Graco GM3000, GM3000 231551, GM3000 231550, GM3000 231552, 231363 Instructions-parts List Manual

...Page 1

INSTRUCTIONS-PARTS LIST

308620

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

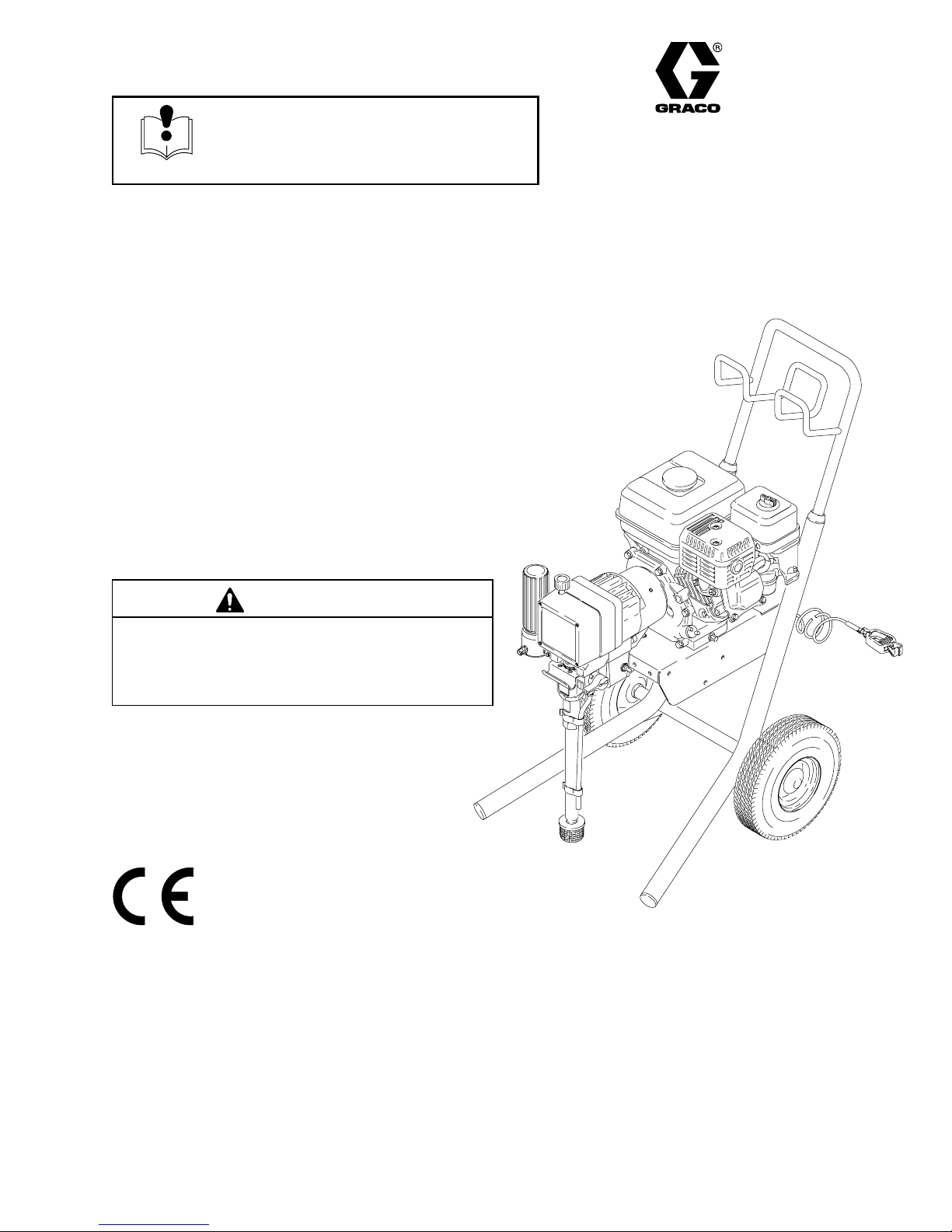

GM3000 Airless Paint Sprayer

3000 psi (210 bar, 21 MPa) Maximum Working Pressure

Model 231363, Series B

Basic Sprayer with Upright Cart

Model 231551

Same as 231363, with hose and gun, RACr X

HandTitet Tip Guard, and 517 size SwitchTipt

Model 231550, Series B

Basic Sprayer with Lo–Boy Cart

Model 231552

Same as 231550, with hose and gun, RACr X

HandTitet Tip Guard, and 517 size SwitchTipt

Rev. K

CAUTION

Always use a minimum hose length of 50 foot

(15 m) 1/4 inch ID or 50 foot (15 m) 3/8 inch ID. An

undersized hose may result in poor equipment

performance and damage to the clutch.

06001B

Model 231363 Shown

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 1996, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Identification and Function 5. . . . . . . . . . . .

Setup 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fueling 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Housing, Connecting Rod, Crankshaft 16. . . . . .

Pressure Control 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pinion, Clutch, Clamp, Field, & Engine 23. . . . . . . . . . .

Pinion Housing 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field & Wiring Harness 27. . . . . . . . . . . . . . . . . . . . . . . . .

Clamp 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Clutch Housing 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displacement Pump Repair 31. . . . . . . . . . . . . . . . . . . . .

Pressure Control Parts list 33. . . . . . . . . . . . . . . . . . . . . .

Upright Sprayer Parts Drawing 34. . . . . . . . . . . . . . . . . .

Upright Sprayer Parts List 35. . . . . . . . . . . . . . . . . . . . . .

Lo-Boy Sprayer Parts Drawing 36. . . . . . . . . . . . . . . . . .

Lo-Boy Sprayer Parts List 37. . . . . . . . . . . . . . . . . . . . . .

Parts List & Drawing – Complete Sprayers 38. . . . . . .

Pinion Assembly Parts list and Drawing 38. . . . . . . . . .

Accessories 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 39. . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Warranty 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

equipment if you do not follow the instructions.

INSTRUCTIONS

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

D This equipment is for professional use only.

D Read all instruction manuals, tags, and labels before operating the equipment.

D Use the equipment only for its intended purpose. If you are not sure, call your distributor.

D Do not alter or modify this equipment. Use only genuine Graco parts.

D Check equipment daily. Repair or replace worn or damaged parts immediately.

D Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

Technical Data on page 39 for the maximum working pressure of this equipment.

D Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

D Do not use hoses to pull equipment.

D Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82_C (180_F) or below –40_C (–40_F).

D Do not lift pressurized equipment.

D Comply with all applicable local, state, and national fire, electrical, and safety regulations.

D Wear hearing protection when operating this equipment.

D Do not use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

3086202

Page 3

WARNING

INJECTION HAZARD

Spray from the gun, leaks or ruptured components can inject fluid into your body and cause extremely

serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also

cause serious injury.

D Fluid injected into the skin may look like just a cut, but it is a serious injury. Get immediate medi-

cal attention.

D Do not point the gun at anyone or at any part of the body.

D Do not put your hand or fingers over the spray tip.

D Do not stop or deflect leaks with your hand, body, glove or rag.

D Do not “blow back” fluid; this is not an air spray system.

D Always have the tip guard and the trigger guard on the gun when spraying.

D Check the gun diffuser operation weekly. Refer to the gun manual.

D Be sure the gun trigger safety operates before spraying.

D Lock the gun trigger safety when you stop spraying.

D Follow the Pressure Relief Procedure on page 12 if the spray tip clogs and before cleaning,

checking or servicing the equipment.

D Tighten all fluid connections before operating the equipment.

D Check the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do not

repair high pressure couplings; you must replace the entire hose.

D Fluid hoses must have spring guards on both ends, to help protect them from rupture caused by

kinks or bends near the couplings.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

D Know the specific hazards of the fluid you are using.

D Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

D Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

FUEL HAZARD

The fuel used in this unit is combustible and when spilled on a hot surface can ignite and cause a fire.

D Do not fill the fuel tank while the engine is running or hot.

EXHAUST HAZARD

The exhaust contains poisonous carbon dioxide which is colorless and odorless.

D Do not operate this equipment in a closed building.

308620 3

Page 4

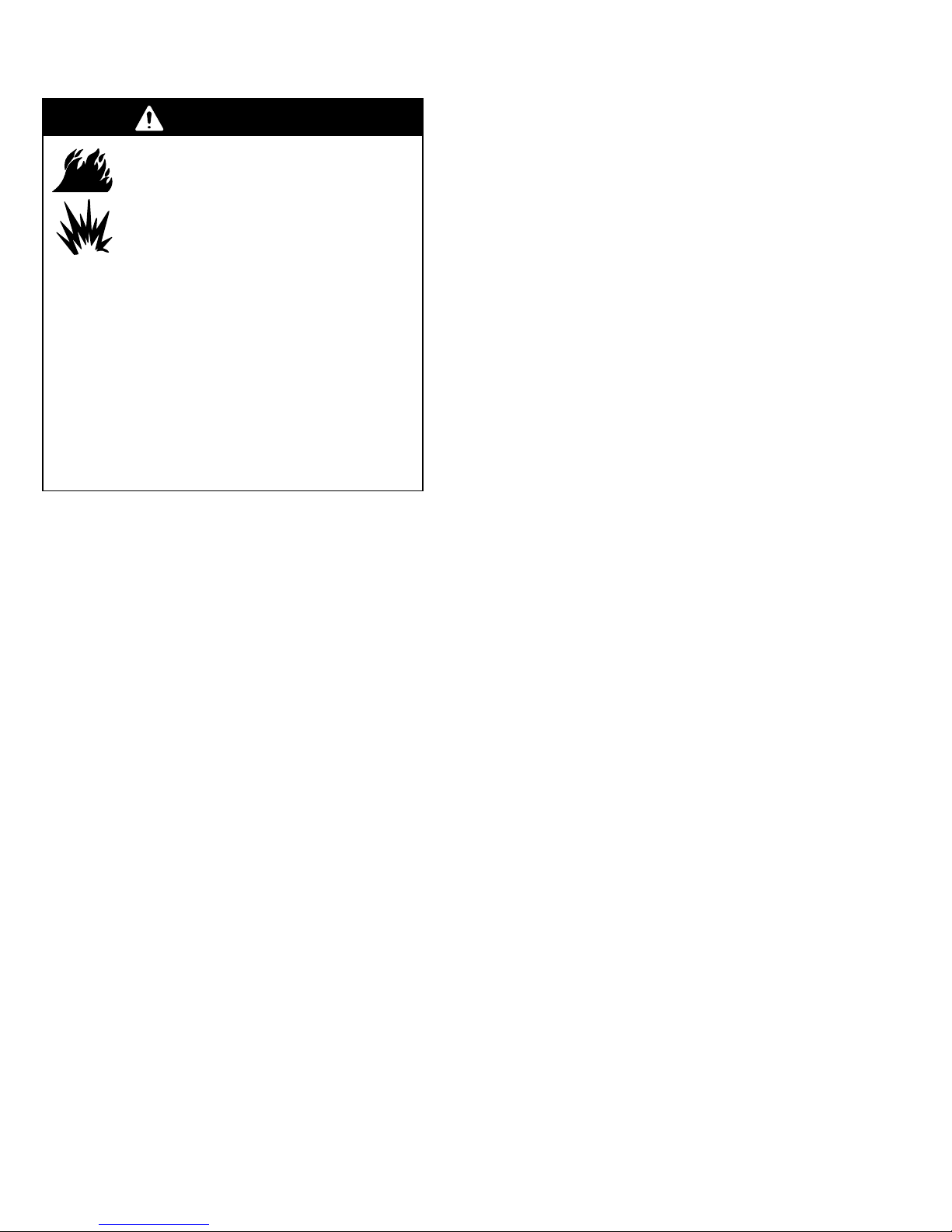

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

D If there is any static sparking or you feel an electric shock while using this equipment, stop spray-

ing immediately. Do not use the equipment until you identify and correct the problem.

D Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

D Keep the spray area free of debris, including solvent, rags, and gasoline.

D Disconnect all electrical equipment in the spray area.

D Extinguish all open flames or pilot lights in the spray area.

D Do not smoke in the spray area.

D Do not turn on or off any light switch in the spray area while operating or if fumes are present.

D Do not operate a gasoline engine in the spray area.

D Ground the sprayer to a true earth ground with the ground wire and clamp (supplied).

D Use only electrically conductive hoses.

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers.

D Keep clear of all moving parts when starting or operating the sprayer.

D Before servicing the equipment, follow the Pressure Relief Procedure on page 12 to prevent the

equipment from starting unexpectedly.

NOTE: This is an example of the DANGER label on your sprayer. This label is available in other languages, free of

charge. See page 39 to order.

FIRE AND

EXPLOSION HAZARD

Spray painting, flushing or cleaning equipment with flammable

liquids in confined areas can result in fire or explosion.

Use outdoors or in extremely well ventilated areas. Ground

equipment, hoses, containers and objects being sprayed.

Avoid all ignition sources such as static electricity from plastic

drop cloths, open flames such as pilot lights, hot objects such as

cigarettes, arcs from connecting or disconnecting power cords

or turning light switches on and off.

Failure to follow this warning can result in death or serious injury.

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

Liquids can be injected into the body by high pressure airless

spray or leaks – especially hose leaks.

Keep body clear of the nozzle. Never stop leaks with any part of the

body. Drain all pressure before removing parts.Avoid accidental

triggering of gun by always setting safety latch when not spraying.

Never spray without a tip guard.

In case of accidental skin injection, seek immediate

“Surgical Treatment”.

Failure to follow this warning can result in amputation or serious

injury.

SKIN INJECTION

HAZARD

3086204

Page 5

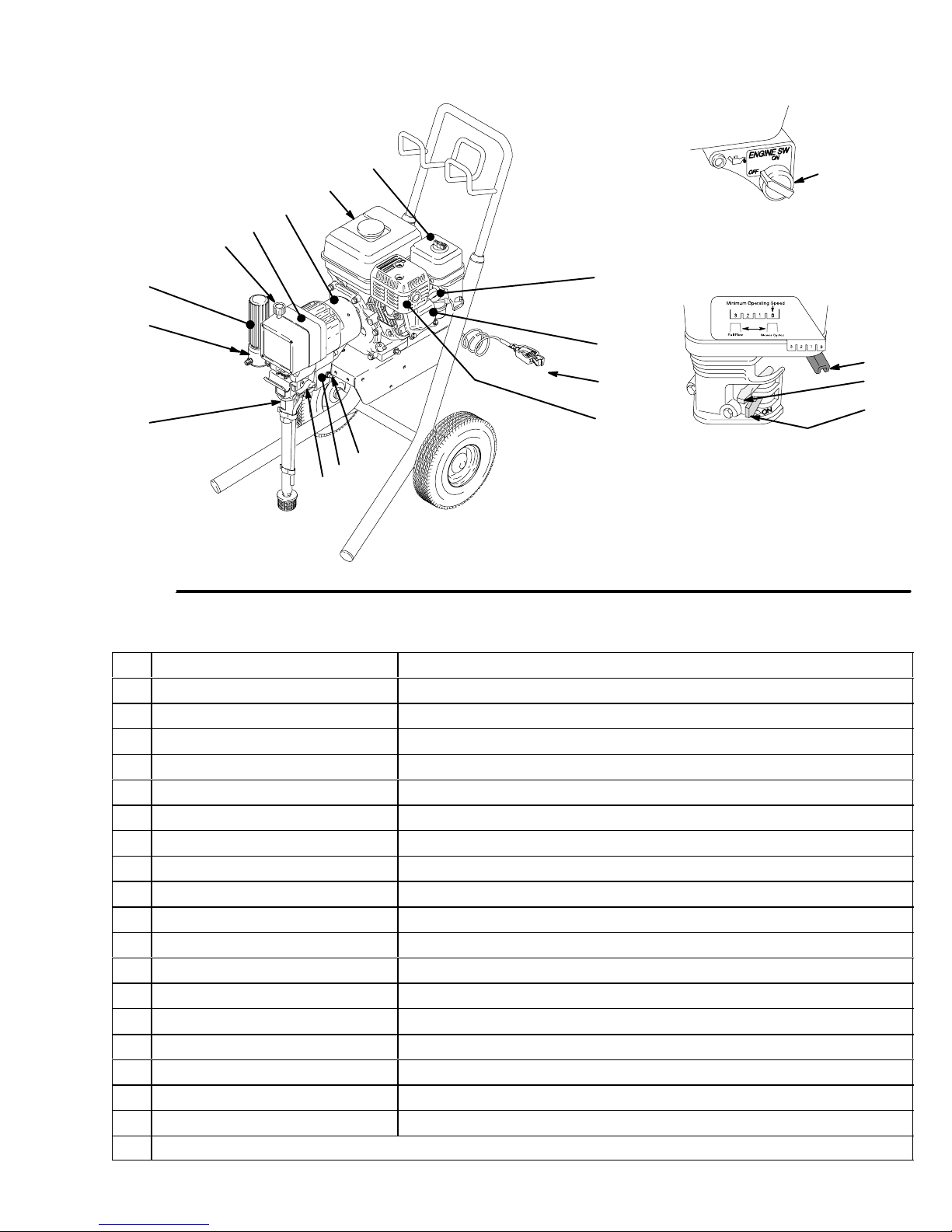

Component Identification and Function

T

L

S

Fig. 1

C

D

P

R

B

F

N

U

E

A

M

V

06001B

K

0015

J

H

G

0016

A Pressure Control Switch ON/OFF, enables/disables clutch function

B Pressure Adjusting Knob Controls fluid outlet pressure

C Air Cleaner* Filters air entering the carburetor

D Fuel Tank* Holds 0.66 gallons (2.5 liters) of [(R+M)/2]; 86 octane gasoline

E Muffler* Reduces noise of internal combustion

F Spark Plug Cable* Routes electrical current to spark plug

G Fuel Valve* On/off valve to regulate fuel flow from gasoline tank to carburetor

H Choke* Enriches air/gasoline mixture for cold starting

J Throttle* Adjusts engine speed for large or small orifice spray tips

K Engine Switch* Enables/disables engine operation

L Fluid Outlet Hose and spray gun are connected here

M Pressure Control Controls clutch cycling to maintain fluid pressure.

N Engine* 4.0 HP gasoline engine

P Clutch Transfers power from engine to drive assembly

R Drive Assembly Transfers power from clutch to displacement pump

S Displacement Pump Provides fluid to be sprayed through spray gun

T Fluid Filter Filters fluid between source and spray gun

U Grounding Clamp and Wire Grounds sprayer system

V Pressure Drain Valve Relieves fluid pressure when open

* For more detailed explanations of these controls, refer to the Honda engine manual; supplied

308620 5

Page 6

Setup

CAUTION

To avoid damaging the pressure control, which may

result in poor equipment performance and component

damage, follow these precautions.

1. Always use nylon spray hose. Never use a wire

braid hose; it is too rigid to act as a pulsation

dampener.

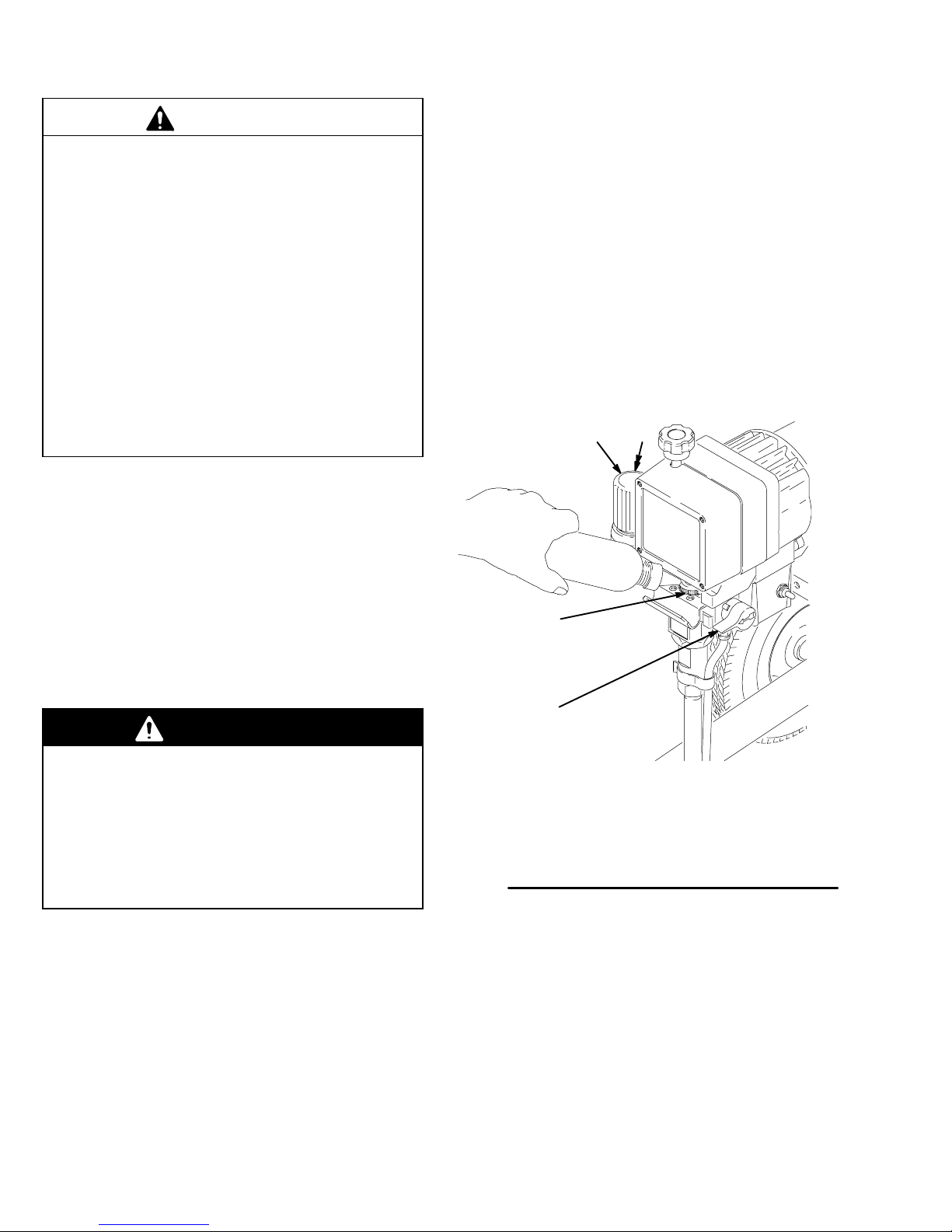

2. Fill packing nut/wetcup. Fill the packing nut/wetcup (A) 1/3 full with Graco Throat Seal Liquid

(TSL), supplied. See Fig. 2.

