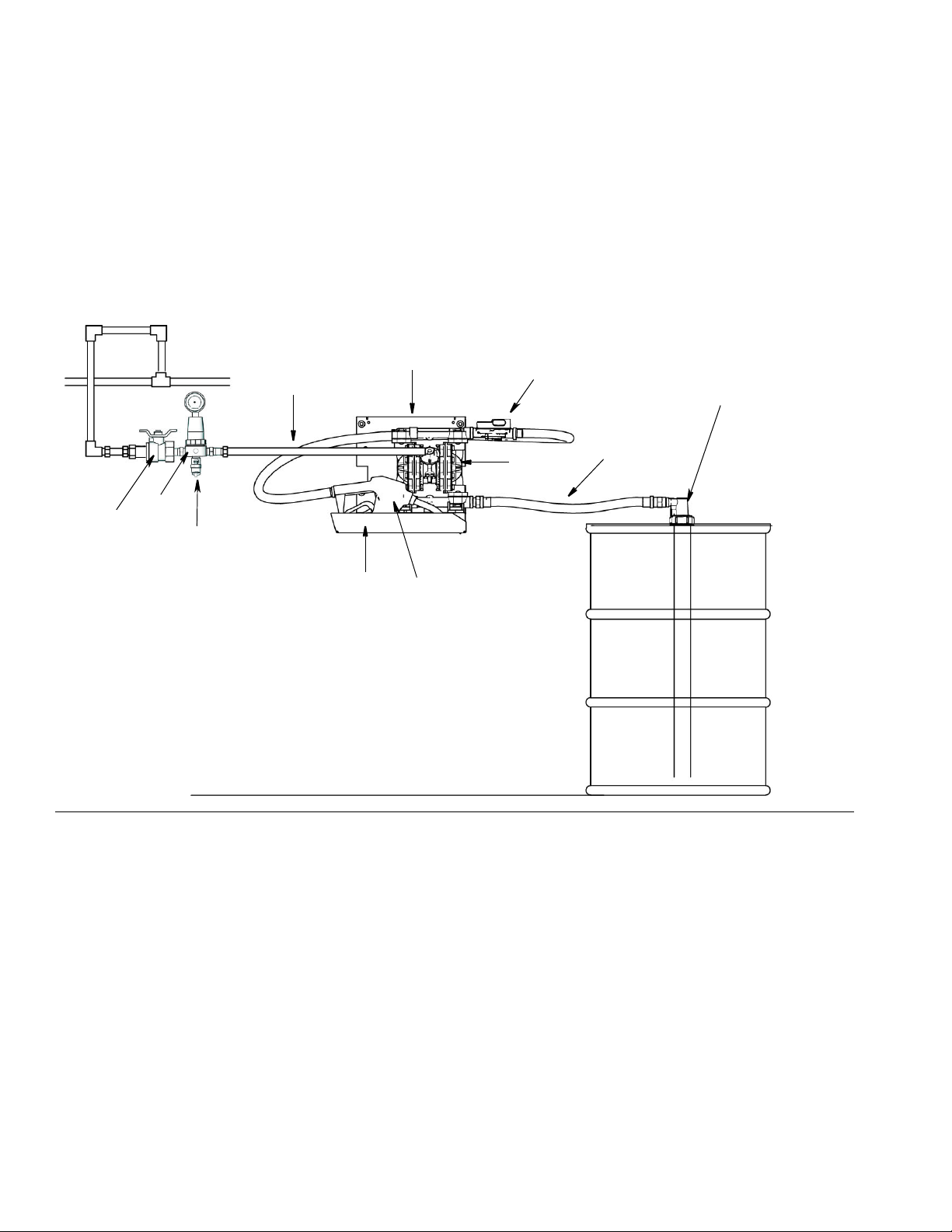

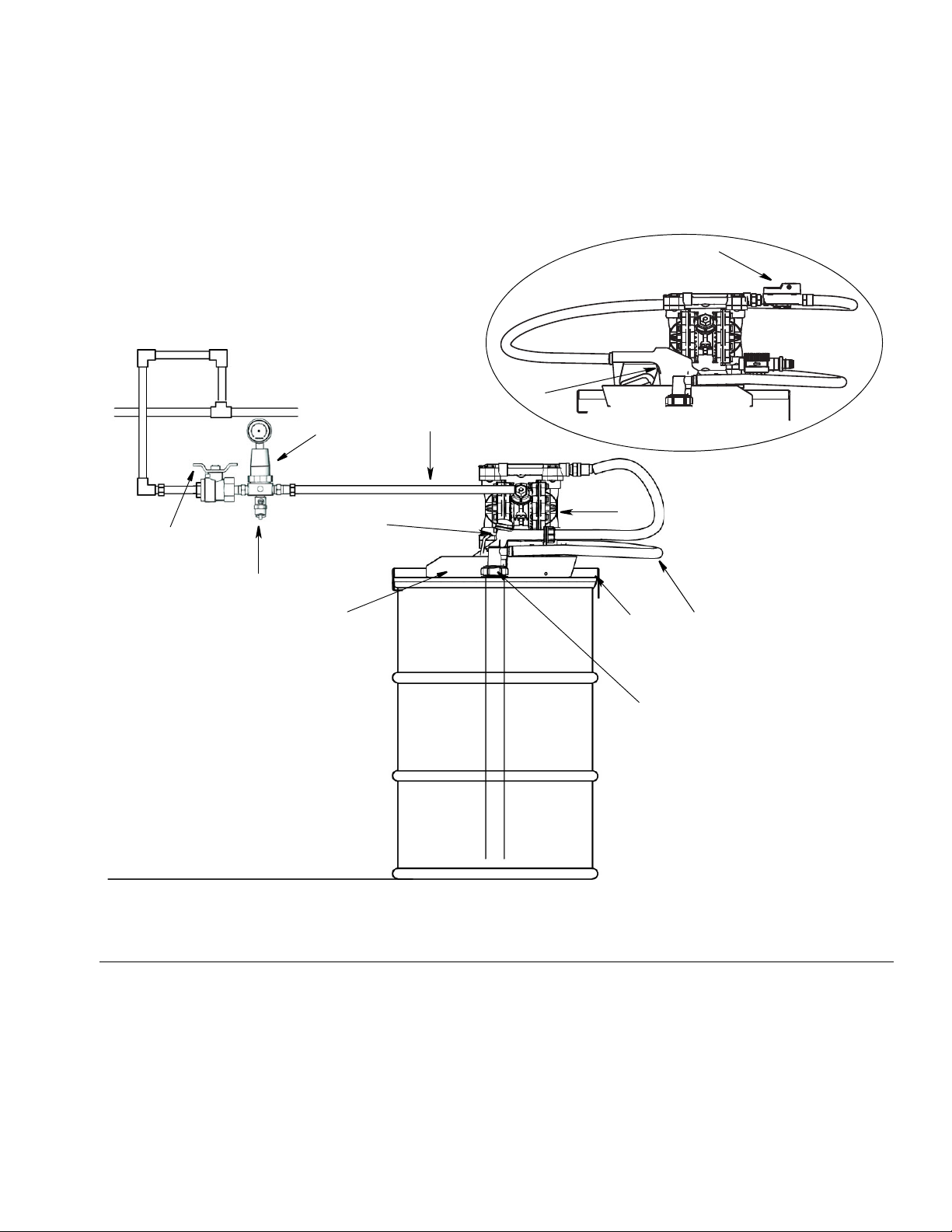

Model 24F947 - Drum Mounted without Meter

A

J

B

D

C

E

F

G

L

K

N

M

Model 24M499

Model 24F947

Model 24M499 - Drum Mounted with Meter

Installation

FIG. 2

Key

APump

B Bleed-type master air valve (required for pump)

C Air supply line

D Pump air regulator

E Fluid supply hose

F Suction kit

3A1189G 5

G Fluid nozzle

J Nozzle tray and bath

K Drum bracket

L Safety valve - set to 50 psi (3.4 bar, 0.34 MPa)

M Meter

N Fluid Nozzle

Page 6

Installation

Installation Date

Drum Bracket Label

Wall Bracket Label

General Installation Information

• The Typical Installation illustrations provided on

pages 4 - 5 are only guidelines for installing system

components. Contact your Graco distributor for

assistance in planning a system to suit your needs.

• To ensure your system is compatible with fluids

being pumped, always use genuine Graco replacement parts and accessories.

• Tighten all connections firmly to avoid air and/or

fluid leaks.

