Page 1

Instructions–Parts List

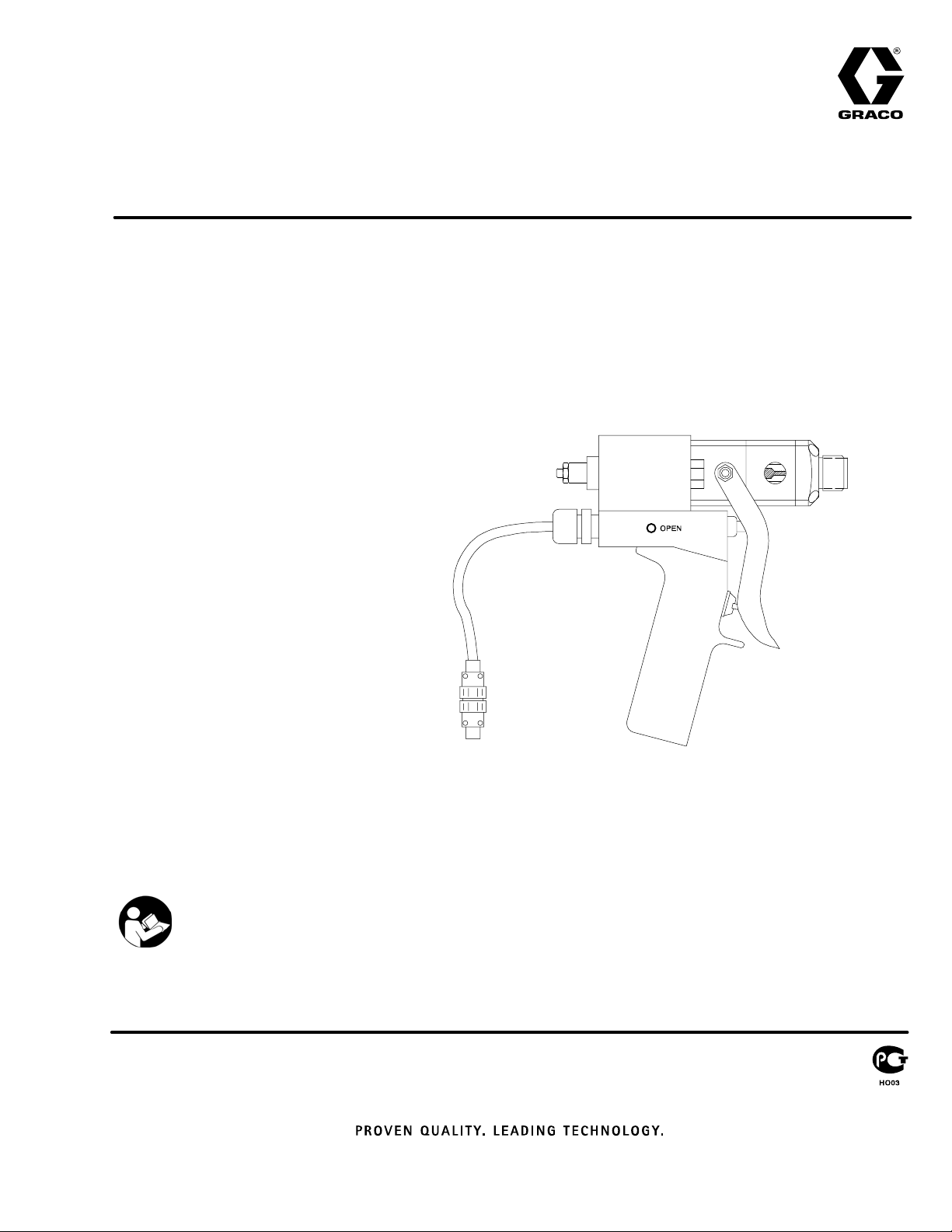

AIR OPERATED, SINGLE COMPONENT DISPENSE VALVE

1K Ultra–Litet

For dispensing a wide variety of single component sealants and adhesives.

4000 psi (28 MPa, 276 bar) Maximum Fluid Working Pressure

120 psi (0.84 MPa, 8.4 bar) Maximum Air Inlet Pressure

See page 2 for Table of Contents

Part No. 965766

Stainless Steel Wetted Parts, Machine

Mount Valve

Part No. 965767

Aluminum Wetted Parts, Hand–held

Valve with internal air switch

Part No. 965768

Aluminum Wetted Parts, Hand–held

Valve with electric switch for remote

operation

Part No. 965786

Aluminum Wetted Parts, Automatic

Machine Mount Valve

308876K

Part No. 243482

Stainless Steel Wetted Parts,

Precision Swirl Orbiter Mounted with

Nozzle Accessory

Part No. 243666

Stainless Steel Wetted Parts,

PrecisionFloR Control Valve

Machine Mount Valve

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

8370A

Model 965768 shown

Page 2

Table of Contents

Symbols

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation/Maintenance 8. . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 30. . . . . . . . . . . . . . . . . . . . . .

Graco Information 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING

SKIN INJECTION HAZARD

Spray from the valve, hose leaks, or ruptured components can inject fluid into your body and cause

extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin

can also cause serious injury.

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

D Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate surgi-

cal treatment.

D Do not point the valve at anyone or at any part of the body.

D Do not stop or deflect leaks with your hand, body, glove or rag.

D Be sure the valve trigger safety operates before dispensing.

D Lock the valve trigger safety when you stop dispensing.

D If the nozzle clogs while dispensing, fully release the trigger immediately.

D Follow the Pressure Relief Procedure on page 8 whenever you: are instructed to relieve pres-

sure; stop dispensing; clean, check, or service the equipment; and install or clean the nozzle.

D Tighten all fluid connections before operating the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

D Use only Graco approved hoses. Do not remove any spring guard that is used to help protect the

hose from rupture caused by kinks or bends near the couplings.

2 308876

Page 3

INSTRUCTIONS

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure stated on the equipment or in the Technical Data

for your equipment. Do not exceed the maximum working pressure of the lowest rated component

in your system.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Do not use hoses to pull equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 180_F (82_C) or below –40_F (–40_C).

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Never use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in this equipment. Such use could result in a serious chemical

reaction, with the possibility of explosion, which could cause death, serious injury, and/or substantial property damage.

3308876

Page 4

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D Ground the equipment and the object being sprayed. Refer to Grounding on page 6.

D If there is any static sparking or you feel an electric shock while using this equipment, stop dis-

pensing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being dispensed.

D Keep the dispense area free of debris, including solvent, rags, and gasoline.

D Extinguish all open flames or pilot lights in the dispense area.

D Do not smoke in the dispense area.

D Do not turn on or off any light switch in the dispense area while operating or if fumes are present.

D Do not operate a gasoline engine in the dispense area.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

