Page 1

Operating Instructions

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

Pressure Roller

Model 243066, Series A

D 20 in. (50 cm) heavy-duty extension

D 45_ swivel adapter

D 9 in. (23 cm) roller frame

D 1/2 in. (13 mm) nap roller cover

309047

Rev. A

3600 psi (24.8 MPa, 248 bar) Maximum Fluid Inlet Pressure

This maximum pressure is only possible if the roller frame is

*

completely plugged. The best operating pressure is the lowest

pressure that provides an even paint supply to the roller and

typically does not exceed 300 psi (2.1 MPa, 21 bar).

*

Airless spray

gun not included

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 2000, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

9593A

Page 2

Warnings and Cautions

Installation

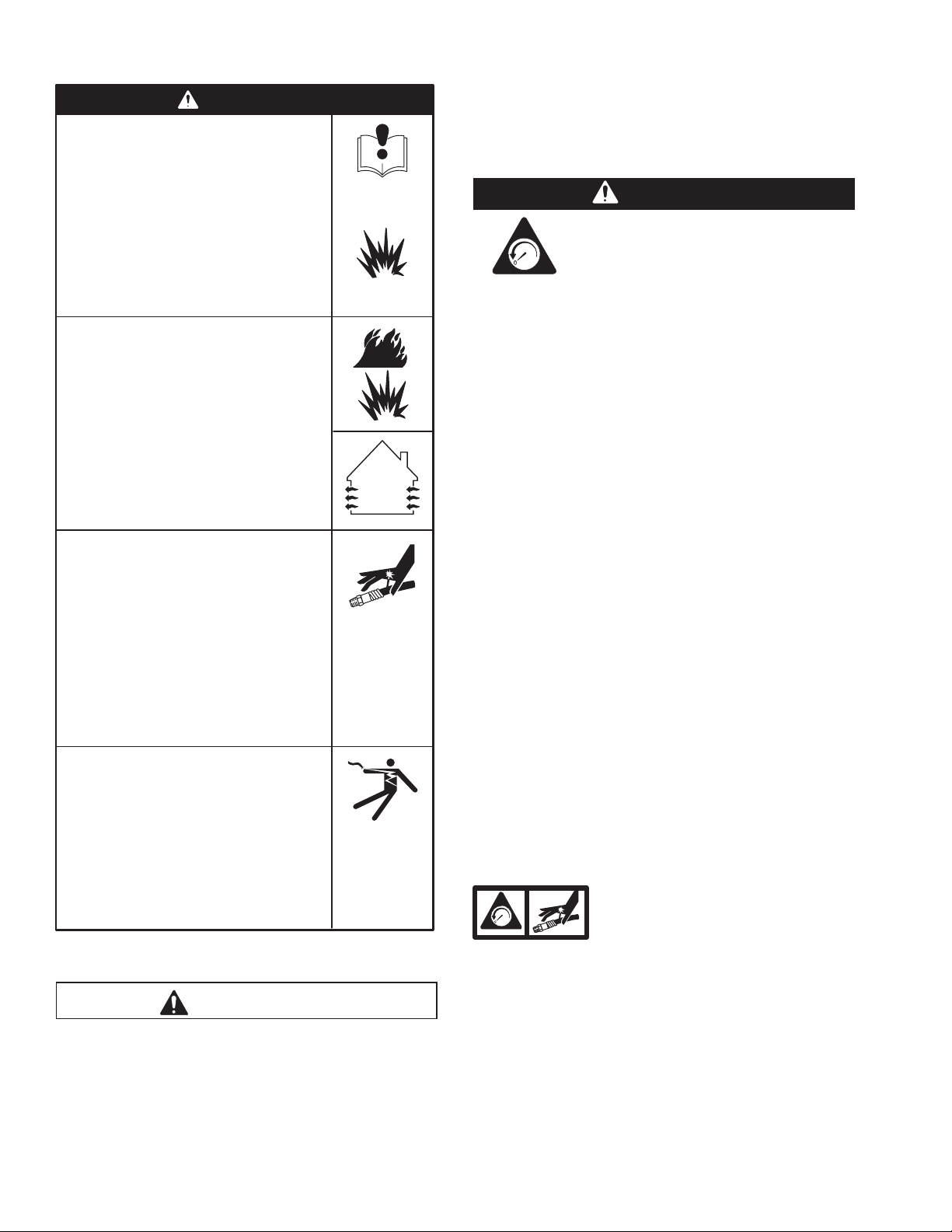

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause the equipment to rupture or

malfunction and result in serious injury.

To help prevent injury

D Do not modify the extension tube or roller

frame or use parts not designed for this

equipment.

D Do not use 1,1,1–trichloroethane, methylene

chloride, other halogenated hydrocarbon solvents or fluids containing such solvents in this or

any other pressurized aluminum equipment.

Such use could result in a chemical reaction,

with the possibility of explosion.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open

flames or sparks can cause a hazardous

condition and result in a fire or explosion and

serious injury.

To help prevent injury from fire or explosion

D Provide fresh air ventilation to avoid the

buildup of flammable fumes from flushing

fluids or the coating being applied.

D Keep the application area free of debris,

including solvent, rags, and gasoline.

FLUID INJECTION HAZARD

If high-pressure fluid pierces your skin, the injury

might look like “just a cut”. But it is a serious

wound. Get immediate medical attention.

To help prevent injection

D Keep your hands and body away form the

roller frame when flushing. High pressure

fluid emitted from the holes in the frame

could cause an injection injury.

