Page 1

Instruction Manual 309497L

EN

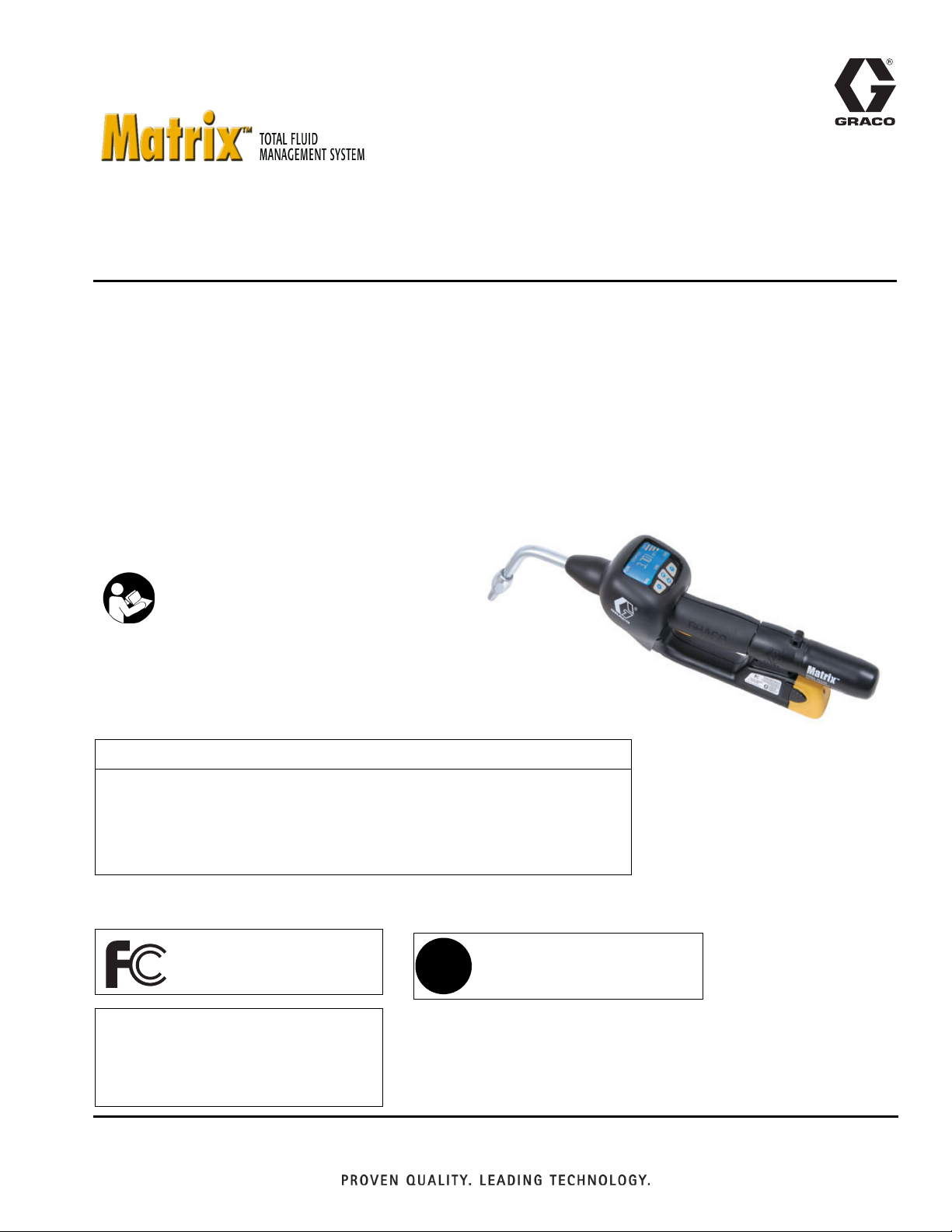

Matrix Meter

Used to dispense petroleum-based lubricants and antifreeze only.

Part No. 246008 Series D, North America (N. A.)

Part No. 249881 Series D, Australia

1500 psi (10.3 MPa, 103 bar) Maximum Working Pressure

600 psi (4.1 MPa, 41.4 bar) Maximum Dynamic Working Pressure (while dispensing)

5 gpm (18.9 lpm) Maximum Flow Rate

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

CAUTION

This dispense valve is:

• Designed to dispense petroleum-based lubricants and antifreeze ONLY.

• Designed for indoor use ONLY.

•NOT designed for in-line installation.

The Matrix Meter contains an RF device with the following approvals:

FCC ID: JHIGNET

IC: 4840AGNET

Industry Canada Statement

The term “IC” before the certification/registration number only signifies that the Industry Canada technical specifications

were met.

Australian Vendor Code: N3845

✓

Page 2

Manual Conventions

Contents

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Programming the Meter . . . . . . . . . . . . . . . . . . . . . 4

Meter Programming . . . . . . . . . . . . . . . . . . . . . . 4

Meter Installation . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure Relief Procedure . . . . . . . . . . . . . . . . . 8

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Pre-installation Procedure . . . . . . . . . . . . . . . . . . 8

Installing Nozzle Extension . . . . . . . . . . . . . . . . . 9

Meter Installation to Hose . . . . . . . . . . . . . . . . . . 9

Pressurizing the System . . . . . . . . . . . . . . . . . . . 9

Meter Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Asleep/Awake Mode . . . . . . . . . . . . . . . . . . . . . 10

High/Low Flow Rate Indicator . . . . . . . . . . . . . . 10

Battery Life Indicator . . . . . . . . . . . . . . . . . . . . . 10

Security Modes . . . . . . . . . . . . . . . . . . . . . . . . . 11

Work Orders and Job Numbers . . . . . . . . . . . . 12

Dispense Options . . . . . . . . . . . . . . . . . . . . . . . 14

Manual Dispense Mode . . . . . . . . . . . . . . . . . . 14

Preset Dispense Mode . . . . . . . . . . . . . . . . . . . 14

Restricted Preset Dispense Mode . . . . . . . . . . 15

Removing and Replacing the Battery . . . . . . . . 15

Quick-Lock

™

Nozzle . . . . . . . . . . . . . . . . . . . . . 15

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Calculating the Calibration Factor . . . . . . . . . . . . 19

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Replacing or Cleaning Filter . . . . . . . . . . . . . . . 21

Replacing Quick-lock

Replacing the Bezel . . . . . . . . . . . . . . . . . . . . . . 22

Replacing the Trigger . . . . . . . . . . . . . . . . . . . . . 24

Replacing the Meter Electronics . . . . . . . . . . . . 28

Parts Drawing for the 246008 and 249881

Electronic Meters . . . . . . . . . . . . . . . . . . . . . . . 32

Parts List for the 246008 and 249881

Electronic Meters . . . . . . . . . . . . . . . . . . . . . . . 33

Nozzle Extension Accessories . . . . . . . . . . . . . . . 34

Kit 246005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Kit 246006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Kit 246007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Technical Specifications . . . . . . . . . . . . . . . . . . . . 35

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 38

Graco Phone Numbers . . . . . . . . . . . . . . . . . . . . . 38

™

Nozzle . . . . . . . . . . . . . 21

Manual Conventions

WARNING

WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious

injury.

CAUTION

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in property damage or

destruction of equipment.

Note

A note indicates additional helpful information.

2 309497L

Page 3

Warnings

Warnings

The following warnings include general safety information for this equipment. More specific warnings are included in

the text where appropriate.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from dispense valve, hose leaks, or ruptured components will pierce skin. This may

look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical treat-

ment.

• Do not point dispense valve at anyone or at any part of the body.

• Do not put your hand over the end of the dispense nozzle.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be

aware that flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground equipment.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a fire extinguisher in the work area.

BATTERY SAFETY

The battery may leak, explode, cause burns, or cause an explosion if mishandled:

• You must use the battery type specified for use with the equipment.

• Sparking can occur when changing batteries. Only replace the battery in a non-hazardous location,

away from flammable fluids or fumes.

• Handle and dispose of battery properly - do not short circuit, charge, force over discharge, disassemble, crush, penetrate, incinerate, or heat the battery to a temperature exceeding 185° F (85° C).

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not use hoses to pull equipment.

• Comply with all applicable safety regulations.

309497L 3

Page 4

Programming the Meter

Programming the Meter

Graco recommends that meters be programmed prior

to installation.

For ease of installation be sure to tag each meter with

the corresponding PC meter number from the Matrix

software. For example: Bay 1, 10W30. These tags are

used for locating the corresponding meter in the

assigned bay or location.

The electronic meter batteries need to be charged

prior to use. See Instruction Manual 309502 for

details.

Meter Programming

Prior to programming the electronic meters,

• Enter the transceiver and tank setup information into the Matrix PC software. If not done,

the software will display an error when attempting to set up meters.

• Navigate to the Meter Setup screen, input the

meter parameters, then select PROGRAM for

the meter being programmed.

1. Insert the battery. See Removing and Replacing

the Battery on page 15.