3. Check the engine oil level. Refer to the Honda

engine manual, supplied. This is a summary of the

information: Remove one of the oil fill plugs (M);

the oil should be almost overflowing. See Fig. 3.

Add oil as necessary.

2. Always use a minimum hose length of 50 foot

(15 m) x 1/4 inch ID or 50 foot (15 m) x 3/8 inch

ID hose.

3. Never install any shutoff device between the filter

(21) and the main hose. See Fig. 2.

4. Always use the main filter outlet (20) for a one

gun operation. Never plug this outlet.

1. Connect hose and gun. (Refer to Fig. 2.)

a. Remove the plastic cap from the 1/4 npsm (m)

filter outlet nipple (20). Screw the main fluid

hose onto the nipple. Read the CAUTION,

above.

b. Connect the whip end hose between the main

fluid hose and the inlet adapter of the gun.

c. Do not use thread sealant, and do not install

the spray tip yet!

WARNING

Recommended lubrication oil: Use a high-quality,

detergent oil, SAE 10W–30, classified “FOR

SERVICE SG or SF”, for regular use and for

breaking–in a new engine.

21

A

46

20

If you supply your own hoses and spray gun, be

sure the hoses are electrically conductive, that the

gun has a tip guard, and that each part is rated for

at least 3000 psi (210 bar, 21 MPa) Maximum

Working Pressure. This is to reduce the risk of

serious injury caused by static sparking, fluid

injection or over-pressurization and rupture of the

hose or gun.

3086206

21 Fluid Filter

46 Pressure drain valve

20 1/4 npsm(m) fluid outlet

A Wetcup

Fig. 2

05832

Page 7

Setup

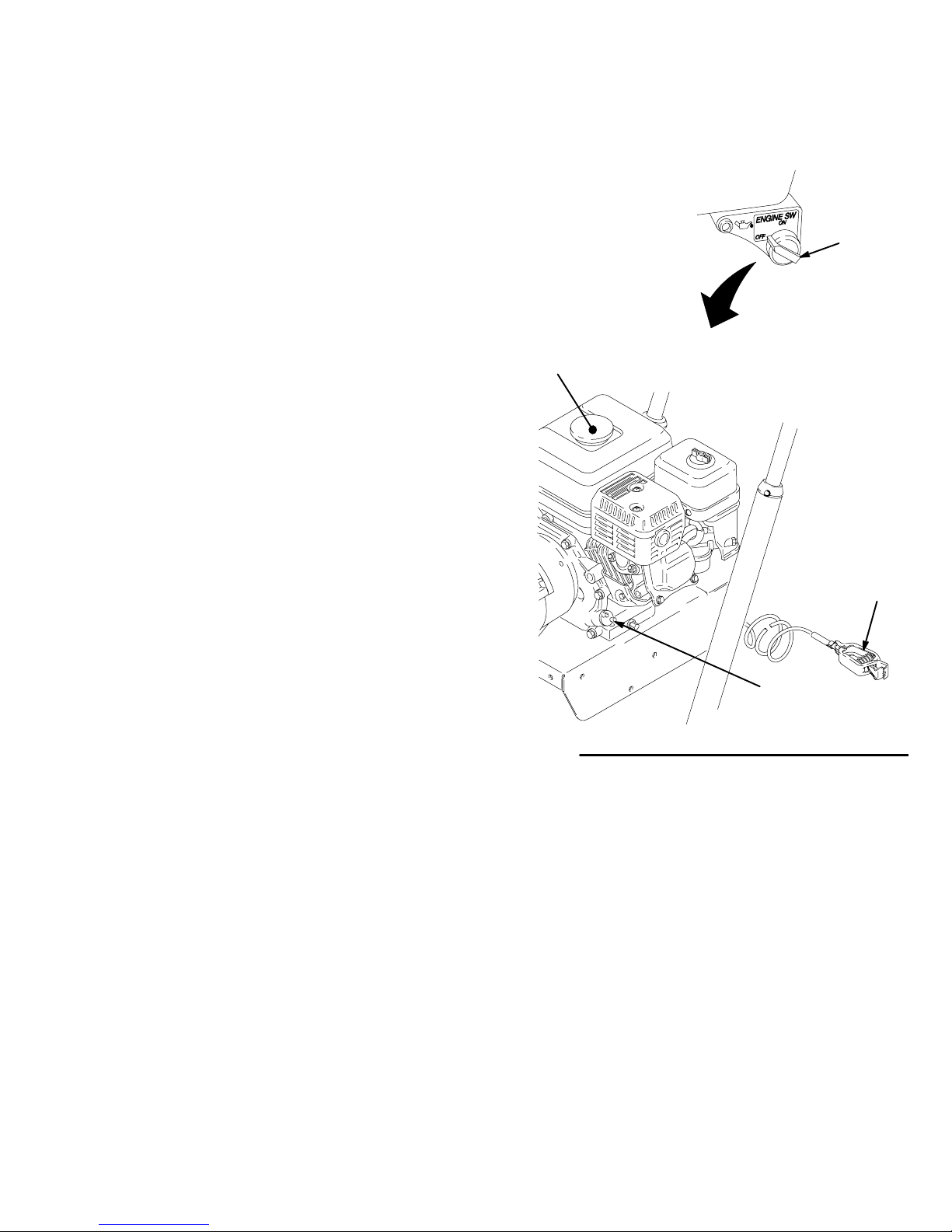

4. Be sure your system is properly grounded

before operating it. Connect the sprayer to a true

earth ground with the grounding wire and clamp

(80) ; for example, a cold water pipe or a ground

rod driven into the earth.

5. Fill the gas tank. See Fueling, page 8.

6. Flush the pump to remove the lightweight oil

which was left in the pump to protect it from corrosion.

a. Before using water–base paint, flush with

mineral spirits, followed by soapy water, and

then flush with clean water.

b. Before using oil–base paint, flush with mineral

spirits, only.

c. See Flushing on page 13 for the flushing

procedure.

7. Prepare the paint according to the manufacturer’s

recommendations.

8. Keep the sprayer upright and level during

operation and whenever it is being moved. See the

CAUTION on page 10.

K

0015

L

a. Remove any skin that may have formed.

b. Stir the paint to mix the pigments.

c. Strain the paint through a fine nylon mesh bag

(available at most paint dealers) to remove the

particles that could clog the filter or spray tip.

This is probably the most important step

toward trouble–free spraying.

80

M

06906A

Fig. 3

308620 7

Page 8

Fueling

WARNING

FIRE AND EXPLOSION HAZARD

Gasoline is extremely flammable and

explosive under certain conditions.

Always turn the engine switch (K) to off

before refueling. (Fig. 3)

Refuel in a well-ventilated area.

Do not smoke or allow flames or sparks in the area

where the engine is refueled or where the gasoline

is stored.

Do not overfill the tank. Make sure the gas fill cap

(L) is securely closed after refueling. (Fig. 3)

2. Gasolines containing alcohol (gasohol). Do not

use gasohol which contains methanol, if the gasohol does not contain cosolvents and corrosion

inhibitors for methanol. Even if it does contain such

additives, do not use the gasohol if it contains

more than 5% methanol or 10 % ethanol.

NOTE: The Honda engine warranty does not cover

the damage resulting from the use of gasolines containing a higher percentage of alcohol than mentioned

in step 2. See the Honda engine manual for more

information.

3. General. Do not use any oil and gasoline mixtures

or contaminated gasoline. Avoid getting any dirt,

dust or water in the fuel tank.

Be careful not to spill fuel when fueling. Fuel vapor

or spilled fuel can ignite. If any fuel is spilled, make

sure the area is dry before starting the engine.

1. Fuel specifications. Use automotive gasoline

with a pump octane number of 86 or higher, or a

research octane number of 91 or higher. Unleaded

fuel minimizes the combustion chamber deposits.

4. Tank Capacity. 0.66 gallons (2.5 liters). Always

leave at least 1/2 in. (13 mm) at the top of the tank

for expansion.

5. Shut off the engine before refueling.

6. After refueling, tighten the fuel tank cap firmly.

3086208

Page 9

Startup

Before You Start the Sprayer

1. See Flushing on page 12 to determine if you

should flush the sprayer.

2. Be sure the gas tank is full.

3. Check the engine oil level.

NOTE: The engine stops automatically, or will not

start, if it is low on oil. Refer to the oil fill procedure in

the Honda engine manual or to step 3, page 6.

4. Be sure the spark plug cable is firmly pushed

onto the plug.

Starting the Sprayer

NOTE: Refer to Fig. 1 as you start the sprayer.

1. When starting a sprayer that IS NOT PRIMED,

remove the spray tip.

2. Place the suction tube into the paint, water or

solvent container, depending on whether you are

flushing or are ready to spray.

3. Open the black fuel shutoff lever by pushing it in

the direction of the arrow.

4. Move the pressure control switch to OFF.

5. To start the engine:

a. Turn the pressure adjusting knob all the way

counterclockwise to the lowest pressure setting.

b. Slide the metal throttle lever away from the

fuel tank to maximum position (fully left).

c. If the engine is cold, close the choke by mov-

ing the gray lever.

d. If the engine is warm, close the choke by

moving the gray lever only half way or not at

all.

e. Turn the engine switch to ON.

WARNING

MOVING PARTS HAZARD

A rope which recoils too quickly may hit

someone and cause serious injury. The

rope could also jam in recoil assembly.

f. Hold the frame of the sprayer with one hand

and pull the starter rope rapidly and firmly.

Continue holding the rope as you let it return.

Pull and return the rope until the engine starts.

