Page 1

INSTRUCTIONS–P

This

manual contains IMPORT

WARNINGS AND INSTRUCTIONS

READ AND RETAIN FOR REFERENCE

ANT

ARTS LIST

PORTABLE

30:1 Ratio President

Hydra-Spray Pumps

100

psi (7 bar) MAXIMUM AIR INLET PRESSURE

3000 psi (210 bar) MAXIMUM FLUID WORKING PRESSURE

Model 224-625, Series A

For cold spray applications

Includes pump and portable cart

Model 231-163

For cold spray applications

Includes pump, portable cart, hose, gun and tip

Model 224-630, Series A

For heated spray applications

Includes pump, portable cart, V

heater mounting kit 222-262, and circulating kit 222-261

iscon

heater

,

307-928

Rev F

Supersedes E

Model 231-160

For heated spray applications

Includes pump, portable cart, V

heater mounting kit 222-262, circulating kit 222-261,

hose, gun and tip

T

ABLE OF CONTENTS

Warnings

Terms 3

Installation 4-11

Operation/Maintenance 12

Parts

How

Accessories 19

Technical

Warranty Back

Graco T

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drawings and Lists

to Order Replacement Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data

.

. . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . .

oll-Free Phone Numbers

iscon

heater

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

.

. . . . . . . . .

.

. . . .

,

2, 3

14-18.

15, 17

Back Cover

Cover

Back Cover

MODEL

224-625 SHOWN

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

COPYRIGHT 1988, GRACO INC.

Page 2

SAFETY

HIGH

PRESSURE FLUID CAN CAUSE SERIOUS INJURY. FOR PROFESSIONAL USE ONL

OBSERVE

FLUID INJECTION HAZARD

General

This

equipment

gun,

leaks or ruptured components can inject fluid through your skin and

into

your body and

need

for amputation. Also, fluid injected or splashed into the eyes or on

the

skin can cause serious damage.

NEVER

point the spray gun at

put

hand or fingers over the spray tip. NEVER try to “blow back” paint; this

is

NOT an air spray system.

ALWA

YS have the tip guard in place on

ALL W

ARNINGS. Read And Understand All Instruction Manuals Before Operating Equipment.

Safety

generates very high fluid pressure. Spray from the spray

cause extremely serious bodily injury

anyone or at any part of the body

the spray gun when spraying.

, including the

. NEVER

W

ARNINGS

Diffuser

The

spray gun dif

when the tip is not installed. Check the dif

tion

the

Follow

tip.

firmly

gun.

diffuser

Tip

ALWAYS

tip

does

of

Pressure Relief Procedure

Aim the spray gun into a grounded metal pail, holding the spray gun

to the pail. Using the lowest possible pressure,

If the fluid emitted is not dif

immediately

Guard

have the tip guard in place on the spray gun while spraying. The

guard alerts you to the fluid injection hazard and

not prevent,

your body close to the spray tip.

Y.

fuser breaks up spray and reduces the risk of fluid injec

fused into an irregular

.

the risk of accidentally placing your fingers or any part

fuser operation regularly

, below

, then remove the spray

trigger the spray

stream, replace the

helps reduce,

.

but

ALWAYS

or

NEVER try to stop or deflect leaks with your hand or body

Be sure equipment safety devices are

use.

Medical

If

CARE AT

exactly

Spray

Be

use.

malfunction

Safety

Whenever

gun

operative.

of

Trigger

Never

helps prevent the gun from triggering accidentally if it is dropped or

bumped.

follow the

removing the spray tip or servicing any system equipment.

Alert––Airless Spray W

any fluid appears

ONCE. DO NOT TREA

what fluid was injected.

Note

to Physician:

to treat the injury surgically as soon as possible

portant

delay

treatment to research toxicity

coatings injected directly into the blood stream. Consultation with a

otic

plastic

surgeon or reconstructive hand surgeon may be advisable.

Pressure Relief Procedure

operating

ounds

to penetrate your skin, get

Injection in the skin

T AS A SIMPLE CUT

is a traumatic injury

. T

oxicity is a concern with some ex

, right, before

properly before each

EMERGENCY MEDICAL

cleaning

.

. T

ell the doctor

.

It is im

. Do

not

Gun Safety Devices

sure all spray gun safety devices are operating properly before each

Do not

remove or modify any part of the spray gun; this can cause a

and result in serious bodily injury

.

Latch

you stop spraying, even

safety latch in the

Failure to set the safety latch can result in accidental triggering

the spray gun.

closed or “safe” position, making the spray gun in

for a moment, always set the spray

Guard

operate the spray gun with the trigger guard removed. This guard

Spray T

Use

tip

ALWAYS

spray tip to clean it.

NEVER

lieved

-

-

-

ip Safety

extreme caution when cleaning or changing spray tips. If the

clogs

while spraying, engage the spray gun safety latch immediately

follow the

wipe of

and the spray gun safety latch is engaged.

Pressure

To

reduce the risk of serious bodily injury

splashing

always follow this procedure whenever you shut off the pump,

checking or servicing any part of the spray system, when in

when

cleaning or changing spray tips, and whenever you stop

stalling,

spraying.

1. Engage

2. Shut

for

at least 10 minutes to allow it and the heater to cool.

3.

Shut of

4. Close

tem).

5. Disengage

6. Hold a metal part of the spray gun firmly to the side of a

grounded

sure.

7. Engage

8. Open

tainer

9. Leave

If

you suspect that the spray tip or hose is

that

pressure has not been fully relieved after following the steps

above,

VER

end coupling and relieve pressure gradually, then loosen completely.

Now clear the tip or hose.

Pressure Relief

f build-up around the spray tip until pressure is fully re

Procedure

and then remove the

Relief Procedure

in the eyes or on the skin, or injury from moving parts,

the spray gun safety latch.

of

f the main power to the heater

f the air to the pump.

the bleed-type

the spray gun safety latch.

metal pail, and

the spray gun safety latch.

the

drain valve (supplied in your system), having a con

ready to catch the drainage.

the drain valve open until you are ready to spray

Y SLOWL

master air valve (supplied in your sys

trigger the spray gun to relieve pres

Y loosen the tip guard retaining nut or hose

, including fluid injection,

, if used. Circulate the

completely clogged, or

spray

fluid

again.

.

-

-

-

-

-

EQUIPMENT MISUSE HAZARD

General

Any misuse of the spray equipment or accessories, such as

overpressurizing,

ids, or using worn or damaged parts, can cause them to rupture and result

in

fluid injection, splashing in the eyes or on the skin, or other serious bod

ily

injury

NEVER

to

malfunction.

CHECK

aged

Always

ommended

307-928

Safety

modifying parts, using incompatible chemicals and flu

, or fire, explosion or property damage.

alter or modify any part of this equipment; doing so

all spray equipment regularly and repair or replace worn or dam

parts immediately

wear protective eyewear

by the fluid and solvent manufacturer

.

, gloves, clothing and

could cause it

respirator as rec

.

-

-

-

-

System

The

WORKING

PRESSURE.

Be

the maximum working pressure of the pump. DO NOT exceed the

mum

tem.

