Page 1

Instructions

ti14059

GLC 4400

Lubrication Controller

For controlling and monitoring single-line resistive, parallel, series progressive and dual

line, automatic lubrication systems. Not for use in explosive atmospheres!

Part No.: 24B591, Series C: DC Power

Part No.: 24B596, Series C: AC Power

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

EN

313855H

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

ELECTRIC SHOCK HAZARD

This equipment must be grounded. Improper grounding, setup, or usage of the system can cause

electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local and national

codes and regulations.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

2 313855H

Page 3

Component Identification

!

A

B

C

D

E

F

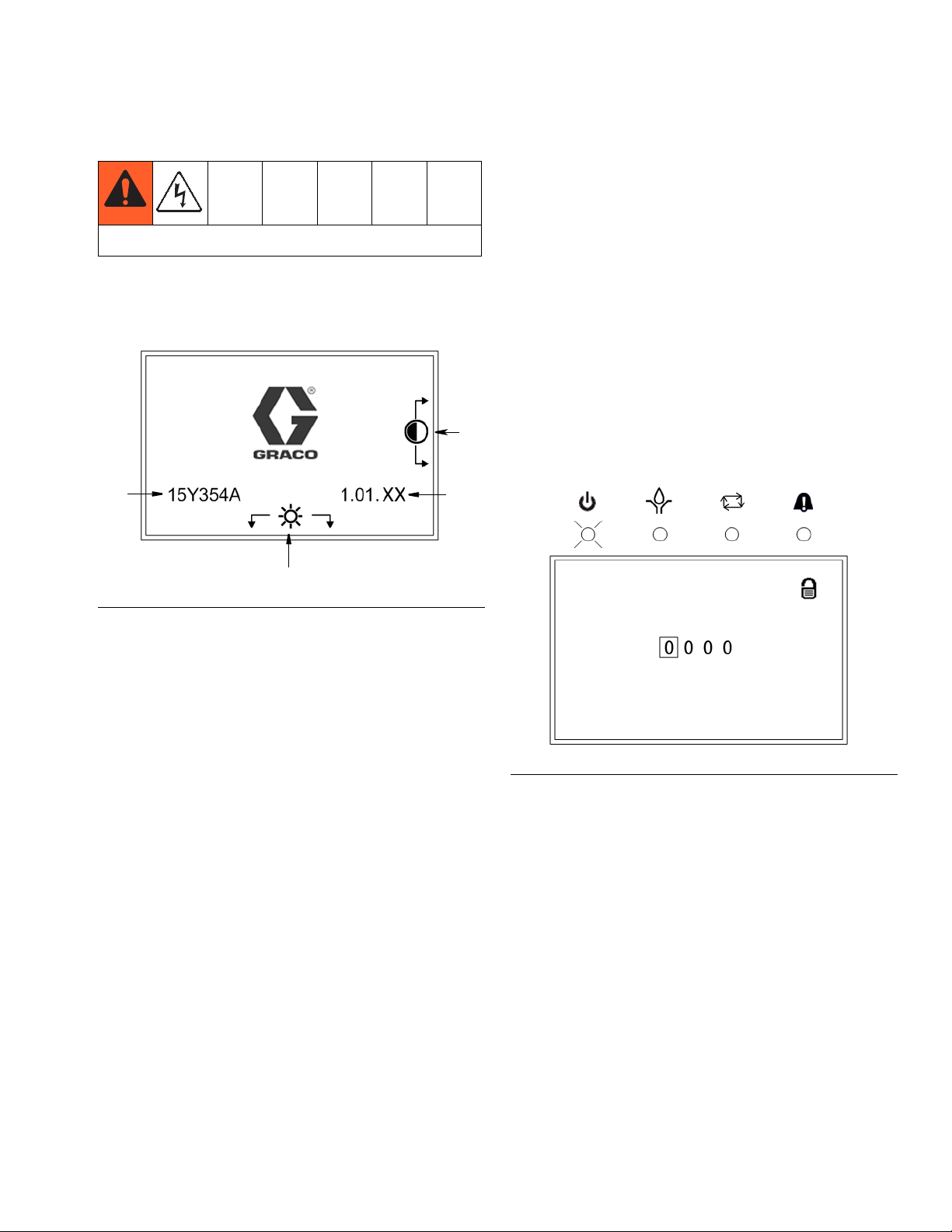

Keypad, Display, and Icons

Component Identification

F

IG. 1

Run Mode Functions

Direction Arrows

A Up and Down Arrow Keys: Adjusts contrast.

B Left and Right Arrow Keys: Adjusts brightness.

• Press the LEFT and RIGHT ARROW keys

simultaneously to manually start a pump cycle.

Keypad Icons

NOTE: Keypad Icons are described on Icon’s page 4.

C ENTER Key: Press and hold for 3 seconds. Allows

access to setup.

D RESET Key: Press and hold for 3 seconds. Resets

unit to normal Pump Off state. Also is used to reset

an alarm condition.

E FUNTION LED: See page 4 for a description of

these icons.

F DISPLAY

313855H 3

Page 4

Component Identification

Icons

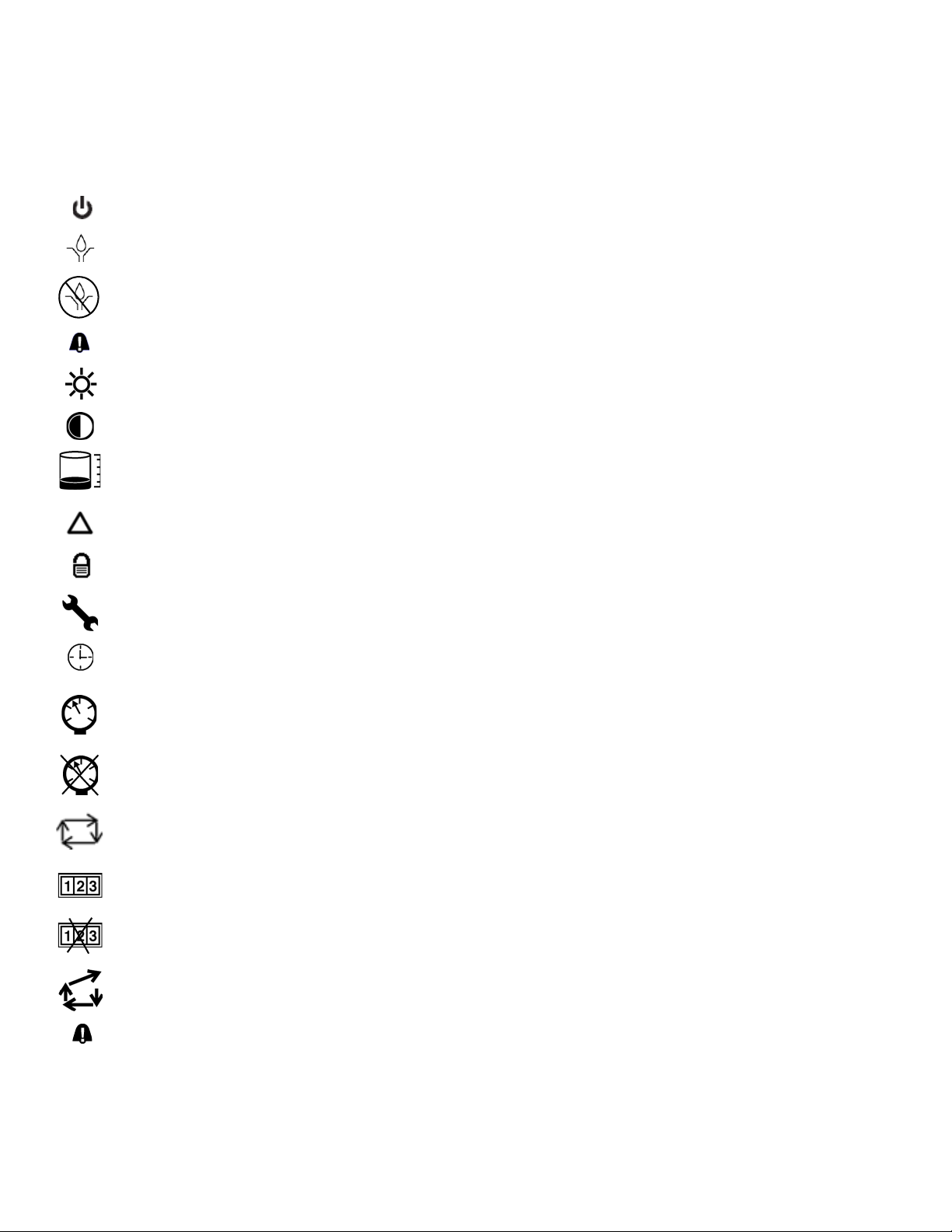

The following icons are used throughout this instruction manual and on the Controller’s Run and Setup Screens.

Refer to this table if you are unsure of an Icon’s meaning.

Power on indicator*. When power is supplied to the Lubrication Controller, Green LED illuminates under Function Icon

located above display screen.

