Page 1

INSTRUCTIONS–PARTS LIST

308718

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

– For Water-Based Materials Only –

ELECTRIC TEXTURE SPRAYER WITH COMPRESSOR

TexSprayt Compact HP

100 psi (0.7 MPa, 7 bar) Maximum Working Pressure

Power Model Description

120V,

60 Hz

231780 Sprayer Model 231801, Series B

with 1-in. fluid hose, 3/8-in. air hose,

and Trigger Gun

231782 Sprayer Model 231801, Series B

with 1-in. fluid hose, 3/8-in. air hose,

and Flex Gun

First choice when

quality counts.

t

Rev. F

240V,

50 Hz

231783 Sprayer Model 231801, Series B

with 1-in. fluid hose, 3/8-in. air hose,

and 3-ft Pole Gun

231788 Sprayer Model 231803, Series B

with 1-in. fluid hose, 3/8-in. air hose,

and Trigger Gun

231790 Sprayer Model 231803, Series B

with 1-in. fluid hose, 3/8-in. air hose,

and Flex Gun

231791 Sprayer Model 231803, Series B

with 1-in. fluid hose, 3/8-in. air hose,

and 3-ft Pole Gun

Model 231780 shown

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

7068B

ECOPYRIGHT 1997, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Identification and Function 4. . . . . . . . . . . .

Preparation 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spray Techniques 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shutdown and Cleanup 14. . . . . . . . . . . . . . . . . . . . . . . .

Pump Maintenance 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing and Reinstalling Compressor 20. . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Removing and Inspecting Cooler 22. . . . . . . . . . . . . . . .

Wiring Diagram 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Warranty 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 28. . . . . . . . . . . . . . . . . . . . . . . . . .

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

INSTRUCTIONS

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

D Do not expose the system to rain. Always store the system indoors.

D Do not alter or modify this equipment. Use only genuine Graco parts.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated component in your system. This

equipment has a 100 psi (0.7 MPa, 7 bar) maximum working pressure at 100 psi (0.7 MPa,

7 bar) maximum air pressure.

D To reduce the risk of serious injury, including electric shock and splashing fluid in the eyes, follow

the Pressure Relief Procedure on page 5 before checking or repairing the compressor.

D Do not use hoses to pull equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 55_C (130_F) or below –40_C (–40_F).

D Do not lift pressurized equipment.

2 308718

Page 3

WARNING

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

Pipe and dispose of exhaust air safely, away from people, animals, and food handling areas.

Never directly inhale compressed air. Compressed air may contain toxic vapors.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

The system is for use only with water-based materials. Use fluids compatible with the

equipment wetted parts. Refer to the Technical Data section of all equipment manuals. Read the

fluid and solvent manufacturer’s warnings.

Ground the equipment. See Grounding and Electrical Requirements on page 6.

If there is any static sparking or you feel an electric shock while using this equipment, stop

spraying immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

Keep the work area free of debris, including solvent, rags, and gasoline.

Locate the sprayer at least 20 ft (6.1 m) away from any explosive vapors, due to arcing parts.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

CLEANING SOLVENT HAZARD WITH PLASTIC PARTS

Use only compatible solvents to clean plastic structural or pressure-containing parts. Many solvents

can degrade plastic parts to the point where they could fail. Such failure could cause serious injury or

property damage. See the Technical Data section on page 27 in this instruction manual and in all

other equipment manuals. Read the fluid and solvent manufacturer’s warnings.

3308718

Page 4

Component Identification and Function

A Air outlet Provides quick disconnect connection for air supply to spray gun

B Pump outlet fitting Provides connection for hose and fluid supply to spray gun

C Air pressure regulator Adjusts air pressure to control air pressure to pump

D ON/OFF switch Power switch that controls 120/240V AC power to sprayer

E Compressor Open frame AC motor, 1 phase, with two-cylinder, oil-less, single-stage

air compressor

F Pump Pressurizes fluid to be sprayed through spray gun

G Cooler Reduces temperature of air from compressor

H Spray gun Uses compressor air to break up and spray texture material

J Hopper Holds texture material;12 gallon (45 liter) maximum capacity

K Air filter Filters incoming air to the compressor

L Material screen Filters material to the pump

M Auxiliary air compressor port Provides connection to replacement or supplemental air compressor

N Gun air valve Shuts off air supply to spray gun

O Air line drain valve Allows air line moisture accumulation to be drained

closed

C

open

N

7136A

H

J

L

F

B

A

G

K

O

M

D

E

7069B

Fig. 1

4 308718

Page 5

Preparation

Compressor Break-in

The first time you use the system, run the compressor

under no load for 15 minutes to break it in, improve its

performance, and lengthen its life.