Fluid

BE

the

the

ture

Pressure

30:1 ratio President pump

PRESSURE at 100 psi (7 bar) MAXIMUM INCOMING AIR

NEVER exceed 100 psi (7 bar) air pressure to the pump.

sure that all spray equipment and

working pressure of any component or accessory used in the sys

can develop 3000 psi (210 bar) MAXIMUM

accessories are rated to withstand

maxi

Compatibility

SURE that all fluids and solvents used are chemically compatible with

wetted parts shown in the

separate component manuals. Always read the manufacturer’s litera

before using fluid or solvent in this pump.

TECHNICAL DATA on the back page or in

-

-

-

Page 3

HOSE SAFETY

High

pressure fluid

ops

a leak,

high

pressure spray emitted from it can cause a fluid injection injury or

other

serious bodily injury or property damage.

ALL FLUID HOSES MUST HAVE SPRING GUARDS ON BOTH

The spring guards help protect the hose from kinks or bends at or

ENDS!

close

to the coupling which can result in hose rupture.

TIGHTEN

fluid can dislodge a loose coupling or allow high pressure spray to be

from the coupling.

emitted

NEVER

use a damaged hose. Before each use, check the entire hose

cuts, leaks,

couplings.

NOT try to recouple high pressure hose or mend it with tape or any

DO

other

device.

fluid.

HANDLE

move

with the inner tube and cover of the hose. DO

to

AND ROUTE HOSES CAREFULLY. Do not pull on hoses to

equipment. Do not use fluids or solvents which are not compatible

temperatures above 180 F (82 C) or below –40 F (–40 C).

in the hoses can be very dangerous. If the hose devel

split or rupture due to any kind of wear

all fluid connections securely before each use. High pressure

abrasion,

If any of

bulging cover

these conditions exist, replace the hose immediately

A repaired hose cannot safely contain the high pressure

, or damage or movement of the hose

, damage or misuse, the

NOT

expose Graco hoses

for

FIRE OR EXPLOSION HAZARD

Static

electricity is created by the flow of fluid through the pump and hose.

If

every part of the

may

occur

occur

when plugging in or unplugging a

ignite

fumes from solvents and the fluid being sprayed,

other

flammable substances, whether you are spraying indoors or out

and can cause a fire or explosion and serious bodily injury and

doors,

property

damage. Do

spray

area when there is any chance of igniting fumes still in the air

If

you experience any static sparking or even a slight shock while using

this

equipment, STOP SPRA

for proper grounding. Do not use the system again until the problem

tem

has

been identified and corrected.

spray equipment is not properly grounded, sparking

, and the system may

not plug in or unplug any power supply cords in the

become hazardous. Sparking may also

power supply cord. Sparks can

YING IMMEDIA

TELY.

Check the entire sys

dust particles and

.

-

Hose Grounding Continuity

Proper

hose grounding continuity is essential to maintaining a grounded

spray

system. Check the electrical resistance of your air and fluid hoses

at

least once a week. If your hose does not have a tag on it which speci

fies the maximum electrical resistance, contact the hose supplier or

manufacturer

in

the appropriate range for your hose to check the resistance. If the

tance

grounded

Also,

MOVING PARTS HAZARD

.

The

piston in the air motor

when

your

fingers or other body parts. Therefore, NEVER operate the pump

with

the air motor plates removed. KEEP CLEAR of moving parts when

starting

any

system component, follow the

2,

to prevent the pump from starting accidentally

10.

-

-

To ground the pump:

To ground the pump, loosen the grounding lug locknut (W) and

washer

wire

Fig

1. Refer to

other

for the maximum resistance limits. Use a resistance meter

exceeds the

or poorly

read

air is supplied to the motor

or operating the pump.

T

o maintain grounding continuity when flushing

,

sure

grounded

(X). Insert one end of a 1.5 mm (12 ga) minimum ground

(Y) into the slot in lug (Z) and tighten the locknut securely

end of the ground wire to a true earth ground.

recommended limits, replace it immediately

grounded hose can make your system hazardous.

FIRE OR EXPLOSION HAZARD

, located behind the air motor plates, moves

. Moving parts can pinch or amputate

Before checking or servicing the pump or

Pressure Relief

always hold a metal part of the spray gun firmly to the side of a

metal

pail, then trigger the spray gun.

page 19 to order a ground wire and clamp. Connect the

, below

Procedure

.

.

or relieving pres

X

resis

. An un

on page

. See

-

-

-

-

Grounding

To reduce the risk of static sparking, ground the pump, object being

sprayed,

CHECK

your

equipment:

1.

2.

3.

4.

5.

6.

7.

8.

9.

and all other spray equipment used or located in the spray area.

your local electrical code for detailed grounding instructions for

area and type of equipment. BE SURE to ground all of this spray

Pump:

use a ground wire and clamp as shown in Fig 1.

Air hoses:

Fluid hoses:

Heater (if used):

Air compressor:

Spray

grounded

Fluid supply container:

Object being sprayed:

All

only

face.

per

use only grounded air hoses.

use only grounded fluid hoses.

refer to the V

follow manufacturer’s recommendations.

gun:

grounding is obtained through connection to a properly

fluid hose and pump.

solvent pails used when flushing,

metal pails, which are conductive, placed on a grounded sur

Do not place the pail on a nonconductive surface, such as pa

or cardboard, which interrupts the grounding continuity

iscon

Heater manual, 307–805.

according to your local code.

according to your local code.

according to local code. Use

.

Fig

W

1

Z

Flushing Safety

Before

flushing, be sure the

grounded.

Procedure on page 2, and remove the spray tip from the spray gun.

-

Always use the lowest possible fluid pressure, and maintain firm

-

metal-to-metal

to

Refer to

contact between the spray gun and the pail during

reduce the risk of fluid injection injury

entire system and flushing pails are properly

Grounding

, at the left. Follow the

, static

sparking and splashing.

Y

Pressure Relief

IMPORTANT

United

States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards – particularly the Gen

Standards, Part 1910, and the Construction Standards, Part 1926 – should be consulted.

eral

0864

flushing

-

TERMS

WARNING Alerts user to avoid or correct conditions that could

CAUTION Alerts user to avoid or correct conditions that could

cause

bodily harm.

damage to or destruction of equipment.

cause

NOTE

Identifies essential procedures or helpful information.

