Page 1

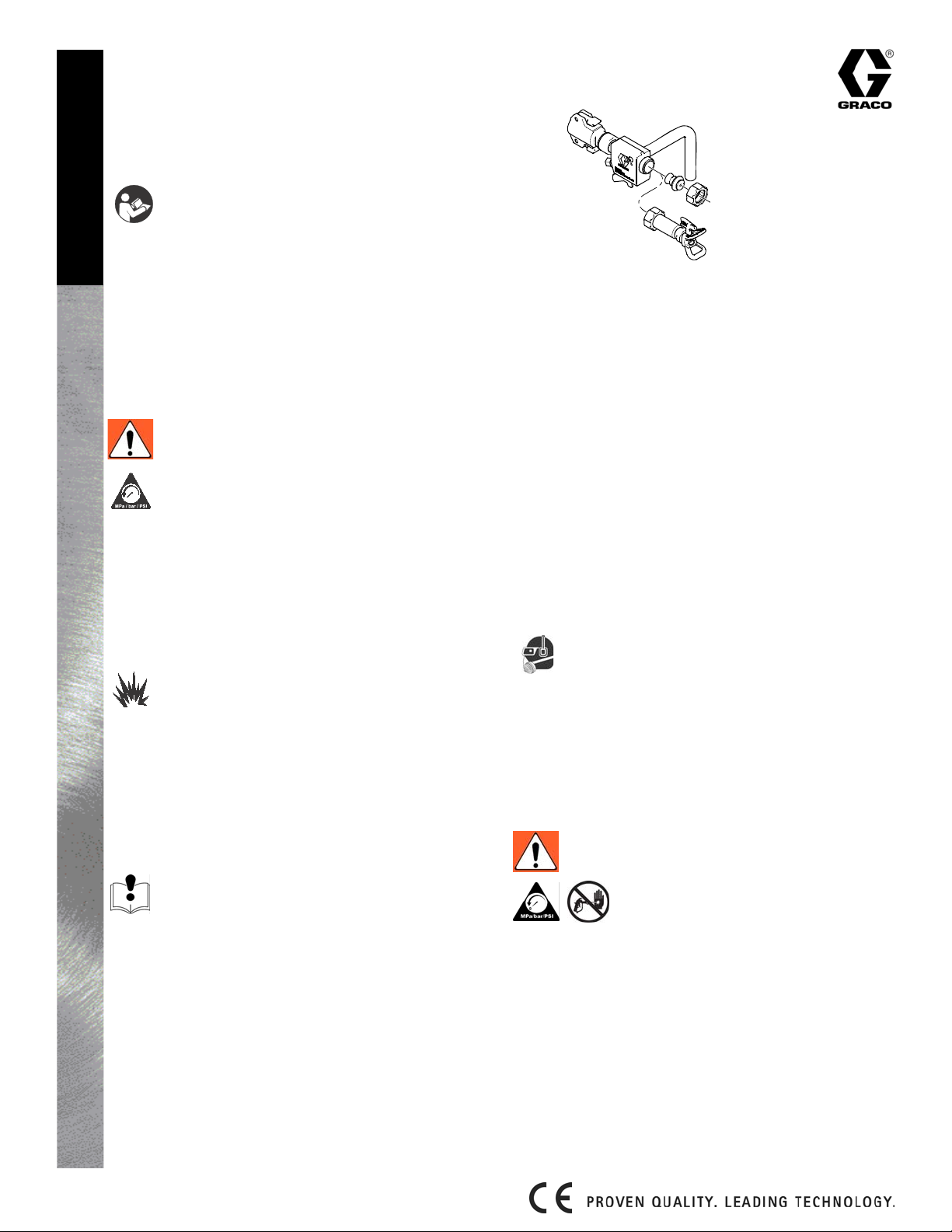

HTX 2030 Applicator

Model: 24B327

313537D

IMPORTANT SAFETY INSTRUCTIONS. Refer to your

sprayer instruction manual for Pressure Relief, priming and

spray instructions. Keep these instructions.

ti13583a

Maximum Fluid Working Pressure: 1,000 psi (6.9 MPa, 69 bar)

English

Maximum Air Working Pressure: 250 psi (1.7 MPa, 17 bar)

- For Water-Based Materials Only -

The following Warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation point

symbol alerts you to a general warning and hazard symbols refer to procedure-specific risks. Refer back to these Warnings.