D Always relieve pressure before you check or

repair leaks and when you turn off pump or stop

painting.

D Never use components rated less than system

Maximum Working Pressure.

ELECTROCUTION HAZARD

Failure to observe the electrical hazards described

below could result in serious injury, including burns

or electrocution.

To help prevent harmful electrical shock

D Avoid contact with power lines.

D Follow all grounding instructions in your

separate pump and gun instruction manual,

and comply with all local, state, and national

fire, electrical, and safety regulations.

D Use only Graco paint hoses.

INSTRUCTIONS

Assemble the pressure roller as shown in the Parts

Drawing on page 3.

Pressure Relief Procedure

WARNING

To help prevent injection injuries,

follow this procedure whenever

you stop painting.

psi/MPa/bar

1. Put gun trigger safety in SAFETY ON position.

2. Shut off power to pump.

3. Put pump prime/drain valve (required for pressure

relief) in DRAIN position to relieve pressure in

system.

4. Put gun trigger safety in SAFETY OFF position,

and trigger gun to relieve any pressure in hose.

5. Put gun trigger safety in SAFETY ON position, and

keep pump prime/drain valve in DRAIN position

until you paint again.

Operation

1. Follow pump priming instructions using lowest

pressure setting at which pump primes.

2. Put pump prime/drain valve in position that

delivers fluid to hose.

3. Disengage gun safety latch, and trigger gun briefly

until paint comes to roller.

4. Experiment with triggering gun and rolling paint.

NOTE: Trigger the gun briefly when you need

more paint. Determine how often you must trigger

the gun to maintain an even paint supply to the

roller.

5. Increase pump pressure only if triggering gun

cannot supply enough paint for your rolling speed.

See Pressure Relief

Procedure on page 2.

Preventing Corrosion Damage and Freezing

CAUTION

Never leave water in the pump, gun, or pressure roller. Doing

so could cause corrosion and damage from freezing. For

storage, flush the system with Graco Pump Armort or

mineral spirits/paint thinner. See Flushing on page 3.

2 309047

6. Whenever you stop painting, relieve the

pressure, and elevate roller end of extension tube

to prevent paint from draining out.

Flush the pump, gun, and pressure roller immediately

after each use to prevent paint from drying in the

pressure roller and damaging it. See Flushing on

page 3.

Page 3

Flushing

Parts Drawing

This is the procedure for flushing the pressure roller.

The pump and gun you are using may have additional

flushing steps, such as cleaning filters and screens.

See the pump and gun flushing instructions.

NOTE: Leave the pressure roller attached to the gun

for this procedure.

See Pressure Relief

Procedure on page 2.

1. Relieve the pressure.

2. Remove roller cover (6) and diffuser from roller

frame as follows (see Parts Drawing at right):

a. Hold roller cover, and unscrew retaining nut.

b. Slide diffuser and roller cover off of roller fame.

c. Pull roller cover off of diffuser.

3. Clean roller cover with compatible fluid, and clean

diffuser by shaking vigorously in pail of compatible

fluid to remove wet paint. Use soft bristled brush to

remove any dried paint on diffuser.

4. Place roller frame (1) in empty waste pail.

5. Prime pump with flushing fluid compatible with

paint you are using, and use the lowest pressure

setting at which pump primes.

6. Put pump prime/drain valve in position that

delivers fluid to hose.

NOTE: Perform Step 7 at the lowest pressure

possible.

7. Trigger gun until flushing fluid coming out of roller

frame is relatively clear.

8. Shut off the pump, and relieve the pressure.

9. To prevent corrosion, lubricate paint holes in roller

frame with lightweight oil that does not contain

silicone.

Pressure Roller,

Model 243066, Series A

retaining nut

1

2

4

5

2

2*

3*

diffuser

6

3

3

7

9593A

HINT:

When replacing gasket (2*) and

o-ring (3*) in swivel adapter (7),

position o-ring first, then press

gasket into place.

Storage

If you are going to store the airless equipment for an

extended period of time after flushing with water-base

fluid, flush again with Graco Pump Armor or mineral

spirits/paint thinner. Leave the fluid in the system

during storage.

Additional Roller Covers

The following pressure roller covers are available at

your local distributor:

107589 9 in. (23 cm); 3/8 in. (9.5 mm) nap

107590 9 in. (23 cm); 1/2 in. (13 mm) nap

107591 9 in. (23 cm); 3/4 in. (19 mm) nap

107592 9 in. (23 cm); 1-1/4 in. (32 mm) nap

Parts List

Ref.

No. Part No. Description Qty.

1 240005 FRAME, roller; 9 in. (23 cm) 1

2 162863 GASKET, non-metallic 3

3 114049 PACKING, o-ring 3

4 232122 TUBE, extension; 20 in. (50 cm) 1

5Y 195804 LABEL, warning 1

6 107590 COVER, roller;

9 in. (23 cm); 1/2 in. (13 mm) nap 1

7 224399 ADAPTER, 45_ swivel 1

Y Call 1–800–328–0211 for free extras.

309047 3

Page 4

Graco Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in

accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty

Program”.

Graco Phone Number

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–690–2894 Toll Free

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Foreign Offices: Belgium, Korea, Hong Kong, Japan

Sales Offices: Minneapolis, Detroit

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

http://www.graco.com

PRINTED IN USA 309047 02/2000

4 309047

Loading...

Loading...