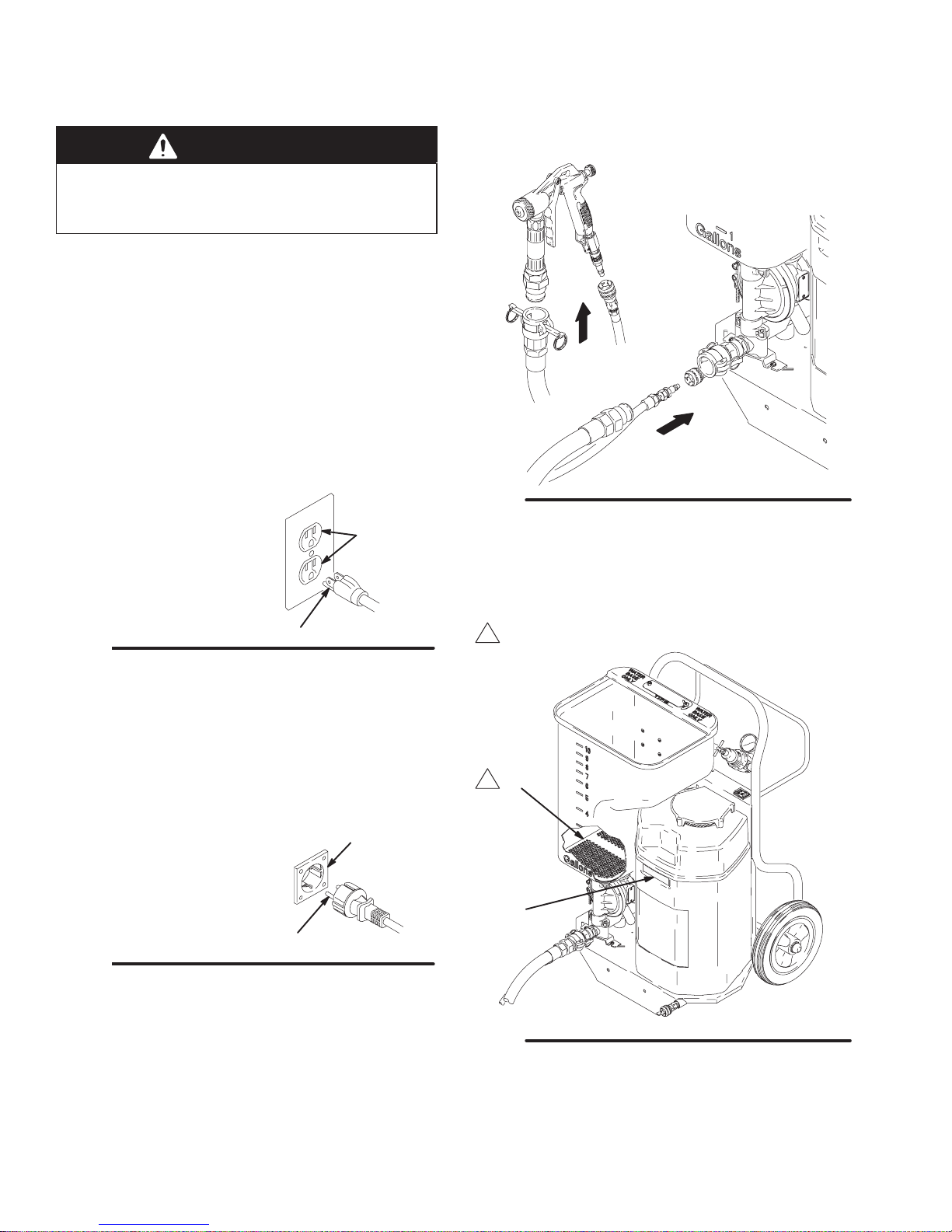

1. Connect the air hose to the air outlet (A) and to the

gun air inlet. Open gun air valve (423), and turn air

restrictor valve (424) all the way to the + position.

See Fig. 2.

WARNING

PRESSURIZED EQUIPMENT HAZARD

The system pressure must be manually relieved to

prevent the system from starting or spraying

accidentally. To reduce the risk of an injury from

accidental spray from the gun, splashing fluid, or

moving parts, follow the Pressure Relief

Procedure whenever you

Are instructed to relieve the pressure

Stop spraying

Check or service any of the system equipment

Install or clean the spray nozzle

Pressure Relief Procedure

423

(shown

open)

424

Fig. 2

2. Turn the ON/OFF switch (D) ON. Run the system

for 15 minutes. Turn the switch OFF. See Fig. 3.

7132A

A

7070B

1. Shut off the system.

2. Trigger the gun, and spray the material back into

the hopper.

3. Open the gun air valve (handle parallel with valve

body).

4. Unplug the electrical power cord.

5. Place a rag over the pump outlet fitting (B in

Fig. 1), and slowly open the cam locks to relieve

residual pressure.

Fig. 3

D

7078B

5308718

Page 6

Preparation

Grounding and Electrical Requirements

WARNING

Improper installation or alteration of the grounding

plug will result in a risk of electric shock, fire or

explosion that could cause serious injury or death.

Extension Cords

Use only an extension cord with an undamaged,

3-prong plug.

For up to 25 ft (7.6 m) cord, use 3-wire, 12 AWG

(1.5 mm2) minimum.

For 25 to 50 ft (7.6 to 15.2 m) cords, use 3-wire,

10 AWG (2.5 mm2) minimum.

120V AC Systems

This equipment requires a 120V AC, 60 Hz, 15A

circuit with a grounding receptacle. See Fig. 4.

grounded

outlets

System Setup

1. Connect the hoses and gun as shown See Fig. 6.

Fig. 6

2. Be sure the air filter (K) and the material screen (L)

are in place. See Fig. 7.

7072B

Fig. 4

grounding prong

Do not alter the ground prong or use an

ungrounded adapter.

A maximum length of 25 ft, 12 AWG or 50 ft,

10 AWG extension cord may be used.

240V AC Systems

This equipment requires a 240V AC, 50 Hz, 16A

circuit with a grounding receptacle. See Fig. 5.

grounded

outlet

grounding prong

Fig. 5

Do not alter the ground prong or use an

ungrounded adapter.

A maximum length of 8 m, 1.5 mm2 or 15 m,

2.5 mm2 extension cord may be used.

3. Plug the power cord into a properly grounded

outlet.

1

Located inside hopper

L

1

K

Fig. 7

07073B

6 308718

Page 7

Preparation

Auxiliary Air Compressor

An external air compressor may be connected

(adapter included) to the auxiliary air compressor port

(L) to supplement or replace the internal air

compressor of the TexSpray. This may be useful when

Additional air is needed to break up hard-to-spray

materials

When the job site does not have the proper electric

service, but a gasoline-powered compressor is

available

WARNING

Overpressurizing the system may cause component rupture and result in serious injury.