Additional, product-specific warnings may be found throughout the body of this manual where applicable.

• Check equipment daily. Repair or replace worn or dam-

WARNINGS

PRESSURIZED EQUIPMENT HAZARD

Fluid from the applicator/dispense valve, leaks, or

ruptured components can splash in the eyes or on

skin and cause serious injury.

• Follow Pressure Relief Procedure in this manual, when

you stop spraying and before cleaning, checking, or servicing equipment

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn

or damaged parts immediately.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes,

in work area can ignite or explode. To help prevent

fire and explosion:

• Keep work area free of debris, including solvent, rags

and gasoline.

• Ground all equipment in the work area. See Grounding

instructions.

• If there is static sparking or you feel a shock, stop oper-

ation immediately. Do not use equipment until you identify and correct the problem.

.

aged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your

distributor for information.

• Route hoses and cables away from traffic areas, sharp

edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull

equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment

when operating, servicing, or in the operating area of

the equipment to help protect you from serious

injury. This equipment includes but is not limited to:

• Protective eyewear and hearing protection

• Clothing and respirator as recommended by the fluid and

solvent manufacturer

•Gloves

Pressure Relief Procedure

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment

manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material,

request MSDS forms from distributor or retailer.

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2008, Graco Inc. is registered to I.S. EN ISO 9001

Instructions/Parts

Follow this Pressure Relief Procedure

whenever instructed to relieve pressure,

stop spraying, check or service equipment,

or install or clean spray tip.

1. Shut off gasoline engine or unplug electric power cord

and turn sprayer pressure control to lowest pressure

setting.

2. Open drain valve at sprayer and verify pressure has

been relieved into supply pail.

If you suspect spray tip or hose is clogged or that pressure

has not been fully relieved after following the steps above,

place thick rag over connection between hose and sprayer or

applicator. Slowly loosen connection to relieve pressure

gradually. Clear hose or tip obstruction.

Page 2

Airless Spray Setup

WARNING

To prevent injury when the applicator is not in use,

always relieve pressure if sprayer is being shut

down or left unattended.

Make sure pressure control is turned off and gasoline engine

is shut off or power cord is unplugged from power source.

Refer to your sprayer instruction manual for priming and spray

instructions.

Connect Applicator to Sprayer

1. Attach supply hose to sprayer fluid outlet.

2. Attach other end of supply hose to applicator swivel (13).

3. Refer to sprayer instruction manual for priming

instructions.

Install Fluid Filter or Plug

1. When spraying fluids with small aggregates, install filter

support (21) and filter (20, 20a) to reduce tip clogging.

2. When spraying with large spray tips and fluids with larger

aggregates, install plug (20b) to prevent fluid from

entering air passage in housing (1).