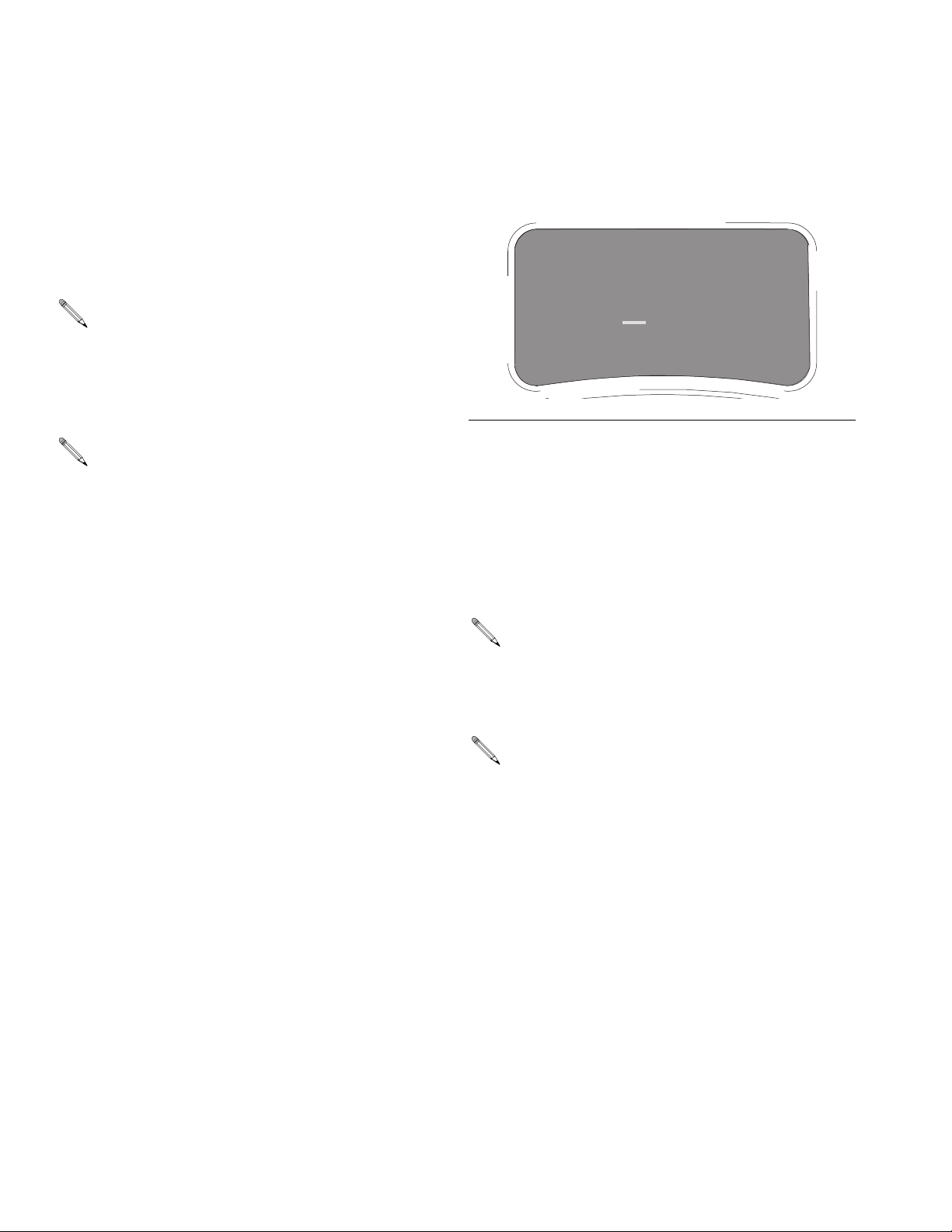

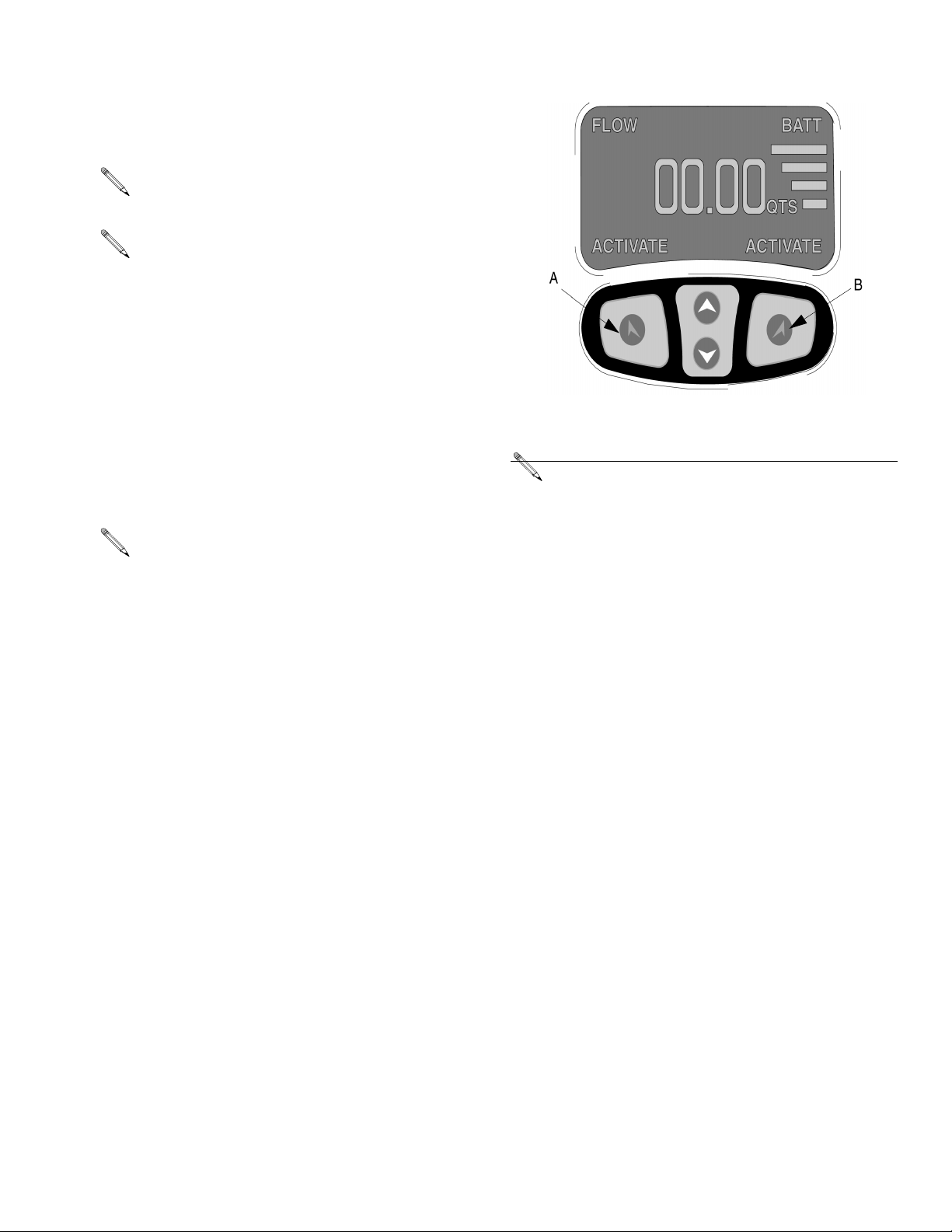

2. When the battery is first inserted, the display shown

in F

IG. 2 appears.

3. To program a meter, simultaneously hold down both

the left keypad button (A) and right keypad button (B)

until both the ACTIVATE words on the display screen

change to PROGRAM (appears on the left) and

SELECT (appears on the right). Release buttons.

4. The screen indicates a Network and Transceiver ID.

See

FIG. 1

.

PROGRAM MODE

2.02.003

NET WK ID A

TRANS ID A

METER ID 500

PROGRAM

F

IG. 1

• If the ID information is correct, press the left (A) keypad button labeled PROGRAM to complete the

meter programming.

• If the ID information is incorrect, use the SELECT

button and up/down arrow button to obtain the correct ID settings. Then press the left (A) keypad button labeled PROGRAM to complete the meter

programming. See F

The meter must be at the ACTIVATE/ACTIVATE

screen for it to be programmed. If you are in Work

Order mode, put a test Work Order into the system

so you can navigate to the ACTIVATE/ACTIVATE

meter screen and re-program.

METER ID is the RF address assigned to the meter

by the PC during programming.

IG. 2.

SELECT

4 309497L

Page 5

5. The meter displays the appropriate programmed

screen and a pop-up window displays on the PC

indicating programming is complete. This process is

repeated for each meter in the system.

The PC software allows a 5 minute period to program the meter.

If the electronic meter is unable to communicate

with the PC during programming, the message NO

SIGNAL appears at the top of the meter display.

6. Once the information is programmed into the electronic meter, the meter can be connected to the dispensing hose in the corresponding bay. If the meter

will not be immediately connected temporarily label

it with the corresponding meter number and location

(i.e. Meter 1, Bay 1, 10W30). The label assures the

correct meter is installed in the correct location in

the system. After the meter is installed in the correct

location, the label can be removed. See Meter

Installation on page 6.

Programming the Meter

F

IG. 2

If PC software revision is 2.01.29 or meter firmware

revision is 2.00.053, meter will display 3 places to

the right of the decimal rather than 2.

If a programmed meter is moved or if the programmed parameters need to be changed, the

meter must be reprogrammed.