• Storage tanks should be securely anchored to prevent shifting or tipping when empty or full.

NOTICE

To maintain the integrity and purity of the AUS32

(Aqueous Urea Solution 32.5%) and ensure proper

operation of equipment:

• Once the system is assembled it must remain

sealed to insure the integrity of the fluid. Breaking the seal on the system can lead to fluid contamination.

Identification Label for CE Mark

Locate the Diesel Exhaust Fluid (DEF) System identification label adhered to the mounting bracket.

Use a permanent marker or ink pen to write the installation date in the space provided and circle the Part Number for the model you ordered.

F

IG. 3 is provided to assist you in finding the location of

this label on the bracket and the Date Code field on the

label.

• After dispensing DEF, drain all the fluid from the

nozzle, making sure it is pointing downward

when stored in the nozzle holder. DEF remaining

in the nozzle tip and exposed to air will crystallize

and can plug the nozzle.

• DO NOT lay the dispensing nozzle on the ground

or on any surface that may contaminate the nozzle tip and compromise the purity of the DEF.

FIG. 3

6 3A1189G

Page 7

Installation

B

6c

6b

6a

E

F

Pump

For complete pump instructions refer to the pump

instruction manual included with your system.

• If necessary, change the orientation of the fluid inlet

and outlet ports on the pump. See pump instruction

manual for this procedure.

• Retorque bolts per specifications.

Air Line

Alpha letters included in the following instructions refer

to letters shown in Typical Installation examples (F

F

IG. 2, pages 4 - 5).

A bleed-type master air valve (B) is required in your

system to relieve trapped air between the valve and

the pump. Trapped air can cause the pump to cycle

unexpectedly, which could result in serious injury

from fluid splashing in the eyes or on skin, injury

from moving parts or contamination from hazardous

fluids.

Locate one bleed-type master air valve (B) close to the

pump and use it to relieve trapped air (F

IG. 4). For drum

mounted installations only, also locate a second master

air valve upstream from all air line accessories and use

it to isolate them during cleaning and repair.

IG. 1 -

1. Using the hardware provided install the air controls

to the air inlet of the pump as shown in F

IG. 4. Use a

minimum 1/4 in. (6.3 mm) ID air hose.

2. Install an air line quick disconnect coupler onto the

end of the air supply line (C) and screw the matting

fitting into the pump air inlet snugly. Do not connect

the coupler to the fitting yet.

Fluid Supply Hose

Numerals used in the following instructions refer to reference numbers used in the Parts Lists provided on

pages 10 - 11.

1. Screw the fluid supply hose (9) fluid fitting into the

pump inlet snuggly. Do not overtighten.

NOTE: At the inlet, if the fluid pressure is greater than

15 psi (0.1 MPa, 1 bar) the diaphragm life will be shortened.

Fluid Suction Kit (6) - 24F532

Numerals used in the following instructions refer to reference numbers used in the Parts Lists provided on

pages 10 - 11.

The DEF System includes a Fluid Suction Kit containing

the following parts - Drum Coupler (6a), Drum Insert

(6b) and Suction Line (6c).

FIG. 5

NOTE: The suction line (6c) can be used with either a

55 gallon drum or larger totes.

FIG. 4

• If using with a large tote

tion line.

• If using with a 55 gallon drum

line to 39 inches (991 mm). Remove all burrs.

: Do NOT trim the suc-

: Trim the suction

3A1189G 7

Page 8

Installation

The suction line is designed to allow for full evacuation

of the container so it will bend slightly when installed.

1. Connect suction tube (6c) to drum insert (6b) to

pump.

2. Insert suction line (6c) into drum.

3. Install drum coupler (6a) into drum insert (6b)

4. Connect hose (E) to pump fitting. Use a flat-blade

screw driver to tighten hose clamp (F).

5. Connect the air supply line (C) to the air controls.

Nozzle (3) Installation: Models 24F878 and

24F947

Numerals used in the following instructions refer to reference numbers used in the Parts Lists provided on

pages 10 - 11.

Wall Mount Model: 24F878

1. Install hose (9) into back of nozzle (3). Wrench

tighten.

