Page 1

INSTRUCTIONS–PARTS LIST

Important Safety Instructions

Read all warnings and instructions

in this manual. Save these

instructions.

To find your local Graco authorized service

center:

Call us at 1–800–690–2894

Visit our website at www.graco.com

309445

Rev. E

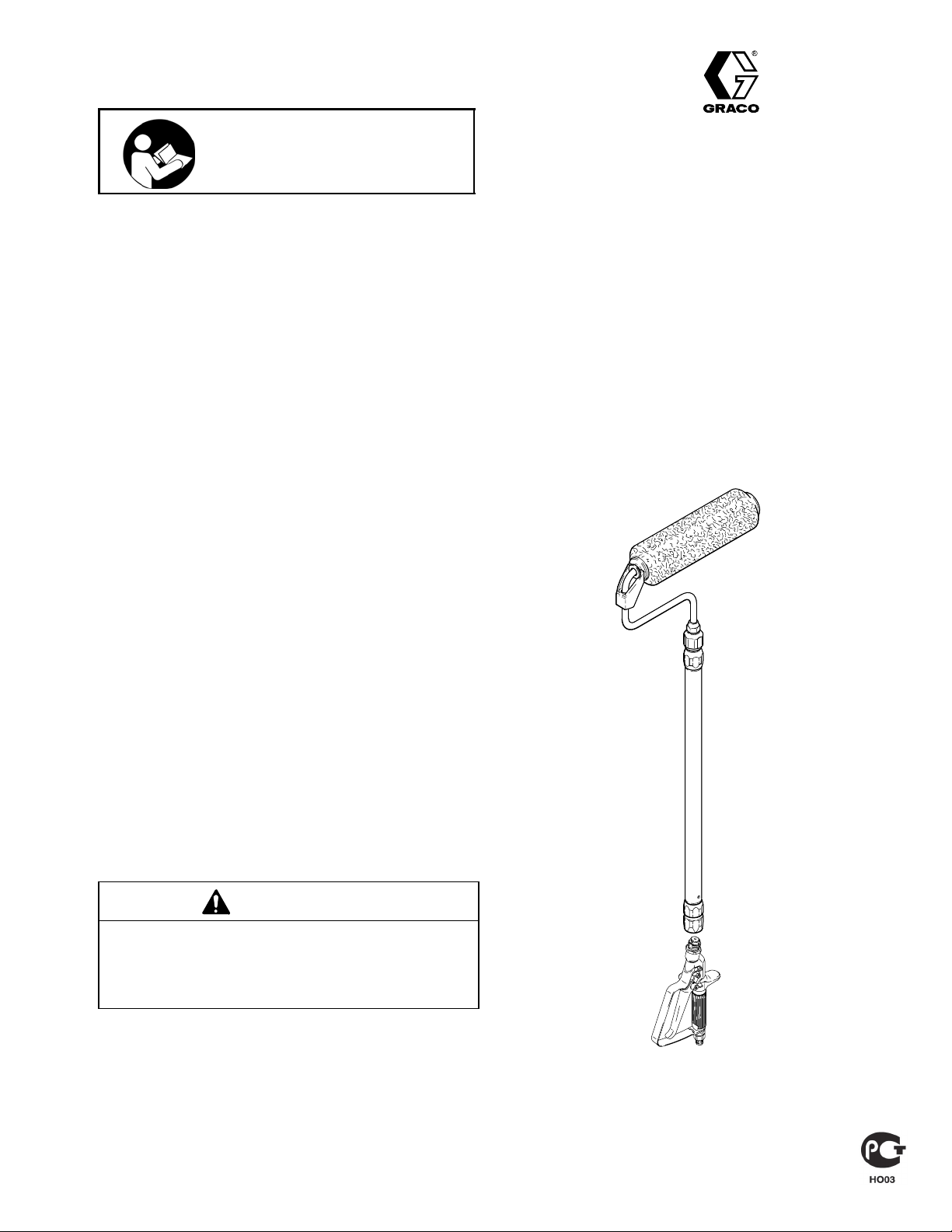

Pressure Roller with 20”

Heavy Duty Extension, EvenFlowt Roller

Frame and Contractort Inline Valve

– For the rolled application of architectural paints and

coatings –

Model 245397, Series C

20 in. (50 cm) Heavy-Duty Extension

9 in. (23 cm) EvenFlow Roller Frame

1/2 in. (13 mm) Nap Roller Cover

Contractor Inline Valve

3600 psi (24.8 MPa, 248 bar) Maximum Fluid Inlet Pressure

The best operating pressure is the lowest pressure that provides

*

an even paint supply to the roller and typically does not exceed

300 psi (2.1 MPa, 21 bar).