309497L 5

Page 6

Programming the Meter

Meter Installation

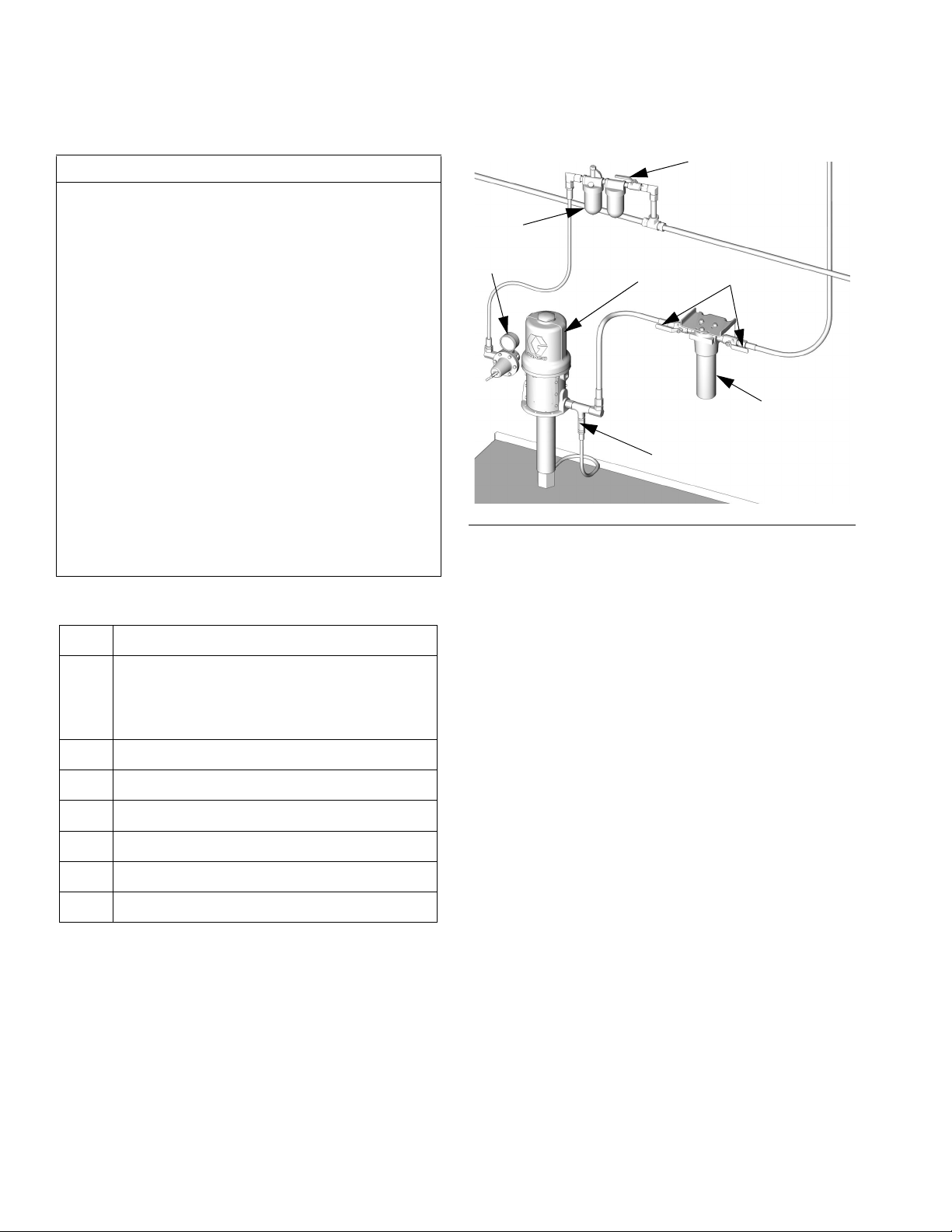

CAUTION

Failure to comply with the following installation

requirements may result in warranty coverage

being denied.

• Fluid lines MUST be thoroughly flushed before

installing Matrix meters

System, Instruction Manual 310652.

• All Matrix systems MUST use the Graco CleanLine System for initial flushing and ongoing operation for all service fluids. See CleanLine

Filtration System, Instruction Manual 310652.

• Pressure relief kits MUST be used on all pumps

within the Matrix system to prevent over-pressurization due to thermal expansion. See Pressure

Relief Kits, Instruction Manual 308403. Select

appropriate relief kits when using high pressure

(1600 psi) CleanLine filters. Low pressure (900

psi) CleanLine filters have a built-in pressure

relief valve.

. See CleanLine Filtration

F

FIG. 3

K

J

H

D

E

G

ti5127

KEY DESCRIPTION, See F

Thermal Pressure Relief Kit must be

D

installed downstream from the pump. The

Thermal Pressure Relief Kit will vary based

on the pump selected

E Fluid shut-off valves (two)

F Air Regulator

G CleanLine Filter System

HPump * †

J Filter and Lubricator Assembly

K Master Bleed Air Valve (ball valve)

* Do not use diaphragm pumps in a Matrix system.

† Special pump packages are required for anti-

freeze. See instruction manual 310650.

IG. 3.

6 309497L

Page 7

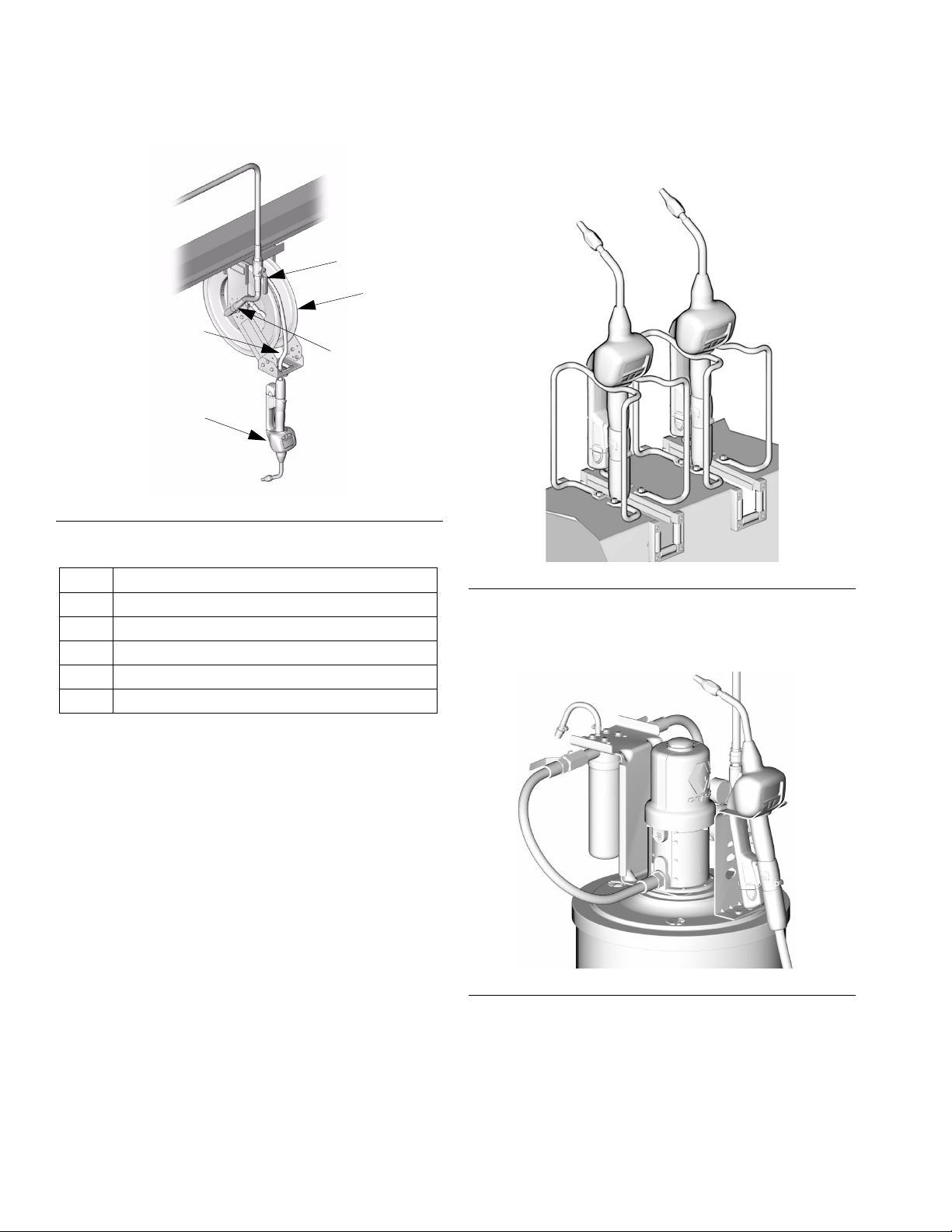

F

IG. 4

Programming the Meter

Mounting Brackets

Mounting bracket kit 249440 is available for resting a

Matrix meter on a console. See F

J

M

K

L

N

IG. 5.

KEY DESCRIPTION, See F

J Fluid shut-off valve

KHose

L Hose reel fluid inlet hose

M Hose reel

Electronic metered dispense valve

N

IG. 4.

ti6733

FIG. 5

Mounting bracket 15B750 is available for resting a

Matrix meter on a 16 gallon drum. See F

IG. 6

F

IG. 6.

ti6732

309497L 7

Page 8

Programming the Meter

Pressure Relief Procedure

WAR NING

Read warnings, page 3, and follow the Pressure

Relief Procedure whenever you:

• are instructed to relieve pressure

• stop operation

• check, clean, or service any of the equipment

1. Turn off the power supply to the pump.

2. Trigger the dispense valve into a waste container to

relieve pressure.

3. Open any bleed-type master air valves and fluid

drain valves in the system.

The Matrix meter must be powered, nozzle open

(counter clockwise), and in dispense mode for fluid

pressure to be relieved.

Pre-installation Procedure

1. Relieve the pressure. Follow the Pressure Relief

Procedure on page 8.

2. Close the shut-off valve (J). See F

3. Ground the hose and reel or console. See Ground-

ing.

4. If this is a new installation or if the fluid in the lines is

contaminated, flush the lines before you install the

metered valve.

CAUTION

Contaminated lines could cause the valve to leak.

Failure to flush may result in warranty coverage being

denied. See CleanLine Filtration System, Instruction

Manual 310652.

IG. 4.

4. Leave the drain valve open until you are ready to

pressurize the system.

Grounding

.

WARNING

The system must be properly grounded. Read warnings, page 3. Refer to the user manuals for the pump

and other system components, and ground the following:

• Pump: Follow the manufacturer's recommendations.

• Air and Fluid hoses: Use only grounded hoses.

• Air compressor: Follow the manufacturer's recommendations.

• Fluid supply container: Follow the local code.

• To maintain grounding continuity when flushing or

relieving pressure, always hold a metal part of the

valve firmly to the side of a grounded metal pail,

then trigger the valve.

8 309497L

Page 9

Programming the Meter

Installing Nozzle Extension

1. Slide the impact guard (40) onto the tube or hose of

the nozzle extension assembly. See F

2. Thread the sealing nut (101, 204, or 303) onto the

spout (102, 202, or 302).

3. Thread the tube or hose in at least three full turns,

position it for proper alignment, and wrench tighten

the sealing nut. The PTFE seal on the sealing nut

must face the valve housing. See F

4. Slide the impact guard (40) over the meter body.

101, 204, or 303

IG. 7.

IG. 7.

102, 202, or 302

CAUTION

Graco recommends using PTFE tape on hose threads

prior to installing the Matrix meter. PTFE tape should

be after the leading thread and clockwise (same direction as meter installs on hose fitting). Caution should

be taken not to get tape into the meter during installation as this can cause the meter to malfunction.

Should the tape be the cause of the malfunction,

Graco warranty will be denied.

2. Apply PTFE tape to the male threads of the hose fitting (P). See caution above. Leave a minimum of

two engaged threads bare to maintain grounding

continuity.