To reduce the risk of overpressurizing the system, do

not use a compressor with an output pressure greater

than 100 psi (70 kPa, 7 bar), or with a delivery greater

than 6.8 scfm at 90 psi (0.19 m3/min. at 60.3 kPa, 6.3

bar).

Removing and Installing the Hopper

1. To remove the hopper (J), loosen the knob (P) until

about 1 in. of thread shows. Lift the hopper straight

up off the unit. See Fig. 8.

2. To install the hopper, position the hopper drain

over the pump inlets while tilting the hopper very

slightly forward. As you engage the inlets,

straighten the hopper and push down. Visually

inspect the pump inlets to be sure the hopper is

fully engaged. Tighten the knob (P). See Fig. 8.

J

P

Hose Size and Lengths

The system comes with a hose set consisting of a

1-in. ID x 25-ft (25 mm x 7.6 m) fluid hose and a

3/8-in. ID air hose. The 1-in. hose set includes an

adapter hose between the gun and main hose. See the

Parts List on page 25.

Use the shortest length possible when spraying.

Increasing hose length decreases sprayer

performance. Do not use more than 75 ft (23 m) of

fluid hose.

Fig. 8

7071A

7308718

Page 8

Preparation

Operation Characteristics

Always start the system with the compressor air

relieved.

How to relieve compressor pressure: Be sure

the gun air valve (423) and air restrictor valve (424)

are open. This relieves compressor air every time

you shut off the system. See Fig. 9.

Air bleeds from the gun nozzle when the gun air

valve (423) is open. See Fig. 9. You may close the

valve to stop the air, or you can leave it open at all

times except while priming the system. See Spray

Techniques on pages 12 and 13 for more gun

characteristics.

423

(shown open)

A compressor unloader valve (30) with two

pressure relief valves (30d) is located under the

compressor guard (16). Air escapes from the valve,

causing a popping sound, when air flow at the gun

is too restricted. The valve resets automatically

when the air flow is increased. See Fig. 10.

If air exhausts through the pump muffler or the

pump starts and then stops, see texture pump

instruction manual 309009.

Always have the fluid hose installed when there is

material in the hopper. If the hose is removed, the

hopper will drain out through the pump.

WARNING

The motor has a thermal overload switch that shuts

down the motor if it overheats.

To reduce the risk of serious bodily injury due to the

system restarting unexpectedly, always turn the

ON/OFF switch (D) OFF if the motor shuts down.

See Fig. 3 on page 5.

Fig. 9

Fig. 10

424

16

7132A

30

30d

7074A

CAUTION

Damage to the power cord could result from

uninterrupted operation. Do not operate sprayer at

maximum pressure for more than 1 hour in any

2-hour period.

8 308718

Page 9

Preparation

Wetting the Hose Before Pumping Texture

Material

Wet the inside of the hose before each use to flush out

sediment and to prevent the texture material from

packing out the hose.

1. The hopper (J) capacity is 12 gallons (45 liters).

Pour a gallon (3.8 liters) of clean water into the

hopper. See Fig. 12 on page 10.

2. Close the gun air valve (423); the system primes

easier if no air is supplied to the gun. See Fig. 11.

3. Turn the ON/OFF switch (D) ON. Aim the gun into

the hopper (J), and trigger the gun to circulate the

water for a few minutes and to wet the inside of

the fluid hose. See Fig. 12.

4. Trigger the gun into a pail to lower the water to the

hopper strainer (L) level. See Fig. 12.

5. Turn the ON/OFF switch (D) OFF.

6. Open the gun air valve (423) to relieve the

compressor air. See Fig. 11.

open

423

closed

Mixing the Material

CAUTION

This system is designed for use with only certain

types of material. Any other use could seriously

damage the unit.

Do not use any solvent-based materials. Use

only water-based materials.

Use only simulated acoustic and gypsum-based

wall texture materials in this system.

Do not spray cementious materials, which will

damage the pump.

Proper material mixture is essential. The pump will

not operate if the material is too thick.

NOTE: Mix the material in a separate container and

pour it into the hopper for best results.

Slowly add one bag of texture material to clean water

as instructed on the bag instructions. Agitate to a

smooth, lump-free consistency. Thin the material as

needed before pouring it into the hopper. Material

must be mixed thoroughly to a consistency that

immediately folds back in as you draw your finger

through the surface of the material. For the best

results, do not use partial bags of material.

Fig. 11

7136A

9308718

Page 10

Startup

Prime the System

1. Fill the hopper (J) with the prepared texture

D

J

material.

2. Install a tip. See the Tip Selection Chart on

page 12.

L

1

1

Located inside hopper

Fig. 12

7073B

3. Open the gun air valve (423) to be sure air

pressure is relieved, then close it. The system

primes easier if no air is supplied to the gun.

4. Be sure there are no kinks in the hose, which

restricts fluid flow.

NOTE: If spraying a simulated acoustic and coarse

aggregate material, disconnect the hose at the gun,

prime the pump and hose, and circulate material back

into the hopper for 10 seconds. Turn off the pump.

Install the gun and tip.

5. Turn the ON/OFF switch (D) ON. Trigger the gun

into a pail. When texture material appears at the

tip, move the gun to the hopper and circulate until

there is a solid stream of texture material.

6. See Spray Techniques on pages 12 and 13 for

proper spray pattern with pump and gun

adjustments.

10 308718

Page 11

Notes

11308718

Page 12

Spray Techniques

Tip Selection Chart

Application Tip Orifice

Fog 1/8 in. high

Simulated

acoustic

3/16 in.

(fine, for small

confined areas)

1/4 in.

(fine to medium)

5/16 in.