CAUTION

Never leave water in the pump, inline valve, or roller frame.

Doing so could cause corrosion and damage from freezing.

For storage, flush the system with Graco Pump Armor or

mineral spirits/paint thinner.

*

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

COPYRIGHT 2001, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Warnings and Cautions

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause the equipment to rupture or

malfunction and result in serious injury.

To help prevent injury

Do not modify the extension tube or roller

frame or use parts not designed for this

equipment.

Do not use 1,1,1–trichloroethane, methylene

chloride, other halogenated hydrocarbon solvents or fluids containing such solvents in this or

any other pressurized aluminum equipment.

Such use could result in a chemical reaction,

with the possibility of explosion.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open

flames or sparks can cause a hazardous

condition and result in a fire or explosion and

serious injury.

To help prevent injury from fire or explosion

Provide fresh air ventilation to avoid the

buildup of flammable fumes from flushing

fluids or the coating being applied.

Keep the application area free of debris,

including solvent, rags, and gasoline.

INSTRUCTIONS

SKIN INJECTION HAZARD

If high-pressure fluid pierces your skin, the injury

might look like “just a cut”. But it is a serious

wound. Get immediate surgical treatment.

To help prevent injection

Keep your hands and body away form the

roller frame when flushing. High pressure

fluid emitted from the holes in the frame

could cause an injection injury.

Always relieve pressure before you check or

repair leaks and when you turn off pump or stop

painting.

Never use components rated less than system

Maximum Working Pressure.

ELECTROCUTION HAZARD

Failure to observe the electrical hazards described

below could result in serious injury, including burns

or electrocution.

To help prevent harmful electrical shock

Avoid contact with power lines.

Follow all grounding instructions in your

separate pump instruction manual, and

comply with all local, state, and national fire,

electrical, and safety regulations.

Use only Graco paint hoses.

2 309445

Page 3

Installation

Assemble pressure roller as shown in Parts Drawing,

page 7. Attach pressure roller assembly to inline

valve.

Pressure Relief Procedure

WARNING

To help prevent injection injuries,

follow this procedure whenever

you stop painting.

psi/MPa/bar

1. Put inline valve trigger safety in SAFETY ON

position (Fig. 1).

2. Shut off power to pump.

When connecting EvenFlow roller frame to the

Contractor Inline Valve, use a wrench to tighten.

3. Turn prime/spray valve to PRIME position to

relieve pressure in system.

4. Put inline valve trigger safety in SAFETY OFF

position, and trigger inline valve to relieve any

pressure in hose.

5. Put inline valve trigger safety in SAFETY ON

position, and keep pump prime/spray valve in

PRIME position until you paint again.

309445 3

Page 4

Operation

WARNING

SKIN INJECTION HAZARD

To reduce the risk of a fluid injection

injury, do not operate the inline valve with

the tip guard or trigger guard removed.

The Contractor Inline Valve can be used as an

airless spray gun by attaching a Handtite Guard

and RAC5 Switchtip.

1. Follow pump priming instructions using lowest

pressure setting at which pump primes.

2. Turn prime/spray valve to SPRAY position.

In-Line Valve Trigger Safety Lever

For SAFETY ON position, rotate trigger safety lever so

it is in line with trigger. For SAFETY OFF position, flip

safety lever so it is 90 to trigger. Fig. 1.

NOTE: In the SAFETY ON position the lever sits in a

detent which holds it in place.

SAFETY ON SAFETY OFF

Fig. 1

Startup

NOTE:

3. Disengage inline valve safety latch, trigger the

inline valve, and roll the surface until paint comes

to roller.

NOTE: Trigger the inline valve briefly only when

you need more paint. Determine how often you

must trigger the inline valve to maintain an even

paint supply to the roller.

4. Increase pump pressure only if triggering inline

valve cannot supply enough paint for your rolling

speed.

Relieve pressure, page 3,

5.

Flush pump, inline valve, and roller frame immediately

after each use to prevent paint from drying in roller

frame and damaging it.

whenever you stop painting.

Elevate roller end of

extension tube to prevent

paint from draining out.

Cleaning

NOTE: Follow this procedure to flush the roller frame

and inline valve. The pump you are using may have

additional flushing steps, such as cleaning filters and

screens. See the pump flushing instructions.

Leave the roller frame attached to the inline valve for

this procedure.

4 309445

Cleaning the EvenFlow Roller Frame

1.

2. Remove roller cover (19) and diffuser (23) from

roller frame as follows (see Parts Drawing):

a. Using your thumb, press down on clip (5) to

release end caps (2 &4), diffuser (23) and

roller cover (19) into a pail.

b. Remove roller cover (19) from diffuser (23).

c. Pull end caps (2 & 4) off diffuser (23).