3307-928

Page 4

KEY

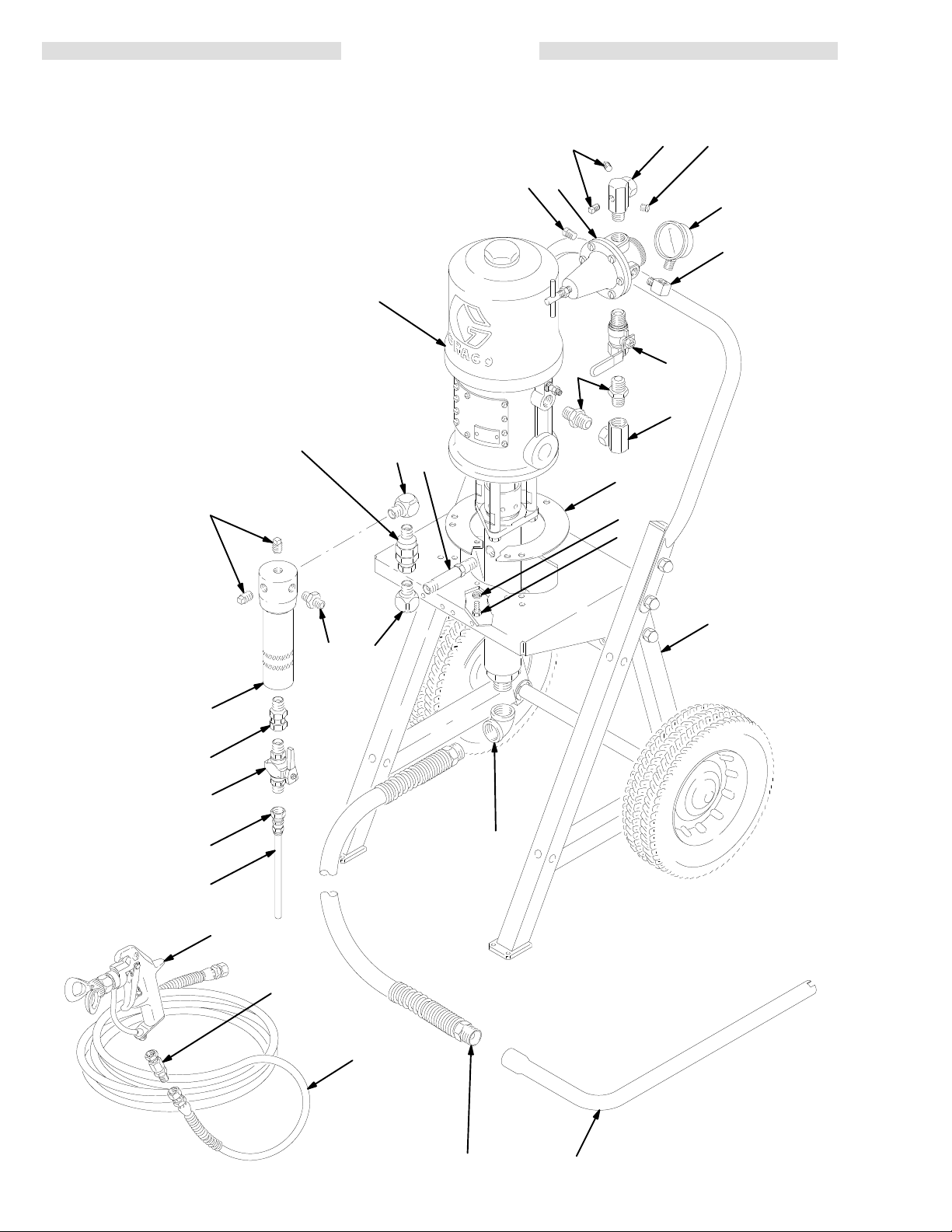

TYPICAL INSTALLATION

A Air

B

C

D

E

F Bleed-T

Y

10

21

22

28

29

32

33 Pump

45 Bleed-T

Model

Line Filter

Main Air Line

Air Line Lubricator

Fluid Hose

Spray Gun

Ground Wire (required)

Drain V

Suction T

Filter Outlet Nipple

Air Regulator

Suction Hose

Fluid Filter

(required)

224-625 Shown

ype Master Air V

alve (required)

ube

ype Master Air V

21

alve

alve

33

29 32

A

F

B

Y

28

45

C

22

E

10

D

0865

4 307-928

Page 5

INSTALLATION

Be

sure that all operators read and understand this entire

manual

nents

Reference numbers and letters in parentheses refer to

the Typical Installation drawing, Figs. 1-5, and the parts

drawings and lists on pages 13-18.

Accessories mentioned are available from your Graco

distributor

sories, be sure they are adequately sized to meet your

system’s

The Typical Installation above is only an example. For as

sistance in designing a system to meet your particular

needs, contact your Graco representative or Graco

Technical

SYSTEM ACCESSORIES

Install an air line filter (A) in the main air line (B), to remove

supply. To provide automatic lubrication of the air motor

install an air line lubricator (C) downstream from the

bleed-type master air valve (45). Install a second bleed

valve

servicing.

and the separate manuals supplied with compo

and accessories before using this equipment.

(see page 19). If you supply your own acces

requirements.

Assistance (see back page).

harmful dirt and moisture from the compressed air

(F) in the main

air line, to isolate the accessories for

WARNING

-

-

-

,

AND GUN CONNECTIONS

HOSE

Refer to the Typical Installation drawing on page 4. Assemble

pump

Connect one end of the fluid hose (D) to the filter outlet

nipple

DO

ond

Close the bleed-type master air valve (45) and the air

regulator (28). Connect the main air line (B) to the 1/2

npt(f)

the suction hose (29) and suction tube

fluid intake.

(22) and the

NOT install the spray tip in the gun yet. T

gun with the sprayer

air regulator inlet.

other to the fluid inlet of the gun (E).

, refer to pages 10 and 1

(21) to the

o use a sec

1.

GROUNDING

WARNING

Before operating the pump, ground the system as

explained under FIRE OR EXPLOSION HAZARD

Grounding

and

on page 3.

-

The

bleed-type master air valve (45) and the fluid

drain valve (10) are supplied with your pump, to

reduce the risk of serious bodily injury includ

help

ing fluid injection, splashing in the eyes or on the

skin,

or injury from moving parts if

ing

or repairing the pump.

The

bleed-type master air valve

trapped

air

cycle unexpectedly. The valve is located down-

stream

The

sure in the displacement pump, hose, and gun;

triggering the gun to relieve pressure may not be

sufficient.

between this valve

is shut of

fluid drain valve

f. T

rapped air can cause the pump to

from the air regulator

and the pump after the

assists in

you are adjust

relieves air

.

relieving fluid pres

-

-

-

5307-928

Page 6

Model

224-625 Shown

33

17

32

ARROW ON

30

BODY MUST

POINT UP

17 39

4

29

21

Fig. 2

6 307-928

0866

Page 7

CONVERTING

ING

SYSTEM

To

convert pump Models 224-625 or 231-163 to a heated

circulating

Viscon

Heater Mounting Kit 222-262

Circulating Kit 222-261

Hose Kit 222-263

THE PUMP T

O A HEA

unit, order the following:

Fluid Heater

, Model 220-522

TED CIRCULA

WARNING

The Viscon Heater must be installed by a quali-

fied

electrician in compliance with all state and lo

cal codes and regulations, to reduce the risk of

electric

installation

shock or other serious bodily injury during

or operation.

The heater requires a 120 VAC, single-phase,

16.7 Amp power supply. Refer to the Viscon

Heater

DO

containing

fire

Manual, 307-805, for further information.

NOT

plug or unplug the power cord in any area

flammable materials or fumes, to

avoid

or explosion resulting in serious bodily injury

T-

NOTE: Reference

example,

Apply 110-1

numbers

marked with an asterisk (for

61*) are included in kit 222-262.

10 pipe sealant (included in the kit) to

all male threads, except at swiveling connections.