Pump On indicator*. When Pump On is running, Yellow LED illuminates under Function Icon located above display

screen. Icon also is displayed on top left side of Prelube Run screens (see page 30).

Pump Off indicator. When Pump Off is running, icon is displayed on top left side of Run screens (see page 31).

Alarm event activated. LED illuminates when an Alarm event occurs. Icon also displays on top right side of Alarm

screen (see page 32).

Brightness adjustment. Use the LEFT/RIGHT Arrow key to adjust display backlight (brighter or darker) (see page 17).

Contrast adjustment. Use the UP/DOWN Arrow key to adjust screen contrast (see page 17).

Low Level Alarm. Icon appears on display screen. Indicates the lubrication fluid level is low.

Change Icon. When icon appears on PIN setup screen, indicates changes can be made to PIN number or new PIN

number can be added.

Lock Icon. Indicates the Setup screens are password protected and require the user to provide the correct PIN number

to access this feature.

Setup mode active. When user is on the Main Setup Screen in the Setup Mode, icon displays on the upper right corner

of the display screen.

Timer mode activated. Displays on right side of screen when a Timer Setup or Run screen is displayed (pages 18, 21,

30 and 31).

Pressure mode activated. Icon displays on right side screen when a Pressure Setup or Run screen is displayed (page

19 and 30).

Pressure mode error. Icon displays on alarm screen to signal the allotted time ran out before the pressure switch was

tripped.

Cycle count mode active*. Yellow LED illuminates under Function Icon located above display screen. Icon also appears

on right side of display screen when a Cycle Setup or Run screen is displayed (page 19 and 31).

Machine count active. Displays on right side of Setup or Run screen when a Machine Count screen is displayed (page

21 and 32).

Machine count error. When icon displays on alarm screen, indicates the set number of machine counts was not

received before time expired (page 32). This would trigger an alarm event.

Cycle switch input error. Icon displays in center of Alarm screen to indicate the allotted time ran out before the

programmed number of cycle switch activations was received (see Alarm Screen, page 32).

Alarm*. Red LED illuminates under symbol located above display screen. Icon also appears on display when no valid

run values have been entered.

*See Field E, page 3 for location of these Function Icons.

4 313855H

Page 5

Installation

Controller

Capabilities

!

B1

B2

B3

C

E

H

G

F

D

Low Reservoir Level

switch (user provided)

Pressure or Cycle Switch

for system control

(user provided

Machine Counts for

System Control

(user provided)

Pressure Switch or Cycle

Switch Alarm

Low Level Alarm

Remote Alarm Device

(Light or Horn)

(user provided)

A

K

J

Installation

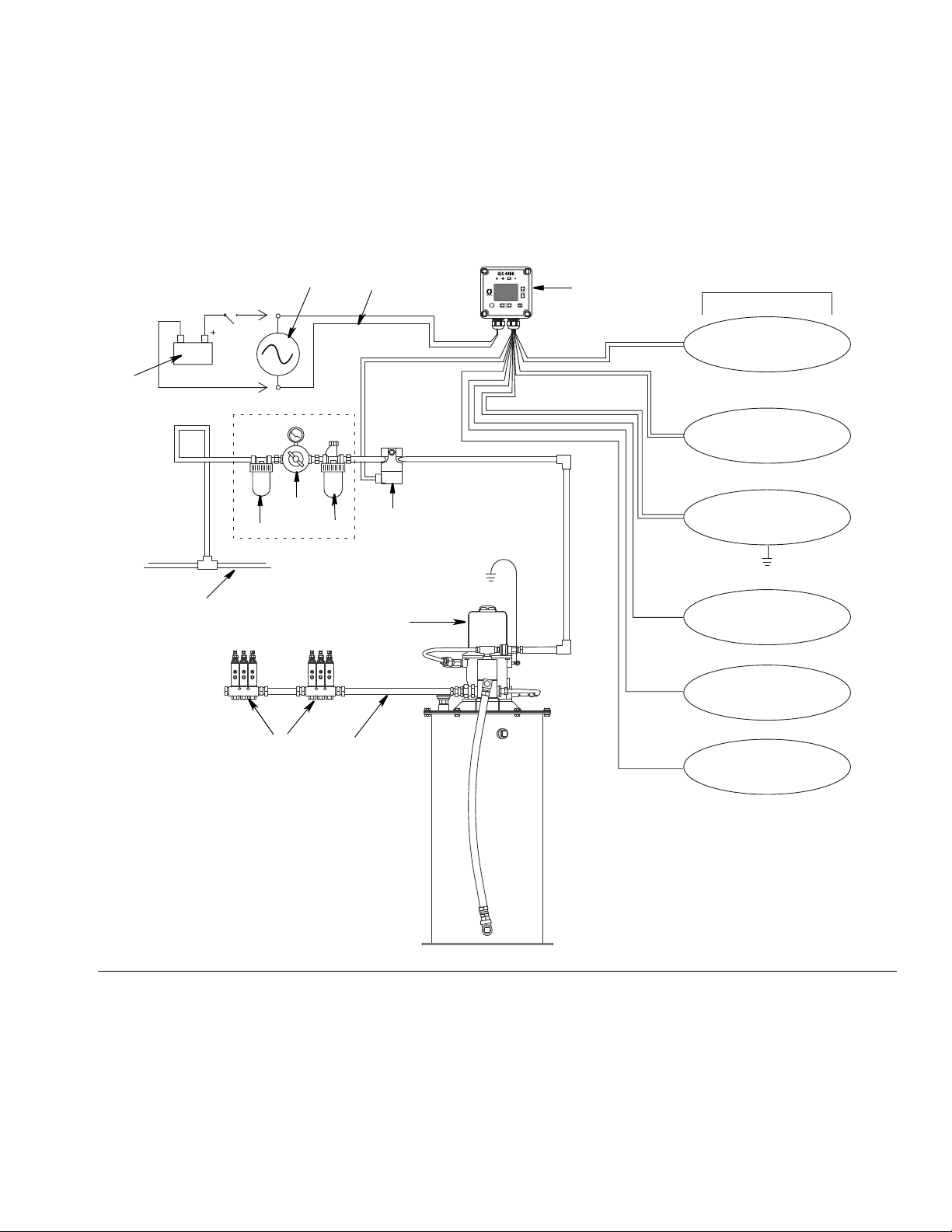

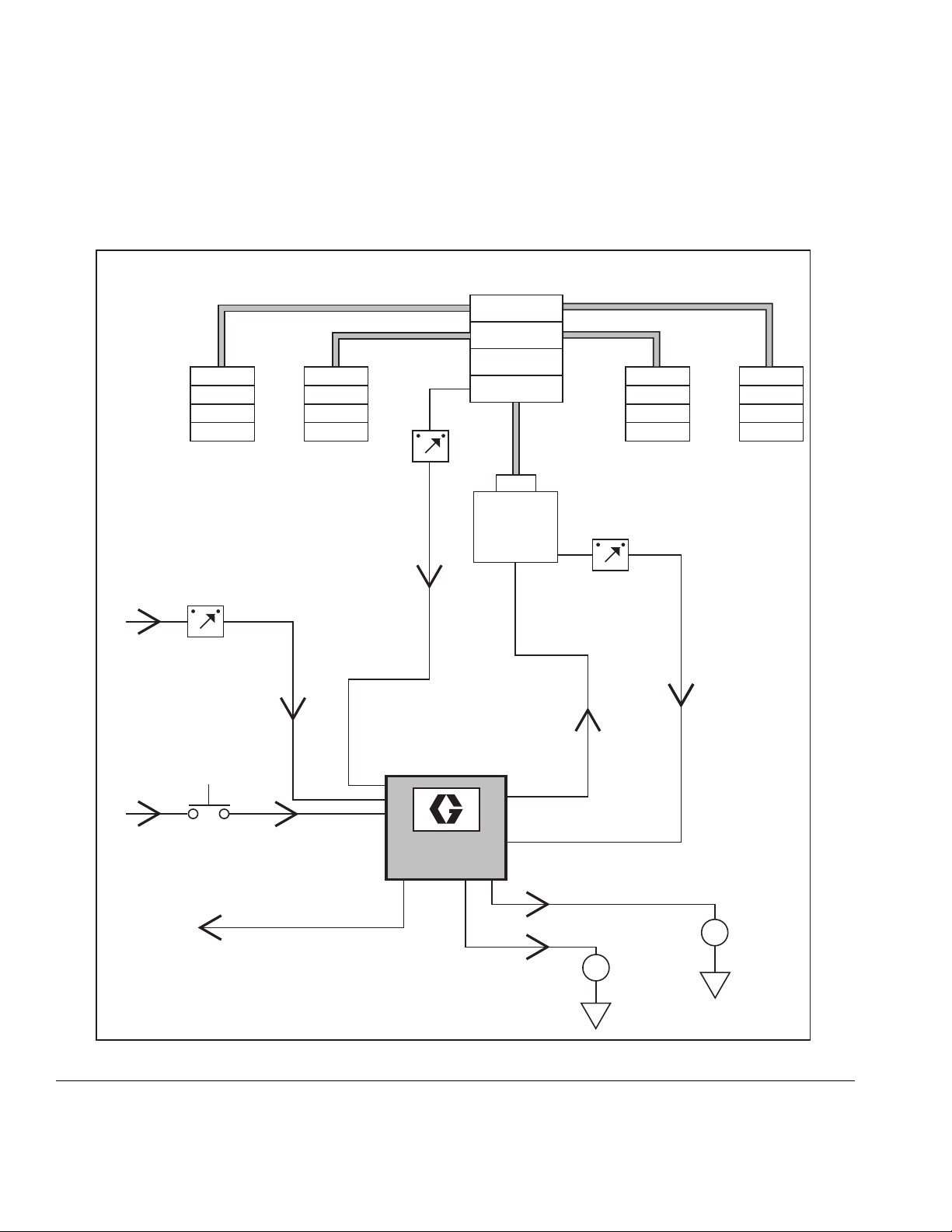

Typical Installation

The installation shown in FIG. 2 is only a guide for selecting and installing system components. Contact your Graco

distributor for assistance in planning a system to suit your needs.