2. Install other end of hose (9) into pump outlet fitting.

Drum Mount Model: 24F947

4. Install meter (10a) to fitting (10c). Wrench tighten.

5. Install fitting (10e) into meter. Wrench tighten.

6. Install hose (9) into fitting (10e).

Mounting Bracket (2) Installation

• When installing bracket, be sure the mounting surface can support the weight of the pump, hoses and

all accessories, as well as the stress caused during

operation.

• On all installations mount the pump using screws

and nuts provided.

• Always keep nozzle bath tray filled with water.

Wall Mounting Kit 24F870 (2): Models 24F531 and

24F878 only

Wall mounted DEF System Models 24F531 and 24F878

include a Mounting Bracket Kit containing the following

parts - Screws (2a), Screws (2b), Washers (2c), Plain

Washers (2d), Hex Nuts (2e), Mounting Plate (2f), Nozzle Bath Holder (2g), Nozzle Holder Bracket (2h) and

screws (2j). The Mounting Bracket and Nozzle Holder

are also identified as items J and M on the Typical

Installation Diagram provided on page 4.

1. Install clamp over end of fluid supply hose (9).

2. Push end of fluid supply hose (9) over end of nozzle

(3) fitting.

3. Position clamp over fitting and hose end. Use a flat

blade screw driver to tighten screw and secure

clamp to the end of hose over barbed fitting.

4. Install other end of hose (9) into pump outlet fitting.

Meter (10) Installation: Models 24F531 and

24M499

Uses Meter Kit 24H293 that includes the following parts:

-Meter (10a), Swivel (10b), Fitting (10c) and Seal (10d)

and Fitting (10e).

1. Install hose (9) into back of nozzle (3). Wrench

tighten.

2. Install pipe swivel fitting (10b) into pump outlet.

Wrench tighten.

3. Install fitting (10c) into swivel (10b). Wrench tighten.

1. Determine location to install mounting plate (2f).

2. Use holes the plate (2f) as a template. Mark mounting hole locations. Use a drill to predrill mounting

holes in mounting surface.

3. Use screws (2a) (provided) to install plate (2f).

4. Align holes in nozzle holder bracket (2h) with holes

in plate (2f). Use screws (2b), nuts (2e) and washers (2d)(provided) to install meter tray plate.

5. Place nozzle bath (2g) in nozzle holder bracket (2h).

Fill bath with water. Keep meter bath filled with

water at all times.

8 3A1189G

Page 9

Operation

Drum Mounting Bracket (2): Model 24F947 or

24M499

Drum mounted DEF System Models 24F947 or 24M499

include a Mounting Bracket Kit containing the following

parts - Screws (2a), Screws (2b), Washers (2d), Hex

Nuts (2e), Mounting Plate (2f), Nozzle Bath Holder (2g),

Nozzle Holder Bracket (2h) and screws (2j). The Mounting Bracket and Nozzle Holder are also identified as

item M on the Typical Installation Diagram provided on

page 5.

1. Assemble pump to bracket.

2. Position drum mounting plate (2f) on top of drum.

3. Use screws (2b), nuts (2e) and washers (2d) (provided) to install mounting plate to pump.

4. Align holes in nozzle holder bracket (2h) with holes

in plate (2f). Use screws (2b), nuts (2e) and washers (2d)(provided) to install meter tray plate.

5. Place nozzle bath tray (2g) in nozzle holder bracket

(2h). Fill bath with water. Keep nozzle bath tray filled

with water at all times.

Flushing

Operation

Alpha letters included in the following instructions refer

to letters shown in Typical Installation examples (F

F

IG. 2, pages 4 - 5).

Priming

1. Hold dispensing nozzle (G) open while at the same

time slowly opening the pump air regulator (D) until

the pump (A) starts to cycle.

2. Allow the pump to cycle slowly until all the air has

been pushed out of the lines and the pump is

primed.

3. If the pump doesn’t prime crack the pump outlet fitting and slowly run the pump until you see fluid filling the pump.

4. Then tighten the connection.

NOTICE

To maintain the integrity and purity of the AUS32

(Aqueous Urea Solution 32.5%) and ensure proper

operation of equipment:

IG. 1 -

After initial assembly and installation, flush the entire

dispensing system by pumping 5-10 gallons of DEF

through it. This purges the system of air and insures any

impurities that may have been in the system are washed

out.

Dispose of the DEF used to flush the system using

approved DEF handling procedures. Do not return the

fluid to the drum or tote or use it in a vehicle.