CAUTION

Never try to start the engine unless fluid pressure is

relieved and the pressure control switch is OFF.

Trying to start the engine when it is pressurized

could damage the recoil system.

g. Open the choke as soon as the engine starts,

except in cold weather. In cold weather, leave

the choke closed for 10 to 30 seconds before

opening it to keep the engine running.

6. Unlock the gun trigger safety.

308620 9

Page 10

Startup

7. Prime the pump:

a. Place the suction tube in the bucket of paint,

water, or solvent.

b. Open the pressure drain valve.

c. Set engine speed to idle.

d. Move the pressure control switch to ON. Turn

the pressure adjusting knob slowly until the

sprayer starts.

e. Run the pump until fluid is flowing smoothly

from the pressure drain valve, indicating the

pump is primed.

f. Move the pressure control switch to OFF.

g. If the pump was primed with water or solvent,

remove the suction tube from the water or

solvent and place it in the paint. Repeat steps

b through f.

h. Close the pressure drain valve.

8. When the pump is primed:

h. Relieve pressure by opening the pressure

drain valve.

i. Close the pressure drain valve.

WARNING

INJECTION HAZARD

To reduce the risk of serious injury from

fluid injection, never operate the spray

gun with the tip guard removed.

9. Install the spray tip in the gun. See the separate

tip instruction manual, 308–644, supplied.

10. Move the pressure control switch to ON.

11. Adjust the engine speed and pump pressure.

Unlock the gun trigger safety. Trigger the gun onto

a test paper to check the spray pattern and atomization. Turn the pressure adjusting knob until you

get a good pattern. Then slowly lower the throttle

setting as far as you can without changing the

spray pattern.

a. Remove the spray tip.

b. Set the engine speed to full flow.

c. Move the pressure control switch to ON. Turn

the pressure adjusting knob slowly until the

sprayer starts.

d. Unlock the gun trigger safety.

e. Trigger the gun into the pail until fluid flows

from the gun. If pumping solvent or solvent–

based paint, hold a metal part of the gun firmly

against a grounded metal pail.

f. Release the gun trigger and lock the gun

trigger safety.

g. Move the pressure control switch to OFF.

CAUTION

Always use the lowest needed fluid pressure and the

lowest needed throttle setting, to increase the life of

the sprayer. Higher settings cause excessive clutch

cycling, premature tip wear and premature pump

wear.

CAUTION

Close the black fuel shutoff lever whenever you are

transporting the sprayer to prevent fuel from flooding

the engine.

Keep the sprayer upright and level when operating it

and when transporting it. This prevents crankcase oil

from leaking into the combustion chamber, which

makes startup very difficult.

30862010

Page 11

Startup

CAUTION

Operating the sprayer with the pump not primed can

lead to premature packing wear and/or damage to

the pump.

Maintenance

Loss of Prime to Pump

Introduction of air into the pump, either by changing

fluids or due to a suction leak, may result in the loss of

prime to the pump. If the pump loses prime, no fluid is

pumped.

To prime the pump, relieve the pressure on the system

by opening the drain valve and following the instruction

on Prime the pump, page 10.

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

DAILY: Check the engine oil level and fill as neces-

sary.

DAILY: Check and fill the gas tank.

AFTER THE FIRST 20 HOURS OF OPERATION

Drain the oil and refill with clean oil.

WEEKLY: Remove the cover of the air filter and

clean the element. Replace the element, if necessary.

If operating in an unusually dusty environment, check

the filter daily and replace it, if necessary.

Replacement elements may be purchased from your

local Honda dealer.

CAUTION

For detailed engine maintenance and specifications,

refer to the separate engine manual, supplied.

WEEKLY: Check the level of the TSL in the displacement pump packing nut. Fill the nut, if necessary. Keep

TSL in the nut to help prevent fluid buildup on the

piston rod and premature wear of the packings.

Monthly: Remove the front cover (9) and fill the

cavity in the connecting rod with non-detergent motor

oil 1/4 in. below the surface. See Fig. 4.

AFTER EACH 100 HOURS OF OPERATION:

Change the oil. Refer to the engine manual for additional maintenance instructions.

SPARK PLUG: Use only an (NGK) BPR6ES or a

(NIPPON DENSO) W20EPR-U plug. Gap the plug to

0.028 to 0.031 inch (0.7 to 0.8 mm). Use a spark plug

wrench when installing and removing the plug.

Fig. 4

Fill to .25 in. below surface with non-detergent

motor oil.

9

06011

308620 11

Page 12

Pressure Relief Procedure

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you:

D are instructed to relieve the pressure,

D stop spraying,

D check or service any of the system equipment,

D install or clean the spray tip.

Flushing

When to Flush

1. Engage the gun safety latch.

2. Turn the engine switch to OFF.

3. Move the pressure control ON/OFF switch to OFF.

4. Disengage the gun safety latch. Hold a metal part

of the gun firmly to a grounded metal pail. Trigger

the gun to relieve pressure.

5. Engage the gun safety latch.

6. Open the pressure drain valve. Leave the pressure

drain valve open until you are ready to spray

again.

7. Disconnect the spark plug cable.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above, VERY SLOWLY

loosen the tip guard retaining nut or hose end coupling

to Relieve the pressure gradually, then loosen completely. Now clear the tip or hose.

1. New Sprayer. This sprayer was factory tested in

lightweight oil,which was left in to protect the pump

parts.

Before using water–base paint, flush with mineral

spirits, followed by a soapy water flush, and then a

clean water flush.

Before using oil–base paint, flush with mineral

spirits.

2. Changing Colors.

such as mineral spirits or water.

3. Changing from water–base to oil–base paint. Flush

with warm, soapy water, then mineral spirits.

4. Changing from oil–base to water–base paint.

with mineral spirits, followed by warm, soapy

water, and then a clean water flush.

Flush with a compatible solvent

Flush

CAUTION

To prevent pump corrosion or damage to pump

components, never leave water or any type of paint

in the sprayer when it is not in use. Pump the water

or the paint out with mineral spirits.

5. Storage.

Water base paint: flush with water, then mineral

spirits and leave the pump, hose and gun filled

with mineral spirits. Shut off the sprayer, remove

the spark plug cable, and open the pressure drain

valve to Relieve the pressure. Leave the drain

valve open.

Oil base paint: flush with mineral spirits and leave

the pump, hose and gun filled with mineral spirits.

Shut off the sprayer, remove the spark plug cable,

and open the pressure drain valve to Relieve the

pressure. Leave the drain valve open.

6. Startup after storage.

Before using water–base paint, flush out the

mineral spirits with soapy water, and then with

clean water.

When using oil–based paint, flush out the mineral

spirits with the paint to be sprayed.

30862012

Page 13

How to Flush

Flushing

WARNING

CAUTION

When changing fluids, do not drain all of the first fluid

from the suction tube before inserting the suction tube

into the another fluid. Not doing so may introduce

excessive air into the pump and cause the pump to

lose prime.

After moving the suction tube to a new fluid, pump the

first fluid and any trapped air, out through the drain

valve before beginning to pump the new fluid to the

guns.

NOTE: The word solvent refers to water or oil-based

solvent.

1. Follow the Pressure Relief Procedure, page 12.

2. Remove the filter bowl and screen; see instruction

manual 308249, supplied. Install the bowl and

support, without the screen, to flush. Clean the

screen separately.

3. Close the pressure drain valve.

4. Put the suction tube in a grounded pail of solvent.

FIRE AND EXPLOSION HAZARD

To reduce static sparking and splashing,

always remove the spray tip from the

gun, and hold a metal part of the gun

firmly to the side of a grounded metal pail when

flushing.

6. Follow Startup on page 9. Keep the gun triggered until clean solvent comes from the nozzle.

Release the trigger and lock the gun trigger safety.

CAUTION

Operation with the pump not primed can lead to

premature packing wear and damage to the pump.

7. Check all fluid connections for leaks. Relieve the

pressure before tightening any connections. Start

the sprayer. Recheck the connections for leaks.

8. Remove the suction tube from the solvent pail.

Unlock the gun trigger safety. Trigger the gun to

force solvent from the hose. Do not let the pump

run dry for more than 30 seconds, to avoid damaging the pump packings. Relieve the pressure.

9. Unscrew the filter bowl and reinstall the clean

screen. Reinstall the bowl, hand tight only.

5. Remove the spray tip from the gun.

10. Follow Storage or Changing Colors, on page 12

Relieve the pressure.

308620 13

Page 14

Troubleshooting

displ

t

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

Check everything in the chart before disassembling the sprayer. See pages 34 through 33 for description of

referenced parts

PROBLEM

The engine or sprayer won’t

start.

The engine won’t “pull over”. Oil is seeping into the combustion chamber. Remove the spark plug. Pull the starter rope 3

The engine operates, but the

acement pump does no

operate. The pressure setting is too low. Turn the pressure adjusting knob clockwise to

CAUSE SOLUTION

The engine switch is not on. Turn on the switch.

The engine is out of gas. Refill the gas tank. See page 8.

The engine oil level is low. Try to start the engine. Replenish the oil, if nec-

The spark plug cable is disconnected or it is

damaged

There is frozen water in the sprayer. Allow the sprayer to thaw completely before

The pressure control switch is turned off. Turn on the switch.

The fluid filter (21) is dirty. Clean the filter. See page 13.

The tip or the tip filter is clogged. Clean the tip or the tip filter. See the gun

The displacement pump rod is stuck due to

dried paint.

essary. See Step 3, page 6.

Reconnect the spark plug cable or replace the

spark plug.

starting it.

or 4 times. Clean or replace the plug. Try to

start the engine. Keep the sprayer upright to

avoid oil seepage.

increase pressure.

instruction manual.

Repair the pump. See page 31.

The connecting rod is worn or damaged. Replace the connecting rod. See page 16.

The drive housing is worn or damaged. Replace the drive housing. See page 16.

The electrical power is not energizing the field. Check the wiring connections. See page 26.

The clutch is worn, damaged, or incorrectly

positioned.

The pinion assembly is worn or damaged. Repair or replace the pinion assembly. See

30862014

With the pressure control switch turned on and

the pressure turned to maximum, use a test

light to check the power at the black and white

wires from the pressure control.

Have the pressure control checked by an authorized Graco dealer.

Replace the clutch. See page 25.

page 23.

Page 15

PROBLEM CAUSE SOLUTION

th

l

The pump output is low on

e upstroke.

The output of the pump is

ow on the downstroke or on

both of the strokes.

The paint leaks into the wetcup.

The fluid delivery is low.

The inlet screen (102) is clogged. Clean the screen.

A piston ball (121) is not seating. Service the piston ball–check. See page 31.

The piston packings are worn or damaged. Replace the packings. See page 31.

A o-ring (119) in the displacement pump is

worn or damaged.

The inlet screen (39) is clogged. Clean the screen.

The piston packings are worn or damaged. Replace the packings. See page 31.