FIG. 2

A Main Air Supply

B Filter/Regulator/Lubricator Assembly

B1 - Filter

B2 - Regulator

G Injector Banks

H Lubrication Controller

J Model 24B591 12/24VDC Power Supply

K Model 24B596 115/230VAC Power Supply

B3 - Lubricator

C Air Solenoid Valve

D Pump Module

E Ignition Switch

F High-Pressure Lubricant Supply Lines

313855H 5

Page 6

Installation

a

a

a

a

*

b

jumper

motor ground

sensor ground

ground

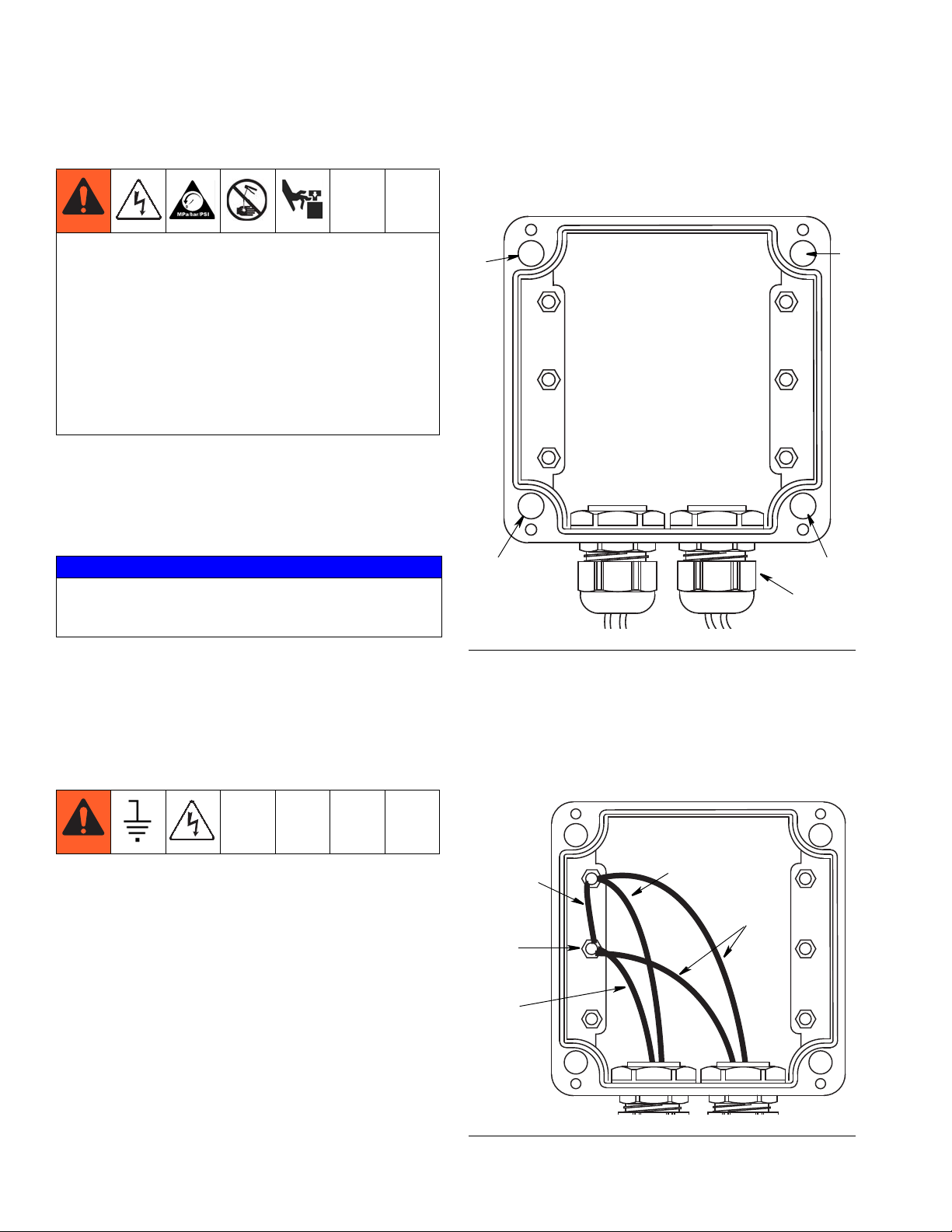

Installing the Lubrication Controller

AUTOMATIC SYSTEM ACTIVATION HAZARD

Unexpected activation of the system could result in serious injury, including skin injection and amputation.

This device has an automatic timer that activates the

pump lubrication system when power is connected or

when exiting the programming function. Before you

install or remove the Lubrication Controller from the

system, disconnect and isolate all power supplies and

relieve all pressure.

1. Select a flat surface to install the Lubrication Controller. Drill mounting holes. Refer to Mounting Hole

Layout provided in the Technical Data section of this

manual, page 34.

#6 screws (not provided) to secure junction box to

mounting surface.

NOTICE

Pre-drill and use designated mounting holes in Lubrication Controller box only. Failure to use designated

mounting holes can cause circuit board damage.

2. Remove Lubrication Controller cover and align junction box with predrilled holes (F

IG. 3, (a). Use four,

Grounding

The equipment must be grounded. Grounding reduces

the risk of static and electric shock by providing an

escape wire for the electrical current due to static build

up or in the event of a short circuit.

1. Loosen M6 screws from (b).

2. Attach up to 3 ground wires to (b) using appropriate

sized M6 ring terminal (not provided).

FIG. 3

* Parts not supplied. To maintain IP69K rating, proper

connectors must be used.

3. If more than 3 wires are used, attach necessary

amount of jumpers to other adjacent screw terminals.