4 308876

Page 5

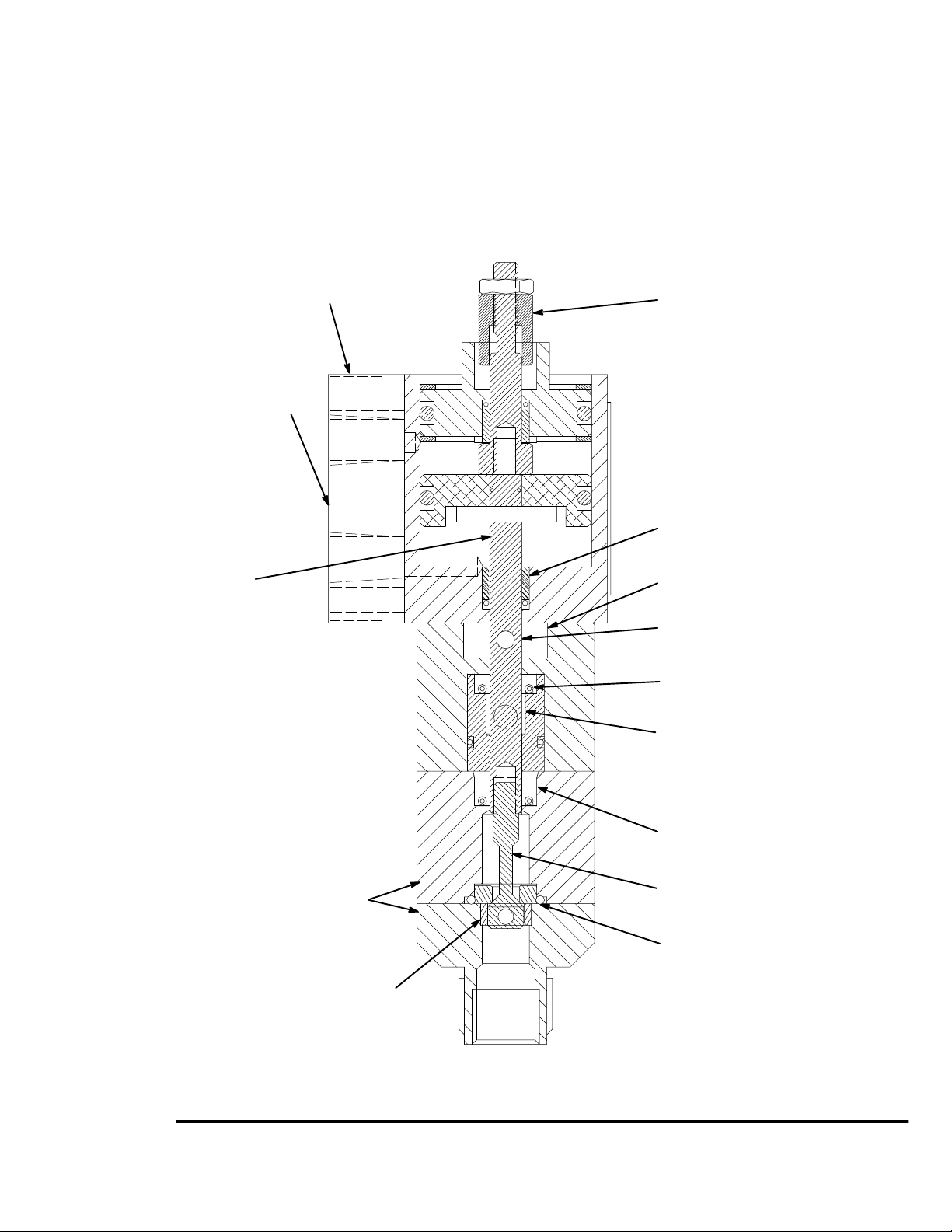

Features

A

D Adjustable forward travel to reduce material surge when

valve opens

D Severe-Dutyt needle and seat for longer operating life

D Lubricated packings for longer seal life

D Lightweight construction reduces operator/machinery

fatigue

4 Control Configurations

1. 1/8 npt(f) ported manifold block

2. Direct solenoid mount with speed control

3. Handle kit with 4-way air valve

4. Handle kit with electric switch

Accessory flow control fittings

to adjust open/close speed.

D Compact size for small X–Y tables, working areas, and

robots

D Handle kit provides easy conversion from automatic to

manual usage

D Stainless steel housing to handle most materials

Travel adjustment (Model 965766,

965767, 965768, and 965786 only)

Replaceable nylon bearings

Shaft is free to align

Aluminum or stainless wetted housings

Snuff back restrictor ring (13) is removable

for high flow applications.

Divorced air section

Hard chrome/stainless steel shaft

Urethane u-cup secondary seals

Self centering plastic bearing

Proven primary seals

Hardened stainless steel needles

Reversible carbide seat for severe duty

Fig. 1

8374B

8374

5308876

Page 6

Installation

A

NOTES:

D Reference numbers and letters in parentheses in

the text refer to the callouts in the figures and

drawings.

D Accessories are available from your Graco

representative. If you supply your own accessories,

be sure they are adequately sized and

pressure-rated to meet the system’s requirements.

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

To reduce the risk of fire, explosion, and

serious injury, proper electrical grounding of every part of your system is essential. Read the warning section Fire

and Explosion Hazard on page 4, and

follow the grounding instructions below.

The following grounding instructions are minimum

requirements for a basic dispensing system. Your

system may include other equipment or objects which

must be grounded. Check your local electrical code for

detailed grounding instructions for your area and type

of equipment. Your system must be connected to a

true-earth ground.

D Pump: ground the pump by connecting ground wire

and clamp as described in your separate pump

instruction manual.

D Fluid supply container: ground according to your

local code.

D Flammable liquids in the spray area: must be in

approved, grounded containers. Do not store more

than the quantity needed for one shift.

D All solvent pails used when flushing: ground

according to local code. Use only metal pails, which

are conductive. Do not place the pail on a

non-conductive surface, such as paper or

cardboard, which interrupts the grounding

continuity.

D To maintain grounding continuity when flushing or

relieving pressure, hold a metal part of the valve

firmly to the side of a grounded metal pail, then

trigger the valve.

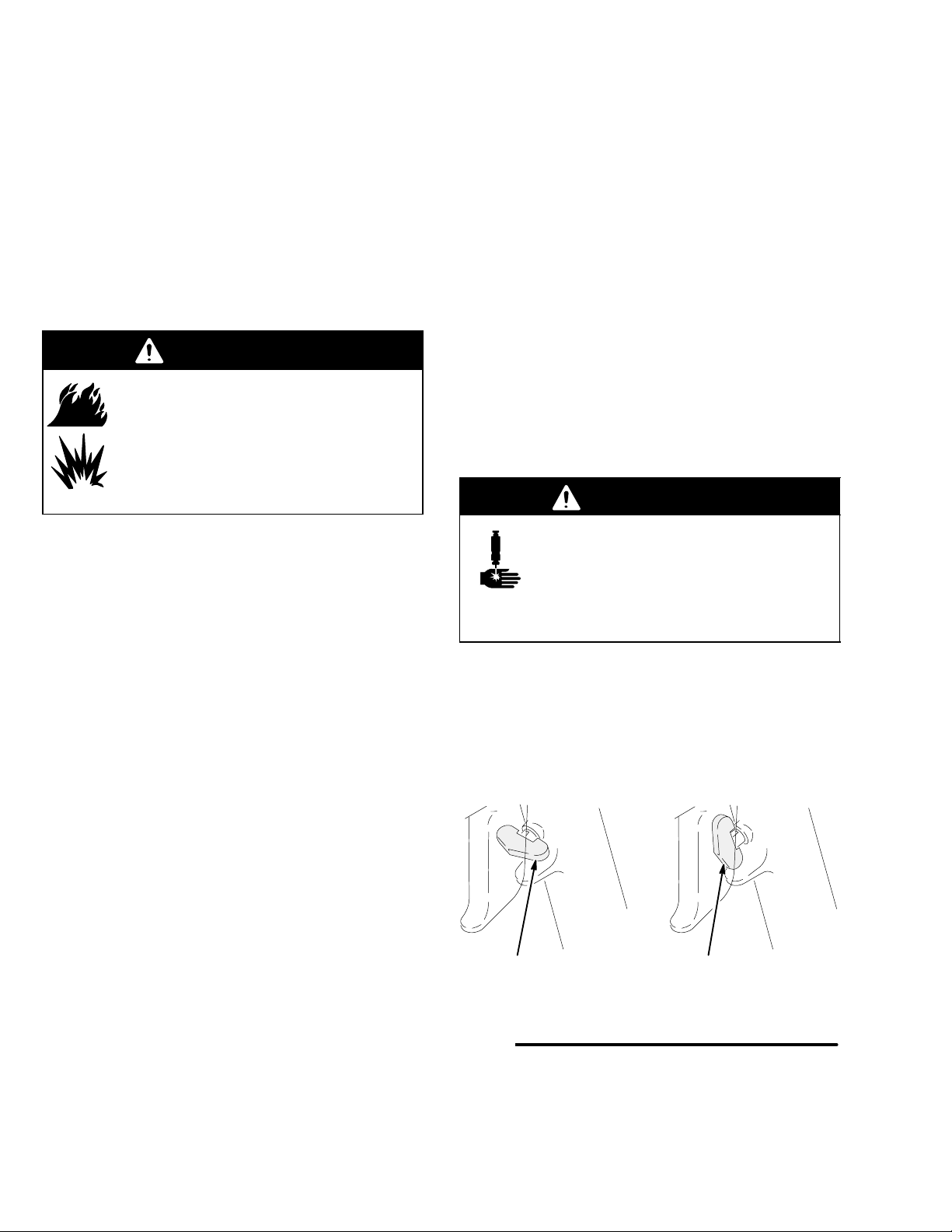

How to Use the Valve Trigger Safety

WARNING

SKIN INJECTION HAZARD

To prevent accidental triggering of the

gun and reduce the risk of a serious inju-

ry, including fluid injection or splashing in

the eyes or on the skin, lock the gun trigger safety

when you stop dispensing.