An intake valve ball is not seating

properly.

The engine speed is too low. Increase the throttle setting. See Step 11, page

The clutch is worn or damaged. Replace the clutch. See page 25.

The wetcup is loose. Tighten the wetcup just enough to stop leak-

The throat packings is worn or damaged. Replace the packings. See page 31.

A displacement rod is worn or damaged. Replace the rod. See page 31.

The inlet screen (39) is clogged. Clean the screen.

The pressure setting is too low. Increase the pressure. See Step 11, page 10.

Replace the o-ring. See page 31.

Clean the intake valve. See page 31.

10.

age.

Fluid is spitting from the gun.

The pump is difficult to prime.

The engine speed is too low. Increase the throttle setting. See Step 11, page

The fluid filter (21), the tip filter or the tip is

clogged or dirty.

There is a large pressure drop in the hose. Use a larger diameter hose.

There is air in the pump or the hose. Check and tighten all the fluid connections.

The tip is partially clogged. Clear the tip. See the gun instruction manual.

The fluid supply is low or empty. Refill the fluid supply. Prime the pump. See

There is air in the pump or the hose. Check and tighten all the fluid connections.

The intake valve is leaking. Clean the intake valve. Be sure ball seat is not

The pump packings are worn. Replace the pump packings. See page 31.

The paint is too thick. Thin the paint according to the supplier’s

The engine speed is too high. Decrease the throttle setting before priming the

10.

Clean the filter. See page 13. Or, see the gun

instruction manual.

Reprime the pump. See page 10.

page 9. Check the fluid supply often to prevent running the pump dry.

Reduce the engine speed and cycle the pump

as slowly as possible during priming.

nicked or worn and that the ball seats well.

Reassemble the valve.

recommendations.

pump. See Step 7, page 10.

308620 15

Page 16

Drive Housing, Connecting Rod, Crankshaft

6. Remove and inspect the crankshaft (8) and the

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

Removal

NOTE: Inspect parts as they are removed. Replace

parts that are worn or damaged.

connecting rod (10).

Installation

7. Lubricate the inside of the drive housing bronze

bearing with SAE non-detergent oil.

8. Install the connecting rod.

1. Remove the displacement pump. See page 31.

2. Remove the pressure control (25). See page 18.

3. Remove the three drive housing screws and lock

washers (15, 16). See Fig. 5 on page 17.

4. Remove the two pinion housing screws (69) and

lock washers (16). See Fig. 5 on page 17.

5. Tap the lower rear of the drive housing (6) with a

plastic mallet to loosen the drive housing. Pull the

drive housing straight off the pinion housing.

CAUTION

Do not allow the gear (19) to fall; it may stay attached to the drive housing or to the pinion housing.

Do not lose the thrust balls (6a and 2d) or let them

fall between the gears, which will damage the drive

housing if not removed. The balls, which are heavily

covered with grease, usually stay in the housing

recesses, but could be dislodged. If the balls are not

in place, the bearings will wear prematurely.

9. Place the large washer (5) and then the small

washer (3) on the crankshaft (8).

10. Insert the crankshaft into the bearing in the drive

housing (6) and connecting rod (10).

11. If replacing the complete drive housing assembly

(6), brush G-n lubricant (supplied) on all gear

teeth. Then recoat the gear teeth with bearing

grease (supplied). Pack the remaining bearing

grease into the bottom part of the drive housing.

Use 0.22 pint of the grease. See Fig. 6.

12. Install gear (19).

13. Install new gasket (64).

14. Work backwards from step 4 to reassemble.

30862016

Page 17

Drive Housing, Connecting Rod, Crankshaft

1

69

16

2

2d

3

19

1

Torque to 100 in–lb (11 N.m)

2 Quantity of three

3

Quantity of one

25

REF A

6a

8

5

Lubricate with SAE

4

non-detergent oil

Fig. 5

4

A

68

65

23

3

9

10

26

2

15

6

16

1

64

05833B

Brush G-n lubricant

and recoat with bearing

grease

Fig. 6

Pack with bearing grease (0.22 pint)

06003

308620 17

Page 18

Pressure Control

WARNING

7. Loosely install the screws (24) and then torque

them to 21 in–lb (2.4 N.m).

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

NOTE: See Fig. 7 for this procedure.

NOTE: The pressure control (25) cannot be repaired

or adjusted. If it has malfunctioned, replace it.

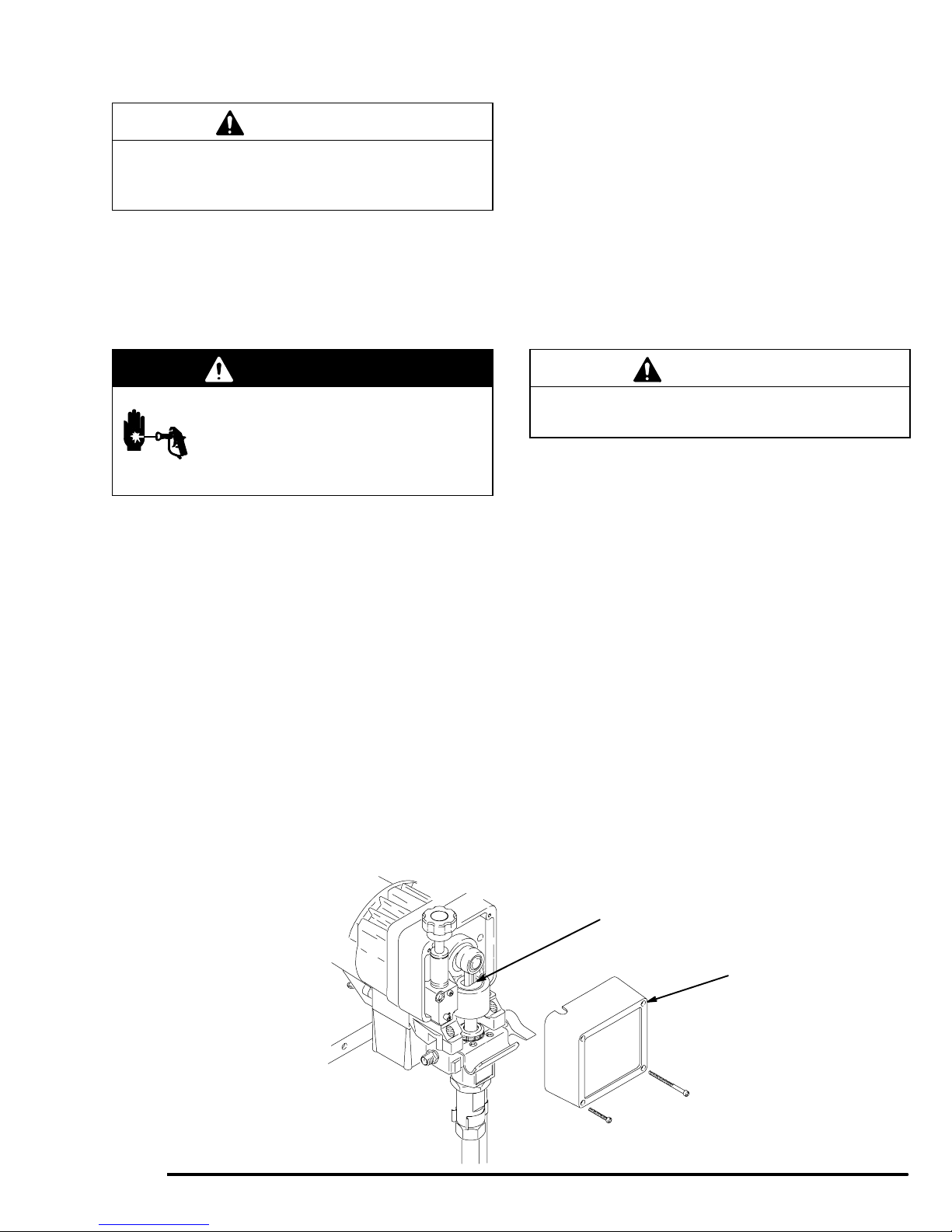

1. Remove the front cover (9). Remove the screws

(65) and lock washers (37). Lower the junction box

(63).

2. Disconnect the harness connector (A) from the

control module inside the box (63).

3. Remove the screws (24). Pull forward on the

pressure adjusting knob and tip the pressure

control (25) forward and up to detach it from the

drive housing (6).

4. Guide the harness (A) through the pinion housing

and drive housing and remove the pressure control.

8. Install the front cover (9). Connect the harness (A)

to the control module leads (B).

9. Install the junction box. Be sure no leads are

pinched against the mounting face of the pinion

housing.

25

1

24

6

9

A

B

5. Guide the harness of the new pressure control

through the drive housing and pinion housing

passages.

6. Install the new pressure control. Tip the pressure

control down and back into the drive housing (6).

Do not pinch or damage the harness (A).

Fig. 7

63

37

65

Torque to

1

21 in–lb (2.4 N.m)

06012

05834

30862018

Page 19

Control Module

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

NOTE: See Fig. 8 for this procedure.

1. Relieve pressure.

2. Remove the junction box screws (65) and lock

washers ( 37) and lower the junction box (63).

3. Remove screw (71) and disconnect harness

connector (A) from the control module in the

junction box.

4. Remove screws (303) and lock washers (304),

disconnect all wires.

5. Install new control module. Reconnect all wires.

6. Work backwards from step 3 to reassemble.

303 304 63

1

A

1 To pressure control switch

Fig. 8

315 314

37

65

71

68

06002

ON/OFF Switch

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

1. Relieve pressure.

2. Remove the junction box screws (65) and lock

washers and remove the junction box (63).

3. Remove the ring (314) and rubber boot (315).

4. Disconnect the red wires from the ON/OFF switch

and remove the switch.

5. Install the switch so the internal tab of the antirotational ring engages with the vertical groove in

the threads of the switch and the external tab

engages with the blind hole of the junction box.

6. Powder the inside of the rubber boot (315) with

talcum, then shake the excess out of the boot.

Install the nut and rubber boot and tighten.

7. Reconnect the ON/OFF switch red wires.

8. Install the junction box. Be sure no leads are

pinched against the mounting face. Also be sure

the gasket (68) is installed.

308620 19

Page 20

Pressure Transducer

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

NOTE: See Fig. 9 for this procedure.

1. Remove the displacement pump. See page 31.

2. Use a pull–twist motion to remove the transducer

(22) from the pump manifold.

3. Clean paint residue from the hole in the manifold;

do not scratch the surface of the hole.

4. Lightly apply oil to the o-ring of the new transducer.

5. Install the transducer in the pump manifold, while

guiding the o-ring and backup ring into place.

6. Align the holes in the transducer as shown by the

arrows in Fig. 9.