FIG. 4

6 313855H

Page 7

Installation

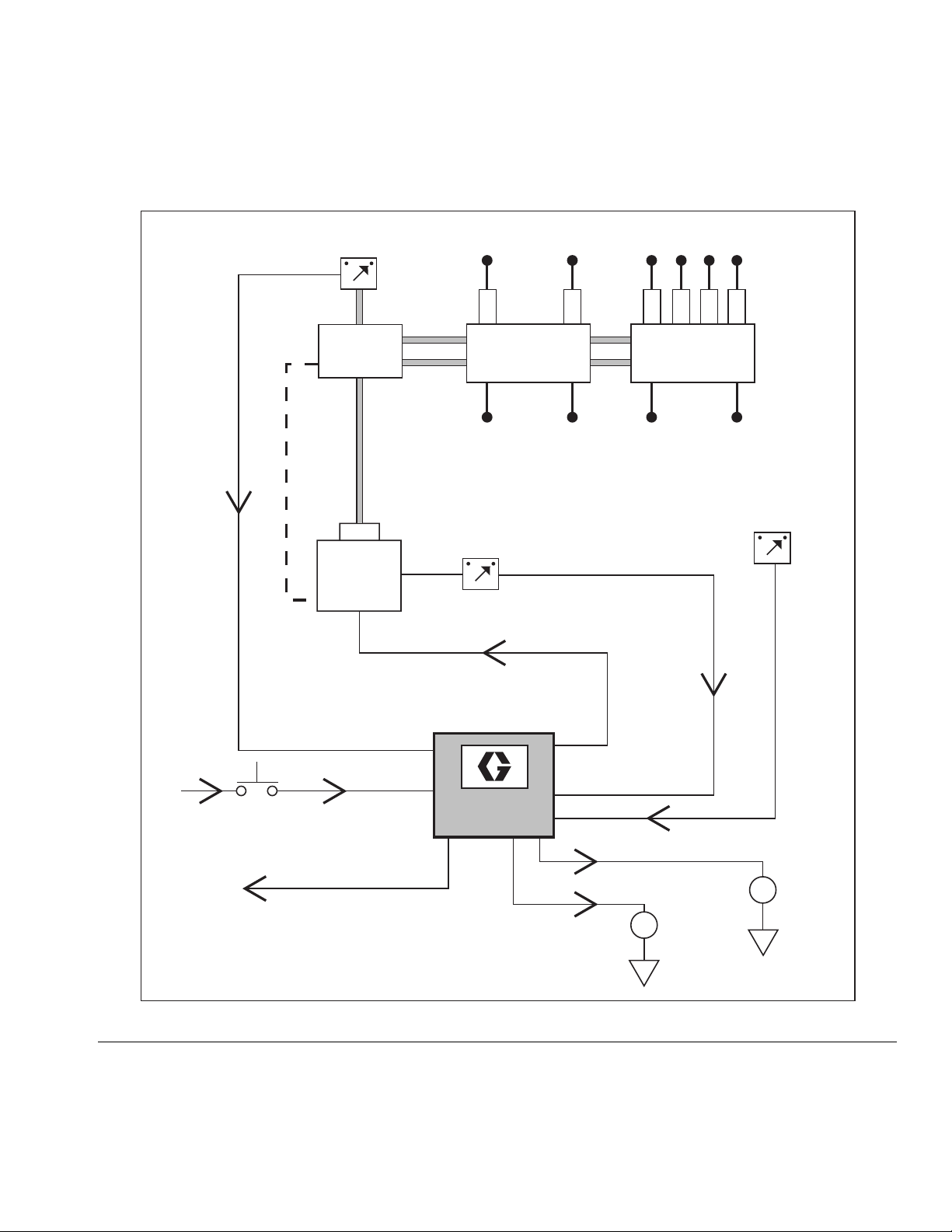

System Configuration and Wiring

The System Configuration Diagrams (FIG. 5 - FIG. 7), Sensor Wiring Diagrams (FIG. 8 - FIG. 10) and Wiring Diagrams

(F

IG. 11 - FIG. 16) on the following pages, show typical Injector, Divider Valve and Dual Line lubrication system config-

urations.

Refer to Table 1, 2 and 3 to determine the Required System Configuration, Sensor Configuration and Wiring Diagram

to use to setup your system.

Table 4 shows additional (optional) setup configurations (F

Table 1: System Configurations

System Figure Page

Divider Valve 5 8

Dual Line 6 9

Injector 7 10

Table 2: Sensor Wiring Configurations

Sensor Figure Page

Dry Contact 8 11

Sourcing 9 11

Sinking 10 11

IG. 17 - FIG. 19).

Table 3: Modes of Operation

Mode Power Figure Page

Time ON/Time OFF DC 11 12

Time ON/Time OFF AC 12 12

Cycle ON or Pressure

ON/Time OFF

Cycle ON or Pressure

ON/Time OFF

Cycle ON or Pressure

ON/Machine Count

OFF

Cycle ON or Pressure

ON/Machine Count

OFF

DC 13 13

AC 14 13

DC 15 14

AC 16 14

Table 4: Optional I/O Wiring Diagrams

System Mode Power Supply Wiring Diagram

Low Level Switch F

External Manual Run F

O.K. Contact Out F

Auxiliary and Low Level

Alarm Out

313855H 7

DC: FIG. 18, page 16

115/230 VAC: F

IG. 17, page 15

IG. 17, page 15

IG. 17, page 15

IG. 19, page 16

Page 8

Installation

GLC 4400

External

Low Level

Alarm

Remote

Manual Run

Machine

Count Switch

Low Level

Switch

Pump

Reservoir

Master Divider Valve

Secondary Divider Valves

Cycle

Switch

Divider Valve System

External O.K.

Pump On/Off

External

Alarm

Cycle

Machine

Count

System Configuration

FIG. 5

8 313855H

Page 9

GLC 4400

External

Alarm

Cycle

Machine

Count

External

Low Level

Alarm

External O.K.

Low Level

Switch

Pump

Reservoir

Dual Line System

Cycle

Switch

Bi-flo

Valves

Lubrication Points

Vent

Line

Pump On/Off

Reverser

Remote

Manual Run

Machine

Count Swtich

Installation

FIG. 6

313855H 9

Page 10

Installation

GLC 4400

External

Low Level

Alarm

Remote

Manual Run

Machine

Count Switch

Low Level

Switch

Pump

Reservoir

Injector System

Pressure

Switch

Injectors

Lubrication Points

Vent

Line

Pump On/Off

External O.K.

External

Alarm

Cycle

Machine

Count

FIG. 7

10 313855H

Page 11

Installation

x = sensor input 1,2,3 or 4

1 (SW +)

2 (IN (x))

3 (SEN (x))

4 (SW -)

J6

1 (SW +)

4 (SW -)

J6

x = sensor input 1,2,3 or 4

2 (IN (x))

3 (SEN (x))

1 (SW +)

4 (SW -)

x = sensor input 1,2,3 or 4

2 (IN (x))

3 (SEN (x))

J6

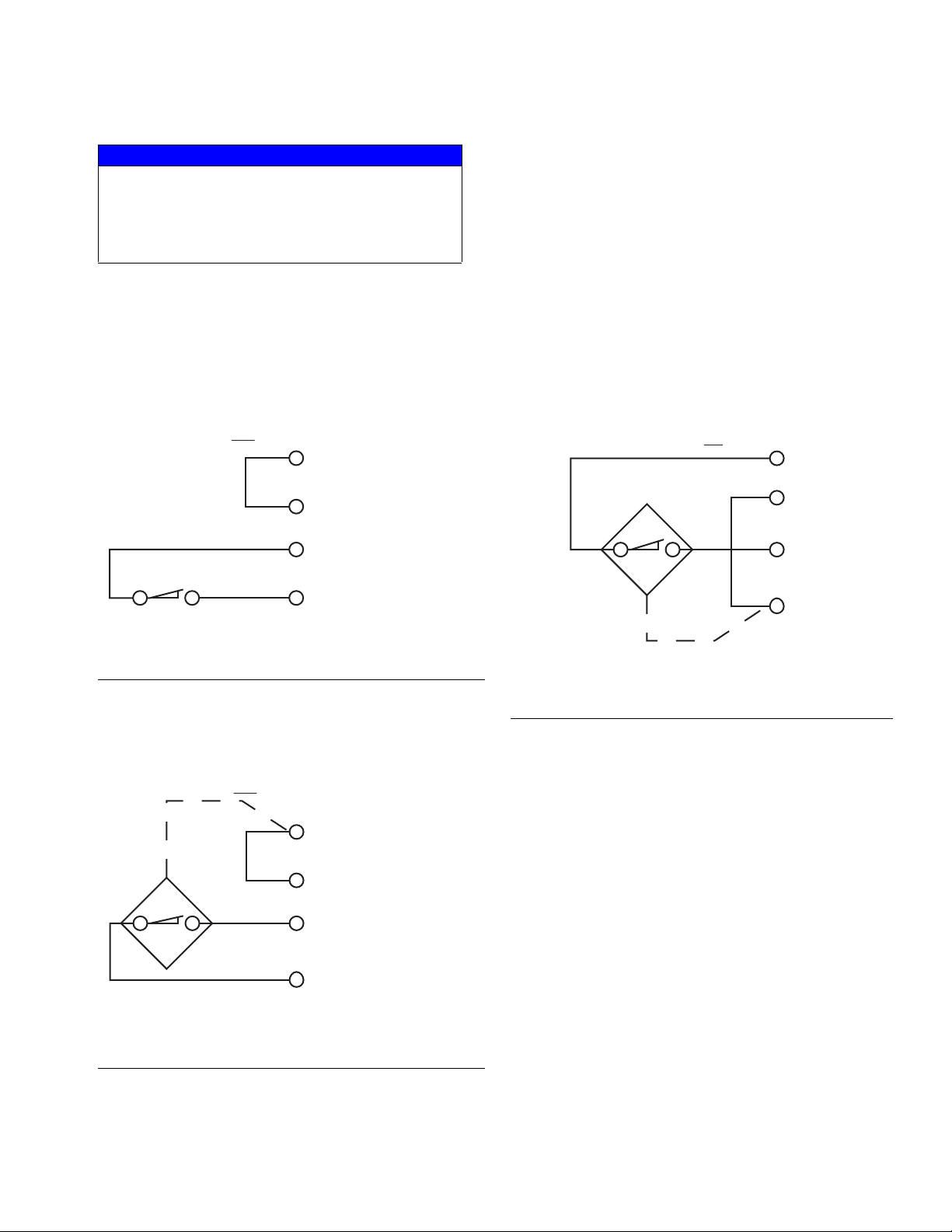

System Wiring

NOTICE

Do not connect any of the SW+ (13,9,5,1) and SW(16,12,8,4) pins together, either directly or via a

switch closure. Doing so will create a short circuit

condition which will disable and potentially damage

the controller.

NOTE: On an AC controller (p/n 24B596), the J7 strip is line (input) voltage but the J6 strip is all 24VDC. On a DC

controller (p/n 24B59‘), the J6 and J7 terminals all carry the input voltage.

