Page 1

INSTRUCTIONS–PARTS LIST

This manual contains

changes not included

throughout the contents.

Please see the second

page of this book (page 1A)

for a description of the

revisions and additions.

308846

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

First choice when

quality counts.

t

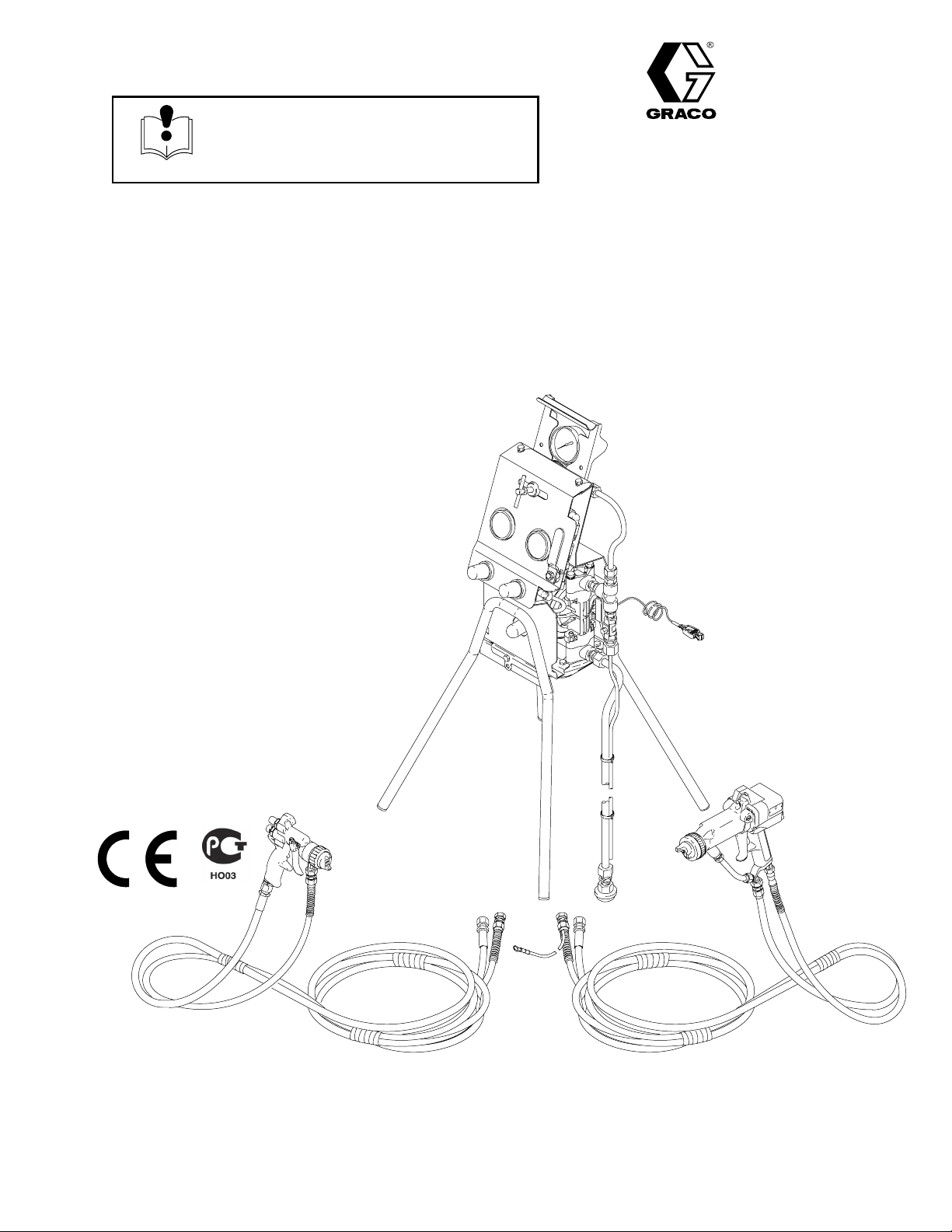

ACETAL HUSKYt 307, ST AND MOUNT

PROt/ Delta Sprayt Packages

Metal fluid fittings and hose couplings are stainless steel.