1. Remove

back

the cover from the electrical box (G) at the

of the heater

. Screw the bushing (66*) into the

inlet of the electrical box. Install the cord grip elbow

(67*)

in the bushing. See Fig. 3.

2. Thread the cord (68*) through the elbow (67*) and

into the electrical box. Attach the black lead to the

leftmost

nal,

and the

terminal, the white lead to the center

green ground wire to the rightmost termi

termi

-

-

nal. Tighten all terminal nuts to 30 in-lb (3.4 N.m).

-

Tighten

the

the nut on the cord grip elbow (67*) to secure

cord. See Fig. 3.

WARNING

The electrical cord (68*) is rated for 105C

(221F). Do not substitute a lower temperature

rated,

generally available cord.

NOTE: Mount

.

the heater (58) on the

follows. T

wo people are required to perform this

operation.

back of the cart as

Installing Heater Mounting Kit 222-262

WARNING

Before installing the heater, heater mounting kit

and

circulating kit, follow the

cedure

on page 2. Disconnect all hoses from the

Pressure Relief Pro

pump.

G

66*

67*

3. Align the heater (58) mounting posts with the four

at the back of the cart’

holes

(H).

See Fig. 4. Secure the heater to the bracket with

the M8 x 1.25 screws and lockwashers

the

heater

Remove the fluid filter (32) from the pump (33). Re

4.

-

move and discard the two elbows (17), check valve

(30),

outlet.

.

and long 3/8 npt nipple (39) from the pump fluid

See Fig. 2.

s pump support bracket

supplied

with

-

Refer to page 8 to continue the procedure.

WHITEBLACK

Fig. 3

68*

TIGHTEN TERMINAL NUTS

T

O 30 in-lb (3.4 N.m)

GREEN (GROUND)

0867

7307-928

Page 8

5. Screw

6. Install the 3/8 npt nipple (61*) in the heater outlet.

7.

Installing Circulating Kit 222-261

Before installing the heater, heater mounting kit

and

cedure

pump.

the check valve (62*) into the pump’

let,

making certain

points away from the pump. Screw the rigid end of

the

adapter (63*) onto the check valve. See Fig. 4.

Screw the male end of the 90 swivel (23*) into the

inlet of the fluid filter (32). Screw the female end of

the swivel (23*) onto the nipple (61*) at the heater

outlet, and tighten securely. When properly assembled,

the

Screw the elbow (64*) into the heater’s inlet.

the 1/2” x 3’ (0.9 m) hose (65*) to the elbow.

the

(63*)

the filter’s outlet

back of the cart.

other end of the hose to the swivel of the adapter

at the pump outlet.

circulating kit, follow the

on page 2. Disconnect all hoses from the

that the arrow on the check valve

nipple (22) will face toward

WARNING

Pressure Relief Pro

s fluid out

Attach

Attach

-

-

mounting

bracket (H), working from the inside. Place another

insulator

of the bracket. Use the screws to attach the back

pressure

et.

4. Screw one of the nipples (22) into the outlet in the

base of the back pressure regulator (76), then

screw

male

elbow

tor,

5. Screw

fluid

elbow faces left. Install the CIRC end of the threeway

is

at the front.

6. Screw a second elbow (44) onto the IN branch of

the three-way valve (70), so the elbow points upward. Connect one end of the hose (72) to the elbow,

let

of the back pressure regulator

holes on the left side of the pump support

(74) on each of

regulator (76) to the pump support

one of the elbows (44) onto the nipple so the

end of the elbow faces forward. Install another

(44) in the inlet of the back pressure

then install another nipple (22) in the elbow

an elbow (44) into the open port of the pump

intake manifold (69), so the female end of the

ball valve (70) in the elbow

and the other end to the nipple (22) at the out

the screws on the outside

, so the valve handle

.

brack

regula

.

-

-

-

NOTE: Reference numbers marked with a symbol (for

example,

Apply 110-1

all male threads, except at swiveling connections.

1. Unscrew

elbow

(4) and set the hose aside. Remove the elbow

(4)

from the pump intake and discard. See Fig. 2.

2. Screw the rigid end of the manifold (69) onto the

intake, and attach the suction hose (29) to the

pump

swivel

end of the manifold. See Fig. 4.

3. Place

a washer

the screws (75). Insert the screws through the

69), are included in kit 222-261.

10 pipe sealant (included in the kit) to

the suction hose (29) from the pump intake

(73) and insulator (74) on each of

7. Connect the drain hose (71) to the DRAIN end of

the

three-way valve (70

8. Connect

inlet

of the back pressure regulator

9. Connect

on

page 5.

the fluid return line to the nipple (22) at the

the air and fluid hoses and

).

.

gun as explained

GROUNDING

WARNING

Before operating the pump, ground the system as

explained under FIRE OR EXPLOSION HAZARD

Grounding

and

on page 3.

8 307-928

Page 9

76

44

22

72

(REF)

74

73

75

33

*62

ARROW ON BODY

MUST POINT A

FROM PUMP

44

B

WAY

*63

7

A

H

*65

(REF)

B

72

71

*68

*67

PART

ITEM 58

OF

69

44

70

66*

29

*23

21

–

22

*61

32

58

64*

H

65*

Fig. 4

A

0868A

9307-928

Page 10

CONVERTING T

To

convert your sprayer to a

following

parts

Models 224-625 and 231-163 (Refer to Fig 5 and the

Parts

NOTE: For Model 224–625, order all of the following

P

ART NO.

162-453

208-663

204-940

210-540

1. Remove

2. Screw the first fluid hose (D) onto a swivel (L), then

3. Screw

applicable paragraph for your model. Order the

listed, and perform the assembly procedure.

Drawing on page 14)

performing this procedure, follow the

Before

sure

Relief Procedure

hoses

from the pump.

parts.

swivel and fluid hose, order only one of each

the following parts.

the

fluid filter (32). Install a 162-453 Nipple (K) in its

place. See Detail A of Fig 5.

screw the swivel onto the fluid inlet of the gun (E).

See

Detail B of Fig

and gun.

el

fluid

filter (32). Screw the second hose onto the

outlet

nipple (K) of the fluid filter

O A TWO-GUN SYSTEM

two-gun system, refer to the

WARNING

Pres-

on page 2. Disconnect

For Model 231-163, which includes a gun,

DESCRIPTION QTY

NIPPLE; 1/4 npt x 1/4 npsm

GUN, airless spray

SWIVEL, straight; 1/4 npt(m) x

1/4 npsm(f) 2

HOSE, fluid; nylon;

1/4” (6 mm) I.D.; 1/4 npsm(fbe);

25 ft (7.6 m) long

the plug (16) from the optional outlet port of

5. Repeat for the other hose, swiv

the first hose onto one outlet nipple (22) of the

. See Detail A.

all

of

other

Model 224-630 and 231-160 (Refer to Fig 5 and the

Parts

Drawing on page 16)

WARNING

performing this procedure, follow the

Before

sure

Relief Procedure

hoses

from the pump.

NOTE: For Model 224-630, order all of the following

parts.