Input Sensor Wiring:

DRY CONTACT SWITCH

FIG. 8

SOURCE SWITCH - 2 or 3 Wire Type

SINK SWITCH - 2 or 3 Wire Type

FIG. 10

IG. 9

F

313855H 11

Page 12

Installation

16 (SW-)

15 (SEN4)

14 (IN4)

13 (SW+)

12 (SW-)

11 (SEN3)

10 (IN3)

9 (SW+)

8 (SW-)

7 (SEN2)

6 (IN2)

5 (SW+)

4 (SW-)

3 (SEN1)

2 (IN1)

1 (SW+)

1(IN)

2(COM)

3(OUT1)

4(COM)

5(OUT2)

6(COM)

7(OUT3)

8(COM)

9(OUT4)

10(OUT4)

11

OUTPUTS

-PWR+

J6J7

Air Solenoid

+

+

(Voltage = Battery Voltage)

Pump Solenoid

Ignition Switch

9 - 30 VDC Battery

Manual

Low

Level

Press/

Cycle

Count

5A max.

NC

16 (SW-)

15 (SEN4)

14 (IN4)

13 (SW+)

12 (SW-)

11 (SEN3)

10 (IN3)

9 (SW+)

8 (SW-)

7 (SEN2)

6 (IN2)

5 (SW+)

4 (SW-)

3 (SEN1)

2 (IN1)

1 (SW+)

1(IN)

2(COM)

3(OUT1)

4(COM)

5(OUT2)

6(COM)

7(OUT3)

8(COM)

9(OUT4)

10(OUT4)

11

OUTPUTS

-PWR+

J6J7

Air Solenoid

Ignition Switch

Manual

Low

Level

Press/

Cycle

Count

100-240 VAC

(Voltage = Line Voltage)

Pump Solenoid

10A max.

NC

Pump ON = Time; Pump OFF = Time

9 - 30VDC

FIG. 11 *Dry Contact, FIG. 8 shown. For other configuration, see FIG. 9 or FIG. 10.

100VAC/240VAC

F

IG. 12

12 313855H

Page 13

System Wiring

16 (SW-)

15 (SEN4)

14 (IN4)

13 (SW+)

12 (SW-)

11 (SEN3)

10 (IN3)

9 (SW+)

8 (SW-)

7 (SEN2)

6 (IN2)

5 (SW+)

4 (SW-)

3 (SEN1)

2 (IN1)

1 (SW+)

1(IN)

2(COM)

3(OUT1)

4(COM)

5(OUT2)

6(COM)

7(OUT3)

8(COM)

9(OUT4)

10(OUT4)

11

OUTPUTS

-PWR+

J6J7

Air or Hydraulic Solenoid

Pump Power or Motor

+

+

Ignition Switch

Manual

Low

Level

Press/

Cycle

Count

(Voltage = Battery Voltage)

Pump Solenoid

9 - 30 VDC Battery

Dry Contact Switch

*

5A max.

NC

Electric Vent Valve

10A max.

16 (SW-)

15 (SEN4)

14 (IN4)

13 (SW+)

12 (SW-)

11 (SEN3)

10 (IN3)

9 (SW+)

8 (SW-)

7 (SEN2)

6 (IN2)

5 (SW+)

4 (SW-)

3 (SEN1)

2 (IN1)

1 (SW+)

1(IN)

2(COM)

3(OUT1)

4(COM)

5(OUT2)

6(COM)

7(OUT3)

8(COM)

9(OUT4)

10(OUT4)

11

OUTPUTS

-PWR+

J6J7

Ignition Switch

Manual

Low

Level

Press/

Cycle

Count

100-240 VAC

(Voltage = Line Voltage)

Pump Solenoid

Dry Contact Switch

*

NC

Air or Hydraulic Solenoid

Pump Power or Motor

Electric Vent Valve

Pump ON = Cycle or Pressure; Pump OFF = Time

9 - 30VDC

Installation

FIG. 13 *Dry Contact, FIG. 8 shown. For other configuration, see FIG. 9 or FIG. 10.

100VAC/240VAC

F

IG. 14 *Dry Contact, FIG. 8 shown. For other configuration, see FIG. 9 or FIG. 10.

313855H 13

Page 14

Installation

5A max.

16 (SW-)

15 (SEN4)

14 (IN4)

13 (SW+)

12 (SW-)

11 (SEN3)

10 (IN3)

9 (SW+)

8 (SW-)

7 (SEN2)

6 (IN2)

5 (SW+)

4 (SW-)

3 (SEN1)

2 (IN1)

1 (SW+)

1(IN)

2(COM)

3(OUT1)

4(COM)

5(OUT2)

6(COM)

7(OUT3)

8(COM)

9(OUT4)

10(OUT4)

11

OUTPUTS

-PWR+

J6J7

+

Ignition Switch

Manual

Low

Level

Press/

Cycle

Count

(Voltage = Battery Voltage)

Pump Solenoid

9 - 30 VDC Battery

Dry Contact Switch

Dry Contact Switch

*

*

NC

Air or Hydraulic Solenoid

Pump Power or Motor

+

Electric Vent Valve

10A max.

16 (SW-)

15 (SEN4)

14 (IN4)

13 (SW+)

12 (SW-)

11 (SEN3)

10 (IN3)

9 (SW+)

8 (SW-)

7 (SEN2)

6 (IN2)

5 (SW+)

4 (SW-)

3 (SEN1)

2 (IN1)

1 (SW+)

1(IN)

2(COM)

3(OUT1)

4(COM)

5(OUT2)

6(COM)

7(OUT3)

8(COM)

9(OUT4)

10(OUT4)

11

OUTPUTS

-PWR+

J6J7

Ignition Switch

Manual

Low

Level

Press/

Cycle

Count

100-240 VAC

(Voltage = Line Voltage)

Pump Solenoid

Dry Contact Switch

Dry Contact Switch

*

*

NC

Air or Hydraulic Solenoid

Pump Power or Motor

Electric Vent Valve

System Wiring

Pump ON = Cycle or Pressure; Pump OFF = Machine Count

9 - 30VDC

FIG. 15 Dry Contact, FIG. 8 shown. For other configuration, see FIG. 9 or FIG. 10.

100VAC/240VAC

F

IG. 16 Dry Contact, FIG. 8 shown. For other configuration, see FIG. 9 or FIG. 10.

14 313855H

Page 15

System Wiring Options

16 (SW-)

15 (SEN4)

14 (IN4)

13 (SW+)

12 (SW-)

11 (SEN3)

10 (IN3)

9 (SW+)

8 (SW-)

7 (SEN2)

6 (IN2)

5 (SW+)

4 (SW-)

3 (SEN1)

2 (IN1)

1 (SW+)

1(IN)

2(COM)

3(OUT1)

4(COM)

5(OUT2)

6(COM)

7(OUT3)

8(COM)

9(OUT4)

10(OUT4)

11

OUTPUTS

-PWR+

J6J7

Manual

Low

Level

Press/

Cycle

Count

O.K. Contact

(Closed = O.K.)

Dry Contact Switch

Dry Contact Switch

*

*

NC

NOTICE

Do not connect any of the SW+ (13,9,5,1) and SW(16,12,8,4) pins together, either directly or via a

switch closure. Doing so will create a short circuit

condition which will disable and potentially damage

the controller.

All Units: Low Level Switch / External Manual Run / O.K. Contact Out

Installation

FIG. 17 Dry Contact, FIG. 8 shown. For other configuration, see FIG. 9 or FIG. 10.

313855H 15

Page 16

Installation

16 (SW-)

15 (SEN4)

14 (IN4)

13 (SW+)

12 (SW-)

11 (SEN3)

10 (IN3)

9 (SW+)

8 (SW-)

7 (SEN2)

6 (IN2)

5 (SW+)

4 (SW-)

3 (SEN1)

2 (IN1)

1 (SW+)

1(IN)

2(COM)

3(OUT1)

4(COM)

5(OUT2)

6(COM)

7(OUT3)

8(COM)

9(OUT4)

10(OUT4)

11

OUTPUTS

-PWR+

J6J7

+

Alarm

Alarm +9-30V

1 Amp Max

1 A Fuse

+

Low

Level

Alarm +9-30V

1 Amp Max

1 A Fuse

Manual

Low

Level

Press/

Cycle

Count

Aux (cycle, pressure, machine count)

NC

16 (SW-)

15 (SEN4)

14 (IN4)

13 (SW+)

12 (SW-)

11 (SEN3)

10 (IN3)

9 (SW+)

8 (SW-)

7 (SEN2)

6 (IN2)

5 (SW+)

4 (SW-)

3 (SEN1)

2 (IN1)

1 (SW+)

1(IN)

2(COM)

3(OUT1)

4(COM)

5(OUT2)

6(COM)

7(OUT3)

8(COM)

9(OUT4)

10(OUT4)

11

OUTPUTS

-PWR+

J6J7

Alarm

Alarm 100-240 VAC

1 Amp Max

1 A Fuse

Low

Level

1 A Fuse

Manual

Low

Level

Press/

Cycle

Count

Aux (cycle, pressure, machine count)

Alarm 100-240 VAC

1 Amp Max

NC

System Wiring Options: Alarm Out

9 - 30VDC

FIG. 18

100/240VAC

F

IG. 19

16 313855H

Page 17

Setup

C

D

A

B

Setup

System Setup - PIN Mode Enabled

See Electric Connection Warning, page 7.