(coarse)

Orange peel 1/8 to 3/16 in. medium to

Splatter coat 1/4 to 5/16 in. low to

Knockdown 5/16 in. low

1

Control air volume with the gun air flow valve (424).

2

For more material volume, try a larger-orifice tip.

2

Air Volume

medium to

high

high

medium

Adjusting the System

1

Sufficient fluid output (volume and pressure) and good

atomization require testing to balance the compressor

air to the gun and pump and proper tip selection. Keep

in mind these important points when adjusting the gun:

Read all of pages 12 and 13 before spraying.

Start the sprayer with the gun air flow valve (424) at

its maximum setting (fully +). If needed, slowly

decrease the gun air flow until you get a good spray

pattern. Use the minimum amount of air at the

spray gun to achieve the proper spray pattern and

to minimize bounce back.

– Test the spray pattern on cardboard. Hold the

gun 18 to 30 in. (457 to 762 mm) from the

surface. Use this spraying distance for most

applications.

– Overlap each stroke 50% in a circular motion.

Select the proper tip for your application. See the

Tip Selection Chart at left. Consider the size of

aggregate in the material and the coarseness of the

spray pattern. Remember, the larger the tip, the

heavier the pattern.

All spraying adjustments are made at the gun.

Material pressure and flow rate adjustments are

made at the regulator.

The compressor provides air to the gun and the

pump; thus, the more air you supply to the gun, the

less that is available for the pump.

– Turning the air flow valve (424) toward (+)

increases air flow through the gun, which

decreases texture material flow through the

pump.

– Turning the air flow valve (424) toward (–)

decreases air flow through the gun, which

increases texture material flow through the

pump.

12 308718

Page 13

Spray Techniques

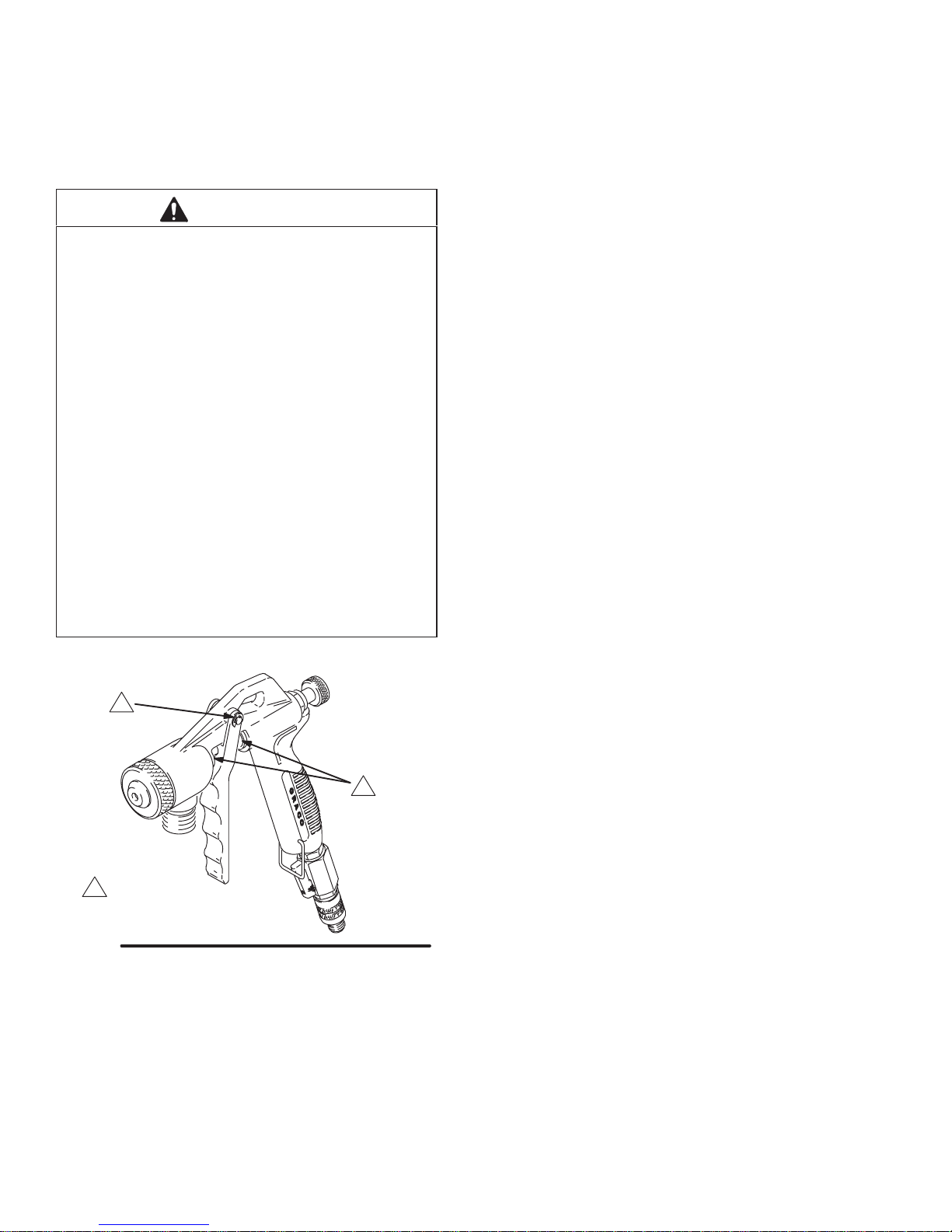

To Get Less Material

Try any one or a combination of these methods:

Screw in the gun fluid regulator knob (418).

Use a smaller tip.

Reduce pump pressure. Use the regulator.

To Get More Material

Try any one or a combination of these methods:

Turn the air flow valve (424) to decrease (–).