100 psi (0.7 MPa, 7 bar) Maximum Fluid Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Inlet Pressure

Packages with Fluid Pressure Regulators

Model No. 240367

with hoses and Delta Spray air spray gun

Model No. 240368

with hoses and Delta Spray HVLP gun

Model No. 240369

with hoses and PRO 3500sc electrostatic gun

Model No. 240370

with hoses and PRO 4500sc electrostatic gun

Model No. 240371

no hoses or gun

Rev. D

Packages with Surge Tanks

Model No. 240379

with hoses and Delta Spray air spray gun

Model No. 240380

with hoses and Delta Spray HVLP gun

Model No. 240381

no hoses or gun

This gun and hose for Delta Spray Air Spray

packages and Delta Spray HVLP packages

8115A

This gun and hose for PRO 3500sc

Electrostatic packages

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1998, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Instruction Manual – Parts List Changes

Improve pressure control instructions (Graco ref. V6557).

Change 30psi HVLP fluid regulator and gauge to 60psi (Graco ref. V6808).

This page contains a summary of changes or additions that do not appear in the contents

of the manual.

1A308846

Page 3

Notes

1B 308846

Page 4

Table of Contents

Symbols

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List and Parts Drawing

240367 to 240371 10. . . . . . . . . . . . . . . . . . . .

240379 and 240381 12. . . . . . . . . . . . . . . . . . .

Fluid Filter Kit 240440 14. . . . . . . . . . . . . . . . . . . . .

Suction Tube Kit 240465 15. . . . . . . . . . . . . . . . . .

Technical Data 16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 20. . . . . . . . . . . . . . . . .

Graco Phone Number 20. . . . . . . . . . . . . . . . . . . . .

PRESSURIZED FLUID HAZARD

Spray from the gun, hose leaks, or ruptured components can splash fluid in the eyes or on the skin

and cause serious injury.

D Do not stop or deflect fluid leaks with your hand, glove, or rag.

Warning Symbol

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

corresponding instructions.

WARNING

WARNING

WARNING

CAUTION

D Follow the Pressure Relief Procedure on page 6 before cleaning, checking, or servicing the

equipment.

D Tighten all fluid connections before each use.

D Check the hoses, tubes, and couplings daily. Replace parts immediately if worn, damaged, or

loose. Permanently coupled hoses cannot be repaired.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in fire or explosion and serious injury.

D Ground the equipment, personnel in or close to the spray area, the object being sprayed, and all

other electrically conductive objects in the spray area. See Grounding on page 5.

D If there is any static sparking while using the equipment, stop spraying immediately. Identify and

correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable vapors from the solvent or the fluid

being sprayed.

D Do not smoke in the spray area.

D Extinguish all open flames or pilot lights in the spray area.

D Do not turn on or off any light switch in the spray area.

D Electrically disconnect all equipment in the spray area.

D Keep the spray area free of debris, including solvent, rags, and gasoline.

D Do not operate a gasoline engine in the spray area.

2 308846

Page 5

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in a serious injury.

D This equipment is for professional use only.

D Read all the instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

D Check the equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated system component. This pack-

age has a 100 psi (0.7 MPa, 7 bar) maximum working pressure.

D Use fluids that are compatible with the equipment wetted parts. See the Technical Data section of

all the equipment manuals. Read the fluid manufacturer’s warnings.

D Route the hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not

expose Graco hoses to temperatures above 180_F (82_C) or below –40_F (–40_C).

D Do not use the hoses to pull equipment.

D Do not move pressurized equipment.

D Wear hearing protection when operating this equipment.

D Comply with all applicable local, state, and national fire, electrical, and other safety regulations.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause a serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled.

D Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

D Store hazardous fluid in an approved container. Dispose of the hazardous fluid according to all

local, state, and national guidelines.

D Wear appropriate protective clothing, gloves, eyewear, and respirator.

D If the pump diaphragm fails, hazardous fluid may be exhausted along with the air.

3308846

Page 6

Setup

CAUTION

This equipment is compatible with most water-based

materials. See the wetted parts in the Technical

Data section and your fluid and solvent

manufacturer’s compatibility information.

Do not use acid catalyzed materials; they are incompatible with the acetal used in this pump.