• Once the system is assembled it must remain

sealed to insure the integrity of the fluid. Breaking the seal on the system can lead to fluid contamination.

• After dispensing DEF, drain all the fluid from the

nozzle, making sure it is pointing downward

when stored in the nozzle holder. DEF remaining

in the nozzle tip and exposed to air will crystallize

and can plug the nozzle.

• DO NOT lay the dispensing nozzle on the ground

or on any surface that may contaminate the nozzle tip and compromise the purity of the DEF.

3A1189G 9

Page 10

Parts

1

2f

3

8

6a

6b

6c

10d

10b

10c

10a

10e

9

2h

2g

2b

2d/2e

Parts

Wall Mounted with Meter: Model 24F531

Wall Mounted without Meter: Model 24F878

Ref Part No. Description Qty

1 24G745 PUMP, diaphragm, 515, plastic,

bsp

2 24F870 KIT, pump bracket, 3 in 1 (See

Kits, page 12)

3 24F529 NOZZLE, w/swivel (model

24F878)

4 110147 REGULATOR, air, 1/4”npt &

gauge (not shown)

5 110223 VALVE, vented 2 way (not

shown)

6 24F532 KIT, suction 1

6a† 124548 COUPLER, quick connect 1

6b† 124549 INSERT 1

6c† 124550 TUBE, down, 47 inch (119.4 cm) 1

7 156971 FITTING, nipple, short (not

shown)

Ref Part No. Description Qty

1

1

1

1

1

2

8 124581 HOSE, cpld, 6', 3/4bspp x cut 1

9 124603 HOSE, 20', 3/4 bspp x 3/4 bspp 1

10 24H293 KIT, meter, auto nozzle (model

24F531 only)

10a 24G738 METER, flow 1

10b† 124964 SWIVEL, pipe, 3/4 x 3/4 bspp 1

10c† 24H292 FITTING, nipple, 3/4 x 1/2 bspp 1

10d† 124965 SEAL, elastomeric, 1/2 bspp 1

10e† 16G760 FITTING, adapter, 3/4 (f) x 1/2

(m) bspp

11 103927 CLAMP, hose (not shown) 2

12 124963 VALVE, safety, air, 50 psi, 1/8 npt

(not shown)

† Parts are included in kit or may be purchased sepa-

rately.

1

1

1

10 3A1189G

Page 11

Drum Mounted without Meter: Model 24F947

2a

3a

14

9a

8

7

1

6a

6b

6c

2b

2d / 2e

2f

2g

2h

3b

9b

10e

10a

10d

10c

10b

Drum Mounted with Meter: Model 24M499

Parts

Ref Part No. Description Qty

1 24G745 PUMP, diaphragm, 515,plastic, bsp 1

2 24F679 KIT, pump bracket, drum mount

(See Kits, page 12)

3a 125078 NOZZLE, manual (model 24F947) 1

3b 24F529 NOZZLE, w/swivel (model 24F499)

4 110147 REGULATOR, air,1/4”npt & gauge

(not shown)

5 110223 VALVE, vented 2 way (not shown) 1

6 24F532 KIT, suction (See Kits, page 12) 1

6a† 124548 COUPLER, quick connect 1

6b† 124549 INSERT 1

6c† 124550 TUBE, down 1

8 124875 HOSE, 2', 3/4 bsp x cut, inlet 1

9a 125079 HOSE, 12”, 3/4 bspp x cut end

(model 24F947)

9b 124671 HOSE, 12', 3/4 bspp x 3/4 bspp

(model 24M499)

Ref Part No. Description Qty

10 24H293 KIT, meter, auto nozzle (model

1

10a 24G738 METER, flow 1

10b† 124964 SWIVEL, pipe, 3/4 x 3/4 bspp 1

10c† 24H292 FITTING, nipple, 3/4 x 1/2 bspp 1

10d† 124965 SEAL, elastomeric, 1/2 bspp 1

1

10e† 16G760 FITTING, adapter, 3/4 (f) x 1/2 (m)

11 103927 CLAMP, hose (not shown) 2

12 124963 VALVE, safety, air, 50 psi,1/8 npt

14 15T366 BOOT, swivel 3/4 black 1

† Parts are included in kit or may be purchased sepa-

1

rately.