1. If you are using one of the hand-held versions of

the valve, lock the valve trigger safety by turning

the latch to a right angle with the gun body. See

Fig. 2.

D Air compressors and hydraulic power supplies:

ground the equipment according to the

manufacturer’s recommendations.

D Fluid hoses: use only grounded fluid hoses with a

maximum of 500 feet (150 m) combined hose

length to ensure grounding continuity. Check the

electrical resistance of your fluid hoses at least

once a week. If your hose does not have a tag on it

which specifies the maximum electrical resistance,

contact the hose supplier or manufacturer for the

maximum electrical resistance limits, replace the

hose immediately.

D Dispensing valve: ground the valve by connecting it

to a properly grounded fluid hose and pump.

6 308876

2. To unlock the valve trigger safety, push the latch

out and turn it parallel with the gun body.

Locked Unlocked

Fig. 2

8459

Page 7

Installation

Connections

D The fluid inlet is 1/4 npt(f).

D The fluid outlet is 1/4 npt(f) or 3/4–16 unf(m).

D Air inlets are 1/8 npt(f).

D See Accessories, page 25, to order air control

valves and tubing.

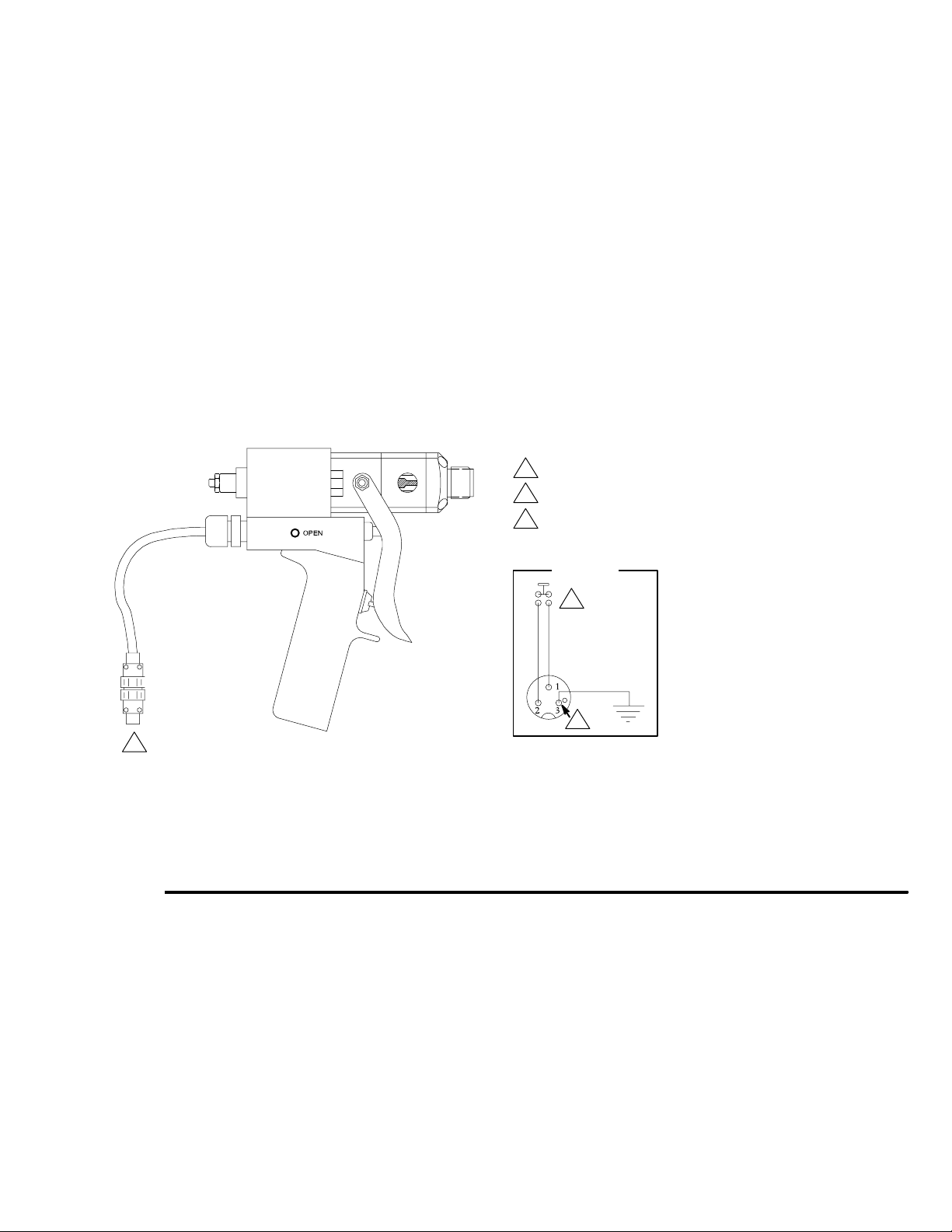

Electric Switch Hand Held Valve

Install a remote 4-way air control valve to operate the

valve. Connect an OPEN air signal air line to the 1/8

npt(f) port on the side of the valve. Connect a CLOSE

air signal air line to the 1/8 npt(f) port on the opposite

side of the valve. Wire the normally open valve switch

to the system control.

Machine Mount Valve

Install a remote 4-way air control valve to operate the

valve. Connect an open air signal air line to the 1/8

npt(f) OPEN port. Connect a close air signal air line to

the 1/8 npt(f) CLOSE port.

Air Switch Hand Held Valve

This valve has a single air inlet and an internal 4-way

spool valve, which directly operates the air piston.

Connect the air line to the 1/8 npt(f) air inlet.

1

Solder to terminals in cable connectors as shown in Detail A.

2

Normally open, momentary contact switch.

3

Ground connection.

1

Fig. 3

Detail A

2

3

Electric Switch Hand Held Valve shown

8370A

7308876

Page 8

Operation

WARNING

COMPONENT RUPTURE HAZARD

To reduce the risk of over-pressurization,

which can cause component rupture and

serious injury, never exceed 3000 psi (21

MPa, 207 bar) fluid pressure, or 120 psi (0.84 MPa,

8.4 bar) air pressure to the valve.

Electric Switch Hand Held Valve

D Be sure the air supply lines are connected correctly

to the OPEN and CLOSE valve air ports.

D To open or close the valve and maintain the open or

closed status, a minimum of 40 psi (280 kPa, 2.8

bar) air pressure must be supplied and maintained

at the OPEN or CLOSE port.

Pressure Relief Procedure

WARNING

SKIN INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you:

D are instructed to relieve the pressure

D stop dispensing

D check or service any of the system equipment

D install or clean the nozzle

1. Shut off the air to the dispense valve, if applicable.

2. Shut off the air to the supply pumps.

3. Close the bleed-type master air valve (required in

your system).

4. Hold a metal part of the valve firmly to the side of a

grounded metal pail, and trigger the dispense

valve to relieve pressure.

5. Open the fluid drain valve (required in your

system), having a grounded metal container ready

to catch the drainage.

D The trigger only activates the electrical switch in the

handle, which turns the remote solenoid on and off.

D Trigger the gun to turn the solenoid on. Release the

trigger to turn the solenoid off.

Machine Mount Valve

D Be sure the air supply lines are connected correctly

to the OPEN and CLOSE valve air ports.

D To open or close the valve and maintain the open or

closed status, a minimum of 40 psi (280 kPa, 2.8

bar) air pressure must be supplied and maintained

at the OPEN or CLOSE port.

To open the valve:

1. Apply air pressure to the OPEN air port on the

valve, and remove air pressure from the CLOSE

air port on the valve.