For Model 231-160, which includes a gun

and

hose kit, order two 162-453 nipples and only

one

of each of the other parts.

P

ART NO.

162-453

100-840 ELBOW

208-327

222-263

1

2

1. Remove

the

fluid filter (32). Install a 162-453 Nipple (K) in its

place. See Detail A of Fig 5.

2.

2

-

Install the 100-840 Elbow (M) in the optional inlet of

the back pressure regulator (76). Screw a 162-453

Nipple

3. Screw the first insulated fluid hose kit (N) onto the

fluid

inlet of the gun

and

gun. See Detail D.

4. Connect

the outlet nipple (22) of the fluid filter (32). Connect

the

fluid supply line of the second hose kit to the other

outlet

return

and

K) of the back pressure regulator (76). See

C.

tail

DESCRIPTION QTY

NIPPLE; 1/4 npt x 1/4 npsm

1/4 npt (m x f)

GUN, airless spray

HOSE KIT

1/4” ID; cpld 1/4 npsm (fbe);

25 ft (7.6 m) long

the plug (16) from the optional outlet port of

(K) into the elbow (M). See Detail C of Fig 5.

the fluid supply line of the first hose kit (N) to

nipple (K). See Detail A. Similarly

lines of the hose kits (N) to the inlet nipples (22

on page 2. Disconnect

, street, 90

, fluid, insulated; nylon;

(E). Repeat for the other hose kit

;

Pres-

all

, connect the

De

2

1

2

2

-

10 307-928

Page 11

DETAIL

A: HOSE CONNECTIONS A

FLUID FIL

TER (ALL MODELS)

32

T

DET

AIL B: ASSEMBL

(MODELS 224–625 AND 231–163)

Y OF HOSE AND GUN

E

L

D

22

(TO

FIRST

GUN)

DET

AIL C: FLUID RETURN CONNECTIONS A

BACK PRESSURE VALVE (MODELS 224-630 AND 231-160 ONL

4422

(FROM

FIRST

GUN)

K

(TO

SECOND

GUN)

0869

T

76

K

(FROM

SECOND GUN)

M

22

44

72

(TO

3–WAY

VALVE)

0870

Y)

0871A

Fig 5

DET

AIL D: ASSEMBL

FLUID RETURN LINE

Y OF HOSE KIT AND GUN (MODELS 224-630 AND 231-160)

EN

FLUID SUPPL

Y LINE

0872

11307-928

Page 12

OPERATION-MAINTENANCE

WARNING

Pressure

To

reduce the risk of serious bodily injury

fluid

injury from moving parts, always follow this procedure

ing

installing, cleaning or changing spray tips, and

whenever

1.

2. Shut off the main power to the heater, if used.

3.

4. Close the bleed-type master air valve (supplied

5.

6. Hold a metal part of the spray gun firmly to the

7.

8. Open

9. Leave

If you suspect that the spray tip or hose is com-

pletely

relieved after following the steps above, VERY

SLOWLY

end coupling and relieve pressure gradually, then

loosen

For your safety, before operating the equipment

be sure all operators have read and fully understand

this manual and all manuals supplied with each

component

Relief Procedure

, including

injection, splashing in the eyes or on

whenever you shut of

or servicing any part of the spray system, when

you stop spraying.

Engage the spray gun safety latch.

Circulate

it

and the heater to cool.

Shut of

in your system).

Disengage the spray gun safety latch.

side of a grounded metal pail, and trigger the

spray

Engage the spray gun safety latch.

having

spray

the fluid for at least 10 minutes to allow

f the air to the pump.

gun to relieve pressure.

the drain valve (supplied in your system),

a container ready to catch the drainage.

the drain valve open until you are ready to

again.

clogged, or that pressure has not been fully

loosen the tip guard retaining

completely

all the

. Now clear the tip or hose.

warnings, cautions and instructions in

or accessory.

f the pump, when check

WARNING

the skin, or

nut or hose

valve.

Hold a metal part of the spray gun firmly to the side

of a grounded metal pail and trigger the gun. Slowly

the

air regulator until the pump

cycle

slowly until all the air is pushed out of the fluid lines.

Release

-

pump

With the pump and lines primed, and with adequate air

pressure and volume supplied, the pump will start and

stop

Follow

then

Use

pressure. Always use the lowest pressure necessary to

achieve

and cause premature wear of the pump packings and

spray

Keep the wet-cup filled with Graco Throat Seal Liquid

(TSL) to help prolong the packing life. Check the tightness of the packing nut weekly. The packing nut should

be tight enough to prevent leakage – no tighter. Always

follow the Pressure Relief Procedure Warning at left

before

Never allow the pump to run dry of the fluid being

pumped. A dry pump will quickly accelerate to a high

speed, possibly damaging itself. If your pump accelerates

check the fluid supply. If the supply container is empty

and air has been pumped into the lines, refill the supply

container

sure

pump

Heated Systems

Operating instructions for a heated circulating system

are provided in the Viscon Heater manual, 307-805.

Read

heater

the gun trigger and engage the safety latch;

will stall against the pressure.

as the spray gun is triggered and released.

the

Pressure Relief Procedure W

install the spray tip in the gun.

the air regulator to control

the desired

tip.

adjusting the packing nut.

quickly

to eliminate all air

, or is running too fast, stop it immediately and

and prime the pump and lines with fluid, being

as described in “Shutdown and Care,” below

and understand all warnings and instructions in

manual before operating a heated system.

results. Higher pressures waste fluid

from the fluid system, or flush the

starts. Allow the pump to

arning

the pump speed and fluid

open

the

at left,

.

the

Flush the Pump Before Using

Pumps are tested with lightweight oil which is left in to

protect

fluid,

ing

Starting and Adjusting the Pump

Be

are

Place

valve (10) for priming. Open the bleed-type master air

12 307-928

the pump parts. T

flush the

it.

pump with a compatible solvent before us

Before flushing,

flushing pails are properly grounded. Refer to

Grounding on page 3. Follow the Pressure Relief Procedure Warning above, and

spray

tip from the gun.

sible fluid pressure, and maintain firm metal-tometal

contact between the gun and the pail during

flushing to reduce the risk of fluid injection, static

sparking,

sure the air regulator and bleed-type

closed.

the suction tube (21) in the fluid pail. Open the drain

and

splashing in the eyes or on the skin.

DO NOT INST

o prevent contamination of the

WARNING

be sure the entire system and

remove the

Always use the lowest pos

master air valve

ALL THE SPRA

Y TIP YET!

-

In

circulating systems, adjust the back pressure regulator

(76)

and pump air pressure regulator (28) to obtain prop

er

spray pressure at the gun and maintain suf

flow to prevent fluid settling.

lation

The

three-way ball valve (70) selects either fluid

or draining. To circulate fluid back to the pump, turn

tion

the handle toward the CIRC end of the valve. To drain

fluid,

turn the handle toward the DRAIN end.

Shutdown and Care

Always

at

the bottom of its stroke to keep fluid from drying on the

exposed displacement rod and damaging throat packings.

Always

the

of

first with water and then with mineral spirits. If you are

pumping

Relieve pressure and leave the mineral spirits in the

pump

follow the

left, whenever you shut

flush

fluid can dry on the displacement rod, and at the end

each day

oil-based fluids, flush with mineral spirits only

to prevent corrosion.