WARNING

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can

cause serious injury or death if splashed

in the eyes or on the skin, inhaled, or

swallowed.

D Read TOXIC FLUID HAZARD on page 3.

D Use fluids and solvents that are compatible with

the equipment wetted parts. Refer to the Technical Data section of all equipment manuals.

Read the fluid and solvent manufacturer’s

warnings.

Preparing the Operator

Anybody who operates this system should be trained

in the safe, efficient operation of all system

components. At a minimum, all operators should

thoroughly read the safety, setup, and operation

sections of this manual.

Preparing the Site

D Use a compressor capable of delivering 40 cfm

(1.12 m3) and a minimum of 80 psi (552 kPa,

5.4 bar) for efficient operation.

D Clear obstacles and debris that could cause an

unsafe operating environment.

D Run a 1/2 in. I.D. air line from your compressed air

supply to the pump location. Be sure the air is dry

and filtered.

D When the bleed-type master air valve (K) is closed

and the pump air regulator is opened, it relieves all

air pressure to the system components.

D Ventilate the spray booth.

General Information

D Always use Genuine Graco Parts and Accessories,

available from your Graco distributor. See the

Product Data Sheet for this package, Form No.

305898. If you supply your own accessories, be

sure they are adequately sized and pressure rated

for your system.

D Reference numbers and letters in parentheses refer

to the callouts in the figures and the parts lists on

pages 10 and 12.

WARNING

To prevent hazardous concentrations of toxic

and/or flammable vapors, spray only in a properly

ventilated spray booth. Never operate the spray

gun unless ventilation fans are operating.

Check and follow all of the national, state, and local

codes regarding air exhaust velocity requirements.

4 308846

Page 7

Setup

Hose Connections

This package is shipped with the hoses connected.

Before you disconnect any hoses, make a note of the

proper connections.

Flush Pump Before First Use

The pump was tested in water. If the test solution

could contaminate the fluid you are pumping, flush the

pump thoroughly with a compatible solvent. See

Flushing the System on page 8.

Grounding

WARNING

To reduce the risk of static sparking, the entire

system must be grounded. Check your local

electrical code for detailed grounding instructions

for your area and type of equipment. Ground all of

this equipment.

HAZARD on page 2.

D

Pump:

One end of the ground wire is already

connected to the pump grounding strip. Connect

the clamp end of the ground wire to a true earth

ground.

Air compressor:

D

recommendations.

D

Object being sprayed:

D

Fluid supply container:

All solvent pails used when flushing:

D

local code. Use only metal pails, which are

conductive. Do not place the pail on a

non-conductive surface, such as paper or

cardboard, which interrupts the grounding

continuity.

Also read FIRE AND EXPLOSION

Follow the manufacturer’s

Follow the local code.

Follow the local code.

Follow the

D

Systems with PRO 3500sc and PRO 4500sc

electrostatic gun:

grounding instructions and warnings in your gun

instruction manual.

Make sure you read all of the

5308846

Page 8

Operation

Using the Gun

See the gun instruction manual for gun operation,

care, flushing, cleaning, and technical data. Read the

entire gun manual before operating the sprayer.

Pressure Relief Procedure

See Fig. 1

WARNING

The system remains pressurized until pressure is

manually relieved. To reduce the risk of serious

injury from pressurized fluid, accidental spray from

the gun, or splashing of any fluid, follow this procedure whenever you

D Stop spraying

D Are instructed to relieve pressure

D Check or service any system equipment

D Install, clean, or change spray nozzles

1. Turn off the air supply to the pump.

2. Be sure the pump air regulator is open by turning

the knob (E) clockwise several turns.

3. Slowly open the gun air regulator (F), and pull the

gun trigger just enough to open only the air valve

in the gun. With the gun air triggered, set the gun

air pressure to 60 psi (413 kPa, 4 bar).

NOTE: Gun air pressure higher than 60 psi (413

kPa, 4 bar) will cause excessive overspray and

lowered efficiency.

4. If your system has a fluid pressure regulator (G),

fully trigger the gun, and fine tune the fluid

pressure to obtain the desired atomization.