When you first turn on power to the Lubrication Controller, the following identification screen displays.

F

IG. 20

A Display Contrast Adjustment: UP and DOWN

Arrows can be used to adjust the display contrast.

1. To access Setup Mode, hold down the ENTER key

for 3 seconds. The PIN ModeScreen shown in F

21 displays.

NOTE:

• The Pin Mode screen shown in F

when the PIN mode is enabled. For setting up systems when the PIN mode is not enabled, go to System Setup instructions on page 18.

• Before the PIN Mode screen shown in F

display, the PIN Mode must be enabled in an previous setup sequence. See PIN Setup, page 25.

IG. 21 only displays

IG. 21 can

IG.

B Brightness Adjustment: LEFT and RIGHT Arrows

can be used to adjust the backlight brightness.

NOTE: Contrast and Brightness adjustments can be

made on any Run Screen at any time.

C Software (Part Number): 15Y354

D (Software) Version: 1.01.XX

NOTE: The example of the Software Version (D) shown

in F

IG. 20 displays “XX” as the last two numerals. On

your Controller’s screen, the “XX” will be replaced by the

current software version numbers.

FIG. 21

2. The PIN Mode screen in F

NOTE: The PIN Code prompt spaces are initially blank.

3. Use the LEFT / RIGHT arrow to position the cursor

over the first blank PIN Code prompt field (F

4. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

PIN code is displayed in the field.

5. Use the RIGHT arrow to move the cursor to the next

field.

6. Repeat steps 4 and 5 for each PIN Code prompt

field.

7. When finished, press ENTER.

IG. 21 displays.

IG. 21).

313855H 17

Page 18

Setup

8. If the PIN Code you entered is correct, the System

Setup Screen, shown in F

9. If the PIN Code you entered is incorrect, the digits

flash. The Code must be re-entered by repeating

steps 4 and 5.

NOTE:

• As soon as any arrow key is pressed, the numerals

stop flashing.

• To leave any Setup Screen and return to normal

operation, press RESET.

IG. 22 displays.

FIG. 23

System Setup

Main Screen

F

IG. 22

1. Use the UP/DOWN arrows to move the cursor up

and down through the list of setup screens (F

2. Press ENTER to display the selected setup screen.

3. When all setup operations are complete, press

RESET to return to normal operation.

IG. 22).

1. Use the UP/DOWN Arrow keys to move the cursor

over PUMP ON.

2. Press ENTER to display the PUMP ON setup

screen.

TIMER Setup

IG. 24

F

NOTE: Time is displayed in HH:MM:SS.

1. Use the Arrow keys to move the cursor over the

PUMP ON time box.

PUMP ON Setup

Pump On is the length of time the pump runs before its

cycle is terminated by either a timer, a specific number

of cycles or a certain pressure threshold is attained.

18 313855H

2. Press ENTER.

3. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

PUMP ON time is displayed in the field.

4. Use the RIGHT arrow to move the cursor to the next

field.

5. Repeat steps 3 and 4 until the desired time is displayed.

6. Use the Arrow keys to move the cursor over the

ENDED BY pull-down list.

Page 19

Setup

7. Press ENTER.

8. Select TIMER from the pull-down list.

9. Press RESET. The Main Screen displays.

NOTE: When TIMER is selected, the Timer Icon will display on the top right corner of the screen.

PRESSURE Setup

F

IG. 25

NOTE: Time is displayed in HH:MM:SS.

CYCLE END Setup

FIG. 26

NOTE: Time is displayed in HH:MM:SS.

1. Use the Arrow keys to move the cursor over the

PUMP ON time box.

2. Press ENTER.

3. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

PUMP ON time is displayed in the field.

1. Use the Arrow keys to move the cursor over the

PUMP ON time box.

2. Press ENTER.

3. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

PUMP ON time is displayed in the field.

4. Use the RIGHT arrow to move the cursor to the next

field.

5. Repeat steps 3 and 4 until the desired time is displayed.

6. Use the Arrow keys to move the cursor over the

ENDED BY pull-down list.

7. Press ENTER.

8. Select PRESSURE from the pull-down list.

9. Press RESET. The Main Screen, page 18 displays.

NOTE: When PRESSURE is selected, the Pressure

Icon will display on the top right corner of the screen.

4. Use the RIGHT arrow to move the cursor to the next

field.

5. Repeat steps 3 and 4 until the desired time is displayed.

6. Use the Arrow keys to move the cursor over the

ENDED BY pull-down list.

7. Press ENTER.

8. Select CYCLE from the pull-down list.

9. Press ENTER.

313855H 19

Page 20

Setup

Cycle Mode Selection

If the Cycle Mode is selected you will also be prompted

to set the desired number of cycles.

NOTE: A cycle is equal to two switch closure transitions

at the cycle switch input.

F

IG. 27

10. Use the Arrow keys to move the cursor over the

CYCLES field.

PUMP OFF Setup

Sets up how the PUMP OFF cycle is ended: Time,

Machine Count switch activation, or Machine Count activations limited by a maximum time.

FIG. 28

1. Use the UP/DOWN Arrow keys to move the cursor

over PUMP OFF.

2. Press ENTER to display the PUMP OFF setup

screen.

11. Press ENTER.

12. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number you

want in the CYCLES field is displayed.

13. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 12.

NOTE: The maximum number of Cycles you can setup

in this field is 99.

14. Press RESET. The Main Screen, page 18 displays.

NOTE: When Cycles is selected, the Cycles Icon displays is the upper right corner of the screen.

To Set the Pump OFF Option

F

IG. 29

1. Use the Arrow keys to move the cursor over the

PUMP OFF pull-down menu.

2. Press ENTER.

3. Use the UP/DOWN Arrow keys to move cursor to

select TIME, COUNT or BOTH.

4. After you make your selection, Press ENTER.

20 313855H

Page 21

Setup

If TIME is selected:

If TIME is selected you will also be prompted to set the

specific amount of time.

F

IG. 30

1. Use the Arrow keys to move the cursor over the

TIME field.

2. Press ENTER.

NOTE: Time is displayed in HH:MM:SS.

1. Use the Arrow keys to move the cursor over the

COUNTS field.

2. Press ENTER.

3. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number you

want in the COUNTS field is displayed.

4. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 3.

NOTE: The maximum number of Counts you can setup

in this field is 9999.

5. Press RESET. The Main Screen, page 18 displays.

If BOTH is selected:

If PUMP OFF is set to BOTH, the GLC 4400 will stay in

the PUMP OFF state until the entered number of

machine counts is received or the time expires.

If TIMEOUT is set to FAULT, an alarm will occur when

the time expires.

3. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

pump off TIME is displayed in the field.

4. Use the RIGHT arrow to move the cursor to the next

field.

5. Repeat steps 3 and 4 until the desired time is displayed.

6. Press RESET. The Main Screen, page 18 displays.

If COUNT is selected:

If COUNT is selected you will also be prompted to set

the specific number of counts.

If TIMEOUT is set to RUN, the unit will enter PUMP ON

when time expires.

If BOTH is selected you will be prompted to set the specific amount of time and determine what occurs when

time expires.

FIG. 32

1. Use the Arrow keys to move the cursor over the

COUNTS field.

2. Press ENTER.

3. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number you

F

IG. 31

313855H 21

want in the COUNTS field is displayed.

Page 22

Setup

4. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 3.

NOTE: The maximum number of Counts you can setup

in this field is 9999.

5. Use the Arrow keys to move the cursor over the

TIME field.

6. Press ENTER.

NOTE: Time is displayed in HH:MM:SS.

7. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

PUMP OFF time is displayed in the field.

8. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 7.

9. Repeat steps 7 and 8 until the desired time is displayed.

10. Press ENTER.

11. Use the Arrow keys to move the cursor over the

TIMEOUT pull-down menu.

POWER UP Setup

FIG. 34

1. Use the UP/DOWN Arrow keys to move the cursor

over POWER UP.

2. Press ENTER to display the POWER UP setup

screen.

Power Up can be programmed one of four ways:

First: At Power Up, the normal lube cycle that was in

process when power was removed, is resumed.

F

IG. 35

F

IG. 33

1. Use the Arrow keys to move the cursor over the

POWER UP pull-down menu.

12. Press ENTER.

2. From the pull-down menu, select OFF.

13. When time expires:

3. Press ENTER.

• Select FAULT if an alarm should occur.

• Select RUN if unit should enter PUMP ON.

4. Use the Arrow keys to move the cursor over the

DELAY pull-down menu.