Unscrew the fluid knob (418) to increase trigger

travel.

Note: Maximum trigger travel occurs when trigger

bail (401) can hold trigger in open position. Fig. 13.

Use a shorter hose.

Use a thinner material mixture.

Try a larger-orifice tip.

Increase pump pressure (use the regulator).

Preventing Material Surge

To prevent material surge at the beginning of a spray

pattern, slowly squeeze the trigger to the fully triggered

position while moving the gun quickly.

For Continuous Spraying

Use the trigger bail (401) to hold the trigger open to

reduce operator fatigue.

Check Material Consistency Periodically

Check and thin the material as needed to maintain the

proper consistency. The material may thicken as it sits

and slow down production or affect the spray pattern.

418

IN

OUT

CAUTION

Turning the knob (418) out too far will remove the

knob and the gun will not shut off when the trigger is

released.

418

401

423

Fig. 13

IN

OUT

424

7134A

Fig. 14

424

401

423

7133A

13308718

Page 14

Shutdown and Cleanup

NOTE: Keep the pump and hose clean when switching

between texture, knockdown, and orange peel

applications. A dirty pump can release a piece of

texture into the finish.

CAUTION

To keep the unit in good operating condition, always

clean it thoroughly and prepare it properly for

storage, even if only for the night. Pay particular

attention to these areas:

Keep the pump wet during non-use to help

prevent contaminants from drying inside the

pump.

Clean the sponge filter at least daily. A dirty filter

allows contaminates into the compressor and

eventually into the pump, resulting in poor

performance and damage.

Removing the material hose will allow the pump

to drain too rapidly; the material hose must

remain connected to keep the pump wet.

Oil the gun daily. See Fig. 15.

Oil the pump air inlet. See Maintenance in

texture pump instruction manual 309009.

See Fig. 16 and Fig. 17

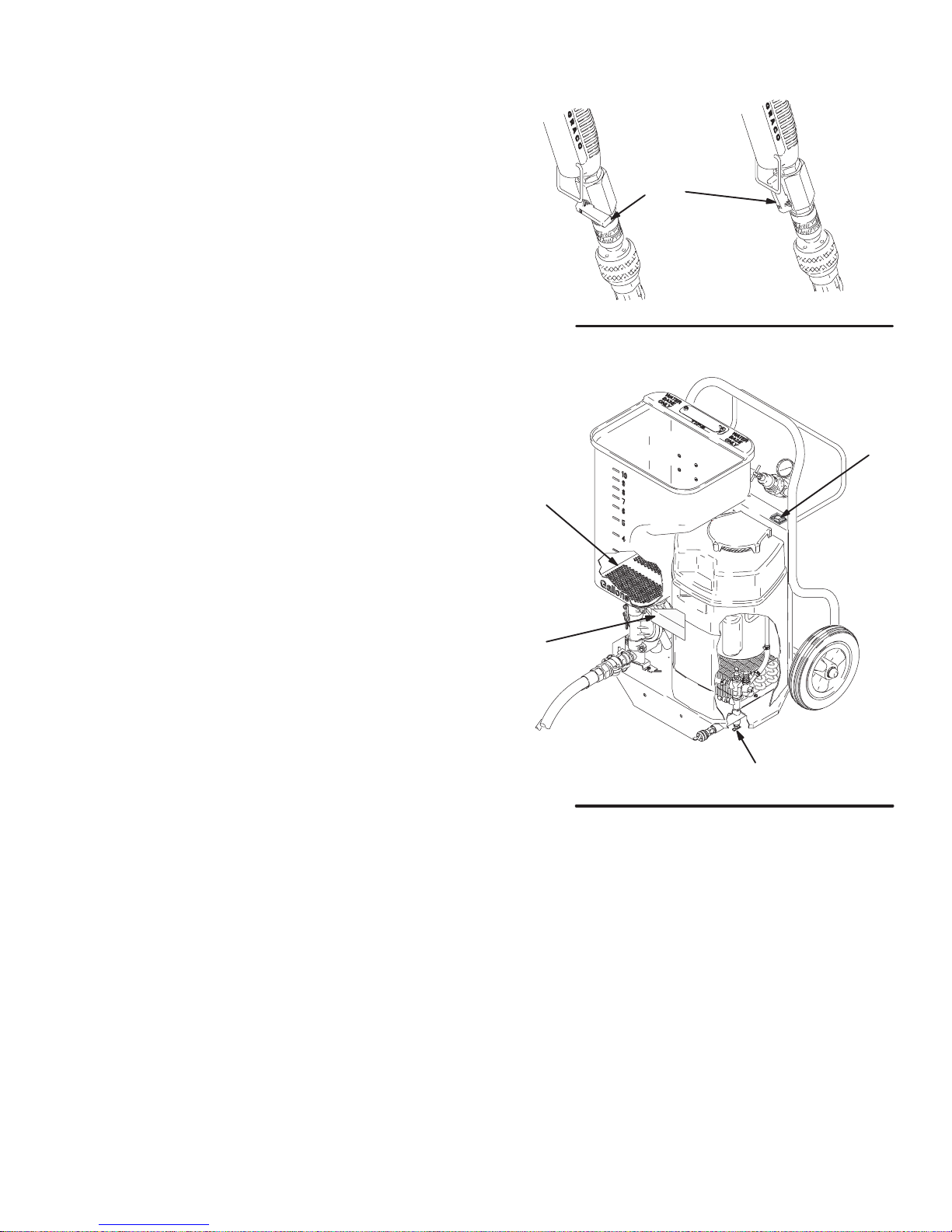

1. Be sure the compressor pressure is relieved by

opening gun air valve (423).

2. Close the gun air valve, and turn the ON/OFF

switch (D) ON.

3. Trigger the gun into a pail to lower the fluid to the

hopper strainer (L) level.