Systems with Fluid Pressure Regulator

See Fig. 1

With the fluid pressure regulator (G), you can control

fluid pressure from the pump to the gun. For an

accurate setting, adjust the fluid regulator only when

the gun is triggered and fluid is flowing through the

regulator. Be sure the jam nut under the T–handle (G)

does not interfere with your adjustments. Tighten the

jam nut to lock in the setting, if desired.

1. To open the fluid regulator, which allows fluid to

flow, turn the T-hand clockwise.

3. Open the bleed-type master air valve (K) to relieve

pump air pressure.

4. Trigger the gun (B) to relieve fluid pressure in the

hoses.

5. Open the recircu lating valve (J) to relieve any fluid

pressure trapped in the system.

Adjusting Pump and Gun Air Regulators

See Fig. 1

NOTE: The pump air regulator knob (E) and gun air

regulator knob (F) have a locking feature. To unlock

the knobs, pull out on them. You will feel them click

out. To lock them at the desired setting, push them

back into the locked position.

Always adjust the pump air regulator (E) and gun air

regulator (F) slowly to prevent surging during startup.

Turn the knobs clockwise to increase pressure, and

counterclockwise to decrease air pressure.

1. Slowly adjust the pump air regulator (E), to set air

pressure to approximately 60 psi (413 kPa, 4 bar).

2. If your system has a fluid pressure regulator, turn

the fluid pressure regulator handle (G) to adjust

the fluid pressure to 40 to 60 psi ( 276 to 413 kPa,

2.8 to 4 bar).

2. To close the fluid regulator, which restricts or shuts

off the fluid flow, turn the T-handle

counterclockwise.

Systems with Surge Tank

See Parts Drawing on page 13

In systems with a surge tank (30), the fluid pressure is

the same as the air pressure applied to the pump

(pump has 1:1 ratio of fluid to air). Adjust the fluid

pressure as required with the pump air regulator (E).

The surge tank filter screen may require periodic

cleaning. First, relieve the pressure. Unscrew the

surge tank cover from its base, and remove the filter

screen. Clean the screen with a compatible solvent,

and reinstall it in the surge tank. Make sure you

reinstall the cover with a firm hand torque to ensure a

good seal.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 6.

NOTE: The pump requires approximately 15 to 20 psi

(103 to 138 kPa, 1 to 1.4 bar)to function. This is the

lowest fluid pressure available. If lower fluid flow is

required, a smaller fluid tip may be required on the

spray device.

6 308846

Page 9

Operation

Priming the System

See Fig. 1

1. Close the gun air regulator (F).

2. If your system has a fluid pressure regulator (G),

close it.

3. Open the recirculating valve (J).

4. Open the bleed-type master air valve (K).

5. Slowly set the pump air regulator (E) pressure to

20 to 30 psi (140 to 210 kPa, 1.4 to 2.1 bar). The

pump cycles quickly, then it slows down when it is

primed. When it is primed, close the recirculating

valve (J); the pump will stall against the pressure.

If the pump does not start, reopen the recirculating

valve for 30 seconds, then close it. Set the pump

air pressure to 40 psi (280 kPa, 2.8 bar).

KEY

A Husky 307 pump

B Gun

C Gun fluid hose

D Gun air hose

B

C

D

E Pump air regulator

F Gun air regulator

G Fluid pressure regulator

H Pump ground wire

J Recirculating valve

K Bleed-type master air valve

L Suction tube and return tube

M Front shield assembly

N Back shield

6. Slowly open the gun air regulator (F), and pull the

gun trigger just enough to open only the air valve

in the gun. With the gun air triggered, set the gun

air pressure to 60 psi (413 kPa, 4 bar).

7. Hold the gun against and aimed into a grounded

metal waste pail, and fully trigger the gun. If your

system has a fluid pressure regulator (G), slowly

open it.

The gun emits air until the fluid arrives. When fluid

flows freely, release the gun trigger.

Delta Spray

regulated Air Spray package or

regulated HVLP package shown

G

Fig. 1

K

F

J

N

D

L

M

C

E

A

H

8116A

7308846

Page 10

Operation

Using the Recirculation Feature

See Fig. 1

The recirculation tube drains unused fluid back into the

fluid container, ensuring an even flow at the gun.

Recirculation also provides gentle fluid agitation. To

recirculate fluid, open the recirculation valve (J) while

you are spraying. To stop recirculation, close the valve.