2. Maintain air pressure on the OPEN air port to keep

the valve open.

To close the valve:

1. Apply air pressure to the CLOSE air port on the

valve, and remove air pressure from the OPEN air

port on the valve.

2. Maintain air pressure to the CLOSE air port to

keep the valve closed.

6. Leave the fluid drain valve open until you are ready

to dispense again.

If you suspect that the dispense needle or hose is

completely clogged, or that pressure has not been fully

relieved after following the steps above, very slowly

loosen the needle retaining nut or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the needle or hose.

8 308876

Page 9

Operation

Air Switch Hand Held Valve

The valve operation is such that there are only two

valve conditions: either fully open or fully closed.

The valve is opened and closed by the internal air

control valve. Trigger the gun to open the valve.

Release the trigger to close the valve.

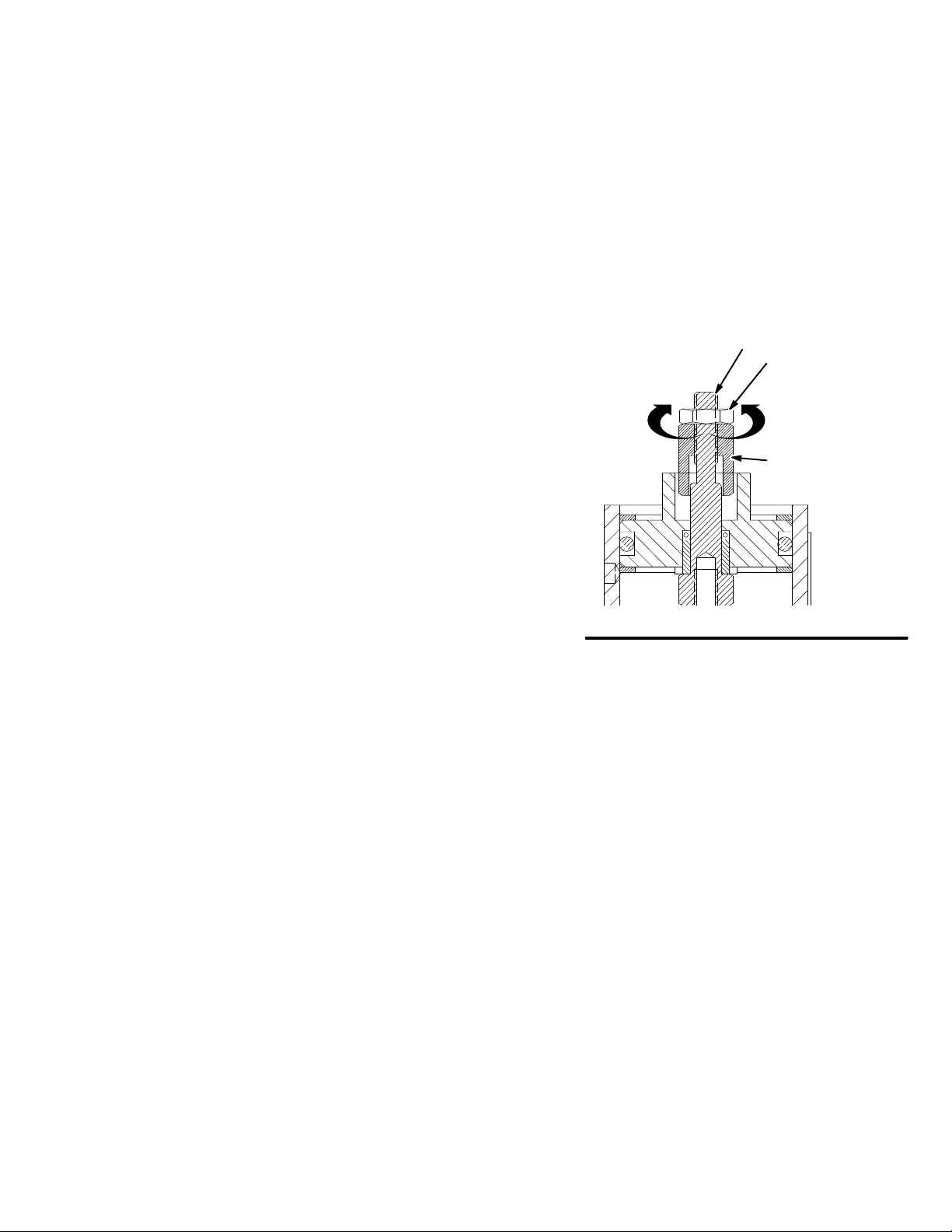

Shaft Stroke Adjustment (Models 965766,

965767, 965768, and 965786 only)

Adjust the shaft stroke to balance the valve between

“snuff-back” and “push-out”.

D A long stroke will give maximum snuff-back but it

may cause push-out when the valve opens.

D Shortening the stroke of the shaft will minimize the

material pushed out when the valve opens and will

also increase the material back pressure through

the valve.

To adjust the shaft stroke:

1. Loosen the hex nut (44) from the adjustment nut

(43).

D The valve is at full stroke when the hex nut

(44) is at the end of the adjustment shaft (42).

D Adjusting the nut (44) on the shaft (42)

towards the valve, or clockwise, will reduce the

stroke length.

D Adjusting the nut away from the valve, or

counterclockwise, will lengthen the stroke.

3. Tighten the hex nut (44) to the adjustment nut (43)

to set the adjustment.

42

44

Shorten Lengthen

43

2. Adjust the nut (44) along the adjustment shaft (42)

to the desired position.

Maintenance

Preventative Maintenance

There is a grease filled secondary seal/bearing area on

the valve shaft. Every 10,000 cycles, or twice each

month, new grease should be flushed across this area.

Each valve has two flush grease fittings. A small

grease gun is provided with each valve.

Fig. 4

To grease the valve:

1. Remove the grease fitting from one side of the

gun.

2. Pump grease (Part No. 115982) across the valve

until clear grease comes out of the other side.

3. Reinstall the grease fitting.

8460

9308876

Page 10

WARNING

SKIN INJECTION HAZARD

To reduce the risk of serious injury

whenever you are instructed to relieve

pressure, always follow the Pressure

Relief Procedure on page 8.

Troubleshooting

1. Relieve the pressure.

2. Check all possible causes to the problem before

disassembling the pump.

PROBLEM

Valve does not open Insufficient air pressure Turn on or turn up air pressure.

Valve does not close

(leaks)

Higher than normal

back-pressure

CAUSE SOLUTION

Air not exhausted from behind air cylinder piston

Shaft adjustment too far closed Adjust the shaft stroke as instructed on page 9.

Insufficient air pressure Turn on or turn up air pressure.

Air not exhausted from behind air cylinder piston

Blockage between needle and seat Remove and clean needle and seat.

Bad or missing gasket between seat

and housing

Needle worn out Replace needle and seat.

Nosepiece plugging up Remove and clean.

Use four-way, relieving-type air valve operator.

Use four-way, relieving-type air valve operator.

Replace gasket (38).

10 308876

Page 11

Service

(Models 965766, 965767, 965768, and 965786 only)

12. Remove the pin (7), o-ring (9), and piston o-ring

WARNING

(6).

SKIN INJECTION HAZARD

To reduce the risk of serious injury

whenever you are instructed to relieve

pressure, always follow the Pressure

Relief Procedure on page 8.

Disassembly

1. Relieve all air and fluid pressure.

2. Disconnect the valve from the system.

3. Remove the four nosepiece screws (15), and pull

the nosepiece (40) away from the valve. Remove

the snuff-back ring (41). See Fig. 5, page 14.

4. Use an 1/8 in. pin punch in the needle hole (A) to

unscrew the needle (27). If the shaft (3) spins,

insert a dowel pin in the shaft hole (B) to hold it

steady, then unscrew the needle (27).

5. Remove the seat (25), gasket (38), and o-ring

(39).

6. Remove the two fluid housing screws (23) and

remove the fluid housing (26). Remove the primary

fluid seal (22) from the fluid housing (26).

7. Pull the bearing/lube housing (19) from the air

cylinder (1). Remove the bearing (21), bearing

o-ring (16), and secondary fluid seal (20). Remove

the grease fittings (18).