4. Half fill the hopper (J) with clean water. Clean the

inside of the hopper with a brush, if needed.

NOTE: The hopper can be removed for cleaning.

See page 7.

5. Trigger the gun into a pail until most of the texture

material is pumped out.

6. Fill the hopper with clean water.

7. Start the sprayer. Spray half the water into a pail.

Trigger the gun into the hopper to circulate the

remaining water for a few minutes.

8. Trigger the gun into the pail to empty the hopper

and the hose.

9. Turn the ON/OFF switch (D) OFF. Open the gun

air valve (423) to relieve compressor pressure.

1

Fig. 15

1

1

Oil here

14 308718

Page 15

Shutdown and Cleanup

10. Keep pump wet during non-use. Pour 12 oz.

(360 ml) of clean water into the hopper drain.

NOTE: In cold weather, store the system where it

will not freeze. If it does freeze, thaw it thoroughly

before using it.

423

open

11. Remove the air filter (K). Wash it thoroughly with

soap and water, and reinstall it.

12. Clean and dry the gun. Oil the gun daily with a few

drops of SAE–10 light oil at the points indicated in

Fig. 15.

13. When the unit cools, rinse the cooler with plain

water.

14. Drain the frame air line after each use as follows:

a. Open the drain cock valve (S).

b. Turn the ON/OFF switch (D) ON.

c. Rock the sprayer back and forth slightly to

drain any moisture in the air line.

d. Turn the ON/OFF switch (D) OFF.

e. Close the drain cock valve (S).

closed

Fig. 16

L

K

7136A

D

Fig. 17

S

7092B

15308718

Page 16

Pump Maintenance

For pump maintenance, troubleshooting, and repair, see texture pump instruction manual 309009.

Troubleshooting

See Pressure Relief Procedure on page 5.

PROBLEM CAUSE SOLUTION

Compressor not starting Trapped air pressure Relieve air pressure by connecting

air hose and opening gun air valve.

Improper power supply Connect to power supply rated for

your sprayer.

Tripped thermal overload in motor Check extension cord. Allow unit to

cool down and try again.

See Grounding and Electrical

Requirements on page 6.

Note: Remove extension cord and

plug unit directly into outlet. If unit

operates correctly, this indicates an

extension cord problem.

Clean filter, air cooler, and cooling

fan. Allow unit to cool down and try

again.

Unloader stuttering, unloading

too early, or unloading too late.

Damaged unloader Replace.

Have motor serviced.

No material output from pump Not enough air pressure to pump Shut off air at the gun, and increase

air pressure to the pump to

maximum. Turn regulator clockwise

to increase.

Material too thick Thin the material. Material must be

mixed thoroughly to a consistency

that immediately folds back in as

you draw your finger through the

surface of the material.

16 308718

Page 17

Troubleshooting

PROBLEM CAUSE SOLUTION

No material output from pump

(continued)

Stalled air valve Reset the pump as follows:

1. Open air to the gun.

2. Turn the unit off.

3. Turn the ON/OFF switch ON,

and trigger the gun into the

hopper until there is a solid

stream of texture material.

If pump continues to stall:

Thin the material. See

too thick

Clean hose and gun. See below.

Try a 1–1/4 in. hose. See below.

See Troubleshooting in texture

pump instruction manual

309009.

Plugged gun or nozzle Relieve pressure, remove gun from

material hose, and cycle pump.

NOTE: A plugged gun or nozzle

may cause the hose and pump to

plug. If necessary, flush hose and

pump with clean water before

cycling material through the hose

with the gun removed.

on page 16.

Material

Plugged hose, or hose too small Relieve pressure. Flush hose with

clean water, or try a 1–1/4 in. hose.

Leaky or damaged duck bills valves

in pump.

NOTE: Under normal use, the duck

bill valves and diaphragms will wear

out at 20,000 gallons. If the material

being sprayed has a stone aggregate, the expected life is 3,000 to

4,000 gallons.

Pump in need of repair See texture pump instruction

Pulsing or surging material Triggering too fast Slowly squeeze trigger to fully open

Leaky or damaged duck bill valves Clean and inspect duck bill valves.

Clean and inspect duck bill valves.

NOTE: Texture Pump Duckbill

V alve Repair Kit 241262 is available

and can be ordered separately.

manual 309009.

position while moving gun quickly in a

circular motion.

NOTE: Texture Pump Duckbill

V alve Repair Kit 241262 is available

and can be ordered separately.

17308718

Page 18

Troubleshooting

PROBLEM CAUSE SOLUTION

Speed of application too slow

Pattern too fine or too much

overspray

Pattern too coarse Material too thick Thin material. Material must be

Not enough air pressure to pump Shut off air at the gun, and increase

air pressure to the pump to maximum. Turn regulator clockwise to

increase.

Material too thick Material must be mixed thoroughly

to a consistency that immediately

folds back in as you draw your finger through the surface of the ma-

terial.

Nozzle too small Increase nozzle size.

Hose plugged or too small. Relieve pressure. Clean hose, or try

a 1–1/4 in. hose.

Leaky or damaged duck bill valves Clean and inspect duck bill valves.

NOTE: Texture Pump Duckbill

V alve Repair Kit 241262 is available

and can be ordered separately.

Pump in need of repair See texture pump instruction

manual 309009.

Material too thin Thicken material. Material must be

mixed thoroughly to a consistency

that immediately folds back in as

you draw your finger through the

surface of the material.

Air pressure at gun too high Decrease air to gun at gun fitting.

Fluid delivery too low Increase nozzle size.

Increase air pressure to pump, or

decrease air to gun at gun fitting.

Turn fluid knob out on gun. See

Spray Techniques on pages 12

and 13.

mixed thoroughly to a consistency

that immediately folds back in as

you draw your finger through the

surface of the material.