When to Shut Down the System

Shut down the system at the end of the work shift and

before checking, adjusting, cleaning, or repairing the

system. Always relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 6.

Flushing the System

Flush the system at the following times:

3. Place the suction tube into a grounded metal pail

of compatible solvent.

4. Make sure the air regulators (E and F) and

bleed-type master air valve (K) are closed. Open

the recirculating valve (J).

NOTE: The gun air regulator (F) always stays

closed during flushing.

5. Open the bleed-type master air valve (K).

6. Slowly open the pump air regulator (E) until the

pump starts. When fluid is flowing through the

recirculating valve (J), close the valve. The pump

will stall against pressure.

7. Hold the gun against a grounded metal waste pail,

and fully trigger the gun. If your system has a fluid

pressure regulator (G), slowly open it until the fluid

flows smoothly.

8. When solvent appears, release the gun trigger.

9. For a first-time flush

solvent for 30 seconds.

: trigger the gun and flush with

D Before the first-time use

D When changing colors

D Before fluid can dry or settle out in a dormant

system.

D Before storing the system

Flush the system as follows (See Fig. 1):

1. Relieve the pressure.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 6.

2. Remove the gun air cap before flushing, and clean

it separately.

For flushing after spraying fluid

and flush with solvent until the system is

thoroughly cleaned. Open the recirculating valve

(J) slightly to clean the recirculation tube. Then

close it.

10. Repeat the procedur e with clean solvent , if

needed.

11. Lift the fluid intake tube from the fluid supply, and

trigger the gun and run the pump until air comes

from the gun.

12. Relieve the pressure.

The system is now ready to be stored or primed with

another fluid. See Priming the System on page 7.

: trigger the gun

8 308846

Page 11

Maintenance

See the separate component instruction manuals for individual component maintenance procedures.

Access to some system components requires that you remove the shields. The following steps are for shield

removal. Shield replacement is the reverse of these steps, so make sure you take notes on the proper hose

connections. Depending on your system, see the Parts Drawings on pages 11 and 13 for number call-outs.

You cannot remove the front shield assembly while the pump and shields are mounted on the stand; thus, before

you can remove the front shield assembly (1) or the back shield (25), you must do the following steps:

1. Disconnect the gun air hose from the gun air regulator.

2. Disconnect the gun fluid hose from the fluid pressure regulator nipple (28) or surge tank nipple (40).

3. Remove the screws (32), nuts (23), and washer (22) from the mounting bracket (45).

4. Lift the entire system from the stand (41)

Front Shield Assembly (1)

1. Disconnect the pump air hose from the pump air

regulator.

2. Loosen, but do not remove, the two front pump

foot screws (24).

3. Loosen, but do not remove, the two top shield

screws (32).

4. If your system has a fluid pressure regulator (40),

make sure the T–handle is horizontal.

5. Pull the front shield assembly free of the system.

1a

1g

1c

1e1f

gun air

1d

regulator

1b

pump air

regulator

1h

Front Shield Assembly Orderable Parts

Ref.

No. Part No. Description Qty .

1a 192995 SHIELD, front 1

1b 1 1 1804 REGULA TOR, air

See instruction manual 308167

1c 160430 GAUGE, pressure 2

1d 1 14362 VALVE, ball 1

1e 159840 ADAPTER 2

1f 188077 NIPPLE 1

1g 1 14369 FITTING, tube 1

1h 1 14370 FITTING, tube 1

Fig. 2

8263A

Back Shield (25)

1. Disconnect the hose (18) that runs from the fluid

pressure regulator (40) or surge tank (30) to the

fitting on the pump outlet pipe tee (5).

2. Loosen, but do not remove, the two top shield

screws (32).

3. Loosen, but do not remove, the two back pump

foot screws (24).

4. Pull the back shield free of the system. The fluid

pressure regulator (40) or surge tank (30) stays

mounted to the back shield.

Gauge Lense Covers

Clear, stick-on/peel-off lense covers are available for

the gauges. These covers protect the gauge lenses

from spray. When they get too dirty to read the

gauges, they can be peeled off, discarded, and

replaced.

NOTE: Several of these lense covers can be stacked

on the lense, and the gauge will still be clearly legible.