13. Use a 1/4 in. pin punch to knock out the bearings

(5) and o-rings (4).

Air Switch Handle (if equipped)

1. Remove the trigger (56).

2. Loosen the set screw above the trigger safety. Pull

off the handle (55).

3. Remove the four retaining screws (60). Pull the

housing (50) and gasket (30) away from the air

cylinder (1).

Air Valve

1. Unscrew the stem guide (58).

2. Remove the trigger pin (59), o-ring (57), spool

(49), spacers (51, 52), o-rings (46, 48) and spring

(47).

3. Remove the bushing (53) from the housing (50)

with the screw (54).

4. Remove the screws (60) and lock-washers (61)

from the air cylinder (1).

Electric Switch Handle (if equipped)

1. Disconnect the power from the gun.

2. The switch, housing, and cable are not repairable.

Replace these parts as a complete assembly.

8. Remove the C-clip (12) from the back of the air

cylinder (1). Push the shaft (3) into the air cylinder

to dislodge the air cylinder cap (11). Remove the

cap o-ring.

9. Remove the internal C-clip (12). Push the shaft (3)

to dislodge the piston (10) assembly from the air

cylinder (1).

10. Remove the adjustment nut (44) from the shaft (3).

11. Remove the adjustment shaft (42) from the shaft

(3).

3. Remove the trigger (56).

4. Loosen the setscrew above the trigger safety. Pull

off the handle (55).

5. Remove the four manifold retaining screws (60).

Pull the housing (50) and gasket (30) away from

the air cylinder (1).

6. Remove the bushing (53) from the housing (50)

with the screw (54).

7. Remove the screws (60) and lock-washers (61)

from the air cylinder (1).

11308876

Page 12

Service

(Models 965766, 965767, 965768, and 965786 only)

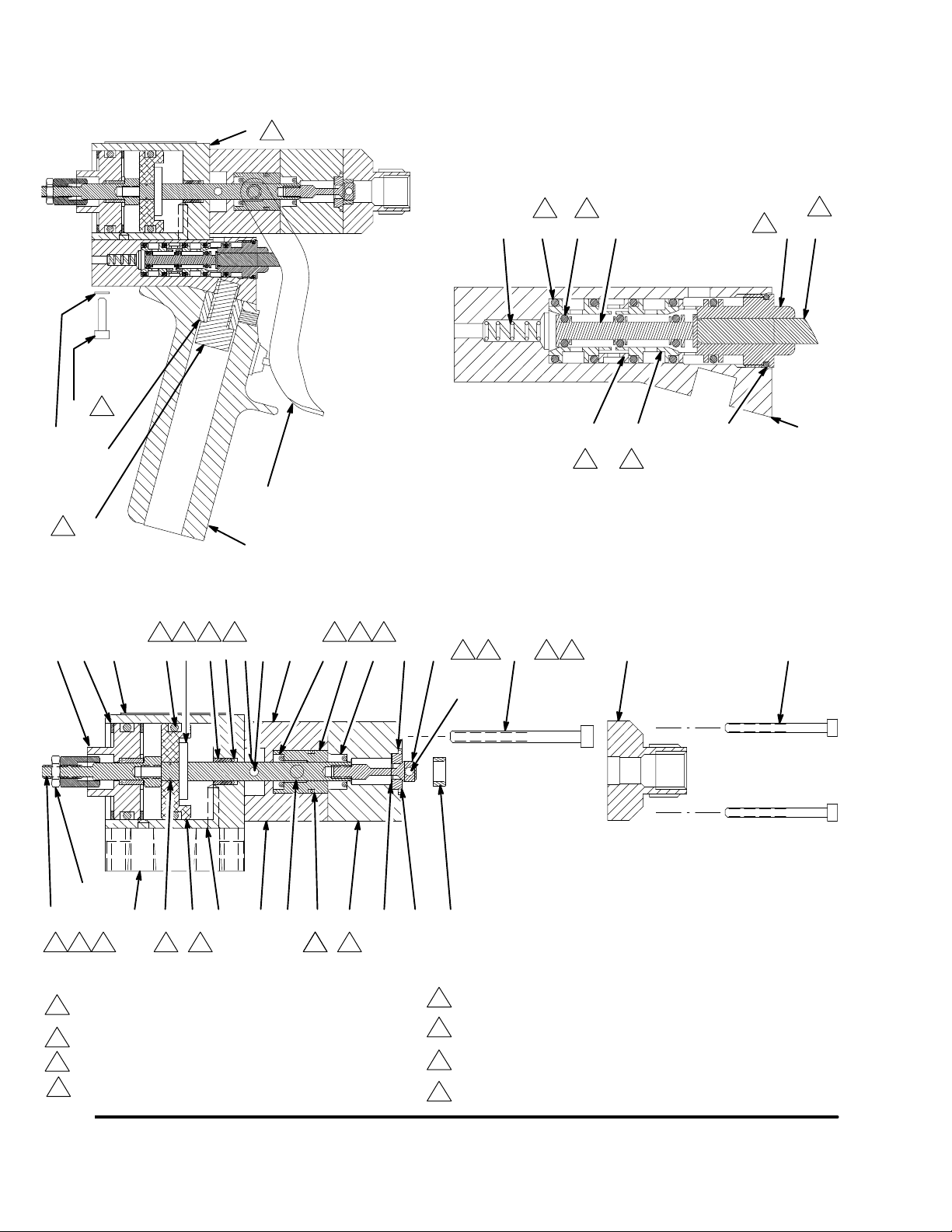

Reassembly

Air Cylinder Section

1. Lubricate the shaft o-rings (4) and the bearings (5)

with grease supplied in the repair kit. Insert o-rings

into the air cylinder (1) and air cap (11) cavities.

See Fig. 5.

2. Press the bearings (5) flush into the air cylinder

housing and air cap, trapping the o-rings (4).

3. Lubricate and reassemble the piston assembly;

piston (10), o-ring (9), dowel pin (7), adjustment

shaft (42), o-ring (6), and shaft (3). Use Loctiter

Primer N7649 and Loctiter TL242, 243, or

equivalent (“blue” Loctite) when assembling the

adjustment shaft (42). Tighten the shaft to 15–20

in–lb (1.7–2.2 NSm). The shaft (3) should hang

with some play to be self-aligning in the bearing.

4. Lubricate the air cylinder (1) ID with the grease

supplied. Push the piston (10) assembly into the

air cylinder.

5. Orient the air inlet manifold (2) (if used) as shown.

Match the gasket openings to the air ports.

Fluid Section

1. Lubricate the bearing (21), o-ring (16) and cup seal

(20). Put the o-ring (16) on the bearing. Carefully

insert the seal (20) into the bearing recess, with

the lips of the o-ring facing into the bearing. Be

careful not to damage the seal lips.

2. Push the bearing (21) seal end first into the

housing (19). Be sure that the grease hole in the

side of the bearing lines up with the grease ports in

the housing (19).

3. Holding the bearing (21) in place, push the bearing

assembly over the shaft (3).

4. Lubricate the main fluid seal (22) and its cavity in

the housing (26). Carefully press the seal, lip-first,

into the housing.

5. Push the housing (26) and seal (22) over the shaft

(3) and up against the bearing housing.

6. Apply anti–seize lubricant (Loctite 56765 or

equivalent) to the fluid housing screws (23) and

loosely install the screws to retain the housings.

Do not tighten the screws yet.

7. Insert the gasket (38) and seat (25). These items

are reversible and can be installed in either

direction.

8. Use Loctite Primer N7649 and Loctite TL242, 243,

or equivalent (“blue” Loctite) when assembling the

needle (27) and tighten to 15–20 in–lb (1.7–2.2

NSm).

9. Apply air pressure to the CLOSE port, or to the

pneumatic trigger valve if installed. This will align

the shaft, seal, and bearing. Tighten the fluid

housing screws (23) oppositely and evenly to

40–45 in-lbs (4.5–5 NSm).

10. Install the nosepiece (40) with the PTFE o-ring

(39), screw (15), and snuff-back ring (41), if used.