3. Clean roller cover (19), caps (2 & 4) and diffuser

(19) with water or a compatible fluid for oil–based

materials.

4. Place roller frame (1) in paint pail. Be sure the

holes in roller frame (1) are facing inside the paint

pail.

Relieve pressure, page 3.

Page 5

5. Prime pump with water or flushing fluid for oil–

based materials. Use the lowest pump priming

pressure setting.

6. Turn prime/spray valve to SPRAY.

NOTE: Perform Step 7 at the lowest pressure possible.

7. Trigger inline valve until flushing fluid begins to

dilute the paint.

8. Place roller frame (1) in another bucket and continue flushing until fluid coming out of the roller frame

(1) is clear.

Storage

If you are going to store the airless equipment for an

extended period of time after flushing with water-base

fluid, flush again with Graco Pump Armor or mineral

spirits/paint thinner. Leave this fluid in the system

during storage.

Cleaning Contractor Inline Valve

1.

2. Push up on bottom of trigger guard and swing it

away from trigger.

3. Unscrew inline valve handle from housing. Remove filter and clean it in compatible solvent.

NOTE: Do not soak entire inline valve in solvent.

Prolonged exposure to solvent can ruin packings.

4. Apply lithium–based grease to threads of inline

valve handle and reassemble inline valve.

Relieve pressure, page 3.

309445 5

Page 6

Notes

6 309445

Page 7

Parts List

ti10642a

23

4

1

5

2

12

14

19

Model 245397, Series A

Ref.

No. Part No. Description Qty.

1 244271* FRAME, roller 1

2 245999 CAP, end (includes seal and retainer) 1

4 246277 CAP, end (includes seal, retainer, and

o–ring) 1

5 197106 CLIP, roller 1

7 15H622 GASKET 1

12 115524 GASKET 1

14 232122 EXTENSION, 20 in. (50 cm) 1

19 107590 ROLLER, cover, 9 inch,

1/2 in. (13 mm) nap 1

23 15B065 DIFFUSER 2

*244271 Frame includes 1, 2, 4, 5, 12, 19, 23.

7

Pressure Roller

Additional Roller Covers

The following pressure roller covers are available at

your local distributor:

107589 9 in. (23 cm); 3/8 in. (9.5 mm) nap

107590 9 in. (23 cm); 1/2 in. (13 mm) nap

107591 9 in. (23 cm); 3/4 in. (19 mm) nap

107592 9 in. (23 cm); 1-1/4 in. (32 mm) nap

Additional Heavy Duty Extensions

The following extensions can be mixed and matched to

create any length pressure roller needed and are

available at your local distributor:

232121 10 in. (25 cm)

232122 20 in. (50 cm)

232123 40 in. (100 cm)

232124 60 in. (150 cm)

232125 80 in. (200 cm)

309445 7

Page 8

119

Parts List

101

108

111

103

110

113

107

102

114

112

105a

120

106

105b

105

105c

105d

TI0667

104

8 309445

Page 9

Contractort In–line Valve

Model 244161

Parts List

Ref.

No. Part No. Description Qty.

101 218070 NEEDLE–DIFFUSER/SEAT KIT 1

102 244193 TRIGGER, valve, In–line

(includes 107) 1

103 196869 GUARD, trigger 1

104 238817 KIT, swivel 1

105 218131 FLUID FILTER ASSEMBLY 1

(standard 50 mesh) includes

replacement parts 5a, 5b, 5c, 5d

105a 179722 RETAINER, spring 1

105b 179731 ELEMENT, strainer 1

105c 179763 SPRING, compression 1

105d 179750 RETAINER, spring 1

106 179733 SEAL, sleeve 1

Ref.

No. Part No. Description Qty.

107 107110 LOCKNUT 1

108 197052 ADAPTER, RAC 1

110 197058 BRACKET, stem 1

111 197568 HOUSING, fluid 1

112 113409 RETAINER, guard 1

113 195788 HANDLE, valve 1

114 104938 PACKING, o–ring 1

119 177538 STUD, trigger 2

120 105334 LOCKNUT 2

Keep these items on hand to reduce down time.

The Contractor Inline Valve contains a paint filter

(218131) inside handle. The primary function of the

paint filter is to prevent clogging of spray tips.

The paint filter may be removed for rolling applica-

tions.

Remove and clean filters after each use.

309445 9

Page 10

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–690–2894 Toll Free

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

10 309445

This manual contains English. MM 309445

Graco Headquarters: Minneapolis

International Offices: Belgium, Korea, China, Japan

GRACO INC.ąP.O. BOX 1441ąMINNEAPOLIS, MNą55440-1441

www.graco.com

9/2001, Revised 9/2007

Loading...

Loading...