Then, as each lense cover gets dirty, only that one

layer will need to be peeled off.

Order as follows:

240441 for 2.5-inch gauges; package of 25

sheets, 12 lense covers to a sheet

240442 for 2-inch gauges; package of 25

sheets, 12 lense covers to a sheet

2

9308846

Page 12

Parts List

Stand-Mount Packages with Fluid Pressure Regulators

Model No. 240367, Delta Spray air spray package

Model No. 240368, Delta Spray HVLP package

Model No. 240369, PRO 3500sc electrostatic package

Model No. 240370, PRO 4500sc electrostatic package

Model No. 240371, no hoses or gun

Ref.

No. Part No. Description Qty.

1 240210 SHIELD ASSY, front

Contains 1a to 1h, shown in Fig. 2 on

page 9

1

4 111917 NIPPLE; Nylon 2

5 113718 TEE, pipe 1

6 113222 CONNECTOR, male 1

7 114363 VALVE, ball; sst 1

8 111811 CONNECTOR, male 1

9 114370 FITTING, tube, quick-connect 1

10 112903 NUT, hex 1

12 D31331 PUMP, Husky 307

See instruction manual 308553

1

13 112899 WASHER, lock 1

16 054175 HOSE; Nylon 10 in.

17 054139 TUBE; Nylon 11.5 in.

18 054188 TUBE; PTFE R 10 in.

19Y 189220 LABEL, warning 1

21 103473 STRAP, tie, wire 3

22 104123 WASHER, spring lock 6

23 102025 NUT, hex 6

24 100021 SCREW, cap, hex head 4

25 192996 SHIELD, back 1

26 104029 LUG, grounding 1

27 113521 ELBOW, street 1

28 189436 NIPPLE 1

29 192994 HANDLE, shield 1

30 112789 WASHER, flat 2

31 100014 SCREW 2

32 100333 SCREW, cap, hex head 4

33 114369 FITTING, tube, quick-connect 1

34 193251 LABEL, product

Models 240367, 240368, and 240371

1

193252 LABEL, product

Models 240369 and 240370

1

37 238909 GROUND WIRE & CLAMP ASSY 1

Ref.

No. Part No. Description Qty.

38 239542 GUN, Delta Spray, air spray

Model 240367

See instruction manual 308742

239561 GUN, Delta Spray, HVLP

Model 240368

See instruction manual 308741

222300 GUN, PRO 3500sc, electrostatic

Model 240369

See instruction manual 307912

224200 GUN, PRO 4500sc, electrostatic

Model 240370

See instruction manual 308131

39 240421 HOSE ASSY, air spray/HVLP;

25 ft (7.6 m)

240368

Models 240367 and

240425 HOSE ASSY, PRO gun;

25 ft (7.6 m)

240370

Models 240369 and

40 236449 REGULATOR, fluid pressure;

0–30 psi (0–207 kPa, 0–2 bar)

Model 240368

See instruction manual 308325

236450 REGULATOR, fluid pressure;

0–100 psi (0–0.6 MPa, 0–7 bar)

Models 240367 and 240369 to 240371

See instruction manual 308325

41 218743 STAND, pump 1

42 108175 PLUG 4

43 109534 STRAINER, suction line 1

44 111864 CONNECTOR, male 2

45 188169 BRACKET 1

46 054139 TUBE, suction 30 in.

47 054175 TUBE, recirculation 32 in.

49 240464 WIRE, ground,

PRO packages

see Note in drawing.

1

1

1

1

1

1

1

1

1

10 308846

Y Extra Warning labels are available for free.

Page 13

Parts Drawing

Stand-Mount Packages with Fluid Pressure Regulators

Model No. 240367, Delta Spray air spray package

Model No. 240368, Delta Spray HVLP package

Model No. 240369, PRO 3500sc electrostatic package

Model No. 240370, PRO 4500sc electrostatic package

Model No. 240371, no hoses or gun

Grounding Detail

26

32

37

40

13

29

27

18

1

34

17

41

17

24

16

33

32

12

9

16

22

23

45

10

22,

23

46

44

18

19

4

21

28

25

24

6

5

4

7

8

49

Note: For PRO packages only, terminal

end of ground wire (49) is assembled

47

between nut and lockwasher on handle

of recirculation valve (7). Bare end of

ground wire is assembled to grounding

lug (26) on pump (42).