The snuff-back ring has an internal bevel on one

end which faces into the nosepiece. Tighten the

nosepiece screws to 15–20 in-lbs (1.7–2.2 NSm).

12 308876

Page 13

Service

(Models 965766, 965767, 965768, and 965786 only)

Air Valve (if equipped)

1. Insert the spring (51) into the housing (50).

2. Lubricate and install an o-ring (46) into the

housing.

3. Install a spacer (52), internal bevel first, into the

housing.

4. Lubricate and install two o-rings (46) and the

spacer (51).

5. Lubricate and install a spacer (52) with the internal

bevel out, and o-ring (46).

6. Lubricate and install o-rings (48) on the spool (49).

Insert the spool with the nub facing out.

7. Lubricate the pin (59) and insert it into the guide

(58). Screw the guide with o-ring (57) into the

housing. Tighten it to 60–70 in-lbs (6.8–7.9 NSm).

8. Orient the gasket (30) to the holes on the air

cylinder (1). Screw the air valve assembly to the

cylinder with the screws (60) and lock-washers

(61). TIghten the screws evenly to 15–20 in-lbs

(1.7–2.2 NSm).

9. Screw the bushing (53) to the housing (50) with

the screw (54). Tighten the screw to 140–150

in-lbs (15.8–16.9 NSm).

10. Attach the handle (55) with the setscrew.

11. Attach the trigger (56) with the grease fittings (18).

12. Test that the trigger safety works properly.

Electric Switch

1. The switch, housing, and cable are not repairable.

Replace these parts as a complete assembly.

2. The switch, housing, and cable assembly are not

user serviceable and must be replaced as an

assembly.

13308876

Page 14

Service

(Models 965766, 965767, 965768, and 965786 only)

1

4

61

4

58 59

8370A

60

2

53

4

4

4647 48 49

51 52

5

57 50

44

56

6

54

1211

13, 14

8375B

44

4 4

6 5 34 28, 29 20 21 22 39

7

55

44

B

2 3

27

7 8

23 40

15

44

42

1

4 4 4

Tighten to 15–20 in-lb (1.7–2.2 NSm). The shaft should hang

1

with some play to be self-aligning in the bearing.

2

Tighten to 15–20 in-lbs (1.7–2.2 NSm).

3

Tighten oppositely and evenly to 40–45 in-lbs (4.5–5 NSm).

4

Lubricate with grease supplied in the repair kit.

2910 16

7

30

19 18

4444

Fig. 5

26

38 25

A

41

5

Tighten to 60–70 in-lbs (6.8–7.9 NSm).

Screw the bushing (53) to the housing (50) with screw (54).

6

Tighten to 140–150 in-lbs (15.8–16.9 NSm).

Apply Loctite Primer N7649 and Loctite TL242, 243, or

7

equivalent (“blue” Loctite).

Apply anti–seize lubricant (Loctite 56765 or equivalent).

8

8371A

14 308876

Page 15

Notes

15308876

Page 16

Parts

(Models 965766, 965767, 965768, and 965786 only)

15

19

18

30 12

1

(965766 &

965786 only)

26

2

9

10

16

38

25

41

42

44

43

11

6

7

5

4

3

28, 29

20

21

22

39

27

23

40

15

8371A

16 308876

Page 17

Parts

Model 965766

Machine Mount Valve

Stainless steel wetted parts

Model 965786

Automatic Machine Mount Valve

Aluminum wetted parts

Ref.

No.

1 626702 HOUSING, air cylinder 1

2 626069 MANIFOLD, air control 1

3 626068 SHAFT, air cylinder 1

4* 156454 O-RING, 010 buna-n 2

5* 551181 BEARING, air cylinder 2

6* 154662 O-RING, 222 buna-n 2

7* 552164 DOWEL PIN 1

9* 157628 O-RING, 006 buna-n 1

10 626703 PISTON, air cylinder 1

11 626704 CAP, air cylinder CAP, air

12 552163 CLIP, internal 1.75 2

13 102817 SCREW, drive 2

14 552161 PLATE, identification 1

15 104371 SCREW, 10–32 x 0.375 4

16*† 103610 O-RING, 014

18 551188 FLUSH GREASE FITTING 2

19 626705 LUBE HOUSING 1

20*† 551191 U-CUP, urethane/EPR 1

21* 626064 BEARING, lube 1

22*† 551190 U-CUP, Polymitet/EPR 1

23n 103926 SCREW, 1/4–20 x 2.25 2

25* 185467 SEAT, C2 carbide 1

26 626731 HOUSING, fluid; stainless

27*} 626062 NEEDLE, hardened stain-

28Y 188377 LABEL, skin injection haz-

29Y 188378 LABEL, read instruction

Part No. Description Qty.

cylinder; Models 965766

and 965786 only

196018 CAP, air cylinder; Models

243482 and 243666 only

fluoroelastomer

steel; Model 965766 and

243282 only

626706 HOUSING, fluid; aluminum;

Model 965786 only

less steel

ard

manual

Model 243482

Orbiter Mounted Valve

Stainless steel wetted parts

Model 243666

PrecisionFlo Control Valve

Stainless steel wetted parts

Ref.

No.

30* 626057 GASKET, air cylinder 1

31 104459 SCREW, 10–32 x 1.75 4

35* 551186 GREASE, 3 oz. tube (not

36 115982 GUN, grease (not shown) 1

37 551187 COUPLER, flush grease

38*† 171860 GASKET, seat 1

39*† 104319 O-RING, 014 PTFE 1

1

1

1

1

1

1

1

1

40 626732 NOSEPIECE, stainless

41* 626060 RING, snuff-back 1

42} 626708 SHAFT, adjustment Models

43 626709 NUT, adjustment Models

44 100166 NUT, full hex, 10–32 Mod-

45 102920 NUT, jam, 10–32 Models

* Included in Rebuild Kit 570268.

† Included in Section Seal Kit 570267.

Y Replacement Instruction and Warning Labels are

} Use Loctite Primer N7649 and Loctite TL242, 243,

n Use anti–seize lubricant (Loctite 56765 or

Part No. Description Qty.

shown)

(not shown)

steel; Models 965766 and

243666 only

626707 NOSEPIECE; aluminum;

Model 965786 only

195957 NOSEPIECE; stainless

steel; Model 243482 only

965766 and 965786 only

965766 and 965786 only

els 965766 and 965786 only

243482 and 2436666 only

available at not cost.

or equivalent (“blue” Loctite) when assembling this

part.

equivalent) when assembling 965766 and 965786.

Use Loctite TL242, 243, or equivalent (“blue”

Loctite) when assembling 243482 and 243666.

1

1

1

1

1

1

1

1

1

17308876

Page 18

61

Parts

63

(965768 only)

60

53

56

54

8375B

55

(965767 only)

47

46 48 49

8370A

58 59

18 308876

51 52

57 50

8372A

Page 19

WARNING

SKIN INJECTION HAZARD

To reduce the risk of serious injury

whenever you are instructed to relieve

pressure, always follow the Pressure

Relief Procedure on page 8.

Service

(Models 243482 and 243666 only)

6. Remove the two fluid housing screws (23) and

remove the fluid housing (26). Remove the primary

fluid seal (22) from the fluid housing (26).

7. Pull the bearing/lube housing (19) from the air

cylinder (1). Remove the bearing (21), bearing

o-ring (16), and secondary fluid seal (20). Remove

the grease fittings (18).

Disassembly

1. Relieve all air and fluid pressure.

2. Disconnect the valve from the system.

3. Remove the four nosepiece screws (15), and pull

the nosepiece (40) away from the valve. Remove

the snuff-back ring (41). See Fig. 5, page 14.

4. Use an 1/8 in. pin punch in the needle hole (A) to

unscrew the needle (27). If the shaft (3) spins,

insert a dowel pin in the shaft hole (B) to hold it

steady, then unscrew the needle (27).

5. Remove the seat (25), gasket (38), and o-ring

(39).

8. Remove the C-clip (12) from the back of the air

cylinder (1). Push the shaft (3) into the air cylinder

to dislodge the air cylinder cap (11). Remove the

cap o-ring.

9. Remove the internal C-clip (12). Push the shaft (3)

to dislodge the piston (10) assembly from the air

cylinder (1).