Fig. 9

22

05835A

7. Install the displacement pump. See page 32.

30862020

Page 21

Models 231550 and 231552

WARNING

Suction Hose

Lubricate

1

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

1. Separate the drain hose (31) from the suction hose

(32).

2. Pull upward on the hose (32) while unscrewing it

from the inlet tube (40). The hose coupling (A)

threads will engage and the hose will separate

from the tube.

3. Replace the o–ring (110) if it is worn or damaged.

4. Lubricate the o–ring (110) and the inlet tube (40)

threads with light grease.

5. Align the suction hose coupling with the threads of

the inlet tube (40). Tighten the hose onto the tube at

least 4 turns to ensure that the threads have disengaged and can function as a swivel joint.

CAUTION

9

1

Fig. 10

32

110

40

A

30

31

Model 231550 Shown

06004A

Misalignment or cross-threading will damage the

parts and/or create shavings which can cause the

o–ring (110) to leak.

308620 21

Page 22

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

Apply thread sealant

1

Apply grease

2

to face of base

Torque into pump

3

43a

3

43b

1

43c

43d

43e

43

manifold to 140 in–lb

(16 N.m)

Handle shown

4

in closed position

4f

43g

Drain Valve

Repair

1. Unscrew the spring retainer (43h) from the valve

body. Remove the spring, washers and stem/ball.

Clean any debris from the ball or seat area.

2. If replacing the gasket (43a) or seat (43b), pry out

the gasket.

NOTE: Whenever the gasket (43a) is removed, replace it with a new one.

3. Coat the o-ring (43d) with grease. Press the stem

into the valve body. Install the spring, washers and

spring retainer into the valve body.

4. Place the seat (43b) in the valve body so the

lapped side is toward the ball. Apply a small

amount of grease to the new gasket (43a) and

install it in the valve body.

43h

2

NOTE: The gasket will protrude from the end of the

valve until the valve is tightened into pump, which

correctly seats the gasket.

44

45

Fig. 11

4

02819

46

1. Turn the handle (46) to the closed position. Drive

out the pin (45). Remove the handle.

2. Remove the base (44).

3. Unscrew the drain valve (43). The gasket (43a)

and seat (43b) will stay in the valve.

Replacement

1. Apply a small amount of thread sealant onto the

valve (43) threads. Tighten the valve into the pump

manifold to 185 in–lb (21 N.m).

2. Lightly grease the face of the base (44) and install

the base. Turn the stem so the pin hole is vertical.

3. Securely install the handle (46) and drive pin (45).

WARNING

INJECTION HAZARD

To reduce the risk of serious injury, keep

the drain valve clean. Check drain valve

operation before spraying.

30862022

Page 23

Pinion, Clutch, Clamp, Field, & Engine

If servicing clutch components only, see page 25.

If no service is needed for internal parts of pinion

housing, remove drive assembly (drive and pinion

housing) from clutch housing. See page 25.

Pinion Housing Removal

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

NOTE: Refer to Fig. 12 for Steps 1 to 5.

1. Follow the Pressure Relief Procedure, page 12.

2. If the drive housing has not yet been removed,

follow steps 1 through 5 of DRIVE HOUSING, on

page 16.

8. Reassemble to drive housing.

CAUTION

Do not lose the thrust ball (2d). Refer to the CAUTION on page 16 for more information

NOTE: To disassemble the pinion, go to page 24. To

disassemble more of the sprayer, go to page 25. To

reassemble the sprayer from this point, skip ahead to

Reassembly, page 30, Step 8.

See page 24.1

2

Brush with G-n lubricant.

3

Pack with bearing grease (0.08 pint)

59

16

3. Remove the two bottom screws (59) and lockwashers (16) first, then remove the top three

screws (59) and lockwashers (16).

4. Pull the pinion housing (2) away from the clutch

housing (1). The armature (51b) will come with it.

5. Pull the armature (51b) off the hub (2h**) of the

pinion housing. Also see Fig. 13.

6. If replacing the complete pinion housing assembly

(2), brush G-n lubricant (supplied) on the pinion

shaft teeth. Then recoat the pinion shaft teeth with

bearing grease (supplied). Pack the remaining

bearing grease in the bottom part of the pinion

housing. Use 0.08 pint of the bearing grease.

7. Install new gasket (64) (supplied).

2

2d

Fig. 12

51b

2

1

1

3

05836C

308620 23

Page 24

Pinion Housing

Lubricate inner and

1

outer diameters

2

Lubricate teeth

Directional

3

arrow on roller

clutch must

face the small

bearing (2n)

Lubricate exterior

4

Back of pinion

5

housing

Press fit small

6

bearing (2n)

and clutch roller

(s) here

Fig. 13

Detail A

2m

2n

1.53

6

2a

5

2c

4

2d

Repairing the Pinion (Fig. 13)

NOTE: Use a hydraulic press if you purchase the pin-

ion parts individually. Otherwise, use Repair Kit No.

223189, which includes the shaft and bearings assembled and lubricated.

If using Repair Kit 223189, follow Steps 1 to 7, below.

1. Remove the small ring (2j) from the hub (2h) and

the large ring (2k) from the bearing recess of the

housing (2a).

2. Push on front of the shaft (2f) to force the bearing

and hub assembly out of the housing (2a).

3. Press the small bearing (2n) and roller clutch (2m)

out of the pinion housing (2a). Remove the new

bearing and roller clutch from the shaft of the kit

and press it into the housing to the dimension

shown. Directional arrow of roller clutch (2m) must

face bearing (2n). See Detail A.

4. Inspect o-ring (2p) and replace if necessary.

5. Install the shaft assembly, pushing it to the shoulder of the housing (2a).

6. Install rings (2k and 2j). Ring (2k) must be installed

with bevel facing back of pinion housing.

7. Go to Reassembly, page 29, Step 7, or continue

on page 24.

2k

2b

2p

2g

1

2f

2

2m

3

4

2n

4

2e

2. Remove the small ring (2j) from the hub (2h). Remove the snap ring (2k) from the bearing recess of

the housing (2a).

KEY

A Round steel bar to

push on shaft (2f)

B Hydraulic press

C Steel bar stock

D Two steel blocks

E Press platform

A

2g

B

Fig. 14

3. Push on the front of the shaft (2f) to force the

bearing and hub assembly out of the housing (2a).

4. Using a hydraulic press, place pieces of steel

bar stock on the inner race of the large bearing

(2g) and press the shaft through the hub and bearing. See Fig. 14.

5. Apply lubricant to the parts as shown in Fig. 13.

6. Press fit the following parts:

D Small bearing (2n) and then the roller clutch

(2m), with the directional arrow facing the

small bearing, into the rear of the housing (2a).

See Detail A in Fig. 13.

2j

2h

06005

2h

C

D

E

01427

If you purchased parts separately, follow steps 1 to

9, below. Disassemble only as far as needed for the

parts being replaced.

NOTE: The old bearing (2g) will be damaged as it is

removed. Have one on hand if you need to remove it

for any reason. Always replace bearing 2g if installing

a new hub 2h.

1. To replace small bearing (2n) or roller clutch (2m),

press the old one out of the pinion housing (2a).

30862024

D Large bearing (2g) to shoulder of shaft (2f).

D Hub (2h) onto the shaft (2f) all the way to the

large bearing (2g).

7. Install the shaft assembly, pushing it to the shoulder of the housing (2a).

8. Install the rings (2k and 2j).

9. Skip ahead to Reassembly, page 30, Step 8, or

continue on page 25.

Page 25

WARNING

Clutch

3. Pull the drive assembly (D) away from the clutch

housing (1).

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

NOTE: The clutch assembly (51) includes the arma-

ture (51b) and rotor (51a). The armature and rotor

must be replaced together so they wear evenly. A new

hub (2h) should be installed as well to ensure long

clutch life.

NOTE: If the drive assembly (D) is not yet separated

from the clutch housing (1), follow Steps 1 to 4. Otherwise, start at Step 5.

NOTE: Refer to Fig. 15 for this procedure.

1. Follow the Pressure Relief Procedure, page 12.

2. Remove the two bottom screws (59) and lockwashers (16) first, then remove the top three

screws (59) and lockwashers (16).

CAUTION

The sprayer may become out of balance with the

drive housing and pinion housing removed. Support

the rear of the cart to prevent the partially disassembled sprayer from falling over.

4. The armature (51b) will move with the drive assembly. Remove the armature from the pinion hub

(2h).

CAUTION

Examine the splined hub (2h**, Fig. 13, page 24) for

wear. Replace as needed. Follow the Pinion Housing

instructions, page 24.

5. There are two ways to remove the rotor (51a).

a. Remove the four socket head capscrews (57)

and lockwashers (16). Install two of the screws

in the threaded holes (E) in the rotor. Alternately tighten the screws until the rotor comes

off. See Fig. 15.

b. You can use a standard steering wheel puller

(A). However, two 1/4–28 x 3 or 4 in. long

screws (B) are also needed. Replace the short

screws of the steering wheel puller with the

longer screws (B). Turn the screws (B) into the

threaded holes (E) of the rotor (51a). Tighten

the capscrew (C) of the tool until the rotor

comes off. See the Detail in Fig. 15.

6. Skip ahead to Reassembly, page 30, Step 6, or

continue on page 26.

Fig. 15

59

16

2h

1

E

A

B

C

05837C

51a

16

57

51b

D

2

18

308620 25

Page 26

Engine

A

NOTE: The engine must be removed before the

Clamp and Clutch Housing can be removed.

CAUTION

The sprayer will be out of balance when the engine,

clutch housing, drive housing and pinion housing are

removed. Support the rear of the cart to prevent the

partially disassembled sprayer from falling over.

CAUTION

The sprayer will experience poor clutch life if a

replacement engine is purchased from another

vendor. The engine for this sprayer is manufactured

by Honda to a special Graco specification.

1. Working under the mounting plate (A), remove the

two lock nuts (78) and then pull the screws (77)

out of the base of the engine. Remove the screw

(61). Disconnect the red wire (B) from the engine

lead (D). Disconnect the black and white wires

from the field. Pull the cable (E) carefully through

the grommet (50) before removing the engine. See

Fig. 16 and 17.

1

D

50

77

2. Lift the engine carefully and place it on a work

bench.

3. Remove the Field and Wiring Harness, Clamp

and Clutch Housing, as instructed on page 27.

NOTE: All service to the engine must be performed by

an authorized Honda dealer.

1

To engine alternator.

50

WHITE

BLACK

1

B

RED

E

78, 87

86

50

D

61

Fig. 17

A

78

06903

Fig. 16

Bottom View of Engine and Cart

30862026

06006

Page 27

Field & Wiring Harness

NOTE: Refer to Fig. 18.

1. Back out the four setscrews (58) holding the field

(53) to the clutch housing (1) approximately 3

turns.

1

2. Pull out the field. The field fits closely to the clutch

housing and must be removed carefully to prevent

jamming.