Air pressure at gun too low Increase air to gun at gun fitting.

Fluid delivery too high Decrease nozzle size.

Decrease air pressure to pump, or

increase air to gun at gun fitting.

Turn fluid knob in on gun. See

Spray Techniques on pages 12

and 13.

18 308718

Page 19

Notes

19308718

Page 20

Removing and Reinstalling Compressor

See Fig. 18

WARNING

HOT SURFACE HAZARD

Be sure the compressor duct work is

cool before removing it. If the sprayer

was operated recently, it will be very hot

and can cause burns.

NOTE: Clean the cooler whenever the compressor is

serviced.

Removing Compressor

1.

2. Remove the hopper.

Relieve the pressure.

See Pressure Relief

Procedure on page 5.

3. Remove the pump foot screws on one end of the

pump (35), and loosen the foot screws on the

other end of the pump. Move the pump out of the

way.

4. Remove the filter cover (20).

5. Remove the two screws (7) and the shroud (18a).

Remove and clean the air filter (K).

6. Remove the compressor guard (16).

7. Remove grounding screw (36) and the two leads

(U) from the bottom of the switch (9).

20

18a

K

9

7

35

76

36

U

18

16

Fig. 18

20 308718

pump foot screws

Page 21

Removing and Reinstalling Compressor

See Fig. 19

8. Tip the TexSpray onto its back.

9. Loosen the hose clamps (28), and pull out the

hose (31).

10. Remove the two screws (76) and saddle-mount

cups (77).

11. Place a piece of cardboard between the

compressor (18) and the cooler (27) to protect the

cooler from damage during step 12.

12. Carefully remove the compressor wires while lifting

the compressor (18) up and away from the cart

frame.

If you are rebuilding the compressor (18), see

DeVILBISS manual OEM–4000–A.

Graco offers repair kits for the two-cylinder

compressor. The repair kits are listed in Accessories

on page 26.

NOTE: For repair assistance or for compressor

service center locations, call your Graco distributor.

Reinstalling Compressor

Reassemble the TexSpray in the reverse order of

Removing Compressor.

NOTE: See the wiring diagram on page 25.

A

28

18

27

31

76

77

A

Fig. 19

7081B

21308718

Page 22

Removing and Inspecting Cooler

WARNING

HOT SURFACE HAZARD

Be sure the compressor duct work is

cool before removing it. If the sprayer

was operated recently, it will be very hot

and can cause burns.

See Fig. 20

1.

2. Loosen the clamp (28) on the hose (29), and

remove the hose from the cooler (27).

3. Remove the screws (7) and cooler (27). Clean the

cooler, and inspect for leaks, dents, or plugging

with dust.

Relieve the pressure.

See Pressure Relief

Procedure on page 5.

28

29

27

A

7

A

Fig. 20

22 308718

7082B

Page 23

Notes

23308718

Page 24

Parts Drawing

Model 231801, Series B and 231803, Series B

20

7

8

18a

A

23

22

10

11

7

14

60

13

71b

71c

71e

72a

71a

18

23(Ref)

A

29(Ref)

7

27

17

16

15

71d

72

18b

18c

21

24

9

36

6

26

33

39

7

51

1

28

B

24

30c

38

37

2

3

25

31

B

30d

30b

30a

12

7

11 2829

79

32

30d

11

7083C

Wiring Diagram

9 (Ref)

white

black

black

75

24 308718

72

72b

white

34 green

white

black

36 (Ref)

green

37 (Ref)

Page 25

Parts List

Model 231801, Series B and 231803, Series B

with 1-in. fluid hose, 3/8-in. air hose, and gun.

Ref

No Part No. Description Qty

1 192243 FRAME, TexSpray twin 1

2 113807 WHEEL, flat-free; urethane 2

3 114817 CAP, hub 2

4 189265 LABEL, danger 2

6 191948 COVER, tool box 1

7 113974 SCREW, machine, slotted, hex

washer head 14

8 108471 KNOB, pronged 1

9 111961 SWITCH, rocker 1

10 113673 GAUGE 1

11 100606 PIPE, close 4

12 208536 COUPLER, air line 2

13 239753 PUMP 1

14 239282 HOPPER; 12 gal. (45 liter) 1

15 290440 LABEL, identification 1

16 191941 GUARD, compressor 1

17 191945 FILTER, air 1

18 COMPRESSOR, air, twin cylinder

includes 18a through 18c

239743 120V, 60 Hz, 15A

(for TexSpray Model 231801) 1

239744 220V, 50 Hz, 12A

(for TexSpray Model 231803) 1

18a DAC244 . SHROUD 1

18b SSF297 . SCREW; 1/4 x 1.125 in. 2

18c ACG18 . CUP, saddle-mount 2

20 191944 COVER, filter 1

21 113406 REGULATOR, air 1

22 162453 NIPPLE 1

23 113813 HOSE, air, cpld; 3/8 in. x 25 in. 1

24 189286 LABEL, warning, moving 2

25 189285 LABEL, caution, hot 1

26 103394 BUSHING, snap 1

27 191940 COOLER, air 1

28 113382 CLAMP, hose 4

29 113810 HOSE, air; 3/8 in. x 13 in. 1

30 239058 REGULATOR, unloader assy. 1

30a 106228 . TEE, street 1

30b 113809 . REGULATOR, unloader 1

30c 113385 . BARB, hose 1

30d 113811 . VALVE, safety 2

Ref.

No. Part No. Description Qty.