10. Remove the pin (7), o-ring (9), and piston o-ring

(6).

11. Use a 1/4 in. pin punch to knock out the bearings

(5) and o-rings (4).

19308876

Page 20

Service

(Models 243482 and 243666 only)

Reassembly

Air Cylinder Section

1. Lubricate the shaft o-rings (4) and the bearings (5)

with grease supplied in the repair kit. Insert o-rings

into the air cylinder (1) and air cap (11) cavities.

See Fig. 5.

2. Press the bearings (5) flush into the air cylinder

housing and air cap, trapping the o-rings (4).

3. Lubricate and reassemble the piston assembly;

piston (10), o-ring (9), dowel pin (7), o-ring (6), and

shaft (3). Tighten the jam nut (45) to 15–20 in-lb

(1.7–2.2 NSm). The shaft (3) should hang with

some play to be self-aligning in the bearing.

4. Lubricate the air cylinder (1) ID with the grease

supplied. Push the piston (10) assembly into the

air cylinder.

5. Orient the air inlet manifold (2) (if used) as shown.

Match the gasket openings to the air ports.

Fluid Section

1. Lubricate the bearing (21), o-ring (16) and cup seal

(20). Put the o-ring (16) on the bearing. Carefully

insert the seal (20) into the bearing recess, with

the lips of the o-ring facing into the bearing. Be

careful not to damage the seal lips.

2. Push the bearing (21) seal end first into the

housing (19). Be sure that the grease hole in the

side of the bearing lines up with the grease ports in

the housing (19).

3. Holding the bearing (21) in place, push the bearing

assembly over the shaft (3).

4. Lubricate the main fluid seal (22) and its cavity in

the housing (26). Carefully press the seal, lip-first,

into the housing.

5. Push the housing (26) and seal (22) over the shaft

(3) and up against the bearing housing.

6. Apply Loctite Primer N7649 and Loctite TL242,

243, or equivalent (“blue” Loctite) to the fluid

housing screws (23) and loosely install the screws

to retain the housings. Do not tighten the screws

yet.

7. Insert the gasket (38) and seat (25). These items

are reversible and can be installed in either

direction.

8. Apply Loctite Primer N7649 and Loctite TL242,

243, or equivalent (“blue” Loctite) to needle (27)

and tighten to 15–20 in–lb (1.7–2.2 NSm).

9. Apply air pressure to the CLOSE port, or to the

pneumatic trigger valve if installed. This will align

the shaft, seal, and bearing. Tighten the fluid

housing screws (23) oppositely and evenly to

40–45 in-lbs (4.5–5 NSm).

10. Install the nosepiece (40) with the PTFE o-ring

(39), screw (15), and snuff-back ring (41), if used.

The snuff-back ring has an internal bevel on one

end which faces into the nosepiece. Tighten the

nosepiece screws to 15–20 in-lbs (1.7–2.2 NSm).

20 308876

Page 21

Parts

(Models 243482 and 243666 only)

12

22 22

2 2

6 5 34 28, 29 20 21 22 39 23 40

13, 14

45

2910 16

Tighten oppositely and evenly to 40–45 in-lbs (4.5–5 NSm).

1

2

Lubricate with grease supplied in the repair kit.

3

Tighten to 15–20 in lbs (17–22 NSm)

4

Apply Loctite Primer N7649 and Loctite TL242, 243, or equivalent

(“blue” Loctite).

7

2 2

30

19 18

222

26

38 25

4

3

27

4

1

40

Model 243482

15

15

Fig. 6

21308876

Page 22

Parts

(Models 243482 and 243666 only)

15

19

18

30

1

9

10

16

38

26

25

41

12

19

45

6

7

5

4

3

28, 29

20

21

22

39

27

Model 243482

31

40

23

40

31

8371A

22 308876

Page 23

Parts

Model 965767

Hand Held Valve with Pneumatic Trigger

Aluminum wetted parts

See page 16 for illustration of items 1–44. See page 18 for illustration of items 46–62.

Ref.

No.

1 626702 HOUSING, air cylinder 1

3 626068 SHAFT, air cylinder 1

4* 156454 O-RING, 010 buna-n 2

5* 551181 BEARING, air cylinder 2

6* 154662 O-RING, 222 buna-n 2

7* 552164 DOWEL PIN 1

9* 157628 O-RING, 006 buna-n 1

10 626703 PISTON, air cylinder 1

11 626704 CAP, air cylinder 1

12 552163 CLIP, internal 1.75 2

13 102817 SCREW, drive, #0 x 0.25 2

14 552161 PLATE, identification 1

16*† 103610 O-RING, 014

18 551188 FLUSH GREASE FITTING 2

19 626705 LUBE HOUSING 1

20*† 551191 U-CUP, urethane/EPR 1

21* 626064 BEARING, lube 1

22*† 551190 U-CUP, Polymitet/EPR 1

23n 103926 SCREW, 1/4–20 x 2.25 2

25* 185467 SEAT, C2 carbide 1

26 626706 HOUSING, fluid; aluminum 1

27*} 626062 NEEDLE, hardened stain-

28Y 188377 LABEL, skin injection haz-

29Y 188378 LABEL, read instruction

30* 626057 GASKET, air cylinder 1

31 104459 SCREW, 10–32 x 1.75 4

35* 115982 GREASE, 3 oz. tube (not

36 551189 GUN, grease (not shown) 1

37 551187 COUPLER, flush grease

38*† 171860 GASKET, seat 1

39*† 104319 O-RING, 014 PTFE 1

Part No. Description Qty.

fluoroelastomer

less steel

ard

manual

shown)

(not shown)

Ref.

No.

40 626707 NOSEPIECE, aluminum 1

41* 626060 RING, snuff-back 1

42} 626708 SHAFT, adjustment 1

43 626709 NUT, adjustment 1

44 100166 NUT, full hex, 10–32 1

46 106559 O-RING, No. 905

47 106561 SPRING 1

48 106560 O-RING, 007

49 178651 SPOOL, 4-way 1

50 626056 HOUSING, air valve 1

1

1

1

1

1

1

51 178652 SPACER, u-shape 1

52 178653 SPACER, air valve 2

53 626055 BUSHING, handle 1

54 551204 SCREW, 3/8–16 x 3/4 1

55 626075 HANDLE 1

56 626083 TRIGGER 1

57 106551 O-RING, 0.5 x 0.6

58 178654 GUIDE, stem 1

59 626053 PIN, trigger 1

60 119156 SCREW, 10–32 x 0.8125 4

61 100020 WASHER, lock, #10 2

62 104765 PLUG, pipe, headless,

* Included in Rebuild Kit 570268.

† Included in Section Seal Kit 570267.

Y Replacement Instruction and Warning Labels are

} Loctite Primer N7649 and Loctite TL242, 243, or

n Anti–seize lubricant (Loctite 56765 or equivalent)

Part No. Description Qty.

5

fluoroelastomer

3

fluoroelastomer

1

fluoroelastomer

1

1/8 npt (not shown)

available at no cost.

equivalent (“blue” Loctite) should be used when

installing this part.

should be used when installing this part.

23308876

Page 24

Parts

Model 965768

Hand Held Valve with Electric Switch

Aluminum wetted parts

See page 16 for illustration of items 1–44. See page 18 for illustration of items 53–63.

Ref.

No.

1 626702 HOUSING, air cylinder 1

3 626068 SHAFT, air cylinder 1

4* 156454 O-RING, 010 buna-n 2

5* 551181 BEARING, air cylinder 2

6* 154662 O-RING, 222 buna-n 2

7* 552164 DOWEL PIN 1

9* 157628 O-RING, 006 buna-n 1

10 626703 PISTON, air cylinder 1

11 626704 CAP, air cylinder 1

12 552163 CLIP, internal 1.75 2

14 552161 PLATE, identification 1

15 104371 SCREW, 10–32 x 0.375 4

16*† 103610 O-RING, 014

18 551188 FLUSH GREASE FITTING 2

19 626705 LUBE HOUSING 1

20*† 551191 U-CUP, urethane/EPR 1

21* 626064 BEARING, lube 1

22*† 551190 U-CUP, Polymitet/EPR 1

23n 103926 SCREW, 1/4–20 x 2.25 2

25* 185467 SEAT, C2 carbide 1

26 626706 HOUSING, fluid; aluminum 1

27*} 626062 NEEDLE, hardened stain-

28Y 188377 LABEL, skin injection haz-

29Y 188378 LABEL, read instruction

30* 626057 GASKET, air cylinder 1

31 104459 SCREW, 10–32 x 1.75 4

35* 115982 GREASE, 3 oz. tube (not

Part No. Description Qty.

fluoroelastomer

less steel

ard

manual

shown)

Ref.