24

P

1

29

wrench tighten to

40

prevent leakage

F

IG. 7

Meter Installation to Hose

1. Slide the rear boot (24) onto the hose. See FIG. 8.

WARNING

Improper grounding can cause a hazardous condition

and result in fire or explosion. Follow instructions in

step 2 to maintain grounding continuity.

1

Slide boot onto

hose before connecting hose

F

IG. 8

ti64317

3. Thread the hose fitting into the swivel (29) of the

meter, and tighten it firmly. See FIG. 8.

4. Slide the rear boot (24) over the fittings and onto the

end of the Matrix meter.

Pressurizing the System

1. Open all dispense position shut-off valves. Start the

pump to pressurize the system. See the Operation

section, page 14, for proper operation of meter.

2. To ensure dispensing accuracy, purge all air from

the fluid lines and dispense valve before using it.

3. Set the system flow to the desired flow rate, which is

typically 1.5-gpm. Do not exceed a 5-gpm flow rate.

309497L 9

Page 10

Meter Operation

Meter Operation

Asleep / Awake Mode

Asleep is a battery-saving mode in which the display

goes blank after two minutes of inactivity during normal

operation. The display comes Awake from sleep mode

when any button is pressed.

High/Low Flow Rate Indicator

The electronic meter dispenses fluids at two different

rates.

As the trigger is partially engaged, the flow rate is low

and is indicated by two bars on the display. See F

IG. 9.

Battery Life Indicator

On the right side of the display is a series of four bars

located under the word BATT. See F

ence of all four bars indicates a fully charged battery.

The bars decline in number as the meter is used and the

battery discharges. All Matrix meter batteries should be

re-charged at the end of the working day to assure good

performance the next work day.

• Batteries can be recharged at anytime without

battery damage.

• At one bar on the display you will have about

20-40% of the charge remaining.

• If a meter is removed from service for an

extended time the battery should be removed

and recharged.

• If you see the message “Remove Low Battery Wait 30 Seconds Then Replace”, remove the

battery, wait 30 seconds, and then replace it

with a charged battery.

• Even when a meter is idle (asleep), the meter is

still functioning and the battery will be used.

IG. 11. The pres-

F

IG. 9

• When the trigger is fully engaged, the flow rate is

high and is indicated by four bars on the display.

See F

IG. 10.

IG. 10

F

FIG. 11

10 309497L

Page 11

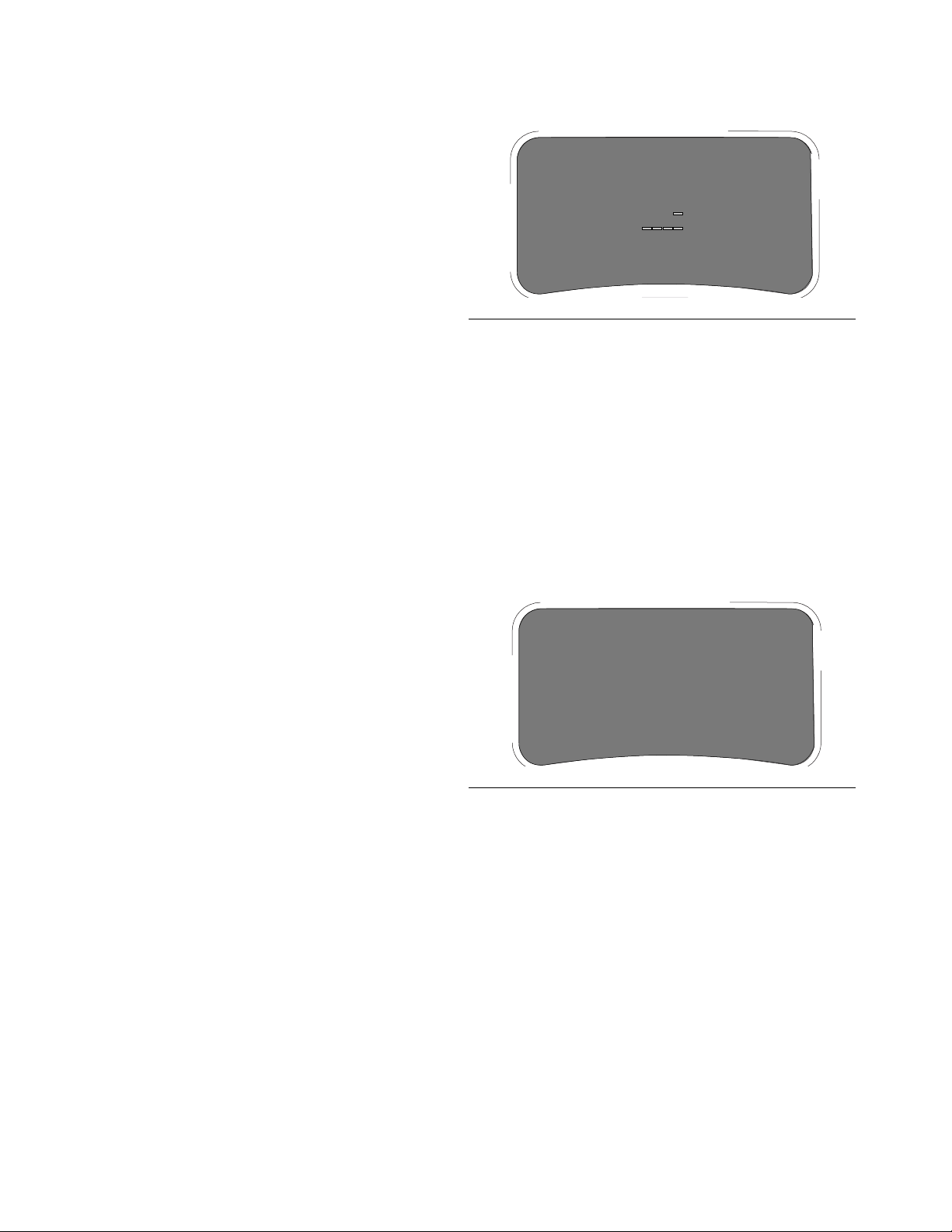

Security Modes

PIN CODE

RIGHTLEFT

2122

ENTER

AUTHORIZATION

REQUIRED

REQUEST

APPROVAL

REQUEST

APPROVAL

When the meters were originally programmed by the

system administrator, one of the following security

choices was entered:

• System Monitoring

•PIN Code

• Parts Room Authorization

Meter Operation

Prior to dispensing, it may be necessary to complete

one of the following security procedures, depending on

the security mode selected.

System Monitoring

When set for system monitoring, no security authorization is required by the operator. However, any amount of

fluid dispensed is automatically sent by the meter to the

PC where it is recorded for future reference.

PIN Code

PIN Code (personal identification number) means that a

four digit PIN code must be entered at the meter to

obtain dispense authorization. To use a meter with PIN

code security:

1. Use the up and down arrow keypad buttons to select

the first number of the PIN code.

2. Press the right keypad button to move the cursor to

the next position.

3. Use the up and down keypad buttons to select the

desired number. Continue this process until the PIN

code number is completed. See F

IG. 12.

F

IG. 12

4. When the pin code is complete, press the right keypad button until the cursor underlines the Enter

option. Press the up arrow on the meter keypad.

This action will enter the PIN code and send it to the

PC.

5. The PC recognizes the PIN code and authorizes the

meter to dispense.

Parts Room Authorization

This mode provides high level security and requires a

Parts Room Administrator to authorize each dispense.

AUTHORIZATION

REQUIRED

REQUEST

APPROVAL

IG. 13

F

REQUEST

APPROVAL

309497L 11

1. Press either the left keypad or right keypad button

under REQUEST APPROVAL. This sends the

request to the parts room administrator’s PC for dispense authorization. See F

2. The administrator grants authorization at the PC,

which then authorizes the meter to dispense.

IG. 13.