1

24M499 only)

bspp

(not shown)

1

1

1

3A1189G 11

Page 12

Technical Data

Bracket (2) Kits

2 - Bracket 24F870: Models 24F531 / 24F878 2 - Bracket 24F679: Model 24F947 / 24M499

2a SCREW, cap, hex head (not shown) 4

2b SCREW, cap, hex head 4

2c WASHER (not shown) 4

2d WASHER, plain 14

2e NUT, hex 7

2f PLATE, pump mount 1

2g HOLDER, nozzle bath 1

2h BRACKET, nozzle holder 1

2j SCREW, HH, 1/4 x 20 x 0.75” (not

2a SCREW, cap, hex head 4

2b SCREW, thumb, 1/4-20 x 2” 2

2d WASHER, plain 12

2e NUT, hex 6

2f PLATE, pump mount 1

2g HOLDER, nozzle bath 1

2h BRACKET, nozzle holder 1

2j SCREW, HH, 1/4 x 20 x 0.75” (not

3

shown)

shown)

Technical Data

Pump

Maximum fluid working pressure 50 psi 0.3 MPA, 3.4 bar

Air pressure operating range 30 to 50 psi 0.2 to 0.3 MPA, 2.1 to 3.4 bar

Operating temperature (based on mechanical stress only and may be altered significantly by pumping certain chemicals.

Consult engineering guides for chemical compatibilities and temperature limits or contact your Graco distributor.

Minimum 40°F 4.4°C

Maximum 88°F 31.0°C

Maximum air consumption 28 scfm 0.672 cubic meters/min.

Maximum free flow delivery 6.5 gpm 25 lpm

Maximum pump speed 163 cpm

Gallons (Liters) per cycle 0.04 gallons 0.15 liters

Sound power level (measured per ISO standard 9614-2)

At 70 psig (0.48 MPa, 4.8 bar) at 50

cycles per minute

At 100 psig (0.7 MPa, 4 bar) at maximum

cycles per minute

Sound pressure level (measured 1 meter from pump)

At 70 psig (0.48 MPa, 4.8 bar) at 50

cycles per minute

At 100 psig (0.7 MPa, 4 bar) at maximum

cycles per minute

Air inlet size 1/4 npt(f)

Air exhaust port size 3/8 npt(f)

Fluid inlet size 1/2 and 3/4 in. bspp (f)

Fluid outlet size 1/2 and 3/4 in. bspp (f)

Wetted parts (in addition to ball, seat and diaphragm materials)

Pump Weight (approximate) 6.5 lbs 2.9 kg

System Weight (approximate) 35 lbs 15.8 kg

US Metric

77 dBa

95 dBa

67 dBa

85 dBa

polypropylene, PTFE, fluoroelastomer, SST

2

12 3A1189G

Page 13

Technical Data

Meter

US Metric

Flow range 0.5 to 15 gpm 1.9 to 57 lpm

Maximum working pressure 50 psi 0.3 MPa, 3.4 bar

Minimum working pressure 5 psi 34 MPa, 0.3 bar

Weight 1.8 lb 0.82 kg

Unit of measurement (Display shows quantity

Factory-set in quarts

in 0.01 increments up to 999.99 gallons,

quarts, pints or liters. Totalizes in gallons or

liters up to 99,999 units.)

Accuracy (At 2.5 gpm (9.5 lpm) at 70°F (21°C),

+/- 2.5% after calibration

with water and 1 gallon dispensed. May

require calibration; out-of-box accuracy is +/5%)

Repeatability (At 2.5 gpm (9.5 lpm), at 70°F

+/- 0.15%

(21°C), with water and 1 gallon dispensed.)

Inlet and outlet 1/2 bspp

Operating temperature range -4°F to 122°F -25°C to 50°C

Storage temperature range -13°F ti 122°F -25°C to 50°C

Wetted parts SST, nickel, fluoroelastomer

Batteries (Recommended batteries: Dura-

®

, Energizer®, Eveready®, EN22®)

cell

®

Duracell

Eveready

is a registered trademark of Duracell Inc.

®

and Energizer® are registered trademarks of Eveready Battery Co., Inc.

2 AA Alkaline

3A1189G 13

Page 14

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM3A1189

For patent information, see www.graco.com/patents.

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2011, Graco Inc. is registered to ISO 9001

www.graco.com

February 2011, revised June 2014

Loading...

Loading...