14. Press ENTER.

5. From the pull-down menu, select OFF.

15. Press RESET. The Main Screen, page 18 displays.

6. Press RESET. The Main Screen, page 18 displays.

NOTE: If Count or Both is selected, the Count Icon displays in the upper right corner of the screen.

22 313855H

Page 23

Setup

Second: At Power Up, a delay occurs, the pump is off;

then the normal lube cycle that was in process when

power was removed, is resumed.

F

IG. 36

1. Use the Arrow keys to move the cursor over the

POWER UP pull-down menu.

2. From the pull-down menu, select OFF.

3. Press ENTER.

4. Use the Arrow keys to move the cursor over the

DELAY pull-down menu.

5. From the pull-down menu, select ON.

6. Press ENTER.

7. Use the Arrow keys to move the cursor over the

DELAY TIME field.

Third: At Power Up, immediately go to PUMP ON

(normal on time)..

FIG. 37

1. Use the Arrow keys to move the cursor over the

POWER UP pull-down menu.

2. From the pull-down menu, select ON.

3. Press ENTER.

4. Use the Arrow keys to move the cursor over the

DELAY pull-down menu.

5. From the pull-down menu, select OFF.

6. Press RESET. The Main Screen, page 18 displays.

Fourth: At Power Up, go to programmed PUMP OFF

delay time; then to normal PUMP ON.

8. Press ENTER.

NOTE: Time is displayed in MM:SS.

9. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

DELAY TIME is displayed in the field.

10. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 9.

F

11. Repeat steps 9 and 10 until the desired time is dis-

IG. 38

played.

12. Press RESET. The Main Screen, page 18 displays.

1. Use the Arrow keys to move the cursor over the

POWER UP pull-down menu.

2. From the pull-down menu, select ON.

3. Press ENTER.

4. Use the Arrow keys to move the cursor over the

DELAY pull-down menu.

313855H 23

Page 24

Setup

5. From the pull-down menu, select ON.

6. Press ENTER.

7. Use the Arrow keys to move the cursor over the

DELAY TIME field.

8. Press ENTER.

NOTE: Time is displayed in MM:SS.

9. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

DELAY TIME is displayed in the field.

10. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 9.

11. Repeat steps 9 and 10 until the desired time is displayed.

12. Press RESET. The Main Screen, page 18 displays.

PULSED Setup

Pulsed Pump Screen

1. Use the Arrow keys to move the cursor over the

PULSE pull-down menu.

2. Press ENTER.

3. Use the UP/DOWN Arrow keys to move cursor to

select ON.

4. Press ENTER.

FIG. 41

F

IG. 39

1. Use the UP/DOWN Arrow keys to move the cursor

over PULSED.

2. Press ENTER to display the PULSED setup screen.

5. Use the Arrow keys to move the cursor over the

TIME OFF field.

6. Press ENTER.

NOTE: The time is displayed in Seconds.

7. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number of the

TIME OFF you are creating is displayed in the field.

8. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 7.

9. Press ENTER.

IG. 42

F

IG. 40

24 313855H

F

Page 25

Setup

10. Use the Arrow keys to move the cursor over the

TIME ON field.

11. Press ENTER.

NOTE: The time is displayed in Seconds.

12. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number of the

TIME ON you are creating is displayed in the field.

13. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 7.

14. Press ENTER.

15. Press RESET. The Main Screen, page 18 displays.

NOTE:

• The maximum Time Off and Time On is

99 seconds.

• The minimum Time Off is 3 seconds.

• The minimum Time On is 0 (zero) seconds.

To enable PIN Code Entry:

FIG. 44

1. Use the Arrow keys to move the cursor over the PIN

pull-down menu.

2. Press ENTER.

3. Use the UP/DOWN Arrow keys to move cursor to

select ON.

4. Press ENTER.

PIN Setup

If protection for the setup mode is desired, a PIN Code

entry can be enabled.

F

IG. 43

1. Use the UP/DOWN Arrow keys to move the cursor

over PIN CODE.

2. Press ENTER to display the PIN CODE setup

screen.

F

IG. 45

5. Use the Arrow keys to move the cursor over the PIN

CODE prompt field.

6. Use the LEFT/RIGHT arrow to position the cursor

over the first blank Pin Code prompt field (F

IG. 21).

7. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

PIN code you are creating is displayed in the field.

8. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 7

9. Repeat steps 7 and 8 for each PIN Code prompt.

10. Press RESET. The Main Screen, page 18 displays.

313855H 25

Page 26

Setup

DISPLAY Setup

F

IG. 46

1. Use the UP/DOWN Arrow keys to move the cursor

over DISPLAY.

2. Press ENTER to display the DISPLAY setup screen.

Display Backlight

The display backlight can be set to turn off after a programmed amount of time. If the backlight is OFF it will

turn back on when any front panel key is pressed.

4. Use the Arrow keys to move the cursor over the

TIME ON field.

FIG. 48

NOTE: Time is displayed in HH:MM.

5. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

TIME ON is displayed in the field.

6. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 5.

IG. 47

F

1. Use the Arrow keys to move the cursor over the

TIMER pull-down menu.

2. From the pull-down menu, select ON.

3. Press ENTER.

7. Repeat steps 5 and 6 until the desired time displays.

8. Press RESET. The Main Screen, page 18 displays.

QUICK CYCLE Setup

IG. 49

F

1. Use the UP/DOWN Arrow keys to move the cursor

over QUICK CYCLE.

2. Press ENTER to display the QUICK CYCLE setup

screen.

26 313855H

Page 27

Setup

Quick Cycle Screen Setup

The Quick Cycle screen setup is used to setup a Troubleshooting profile.

F

IG. 50

1. Use the Arrow keys to move the cursor over the

CYCLES field.

2. Press ENTER.

3. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number you

want in the CYCLES field is displayed.

12. Repeat steps 7 - 9 for the TIME OFF field.

13. Use the Arrow keys to move the cursor over the

pull-down menu.

14. Select ON.

15. The Quick Cycle begins.

NOTE:

• The maximum Time Off and Time On is 99 seconds.

• When complete, the system returns to the Run

Mode. It does not come back to the Quick Cycle

Setup Screen.

LOW LEVEL FILTERING Setup

4. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 3.

NOTE: The maximum number of Cycles you can setup

in this field is 99.

5. Use the Arrow keys to move the cursor over the

TIME ON field.

6. Press ENTER.

NOTE: Time On and Time Off in QUICK CYCLE mode

only, are displayed in Seconds.

7. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number you

want to use in the TIME ON field is displayed in the

field.

8. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 7.

9. Press ENTER.

10. Use the Arrow keys to move the cursor over the

TIME ON field.

FIG. 51

1. Use the UP/DOWN Arrow keys to move the cursor

over LL FILTERING.

2. Press ENTER to display the LL FILTERING setup

screen.

11. Press ENTER.

313855H 27

Page 28

Setup

Low Level Filtering Screen Setup

The Low Level Filtering screen setup is used to filter out

spurious signals from rotating paddle type low level sensors.

NOTE: When using the GLC4400 with the G3 Automatic

Lubrication Pump, it is recommended that the low level

filtering be set to G3 defaults.

The NUMBER field determines how many signal activations are required to set a fault.

The TIME field determines the amount of RUN time

required without an activation to reset the activation

count to 0 (zero).

8. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 7.

9. Repeat steps 7 and 8 until the desired time is displayed.

10. Press ENTER.

11. If the default values for the G3 Automatic Lubrication Pump are intended to be used, use the

UP/DOWN arrows to move to the G3 DEFAULT

field.

12. Press ENTER. The NUMBER and TIME values will

be updated to the G3 default value.

13. Press RESET. The Main Screen, shown on page

18, displays.

F

IG. 52

1. Use the Arrow keys to move the cursor over the

NUMBER field.

2. Press ENTER.

3. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number you

want in the NUMBER field is displayed.

4. Use the RIGHT arrow to move the cursor to the next

field. Repeat step 3.

NOTE: The maximum number of Counts you can setup

in this field is 99.

5. Use the Arrow keys to move the cursor over the

TIME field.

6. Press ENTER.

NOTE: Time is displayed in HH:MM:SS.

7. Use the UP/DOWN arrows to move up and down

through the numbers 0-9 until the first number in the

TIME field is displayed.

28 313855H

Page 29

Run Mode

C

D

A

B

A

B

C

D

When you first turn the Lubrication Controller power on,

the identification screen shown in F

IG. 53 displays.

Run Mode

FIG. 53

A Display Contrast Adjustment: UP and DOWN

Arrows can be used to adjust the display contrast.

B Backlight Brightness Adjustment: LEFT and

RIGHT Arrows can be used to adjust the backlight

brightness.

NOTE: Contrast and Brightness adjustments can be

made on any Run Screen at any time.

C Software (Part Number): 15Y354

D (Software) Version: 1.01.XX

Screen Identification

The following screen is only shown as an example of the

information that is displayed on a Run screen. A complete description of the icons and symbols shown in F

54 is provided on page 3.

IG.