Page 12

Meter Operation

WORKORDER

SELECTSELECT

ENTER NEW

2ACO

-

32567

- IC9

2AC03

-

458A1

-

2233A

-

ENTER WORKORDER

RIGHTLEFT

WORKORDER JOB

ENTERCANCEL

2AC03

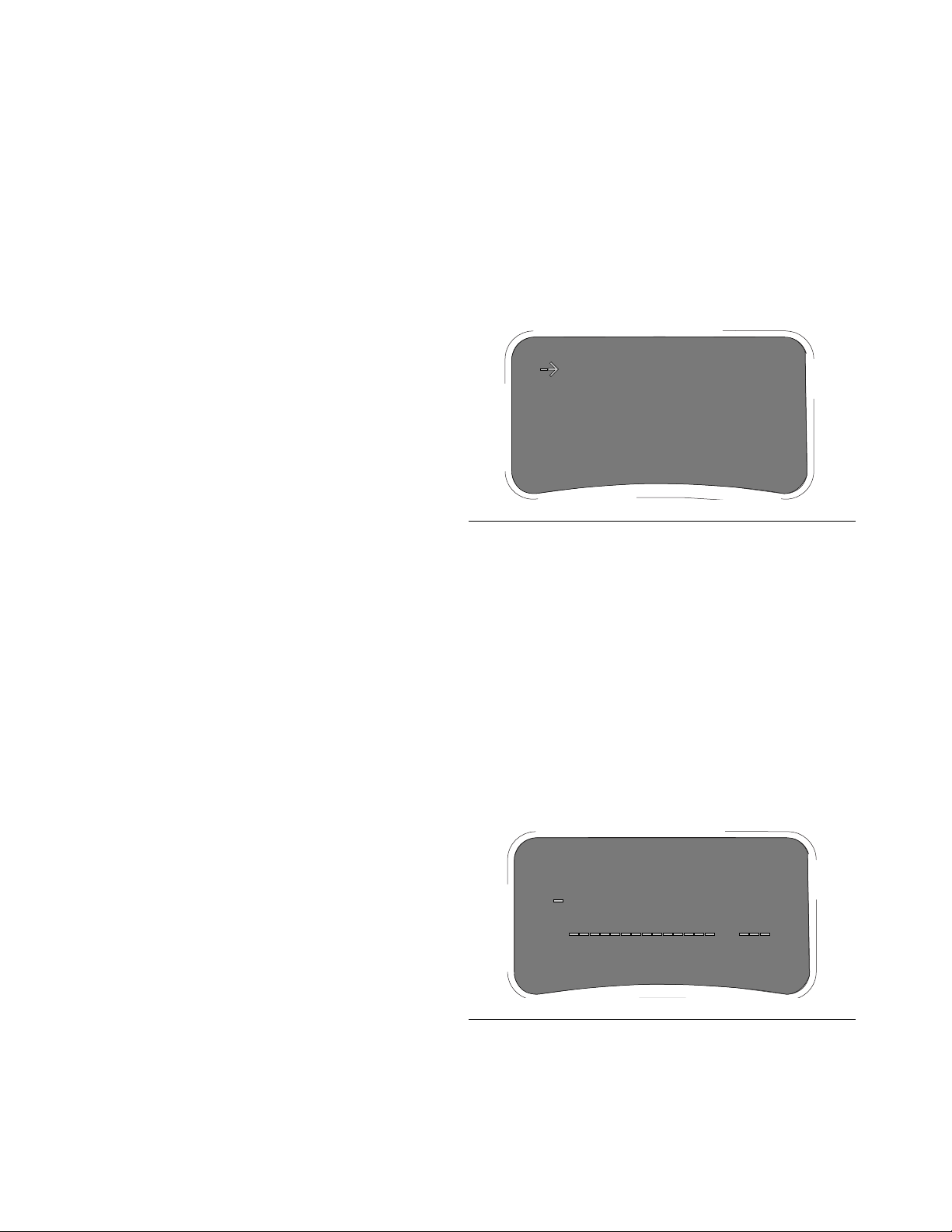

Work Orders and Job Numbers

When the meters were programmed by the System

Administrator, one of the two Work Order processing

methods below was selected.

• Work Order/Job Number at the PC only

• Work Order/Job Number at the PC and Meter

Work Orders are a maximum of (12) characters and the

Job Number is a maximum of (3) characters. The Work

Order number is separated from the Job Number with a

dash (-).

The characters A-Z, 0-9, dash (-); forward slash (/),

period (.), or space can be used when assigning a Work

Order or Job Number. One Work Order can have more

than one service using an extension in the order number

(i.e., 123456.oil, 123456.atf). The meter can receive up

to five (5) work orders at a time. See F

IG. 14.

Assigning Work Orders and Job Numbers

from the PC

Work Orders and Job Numbers are assigned to a meter

from the PC using the “Entering Work Orders” button in

the software. This feature is password protected.

1. Click on the Entering Work Orders button. Type in

the user name and password and click Submit.

1. At the Work Order/Job Number meter screen,

select the Enter New option using the up and down

keypad buttons. When the arrow is positioned prior

to the Enter New option, push either one of the two

outside keypad buttons to Select the option. This

will take you to a second screen to enter the Work

Order/Job Number. Matrix meters can display up to

5 work orders and the Enter New command. See

F

IG. 14.

ENTER NEW

2ACO 32567 - IC9

2AC03 458A1 2233A -

F

IG. 14

2. On the second Work Order/Job Number screen, the

cursor defaults to the first character position for

entering the Work Order (up to 12 characters). Use

the up and down keypad buttons to select a number,

letter, or character for the first digit of the Work

Order.

2. Click on the Add Work Order box. Select meter

from the pull down screen. Type in a Work Order (up

to 12 characters). Tab or mouse click to the Job

Number box and enter the Job Number (up to 3

characters) if desired, then click Send.

3. If the Work Order is received by the designated

meter, the PC Work Order list will be updated to

show “Dispense Pending” in the status column.

If the Work Order is not received by the meter, a pop-up

box appears indicating that the Work Order could not be

sent to the assigned meter. You then can click Retry or

Cancel.

Assigning Work Orders and Job Numbers

3. Press the right keypad button to move the cursor to

the next character position. Use the arrow keypad

buttons to select the character desired. Continue

this process until the Work Order is completed. See

F

IG. 15.

F

IG. 15

at the Meter

Work Orders and Job Numbers can be assigned at the

meter using the meter Work Order screen and meter

keypad buttons. The screen shows previously assigned

Work Orders and the Enter New option.

To enter a new Work Order follow the procedure below:

12 309497L

4. Press the right keypad button and navigate to the

first position to enter the Job Number if desired.

Enter the Job Number in the same manner as you

entered the Work Order number.

Page 13

Meter Operation

EMERGENCY MODE

RIGHTLEFT

1222

ENTER

5. When the numbers are complete, press the right

keypad button until the cursor underlines the Enter

option. Press the up arrow on the meter keypad

display. This action will enter the new Work Order to

the list on the first screen.

To Cancel a Work Order press either the right or

left keypad button on the meter until the cursor

underlines the Cancel option. Push the up arrow

on the keypad to cancel the Work Order entry. This

will take you back to the first Work Order/Job Number screen.

Work Order Validation Mode: The default operation

mode for either work order method is validation mode.

This mode is recommended for maximum protection

against unauthorized dispenses and maximum integrity

of the Matrix database.

Emergency Mode

If the communication link is lost (power loss, computer

crash), the meters will continue to function if they are

placed in the Emergency Mode.

During Emergency Mode, the meter continues to

store dispense history and will communicate this

information to the PC when the communication link

is restored.

Placing a Meter in the Emergency Mode

The Emergency Code Number must be provided by the

system administrator before performing this procedure.

1. Select the meter(s) to place in the Emergency

Mode.

2. Simultaneously hold down both the left and right

keypad buttons until ACTIVATE appears in the

lower left and right corners of the meter display.

3. Press the UP arrow keypad button once which takes

you to the Emergency Mode screen.

4. Enter the four-digit Emergency Code Number. Position the cursor under the word ENTER and press

the UP arrow on the keypad. Meter security is

bypassed and the meter is now in the Emergency

Mode. This procedure must be repeated for each

meter placed into the Emergency Mode.

5. When communication is restored, each meter

placed into Emergency Mode must be re-pro-

grammed with its original settings.

After the meter is placed in Emergency Mode, the

battery must remain in the meter until the display

goes blank. If not, the meter will revert to it’s original programming.

F

IG. 16

309497L 13

Page 14

Meter Operation

Dispense Options

The meter dispense options are determined by the system administrator at the time the meter is programmed.

Meter dispense options include:

• Manual Dispense Mode

• Preset Dispense Mode

• Restricted Preset Dispense Mode

To change the meter from one mode to another,

you must reprogram the meter. See Programming

the Meter on page 4.

Manual Dispense Mode

To dispense fluids in this mode:

1. If necessary, enter the PIN code, Parts Room

Authorization request and/or the Work Order

request.

2. Press the left or right keypad button under ACTIVATE to begin communication with the PC. Both

ACTIVATE words on the display screen will change

to END.

3. Pull the meter trigger to dispense. The meter counts

up to the desired amount.

4. Release the trigger when the desired amount is

obtained. Then press the right or left keypad button

to end the dispense. This logs the dispense amount

to the PC and returns the meter to its programmed

entry screen.

If END is not pressed, after five minutes the meter

will automatically end the job and log the dispense

to the PC.

Preset Dispense Mode

Meters programmed in preset mode count down from a

specified value to zero and shut off automatically. The

preset value can be increased or decreased from the initial value using the up and down keypad buttons.

1. If necessary, enter the PIN code, Parts Room

Authorization request and/or work order request.

2. Press ACTIVATE to enter the dispense mode. The

preset default amount entered into the PC will

appear on the meter.

F

IG. 17

3. If desired press the arrow up or arrow down keypad

button to change the preset amount.

4. Press the right keypad button under the word

CLEAR to zero out the preset amount. The arrow up

and arrow down keypad buttons are used to enter a

new amount of fluid to dispense.

5. Pull and release the meter trigger to start the dispense. The meter dispenses the preset amount and

shuts off.

Flow can be stopped at any time during the dispense by

pressing the meter trigger or any button on the meter

display.

See FIG. 17.

OR

An appropriate preset amount can be set for each

work order when entering work orders at the PC.

Once the preset amount is dispensed, the meter display

automatically changes to read TOP OFF MODE. This

allows the operator to add additional fluid after the preset amount is dispensed. The Top Off amount to be dispensed can be limited during meter programming. See

F

IG. 18.

14 309497L

Page 15

Meter Operation

F

IG. 18

6. If the operator wants to top-off fluids, press the left

arrow key to display the TOP-OFF MODE. See F

IG.

19.

Removing and Replacing the

Battery

1. Remove the battery by pressing in on both battery

lock buttons (E) and pulling the battery (F) out and

away from the meter. See F

2. Place the battery in the battery charger. See

Instruction Manual 309502 for details.

3. Replace the battery by pressing in on both battery

lock buttons (E) and pushing the battery (F) into the

meter.

If the meter displays a low battery warning, wait 30

seconds before installing a new battery. See Battery Life Indicator page 10.

.

E

IG. 20.

IG. 19

F

7. Pull the trigger to dispense the desired fluid amount

for top-off.

8. Press END to complete the job. See F

IG. 19. This

logs the dispense to the PC and returns the meter to

its programmed entry screen.

If END is not pressed, after 5 minutes the meter will

time out and log the dispense to the PC.

Restricted Preset Dispense

Mode

When meters are programmed in restricted preset

mode, the specified dispense value cannot be

increased, only decreased. The functionality of this feature is identical to Preset Dispense Mode (see Preset

Dispense Mode beginning on page 14) except that the

preset value can only decreased with the down keypad

button.

F

IG. 20

F

ti64318

Quick-Lock™ Nozzle

The nozzle opens and closes with LESS THAN

one turn.

1. To close the nozzle to prevent dripping, rotate left

(counter clockwise) until tight. See F

2. To open the nozzle for dispensing, rotate right

(clockwise) until fully open.

IG. 21.

Open

Close

ti64319

F

IG. 21

309497L 15

Page 16

Troubleshooting

Troubleshooting

WAR NING

Read warnings, page 3.

Problem Cause Solution

Battery display

bars do not appear.

Meter display does

not activate.

Slow or no fluid

flow from meter.

Battery has low charge. Recharge battery.

Battery is dead. Attempt to recharge a dead battery using procedures

Battery inserted too soon. Wait 30 seconds and reinstall fully charged battery.

Cable connections are loose or disconnected.

Electronic display is damaged.