30

31

42

39

38

44

43

38

222300

shown

39

8047A

11308846

Page 14

Parts List

Stand-Mount Packages with Surge Tanks

Model No. 240379, Delta Spray air spray package

Model No. 240380, Delta Spray HVLP package

Model No. 240381, no hoses or gun

Ref.

No. Part No. Description Qty.

1 240210 SHIELD ASSY, front

Contains 1a to 1h, shown in Fig. 2 on

page 9

3 054139 TUBE, suction 30 in.

4 111917 NIPPLE; Nylon 2

5 113718 TEE, pipe 1

7 114363 VALVE, ball; sst 1

8 111811 CONNECTOR, male 1

9 114370 FITTING, tube, quick-connect 1

10 112903 NUT, hex 1

12 D31331 PUMP, Husky 307

See instruction manual 308553

13 112899 WASHER, lock 1

16 054175 HOSE; Nylon 10 in.

17 054139 TUBE; Nylon 11.5 in.

18 054188 TUBE; PTFE R 10 in.

19Y 189220 LABEL, warning 1

21 103473 STRAP, tie, wire 3

22 104123 WASHER, spring lock 6

23 102025 NUT, hex 6

24 100021 SCREW, cap, hex head 4

25 192996 SHIELD, back 1

26 104029 LUG, grounding 1

1

1

Ref.

No. Part No. Description Qty.

27 114456 FITTING, elbow, male 2

28 054175 TUBE, recirculation 32 in.

29 192994 HANDLE, shield 1

30 111911 STRAINER, line 1

31 106285 BOLT, “U” 2

32 100333 SCREW, cap, hex head 4

33 114369 FITTING, tube, quick-connect 1

34 193253 LABEL, product 1

37 238909 GROUND WIRE & CLAMP ASSY 1

38 239542 GUN, Delta Spray, air spray;

25 ft (7.6 m)

See instruction manual 308742

239561 GUN, Delta Spray, HVLP;

25 ft (7.6 m)

See instruction manual 308741

39 240421 HOSE ASSY, air spray/HVLP 1

40 188089 NIPPLE 1

41 218743 STAND, pump 1

42 108175 PLUG 4

43 109534 STRAINER, suction line 1

44 111864 CONNECTOR, male 2

45 188169 BRACKET 1

Y Extra Warning labels are available for free.

Model 240379

Model 240380

1

1

12 308846

Page 15

Parts Drawing

Stand-Mount Packages with Surge Tanks

Model No. 240379, Delta Spray air spray package

Model No. 240380, Delta Spray HVLP package

Model No. 240381, no hoses or gun

1

34

Grounding Detail

26

13

10

17

17

24

41

16

33

32

12

9

16

37

22

23

45

22,

23

31

30

40

32

19

18

27

4

5

44

21

3

4

7

8

28

27

18

25

24

29

32

42

44

43

38

39

8048A

13308846

Page 16

Accessory Fluid Filter Kit

Fluid Filter Kit 240440

Ref.

No. Part No. Description Qty.

101 114361 FILTER, fluid 1

102 113322 CONNECTOR, male 1

103 054188 TUBE; PTFE;R3/8” O.D. 8 in.

104 113534 ELBOW, male x female 2

105 111917 NIPPLE; Nylon 1

The Fluid Filter Kit, listed above, can be installed to

filter fluid drawn by the suction tube after it comes out

of the pump. Install the Fluid Filter Kit as follows (see

Fig. 3):

{ To avoid sharp bends in the tube, you may have to cut

it to a shorter length.

} Apply Graco Thread Sealer, or LoctiteR 567, or equiv-

alent to male threads.

Y For initial installation, make sure the dome is firmly

hand tightened onto the filter body . Do not use a

tool. During subsequent service, hand tighten

more firmly to prevent drips.

1. Apply thread sealant (specified in Fig. 3) to all

male threads in this kit.

2. Remove the male connector (6) and the PTFE R

tube (18) that connect to the top of the tee (5).

See the Parts drawing on page .