31 113812 HOSE, air; 3/8 in. x 3 in. 1

32 290491 LABEL, instruction 1

33 192249 CLIP, spring, switch 1

34 239289 CONDUCTOR, electrical 1

35 186620 LABEL, symbol, ground 1

36 111593 SCREW 1

37 113799 INLET, AC power 1

38 192149 PLUG, retainer 1

39 106520 SCREW, thread forming 2

41 290539 LABEL, caution 1

43 169970 FITTING, line, air, (m) 1

46 113397 BALL, sponge; 30 mm

(not shown)

48 CORD SET, 25 ft, USA, 14 awg 1

239290 120V, 60 Hz, 15A

(for TexSpray Model 231801) 1

239291 220V, 50 Hz, 12A

(for TexSpray Model 231803) 1

51 113491 CLAMP 1

60 192211 FILTER, hopper 1

71 238810 1-in. GUN KIT

(includes items 71a through 71e)

71a 224722 . TEXTURE GUN

(for Models 231780 & 231788)

See manual 308162

71b 187633 . HOSE ADAPTER 1

71c 113392 . COUPLER, 1 in. male 1

71d 169967 . FITTING, air line 1

71e 191223 . GASKET, coupler, 1 in. 1

72 239697 . HOSE SET, 1 in. fluid hose, 1

3/8 in. air hose;

72a 113668 COUPLER, 1 in. (f) 1

72b 113675 COUPLER, 1 in. (m) 1

75 TEXTURE GUN KIT

238080 FLEX GUN

includes 72a, 72b

(for Models 231782 & 231790)

See manual 308603

238807 POLE GUN, 3 ft (not shown)

(for Models 231783 & 231791)

See manual 308603

79 114041 VALVE, drain cock 1

1

1

1

1

Replacement Danger and Warning labels, tags and

cards are available at no cost.

25308718

Page 26

Accessories

Hose Cleanup Balls 238043

5 sponge rubber balls to help scrub interior surface of

hose during cleanup

Pole Spray Gun 238807

Rigid 3-ft extension spray gun for spraying hard to

reach places.

Garden Hose Flush Adapter 190952

Adapts 1 in. outlet to 3/4 in. hose.

Fine Finish Kit 237855

Screw-on nozzle adapter for trigger gun for fine knock

down or orange peel finish.

Connecting Rod Kit 239740

Service parts kit for compressor connecting rod

replacement.

Compressor Cyl/Comp Ring Kit 239741

Service parts kit for cylinder and compression ring

replacement.

Compressor Valve Plate Kit 239742

Service parts kit for valve plate assembly. Includes

instructions.

Texture Pump Kit 239753

Service parts kit for texture pump assembly. Includes

instructions.

110V/60Hz Compressor Replacement Kit 239743

Service parts kit for 110V, 60 Hz compressor

replacement.

220V/50Hz Compressor Replacement Kit 239744

Service parts kit for 220V, 50 Hz compressor

replacement.

HOSE SETS

25 ft, 1 in. Clear, Braided 239697

Complete hose set for TexSpray units. Material made

of clear PVC with nylon braid reinforcing. Light-weight

standard hose with system.

25 ft, 1-1/4 in. Clear 239698

Complete hose set for TexSpray units. Same as

239297 except diameter is 1–1/4 in. Allows greater

production rates and longer hose lengths with some

texture materials.

25 ft, 1 in. Black 239699

Complete hose set for TexSpray units. Material made

of black reinforced rubber. Heavy, duty, rugged hose.

The most abrasion-resistant hose.

26 308718

Page 27

Technical Data

Maximum air and fluid working pressure 100 psi. . . . . .

(0.7 MPa, 7 bar)

Air pressure operating range 25 to 100 psi . . . . . . . . . .

(0.17 to 0.7 MPa, 1.7 to 7 bar)

Compressor specifications AC brushless open motor,.

thermally protected, oil-less;

120/240V, 60/50 Hz,15/13A

Compressor air consumption 11.9 displacement scfm. .

8.5 scfm at 40 psi (0.238 m

6.8 scfm at 90 psi (0.19 m

Generator required 7 kW. . . . . . . . . . . . . . . . . . . . . . . . . .

Hopper capacity

Maximum 12 gallons (45 liters). . . . . . . . . . . . . . . . . . .

Operating 10 gallons (38 liters). . . . . . . . . . . . . . . . . .

3

/min at 2.8 bar)

3

/min at 6.3 bar)

Maximum delivery with texture material 1 to 1.5 gpm. .

(3.8 to 5.7 lpm)

Dimensions

Length 23 in. (584 mm) with handle. . . . . . . . . . . . . . .

Width 24 in. (610 mm) . . . . . . . . . . . . . . . . . . . . . . . . . .

Height 40 in. (1016 mm). . . . . . . . . . . . . . . . . . . . . . . .

Weight

Without hoses or gun 113 lb (51 kg). . . . . . . . . . . . . . .

With hoses and gun 125 lb (57 kg). . . . . . . . . . . . . . . .

Wetted parts acetal, glass-filled acetal, . . . . . . . . . . . . . .

Buna–N, aluminum, brass, polyethylene

Sound data

Sound pressure level * 79 dB(A). . . . . . . . . . . . . . . . . .

Sound power level 87.5 dB(A). . . . . . . . . . . . . . . . . . .

* Measured while spraying at 1 m.

Measured per ISO-3744.

27308718

Page 28

Graco Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale by an authorized Graco distributor to the original purchaser for use. With the exception of any special, extended, or limited

warranty published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in

accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER W ARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property , or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty , the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty

Program”.

Graco Phone Number

TO PLACE AN ORDER

, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–690–2894 T oll Free

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Foreign Offices: Belgium, Korea, Hong Kong, Japan

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

PRINTED IN U.S.A. 308718 April 1997, Revised July 1999

28 308718

Sales Offices: Minneapolis, Detroit

http://www.graco.com

Loading...

Loading...