CleanLine filter system is clogged. Clean or replace the CleanLine filter. Refer to the Clean-

Meter is not in dispense mode. See dispense options, page 14.

Matrix meter filter is clogged. Clean or replace the Matrix meter filter element. See

Pump pressure is low. Turn up air pressure to the pump. SeeTechnical Speci-

Pump or reel fluid shut-off valve is

not fully open.

Meter hydraulic valve is not functioning.

Electronic board connections may be

loose or disconnected.

Trigger membrane switch is damaged - flow bars DO NOT show on

the meter display when the trigger IS

actuated.

Meter valve is blocked with debris flow bars DO show on the meter display when trigger IS actuated.

Quick close nozzle is closed. Open nozzle, see F

A hydraulic quick disconnect was

used to connect the meter to the dispense hose, allowing debris to clog

meter.

Relieve pressure before you check or repair the meter.

Follow the Pressure Relief Procedure, page 8.

Be sure all other valves and controls and the pump are

operating properly. If using the chart below to troubleshoot is not successful, contact your Graco distributor

for repairs or component replacement.

outlined in the Battery Charger Instruction Manual

(309502). If procedure does not restore a normal

charge, replace the battery.

Ensure cables are properly connected. See page 22.

Replace with Bezel Repair Kit (246438). See page 33.

Line Filter System Instruction Manual (310652).

Cleaning or Replacing the FIlter page 21.

fications page 35.

Fully open pump or reel fluid shut-off valve.

If meter bars are lit indicating flow, the nozzle tip is fully

open, and the fluid flow has been verified to the meter

valve inlet, then the meter hydraulic valve has failed and

the meter should be replaced.

Verify that all connectors are connected or re-seated to

the board connections. See page 22.

Replace the trigger membrane using the Trigger Repair

Kit (246439 N. A., 249883 Australia). See page 33.

Flush the valve with mineral spirits at high pressure and

flow. Warning: do not exceed the maximum working

pressure of the meter (1500psi - 103 bar).

IG. 21 on page 15.

Quick disconnects should not be used with Matrix product, doing so voids the warranty.

16 309497L

Page 17

Problem Cause Solution

Meter does not

stop dispensing.

Meter valve is blocked with debris flow bars DO NOT show on the meter

display when the trigger IS NOT actuated.

Flush the valve with mineral spirits at high pressure and

flow. Warning: Do not exceed the maximum working

pressure of the meter (1500 psi - 103 bar). If flushing

does not resolve the problem, the meter should be

replaced.

Trigger or trigger membrane switch is

damaged - flow bars DO show on the

meter display when the trigger IS

NOT actuated.

Dynamic System Pressure (while dispensing) exceeds the recommended

Replace the trigger and trigger membrane using the

Trigger Repair Kit (246439 N. A., 249883 Australia). See

page 33. Do not use clamps or wire ties to hold trigger

during dispense, doing so voids the warranty.

Reduce system pressure. A lower ratio pump may be

required to reduce pressure and maintain sufficient flow.

600 psi (4.1 MPa, 41.4 bar).

A hydraulic quick disconnect was

used to connect the meter to the dis-

Do not use quick disconnects with Matrix product. Use

of quick disconnects voids the warranty.

pense hose, allowing debris to block

meter.

Displayed dispensed amount is

not accurate.

Meter will not take

work orders.

Meter is not programmed for the cor-

Verify meter programming.

rect fluid type.

Meter gears are worn. Meter requires calibration due to wear. See page 19.

Battery has low charge or is dead. Recharge battery.

Battery inserted too soon. Wait 30 seconds and reinstall fully charged battery.

Meter may not be programmed. Reprogram meter.

Battery may have been pulled during

Reprogram meter.

programming.

Two meters may be programmed as

Ensure each meter is programmed individually.

the same meter.

Meter work order list is full. Normal operation. Meter will hold up to 5 work orders.

Meter has intermittent or no RF communication.

Meter is outside RF communication

range of transceiver.

Two meters may be programmed as

Reposition transceiver or add a transceiver.

Ensure each meter is programmed individually.

the same meter.

PC or transceiver is off. Turn PC on, open Matrix application, and check power

on transceiver.

Meter will not program.

Incorrect COM port selected for

transceiver connection.

Change to correct COM port at the PC in Matrix trans-

ceiver configuration screen.

Transceiver is not powered up. Power up transceiver, wait 30 seconds or until red lights

go blank and green light remains on alone.

Transceiver dip switches are not set

See transceiver manual 309498 to set dip switches.

for the communication cable being

used.

Matrix program is not in programming

mode.

The five-minute programming session has expired.

Network and transceiver settings on

the meter are not correctly set.

Meter is outside RF communication

Place PC in programming mode. See Programming the

Meter, page 4.

Place PC in programming mode. See Programming the

Meter, page 4.

Make appropriate settings. See Programming the Meter,

page 4.

Reposition transceiver or add a transceiver.

range of transceiver.

Troubleshooting

309497L 17

Page 18

Troubleshooting

Problem Cause Solution

Meter has been in

service for an

extended period of

time and begins to

work erratically

such as loss of

Work Orders or

Security settings.

Meter leaks. Extension may be loose from meter

Meter cuts on and

off during preset

dispense.

Meter displays

“active trig”

E-Prom on meter board has reached

the end of its life.

fluid housing.

Swivel connection at hose may be

leaking.

The trigger is being held during preset dispense.

Trigger or trigger membrane switch is

damaged - flow bars DO show on the

meter display when the trigger IS

NOT actuated.

Trigger or trigger membrane switch is

damaged - flow bars DO show on the

meter display when the trigger IS

NOT actuated.

Trigger is being held before activating

meter for dispense.

Attempt to reprogram the meter. If you see a pop-up

screen on the PC that says, “Memory Failure” and/or the

meter screen defaults to the ACTIVATE/ACTIVATE

screen, the E-Prom on the meter board must be

changed. Install the Electronics Repair Kit (246675).

The Electronics Repair Kit includes a new meter board

with E-Prom. The meter then can be reprogrammed to

the features desired.

Tighten seal nut using two wrenches.

Clean, seal, and tighten joint.

Release the trigger during preset dispense.

Replace the trigger and trigger membrane using the

Trigger Repair Kit (246439 N. A., 249883 Australia). See

page 33. Do not use clamps or wire ties to hold trigger

during dispense, doing so voids the warranty.

Replace the trigger and trigger membrane using the

Trigger Repair Kit (246439). See page 33. Do not use

clamps or wire ties to hold trigger during dispense, doing

so voids the warranty.

Release trigger to activate meter.

* To use the Matrix Emergency Mode contact the Matrix System Administrator in your facility.

18 309497L

Page 19

Calculating the Calibration Factor

Calculating the Calibration Factor

Use the following tables and formulas to calculate the change to the calibration factor.

Example of Calibration Adjustment for Motor Oil (quarts - 368)

Dispense into a clean, calibrated, volumetric measuring flask until the meter display indicates 1 quart of fluid has

been dispensed.

For greater accuracy, submerge the nozzle and let the air settle out of the fluid for ten minutes before noting the

volume.

• In the following example, the flask shows the volume is less than one quart (-1.2 ounces). See the left column

and find the number closest to -1.2 ounce value which is 1.0.

• Look for the corresponding number in the right column, which is +12. If the current calibration factor is 368, add

12 to get the new calibration factor of 380.

• Change this factor for a fluid in Tank Setup and for given meter(s) in Meter Setup.

Metric Measurement

Measuring in liters, and 1 liter is dispensed

Error in Milliliters (ml) Change Calibration

Factor by:

+ 50 - 20 + 1.7 - 20

+ 40 - 16 + 1.4 - 16

+ 30 - 12 + 1.0 - 12

+ 20 - 8 + 0.68 - 8

+ 10 - 4 + 0.34 - 4

+ 0 no change 0 no change

- 10 + 4 - 0.34 + 4

- 20 + 8 - 0.68 + 8

- 30 + 12 - 1.0 + 12

- 40 + 16 - 1.4 + 16

- 50 + 20 - 1.7 + 20

The table on the right lists approximate calibration factors for different fluids. Your calibration number may vary

slightly due to temperature or flow rate.

U.S. Measurement

Measuring in quarts, and 1 quart is dispensed

Error in U.S. ounces

(oz.)

Fluid

Oil (10W-30) 368 389

Gear Lube 375 396

Automatic Transmission Fluid 368 389

Antifreeze 348 368

Change Calibration

Factor by:

Calibration

Number

Quarts Liters

309497L 19

Page 20

20 309497L

Page 21

Service

WAR NING

Service

29

6

9

Read warnings, page 3.

Follow the Pressure Relief Procedure, page 8,

whenever you:

• are instructed to relieve pressure

• stop operation

• check, clean, or service any of the equipment

The low-battery and dead-battery displays are explained

in the Troubleshooting chart on page 16.

To change the battery see Removing and Replacing

the Battery on page 15.

Replacing or Cleaning Filter

To replace or clean the filter, do the following:

1. Relieve the pressure.

2. Unscrew the hose from the swivel (29). See F

3. Remove the o-ring (6), and remove the filter (9) from

its seat in the swivel (29) with an o-ring pick.

IG. 22.

m

a

e

r

t

s

n

w

o

D

ti64320

FIG. 22

Replacing Quick-lock™ Nozzle

The quick-lock nozzle (101, 201, or 301) is not serviceable. If the nozzle leaks, replace it as follows. See F

23.

1. Remove the old nozzle from the extension with an

open-end adjustable wrench on the flats (A) of the

nozzle stem.

2. Thread the new nozzle (101, 201, or 301) onto the

extension. With an open-end adjustable wrench on

the flats (A) of the nozzle stem, firmly tighten the

nozzle. the flats (A) of the nozzle stem, firmly tighten

the nozzle.

101

IG.

4. Thoroughly clean the filter with solvent, or replace

with the new filter.

5. Push the new or cleaned filter (9) into the swivel

(29), and make sure it’s properly seated. Replace

ti64328

A

the o-ring (6).

Be sure to position the new filter (9) so the concave

side of the screen points downstream. See

6. Screw the hose back into the swivel (29).

309497L 21

FIG. 22

.