FIG. 54

A Operating Mode Identification - Sets up Pump On/

Pump Off, page 22.

B Time Counter - Actual elapsed time counts down while

the pump runs - set up in Pump On Setup, page 18.

C Progression Bar - Real-time, visual representation of the

elapsed time the pump has been on. Runs in conjunction

with B.

D Total Pump On Time - Shows the total amount of time

the pump is on. Setup on the Pump On setup screen,

page 18.

313855H 29

Page 30

Run Mode

A

D

C

A

B

C

D

Prelube Power Up

F

IG. 55

If Prelube is enabled (page 22), the programmed prelube sequence occurs.

• The Timer icon (D) displays and indicates the Timer

Mode.

Pump On Ended with Pressure

If no Prelube sequence has been selected, the lube

cycle that was in progress at power down is resumed.

Pump On Ended with Time

F

IG. 56

If the Pump On sequence has been programmed to be

ended by TIME:

FIG. 57

If the Pump On sequence has been programmed to end

by a pressure switch:

• The GLC 4400 pump output relay activates (J7-3)

and will stay on until a switch closure is received

(J6-3) (see Setup Menus, Pump On, page 19).

• The Pump On LED (A) remains on during this time.

• The Pump On (C) icon displays.

• The Cycle LED (B) illuminates and Pressure Mode

icon (D) displays to indicate the pressure switch.

• If the pressure switch closure is not received before

time expires, an alarm occurs.

NOTE: If Pump On is ended by a pressure switch and

no Power Up delay is selected, when power to the GLC

4400 is turned on, the GLC 4400 starts at the beginning

of the Pump On time instead of resuming the Pump On

time where it left off.

• The GLC 4400 pump output relay activates (J7-3)

and will stay on until the time expires. (see Setup

Menus, Pump On, page 18).

• The Pump On LED (A) remains on during this time.

• The Pump On (C) icon displays.

30 313855H

Page 31

Run Mode

A

B

C

E

D

A

D

C

A

B

C

D

Pump On Ended with Cycle Switch

Activation

F

IG. 58

If the Pump On sequence has been programmed to end

by a Cycle Switch Activation:

• The GLC 4400 pump output relay activates (J7-3)

and will stay on until the correct number of cycle

switch closures is received (J6-3) (see Setup

Menus, Cycle End Setup page 19).

• The Pump On LED (A) remains on during this time.

• The Pump On (C) icon displays.

• The Cycle LED (B) and Cycle Count Mode icon (D)

display indicating the cycle switch is activated.

• The cycle indicator bar (E) displays a visual representation

of the cycle switch closures received.

Pump Off Ended with Time

FIG. 59

If the Pump Off sequence has been programmed to be

ended by TIME:

• The GLC 4400 pump output relay activates (J7-3)

and will stay off until the time expires. (see Setup

Menus, Pump Off, page 20).

• The Pump On LED (A) remains off during this time.

• The Pump Off icon (C) displays.

• The Timer Mode icon (D) displays and indicates the

Timer Mode.

Pump Off Ended with Machine Counts

• If the set number of cycle switch closures is not

received before time expires, an alarm occurs.

F

IG. 60

313855H 31

If the Pump Off sequence has been programmed to be

ended by MACHINE COUNTS:

Page 32

Run Mode

A

C

E

D

B

• The GLC 4400 pump output relay activates (J7-3)

and will stay off until the correct number of counts

(J6-15) occur (see Setup Menus, Pump Off, page

20).

• The Pump On LED (A) remains off during this time.

• The Pump Off icon (C) displays.

• The Cycle LED (B) and Machine Count icon (D) display and indicate the Machine Count Switch activation.

Pump Off Ended with Machine Counts; Max

Time Entered

Alarms Screen

When a cycle alarm event occurs the Alarm Screen,

shown in F

FIG. 62

To clear an alarm, hold down the Clear Key on the display Keypad (see page 3).

IG. 62 displays.

F

IG. 61

If the Pump Off sequence has been programmed to be

ended by MACHINE COUNTS with a maximum time:

• The GLC 4400 pump output relay activates (J7-3)

and will stay off until the correct number of counts

(J6-15) occur (see Setup Menus, Pump Off, page

20).

• The Pump On LED (A) remains off during this time.

• The Pump Off icon (C) displays.

• The Cycle LED (B) and Machine Count icon (D) display and indicate the Machine Count Switch activation.

• The counts indicator bar (E) displays a visual representation

of the machine counts received.

• If the set number of machine counts is not received

before time expires, an alarm occurs.

The following is a list of other alarm events that may display.

Low Level Alarm. Icon appears on display screen.

Indicates the lubrication fluid level is low.

Pressure mode error. Icon displays on alarm screen

to signal the allotted time ran out before the pressure

switch was tripped.

Machine count error. When icon displays on alarm

screen, indicates the set number of machine counts

was not received before time expired. This would

trigger an alarm event.

Cycle switch input error. Icon displays in center of

Alarm screen to indicate the allotted time ran out

before the programmed number of cycle switch

activations was received.

32 313855H

Page 33

Troubleshooting

Description Problem Solution

No power supplied to solenoid

Timer fails to activate solenoid

Solenoid faulty Replace solenoid

Timer faulty Replace timer

Low level or other alarm Refill reservoir

Pressure switch fails to shut down

system

Program Settings

Description

TIMER Setup, page 18 HH:MM:SS (00:00:01 - 99:59:59)

PRESSURE Setup, page 19 HH:MM:SS (00:00:01 - 99:59:59)

CYCLE END Setup, page 19 HH:MM:SS (00:00:01 - 99:59:59)

CYCLE MODE Selection, page 20 Cycles = 01 - 99

Pressure switch incorrectly wired Verify proper connections

Pressure switch faulty Replace pressure switch

Timer faulty Replace timer

Modes of Operation

Maximum / Minimum and Additional Comments

Time, Pressure or Cycles

Troubleshooting

Power light off: Timer is not receiving

power. Verify connections and verify

power supply.

Power light on: Verify solenoid connections

PUMP ON Setup, page 18

PUMP OFF Setup, page 20

POWER UP Setup, page 22 MM:SS (00:01 - 59:59)

PULSED Output (pump), page 24 Maximum Time OFF and Time ON: SS (01-99)

PIN Number Setup, page 25

QUICK CYCLE SCREEN Setup, page 26

PRELUBE on Power Up, page 30

Pump ON Time: HH:MM:SS (00:00:01 - 99:59:59)

Cycles: 01 - 99 (only used when mode of operation = cycles)

Time, Count or Both

Pump OFF Time: HH:MM:SS. (00:00:01 - 99:59:59)

Count: 01 - 9999

ON / OFF

0000 - 9999

Cycles = 01 - 99

Time ON and Time OFF: SS (01-99)

Execute: YES / NO

YES / NO

Delay: YES / NO

TIME: MM:SS (00:01 - 59:59)

313855H 33

Page 34

Technical Data

Technical Data

Input Contact

Power Source DC - model 24B591 9 - 30 VDC

Power Source AC - model 24B596 100 VAC to 240 VAC - 50/60 Hz

Power consumption 24 Watts

Cycle Pressure Control Input (optional) Normally open pressure or cycle switch

Machine Count Control Input (optional) Machine count control switch

Lubrication level (optional) Normally open level switch, closes upon low level

Remote Manual Run Input Normally open remote manual run switch

Outputs

Pump control Pump Control Voltage = Power Source

Voltage Power Source

Max Switching Voltage 250 VAC, 100 VDC

Max Switching Current 10 A (AC), 5A (DC)

Minimum Switching Capacity 100 mA @ 5 VDC

Low Level Alarm, normally open (optional)

Voltage Power Source

Max Switching Voltage 250 VAC, 30 VDC

Max Switching Current 5A (AC), 5A (DC)

Minimum Switching Capacity 100 mA @ 5 VDC

Auxiliary Alarm, normally open (optional)

Voltage Power Source

Max Switching Voltage 250 VAC, 30 VDC

Max Switching Current 5A (AC), 5A (DC)

Minimum Switching Capacity 100 mA @5 VDC

Status OK, normally open (optional) Voltage-free Contact

Voltage Power Source

Max Switching Voltage 250 VAC, 100 VDC

Max Switching Current 10 A (AC), 5A (DC)

Minimum Switching Capacity 100 mA @ 5 VDC

Protection grade

Enclosure Material Fiberglass reinforced polyester

Membrane Material Polyester

Bushing Ethylene Propylene Diene Monemer Rubber (EDPM)

Operating temperature range - 40°F to 145°F (- 40°C to 63°C)

Storage Temperature - 13°F to 145°F (- 25°C to 63°C)

IP69K

34 313855H

Page 35

Dimensions

4.8 in. (122 mm)

4.72 in.

(120 mm)

3.58 in.

(90.85 mm)

4.17 in.

(105.92 mm)

3.23 in.

(82.0 mm)

Dimensions Mounting Hole Layout

313855H 35

Page 36

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2009, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 313855

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised December 2013

Loading...

Loading...