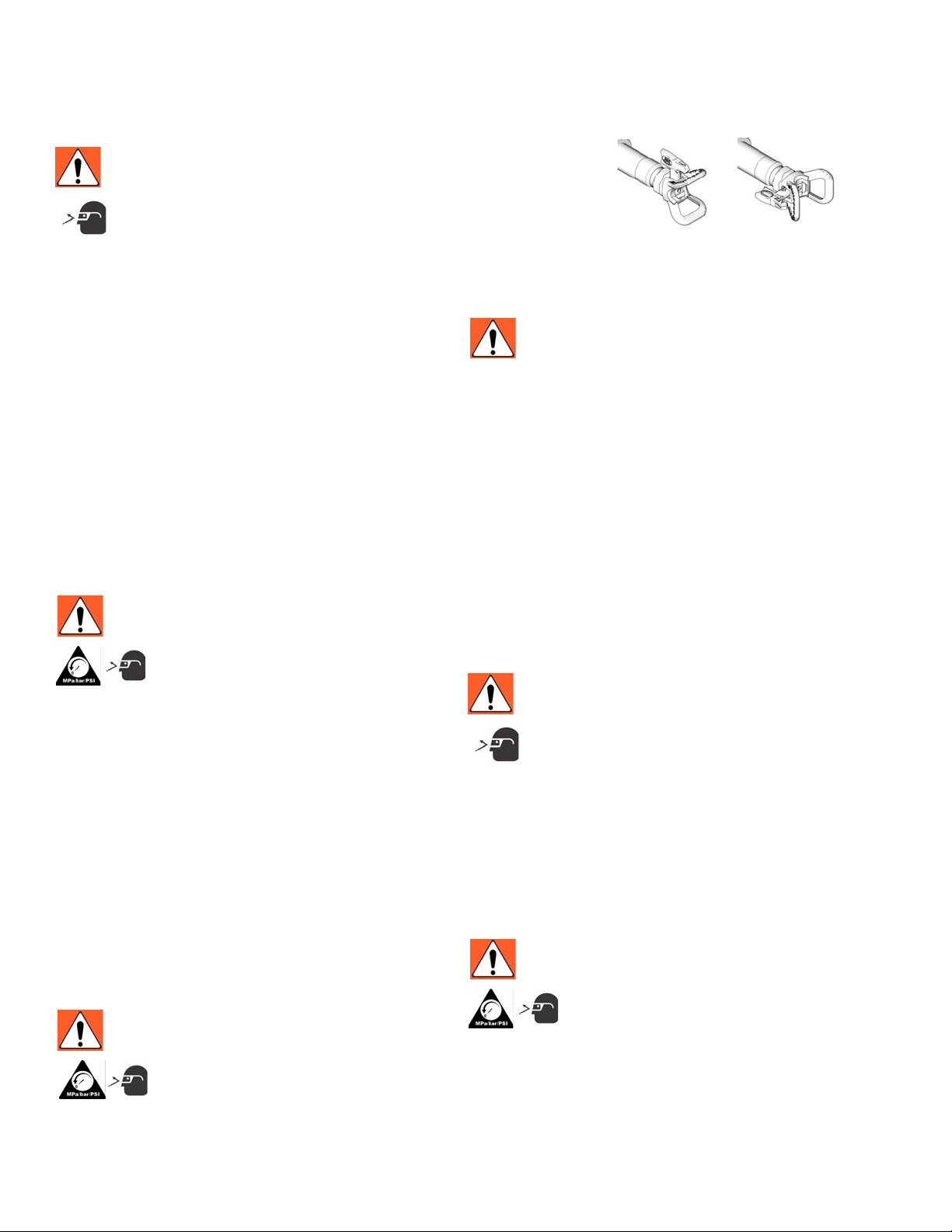

Install Applicator Tip and Guard

WARNING

2. Loosen guard

retaining nut.

3. Align guard (32)

horizontally to

spray a horizontal

pattern.

4. Align guard (32)

vertically to spray

a vertical pattern.

(3) Horizontal

ti11908a

(4) Vertical

ti11909a

Clearing Clogs

WARNING

1. Relieve pressure (see Pressure Relief procedure).

2. Rotate tip (31) 180°. Open applicator into hopper or onto

ground to remove clog.

3. Rotate tip (31) 180° back to spray position.

Cleanup

Thoroughly flush applicator after each work session before

fluid begins to cure in applicator. Remove check valve (2) and

clean all residue from air passages. Store in a dry location. Do

not leave the applicator or any parts in water or cleaning

solvents.

NOTE: Check valve (15) will be damaged if any object is

inserted into valve.

1.If equipment has recently been operated,

relieve pressure.

2.Using a pencil or similar object, insert seal

(25) into back of guard (32).

3. Install guard (32) onto end of applicator.

4. Insert tip (31) in guard (32). Tighten retaining nut.

Operation

Spraying

1. Be sure the arrow shaped tip (31) faces forward (spray).

2. Hold applicator perpendicular and approximately

40 in. (1 m) from surface. Move applicator first, then open

applicator to spray a test pattern.

3. Slowly increase pump pressure until coverage is uniform

and even (see sprayer instruction manual for additional

information).

Aligning Spray

WARNING

1.Relieve pressure.

Air Spray Setup

WARNING

To prevent injury when the applicator is not in use,

always relieve pressure if sprayer is being shut

down or left unattended.

Connect Applicator to Sprayer

1. Attach supply hose to sprayer fluid outlet.

2. Attach other end of supply hose to applicator swivel (13).

3. Install air hose to applicator check valve (15).

4. Refer to sprayer instruction manual for priming

instructions.

Install Applicator Air Nozzle

WARNING

1.If equipment has recently been operated,

relieve pressure.

2.Install air nozzle (10, 27, 28, 29) and

retaining ring (11).

2 313537D

Page 3

Operation

Spool Valve Repair

Spraying

1. Set material flow (see sprayer instruction manual for

additional information).

2. Spray test pattern

3. Turn air knob on and adjust, and/or select another

air nozzle, for desired pattern.