Pressure

the pump with a compatible solvent before

. If you are pumping water-based fluid,

Relief Procedure W

of

f the pump. Stop the pump at

ficient circu

circula

arning

flush

-

-

-

.

Page 13

PARTS

ARTS LISTS

P

DRA

AND

WINGS

13307-928

Page 14

Model

224–625,

Includes items 1–56

Model 231–163

Includes items 1–79

Series A

PARTS

33

DRA

WING

16

28

5

20

5

6

15

16

32

54

10

ARROW ON

30

BODY MUST

POINT UP

22

17

17

39

37

45

18

47

1

3

7

14 307-928

55

56

77

79

78

29

4

21

0873A

Page 15

Model

224–625, Series A

Includes items 1–56

Model 231–163

Includes items 1–79

PARTS LIST

REF

NO. P

ART NO.

1 100–016 LOCKW

DESCRIPTION

ASHER, spring; 1/4”

3 100–270 CAPSCREW

1/4–20 x 5/8” long

4 100–349 ELBOW

5 100–403

6 101–180

PLUG, pipe, sq hd; 1/8 npt

GAUGE, air pressure;

, 90; 3/4 npt(fbe)

0–200 psi (0–14 bar)

7 224–044 CART

, portable

See 308–136 for parts

10 210–658

BALL VALVE; 3/8 npt(mbe)

See 306–861 for parts

15 187–357 ELBOW

, street, 90;

1/4 npt (m x f)

16 100–509

17 155–699 ELBOW

18 157–416

PLUG, pipe, sq hd; 1/4 npt

, 90; 3/8 npt (m x f)

UNION, 90; 1/2 npt(f) x

1/2 npsm(f) swivel

20 162–376

MANIFOLD; 1/2 npt (m x f)

90

swivel; 3 holes (1/8 npt)

in body

21 165–767

SUCTION TUBE; 3/8 npt;

18” (457 mm) long 1

22 162–453

28 206–197

NIPPLE; 1/4 npt x 1/4 npsm

AIR REGULA

1/2 npt(f) inlet and outlet;

0–125 psi (0–9 bar) range

29 214–960

HOSE, suction; 3/4” ID; nylon;

coupled 3/4 npt (mbe);

3.5’ (1 m) long, w/spring guard

, hex hd;

TOR

QTY

REF

2

NO. P

ART NO.

30 206–831

DESCRIPTION

CHECK V

See 306–861 for parts

2

31 206–994 THROA

1

3

32 218–029

1 pint (0.5 liter); not shown

FLUID FIL

See 307–273 for parts

1

33 223–586

30:1 PRESIDENT PUMP

See 306–981 for parts

1

37 158–491

39 160–790

1

45 107–142 VAL

NIPPLE; 1/2 npt

NIPPLE; 3/8 npt

1/2 npt (m x f)

1

3

2

1

47 188–595

54 155–665

55 205–448

56 185–973

MOUNTING BRACKET

UNION, adapter; 3/8 npt(m) x

3/8 npsm(f) swivel

COUPLING, hose; 3/8 npsm(f)

HOSE, nylon; 1/4” (6 mm) ID;

28” (71

77 208–663 HYDRA–SPRA

1

78 223–540

See 307–046 for parts

HOSE, fluid; nylon;

1/4” (6 mm) ID;

1

coupled 1/4 npsm (fbe);

25’ (7.6 m) long

79 204–940 SWIVEL

1

See 306–861 for parts

1

ALVE

T SEAL LIQUID;

TER

VE, air

, bleed–type;

1 mm) long

Y GUN

, pump

QTY

1

1

1

1

2

1

1

1

1

1

1

1

1

1

HOW T

1 To be sure you receive the correct replacement parts, kits or

accessories, always give all of the information requested in the

chart

below

2.

Check

the

3.

Order all parts from your nearest Graco distributor

6 digit

Part Number

.

the parts list

ref. no. when ordering.

O ORDER P

to identify the correct part number; do not use

Qty

Part Description

ARTS

.

15307-928

Page 16

Model

224–630, Series A

Includes items 1–76

Model 231–160

Includes items 1–85

*67

*68

66*

PARTS

*61

58

32

DRA

23*

WING

16

22

28

16

5

20

5

6

7

(REF)

PART

OF

ITEM 58

*64

*65

REF

. NO. 78 HOSE KIT

INCLUDES ITEMS 79–85

A

22

*65

*62

ARROW ON BODY

MUST POINT A

FROM PUMP

WAY

72

71

57

10

76

44

A

*63

74

33

73

44

75

37

47

15

45

37

18

1

3

7

69

79

16 307-928

77

85

81

84

70

44

83

82

80

21

29

0875B

Page 17

Model

224–630, Series A

Includes items 1–76

Model 231–160

Includes items 1–85

PARTS LIST

REF

NO. P

ART NO.

1 100–016 LOCKW

DESCRIPTION

ASHER, spring; 1/4”

3 100–270 CAPSCREW

1/4–20 x 5/8” long

5 100–403

6 101–180

PLUG, pipe, sq hd; 1/8 npt

GAUGE, pressure, air;

0–200 psi (0–14 bar)

7 224–044 CART

, portable

See 308–136 for parts

10 210–658

DRAIN VALVE; 3/8 npt(mbe)

See 306–861 for parts

15 187–357 ELBOW

, street, 90_;

1/4 npt (m x f)

16 100–509

18 157–416

PLUG, pipe, sq hd; 1/4 npt

UNION, 90_; 1/2 npt(f) x

1/2 npsm(f) swivel

20 162–376

MANIFOLD; 1/2 npt (m x f)

90_

swivel; 3 holes (1/8 npt)

in body

21 165–767

SUCTION TUBE; 3/8 npt;

18” (457 mm) long 1

22 162–453[

23 155–494*

NIPPLE; 1/4 npt x 1/4 npsm

ADAPTER, union, 90

3/8 npt(m) x 3/8 npt(f) swivel

28 206–197

AIR REGULA

1/2 npt(f) inlet and outlet;

0–125 psi (0–9 bar) range

29 214–960

HOSE, suction; 3/4” ID; nylon;

coupled 3/4 npt (mbe);

3.5’ (1 m) long, w/spring guard

31 206–994 THROA

T SEAL LIQUID;

1 pint (0.5 liter); not shown

32 218–029

FLUID FIL

TER

See 307–273 for parts

33 223–586

30:1 PRESIDENT PUMP

See 306–981 for parts

37 158–491

44 100–840[ ELBOW

NIPPLE; 1/2 npt

, street, 90_;

1/4 npt (m x f)

VE, air

45 107–142 VAL

, bleed–type;

1/2 npt (m x f)

47 188–595

57 150–286

58 220–522 VISCON@

MOUNTING BRACKET

ADAPTER; 3/8 npt (m x f)

HEA

See 307–805 for parts

61 156–849*

62 206–962*

63 159–801*

NIPPLE; 3/8 npt

CHECK VALVE; 3/8 npt (mbe)

UNION, adapter

3/8 npt(f) x 1/2 npsm(f) swivel

64 158–683* ELBOW

65 235–022*

HOSE, fluid; nylon; 1/2” ID;

, 90_; 1/2 npt (m x f)

cpld 1/2 npt (mbe);

3’ (0.9 m) long

66 107–219*

BUSHING; 3/4 npt(m) x

1/2 npt(f) 1

67 102–363* ELBOW

, cord grip, 90

1/2 npt (m); includes nut,

68 110–160*

washer

CORD ASSY

600V

, and grommet

; 20 AMP; 105_C (221

6.5 ft (2 m) long

69 166–998[

MANIFOLD, inlet; 1/4 npt(f) x

3/4 npt(f) x 3/4 npsm(f) swivel

, hex hd;

_;

TOR

, pump

TER (120V)

, 90

_;

_;

, heater; 12 A

WG;

_F);

QTY

REF

NO. P

70 214–711[

2

ART NO.