F

IG. 23

201

301

ti64329

A

A

ti64330

Page 22

Service

Replacing the Bezel

Bezel Repair Kit 246438 is available and can be ordered

separately. See the Parts List for the 246008 and

249881 Electronic Meters on page 33. The parts with a

★ next to their reference numbers are included in this

repair kit.

12

When repairing the meter using the Bezel Repair Kit, be

sure to use all of the new parts. To replace the parts do

the following.

CAUTION

Be sure to use the disposable grounding wrist strap

included with the repair kit. Static electricity can damage the electrical components as the meter is

repaired.

1. Relieve the Pressure.

WARNING

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the Pressure

Relief Procedure on page 8.

2. Remove the battery (11). See Parts Drawing for

the 246008 and 249881 Electronic Meters on

page 32.

42 (both sides)

FIG. 24

8. Pull apart the two cover halves leaving all parts in

the right cover half (18). See F

All services to the meter should be done using the

right cover half (18) of the meter. If parts should disengage as the covers are separated, reposition the parts

back into the right cover half (18).

19

IG. 25.

18

3. Slide the rear boot (24) off the hose.

4. Remove the meter from the fluid hose.

F

5. Remove the impact guard (40) from the meter.

6. With a phillips screwdriver remove the four phillips

screws (42) holding the bezel to the cover halves

(18 & 19). See F

7. With a T-10 torx driver remove the remaining eleven

screws (12) holding the cover halves together (18 &

19).

22 309497L

IG. 24.

IG. 25

Page 23

9. Pull the bezel (31) away and up from the right cover

half (18). See F

IG. 26.

Service

When reconnecting cable C to the circuit board

(112), ensure that the cable is positioned with the white

tab facing up and that the cable is straight before pushing in (closing) the clasp. See F

IG. 28.

IG. 26

F

C

B

A

F

IG. 27

10. Disconnect the cables/wires (A, B, & C) that connect

the bezel (31) to the circuit board (112). Discard the

old bezel (31). See F

IG. 27 and FIG. 28.

FIG. 28

12. Replace the bezel (31) onto the right meter cover

half (18).

Ensure that all meter parts are positioned securely

and in the correct location. Ensure that all cables are

routed correctly throughout the meter and will not be

pinched or kinked when the halves are reassembled

See F

IG. 29 and FIG. 30.

Ensure that the black antenna wire is not positioned between the ribbon cables. Pull antenna away

from the cable as shown. See F

IG. 31.

11. Reconnect the cables/wires (A, B, & C) from the

new bezel (31) to the circuit board (112).

309497L 23

Page 24

Service

F

IG. 29

13. Assemble the covers (18 & 19). Insert several of the

screws (12) to temporarily hold the cover halves (18

& 19) together. Test the display by inserting a battery (11) and powering on the unit.

If the display does not appear:

• make sure that a charged battery (11) is being

used.

• check that the connections from the new bezel

(31) to the circuit board (112) are fastened correctly and securely.

• check that all remaining parts are repositioned

securely and in the correct location.

14. If the display appears and is operating correctly,

replace the remaining screws (12) and (42) that fasten the cover halves (18 & 19) together. Torque all

screws to 7 - 10 in. lbs.

15. Replace the rear boot (24) and impact guard (40).

IG. 30

F

16. Attach the meter to the fluid line by following steps

listed on page 9.

Replacing the Trigger

Trigger Repair Kits 246439 for meter 246008 and

249883 for meter 249881 are available and can be

ordered separately. See the Parts List for the 246008

and 249881 Electronic Meters on page 33. The parts

with a ✓ next to their reference numbers are included in

this repair kit.

The PSM switch (101) comes attached to the right

meter cover half (18). Do not remove it during the

meter cover repair procedure.

When repairing the meter using the Trigger Repair Kit,

use all of the new parts. To replace the parts do the fol-

lowing.

CAUTION

Be sure to use the disposable grounding wrist strap

included with the repair kit. Static electricity can damage the electrical components within the meter as the

repair is completed.

IG. 31

F

24 309497L

Page 25

1. Relieve the Pressure.

WARNING

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the Pressure

Relief Procedure on page 8.

1. Remove the battery (11). See Parts Drawing for

the 246008 and 249881 Electronic Meters on

page 32.

2. Slide the rear boot (24) off the hose.

3. Remove the meter from the fluid hose.

4. Remove the impact guard (40) from the meter.

5. With a phillips screwdriver remove the four phillips

screws (42) holding the bezel to the cover halves

(18 & 19). See F

IG. 32.

6. With a T-10 torx driver remove the remaining eleven

screws (12) holding the cover halves together (18 &

19).

All services to the meter should be done using the

right cover half (18) of the meter. If parts should disengage as the covers are separated, reposition the parts

back into the right cover half (18). See F

IG. 33.

19

18

IG. 33

F

8. Place the new right cover (18) along side of the

meter.

Service

12

42 (both sides)

FIG. 32

7. Pull apart the two cover halves leaving all parts in

the right cover half (18).

9. Remove the old trigger components (13, 14, 22, 23,

36, & 37) and discard.

246008 and 249881 Electronic Meters

See

Parts Drawing for the

on page 32.

10. Remove the RF Board (103) from the right meter

housing (18) and disconnect the PSM switch (101)

by pulling the cable from the RF Board (103). See

F

IG. 35.

11. Plug connector end of the new PSM switch (101)

into the new RF Board (103) connector.

12. Transfer all remaining parts from the old meter cover

half (18) to the new meter cover half (18). Discard

the old meter cover halves (18) and (19).

13. The two ribs (E) of the new meter cover fit

between the two bolts (F) of the meter housing. Be

sure not to pinch or crimp the circular switch cable

(D) on the new cover half. See F

IG. 34.

309497L 25

Page 26

Service

D

F

F

E

E

IG. 34

F

14. Insert the RF Board (103) into the new right meter

half (18). See F

IG. 35.

Ensure that the RF Board (103) is positioned

securely in the slots (A) of the new right meter half (18).

See F

IG. 35.

101

A

23

37

ti4323

FIG. 36

16. Make sure that all other meter parts are positioned

securely and in the correct location. See F

IG. 37.

IG. 37

F

17. Attach the bezel (31) to the right meter housing (18).

103

F

IG. 35

Ensure that all meter parts are positioned securely

and in the correct location. Ensure that all cables

15. Slide the trigger assembly (13, 14, 22, 23, 36, & 37)

back onto the mounting peg on the right half of the

meter (18). See F

IG. 36.

are routed correctly throughout the meter and will

not be pinched or kinked when the halves are reassembled See F

IG. 38 and FIG. 39.

Ensure that the circular trigger plunger (23) is centered with the trigger switch. Also ensure that the trigger

spring (37) is securely slid into position. See F

26 309497L

IG. 36.

Page 27

Ensure that the black antenna wire is not positioned

between the ribbon cables. Pull antenna away from

the cable as shown. See F

F

IG. 38

IG. 40.

Service

FIG. 40

18. Assemble the covers (18 &19). Insert several of the

screws to hold the cover halves together. Test the

display and trigger by inserting a battery and powering on the unit. If display does not appear or trigger

does not function:

F

IG. 39

• make sure that a charged battery (11) is being

used.

• check that the connections from the new bezel

(31) to the circuit board (112) are fastened correctly and securely.

• check that all parts are repositioned securely

and in the correct location.

• check that the trigger connection to the RF

board (103) is fastened correctly and securely.

• check that the trigger switch is centered prop-

erly and that no gaps have formed between the

switch and circular indent.

19. If the display appears, test the trigger to be sure that

both dispense settings work correctly. Replace the

remaining screws (12) and (42) that hold the cover

halves together. Torque all screws to 7 - 10 in. lbs.

309497L 27

Page 28

Service

Replacing the Meter Electronics

Electronics Repair Kits 246675 for meter 246008 and

249882 for meter 249881 are available for replacing the

Matrix meter electronics. See the Parts List for the

246008 and 249881 Electronic Meters on page 33.

The parts with a † next to their reference numbers are

included in the Electronics Repair Kit.

12

When repairing the meter using the Electronics Repair

kit be sure to use all of the new parts. To replace the

electronics do the following.

The PSM switch (101) comes attached to the right

meter cover half (18). Do not remove it during the

meter electronics repair procedure.

CAUTION

Be sure to use the disposable grounding wrist strap

included with the repair kit. Static electricity can damage the electrical components within the meter during the repair.

1. Relieve the Pressure.

WARNING

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the Pressure

Relief Procedure on page 8.

42 (both sides)

FIG. 41

7. Pull apart the two cover halves leaving all parts in

the right cover half (18).

All services to the meter should be done using the

right cover half (18) of the meter. If parts should disengage as the covers are separated, reposition the parts

back into the right cover half (18). See F

19

IG. 42.

18

1. Remove the battery (11). See Parts Drawing for

the 246008 and 249881 Electronic Meters on

page 32.

2. Slide the rear boot (24) off the hose.

3. Remove the meter from the fluid hose.

4. Remove the impact guard (40) from the meter.

5. With a phillips screwdriver remove the four phillips

screws (42) holding the bezel to the cover halves

(18 & 19). See F

6. With a T-10 torx driver remove the remaining eleven

screws (12) holding the cover halves together (18 &

19).

28 309497L

IG. 41.

F

IG. 42

8. Place the new right cover (18) along side of the

meter.

9. Remove the trigger assembly (13, 14, 22, 23, 36, &

37) from the old cover (18) and set aside.

10. Remove the meter housing from the old right cover

(18).

11. Disconnect the cables/wires (A, B, C, & D) that connect the bezel (31) to the circuit board (112) and the

valve housing to the circuit board. See F

IG. 43.

Page 29

Service

12. Remove the three screws (41) holding the PC Board

(112) to the meter housing. See F

IG. 43. Note that

there is a washer (44) on each screw (41) between

the board and the meter housing boss.

13. Remove the RF Board (103) from the cover half and

disconnect the PSM switch cable (H) from the RF

board (103). Set the old electronics (112, 103)

aside. See F

IG. 44 and FIG. 46.

14. Connect the new circuit board (112) to the valve

housing using three screws (41). See F

IG. 43. Be

sure to install a washer (44) on each screw (41)

between the PC Board and the meter housing boss.