3. Thread the nipple (105) into the female threads of

the elbow (104).

4. Thread the nipple (105), with the elbow (104)

attached to it, into the tee (5).

5. Thread the fluid filter (101) onto the male threads

of the elbow (104).

6. Thread the male connector (102) into the fluid filter

(101).

7. Turn the fluid filter/male connector assembly

towards the elbow (27). This makes connecting

the tube (103) in step 8 easier.

8. Cut the PTFERtube (103) to the proper length,

and install it to run from the male connector (102)

to the elbow (27).

Fig. 3

27

103{

103}

102}

101Y

104}

105}

5

8114A

14 308846

Page 17

Accessory Suction Tube Kit

Suction Tube Kit 240465

Ref.

No. Part No. Description Qty.

201 232692 KIT ASSEMBLY, suction tube 1

202 193411 NIPPLE 1

203 193459 TUBE, recirculation 1

204 103473 TIE, wire 5

The Suction Kit, listed above, can be installed for

drawing fluid from a container that is not directly under

the unit. Install the Suction Kit as follows (see Fig. 4):

1. Remove the following parts from the stand unit:

recirculation tube (28), suction tube (3), male

connector (44), and suction line strainer (43). See

the Parts Drawing on page 13.

2. Apply thread sealant (specified in Fig. 4) to the

threads of the nipple (202).

3. Thread the nipple (202) into the pump inlet.

4. Thread the fitting of the suction tube assembly

(201) onto the nipple (202).

5. Install the new, longer recirculation tube (203) in

place of the old one.

6. Bundle the new suction tube (201) and

recirculation tube (203) with the wire ties (204).

} Apply Graco Thread Sealer, or LoctiteR 567, or equiv-

alent to threads.

202}

201

203 204

Fig. 4

8172A

7. Route the new tubes into the remote fluid

container.

15308846

Page 18

Technical Data

Category Data

Maximum fluid working pressure 100 psi (0.7 MPa, 7 bar)

Maximum incoming air pressure 100 psi (0.7 MPa, 7 bar)

Maximum operating temperature 120_ F (49_ C)

Gun See separate gun instruction manual.

Pump See separate pump instruction manual.

Fluid pressure regulator See separate fluid pressure regulator instruction manual.

Air pressure regulators See separate air pressure regulator instruction manual.

Wetted parts: fluid hoses for Delta guns nylon, stainless steel

Wetted parts: fluid hoses for PRO guns nylon, nickel-chrome plate

Wetted parts: other fluid hoses and tubing nylon, PTFE R

Wetted parts: fluid fittings nylon, acetal, 304/316 stainless steel

Weight (without hoses or gun):

packages with fluid pressure regulator Approx. 30 lb (14 kg)

packages with surge tank Approx. 28 lb (12.5)

Sound data:

Sound power level*

at 70 psi 0.48 MPa, 4.8 bar) and 115 cpm

Sound pressure level

at 70 psi 0.48 MPa, 4.8 bar) and 115 cpm

68 dB(A)

81.5 dB(A)

* Sound power level was measured per ISO Standard 3744.

TeflonR is a registered trademark of the DuPont Corporation.

16 308846

Page 19

34.0 in.

(864 mm)

Dimensions

17.5 in.

(445 mm)

16.5 in.

(419 mm)

8171A

17308846

Page 20

Notes

18 308846

Page 21

Notes

19308846

Page 22

Manual Change Summary

This manual went from Rev. A to Rev. B to make the following changes:

D Model No. 240371 (regulated packages with no hoses or gun) and Model No. 240381 (surge tank packages with

no hoses or gun) are added. See the front cover and the Parts Lists on pages 10 and 12.

D Part No. changes are made in the Parts Lists on pages 10 and 12: The pump foot screws (Ref No. 24) are

changed from 104119 to 100021.

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in

accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER W ARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property , or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer . Graco wi ll provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty , the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Phone Number

TO PLACE AN ORDER

, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–367–4023 T oll Free

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Foreign Offices: Belgium, England, Korea, France, Germany , Hong Kong, Japan

Sales Offices: Minneapolis, Detroit

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

www.graco.com

PRINTED IN USA 308846 March 1998, Revised January 2000

20 308846

Loading...

Loading...