2

71 206–965[

3

72 206–966[

1

1

73 100–527[ W

74 167–002[ INSULAT

1

75 102–254[ SCREW

1

76 206–819[ REGULAT

3

77 208–327

1

78 222–263

1

79 223–759 .

3

80 169–797 .

81 169–795 .

1

82 100–139 .

83 159–840 .

1

84 214–701 .

1

85 210–500 . FIL

1

1

*

1

2

4

Included in Heater Mounting Kit 222–262. See page

18.

[

Included in Circulating Kit 222–261. See page 18.

1

1

1

1

1

1

1

1

1 To be sure you receive the correct replacement parts, kits or

accessories, always give all of the information requested in the

chart

below

2.

Check

the

3.

Order all parts from your nearest Graco distributor

6 digit

Part Number

.

the parts list

ref. no. when ordering.

1

1

1

1

DESCRIPTION

BALL VALVE, three–way;

1/4 npt(m)

See 306–861 for parts

HOSE, drain; nylon; 1/4” ID;

cpld 1/4 npsm(f)

HOSE; PTFE;r1/4” ID;

cpld 1/4 npsm (fbe) swivel;

18” (457 mm) long 1

ASHER, wrought; 1/4”

OR, heat

, hex hd; 1/4–20 x

7/8” (19 mm) long 2

OR, back pressure

See 306–860 for parts

GUN, airless spray

See 307–046 for parts

HOSE KIT

Includes items 79–85

HOSE, fluid, insulated; nylon;

1/4” ID; cpld 1/4 npsm (fbe)

swivel; 25 ft (7.6 m) long

NIPPLE; 1/4 npsm x 1/8 npt

MANIFOLD; 1/8 npt(f)

PLUG, hex socket; 1/8 npt

ADAPTER; 1/8 npt(m) x

1/4 npt(f) 1

HOSE, fluid; nylon; 3/16” ID;

cpld 1/4 npt(m) x 1/4 npsm(f)

swivel; 3 ft (0.9 m) long

TER, fluid, in–line;

100 mesh; 1/4 npsm(m) x

1/4 npsm(f) swivel

HOW T

O ORDER P

to identify the correct part number; do not use

Qty

Part Description

ARTS

.

QTY

1

1

2

4

1

1

1

1

2

1

1

1

1

17307-928

Page 18

HEATER MOUNTING KIT 222–262

CIRCULATING KIT 222–261

Required to convert Models 224–625 and 231–163 to

heated

Includes 6 ml supply of sst pipe sealant 1

units. Consists of:

Ref. No.

23 1 65 1

61 1 66 1

62 1 67 1

63 1 68 1

64 1

Qty

Ref. No.

MANUAL

Listed below by the assembly

parts.

Assembly Ref

Changed Status No.

All Models

Qty

10–110.

CHANGE SUMMAR

ADDED 47 188–595 Bracket

Required

culating

Includes 6 ml supply of sst pipe sealant 1

to convert Models 224–625 and 231–163 to cir

units. Consists of:

Ref. No.

22 2 72 1

44 4 73 2

69 1 74 4

70 1 75 2

71 1 76 1

Qty

Ref. No.

10–110.

Y

changed are ADDED

Part No.

Name

-

Qty

18 307-928

Page 19

ACCESSORIES

USE GENUINE GRACO PARTS AND ACCESSORIES

Must

be purchased separately

GROUNDING CLAMP 103–538

GROUND WIRE 208–950

25 ft (7.6 m) long, 12 gauge (1.5 mm

AIR LINE LUBRICA

TOR

250 psi (17.5 bar) MAXIMUM WORKING PRESSURE

214–848

214–849

1/2 npt inlet and outlet

3/4 npt inlet and outlet

.

)

GROUNDED NYLON FLUID HOSE

3000 psi (210 bar) MAXIMUM WORKING PRESSURE

Part

No.

214–700

214–701

210–540

210–541

214–703

214–705

214–920

ID Length

3/16” (4.8 mm)

3/16” (4.8 mm)

1/4” (6.4 mm)

1/4” (6.4 mm)

3/8” (9.5 mm)

3/8” (9.5 mm)

3/8” (9.5 mm)

2 ft (610 mm)

(fbe) swivel

3 ft (914 mm)

25 ft (7.6 m)

50 ft (15.2 m)

(fbe) swivel

25 ft (7.6 m)

50 ft (15.2 m)

100 ft (30.4 m)

Thd. Size

1/4 npsm

1/4 npt(m)

x 1/4

npsm(f)

swivel

1/4 npsm

(fbe) swivel

1/4 npsm

3/8 npt

(mbe)

3/8 npt

(mbe)

3/8 npt

(mbe)

AIR LINE FIL

TER

250 psi (17.5 bar) MAXIMUM WORKING PRESSURE

106–149

106–150

GROUNDED BUNA–N AIR SUPPL

1/2 npt inlet and outlet

3/4 npt inlet and outlet

Y HOSE

175 psi (12 bar) MAXIMUM WORKING PRESSURE

Part

No.

205–418

205–216

205–273

208–594

BACK

PRESSURE REGULATOR 206–819

ID Length

1/2” (13 mm)

1/2” (13 mm)

1/2” (13 mm)

1/2” (13 mm)

6 ft (1.8 m)

15 ft (4.5 m)

25 ft (7.6 m)

50 ft (15 m)

Thd. Size

1/2 npt(m)

1/2 npt(m)

1/2 npt(m)

1/2 npt(m)

3000 psi (210 bar) MAXIMUM WORKING PRESSURE

Use

in circulating system fluid return line to regulate back

pressure to gun and maintain proper circulating pressure.

FLUID

PRESSURE REGULATOR 206–661

3000 psi (210 bar) MAXIMUM WORKING PRESSURE

Use

at each gun drop in multiple gun systems, to regulate

fluid

pressure to each gun.

STAINLESS

STEEL AIRLESS SPRA

Y GUN

5000 psi (350 bar) MAXIMUM WORKING PRESSURE

208–327

208–663

208–664

220–954 .090”

VISCON

.037” orifice, 2–finger trigger

.090” orifice, 2–finger trigger

.090” orifice, 4–finger trigger

orifice, 2–finger trigger

Less

FLUID HEA

tip guard

TER 220–522

, RAC IV Drip

4000 psi (276 bar) MAXIMUM WORKING PRESSURE

Reduces fluid viscosity for easier spraying. 120 V, single–phase,

Manual

16.7 Amp. Stainless steel. Refer to

307–805.