41

C

41

D

FIG. 44

When reconnecting cable D be sure that the wires

from the valve housing are properly inserted in the valve

housing wire retainer hook (G). See F

IG. 48.

16. Place the meter housing into the new right cover

half (18) being careful not to dislodge the PSM

switch (101).

B

A

IG. 43

F

41

15. Connect the cables/wires (A, B, C, & D) that connect

the bezel (31) and the valve housing to the circuit

board (112). See F

IG. 43 and FIG. 44.

When reconnecting cable C to the circuit board

(112), ensure that the cable is positioned with the white

tab facing up and that the cable is straight before pushing in (closing) the clasp. See F

IG. 44.

The two ribs (E) of the new meter cover fit between

the two bolts (F) of the meter housing. Be sure not to

pinch or crimp the circular switch cable (D) on the new

cover half. See F

IG. 45.

D

F

F

E

E

F

IG. 45

17. Plug connector end of the new PSM switch (101)

into the RF Board (103). See F

IG. 46.

309497L 29

Page 30

Service

18. Insert the RF Board (103) into the meter cover (18).

Make sure that the RF board (103) fits securely into

the two slots (A). See F

IG. 46.

101

A

103

F

IG. 46

Ensure that all meter parts are positioned securely

and in the correct location. Ensure that all cables are

routed correctly throughout the meter and will not be

pinched or kinked when the halves are reassembled

See F

IG. 47 and FIG. 48.

Ensure that the black antenna wire is not positioned between the ribbon cables. Pull antenna away

from the cable as shown. See F

IG. 49.

G

FIG. 48

F

IG. 49

19. Slide the trigger assembly (13, 14, 22, 23, 35, & 36)

onto the mounting peg on the right side of the new

meter half (18). See

IG. 47

F

30 309497L

FIG. 36.

Page 31

Make sure that the trigger plunger (23) is centered

with the circular trigger switch. Also ensure that the trigger spring (37) is slid fully into position. Make sure that

all other meter parts are positioned securely and in the

correct location. See F

IG. 50.

37

23

F

IG. 50

Service

21. Assemble the covers (18 & 19). Insert several of the

screws (12) to hold the cover halves (18 & 19)

together. Test the display and trigger by inserting a

battery (11) and powering on the unit. It may take a

minute or so before the display starts.

22. If the display appears test the trigger to be sure that

both dispense settings work correctly. If the display

does not appear or the trigger does not function:

• make sure that a charged battery (11) is being

used.

• check that the connections from the new bezel

(31) to the circuit board (41) are fastened correctly and securely.

• check that all parts are repositioned securely

and in the correct location.

• check that the trigger connection to the RF

board (3) is fastened correctly and securely.

• check that the trigger switch is centered prop-

erly and that no gaps have formed between the

switch and circular indent.

20. Replace the bezel (31) onto the right meter cover

half (18).

23. Replace the remaining screws (12) and (42) that

hold the cover halves together. Torque all screws to

7 - 10 in. lbs.

309497L 31

Page 32

Parts Drawing for the 246008 and 249881 Electronic Meters

Parts Drawing for the 246008 and 249881 Electronic

Meters

31†★

3†

†

✓

40

41†

†

✓

37

†

✓

22

8

23

13

†

36

✓

14

†

✓

6

7

†

✓

12★†✓

5

1

2

3

4

5

44†

4

3

meter housing

43†✓

(not available for sale)

8

42★†✓

19†

✓

torque to 20 - 25 ft. lbs

apply thread sealant when reassembling

torque to 7 - 10 in. lbs

remove screws with a T-10 torx driver

remove screws with a Phillips screw driver

4†✓

2

1

29

9

6

6

plunger must be inserted fully shouldered against the

end of the spring.

spring must be inserted firmly into trigger with a

7

clockwise screwing motion. When fully assembled

plunger should sit level with the underside surface of

the trigger.

8

torque to 3 - 4 in. lbs

18†✓

24

ti4307

11

32 309497L

Page 33

Parts List for the 246008 and 249881 Electronic Meters

Parts List for the 246008 and 249881 Electronic Meters

Ref.

No. Part No. Description Qty.

3† MODULE, control, elec 1

4†✓ SWITCH, PSM, two position 1

6 109018 PACKING, o-ring 1

9 114017 FILTER, 80 mesh 1

11 117310 BATTERY, 9.6V NMH rechargable 1

12†★✓ SCREW, mach, torx, 5-20x1/2 11

13†✓ SPRING, plunger 1

14†✓ SPRING, return 1

18†✓ COVER, valve right 1

19†✓ COVER, valve left 1

22†✓ TRIGGER 1

23†✓ PLUNGER, trigger 1

Ref.

No. Part No. Description Qty.

24 15D587 BOOT, rear 1

29 240416 SWIVEL, straight 1

31†★ BEZEL 1

36†✓ PLUNGER, inside trigger 1

37†✓ SPRING, inside plunger 1

40†★✓15D618 GUARD, impact 1

41† SCREW, mach, HD, cross 3

42†★✓ SCREW, phillips 4

43†✓ RING, quad 1

44† WASHER 3

A grounding strap part no. 112190 is included with

each of the following kits.

CAUTION

Static electricity can damage the electronic components within the meter if the grounding wrist strap provided is not used during repair kit service.

★ Included in Bezel Repair Kit 246438.

✓ Included in Trigger Repair Kit 246439 for meter

246008 or kit 249883 for meter 249881.

† Included in Electronics Repair Kit 246675 for meter

246008 or kit 249882 for meter 249881.

309497L 33

Page 34

Nozzle Extension Accessories

Nozzle Extension Accessories

Kit 246005

Nozzle Extension Assembly, rigid 45°

Includes:

Ref.

No. Part No. Description

101 246003 NOZZLE, quick close 1

This same kit is available for antifreeze applications

(248319). Antifreeze nozzles are made from brass

(gold) instead of steel (silver).

Qty.

101

ti64328

Kit 246006

Nozzle Extension Assembly, rigid, 90°

Includes:

Ref.

No. Part No. Description

201 246003 NOZZLE, quick close 1

Qty.

Kit 246007

Nozzle Extension Assembly, flexible hose

Includes:

Ref.

No. Part No. Description

301 246003 NOZZLE, quick close 1

Qty.

201

ti64329

301

This same kit is available for antifreeze applications

(248320). Antifreeze nozzles are made from brass

(gold) instead of steel (silver).

ti64330

34 309497L

Page 35

Technical Specifications

Maximum Fluid Working Pressure 1500 psi (10.3 MPa, 103 bar)

Technical Specifications

Operating pressure range (

Maximum Dynamic Working Pressure

(while dispensing) (★)

Flow Range 0.26 to 5 gpm (1 to 18.9 lpm)

Weight (with battery and rigid nozzle extension 4.5 lb (2.0 kg)

Units of measurement user selectable, pints, quarts, gallons or liters

Maximum recorded dispense volume 999.00 units

Maximum preset volume 900.0

Inlet size 1/2” npt(f)

Outlet size 3/8” npt(f)

Operating temperature range 32° F to 120° F (0° C to 49° C)

Storage temperature range -30° F to 120° F (-34° C to 49° C)

Battery rechargeable nickel-metal hydride 9.6 VDC

Battery Warranty 6 months

Battery storage temperature range 50° F to 86° F (10° C to 30° C)

Wetted parts zinc, stainless steel, carbon steel, polyurethane, nitrile rubber

Fluid compatibility lubricating oils, antifreeze mixtures

* ◆)

100 to 1500 psi (0.7 to 10.3 MPa) (7 bar to 103 bar)

600 psi (4.1 MPa, 41.4 bar)

Accuracy (†) +/- 0.5 percent

Repeatability (‡) +/- 0.15 percent

RF Communication 902-928 MHz frequency hopping, spread-spectrum - N. A.

915-928 MHz frequency hopping, spread-spectrum - Australia

Unobstructed RF Communication Range (based on

building construction and RF environment)

Obstructed RF Communication Range (based on

building construction and RF environment)

Approvals (for RF device contained in meter

246008)

Conformity (for RF device contained in meter

249881)

300-500 ft. (91.0-152.0 m)

250-300 ft. (76.2-91.0 m)

FCC, Industry Canada (IC)

ACMA (Australia)

* Minimum pressure loss at 1.5 gpm (5.7 lpm) with 30-weight oil at 70° F (21° C) is 70 psi.

† At 2.5 gpm (9.5 lpm), at 70° F (21° C) with 10-weight oil, and 1 gallon dispensed. May require calibration.

‡ At 2.5 gpm (9.5 lpm), at 70° F (21° C) with 10-weight oil, and 1 gallon dispensed.

◆Specification based on 30W oil. Lighter viscosity fluid (i.e., anti-freeze) will require a slightly higher inlet fluid

pressure to open the Matrix valve.

★Using 30W oil at 70°F (21°C). Maximum pressure will be slightly lower with higher viscosity fluids (i.e., gear oil).

A lower ratio pump may be required to reduce system pressure and maintain sufficient flow.

309497L 35

Page 36

36 309497L

Page 37

Dimensions

A 17.5 in. (444.5 mm) overall length without nozzle dispense kit

B

4.75 in. (120.6 mm) overall width

C

5.25 in. (133.3 mm) overall height

Dimensions

B

C

A

ti64306

309497L 37

Page 38

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship

on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by

Graco, Graco will, for a period of twenty-four months from the date of sale, repair or replace any part of the equipment determined

by Graco to be defective with the exception of the Matrix Meter Battery, part number 117310 which has a warranty period of six

months from the date of sale to the original purchaser. This warranty applies only when the equipment is installed, operated and

maintained in accordance with Graco's written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused

by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering,

or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the

incompatibility of Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper

design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by

Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor

for verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts.

The equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose

any defect in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts,

labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco's sole obligation and buyer's sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no

other remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or

property, or any other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within

two (2) years of the date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not

manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer.

Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying

equipment hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach

of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal

proceedings entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les

parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et

procédures judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les

procedures concernées.

Graco Phone Numbers

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6928 or Toll Free: 1-800-533-9655, Fax: 612-378-3590

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2003, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions. This manual contains English. MM 309497

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revised July 2012

Loading...

Loading...