Note: Air continues to flow when handle is in off position

to keep material out of air passages.

Cleanup

Flush applicator after each work session before fluid

begins to cure in applicator. Remove check valve (15)

and clean all residue from air passages. Store in a dry

location. Do not leave the applicator or any parts in

water or cleaning solvents.

NOTE: Check valve (15) will be damaged if any object is

inserted into valve.

Technical Data

WARNING

Before performing any maintenance on applicator, read

all warnings on front cover of this manual and relieve

pressure.

Spool Valve Removal

1. Remove screw (3d) and handle (8) from spool (3).

2. Remove retaining ring (3c) and bearing (3b).

3. Remove spool (3) from housing (1).

Spool Valve Installation

1. Apply grease (supplied with Kit 24B329) to spool,

o-rings and bearing and inside of housing.

2. Assemble o-rings onto spool.

3. Install spool in housing and bearing. Secure with

retaining ring (3c).

4. Install handle with screw.

All sealing surfaces must be clean to prevent leaks

and damage to equipment.

Maximum fluid working pressure 1000 psi (6.9 MPa, 69 bar)

Maximum air working pressure 250 psi (1.7 MPa, 17 bar)

Air Requirements 30 scfm (0.84 m3/min) Maximum

Fluid Inlet Size 1 in.(m) cam and groove (Graco HP)

Air Inlet Size 1/4 npsm(m)

Wetted Parts Aluminum, stainless steel, PE, POM, polyurethane, nitrile, nylon, PVC, tungsten

carbide

Weight † 2.9 lb (1,3 kg)

Height 5.8 in. (14,7 cm)

Width 7.0 in. (17,8 cm)

Length † 12.7 in. (32,3 cm)

Sound Data without Air (applicator

only):

Sound Pressure Level 84dB(A)*

Sound Power Level 83dB(A)*

Sound Data with Air (applicator

only):

Sound Pressure Level 118dB(A)*

Sound Power Level 118dB(A)*

* Spraying simulated acoustical texture under typical conditions as specified by the material manufacturer.

† Airless configuration

313537D 3

Page 4

19

Parts

13

12

14

15

4

33a

33

34

35

36

17

3b

3c

8

3

3d

Qty. Part Description Qty.

1 15W371 HOUSING, valve, htx 1

3 24B329 KIT, spool, includes 3a - 3d, 8

3a* 121576 PACKING, o-ring, urethane 114 2

3b* 15W376 WASHER, bearing 1

3c* 122205 RING, retaining, internal 1

3d* 113045 SCREW, sems, mach, phillips 1

4 122206 PIN, drive 1

8* 15W377 HANDLE, valve 1

10 248524 NOZZLE, 4 mm, rnd 1

11 15Y137 RING, retaining, splined 1

12 111027 PACKING, o-ring 1

13 24B568 SWIVEL, assy, htx 1

14 15U368 NUT, cap, 1/4-18 npsm 1

15 289919 KIT, check valve 1

17 122521 SCREW, machine, 1/4-20 x 2.5 1

18 24B328 HANDLE, applicator (includes 17) 1

19 289874 COUPLER, female, qd 1

20† 289922 FILTER, screen, texture, 18 mesh 1

20a† 289923 FILTER, screen, texture, 30 mesh 1

20b 15X791 PLUG, air, passage 1

18

1

10,27,28,29

11

31

20

21

22

23

11

25

??

32

ti14501b

Qty. Part Description Qty.

21 277789 SUPPORT, filter 2

22 15U687 SEAL, adapter, filter, texture 1

23 15D727 ADAPTER, ghd Rac 1

25 246453 KIT, gasket and seat (5 sets) 1

27 248525 NOZZLE, 6mm, rnd 1

28 248526 NOZZLE, 8mm, rnd 1

29 248527 NOZZLE, 10mm, rnd 1

31 LTX671 TIP, spray, Rac X (671) 1

32 246215 GUARD, Rac X 1

33 169967 FITTING, air QD 1

34 121591 KNOB, valve 1

35 112779 VALVE, needle 1

36 156823 UNION, swivel 1

* Included in Spool Repair Kit 24B329

† Includes support 21

For complete warranty information contact your local Graco distributor, call Graco customer service:

All written and visual data contained in this document reflects the latest product information available at the time of publication.

1-800-690-2894 or visit our website: www.graco.com.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 313537

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

02/2009

Loading...

Loading...