Instruction

WARNING: Not for use in hazardous areas containing

flammable

INSULA

materials or fumes.

TED HOSE KIT 222–263

3000 psi (210 bar) MAXIMUM WORKING PRESSURE

25 ft. (7.6 m) nylon fluid hose for use with heated systems.

Includes in–line fluid filter

3

ft. (0.9 m) whip hose.

HEA

TER CONVERSION KITS

Use

to convert pump Models 224–625 and

, circulating manifold,

231–163 to a

and

heated circulating spray system. See pages 16–18 for

The V

iscon

parts.

Kit

222–263 are also required, and must be ordered sep

arately

(see above).

222–262

222–261

SST PIPE SEALANT 1

Heater 220–522 and Insulated Hose

Heater Mounting Kit

Circulating Kit

10–110

Apply to all non–swiveling pipe connections.

6 ml supply

.

19307-928

-

-

Page 20

TECHNICAL

PTFE

DA

TA

Maximum

Maximum

Ratio 30:1

Maximum

pump speed

working pressure

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

incoming air pressure

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3000 psi (210 bar)

100 psi (7 bar)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

recommended

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60 cpm (1.0 gpm [3.8 liters/min])

at continuous operation

Air

consumption

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(0.79 m

approx. 23 scfm

/min) at 1.0 gpm

(3.8 liter/min) flow rate at

70 psi (4.8 bar) air pressure

W

etted parts

is

a registered trademark

THE

.

. . . . . . . . . . . . . . . . . . . .

GRACO W

ARRANTY AND DISCLAIMERS

See separate component instruction manuals

WARRANTY

Graco

warrants all equipment manufactured by it and bearing its name to be free from defects in material and workman

ship on the date of sale by an authorized Graco distributor to the original purchaser

for

breach of this warranty

, Graco

will, for a period of twelve months from the date of sale, repair or replace any part of the

equipment proven defective. This warranty applies only when the equipment is

accordance with Graco’

This

warranty does not cover

misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

lation,

substitution

of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the

incompatibility with Graco equipment of

improper

als

design, manufacture, installation, operation or

not supplied by Graco.

s written recommendations.

, and Graco shall not be liable for

structures, accessories, equipment or materials not supplied by Graco, or the

, any malfunction, damage or wear caused by faulty

maintenance of structures, accessories, equipment or materi

for

use. As purchaser’s sole remedy

installed, operated and maintained in

instal

-

-

-

This

warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco

distributor for verification of the claim. If the claimed defect is verified, Graco will repair or replace free of charge any

defective parts. The equipment will be returned to the original purchaser transportation prepaid. If inspection of the

equipment

charges

DISCLAIMERS AND LIMIT

THE

TERMS OF THIS WARRANTY CONSTITUTE PURCHASER’S SOLE AND EXCLUSIVE REMEDY AND ARE IN LIEU OF ANY OTHER W

RANTIES

POSE,

EVERY

NO

CASE SHALL GRACO’S LIABILITY EXCEED THE AMOUNT OF THE PURCHASE PRICE. ANY ACTION FOR BREACH OF W

BE

BROUGHT WITHIN TWO (2) YEARS OF THE DA

EQUIPMENT

GRACO

PURPOSE,

These

does not disclose any defect in material or workmanship, repairs will be made at a reasonable charge, which

may include the costs of parts, labor and transportation.

ATIONS

(EXPRESS OR IMPLIED), INCLUDING W

AND OF ANY NON–CONTRACTUAL LIABILITIES, INCLUDING PRODUCT

FORM OF LIABILITY FOR DIRECT

, SPECIAL OR CONSEQUENTIAL DAMAGES OR LOSS IS EXPRESSL

NOT COVERED BY GRACO W

MAKES NO W

WITH RESPECT T

ARRANTY

, AND DISCLAIMS ALL IMPLIED W

O ACCESSORIES, EQUIPMENT

items sold, but not manufactured by Graco (such as electric motor

ARRANTY OF MERCHANT

TE OF SALE.

ARRANTY

ARRANTIES OF MERCHANT

, MA

TERIALS, OR COMPONENTS SOLD BUT NOT MANUF

ABILITY OR W

LIABILITIES, BASED ON NEGLIGENCE OR STRICT LIABILITY

ARRANTY OF FITNESS FOR A P

Y EXCLUDED AND DENIED. IN

ABILITY AND FITNESS FOR A P

ACTURED BY GRACO.

ARTICULAR

ARRANTY MUST

ARTICULAR

, switches, hose, etc.) are subject to the war

AR-

PUR

ranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for

breach

of these warranties.

IMPORTANT PHONE NUMBERS

TO

PLACE AN ORDER

or call this number to identify the distributor closest to

you:

1–800–328–0211 T

, contact your Graco distributor

oll Free

,

FOR TECHNICAL ASSISTANCE, service repair infor-

or assistance

mation

equipment: 1–800–543–0339 T

regarding the application of Graco

oll Free

.

-

20 307-928

Sales Offices:

Foreign Offices:

GRACO INC.P.O. BOX 1441

Atlanta, Dallas, Detroit, Los Angeles, Mt. Arlington (N.J.)

Canada; England; Switzerland; France; Germany; Hong Kong; Japan; Korea

PRINTED

MINNEAPOLIS, MN

IN U.S.A. 307–928 12–88 Revised 5/93

55440–1441

Page 21

3X7–928

Rev. H

Supersedes

and PCN G

Rev

. F

Parts

Change Notice

Some parts in Rev. F of manual 307–928 have changed but have not yet been changed in the

instruction manual. Please note the changes below and mark them in your manual or keep this

sheet with your manual.

Series

Assembly

Model 231–163

only

Model 231–160

Other

Page 15:

No.

Changes

Add the following note after the parts list:

Letter

Change

B 100–403 5 Plug

Part That

Changed

101–180 6 Gauge

206–197 28

208–663 77

208–327 77

Ref

No.

Part Description

Air Regulator

Airless

Spray Gun

Airless

Spray Gun

Description of Change

Replaced by Part No. 100–139 Plug.

Replaced by Part No. 100–960 Gauge.

Replaced by Part No. 104–266 Air

Regulator

Replaced by Part No. 235–460 Airless

Spray Gun. See 308–236 for parts.

Replaced by Part No. 235–462 Airless

Spray Gun. See 308–236 for parts.

. See 308–167 for parts.

* These parts are included in Regulator Kit 238–898, used on Model 231–163.

*

100–139 Plug (ref. no. 5), quantity 3

*

100–960 Gauge (ref. no. 6), quantity 1

*

187–357 Elbow (ref. no. 15), quantity 1

*

100–509 Plug (ref. no. 16), quantity 1

*

162–376 Manifold (ref. no. 20), quantity 1

*

104–266 Air Regulator (ref. no. 28), quantity 1.

May 9, 1996

Loading...

Loading...