3. Pull the plastic caps (B) off the wire screws (79) in

both places on the field. Remove the screws and

remove the wire (A).

4. Skip ahead to Reassembly, page 28, Step 4 or

continue on page 27.

Clamp

NOTE: A standard steering wheel puller and two

1/4–28 x 3 or 4 in. long screws are required to remove

the clamp.

NOTE: Refer to Fig. 19.

1. Loosen the two screws (57) on the clamp (55),

working through the slot at the bottom of the clutch

housing (1).

Fig. 18

1

A

B

C

53

79

58

A

B

05839

2. Install two screws (B) of the tool (A) in two of the

threaded holes in the clamp (55). Tighten the

screw (C) until the clamp comes off.

3. Skip ahead to Reassembly, page 28, Step 2, or

continue below.

Clutch Housing

NOTE: Refer to Fig. 20.

CAUTION

If the clutch housing is removed from the engine a

special alignment tool is required to reinstall it.

1. Remove the four capscrews (83) and lockwashers

(84) which hold the clutch housing (1) to the engine.

2. Remove the engine key (56).

3. Pull off the clutch housing (1).

4. Skip ahead to Reassembly, page 28, Step 1.

Fig. 19

Fig. 20

55

57

05840

56

1

84

83

05841A

308620 27

Page 28

Reassembly

0

CAUTION

The sprayer will be out of balance when only the

engine and clutch housing are installed. Support the

rear of the cart to prevent the sprayer from falling

over.

1. Install the clutch housing (1), capscrews (83) and

lockwashers (84) on the engine. Use special

alignment tool to position clutch housing on engine. Torque screws (83) to 200 in-lb (22 Nm).

2. Install the engine shaft key (56). See Fig. 21.

3. Press the clamp (55) onto the engine shaft (A).

Maintain the 1.41 inch 0.01 (35.8 0.25 mm)

dimension shown in Fig. 22.

Torque the screws oppositely and

1

evenly to 25 in–lb (2.8 N@m).

2

Slot.

Torque the screws to 200 in–lb (22

3

N@m).

Apply low strength thread locker to set

4

screws (58).

Torque the screws to 120 in–lb (14 N@m).

5

To check the dimension, place a rigid, straight

steel bar (B) across the face of the clutch housing

(1). Use an accurate measuring device to measure

the distance between the bar and the face of the

clamp. Adjust the clamp as necessary. Torque the

two screws (57) to 120 in–lb (14 N.m).

4. Connect the wires of the harness (D) with the

screws (79) in both places on the field (wires can

be attached to either connection). Pull the plastic

caps (C) up and snap them over the screws. Install

the field in the clutch housing. Push the wire

harness through the slot in the clutch housing.

Align the setscrew holes in the field and the clutch

housing (1). Hand tighten the setscrews (58)

oppositely and evenly. See Fig. 21.

56

Fig. 21

53

55

84

3

83

A

57

58

1

2

5

1

4

D

C

79

05842A

30862028

Page 29

The face of the housing.

1

2

1.41 ".010 inch (35.8 ".25 mm).

3

Torque the screws to

120 in–lb (14 N.m).

1

1

B

Reassembly

The sprayer will be out of balance when only the

engine and clutch housing are installed. Support the

rear of the cart to prevent the sprayer from falling

over.

5. Place the engine (48) assembly on the cart. Align

the mounting holes. Carefully guide the engine

wire and wiring harness (E) from the field, through

the appropriate grommets (50) in the mounting

plate (A). Install the flange screws (77) and locknuts (78). Install the screw (61). Tighten all three

screws. Connect the engine wire to the red wire

(B), and connect the black and white wires as

shown in the Detail drawing in Fig. 16.

58

2

3

CAUTION

Fig. 22

05078

308620 29

Page 30

Reassembly

6. Be sure the face of the rotor (51a) and the clamp

(55) are free of all burrs. Install the rotor, lockwashers (16) and capscrews (57). Torque the

capscrews to 7 ft–lb (9.5 N.m). See Fig. 23.

7. After installing the rotor (51a) the air gap must be

adjusted between the rotor and the field (53).

Tighten the setscrews (58) oppositely and evenly.

Pull the engine recoil rope to assure that the

engine turns freely, and there is no contact between the rotor and the field. If there is contact,

loosen the setscrews and reposition the field.

NOTE: With the autogap style armature, the gap between the rotor and the armature is critical for proper

operation. The clutch kits with an autogap style armature include a cardboard spacer (p/n 186857) to set

the proper gap. This spacer is for use only

during

installation.

1

Torque the screw to 7 ft–lb (9.5 N.m).

The face must be clean.

2

To engine alternator.

3

4

Spline

5

Chamfered end of hub (2h)

Apply low strength thread locker.

6

Torque to 100 in.-lb (Nm).

7

2h

5

8. Clean the face of the armature (51b). With the flat

side of the armature facing the rotor (51a), slide

the armature onto the hub (2h) in the drive/pinion

assembly (D) just until the chamfered end of the

hub (2h) protrudes through the armature. See

Detail B, Fig. 23. There will be significant resistance. Attach the cardboard spacer, supplied with

the clutch kit, to the face of the armature. Bend

tabs over outside diameter of armature.

Brace the cart against a wall to keep it from rolling.

Push the drive/pinion assembly onto the clutch

housing (1). There will be significant resistance.

When the mating surfaces of the drive/pinion assembly and the clutch housing (1) are flush, remove the drive/pinion assembly. Remove the

cardboard spacer.

9. Assemble the drive assembly (D) to the clutch

housing (1), using the capscrews (59) and lockwashers (16). See Fig. 23.

48

6

58

7

59

16

06007

Detail B

Fig. 23

52

1

2

51a

16

1

57

2

51b

D

53

50

77

4

61

05843C

A

78

05843B

30862030

Page 31

Displacement Pump Repair

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 12.

NOTE: Packing Repair Kit 235703 is available. Refer-

ence numbers of parts included in the kit are marked

with an asterisk, i.e., (121*). For the best results, use

all the new parts in the kit, even if the old ones still look

good.

Removing the pump (See Fig. 24.)

1. Flush the pump, if possible. Relieve pressure. Stop

the pump with the piston rod (107) in its lowest

position, if possible.

2. Remove the filter (21).

3. Remove suction hose or tube (40).(For suction

hose, refer to page 21.

NOTE: If repairing only the intake valve assembly, go

to Intake valve repair, in manual 308190.

NOTE: To minimize down time, and for the best sprayer

performance, clean the transducer (see page 20) whenever you repack the pump. Replace these parts as needed.

21

9

107

1

17

12

4. Use a screwdriver to push the retaining spring (12)

up and push out the pin (11).

5. Loosen the screws (17). Remove the pump (18).

11

18

30

120

*122

*121

*119

Fig. 24

118

Torque to

40

2

39

1

50 ft–lb (68 N.m)

2

Apply sealant

Model 231363 Shown

05844

308620 31

Page 32

Displacement Pump Repair

8

Repairing the pump

See manual 308190 for pump repair instructions.

Installing the pump (See Fig. 24 and 25.)

1. Mount the pump on the drive housing. Tap it into

the alignment pins with a soft hammer. Tighten the

screws (17) to 50 ft-lb (68 N.m).

WARNING

MOVING PARTS HAZARD

Be sure the retaining spring (12) is firmly

in the groove all the way around, to

prevent the pin (11) from working loose

due to vibration. See Fig. 25.

If the pin works loose, it or other parts could break

off due to the force of the pump action. These parts

could be projected into the air and result in serious

injury or property damage, including the pump

connecting rod or drive housing.

2. Align the hole in the rod (107) with the connecting

rod assembly (10). Use a screwdriver to push the

retaining spring (12) up and push in the pin (11).

Push the retaining spring (12) into place around

the connecting rod.

3. Reconnect the suction and drain hoses. Install the

front cover (9). On The lo-boy sprayer inspect the

o-ring (110). Replace the o-ring if it is worn or

damaged.

4. Tighten the packing nut (102) just enough to stop

leakage, but no tighter. Fill the packing nut/wet-cup

1/3 full with Graco TSL. Push the plug (123) into

the wet-cup.

11

10

17

12

102

1

123

Torque to

1

50 ft–lb (68 N.m)

Fig. 25

0600

30862032

Page 33

Pressure Control Parts List

238672 Pressure Control for the GM3000 Sprayers

Ref

No. Part No. Description Qty

301 280340 HOUSING, box, junction 1

302 238660** TRIAC 1

303 100035 SCREW, panhead, 10–24 x 2 inch 2

304 157021** LOCKWASHER, No. 10 3

305 108783** SCREW. filhd, 1

306 100284** NUT, hex 1

307 107070** SCREW, flat hd 2

308 103181** LOCKWASHER 2

309 100072** NUT, hex 2

310 111936** RECTIFIER, bridge 1

Parts Drawing –

Pressure Control

310**

316

71

303

304

301

305**

312**

2

Ref

No. Part No. Description Qty

311 238676 CONDUCTOR, electrical 1

312** 191242 PLATE, module 1

313 105679 SWITCH, toggle 1

314 105658 RING, locking 1

315 105659 BOOT, toggle 1

316 238791 CONDUCTOR, electrical 1

**Included in Repair Kit No. 238661.

Y Replacement Danger and Warning labels, tags, and

cards are available free.

Wiring Schematic –

Pressure Control

To Microswitch

304** 306**

307**

302**

308** 309**

314

315

1

1 To pressure control switch

2 Apply thermopaste between 301 and 312;

310 and 312; 302 and 312

37

65

313

311

68

06002

311

RED

313

302

RED

GROUND

GREEN

-

+

To Microswitch

310

WHITE BLACK

06010

308620 33

Page 34

Model 231363

21

Upright Sprayer Parts Drawing

69

16

1

24

25

7

1

67

8a

3

2d

DETAIL

8b

19

8

29

47

20

27

23

26

75

76

74

73

11

10

15

16

6a

2

68

63

3

37

9

12

64

65

37

6

1

22

90

1

20

92

91

17

59

58

44

45

46

56

66

48

28

2

77

81

50

13

14

18

30

40

39

16

51a

53

54

55

43

31

32

33

83

84

16

1

57

51b

3

85

16

57

79

78

80

89

1

1

Label

2

See the detail, above.

3

See page 38 for the parts.

30862034

61

38

49

34

35 36

05846D

Page 35

Upright Sprayer Parts List

Model 231363, Series A

Ref.

No. Part No. Description Qty.