No.

36 551189 GUN, grease (not shown) 1

37 551187 COUPLER, flush grease

38*† 171860 GASKET, seat 1

39*† 104319 O-RING, 014 PTFE 1

40 626707 NOSEPIECE, aluminum 1

41* 626060 RING, snuff-back 1

42} 626708 SHAFT, adjustment 1

43 626709 NUT, adjustment 1

44 100166 NUT, full hex, 10–32 1

53 626055 BUSHING, handle 1

54 551204 SCREW, 3/8–16 x 3/4 1

1

1

1

1

1

55 626075 HANDLE 1

56 626083 TRIGGER 1

60 119156 SCREW, 10–32 x 0.8125 4

61 100020 WASHER, lock, #10 2

63 949706 SWITCH ASSEMBLY 1

* Included in Rebuild Kit 570268.

† Included in Section Seal Kit 570267.

Y Replacement Instruction and Warning Labels are

} Loctite Primer N7649 and Loctite TL242, 243, or

n Anti–seize lubricant (Loctite 56765 or equivalent)

Part No. Description Qty.

1

(not shown)

available at not cost.

equivalent (“blue” Loctite) should be used when

installing this part.

should be used when installing this part.

24 308876

Page 25

Accessories

Plastic Tube Fittings to Connect Air Signals

Tube OD 1/8 NPT (M) Straight 1/8 NPT (M) 90º Swivel Tube Tee

1/8 in.

5/32 in.

1/4 in.

Tube OD 1/4 NPT (M) Straight 1/4 NPT (M) 90º Swivel

5/32 in.

1/4 in.

598329

104172

598252

104165

513826

598140

597151

598327

C19391

551203

514435

111167

Plastic Tubing for Air Signal Lines

Part No. Description

513063 1/8 in. O.D. Nylon

514607 5/32 in. O.D. Nylon

C12509 1/4 in. O.D. Nylon

Air Signal Accessories

551201 Air Cylinder Speed Control 90_ Fitting

1/8 npt(f) inlet, 1/8 npt(m) outlet

Mount on CLOSE port to control opening speed for

soft start. Mount on OPEN port to control closing

speed for less snuff–back.

104661 Quick Exhaust Valve

1/8 npt(f) inlet and outlet, 1/4 npt(f) exhaust

Used to speed up opening or closing action of the 1K

Ultra–Lite Valve

104632 Pump Pilot Valve

1/2 npt (f) line ports, 1/8 npt(f) pilot port

3–way air piloted air valve to turn air powered

proportioning pump on with hand gun signal.

4-Way Solenoids and Solenoid

Accessories

626144 Manifold

To direct mount solenoid to 1K Ultra–Lite Valve.

551316 120 Volt ac Solenoid

For use with 626144 Manifold.

551317 24 Volt dc Solenoid

For use with 626144 Manifold.

551347 120 Volt ac Solenoid

Remote mount, 1/8 npt (f) ports

551348 24 Volt dc Solenoid

Remote mount, 1/8 npt(f) ports

551349 120 Volt ac Din Plug

With screw terminals for above solenoids

551350 24 Volt dc Din Plug

With screw terminals for above solenoids

Optional Main Fluid Needle Packings (22)

Part No. Description

551192 Urethane U–Cup with EPDM o–ring

spreader

551193 Reinforced PTFE U–Cup with 302

stainless steel spreader

25308876

Page 26

Accessories

Fluid Nozzles

Zinc-plated steel nozzles, 1/8 npt*

Part No. Orifice Length

607665 0.125 in. (3.17 mm) 2 in. (51 mm)

161505 0.09 in. (2.28 mm) 2 in. (51 mm)

164799 0.055 in. (1.39 mm) 2-1/8 in. (54 mm)

* Requires a 1/8 npt(f) bushing. Order 168683 Nozzle

Bushing.

Nozzles for use with 188253

flange nut.

8462A

Part No. Orifice Length

C00005 0.187 in. (4.75 mm) 1.656 in. (42 mm)

C00007 0.093 in. (2.36 mm) 2 in. (51 mm)

C00008 0.250 in. (2.28 mm) 2 in. (51 mm)

C00009 0.172 in. (4.37 mm) 2 in. (51 mm)

C00010 0.062 in.(1.57 mm) 2 in. (51 mm)

C00011 0.375 in. (9.53 mm) 2 in. (51 mm)

C00012 0.156 in. (3.96 mm) 2 in. (51 mm)

C00013 0.046 in. (1.17 mm) 2 in. (51 mm)

C00014 0.031 in. (0.79 mm) 2 in. (51 mm)

C00015 0.156 in. (3.96 mm) 1.812 in. (46 mm)

168683 Nozzle Bushing

Zinc-plated steel, 1/8 npt

Kits

949631 Conversion Kit

Pneumatic 4–way valve with housing, handle, and

trigger and other parts necessary to convert 965766 or

965786 to a hand held valve.

949632 Conversion Kit

Electric switch style handle kit to convert 965766 or

965786 to a hand held valve.

570267 Seal Kit

With Polymitet main packing (standard)

570268 Rebuild Kit

With Polymitet main packing (standard)

570299 Seal Kit

With PTFE main packing (optional)

570300 Rebuild Kit

With PTFE main packing (optional)

512135 Plastic Fluid Nozzle

1/4 npt, 0.062 in. (1.57 mm) orifice, 2-1/2 in.

(63.5 mm) long

26 308876

Page 27

Technical Data

Category Data

Maximum Fluid Pressure 4000 psi (28 MPa, 276 bar)

Maximum Cylinder Air Pressure 120 psi (0.84 MPa, 8.4 bar)

Air inlets (open and close ports) 1/8 npt(f)

Fluid Inlet 1/4 npt(f)

Fluid Outlet 1/4 npt(f) and 3/4–16 unf(m)

Fluid Viscosity Range 20 cps to 1 million cps

Snuffer Action Fluid Section Isolation chamber with zerk fittings

Divorced Air Cylinder Piston cylinder, EP o-rings

Weight

Aluminum Valve

Stainless Steel Valve

Handle Kit

Wetted Parts

Aluminum Valve aluminum, 303 stainless steel, 17–4 PH stainless steel, C2 car-

Stainless Steel Valve 303 stainless steel, 17–4 PH stainless steel, C2 carbide, hard

Severe-duty Components

Shaft

Snuffer Needle

Seat

Shaft Seal, standard

Shaft Seal, optional

1.43 lb (0.65 kg)

2.07 lb (0.94 kg)

0.77 lb (0.35 kg)

bide, hard chrome, ethylene propylene, Parker Polymitet, PTFE

chrome, ethylene propylene, Parker Polymitet, PTFE

Hard chrome over 303 stainless steel

Hardened 440–C stainless steel

Reversible, solid C2 carbide inserts

High density Parker Polymitet

PTFE

Loctiter is a registered trademark of the Loctite Corporation.

27308876

Page 28

Dimensions

6.13 in.

(155.7 mm)

1.42 in.

(36.07 mm)

1.75 in.

(44.45 mm)

2.25 in.

(57.15 mm)

0.88 in.

(22.35 mm)

1.75 in.

(44.45 mm)

3.5 in.

(88.9 mm)

1.63 in.

(41.4 mm)

2.25 in.

(57.15 mm)

Direct Mount Solenoid

(optional)

5 in.

(127 mm)

8370A

28 308876

Page 29

Notes

29308876

Page 30

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

For the latest information about Graco products, visit www.graco.com.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

30 308876

This manual contains English. MM 308876

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 1998, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 04/2009

Loading...

Loading...