1 191207 HOUSING, clutch 1

2 238684 HOUSING, pinion 1

See page 38 for parts

6 238691 DRIVE HOUSING 1

6a 100069 BALL 1

7 176904 LABEL, designation 1

8 235558 CRANKSHAFT 1

8a 180131 BEARING, thrust 1

8b 107434 BEARING, thrust 1

9 187789 COVER, front, blue 1

10 218359 CONNECTING ROD 1

11 176818 PIN, headless, 3/8” dia. x 1” 1

12 176817 SPRING, retaining 1

13 112777 SCREW, mach, ovl hd, 10–24 x .375 2

14 190321 HANGER, pail 1

15 103345 SCREW, socket head, 3

1/4–20 x 1–1/4”

16 105510 LOCKWASHER, 1/4” 16

17 111706 CAPSCREW, 7/16–14 x 1–3/4” 2

18 235699 PUMP, displacement 1

See manual 308190 for parts

19 238802 GEAR REDUCER 1

20 162453 NIPPLE, hex, 1/4 npsm x 2

1/4 npt, 1–3/16”

21 239425 FILTER, fluid 1

See Manual 308249 for parts

22 235009 PRESSURE TRANSDUCER 1

23 114415 SCREW, filh, 8–32 x 1–1/4” 1

24 114416 SCREW, filh, 10–24 x 1–5/8” 2

25 238799 SWITCH, pressure control 1

26 111705 SCREW, filh, 8–32 x 2–1/2” 3

27 290364 LABEL, identification, front 1

28 238187 HANDLE & HOSE RACK 1

29 192027 SLEEVE 2

30 108982 CONNECTOR, tube 1

31 181102 CLIP, spring 1

32 186549 DRAIN TUBE 1

33 186245 CLIP, spring 1

34 106062 WHEEL, semi–pneumatic 2

35 101242 RING, retaining, wheel 2

36 104811 HUBCAP 2

37 100020 WASHER 4

38 108691 PLUG, tubing 2

39 183770 STRAINER, inlet, 1/2–14 npsm 1

40 192169 TUBE, suction 1

43 235014 DRAIN VALVE 1

See Fig.11

43a 111699 GASKET 1

43b 187615 SEAT 1

43c 187621 HOUSING, valve, drain 1

43d 168110 O-RING 1

43e 224968 STEM, valve, drain 1

43f 111599 WASHER, flat 1

43g 187623 SPRING, compression 1

Ref.

No. Part No. Description Qty.

43h 187622 RETAINER, spring, valve 1

44 224807 BASE, valve 1

45 111600 PIN, grooved, 3/32 x 1” 1

46 187625 HANDLE, drain valve 1

47 100721 PLUG, pipe, headless, 1/4–18 nptf 1

48 108879 ENGINE, gasoline 1

49 239422 CART 1

50 109099 BUSHING, snap 2

51 238798 CLUTCH ASSEMBLY 1

51a ROTOR, clutch 1

51b ARMATURE, clutch 1

53 238803 FIELD, clutch 1

54 108800 PIN, dowel, 5/16 x 1” 1

55 188426 CLAMP, mounting, rotor 1

56 183401 KEY, parallel, 3/16” sq x 7/8” 1

57 108803 CAPSCREW, hex sch, 1/4–28 x 1.0” 6

58 108801 SETCREW, 1/4” 4

59 100644 CAPSCREW, sch, 1/4–20 x 3/4” 5

61 113802 CAPSCREW, hex hd, 3/8–16 x 5/8” 1

63 238672 PRESSURE CONTROL 1

64 191258 GASKET, housing 1

65 111703 SCREW, filh, 10–24 x 3” 4

66 189919 PLATE, designation 1

67 290228 LABEL, caution 1

68 187963 GASKET 1

69 100643 SCREW, socket head, 1/4–20 x 1” 2

71 110637 SCREW, 10–24 X 3/8” 1

72 290061 LABEL, warning 1

73 109032 SCREW, recess pnh,

self–tap “F”, No. 10–24 x 1/4” 4

74 112827 BUTTON, snap 2

75 183350 WASHER, plain, 0.90” 2

76 108068 PIN, spring, straight, 3/16” 2

77 110837 SCREW, serrated flange, hex hd,

5/16–18 unc–2a x 1.5” 2

78 110838 LOCKNUT, heavy hex, 5/16–18 3

79 109033 SCREW, bdgh, 6–32 x 3/16” 2

80 237686 GROUNDING CLAMP & WIRE 1

81 112798 SCREW, mach thd, 1/4–20 x 0.375 1

See Pressure Control Parts, page 33

83 109031 CAPSCREW,1/2 sch, 5/16–24 x 1” 4

84 104008 LOCKWASHER 4

85 221183 CONDUCTOR, electrical 1

86 108868 CLAMP, wire 1

See Fig. 16

87 101344 SCREW, cap, 5/16–18 x 7/8” 1

See Fig. 16

89 LABEL, warning, See page 39 1

90 181867 LABEL, warning 1

91 192014 PLATE, indicator 1

92 113684 RIVET, blind 2

Y Extra warning labels available free of charge.

308620 35

Page 36

Lo-Boy Sprayer Parts Drawing

Model 231550, Series A

REF 31

REF 32

21

47

20

9

23

27

1

26

110

11

32

40

12

20

3

33

109

24

10

51b

25

15

57

16

17

16

39

18

67

7

1

1

22

51a

8a

31

30

53

54

69

16

3

2d

8b

19

8

DETAIL

29

74

3

6a

64

2

68

63

37

65

75

76

73

37

6

1

43

55

44

45

83

84

90

46

56

58

59

16

2

1

92

91

28

48

77

81

66

1

50

80

57

16

85

89

1

79

78

Label

1

2

See the detail, above.

3

See page 38 for parts

30862036

61

38

49

34

35 36

05980D

Page 37

Lo-Boy Sprayer Parts List

Model 231550, Series A

Ref.

No. Part No. Description Qty.

1 191207 HOUSING, clutch 1

2 238684 HOUSING, pinion 1

See page 38 for parts

6 238656 DRIVE HOUSING 1

6a 100069 BALL 1

7 176904 LABEL, designation 1

8 235558 CRANKSHAFT 1

8a 180131 BEARING, thrust 1

8b 107434 BEARING, thrust 1

9 187789 COVER, front, blue 1

10 218359 CONNECTING ROD 1

11 176818 PIN, headless, 3/8” dia. x 1” 1

12 176817 SPRING, retaining 1

15 103345 SCREW, socket head, 3

1/4–20 x 1–1/4”

16 105510 LOCKWASHER, 1/4” 16

17 111706 CAPSCREW, 7/16–14 x 1–3/4” 2

18 235699 PUMP, displacement 1

See manual 308190 for parts

19 238802 GEAR REDUCER 1

20 162453 NIPPLE, hex, 1/4 npsm x 2

1/4 npt, 1–3/16”

21 239425 FILTER, fluid 1

See Manual 308249 for parts

22 235009 PRESSURE TRANSDUCER 1

23 114415 SCREW, filh, 8–32 x 1–1/4” 1

24 114416 SCREW, filh, 10–24 x 1–5/8” 2

25 238799 SWITCH, pressure control 1

26 111705 SCREW, filh, 8–32 x 2–1/2” 3

27 290364 LABEL, identification, front 1

28 238187 HANDLE & HOSE RACK 1

29 192027 SLEEVE 2

30 108982 CONNECTOR, tube 1

31 191640 TUBE, drain 1

32 191619 TUBE, suction 1

33 178342 CLIP, spring 2

34 106062 WHEEL, semi–pneumatic 2

35 101242 RING, retaining, wheel 2

36 104811 HUBCAP 2

37 100020 WASHER 6

38 108691 PLUG, tubing 2

39 235004 STRAINER, inlet, 3/4–16 unf 1

40 187627 TUBE, suction 1

43 235014 DRAIN VALVE 1

See Fig.11

43a 111699 GASKET 1

43b 187615 SEAT 1

43c 187621 HOUSING, valve, drain 1

43d 168110 O-RING 1

43e 224968 STEM, valve, drain 1

43f 111599 WASHER, flat 1

43g 187623 SPRING, compression 1

43h 187622 RETAINER, spring, valve 1

44 224807 BASE, valve 1

Ref.

No. Part No. Description Qty.

45 111600 PIN, grooved, 3/32 x 1” 1

46 187625 HANDLE, drain valve 1

47 100721 PLUG, pipe, headless, 1/4–18 nptf 1

48 108879 ENGINE, gasoline 1

49 238685 CART 1

50 109099 BUSHING, snap 2

51 238798 CLUTCH ASSEMBLY 1

51a ROTOR, clutch 1

51b ARMATURE, clutch 1

53 238803 FIELD, clutch 1

54 108800 PIN, dowel, 5/16 x 1” 1

55 188426 CLAMP, mounting, rotor 1

56 183401 KEY, parallel, 3/16” sq x 7/8” 1

57 108803 CAPSCREW, hex sch, 1/4–28 x 1.0” 6

58 108801 SETCREW, 1/4” 4

59 100644 CAPSCREW, sch, 1/4–20 x 3/4” 5

61 113802 CAPSCREW, hex hd, 3/8–16 x 5/8” 1

63 238672 PRESSURE CONTROL 1

64 191258 GASKET, housing 1

65 111703 SCREW, filh, 10–24 x 3” 4

66 189919 PLATE, designation 1

67 290228 LABEL, caution 1

68 187963 GASKET 1

69 100643 SCREW, socket head, 1/4–20 x 1” 2

71 110637 SCREW, 10–24 X 3/8” 1

72 290061 LABEL, warning 1

73 109032 SCREW, recess pnh,

self–tap “F”, No. 10–24 x 1/4” 4

74 112827 BUTTON, snap 2

75 183350 WASHER, plain, 0.90” 2

76 108068 PIN, spring, straight, 3/16” 2

77 110837 SCREW, serrated flange, hex hd,

5/16–18 unc–2a x 1.5” 2

78 110838 LOCKNUT, heavy hex, 5/16–18 3

79 109033 SCREW, bdgh, 6–32 x 3/16” 2

80 237686 GROUNDING CLAMP & WIRE 1

81 112798 SCREW, mach thd, 1/4–20 x .375 1

See Pressure Control Parts, page 33

83 109031 CAPSCREW,1/2 sch, 5/16–24 x 1” 4

84 104008 LOCKWASHER 4

85 221183 CONDUCTOR, electrical 1

86 108868 CLAMP, wire 1

See Fig. 16

87 101344 SCREW, cap, 5/16–18 x 7/8” 1

See Fig. 16

89 LABEL, warning, See page 39 1

90 181867 LABEL, warning 1

91 192014 PLATE, indicator 1

92 113684 RIVET, blind 2

109 103473 CLAMP, cable 2

110 104938 O-RING 1

Y Extra warning labels available free of charge.

308620 37

Page 38

Parts List & Drawing – Complete Sprayers

Models 231551 and 231552

GM3000 Airless Paint Sprayer

Includes items 201 to 204

Ref

No. Part No. Description Qty

201 231363 GM3000 Upright Sprayer

See parts list on page 35 1

231550 GM3000 Lo-Boy Sprayer